Oblong Rubber Grommets: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for oblong rubber grommets

In today’s competitive industrial landscape, sourcing reliable oblong rubber grommets poses a significant challenge for businesses looking to ensure the longevity and functionality of their products. These essential components are critical for protecting wires and cables from abrasion and environmental damage, making them indispensable in various applications across multiple sectors. This comprehensive guide serves as a vital resource for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, including key markets like Brazil and Saudi Arabia.

Within this guide, readers will discover a wealth of information covering the diverse types of oblong rubber grommets available, their specific applications, and the nuances of supplier vetting to ensure quality and compliance. Additionally, we delve into cost considerations, allowing businesses to make informed purchasing decisions that align with their operational budgets and project timelines.

By empowering buyers with actionable insights and a detailed understanding of the global market dynamics surrounding oblong rubber grommets, this guide aims to streamline the sourcing process. Whether you are a procurement manager, project engineer, or business owner, you will find the necessary tools to navigate this specialized market and secure the best components for your needs.

Understanding oblong rubber grommets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type-A Grommets | Standard oval shape, versatile sizes | Electrical enclosures, machinery housing | Pros: Cost-effective, widely available. Cons: Limited in specialized applications. |

| Type-B Grommets | Enhanced durability, higher temperature resistance | Automotive, aerospace applications | Pros: Long-lasting, suitable for extreme conditions. Cons: Higher cost than standard types. |

| Blind Hole Oval Grommets | Designed for blind holes, easy installation | Sheet metal fabrication, HVAC systems | Pros: Simplified installation, prevents damage. Cons: Less flexibility in application compared to others. |

| Waterproof Grommets | Sealed design for moisture resistance | Marine, outdoor equipment | Pros: Protects against water ingress. Cons: May be more expensive due to specialized materials. |

| Silicone Grommets | Made from silicone, high-temperature tolerance | Electronics, high-performance machinery | Pros: Excellent heat resistance, versatile. Cons: Higher price point, limited color options. |

What are the Characteristics of Type-A Grommets?

Type-A grommets are the most commonly used rubber grommets, characterized by their standard oval shape and a wide range of sizes. They are primarily utilized in electrical enclosures and machinery housings to protect wires and cables from abrasion and damage. When purchasing Type-A grommets, buyers should consider the specific dimensions required for their applications, as well as the material properties to ensure compatibility with their operational environment.

How Do Type-B Grommets Differ from Other Variations?

Type-B grommets are designed with enhanced durability and higher temperature resistance, making them ideal for automotive and aerospace applications. These grommets can withstand harsher conditions and are often made from materials that offer better longevity. Buyers should evaluate the expected environmental conditions and performance requirements when selecting Type-B grommets, as the investment may yield significant long-term benefits in terms of reliability and performance.

Why Choose Blind Hole Oval Grommets for Specific Applications?

Blind hole oval grommets are specifically engineered for installation in blind holes, allowing for easy insertion without the need for additional fastening. They are commonly used in sheet metal fabrication and HVAC systems, where simplicity and efficiency are key. When purchasing these grommets, buyers should ensure that the hole specifications align with the grommet dimensions to avoid installation issues.

What Advantages Do Waterproof Grommets Offer?

Waterproof grommets feature a sealed design that provides moisture resistance, making them suitable for marine and outdoor equipment applications. These grommets are particularly valuable in environments where exposure to water is a concern, as they help prevent corrosion and damage to internal components. Buyers should assess the level of moisture exposure in their applications to determine if waterproof grommets are necessary, considering their potential higher costs.

When Should Silicone Grommets Be Considered?

Silicone grommets are made from silicone material, offering exceptional heat resistance and flexibility, which makes them suitable for high-performance machinery and electronics. Their ability to withstand extreme temperatures while maintaining integrity is a significant advantage in demanding applications. Buyers should consider the specific temperature ranges and chemical exposures their applications will encounter, as this will influence the decision to invest in silicone grommets over other types.

Key Industrial Applications of oblong rubber grommets

| Industry/Sector | Specific Application of Oblong Rubber Grommets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Cable management in vehicle assemblies | Prevents wear and tear on wiring, enhancing vehicle longevity | Material durability (e.g., heat, oil resistance), customization options |

| Electronics | Insulation for electrical components in devices | Reduces risk of electrical short circuits and enhances safety | Compliance with international standards, size specifications |

| Construction | Protection for cables and pipes in building frameworks | Minimizes damage during installation, ensuring structural integrity | Weather resistance, compatibility with various materials |

| Aerospace | Sealing and insulation for aircraft wiring | Increases safety and reliability of electrical systems | High-temperature resistance, lightweight materials |

| Industrial Equipment | Vibration dampening in machinery | Reduces noise and extends equipment lifespan | Custom sizes, resistance to chemicals and extreme conditions |

How Are Oblong Rubber Grommets Utilized in the Automotive Industry?

In the automotive sector, oblong rubber grommets are essential for managing cables within vehicle assemblies. They effectively protect wiring from abrasion caused by movement and environmental factors, which prolongs the life of electrical systems. Buyers from regions like Africa and South America should consider sourcing grommets that meet specific durability standards against heat and oil exposure, as these factors are critical for maintaining vehicle performance in diverse climates.

What Role Do Oblong Rubber Grommets Play in Electronics?

In the electronics industry, oblong rubber grommets are utilized primarily for insulating electrical components within devices. They serve to prevent short circuits by safeguarding wires that pass through metal casings. For international buyers, especially in the Middle East and Europe, it is crucial to ensure that the grommets comply with relevant safety standards and that the dimensions are suitable for their specific applications, as improper sizing can lead to increased risks of electrical failures.

Why Are Oblong Rubber Grommets Important in Construction?

In construction, oblong rubber grommets are used to protect cables and pipes that run through structural frameworks. They help to minimize damage during installation, which is essential for maintaining structural integrity. Buyers in this sector should prioritize grommets that offer weather resistance and compatibility with a variety of building materials, particularly in regions with extreme weather conditions, such as parts of Africa and the Middle East.

How Do Oblong Rubber Grommets Enhance Safety in Aerospace Applications?

Oblong rubber grommets are critical in aerospace for sealing and insulating aircraft wiring. They contribute to the safety and reliability of electrical systems, which is paramount in aviation. Buyers must consider sourcing grommets that can withstand high temperatures and are made from lightweight materials to ensure compliance with strict aerospace regulations, especially for international contracts in Europe and beyond.

What Benefits Do Oblong Rubber Grommets Provide for Industrial Equipment?

In industrial settings, oblong rubber grommets are used primarily for vibration dampening in machinery. They help reduce noise and prolong equipment lifespan by absorbing shocks and vibrations. Buyers should focus on sourcing grommets that are custom-sized and resistant to chemicals, particularly in industries dealing with harsh environments, ensuring they can withstand the specific operational conditions prevalent in regions like South America and the Middle East.

3 Common User Pain Points for ‘oblong rubber grommets’ & Their Solutions

Scenario 1: Challenges with Material Selection for Oblong Rubber Grommets

The Problem: B2B buyers often struggle with choosing the right material for oblong rubber grommets. With various materials available—such as NBR, EPDM, and silicone—each possessing unique properties that cater to specific applications—selecting the wrong one can lead to premature failure. For instance, using a standard rubber grommet in high-temperature environments can cause it to degrade quickly, resulting in costly downtime and potential damage to sensitive equipment. This challenge is particularly acute for manufacturers in industries like automotive or electronics, where reliability is paramount.

The Solution: To mitigate this issue, it is crucial to conduct a thorough assessment of the operational environment before making a purchase. Buyers should consider factors such as temperature extremes, exposure to chemicals, and mechanical stresses. Consulting with suppliers who offer technical support can be invaluable; they can provide guidance on which materials are best suited for specific applications. For example, if the application involves exposure to oils and fuels, opting for NBR grommets would be advisable due to their excellent oil resistance. Additionally, buyers should request samples to test compatibility before placing large orders, ensuring that the selected grommets meet all performance requirements.

Scenario 2: Sizing Issues Leading to Installation Challenges

The Problem: Sizing discrepancies are a common frustration for B2B buyers of oblong rubber grommets. An incorrect size can lead to significant installation challenges, including gaps that allow moisture and contaminants to enter, or overly tight fits that can cause damage during installation. This is particularly problematic for companies involved in manufacturing or assembly processes, where precision is critical. As a result, not only do they waste time and resources on reordering, but they also risk project delays that can impact overall productivity.

The Solution: To prevent sizing issues, it is essential to utilize a comprehensive grommet sizing chart that aligns with the specific application requirements. Buyers should measure the groove diameter, groove width, and overall thickness to ensure a proper fit. Engaging with suppliers who offer customizable options can also be beneficial; this allows companies to specify dimensions that meet their exact needs. Additionally, implementing a standardized procedure for measuring and selecting grommets during the design phase can streamline the procurement process. Training staff on proper measurement techniques can further reduce the risk of errors, ultimately leading to smoother installations and enhanced operational efficiency.

Scenario 3: Performance Under Extreme Conditions

The Problem: Many B2B buyers face the challenge of ensuring that oblong rubber grommets perform optimally under extreme conditions. Industries such as construction and aerospace often expose components to harsh environments, including extreme temperatures, UV radiation, and chemical exposure. If the grommets fail in these conditions, it can lead to severe repercussions, including equipment failure and safety hazards. Buyers need assurance that the products they purchase will withstand these challenges without compromising performance.

The Solution: To address this concern, buyers should prioritize sourcing grommets that are specifically designed for extreme conditions. This involves looking for products with certifications or ratings that confirm their durability against heat, chemicals, and UV radiation. Suppliers often provide detailed technical specifications and performance data, which can guide purchasing decisions. Additionally, opting for grommets made from materials like silicone or FKM can provide enhanced resistance to extreme temperatures and chemical exposure. For projects with particularly stringent requirements, engaging in discussions with suppliers about custom formulations can lead to the development of tailored solutions that meet specific environmental challenges, ensuring long-lasting performance.

Strategic Material Selection Guide for oblong rubber grommets

What Are the Key Properties of Common Materials Used for Oblong Rubber Grommets?

When selecting materials for oblong rubber grommets, it is essential to consider their properties, performance, and suitability for specific applications. Here, we analyze four common materials: Natural Rubber (NR), Nitrile Rubber (NBR), Ethylene Propylene Diene Monomer (EPDM), and Silicone Rubber. Each material has unique characteristics that can significantly impact the performance of grommets in various environments.

How Does Natural Rubber (NR) Perform in Grommet Applications?

Natural rubber is known for its excellent elasticity and tensile strength, making it a popular choice for grommets. It typically performs well in moderate temperature ranges, with a maximum operational temperature around 80°C. However, it is not very resistant to oils or chemicals, which can lead to degradation in certain applications.

Pros: High elasticity and strength, cost-effective, and easy to manufacture.

Cons: Limited chemical resistance and temperature tolerance.

Impact on Application: Best suited for applications where flexibility and moderate temperatures are essential, but not ideal for environments with oil exposure.

Considerations for International Buyers: Compliance with ASTM standards is common, but buyers should ensure compatibility with local regulations in their regions, such as those in Brazil or Saudi Arabia.

What Advantages Does Nitrile Rubber (NBR) Offer for Grommets?

Nitrile rubber, or NBR, is well-regarded for its oil and fuel resistance, making it a suitable choice for automotive and industrial applications. It can withstand temperatures up to 120°C, providing a good balance of flexibility and durability.

Pros: Excellent oil resistance, good mechanical properties, and moderate temperature tolerance.

Cons: Limited resistance to ozone and UV exposure, which can lead to degradation.

Impact on Application: Ideal for environments where oil exposure is prevalent, such as automotive or machinery applications.

Considerations for International Buyers: NBR is widely accepted in various markets; however, it is crucial to check for compliance with regional standards, particularly in oil-rich regions like the Middle East.

Why Choose Ethylene Propylene Diene Monomer (EPDM) for Grommets?

EPDM is a synthetic rubber known for its outstanding weather resistance, UV stability, and ozone resistance. It can operate effectively in temperatures ranging from -40°C to 120°C, making it suitable for outdoor applications.

Pros: Excellent weather and ozone resistance, good thermal stability, and long service life.

Cons: Poor oil and solvent resistance, which limits its use in certain industrial applications.

Impact on Application: Best for outdoor or exposed environments, such as construction or automotive applications, where UV exposure is a concern.

Considerations for International Buyers: EPDM is compliant with various international standards, making it a reliable choice for buyers in diverse markets, including Europe and Africa.

What Role Does Silicone Rubber Play in Grommet Selection?

Silicone rubber is favored for its extreme temperature resistance, capable of withstanding temperatures from -60°C to 230°C, and even higher in specialized applications. It offers excellent flexibility and durability, making it suitable for a wide range of applications.

Pros: High-temperature resistance, excellent flexibility, and good electrical insulation properties.

Cons: Generally higher cost and less resistance to mechanical wear compared to other rubbers.

Impact on Application: Ideal for applications requiring extreme temperature stability, such as in aerospace or high-heat environments.

Considerations for International Buyers: Silicone grommets often meet strict international standards, making them suitable for high-tech industries in regions like Europe.

Summary of Material Selection for Oblong Rubber Grommets

| Material | Typical Use Case for Oblong Rubber Grommets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber (NR) | General-purpose applications, moderate temperatures | High elasticity and cost-effective | Limited chemical resistance | Low |

| Nitrile Rubber (NBR) | Automotive and industrial applications | Excellent oil resistance | Limited ozone and UV resistance | Medium |

| Ethylene Propylene Diene Monomer (EPDM) | Outdoor applications, UV exposure | Excellent weather resistance | Poor oil resistance | Medium |

| Silicone Rubber | High-temperature applications | Extreme temperature resistance | Higher cost | High |

This guide provides a comprehensive overview of the materials used in oblong rubber grommets, helping international buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for oblong rubber grommets

What Are the Key Stages in the Manufacturing Process of Oblong Rubber Grommets?

The manufacturing process for oblong rubber grommets involves several critical stages, each designed to ensure the final product meets specific performance and quality standards.

-

Material Preparation: The process begins with the selection of suitable elastomer materials, including natural rubber (NR), nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), silicone, neoprene, and fluorocarbon (FKM). Each material is chosen based on the application’s requirements, such as temperature resistance, chemical exposure, and mechanical properties. The raw materials undergo precise formulation, where additives like fillers, accelerators, and curing agents are mixed to achieve desired physical characteristics.

-

Forming: The next stage is the forming process, which typically involves methods such as injection molding, compression molding, or transfer molding. Injection molding is often preferred for its efficiency and ability to produce complex shapes with tight tolerances. The prepared rubber compound is heated and injected into molds that define the grommet’s shape and dimensions. This stage is critical as it determines the consistency and quality of the grommet.

-

Assembly: For grommets that require additional components or features, the assembly stage integrates these elements. This might include inserting metal rings for added strength or incorporating specific design features that facilitate installation. Although many oblong rubber grommets are single-piece products, the assembly process ensures that any multi-component designs are securely bonded.

-

Finishing: After forming and assembly, the grommets undergo finishing processes, which may involve trimming excess material, surface treatments, or applying protective coatings. This stage enhances the aesthetic appeal and functionality of the grommets, ensuring they are ready for their intended applications.

How Is Quality Assurance Implemented During the Manufacturing of Oblong Rubber Grommets?

Quality assurance is a critical component of the manufacturing process for oblong rubber grommets, ensuring that products meet both international standards and customer specifications.

-

Adherence to International Standards: Manufacturers often comply with international quality management standards, such as ISO 9001, which outlines a framework for consistent quality. Additionally, industry-specific certifications like CE marking for European markets or API standards for the oil and gas sector may also be relevant. These certifications signal to buyers that the products have undergone rigorous testing and meet high-quality benchmarks.

-

Quality Control Checkpoints: Several quality control checkpoints are established throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon receipt to ensure they meet specified quality criteria.

– In-Process Quality Control (IPQC): During manufacturing, various parameters such as temperature, pressure, and material flow are monitored to maintain consistency.

– Final Quality Control (FQC): After production, finished grommets are subjected to a series of tests, including dimensional checks, tensile strength testing, and environmental resistance evaluations. -

Common Testing Methods for Oblong Rubber Grommets: Testing methodologies include:

– Tensile Testing: Measures the strength and elasticity of the rubber.

– Compression Set Testing: Evaluates the grommet’s ability to return to its original shape after being compressed.

– Heat Aging Tests: Assess how materials withstand prolonged exposure to elevated temperatures.

– Chemical Resistance Tests: Ensure the grommets can endure exposure to various chemicals without degradation.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying supplier quality control is paramount. Here are several ways to conduct due diligence:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control measures, and overall operational efficiency of suppliers. This firsthand observation can reveal the supplier’s commitment to quality and adherence to international standards.

-

Requesting Quality Reports: Buyers should request detailed quality control reports that outline testing methodologies, results, and compliance with relevant standards. This documentation serves as evidence of the supplier’s quality assurance practices.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality management systems and product quality. These inspections can be scheduled at various stages of production, from raw material sourcing to final product evaluation.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control and certification nuances when sourcing oblong rubber grommets:

-

Cultural and Regulatory Differences: Buyers should be aware that different regions may have varying quality standards and regulatory requirements. For example, the European Union has strict regulations regarding product safety and environmental impact, which may not be as stringent in other regions.

-

Understanding Certification Validity: It’s essential to verify that certifications are current and applicable to the specific products being purchased. Buyers should request copies of certificates and check their validity with issuing bodies to ensure compliance.

-

Building Relationships with Suppliers: Establishing strong relationships with suppliers can facilitate better communication regarding quality expectations and standards. Regular engagement can help ensure that suppliers remain aligned with buyers’ quality requirements.

By understanding the intricacies of manufacturing processes and quality assurance for oblong rubber grommets, international B2B buyers can make informed decisions, ensuring they procure high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘oblong rubber grommets’

Introduction

This practical sourcing guide aims to assist B2B buyers in the procurement of oblong rubber grommets. By following this step-by-step checklist, you can ensure that you select the right products and suppliers to meet your specific needs, whether for electrical insulation, mechanical protection, or aesthetic purposes.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it is crucial to clearly define the specifications of the oblong rubber grommets you require. Consider factors such as the dimensions (outer and inner diameters), material composition (e.g., NR, NBR, EPDM), and any specific performance characteristics like temperature resistance or UV stability. Establishing these parameters early will streamline the sourcing process and help you communicate effectively with potential suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in rubber grommets. Use industry directories, trade shows, and online platforms to compile a list of manufacturers. Pay attention to their product range, production capabilities, and market reputation to ensure they align with your requirements.

Step 3: Evaluate Supplier Certifications

Verify the certifications and quality standards of potential suppliers. Look for ISO certifications, compliance with industry standards, and any relevant local regulations. Ensuring that your supplier meets these certifications is vital as it reflects their commitment to quality and reliability, which can significantly impact your final product.

Step 4: Request Samples for Testing

Once you’ve narrowed down your options, request samples of the oblong rubber grommets you are considering. Testing samples allows you to evaluate the physical properties, such as flexibility, hardness (measured in Shore A), and compatibility with your application. This step is crucial to confirm that the grommets will perform as expected in real-world conditions.

Step 5: Assess Pricing and Payment Terms

Compare pricing from different suppliers while considering the overall value, not just the lowest cost. Request detailed quotes that outline unit costs, bulk discounts, and shipping fees. Additionally, clarify payment terms, including deposit requirements and credit options, to avoid any financial surprises later in the transaction.

Step 6: Review Lead Times and Delivery Options

Discuss lead times and shipping methods with your shortlisted suppliers. Understanding how long it will take for your order to be fulfilled and delivered is essential for planning your production schedules. Ask about their ability to meet urgent requests or last-minute changes to ensure flexibility in your supply chain.

Step 7: Establish a Clear Communication Channel

Finally, set up a communication channel with your chosen supplier. Clear and consistent communication is key to addressing any concerns, tracking orders, and ensuring that any adjustments to specifications are managed effectively. Establishing this rapport will help foster a long-term partnership that can benefit your business in future procurement endeavors.

By following these steps, you can effectively navigate the sourcing process for oblong rubber grommets, ensuring that you make informed decisions that align with your operational needs.

Comprehensive Cost and Pricing Analysis for oblong rubber grommets Sourcing

When sourcing oblong rubber grommets, understanding the cost structure and pricing dynamics is essential for B2B buyers. The total cost can be broken down into several components, each influencing the final price.

What Are the Key Cost Components for Oblong Rubber Grommets?

-

Materials: The type of rubber used significantly impacts costs. Common materials include natural rubber (NR), neoprene, EPDM, and silicone, with costs varying based on properties like heat resistance and durability. Specialty materials designed for specific applications (e.g., oil resistance, UV stability) typically come at a premium.

-

Labor: Labor costs are tied to the manufacturing process, which can include molding, machining, and assembly. In regions with higher labor costs, such as parts of Europe, the overall price will reflect this. Conversely, sourcing from countries with lower labor costs may offer savings but could introduce risks related to quality control.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance of equipment. Efficient manufacturing processes can help reduce overhead, allowing suppliers to offer more competitive pricing.

-

Tooling: Custom grommets often require specialized tooling, which can be a significant upfront cost. This expense is typically amortized over the production run, so larger orders can reduce the per-unit cost.

-

Quality Control (QC): Ensuring that grommets meet industry standards and specifications incurs additional costs. Certifications (e.g., ISO, ASTM) can enhance credibility but may also raise prices.

-

Logistics: Shipping and handling fees vary based on the distance, weight, and volume of the order. Incoterms (International Commercial Terms) also play a critical role, dictating responsibilities for shipping and risk, which can affect the overall cost.

-

Margin: Suppliers will apply a markup to cover their costs and generate profit. This margin can vary based on market demand, competitive landscape, and supplier reputation.

How Do Pricing Influencers Impact Grommet Costs?

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically benefit from bulk pricing, which can significantly lower the per-unit cost. Buyers should consider their needs carefully to avoid excess inventory while maximizing cost efficiency.

-

Specifications and Customization: Grommets with unique dimensions or special material properties may incur additional costs. Custom designs can lead to longer lead times, impacting pricing.

-

Quality and Certifications: Higher quality grommets that adhere to rigorous standards may command higher prices. Buyers should weigh the importance of quality against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with proven track records may charge more due to their experience and quality assurance processes.

What Are Essential Tips for Negotiating Grommet Prices?

-

Leverage Volume: When negotiating, emphasize potential order volumes. Suppliers may be willing to offer discounts for larger commitments.

-

Understand Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with the grommets, including maintenance, replacement, and potential downtime from failures.

-

Explore Various Suppliers: Don’t settle for the first quote. Comparing multiple suppliers can reveal significant pricing differences and help identify the best overall value.

-

Be Aware of Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, factors such as tariffs, import duties, and currency fluctuations can affect overall costs. Negotiating terms that account for these variables can lead to more favorable pricing.

Disclaimer on Indicative Prices

Prices for oblong rubber grommets can fluctuate based on market conditions, material costs, and supplier pricing strategies. It’s advisable for buyers to request formal quotations to obtain accurate pricing tailored to their specific requirements.

Alternatives Analysis: Comparing oblong rubber grommets With Other Solutions

Exploring Alternatives to Oblong Rubber Grommets

When considering solutions for protecting wires and cables or reinforcing openings, it’s essential to evaluate various alternatives to oblong rubber grommets. Different materials and technologies can offer unique benefits depending on the application, performance requirements, and cost constraints. This analysis compares oblong rubber grommets with two viable alternatives: silicone grommets and plastic cable management systems.

Comparison Table

| Comparison Aspect | Oblong Rubber Grommets | Silicone Grommets | Plastic Cable Management Systems |

|---|---|---|---|

| Performance | Excellent abrasion and impact resistance; flexible under various temperatures | Superior thermal stability; resistant to UV and ozone degradation | Good for organization; less effective in high-stress environments |

| Cost | Moderate | Slightly higher than rubber grommets | Generally lower cost; varies by complexity |

| Ease of Implementation | Easy to install; requires minimal tools | Similar installation ease; may require specific adhesives | Varies; some systems may require more time to install |

| Maintenance | Low maintenance; durable | Low maintenance; long lifespan | Moderate; may need occasional replacement due to wear |

| Best Use Case | Electrical applications in harsh environments | Applications requiring thermal stability and UV resistance | Organizing and protecting multiple cables in non-critical environments |

Detailed Breakdown of Alternatives

Silicone Grommets

Silicone grommets are a notable alternative to oblong rubber grommets, particularly in scenarios where thermal stability is paramount. They perform exceptionally well in high-temperature environments and are resistant to UV and ozone, making them ideal for outdoor applications. However, the cost of silicone grommets is typically higher than that of traditional rubber options. While they offer similar ease of installation, the additional expense may deter budget-conscious buyers. Their durability and resistance to environmental factors make them a solid choice for long-term use.

Plastic Cable Management Systems

Plastic cable management systems serve as another alternative, particularly in non-critical environments. These systems can efficiently organize and protect multiple cables, providing a clean and professional look. They are generally more affordable than rubber or silicone grommets, which can be appealing for large-scale projects. However, plastic systems may not offer the same level of abrasion resistance or durability under high-stress conditions. Their installation can vary in complexity, with some requiring more time and tools than grommets. For applications where organization is key and environmental stressors are minimal, plastic cable management can be a practical solution.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right solution for protecting wires or reinforcing openings, B2B buyers should consider their specific requirements, including the operating environment, budget, and installation capabilities. Oblong rubber grommets provide excellent performance and durability, making them suitable for a wide range of applications. However, if thermal stability or UV resistance is critical, silicone grommets may be the better option despite the higher cost. Alternatively, for projects focused on organization and aesthetics, plastic cable management systems offer a cost-effective and visually appealing solution. Evaluating these factors will help buyers make an informed decision that aligns with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for oblong rubber grommets

What Are the Key Technical Properties of Oblong Rubber Grommets?

When selecting oblong rubber grommets for your applications, understanding their critical technical properties can significantly influence performance and compatibility. Here are some essential specifications to consider:

-

Material Composition

Oblong rubber grommets are made from various elastomers, including Neoprene, EPDM, and Silicone. Each material offers different properties: Neoprene is known for its oil resistance, while EPDM excels in weather and ozone resistance. Choosing the right material ensures that the grommet will withstand environmental factors and mechanical stress, making it crucial for long-term reliability. -

Hardness (Shore A)

The hardness of rubber grommets is measured on the Shore A scale, typically ranging from 30 to 80. This measurement indicates the grommet’s flexibility and ability to seal effectively. A softer grommet may offer better cushioning and fit, while a harder grommet may provide better durability. Selecting the appropriate hardness is vital for achieving the desired balance between flexibility and resilience in your application. -

Temperature Resistance

Oblong rubber grommets can withstand a wide temperature range, often from -40°C to 230°C, with specialized variants capable of enduring temperatures as high as 800°C. Understanding the temperature conditions your grommets will face is essential for preventing premature failure and ensuring the safety and efficiency of your operations. -

Size and Tolerances

Precise dimensions, including outside diameter, inside diameter, groove diameter, and thickness, are critical for ensuring a proper fit within your application. Tolerances in these dimensions can affect the grommet’s sealing ability and overall performance. Working with manufacturers who provide detailed size charts and tolerances can help you avoid costly errors in your projects. -

Resistance Properties

Many oblong rubber grommets are designed to resist specific environmental factors, including UV light, oils, and chemicals. This resistance is crucial for applications exposed to harsh conditions, as it extends the life of the grommets and reduces maintenance costs. Assessing these properties helps you choose grommets that will perform reliably in your specific environment.

What Common Trade Terms Should You Know When Purchasing Oblong Rubber Grommets?

Familiarizing yourself with industry terminology can streamline your purchasing process and facilitate clearer communication with suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end products. Understanding whether a supplier is an OEM can help you assess the quality and reliability of the grommets you are purchasing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ helps you gauge whether a supplier meets your purchasing needs, especially if you’re looking for bulk orders or specific customizations. -

RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers for specific products. Providing detailed specifications in your RFQ can lead to more accurate and competitive quotes, ensuring you get the best deal. -

Incoterms (International Commercial Terms)

These are standardized shipping terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps clarify who is responsible for shipping costs, insurance, and the risk of loss, which is crucial for effective logistics management. -

Custom Grommet Services

Many suppliers offer custom grommet services, allowing you to specify dimensions, materials, and properties tailored to your application. Understanding this service can help you meet unique project requirements effectively. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time is essential for planning your project timelines and ensuring that you have the necessary components when needed.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their operations and ensure the successful application of oblong rubber grommets.

Navigating Market Dynamics and Sourcing Trends in the oblong rubber grommets Sector

What Are the Key Market Trends Affecting Oblong Rubber Grommets?

The global market for oblong rubber grommets is experiencing dynamic shifts driven by several factors. The surge in manufacturing across various sectors, including automotive, electronics, and construction, has heightened the demand for reliable components that enhance durability and safety. In regions like Africa and South America, infrastructure development is catalyzing growth, while in Europe and the Middle East, industries are increasingly focused on efficiency and sustainability.

Emerging technologies such as automation and IoT integration are reshaping sourcing strategies, enabling buyers to leverage data analytics for better inventory management and cost optimization. Additionally, the rise of e-commerce platforms is facilitating easier access to suppliers, allowing international buyers to source products directly from manufacturers, thereby reducing lead times and improving supply chain efficiency.

As businesses seek to remain competitive, customization has become a key trend, with suppliers offering tailored solutions to meet specific industry needs. This shift towards bespoke manufacturing is particularly relevant for oblong rubber grommets, which can be designed to accommodate unique specifications regarding size, hardness, and resistance to environmental factors.

How Is Sustainability Influencing the Sourcing of Oblong Rubber Grommets?

Sustainability is becoming an essential consideration in the sourcing of oblong rubber grommets. The environmental impact of rubber production, including deforestation and pollution, has prompted buyers to seek alternatives that minimize ecological footprints. Ethical sourcing practices are gaining traction, with companies increasingly prioritizing suppliers who adhere to sustainable manufacturing processes and responsible sourcing of raw materials.

The demand for ‘green’ certifications is on the rise, as buyers look for suppliers that utilize eco-friendly materials, such as recycled rubber or biobased alternatives. Certifications like ISO 14001 can serve as indicators of a supplier’s commitment to environmental management, providing buyers with confidence in their sourcing decisions.

Furthermore, companies are recognizing that sustainable practices not only contribute to environmental protection but can also enhance brand reputation and customer loyalty. As global consumers become more environmentally conscious, the pressure is on B2B buyers to ensure that their supply chains align with these values.

What Is the Historical Context Behind Oblong Rubber Grommets?

The evolution of oblong rubber grommets can be traced back to the early days of industrialization when the need for effective cable management and protection became apparent. Originally made from natural rubber, advancements in materials science have led to the development of synthetic alternatives such as EPDM and silicone, which offer enhanced durability and resistance to extreme temperatures and environmental conditions.

Over the decades, the applications of rubber grommets have expanded significantly, now encompassing a wide range of industries from automotive to electronics. The introduction of custom grommet solutions has allowed manufacturers to cater to specific needs, reflecting the growing complexity of modern machinery and consumer products. Today, oblong rubber grommets are recognized not only for their functional benefits but also for their role in promoting safety and efficiency across various sectors.

By understanding these market dynamics, sustainability considerations, and historical developments, international B2B buyers can make informed sourcing decisions that align with their operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of oblong rubber grommets

-

How do I select the right oblong rubber grommets for my application?

Choosing the appropriate oblong rubber grommets involves considering several factors, including the size, material, and application environment. Measure the dimensions of the holes where the grommets will be installed, ensuring the outside and inside diameters match your requirements. Materials like EPDM, silicone, or neoprene offer various properties such as temperature resistance and flexibility, making them suitable for different applications. Additionally, consider factors like exposure to chemicals or UV light to select grommets that will withstand your specific operational conditions. -

What are the common uses for oblong rubber grommets in industrial settings?

Oblong rubber grommets are widely used in industrial applications to protect wires and cables that pass through metal or plastic panels. They prevent abrasion and damage, ensuring the longevity of electrical components. Additionally, they can reinforce openings, isolate vibrations, and protect against environmental factors like moisture and dust. Industries such as automotive, electronics, and machinery frequently utilize these grommets for effective cable management and protection. -

Can I customize oblong rubber grommets for specific requirements?

Yes, many suppliers offer customization options for oblong rubber grommets. You can specify dimensions, material properties, and even color to meet your unique needs. When requesting custom grommets, provide detailed specifications, including size, hardness (measured in Shore A), and any resistance requirements such as oil or high temperatures. This ensures that the final product perfectly fits your application, enhancing performance and durability. -

What is the minimum order quantity (MOQ) for oblong rubber grommets?

Minimum order quantities for oblong rubber grommets vary by supplier and are often influenced by the type of customization required. Standard grommets may have lower MOQs, while custom-designed grommets could require larger orders to justify production costs. It’s advisable to communicate directly with suppliers to understand their MOQ policies and negotiate terms that align with your purchasing needs, especially if you are looking to source in bulk. -

What payment terms should I expect when sourcing oblong rubber grommets internationally?

Payment terms can vary significantly among suppliers, especially in international trade. Common terms include advance payment, partial payments, or letters of credit. Many suppliers may require a deposit upfront, with the balance due prior to shipping. It’s crucial to clarify payment conditions during negotiations and consider using secure payment methods that protect both parties. Always ensure you have a written agreement outlining the payment schedule to avoid misunderstandings. -

How do I ensure quality assurance when sourcing oblong rubber grommets?

To ensure quality assurance when sourcing oblong rubber grommets, request certifications and quality control processes from suppliers. Look for ISO certifications or compliance with international standards that demonstrate their commitment to quality. Additionally, consider requesting samples before placing a bulk order to evaluate the product’s performance and fit. Establishing clear communication about your quality expectations upfront can help mitigate issues during production. -

What logistics considerations should I keep in mind when importing oblong rubber grommets?

Logistics are critical when importing oblong rubber grommets, especially regarding shipping methods, timelines, and customs regulations. Evaluate options such as air freight for faster delivery or sea freight for cost-effectiveness. Additionally, ensure that your supplier is aware of the necessary documentation for customs clearance to avoid delays. Working with a reliable freight forwarder can help streamline the process and ensure compliance with import regulations specific to your country. -

What are the benefits of sourcing oblong rubber grommets from international suppliers?

Sourcing oblong rubber grommets from international suppliers can offer significant benefits, including cost savings, access to a broader range of products, and enhanced innovation. Suppliers from different regions may provide competitive pricing due to lower manufacturing costs or specialized materials unavailable locally. Additionally, international suppliers often have extensive experience and expertise in various applications, which can lead to superior product quality and service. However, it is essential to conduct thorough due diligence to ensure reliability and compliance with international trade standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Oblong Rubber Grommets Manufacturers & Suppliers List

1. Rubber Grommet – Oval Grommets

Domain: rubber-grommet.com

Introduction: {‘product_type’: ‘Oval Grommets’, ‘materials’: [‘NR’, ‘NBR’, ‘EPDM’, ‘Silicone’, ‘Neoprene’, ‘FKM’], ‘colors’: [‘Black’, ‘White’, ‘Custom Pantone’], ‘hardness_range’: ’30-80 Shore A’, ‘temperature_range’: ‘-40℃ to 230℃’, ‘high_temperature_resistance’: ‘up to 800℃’, ‘custom_services’: ‘Available’, ‘size_chart’: [{‘part_no’: ‘OG9006’, ‘outside_dia’: ’10×19.5′, ‘inside_dia’: ‘4×13.5’, ‘groove_dia’: ‘…

2. Gteek – Oval Rubber Grommets

Domain: gteek.com

Registered: 2017 (8 years)

Introduction: This company, Gteek – Oval Rubber Grommets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. GrommetSeal – Oval Rubber Grommets

Domain: grommetseal.com

Registered: 2019 (6 years)

Introduction: Oval Rubber Grommet has an oval or egg-shaped opening for various cables, tubing, or wires. Ideal for irregular or curved surfaces. Made of high-quality rubber materials like neoprene, EPDM, or silicone rubber, known for durability, weather resistance, and high temperature and pressure tolerance. Provides a snug fit, sealing openings to prevent dust, debris, and water from entering. Available in d…

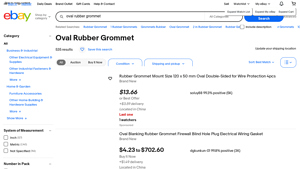

4. QCQIANG – 26pcs Oval Rubber Grommets

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Oval Rubber Grommet products available on eBay include various options such as: 1. QCQIANG 26pcs Double-Sided Hole Oval Rubber Grommets priced at $22.95 with free delivery in 2-4 days. 2. Elliptical Blanking Rubber Grommets priced between $4.35 to $47.44 plus $3.99 delivery. 3. 2Set Side Cover Grommet Single Side Rubber Oval Washer priced at $11.90 with free delivery. 4. 45PCS Rubber Grommet Kit w…

5. Rubber Grommet – Key Product Details

Domain: store.rubber-grommet.com

Registered: 2019 (6 years)

Introduction: Key product details for Oval Grommets (OG) include:

– Product Codes: OG9001, OG9002, OG9003, OG9004, OG9005, OG9006, OG9007, OG9008, OG9009, OG9010, OG9011, OG9012

– Prices: $0.64, $1.97, $5.86, $1.00, $0.46, $0.45, $0.33 (multiple products at this price)

– Total Products Listed: 127

– Categories: Oval Grommets, Rubber Grommets, Waterproof Grommets, etc.

6. Minor Rubber – Oval Rubber Grommets

Domain: minorrubber.com

Registered: 1998 (27 years)

Introduction: Minor Rubber offers a variety of in-stock and custom oval rubber grommets, including blind hole grommets and oblong grommets. The inventory includes several specifications for groove width, thickness, and overall dimensions. Key features include: Materials: BUNA-N, Silicone, Neoprene; Colors: Black and Red. The company also manufactures Mil-Spec grommets for military applications and can accommoda…

7. Big Rig Chrome Shop – Oval Rubber Grommet

Domain: bigrigchromeshop.com

Registered: 2003 (22 years)

Introduction: {“name”: “Oval Rubber Grommet”, “sku”: “RMI-40673”, “price”: “$2.09”, “description”: “The Oval Rubber Grommet is a practical and versatile product designed to fit most makes and models. Made from durable rubber, this grommet is sold individually, making it a cost-effective solution for various applications. Its oval shape ensures a secure fit and provides excellent protection against dust, moistur…

8. McMaster – Oval Rubber Sealing Grommets

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Oval Rubber Sealing Grommets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

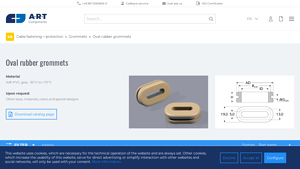

9. Art Components – Oval Rubber Grommets

Domain: artcomponents.com

Registered: 2007 (18 years)

Introduction: {“product_name”: “Oval Rubber Grommets”, “material”: “Soft PVC”, “colors”: [“gray”, “black”], “temperature_range”: {“min”: “-30°C”, “max”: “+70°C”}, “UL_listing”: “UL-94 HB”, “RoHS_compliant”: “Yes”, “sizes”: [{“part_number”: “DT PKL 0519-1427/1933-30 gr”, “mounting_hole_chassis”: “27,0×13,0 mm”, “outside_diameter”: “33,0×19,0 mm”, “inner_diameter”: “19,0×5,0 mm”}, {“part_number”: “DT PKL 0519-142…

Strategic Sourcing Conclusion and Outlook for oblong rubber grommets

In the competitive landscape of manufacturing and assembly, strategic sourcing of oblong rubber grommets is crucial for ensuring product integrity and operational efficiency. As businesses look to optimize their supply chains, understanding the diverse materials, sizes, and customization options available will empower buyers to make informed decisions. By leveraging high-quality grommets, companies can enhance the durability and performance of their products, particularly in sectors like automotive, electronics, and construction.

Moreover, the ability to source grommets tailored to specific environmental conditions—such as temperature extremes or exposure to chemicals—adds significant value. For international buyers from regions like Africa, South America, the Middle East, and Europe, establishing strong partnerships with reliable suppliers is essential for maintaining a consistent flow of materials that meet stringent quality standards.

Looking ahead, the demand for oblong rubber grommets is expected to grow, driven by advancements in technology and increased industrial activities. Buyers should actively engage with manufacturers and suppliers to explore innovative solutions that not only meet current needs but also anticipate future challenges. Embrace the opportunity to enhance your supply chain and ensure your projects are equipped with the best grommet solutions available.