Top 8 Square Tube 2X4 Suppliers (And How to Choose)

Introduction: Navigating the Global Market for square tube 2×4

In an increasingly interconnected world, sourcing high-quality square tube 2×4 products presents a significant challenge for international B2B buyers. Whether you’re in Brazil looking to enhance your construction projects or in Nigeria seeking durable materials for manufacturing, the complexities of global supply chains can complicate the procurement process. This guide aims to simplify your journey by providing comprehensive insights into the diverse types of square tube 2×4 available, their various applications across industries, and essential tips for vetting suppliers effectively.

Understanding the specifications of square tube 2×4—such as gauge, material options, and finishes—is crucial for making informed purchasing decisions. This guide will delve into the cost implications of different materials, the benefits of sourcing locally versus internationally, and the best practices for negotiating with suppliers. Additionally, we will explore the regulatory considerations and logistical challenges that may arise when importing these products into regions such as Africa, South America, the Middle East, and Europe.

By equipping you with actionable information and strategies, this guide empowers you to navigate the global market confidently. Our goal is to help you make informed decisions that enhance your operational efficiency and project outcomes, ultimately leading to successful procurement of square tube 2×4 that meets your specific business needs.

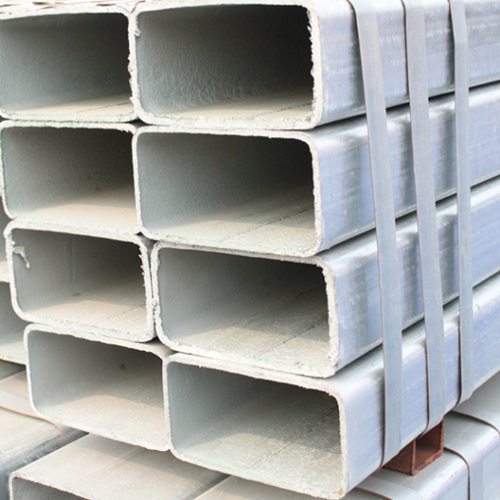

Understanding square tube 2×4 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Carbon Steel Square Tube | High strength, cost-effective, and widely available | Construction, automotive, and manufacturing | Pros: Cost-effective and strong; Cons: Prone to rust without coating. |

| Galvanized Square Tube | Coated with zinc for corrosion resistance | Outdoor structures, fencing, and HVAC | Pros: Excellent corrosion resistance; Cons: Slightly higher cost due to coating. |

| Aluminum Square Tube | Lightweight, resistant to corrosion, and easy to work with | Aerospace, automotive, and marine applications | Pros: Lightweight and non-corrosive; Cons: More expensive than steel. |

| Stainless Steel Square Tube | High corrosion resistance and aesthetic appeal | Food processing, medical equipment, and architecture | Pros: Durable and hygienic; Cons: Higher material cost and weight. |

| Structural Square Tube | Designed for load-bearing applications with various wall thicknesses | Heavy construction and industrial applications | Pros: Strong and versatile; Cons: Heavier and may require specialized handling. |

What are the Characteristics of Carbon Steel Square Tubes?

Carbon steel square tubes are known for their high strength and affordability, making them a popular choice in various industries. Typically available in various wall thicknesses, these tubes offer a robust solution for applications in construction, automotive, and manufacturing sectors. When purchasing, buyers should consider the potential for rust, as untreated carbon steel can corrode over time. Opting for a protective coating can mitigate this issue, enhancing longevity and performance.

How Does Galvanized Square Tubing Benefit Outdoor Applications?

Galvanized square tubing is coated with zinc to provide superior corrosion resistance, making it ideal for outdoor applications such as fencing and HVAC systems. This type of tubing retains the strength of carbon steel while offering enhanced durability against environmental factors. B2B buyers should weigh the slightly higher cost of galvanized tubing against its long-term benefits, including reduced maintenance and replacement costs due to its protective coating.

Why Choose Aluminum Square Tubes for Lightweight Applications?

Aluminum square tubes are favored for their lightweight nature and excellent corrosion resistance, making them suitable for industries like aerospace, automotive, and marine. Their ease of fabrication allows for diverse applications, such as structural components and decorative elements. However, buyers should be aware that aluminum generally comes at a higher price point than steel, which could affect budget considerations for large-scale projects.

What are the Advantages of Stainless Steel Square Tubes?

Stainless steel square tubes are prized for their exceptional corrosion resistance and aesthetic appeal, particularly in food processing and medical equipment applications. This material is not only durable but also easy to clean, making it suitable for environments where hygiene is paramount. While the initial investment is higher compared to other materials, the longevity and low maintenance of stainless steel can justify the cost for many B2B buyers.

How Does Structural Square Tubing Support Heavy Construction?

Structural square tubing is engineered for load-bearing applications, available in various wall thicknesses to suit specific strength requirements. This type of tubing is often used in heavy construction and industrial settings, where strength and reliability are critical. Buyers should consider the weight of structural tubes and ensure they have the necessary handling equipment, as these products can be heavier than other tubing types.

Key Industrial Applications of square tube 2×4

| Industry/Sector | Specific Application of square tube 2×4 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction and Building | Structural frameworks for commercial buildings | Provides strength and durability for load-bearing structures | Ensure compliance with local building codes and standards; consider corrosion resistance for outdoor applications. |

| Manufacturing | Machinery frames and supports | Enhances stability and safety of industrial equipment | Evaluate material grades and thickness for specific load requirements; consider sourcing from local suppliers to reduce lead times. |

| Transportation and Logistics | Support structures for trailers and shipping containers | Increases structural integrity and safety during transport | Assess weight limits and compatibility with existing systems; prioritize suppliers with quality certifications. |

| Automotive | Chassis and frame components | Contributes to the overall strength and safety of vehicles | Ensure materials meet automotive industry standards; consider sourcing from suppliers with proven track records in automotive applications. |

| Furniture and Design | Frameworks for custom furniture | Allows for innovative designs with robust support | Look for suppliers offering customization options; consider aesthetic finishes for consumer-facing products. |

How is square tube 2×4 utilized in construction and building sectors?

Square tube 2×4 is widely used in the construction industry for creating structural frameworks in commercial buildings. Its strength and durability make it ideal for load-bearing applications, ensuring that buildings can withstand various environmental stresses. International buyers, particularly in regions like Africa and South America, should prioritize suppliers that comply with local building codes and offer corrosion-resistant options, especially for projects exposed to harsh weather conditions.

What role does square tube 2×4 play in manufacturing?

In the manufacturing sector, square tube 2×4 serves as a vital component in machinery frames and supports. By providing enhanced stability and safety, it helps maintain operational efficiency in industrial environments. Buyers in this sector must evaluate the material grades and thickness to meet specific load requirements, while also considering sourcing from local suppliers to minimize lead times and shipping costs.

How is square tube 2×4 applied in transportation and logistics?

Within transportation and logistics, square tube 2×4 is integral to the construction of support structures for trailers and shipping containers. Its robust nature increases structural integrity, ensuring the safe transport of goods. For international buyers, it’s crucial to assess weight limits and compatibility with existing systems. Prioritizing suppliers with quality certifications can further enhance safety and reliability during transport.

What is the significance of square tube 2×4 in the automotive industry?

Square tube 2×4 is essential in the automotive industry for creating chassis and frame components. This application is critical as it contributes significantly to the overall strength and safety of vehicles. Buyers should ensure that materials sourced meet stringent automotive industry standards, and they should consider working with suppliers who have a proven track record in providing high-quality automotive components.

How does square tube 2×4 enhance furniture and design applications?

In the realm of furniture and design, square tube 2×4 is utilized for frameworks in custom furniture pieces. This allows designers to create innovative and aesthetically pleasing products while ensuring robust support. Buyers should look for suppliers offering customization options and consider the aesthetic finishes that align with consumer preferences, which can greatly enhance marketability in diverse regions.

3 Common User Pain Points for ‘square tube 2×4’ & Their Solutions

Scenario 1: Difficulty in Specifying the Right Gauge and Material for Structural Integrity

The Problem: B2B buyers often struggle with selecting the correct gauge and material for square tube 2×4 applications. This challenge is exacerbated by varying regional standards, availability of materials, and specific load requirements for different projects. For instance, a buyer in Nigeria may require a heavier gauge for structural support in a construction project, while a buyer in Brazil might focus on cost-effectiveness without compromising safety. Miscalculations or poor specifications can lead to project delays, increased costs, and safety hazards.

The Solution: To overcome this challenge, buyers should engage in thorough project assessment and consult with structural engineers to determine the precise load requirements and environmental factors. It’s crucial to understand the differences between materials such as carbon steel, galvanized steel, and aluminum, as each offers unique benefits. Buyers can leverage online calculators and structural design software to validate their specifications. Additionally, sourcing from suppliers with a comprehensive range of products, including detailed technical sheets, can facilitate informed decision-making. Establishing a direct line of communication with manufacturers to discuss specific project needs can also ensure that the correct gauge and material are procured, thereby enhancing structural integrity.

Scenario 2: Challenges in Supply Chain and Availability of Square Tube 2×4

The Problem: International buyers frequently encounter supply chain issues, especially when sourcing square tube 2×4 from distant suppliers. Fluctuations in demand, shipping delays, and regional restrictions can lead to stock shortages or longer lead times. For example, a buyer in the Middle East might find that their usual supplier is out of stock due to increased demand from a local construction boom, leading to project delays and increased costs.

The Solution: To mitigate supply chain challenges, buyers should diversify their supplier base and establish relationships with multiple vendors, both locally and internationally. This approach ensures that if one supplier faces delays, alternatives can be quickly accessed. It’s also advisable to maintain a buffer stock of essential materials, particularly during peak seasons when demand surges. Leveraging technology, such as inventory management systems, can provide real-time updates on stock levels and alert buyers when reordering is necessary. Buyers should also consider engaging suppliers that offer flexible shipping options, including expedited shipping or drop-shipping services, to minimize delays and maintain project timelines.

Scenario 3: Difficulty in Understanding and Meeting Compliance Standards

The Problem: B2B buyers often face confusion regarding compliance with local and international standards for square tube 2×4, which can vary significantly across regions. In Europe, for example, there may be strict guidelines regarding material specifications and sustainability standards, while buyers in South America might encounter fewer regulations. This disparity can lead to purchasing materials that are not compliant, resulting in costly rework or fines.

The Solution: To navigate compliance issues, buyers should invest time in researching the relevant regulations and standards applicable to their region and industry. This includes understanding certifications such as ISO standards, ASTM specifications, or any local building codes. Engaging with industry associations or regulatory bodies can provide valuable insights into compliance requirements. Additionally, buyers should prioritize sourcing materials from suppliers who are transparent about their compliance with these standards and can provide necessary certifications. Regular training and updates on regulatory changes can also equip buyers with the knowledge needed to stay compliant and avoid potential pitfalls in their projects.

Strategic Material Selection Guide for square tube 2×4

When selecting materials for square tube 2×4 applications, it’s essential to consider the performance characteristics, cost implications, and specific regional requirements. Below is an analysis of four common materials used in the manufacturing of square tubes, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Carbon Steel for Square Tube 2×4?

Carbon steel is one of the most widely used materials for square tubes due to its excellent strength-to-weight ratio and versatility. It typically has a high tensile strength, making it suitable for structural applications. Carbon steel tubes can withstand high temperatures and pressures, making them ideal for various industrial applications. However, they are prone to corrosion if not properly treated or coated.

Pros: Carbon steel is relatively inexpensive and readily available. Its strength makes it suitable for load-bearing applications, and it can be easily welded and fabricated.

Cons: The main drawback is its susceptibility to rust and corrosion, which necessitates protective coatings or galvanization, especially in humid or corrosive environments.

Impact on Application: Carbon steel square tubes are compatible with various media, including water and air, but they may not be suitable for corrosive substances without appropriate treatment.

Considerations for International Buyers: Compliance with standards such as ASTM A500 is crucial. Buyers from regions like Africa and South America should ensure that the suppliers provide adequate corrosion protection, especially in coastal areas.

How Does Aluminum Compare for Square Tube 2×4 Applications?

Aluminum is another popular choice for square tubes, valued for its lightweight and corrosion-resistant properties. It has a lower density than steel, making it easier to handle and transport. Aluminum tubes can withstand moderate temperatures and pressures, making them suitable for various applications, particularly in the automotive and aerospace industries.

Pros: The primary advantage of aluminum is its resistance to corrosion, which reduces maintenance costs over time. It is also recyclable, aligning with sustainability goals.

Cons: Aluminum is generally more expensive than carbon steel and has a lower tensile strength, which may limit its use in heavy-load applications.

Impact on Application: Aluminum square tubes are suitable for applications where weight savings are critical, such as in mobile structures or lightweight frames.

Considerations for International Buyers: Compliance with standards such as ASTM B221 is essential. Buyers in Europe and the Middle East should be aware of local regulations regarding aluminum recycling and environmental impact.

What Are the Benefits of Stainless Steel for Square Tube 2×4?

Stainless steel is renowned for its exceptional corrosion resistance and durability, making it an excellent choice for square tubes used in harsh environments. It can withstand high temperatures and pressures, making it suitable for applications in the chemical and food processing industries.

Pros: The key advantage of stainless steel is its longevity and minimal maintenance requirements due to its corrosion resistance. It is also aesthetically pleasing, making it suitable for architectural applications.

Cons: The main limitation is its higher cost compared to carbon and aluminum, which may not be feasible for all projects.

Impact on Application: Stainless steel square tubes are ideal for applications involving corrosive substances or high hygiene standards, such as in food processing.

Considerations for International Buyers: Compliance with standards like ASTM A554 is critical. Buyers from regions with stringent food safety regulations, such as Europe, must ensure that the stainless steel used meets these requirements.

What Role Does Galvanized Steel Play in Square Tube 2×4 Selection?

Galvanized steel, which is carbon steel coated with zinc, offers enhanced corrosion resistance, making it suitable for outdoor and industrial applications. The zinc coating protects the steel from rust, extending its lifespan.

Pros: The primary advantage is its cost-effectiveness combined with corrosion resistance. Galvanized steel is also readily available and easy to work with.

Cons: While the zinc coating provides good protection, it can wear off over time, especially in abrasive environments, necessitating periodic maintenance.

Impact on Application: Galvanized square tubes are suitable for applications exposed to moisture or corrosive environments, such as construction and outdoor structures.

Considerations for International Buyers: Compliance with standards such as ASTM A123 is essential. Buyers in humid climates, such as in Nigeria or Brazil, should prioritize galvanized options to ensure longevity.

Summary Table

| Material | Typical Use Case for square tube 2×4 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural applications | High strength and low cost | Prone to corrosion | Low |

| Aluminum | Lightweight structures | Corrosion resistance | Higher cost and lower strength | High |

| Stainless Steel | Food processing, chemical industries | Excellent corrosion resistance | High cost | High |

| Galvanized Steel | Outdoor structures | Cost-effective corrosion protection | Zinc coating wears off over time | Medium |

This strategic material selection guide provides insights into the various materials used for square tube 2×4 applications, helping international B2B buyers make informed decisions based on performance, cost, and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for square tube 2×4

What Are the Key Stages in the Manufacturing Process of Square Tube 2×4?

The manufacturing of square tube 2×4 involves several critical stages designed to ensure precision and quality. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The process begins with selecting high-quality raw materials, typically carbon steel, aluminum, or stainless steel. The chosen material is then cut into appropriate lengths and shapes, often utilizing advanced cutting techniques such as laser or plasma cutting for precision. This initial step is crucial, as the quality of the raw material directly impacts the final product’s integrity and performance. -

Forming Techniques

Forming is a vital stage where the prepared material is shaped into a square tube. Common techniques include hot rolling, cold rolling, and extrusion. In hot rolling, the steel is heated above its recrystallization temperature, allowing it to be shaped more easily. Cold rolling, on the other hand, involves shaping the material at room temperature, which enhances its strength through strain hardening. Extrusion is another method where the material is pushed through a die to create the desired cross-section. -

Assembly Processes

Once the tubes are formed, they may require assembly, especially if they are part of larger structures or systems. This may involve welding sections together or attaching additional components, such as fittings or connectors. Precision in this stage is critical to ensure structural integrity and compatibility with other components. -

Finishing Operations

The final stage involves various finishing processes, which may include surface treatment, coating, or galvanizing. These processes enhance the aesthetic appeal, durability, and corrosion resistance of the square tubes. Techniques such as powder coating or galvanizing are commonly employed to protect the metal from environmental factors.

How Is Quality Assurance Implemented in Square Tube Manufacturing?

Quality assurance (QA) is essential in the manufacturing of square tube 2×4, ensuring that products meet international standards and customer expectations. This involves several checkpoints and methodologies throughout the production cycle.

-

International Standards and Certifications

Adhering to international quality standards, such as ISO 9001, is vital for manufacturers aiming to establish credibility in the global market. ISO 9001 outlines requirements for a quality management system (QMS) that helps organizations enhance customer satisfaction through effective process management. Additionally, industry-specific certifications like CE marking in Europe and API standards for oil and gas applications may be required, depending on the intended use of the square tubes. -

Quality Control Checkpoints

Quality control (QC) checkpoints are integral to maintaining product standards. These checkpoints typically include:

– Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with specified standards before they enter the production process.

– In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to ensure that processes are being followed correctly and that products are within tolerance levels.

– Final Quality Control (FQC): After production, a comprehensive examination of the finished products is conducted to verify their quality and compliance with specifications. -

Common Testing Methods

Various testing methods are employed to ensure the quality of square tubes. These may include:

– Dimensional Inspection: Measuring the length, width, and thickness to ensure they meet specified tolerances.

– Mechanical Testing: Evaluating the strength and ductility of the material through tensile testing or impact testing.

– Non-Destructive Testing (NDT): Techniques such as ultrasonic or magnetic particle testing are used to detect internal flaws without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, especially those in international markets like Africa, South America, the Middle East, and Europe, must be diligent in verifying supplier quality control practices. Here are actionable steps buyers can take:

-

Conduct Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes, quality management systems, and adherence to international standards. Buyers should consider scheduling these audits to assess compliance with ISO 9001 and other relevant certifications. -

Request Quality Assurance Reports

Suppliers should be willing to provide detailed quality assurance reports, including results from IQC, IPQC, and FQC. These reports can help buyers understand the supplier’s QC processes and outcomes. -

Engage Third-Party Inspection Services

Utilizing third-party inspection services can offer an unbiased evaluation of the supplier’s products. These inspections can be performed at various stages of production, providing peace of mind regarding product quality.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate specific nuances regarding quality control and certifications when sourcing square tube 2×4. These considerations include:

-

Understanding Regional Standards

Different regions may have unique standards and regulations governing product quality. For example, CE marking is mandatory in Europe for many products, while ANSI or ASTM standards may be applicable in the U.S. Buyers should familiarize themselves with these regulations to ensure compliance. -

Cultural and Legal Considerations

Understanding cultural and legal differences in supplier countries is crucial. This includes recognizing how quality assurance practices may vary and ensuring that contracts specify adherence to the agreed-upon standards. -

Logistics and Supply Chain Management

Quality control extends beyond manufacturing to logistics and supply chain management. Ensuring that products are handled and transported in a manner that preserves their quality is vital. Buyers should work closely with suppliers to establish quality checkpoints throughout the logistics process.

Conclusion

The manufacturing processes and quality assurance measures for square tube 2×4 are critical for ensuring product reliability and performance. By understanding these processes and actively engaging in quality verification, B2B buyers can make informed decisions that align with their operational needs and standards. This proactive approach not only fosters trust with suppliers but also enhances the overall quality of the products sourced for various applications across different industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘square tube 2×4’

In the competitive landscape of international B2B sourcing, procuring square tube 2×4 can be a complex process. This step-by-step checklist is designed to guide buyers through each critical phase of sourcing, ensuring that they make informed decisions that align with their operational needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to clearly outline your technical requirements. This includes dimensions, material type (e.g., carbon steel, stainless steel, or aluminum), wall thickness, and any specific industry standards your product must meet. Having a well-defined specification helps streamline the sourcing process and minimizes the risk of receiving incorrect products.

Step 2: Identify Your Budget and Quantity Needs

Establishing a budget and determining the quantity required are pivotal for effective sourcing. Consider not only the cost of the square tubes but also shipping, customs duties, and any additional fees. Knowing your budget and quantity can help you negotiate better pricing and avoid over-ordering or under-ordering.

Step 3: Research and Shortlist Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in square tube 2×4. Use industry directories, trade shows, and online marketplaces to compile a list. Focus on suppliers that have a proven track record, positive customer reviews, and experience serving your target markets, such as Africa, South America, the Middle East, and Europe.

Step 4: Evaluate Supplier Certifications and Compliance

Before finalizing any supplier, verify their certifications and compliance with international standards. Look for ISO certifications, quality management systems, and adherence to local regulations. This step is crucial to ensure that the products you receive will meet safety and quality standards, reducing the risk of costly returns or project delays.

Step 5: Request Samples and Conduct Quality Checks

Once you have shortlisted potential suppliers, request samples of the square tube 2×4. This allows you to assess the quality of materials, finish, and dimensions firsthand. Conducting quality checks at this stage can save you time and money in the long run by ensuring that the products meet your specifications.

Step 6: Negotiate Terms and Conditions

Engage in discussions with your chosen suppliers to negotiate pricing, payment terms, delivery schedules, and warranties. Clear communication of expectations can prevent misunderstandings later in the process. Ensure that all terms are documented to protect both parties and facilitate a smoother transaction.

Step 7: Finalize Purchase Order and Monitor Delivery

Once terms are agreed upon, finalize your purchase order and set up a system to monitor the delivery process. Keep in regular contact with the supplier to track the status of your order and address any potential issues promptly. Effective communication during this stage is vital to ensure timely delivery and to maintain a good relationship with your supplier.

By following this checklist, B2B buyers can navigate the complexities of sourcing square tube 2×4 more effectively, ensuring that their procurement process is efficient and aligned with their business goals.

Comprehensive Cost and Pricing Analysis for square tube 2×4 Sourcing

What Are the Key Cost Components for Sourcing Square Tube 2×4?

When sourcing square tube 2×4, understanding the cost structure is crucial for effective budgeting and decision-making. The main cost components include:

-

Materials: The primary expense is often the raw materials. For square tube 2×4, carbon steel is commonly used, but variations such as stainless steel or aluminum can significantly affect costs. Prices fluctuate based on market demand, availability, and location.

-

Labor: Labor costs encompass the wages of workers involved in manufacturing and assembling the product. These costs can vary by region, impacting the overall pricing structure.

-

Manufacturing Overhead: This includes utilities, maintenance, and indirect labor associated with the manufacturing process. Efficient production methods can help mitigate these costs.

-

Tooling: Initial tooling costs can be substantial, especially for custom specifications. These costs are often amortized over large production runs, making it essential to consider order volume.

-

Quality Control (QC): Rigorous quality checks ensure the product meets specified standards. While this adds to the cost, it is essential for maintaining product integrity and minimizing returns.

-

Logistics: Transporting materials and finished products incurs additional costs. Factors such as distance, mode of transport, and fuel prices can influence logistics expenses.

-

Margin: Suppliers typically add a profit margin to their costs. This margin can vary significantly based on market conditions, competition, and supplier reputation.

How Do Price Influencers Impact Square Tube 2×4 Costs?

Several factors influence the pricing of square tube 2×4 beyond the basic cost components:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk pricing, significantly reducing the per-unit cost. Understanding the MOQ can help buyers negotiate better deals.

-

Specifications and Customization: Custom sizes or specific coatings (e.g., galvanized, powder-coated) can lead to increased costs. Buyers should assess whether customization is necessary for their applications.

-

Material Quality and Certifications: Higher quality materials and compliance with international standards (ISO, ASTM) typically command higher prices. Buyers should weigh the benefits of premium materials against their budget constraints.

-

Supplier Factors: The reputation, reliability, and location of the supplier can also affect pricing. Established suppliers may charge more due to perceived value and lower risks.

-

Incoterms: Understanding the chosen Incoterms (e.g., FOB, CIF) is essential for calculating total landed costs. These terms dictate who bears the responsibility for shipping, insurance, and tariffs, impacting the overall pricing strategy.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Square Tube 2×4?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several strategies to enhance cost-efficiency:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Establishing a good relationship can lead to better terms and discounts.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but all associated costs, including shipping, handling, and potential tariffs. A lower upfront cost may not always lead to overall savings.

-

Pricing Nuances for International Buyers: Currency fluctuations and geopolitical factors can affect pricing. Buyers should stay informed about market trends and potential risks.

-

Leverage Local Suppliers: Whenever possible, sourcing from local suppliers can reduce logistics costs and lead times, providing a competitive edge.

-

Evaluate Long-Term Partnerships: Building long-term relationships with suppliers can lead to better pricing and service. Regularly reviewing supplier performance can help ensure quality and cost-effectiveness.

Disclaimer

The prices and cost structures discussed are indicative and can vary based on market conditions and specific buyer requirements. Always conduct thorough research and obtain multiple quotes before making purchasing decisions.

Alternatives Analysis: Comparing square tube 2×4 With Other Solutions

Understanding Alternatives to Square Tube 2×4 in Structural Applications

In the realm of structural applications, selecting the right material is crucial for ensuring durability, cost-effectiveness, and ease of use. While the square tube 2×4 has established itself as a popular choice in various industries, several alternatives exist that may better meet specific project requirements. This analysis will explore these alternatives, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Square Tube 2×4 | Rectangular Tube 4×2 | I-Beam |

|---|---|---|---|

| Performance | High strength-to-weight ratio; versatile | Similar strength; slightly less versatile | Excellent load-bearing capacity; ideal for beams |

| Cost | Moderate pricing; widely available | Similar to square tube; varies by supplier | Generally higher due to manufacturing complexity |

| Ease of Implementation | Simple to cut and weld; commonly used | Easy to work with; more complex joints | Requires specialized equipment for cutting and welding |

| Maintenance | Low maintenance; corrosion-resistant options available | Low maintenance; similar properties | Low maintenance; may require protective coatings |

| Best Use Case | General construction, frames, and supports | Structural applications needing specific dimensions | Heavy-duty construction, bridges, and industrial applications |

Detailed Breakdown of Alternatives

Rectangular Tube 4×2

The rectangular tube 4×2 is an excellent alternative to the square tube 2×4, offering similar strength characteristics but with slightly different dimensions. This type of tubing can be advantageous in applications where space optimization is crucial, allowing for more efficient use of materials. However, it may not be as versatile for certain framing applications due to its shape, which might limit design flexibility.

I-Beam

The I-beam is a robust structural component that excels in heavy load-bearing situations. Its design allows for maximum strength with minimal material, making it ideal for large structures such as bridges and commercial buildings. While it offers superior performance, the cost and complexity of implementation can be higher than that of square tube or rectangular tube options. Projects that require high load capacities over long spans would benefit most from this alternative.

Conclusion: Making the Right Choice for Your Structural Needs

When determining the best material for a project, B2B buyers must carefully consider their specific requirements, including load capacity, cost constraints, and ease of use. Square tube 2×4 is an excellent all-around choice for general construction, but alternatives like rectangular tubes and I-beams can provide specific advantages in certain applications. Understanding the performance characteristics and practical implications of each option will empower buyers to make informed decisions that align with their project goals. Ultimately, the right choice will depend on the unique demands of each project, ensuring that structural integrity and cost-effectiveness are maintained.

Essential Technical Properties and Trade Terminology for square tube 2×4

What Are the Key Technical Properties of Square Tube 2×4?

When sourcing square tube 2×4 for various applications, understanding its technical properties is crucial for ensuring that the material meets specific performance requirements. Here are some essential specifications to consider:

-

Material Grade

The most common material grades for square tube 2×4 are ASTM A500 Grade B and ASTM A36. ASTM A500 Grade B is often preferred for structural applications due to its higher yield strength, while ASTM A36 is a general-purpose steel that provides good weldability and machinability. Choosing the right material grade impacts the strength, durability, and suitability for specific projects. -

Wall Thickness

Wall thickness varies, typically ranging from 0.065 inches to 0.25 inches. Thicker walls provide enhanced strength and load-bearing capacity, which is essential for structural applications. Understanding wall thickness helps buyers assess the square tube’s ability to withstand stress and impacts, which is particularly important in construction and manufacturing. -

Length and Tolerance

Standard lengths for square tube 2×4 are often 20 feet or 24 feet, with tolerances varying by manufacturer. Tolerance refers to the permissible variation in dimensions, ensuring that the square tube fits precisely in applications. Accurate lengths and tolerances are vital for project planning, as they affect cutting, fabrication, and installation processes. -

Finish

Common finishes include hot-rolled, cold-rolled, and galvanized. Hot-rolled steel is typically less expensive and suitable for many structural uses, while cold-rolled offers a smoother finish and tighter tolerances. Galvanization provides corrosion resistance, making it ideal for outdoor applications. The choice of finish influences durability, maintenance requirements, and overall project costs. -

Weight

The weight of square tube 2×4 is an important consideration, especially for logistics and transport. It typically weighs around 4.7 lbs per foot for a 0.065-inch wall thickness. Knowing the weight helps buyers calculate shipping costs and assess the handling requirements during installation.

Which Trade Terminology Should B2B Buyers Know for Square Tube 2×4?

Familiarity with industry-specific jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms related to square tube 2×4:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of square tubes, buyers may seek OEMs for customized solutions that meet specific project requirements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, as it can affect overall project costs and supply chain efficiency. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products or services. B2B buyers often use RFQs to compare prices and terms, ensuring they receive competitive offers for square tube 2×4. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Understanding these terms is vital for managing risks associated with shipping, insurance, and customs clearance when importing square tube 2×4 from different regions. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. It’s a critical factor in project planning and inventory management, as longer lead times can affect timelines and project execution. -

Weldability

This term describes how easily a material can be welded. For square tube 2×4, weldability affects its application in structural and fabrication projects. Understanding weldability ensures that the selected material can be effectively joined with other components in construction or manufacturing processes.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing square tube 2×4, ensuring they select the right materials for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the square tube 2×4 Sector

What Are the Key Market Dynamics and Trends Influencing Square Tube 2×4 Sourcing?

The global market for square tube 2×4 products is influenced by several key drivers, particularly in the context of international B2B transactions. Rapid urbanization and infrastructural development in emerging markets like Nigeria and Brazil create a heightened demand for durable construction materials. In addition, advancements in manufacturing technologies, such as automated welding and precision cutting, are enhancing the efficiency and cost-effectiveness of square tube production. As companies strive for competitive pricing, buyers are increasingly turning to international suppliers who can offer both quality and value.

Moreover, the rise of digital procurement platforms is reshaping how international buyers source materials. These platforms enable buyers to compare prices, assess supplier reliability, and streamline order processes, thereby reducing lead times. Another trend is the growing emphasis on customized solutions. Many manufacturers are now offering tailored specifications for square tubes, allowing buyers to meet specific project requirements while optimizing material usage.

How Is Sustainability Impacting the Sourcing of Square Tube 2×4 Products?

Sustainability has become a pivotal concern in the sourcing of square tube 2×4 products. Environmental impacts associated with steel production, such as carbon emissions and resource depletion, are driving buyers to seek out ethically sourced materials. Many suppliers are now adopting green certifications, indicating compliance with environmental standards and sustainable practices. For instance, certifications like ISO 14001 and LEED (Leadership in Energy and Environmental Design) are becoming increasingly important to buyers focused on sustainability.

Additionally, the integration of recycled materials in the production of square tubes not only reduces the carbon footprint but also addresses the increasing demand for eco-friendly products. B2B buyers are encouraged to inquire about the percentage of recycled content in the materials they are sourcing. By prioritizing suppliers who demonstrate a commitment to sustainability, businesses can enhance their corporate social responsibility profiles while meeting regulatory requirements.

What Has Been the Evolution of Square Tube 2×4 in the Market?

The square tube 2×4 has evolved significantly over the decades, initially gaining traction in the construction and manufacturing sectors due to its structural integrity and versatility. Early uses were primarily in basic construction frameworks; however, as technology advanced, so did the applications for square tubes. The introduction of new alloys and manufacturing techniques has improved the strength-to-weight ratio, making them suitable for a wider range of applications, including automotive and aerospace sectors.

Today, square tube 2×4 products are not only valued for their utility but also for their aesthetic appeal, leading to their incorporation in design and architectural elements. As global trade continues to expand, the sourcing of these materials has become increasingly international, with buyers seeking quality and sustainability at competitive prices.

Conclusion

Navigating the complexities of the square tube 2×4 sector requires an understanding of market dynamics, sustainability considerations, and the historical evolution of these materials. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should remain vigilant about emerging trends and align their sourcing strategies with ethical and sustainable practices to maximize their competitive advantage in the marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of square tube 2×4

-

How do I ensure quality when sourcing square tube 2×4 internationally?

To ensure quality when sourcing square tube 2×4, start by vetting suppliers through due diligence. Request certifications such as ISO 9001, which indicates adherence to quality management standards. Ask for material test reports and inquire about their manufacturing processes. Additionally, consider visiting the factory or using third-party inspection services to evaluate product quality before shipment. This proactive approach helps mitigate risks and ensures you receive materials that meet your specifications. -

What are the typical dimensions and specifications for square tube 2×4?

Square tube 2×4 typically measures 2 inches by 4 inches in cross-section, with various wall thicknesses available, such as 11 gauge or .065 inches. The length can vary, commonly offered in 12-foot or 20-foot lengths. It’s essential to specify the gauge, finish (e.g., galvanized, black, or stainless steel), and any additional treatments (like powder coating) based on your project’s requirements. Custom dimensions may also be available upon request. -

What is the minimum order quantity (MOQ) for square tube 2×4?

Minimum order quantities for square tube 2×4 can vary widely by supplier and region. Typically, MOQs range from a few hundred to several thousand units, depending on the supplier’s production capacity and your specific requirements. When negotiating, consider discussing flexibility in MOQs for initial orders, especially if you’re testing a new supplier or entering a new market. This can help you manage inventory risks while still accessing the materials you need. -

What payment terms should I expect when sourcing square tube 2×4?

Payment terms can vary significantly among suppliers. Common options include 30% upfront and 70% upon delivery, or 100% payment in advance for smaller orders. Some suppliers may offer letters of credit for larger transactions, which can provide additional security. Always clarify payment terms before finalizing contracts, and consider negotiating terms that align with your cash flow needs. It’s advisable to use secure payment methods to protect your investment. -

How can I customize square tube 2×4 for my project needs?

Customization options for square tube 2×4 typically include variations in size, wall thickness, and finish. Some suppliers also offer services like cutting, drilling, or bending to meet specific project requirements. To initiate customization, provide detailed specifications and drawings to your supplier. It’s advisable to confirm lead times and any additional costs associated with custom orders, as these can impact your project timeline and budget. -

What logistics considerations should I keep in mind when importing square tube 2×4?

Logistics for importing square tube 2×4 involves several key considerations: shipping methods (air vs. sea), customs regulations, and delivery timelines. Ensure you understand the total landed cost, including shipping, tariffs, and handling fees. Partner with a reputable freight forwarder familiar with your region’s import regulations to streamline the process. Additionally, confirm the supplier’s shipping capabilities and ensure they provide proper documentation for customs clearance. -

How do I assess supplier reliability for square tube 2×4?

Assessing supplier reliability involves researching their history, client testimonials, and industry reputation. Request references from previous clients and evaluate their responsiveness to inquiries. Conduct a background check on their financial stability and production capabilities. Consider starting with a smaller order to evaluate their service and product quality before committing to larger quantities. Building a long-term relationship with a reliable supplier can enhance your supply chain resilience. -

What are the common applications for square tube 2×4 in construction and manufacturing?

Square tube 2×4 is widely used in various applications, including structural supports, framework for buildings, and manufacturing of furniture and equipment. Its strength and versatility make it suitable for construction projects, such as scaffolding, railings, and sign frames. Understanding the specific requirements of your application will help you select the appropriate material grade and finish, ensuring durability and performance in your projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Square Tube 2X4 Manufacturers & Suppliers List

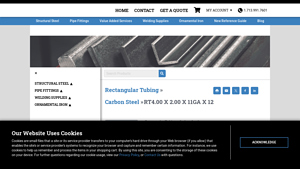

1. Steel Supply – RT4.00 X 2.00 X 11GA X 12 Rectangular Tubing

Domain: steelsupplylp.com

Registered: 2005 (20 years)

Introduction: {“Product Name”:”RT4.00 X 2.00 X 11GA X 12″,”SKU”:”183503″,”Weight”:”56.40 lbs”,”Length”:”144 inches (12 feet)”,”Material”:”A500 Carbon Steel”,”Size”:”4.00 x 2.00 inches”,”Wall Thickness”:”11 gauge”,”Description”:”RECTANGULAR TUBING”,”Price by Quantity”:{“1 – 49″:”$70.47″,”50 – 99″:”$63.96″,”100 – 199″:”$62.62″,”200 +”:”$61.62″},”First Cut Price”:”$10.00″,”Additional Cuts Price”:”$8.00″,”Tolerance…

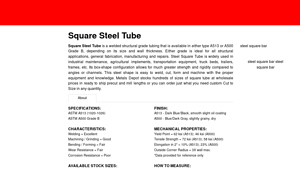

2. MetalsDepot® – Steel Square Tube

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: MetalsDepot® – Buy Steel Square Tube Online! Square Steel Tube is a welded structural grade tubing available in type A513 or A500 Grade B, ideal for structural applications, general fabrication, manufacturing, and repairs. Common uses include industrial maintenance, agricultural implements, transportation equipment, truck beds, trailers, and frames. It offers greater strength and rigidity compared…

3. King Metals – Rectangular Tube 4 x 2 x 11 Ga

Domain: kingmetals.com

Registered: 1999 (26 years)

Introduction: This company, King Metals – Rectangular Tube 4 x 2 x 11 Ga, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

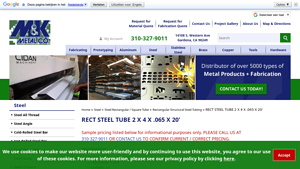

4. MK Metal – RECT STEEL TUBE 2 X 4 X .065 X 20′

Domain: mkmetal.net

Registered: 1999 (26 years)

Introduction: {“Product Name”: “RECT STEEL TUBE 2 X 4 X .065 X 20′”, “Dimensions”: {“Width”: “2 in”, “Height”: “4 in”, “Thickness”: “.065 in”, “Length”: “20 ft”}, “Weight per Foot”: “2.595 lbs/sqft”, “Price per Piece”: “$111.03”, “Material”: “Steel”, “Contact Number”: “310-327-9011”, “Location”: “14108 S. Western Ave, Gardena, CA 90249”}

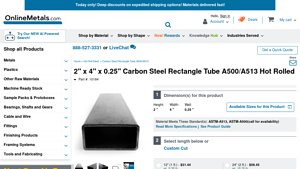

5. Online Metals – Carbon Steel Rectangle Tube

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: {“dimensions”:{“height”:”2 inch”,”width”:”4 inch”,”wall”:”0.25 inch”},”material”:”Carbon Steel”,”type”:”Rectangle Tube”,”standards”:”ASTM-A513, ASTM-A500″,”part_number”:”10184″,”production_method”:”Hot Rolled”,”weight_per_foot”:”9.38 pounds”,”available_lengths”:[{“length”:”12 inch”,”price”:”$31.44″,”weight”:”9.38 lb”},{“length”:”24 inch”,”price”:”$59.45″,”weight”:”18.76 lb”},{“length”:”36 inch”,”p…

6. Metal Supermarkets – Square Tube

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Square tube is a hollow, square-shaped structural material commonly made from metals like steel, stainless steel, or aluminum. It is highly versatile and widely utilized across various industries for its strength, durability, and adaptability. Available metal types include Mild Steel, Stainless Steel, and Aluminum. Applications include building construction, railings, and signposts. Square tubing …

7. Speedy Metals – Rectangular Steel Tube

Domain: speedymetals.com

Registered: 2001 (24 years)

Introduction: {“Dimensions”: {“Width”: “2 inch”, “Height”: “4 inch”, “Wall Thickness”: “.188 inch”}, “Material”: “Steel”, “Shape”: “Rectangular Tube”, “Weight”: {“12 inch”: “6.8700 lbs”, “18 inch”: “10.3050 lbs”, “24 inch”: “13.7400 lbs”, “36 inch”: “20.6100 lbs”, “48 inch”: “27.4800 lbs”, “60 inch”: “34.3500 lbs”}, “Base Price”: “$2.08 per inch”, “Cutting Tolerance”: {“Length”: “+1/8 inch, -0”}, “Max Length fo…

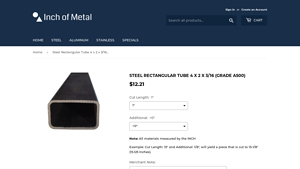

8. Inch of Metal – Steel Rectangular Tube 4 x 2 x 3/16 (Grade A500)

Domain: inchofmetal.com

Registered: 2012 (13 years)

Introduction: {‘product_name’: ‘Steel Rectangular Tube 4 x 2 x 3/16 (Grade A500)’, ‘price’: ‘$12.21’, ‘dimensions’: {‘width’: ‘4.000 inches’, ‘height’: ‘2.000 inches’, ‘thickness’: ‘0.188 inches’}, ‘weight_per_foot’: ‘6.87 pounds’, ‘material_grade’: ‘A500’, ‘description’: ‘Steel square and rectangular tubing are low carbon cold formed electric resistance welded tubes. These types of tubes offer a high strength-…

Strategic Sourcing Conclusion and Outlook for square tube 2×4

As global markets evolve, the strategic sourcing of square tube 2×4 remains a critical component for businesses looking to optimize their supply chains. By understanding the diverse applications of this versatile material across sectors such as construction, manufacturing, and automotive, buyers can leverage its strength and durability to meet their specific project needs. Engaging with reliable suppliers who offer value-added services, such as customized lengths and finishes, can enhance operational efficiency and reduce costs.

Furthermore, international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should prioritize suppliers who demonstrate a commitment to sustainability and quality assurance. This not only ensures compliance with regional regulations but also fosters long-term partnerships built on trust and reliability.

Looking ahead, the demand for square tube 2×4 is projected to grow, driven by infrastructure development and industrial expansion. It is imperative for businesses to stay informed about market trends and emerging technologies that can enhance product offerings. By strategically sourcing square tube 2×4, companies can position themselves for success in a competitive landscape. Connect with trusted suppliers today to unlock the full potential of your projects and drive business growth.