Plastic Yard Glass: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for plastic yard glass

The global market for plastic yard glass presents a unique challenge for B2B buyers seeking to source high-quality, versatile drinkware that meets both aesthetic and functional demands. Sourcing plastic yard glass involves navigating a landscape filled with various types, applications, and suppliers, each offering different features, pricing structures, and customization options. As events and gatherings become more popular across regions such as Africa, South America, the Middle East, and Europe, the demand for eye-catching and practical beverage containers has surged, making it essential for businesses to identify the right products that align with their branding and customer preferences.

This comprehensive guide will delve into the multifaceted world of plastic yard glass, covering everything from the various types available—such as half-yard and full-yard options—to their diverse applications in outdoor venues, parties, and promotional events. Additionally, the guide will provide valuable insights into supplier vetting processes, cost considerations, and effective customization strategies. By equipping international B2B buyers with the knowledge they need to make informed purchasing decisions, this resource aims to streamline the sourcing process, ultimately enhancing customer satisfaction and boosting sales potential across diverse markets. Whether you are a small bar in Nigeria or a large festival organizer in Europe, understanding the nuances of plastic yard glass can empower your business to stand out in a competitive marketplace.

Understanding plastic yard glass Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Half Yard Glass (24 oz) | 16 inches tall, wide base, available in vibrant colors | Outdoor events, parties, bars, restaurants | Pros: Eye-catching, versatile for various beverages. Cons: Bulk purchasing may be required for discounts. |

| Custom Printed Yard Glass | Personalized with logos and designs | Promotional events, branding for bars and restaurants | Pros: Enhances brand visibility, customizability. Cons: Higher initial costs for custom designs. |

| Mini Yard Glass (18 oz) | Shorter than standard yard glasses, compact design | Small gatherings, themed parties, festivals | Pros: Easier to handle, suitable for limited space. Cons: Limited beverage capacity compared to larger options. |

| Full Yard Glass (32 oz) | Tallest option, designed for larger servings | Sporting events, festivals, and large parties | Pros: Ideal for high-volume beverage service. Cons: Less portable due to size. |

| Specialty Yard Glass | Unique shapes or materials (e.g., neon colors) | Themed parties, bars with unique drink offerings | Pros: Distinctive and fun, attracts attention. Cons: May not fit all standard accessories like straws or lids. |

What Are the Key Characteristics of Half Yard Glasses?

The half yard glass, typically 24 ounces, stands at 16 inches tall and features a broad base for stability. Its vibrant color options make it a favorite for outdoor events, parties, and bars. When purchasing, B2B buyers should consider the glass’s visibility and appeal at events, which can enhance the overall experience for guests. Bulk purchasing often yields cost savings, making it an attractive option for businesses looking to stock up.

How Do Custom Printed Yard Glasses Enhance Branding?

Custom printed yard glasses allow businesses to showcase their logos and event details, making them perfect for promotional activities. These glasses are commonly used in bars and restaurants to enhance brand visibility. Buyers should be aware that while the initial costs for custom designs may be higher, the marketing potential and customer engagement can justify the investment. Ensuring quality printing and material is crucial for long-lasting impressions.

What Makes Mini Yard Glasses Suitable for Small Gatherings?

Mini yard glasses, typically holding 18 ounces, offer a more compact design that is easier to handle. They are ideal for small gatherings, themed parties, or festivals where space may be limited. B2B buyers should consider how these glasses can simplify service and enhance the drinking experience without sacrificing style. Their lower capacity can also reduce waste, appealing to environmentally conscious businesses.

Why Choose Full Yard Glasses for High-Volume Events?

Full yard glasses, often 32 ounces, are designed for high-volume beverage service at sporting events, festivals, and large parties. Their substantial size allows for fewer refills, which can streamline service during busy events. Buyers should evaluate the trade-offs between portability and capacity, as larger glasses may be less convenient for guests to carry. However, their ability to hold more beverage can significantly enhance customer satisfaction.

What Are the Benefits of Specialty Yard Glasses?

Specialty yard glasses come in unique shapes or materials, such as neon colors, making them perfect for themed parties and bars with unique drink offerings. These glasses attract attention and can be a conversation starter, adding a fun element to any event. B2B buyers should consider the novelty factor and how these glasses can differentiate their offerings. However, compatibility with standard accessories like straws and lids may vary, so careful selection is necessary.

Key Industrial Applications of plastic yard glass

| Industry/Sector | Specific Application of Plastic Yard Glass | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Outdoor Events and Festivals | Enhances customer experience and brand visibility | Bulk purchasing options, customization for branding |

| Food and Beverage | Bars and Restaurants | Cost-effective drinkware that reduces breakage | Material safety standards, BPA-free certification |

| Promotional Products | Corporate Events and Giveaways | Custom branding opportunities to enhance marketing efforts | Minimum order quantities, lead times for production |

| Entertainment Venues | Theme Parks and Concerts | Durable and fun drinkware that attracts customers | Color variety, ease of transport and storage |

| Retail and Souvenirs | Gift Shops and Tourist Attractions | Unique souvenir options that can be personalized | Customization options, bulk discounts for large orders |

How is Plastic Yard Glass Used in the Hospitality Industry?

In the hospitality sector, plastic yard glasses are ideal for outdoor events and festivals, where traditional glassware poses a risk of breakage. These durable, lightweight glasses enhance the customer experience by allowing for easy handling of large beverages while promoting brand visibility through customization. International buyers, particularly from regions like Africa and South America, should consider sourcing these glasses in bulk to meet high demand during peak seasons, ensuring they comply with local safety regulations regarding food-grade materials.

What Role Does Plastic Yard Glass Play in Food and Beverage Businesses?

Bars and restaurants utilize plastic yard glasses to serve drinks in a fun and engaging manner, reducing the risk of injury from broken glass. These glasses are particularly beneficial in high-traffic areas where accidents are more likely to occur. For B2B buyers from the Middle East and Europe, sourcing BPA-free plastic yard glasses is crucial to meet health standards and customer expectations. Additionally, considering the aesthetic appeal and durability of the product can significantly impact customer satisfaction and repeat business.

How Can Promotional Products Benefit from Plastic Yard Glass?

Plastic yard glasses serve as excellent promotional products for corporate events and giveaways. Businesses can customize these glasses with their logos, creating a memorable branding tool that attendees will take home. This strategy not only enhances marketing efforts but also fosters brand loyalty. Buyers, especially from regions with vibrant promotional cultures, such as Nigeria and Vietnam, should focus on suppliers that offer competitive pricing and quick turnaround times to ensure timely delivery for events.

Why Are Plastic Yard Glasses Important for Entertainment Venues?

In entertainment venues like theme parks and concert arenas, plastic yard glasses attract customers with their novelty and fun factor. They provide a unique way to serve beverages, enhancing the overall experience for visitors. For international buyers, considerations such as color variety and ease of transportation are essential. Ensuring that suppliers can provide a range of colors and sizes can help venues cater to diverse customer preferences while maintaining efficient inventory management.

How Do Retail and Souvenir Markets Utilize Plastic Yard Glass?

Retailers and souvenir shops leverage plastic yard glasses as unique items that can be personalized for tourists. These glasses serve as memorable keepsakes that reflect local culture or events, appealing to visitors looking for distinctive gifts. B2B buyers in this sector should consider sourcing options that include customization capabilities and bulk discounts, allowing them to maximize profit margins while meeting customer demands for personalized products.

3 Common User Pain Points for ‘plastic yard glass’ & Their Solutions

Scenario 1: Navigating Quality Concerns in Bulk Orders

The Problem: B2B buyers often grapple with the challenge of ensuring product quality when ordering plastic yard glasses in bulk, especially when sourcing from international suppliers. The risk of receiving inferior products that do not meet safety and durability standards can lead to dissatisfaction among customers and potential loss of business reputation. Buyers may also find discrepancies in the product specifications provided by different suppliers, which complicates their decision-making process.

The Solution: To mitigate quality concerns, B2B buyers should establish clear communication with suppliers regarding product specifications and quality certifications. Request samples before placing a large order to verify the material used—preferably BPA-free food-grade plastic— and ensure it aligns with your expectations. Additionally, consider working with suppliers who provide guarantees or warranties on their products. Implementing a robust supplier evaluation process that includes checking reviews, ratings, and past client feedback can also help in selecting reliable vendors. Finally, consider establishing a quality assurance protocol that includes inspections upon delivery to ensure that the received products match the agreed-upon specifications.

Scenario 2: Overcoming Customization Challenges for Events

The Problem: For businesses organizing events, finding plastic yard glasses that can be customized to reflect their brand or theme poses a significant challenge. Many suppliers may have limitations on the types of customization available or may not offer competitive pricing for small to medium-sized orders. This can result in a lack of unique branding opportunities, which diminishes the potential for effective marketing at events.

The Solution: To address customization challenges, B2B buyers should seek suppliers who specialize in personalized plastic yard glasses and have flexible ordering options. When requesting quotes, specify your customization needs, such as color, size, and imprint details, and ask about minimum order quantities. Look for suppliers that offer bulk discounts and a range of customization techniques, such as screen printing or pad printing, to achieve the desired look. Additionally, consider exploring partnerships with suppliers who can provide design assistance to ensure that your branding is effectively represented on the glasses. Engaging with local suppliers may also yield better customization options and faster turnaround times.

Scenario 3: Managing Seasonal Demand Fluctuations

The Problem: B2B buyers often face the challenge of managing inventory levels of plastic yard glasses in response to seasonal demand fluctuations, particularly during peak times like summer events or holidays. Over-ordering can lead to excess inventory costs, while under-ordering risks stockouts and missed sales opportunities. This balancing act can be particularly difficult for businesses operating in regions with varying peak seasons.

The Solution: To effectively manage seasonal demand fluctuations, B2B buyers should utilize demand forecasting techniques based on historical sales data and market trends. Collaborating with suppliers to establish flexible ordering arrangements, such as consignment or just-in-time inventory, can help maintain optimal stock levels without incurring significant holding costs. Implementing a robust inventory management system can also facilitate real-time tracking of stock levels and sales patterns, enabling buyers to adjust orders proactively. Additionally, consider diversifying your product offerings by including a range of sizes, colors, and styles of plastic yard glasses to appeal to different customer segments throughout the year, ensuring that your business can adapt to varying demand effectively.

Strategic Material Selection Guide for plastic yard glass

When selecting materials for plastic yard glasses, several common options are available, each with distinct properties, advantages, and limitations. Understanding these materials can help international B2B buyers make informed decisions that align with their operational needs and market preferences.

What Are the Key Properties of Polypropylene (PP) for Plastic Yard Glasses?

Polypropylene (PP) is a widely used thermoplastic known for its versatility. It has a temperature resistance of up to 100°C (212°F) and is resistant to many chemicals, making it suitable for a variety of beverages. Its lightweight nature contributes to ease of handling and transportation, which is particularly advantageous for bulk orders.

Pros and Cons of Polypropylene:

– Pros: PP is durable, resistant to impact, and has a good balance of rigidity and flexibility. It is also cost-effective, making it a popular choice for manufacturers.

– Cons: While it has decent UV resistance, prolonged exposure can lead to color fading. Additionally, it may not be suitable for hot beverages due to its lower heat resistance compared to other plastics.

Impact on Application: PP is compatible with a range of beverages, including alcoholic and non-alcoholic drinks. However, caution is advised when using it for hot liquids.

Considerations for International Buyers: Compliance with international standards such as FDA and EU regulations is crucial. Buyers in regions like Africa and South America should also consider local regulations regarding food safety and material recyclability.

How Does Polyethylene Terephthalate (PET) Perform in Yard Glass Applications?

Polyethylene Terephthalate (PET) is another common material for plastic yard glasses, particularly known for its clarity and strength. It can withstand temperatures up to 60°C (140°F) and has excellent barrier properties against moisture and gases.

Pros and Cons of PET:

– Pros: PET is lightweight, shatter-resistant, and provides a high-quality finish that enhances branding opportunities through clear printing. It is also recyclable, appealing to environmentally conscious consumers.

– Cons: PET is less resistant to heat than other materials, limiting its use for hot beverages. Additionally, it can be more expensive than PP.

Impact on Application: PET is ideal for cold beverages, making it suitable for outdoor events and parties. Its clarity allows for attractive presentation, but care must be taken with temperature-sensitive products.

Considerations for International Buyers: Buyers should ensure that PET products meet local recycling regulations, especially in regions with stringent environmental laws, such as Europe.

What Are the Advantages of Polystyrene (PS) in Yard Glass Manufacturing?

Polystyrene (PS) is a popular choice for disposable yard glasses due to its low cost and ease of manufacturing. It is typically used in applications requiring single-use products and can withstand temperatures up to 70°C (158°F).

Pros and Cons of Polystyrene:

– Pros: PS is very affordable and can be easily molded into various shapes, making it a flexible option for manufacturers. It also provides good clarity for visual appeal.

– Cons: PS is less durable than other plastics and can crack or break under stress. It is not recyclable in many regions, raising environmental concerns.

Impact on Application: PS is best suited for cold beverages and events where disposability is a priority. However, its lower durability may limit its use in high-traffic venues.

Considerations for International Buyers: Compliance with environmental regulations is essential, especially in markets like Europe, where single-use plastics face increasing scrutiny.

How Does Acrylonitrile Butadiene Styrene (ABS) Compare for Yard Glasses?

Acrylonitrile Butadiene Styrene (ABS) is known for its toughness and impact resistance, making it suitable for yard glasses that require a robust design. It can withstand temperatures of up to 80°C (176°F).

Pros and Cons of ABS:

– Pros: ABS is highly durable, resistant to impact, and offers good dimensional stability. It is also easy to print on, making it ideal for custom branding.

– Cons: ABS is generally more expensive than other plastics and may not be as environmentally friendly due to its lower recyclability.

Impact on Application: ABS is suitable for both cold and warm beverages, providing versatility in product offerings. However, its higher cost may deter some budget-conscious buyers.

Considerations for International Buyers: Buyers should verify compliance with relevant standards and consider the environmental impact of ABS, particularly in regions with strict sustainability regulations.

| Material | Typical Use Case for plastic yard glass | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | General-purpose yard glasses | Durable and cost-effective | Limited UV resistance | Low |

| Polyethylene Terephthalate (PET) | Cold beverage serving | High clarity and recyclability | Limited heat resistance | Medium |

| Polystyrene (PS) | Disposable yard glasses | Low manufacturing cost | Less durable and non-recyclable | Low |

| Acrylonitrile Butadiene Styrene (ABS) | Robust yard glasses | High impact resistance | Higher cost and lower recyclability | High |

This strategic material selection guide provides essential insights for international B2B buyers, enabling them to make informed decisions that align with their operational needs and market dynamics.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic yard glass

What Are the Key Manufacturing Processes for Plastic Yard Glass?

The manufacturing of plastic yard glasses involves several critical stages, each designed to ensure the final product meets quality and safety standards. The main stages in the manufacturing process include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Plastic Yard Glass Production?

The first step in manufacturing plastic yard glasses is the preparation of raw materials, primarily thermoplastics like polypropylene (PP) or polyethylene (PE). These materials are selected for their durability, flexibility, and safety in food contact applications. Suppliers typically source high-quality resins that comply with international food safety regulations, ensuring that the final product is suitable for beverages.

Once the materials are sourced, they undergo a process of granulation, where they are broken down into small pellets. This granulation process is critical, as it affects the flow and molding characteristics of the plastic. Quality control begins at this stage, with inspections to verify that the material meets specifications for color, clarity, and absence of contaminants.

What Techniques Are Used in Forming Plastic Yard Glasses?

After material preparation, the next stage is forming the glasses. The most common technique used is injection molding, which involves melting the plastic pellets and injecting them into molds that shape the glass. This method allows for high precision and repeatability, essential for meeting the design specifications.

Another technique is blow molding, particularly for larger and hollow designs. In this process, air is blown into a molten tube of plastic, expanding it to fit the mold. Both methods require rigorous monitoring of temperature and pressure to ensure consistent product quality.

How Are Plastic Yard Glasses Assembled and Finished?

Following the forming process, assembly may be necessary if the yard glasses include additional components like lids or straws. This stage involves quality checks to ensure that each component fits correctly and functions as intended.

Finishing processes, such as trimming excess plastic and surface treatment, are also crucial. These processes enhance the aesthetics and usability of the glasses. For instance, some manufacturers may apply a UV protective layer to prevent discoloration from sun exposure, particularly important for outdoor events.

What Quality Assurance Measures Are Essential for Plastic Yard Glass?

Quality assurance in the production of plastic yard glasses is paramount, given the global demand and varying international standards. Manufacturers typically adhere to several quality standards, including ISO 9001, which ensures that their quality management systems are robust.

Which International Standards Should B2B Buyers Consider?

For B2B buyers, understanding the relevant international standards is crucial. ISO 9001 certification indicates that a manufacturer has established processes for quality management and continuous improvement. Other relevant certifications may include:

- CE Marking: This certification indicates compliance with European health, safety, and environmental protection standards.

- BPA-Free Certification: Particularly important for food and beverage products, this certification ensures that the plastic used does not contain bisphenol A, a chemical linked to health risks.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are integrated throughout the manufacturing process to ensure that each batch of yard glasses meets established standards. These checkpoints typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify issues before they affect product quality.

- Final Quality Control (FQC): The final inspection ensures that the finished products meet all specifications before packaging and shipping.

How Can B2B Buyers Verify Supplier Quality Assurance?

B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify supplier quality assurance. Here are some actionable strategies:

What Methods Can Buyers Use to Conduct Supplier Audits?

Conducting supplier audits is an effective way to assess a manufacturer’s quality assurance processes. Buyers should look for:

- Documentation: Request quality management system documentation, including ISO certifications and quality assurance reports.

- On-Site Visits: If feasible, conducting on-site visits allows buyers to evaluate the manufacturing environment and quality control practices firsthand.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality processes.

How Can Buyers Access Quality Reports and Testing Results?

Buyers should request access to quality reports and testing results as part of the procurement process. Common testing methods that manufacturers may use include:

- Material Testing: Ensures that the plastics used meet food safety and durability standards.

- Performance Testing: Assesses the glasses’ ability to withstand thermal and mechanical stress.

- Compliance Testing: Verifies that products meet international standards for safety and quality.

What Are the Unique Quality Control Considerations for International Buyers?

For international buyers, particularly from diverse markets, understanding the nuances of quality control is essential. Different countries may have varying regulations regarding food safety and product durability.

Buyers should familiarize themselves with the local regulations in their regions and ensure that their suppliers comply with these standards. This knowledge not only helps in avoiding compliance issues but also builds trust in the supplier relationship.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for plastic yard glasses is essential for B2B buyers. By focusing on these elements, buyers can make informed decisions, ensuring that they source high-quality products that meet their needs and adhere to international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic yard glass’

Introduction

Sourcing plastic yard glasses for your business can be a rewarding yet challenging endeavor. This guide provides a practical checklist that outlines the essential steps to ensure you procure high-quality products that meet your specific needs. By following this step-by-step approach, you can mitigate risks, secure favorable terms, and establish reliable supplier relationships.

1. Identify Your Requirements

Understanding your specific needs is the first step in the sourcing process. Consider factors such as size, color, material quality, and intended use (e.g., events, promotions, or retail). This clarity will help you communicate effectively with suppliers and narrow down your options.

- Size Variations: Common sizes include 18 oz and 24 oz; determine which fits your target market best.

- Material Specifications: Ensure the plastic used is BPA-free and food-grade to meet health and safety standards.

2. Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in plastic yard glasses. Utilize online marketplaces, trade shows, and industry directories to compile a list of candidates.

- Supplier Reviews: Look for customer testimonials and ratings to gauge reliability and product quality.

- Industry Experience: Suppliers with a proven track record in your region or industry may better understand local regulations and market demands.

3. Evaluate Supplier Capabilities

Before making a decision, assess each supplier’s production capabilities and flexibility. This includes their ability to handle your order volume, customization options, and lead times.

- Customization Options: Verify if they can accommodate your branding needs, such as logo printing and color choices.

- Minimum Order Quantities (MOQs): Ensure their MOQs align with your purchasing strategy to avoid overcommitting.

4. Request Samples

Always request product samples before finalizing your order. This step is critical to evaluate the quality and suitability of the yard glasses for your intended use.

- Quality Assessment: Check for durability, clarity, and overall aesthetics.

- Functionality Testing: If applicable, test the glasses with different beverages to see how they perform in real-world conditions.

5. Verify Certifications and Compliance

Confirm that the suppliers adhere to relevant industry standards and regulations. This step is vital to ensure that the products are safe and compliant with local laws, especially if you’re sourcing internationally.

- Certifications to Look For: ISO, FDA, or local health department approvals can indicate quality assurance.

- Material Compliance: Ensure the materials used meet the safety requirements for food and beverage contact.

6. Negotiate Terms and Pricing

Once you’ve shortlisted suppliers, enter negotiations regarding pricing, payment terms, and delivery schedules. This is an opportunity to secure favorable conditions that align with your budget and operational needs.

- Bulk Discounts: Inquire about price breaks for larger orders, which can significantly reduce costs.

- Payment Flexibility: Discuss payment options that suit both parties, such as deposits or installment payments.

7. Establish a Communication Plan

Effective communication is crucial for a successful partnership. Before finalizing your order, ensure that you have a clear line of communication with your supplier.

- Point of Contact: Identify a specific contact person for quick resolution of any issues that may arise.

- Regular Updates: Agree on a schedule for progress updates regarding your order, including production and shipping timelines.

By following these steps, you can streamline your sourcing process for plastic yard glasses and build strong supplier relationships that benefit your business in the long run.

Comprehensive Cost and Pricing Analysis for plastic yard glass Sourcing

What Are the Key Cost Components in Sourcing Plastic Yard Glass?

When sourcing plastic yard glasses, several cost components contribute to the overall pricing structure. The primary components include:

-

Materials: The type of plastic used (e.g., BPA-free, food-grade PVC) significantly influences costs. High-quality materials may have a higher upfront cost but can result in better durability and customer satisfaction.

-

Labor: Labor costs vary by region and can impact pricing, especially if manufacturing occurs in countries with higher wage standards. Skilled labor is often required for quality assurance and customization processes.

-

Manufacturing Overhead: This encompasses the costs associated with running a production facility, including utilities, equipment maintenance, and administrative expenses. A well-managed overhead can lead to more competitive pricing.

-

Tooling: If custom molds are required for specific designs or logos, tooling costs can be substantial. These costs are typically amortized over larger production runs, making higher volume orders more cost-effective.

-

Quality Control (QC): Ensuring that products meet quality standards is essential. QC processes incur costs but are necessary to avoid defects and maintain brand reputation.

-

Logistics: Shipping and handling costs can fluctuate based on distance, shipping methods, and volumes. Incoterms will also affect who bears these costs, influencing the final price.

-

Margin: Suppliers will add a profit margin to cover their costs and risks. Understanding the typical margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Affect Plastic Yard Glass Costs?

Several factors can significantly influence the pricing of plastic yard glasses:

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing tiers. Bulk orders typically attract lower per-unit prices due to economies of scale.

-

Specifications and Customization: Custom designs, colors, or sizes can increase costs. Buyers should assess whether customization aligns with their marketing strategy and budget.

-

Materials and Quality Certifications: Higher-grade materials and certifications (e.g., food safety standards) can elevate prices. However, these attributes may justify a higher price point in markets prioritizing safety and quality.

-

Supplier Factors: The reputation and reliability of suppliers can impact costs. Established suppliers might charge more due to their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Different shipping arrangements can drastically affect pricing. Understanding Incoterms (e.g., FOB, CIF) helps buyers anticipate potential hidden costs related to shipping and insurance.

What Are the Best Negotiation Strategies for International Buyers?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to optimize their sourcing of plastic yard glasses:

-

Leverage Volume Discounts: Combining orders with other businesses or committing to larger volumes can help negotiate better pricing. Suppliers often provide tiered pricing based on order size.

-

Assess Total Cost of Ownership: Evaluate not just the purchase price but also logistics, storage, and potential wastage costs. A lower initial price may lead to higher overall expenses.

-

Understand Local Market Conditions: Familiarize yourself with regional pricing trends and economic factors affecting supplier costs. This knowledge can be advantageous during negotiations.

-

Request Samples: Before finalizing orders, request product samples to evaluate quality. This step can prevent costly mistakes if the delivered products do not meet expectations.

-

Build Long-Term Relationships: Establishing a rapport with suppliers can lead to better pricing and priority service. Trust often translates into more favorable terms over time.

What Should International Buyers Consider Regarding Pricing Nuances?

International buyers must be aware of specific pricing nuances that can affect their sourcing strategies:

-

Tariffs and Import Duties: Different countries impose varying tariffs on imported goods. Understanding these can help buyers anticipate additional costs.

-

Currency Fluctuations: Exchange rates can impact overall costs. Buyers should consider locking in prices or using financial instruments to mitigate risks related to currency fluctuations.

-

Cultural Considerations: Negotiation styles and business practices vary by region. Being culturally aware can facilitate smoother negotiations and foster better supplier relationships.

By understanding these cost components, price influencers, and negotiation strategies, international buyers can make informed decisions when sourcing plastic yard glasses, ultimately achieving more favorable outcomes.

Alternatives Analysis: Comparing plastic yard glass With Other Solutions

Understanding Alternative Solutions to Plastic Yard Glass

In the world of event and promotional drinkware, plastic yard glasses are a popular choice due to their unique design and functionality. However, businesses often look for alternatives that may better suit their needs in terms of cost, performance, and other factors. This analysis compares plastic yard glasses with other viable options, providing B2B buyers with insights to make informed decisions.

| Comparison Aspect | Plastic Yard Glass | Reusable Drinkware (e.g., Stainless Steel) | Disposable Cups (e.g., Paper or Plastic) |

|---|---|---|---|

| Performance | Durable, holds large volumes, fun design | High thermal retention, long-lasting | Convenient for single use, lightweight |

| Cost | Moderate (approx. $2-$3 each) | Higher initial investment (approx. $5-$10) | Low cost (approx. $0.10-$0.50 each) |

| Ease of Implementation | Easy to source in bulk, customizable | Requires sourcing from specialized suppliers | Readily available in various locations |

| Maintenance | Easy to clean, dishwasher safe | Requires regular cleaning, may dent | No maintenance needed, single-use only |

| Best Use Case | Events, parties, outdoor gatherings | Corporate events, long-term promotions | Festivals, casual events, quick service |

What Are the Pros and Cons of Reusable Drinkware?

Reusable drinkware, particularly stainless steel options, offers significant advantages in terms of performance and environmental impact. These containers are designed to keep beverages hot or cold for extended periods, making them ideal for outdoor events. However, they come with a higher upfront cost and require regular maintenance to keep them in optimal condition. They are best suited for corporate events or promotions where long-term branding and sustainability are priorities.

How Do Disposable Cups Compare?

Disposable cups, whether paper or plastic, are the most cost-effective and convenient option for large gatherings. They eliminate the need for cleaning and are readily available in various designs and sizes. However, their performance is limited; they often cannot hold large volumes and are less durable. Additionally, they contribute to environmental waste, which may not align with the values of businesses looking to implement sustainable practices. Disposable cups are best used for casual events or situations where quick service is essential.

Making the Right Choice: Which Solution Fits Your Needs?

When selecting the right drinkware solution, B2B buyers should carefully consider their specific needs and event types. Plastic yard glasses are excellent for memorable gatherings where presentation and fun are paramount, while reusable drinkware serves a more eco-conscious audience looking for durability and thermal performance. Disposable cups may be the best option for large-scale events where convenience and cost-efficiency are critical. Understanding these alternatives can guide businesses in making informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for plastic yard glass

What Are the Key Technical Properties of Plastic Yard Glass?

When considering plastic yard glasses for your business, it’s essential to understand their critical technical properties. Here are several specifications that are particularly important for B2B buyers:

-

Material Grade

Plastic yard glasses are typically made from food-grade, BPA-free materials such as polycarbonate or PVC. The material grade affects durability, safety, and compliance with food safety regulations. For international buyers, ensuring that the material meets local regulations is crucial, as it can influence marketability and consumer trust. -

Capacity and Dimensions

Common sizes for plastic yard glasses range from 18 oz to 24 oz, with dimensions varying based on design. For instance, a 24 oz glass may stand approximately 16 inches tall with a diameter of 3 inches at its widest point. Understanding these dimensions is vital for logistical planning, such as storage and shipping, as well as for ensuring compatibility with accessories like lids and straws. -

Tolerance

Tolerance refers to the allowable deviation in dimensions during manufacturing. For instance, a tolerance of ±0.5 inches in height can affect stacking and transportation. For B2B buyers, knowing the tolerance levels helps in assessing product consistency and quality assurance, which are critical for maintaining brand integrity. -

Imprint Area and Customization Options

Many suppliers offer custom printing on yard glasses, with standard imprint areas usually around 4″H x 1″W. This feature allows businesses to promote their brand through logos and designs, enhancing marketing efforts. Understanding the customization options available can help businesses leverage promotional opportunities effectively. -

Recyclability and Sustainability

The recyclability of plastic yard glasses is increasingly important in today’s market. Many manufacturers provide options that are recyclable, aligning with global sustainability trends. B2B buyers should consider this aspect, as it can be a selling point in environmentally-conscious markets. -

Dishwasher Safety

Most plastic yard glasses are top-rack dishwasher safe, although this can impact the longevity of printed designs. For businesses that prioritize easy maintenance for their customers, confirming dishwasher safety can enhance the product’s appeal.

What Are Common Trade Terms Used in the Plastic Yard Glass Industry?

Understanding the terminology associated with plastic yard glasses is crucial for effective communication and negotiation. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that are used in another company’s end products. In the context of plastic yard glasses, an OEM might create the glasses for a brand that sells them under its name. Understanding OEM relationships can help buyers find reliable manufacturers. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. For plastic yard glasses, MOQs can vary significantly based on the supplier and customization options. Knowing the MOQ is essential for budgeting and inventory management, especially for smaller businesses. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for specific quantities of products. When sourcing plastic yard glasses, sending out RFQs can help businesses compare offers and negotiate better deals. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is important for B2B buyers engaged in cross-border trade, as they dictate shipping, risk, and cost responsibilities. -

Lead Time

This refers to the amount of time it takes from placing an order until the product is delivered. For plastic yard glasses, lead times can vary based on customization and production schedules. Understanding lead times is critical for planning inventory and meeting market demands. -

Color Matching and Customization

This term refers to the process of ensuring that the colors used in printing or manufacturing match the desired specifications. For brands looking to maintain consistency in their product offerings, understanding color matching processes is key in the customization of plastic yard glasses.

By familiarizing yourself with these essential properties and trade terms, you can make informed decisions that align with your business goals and market needs.

Navigating Market Dynamics and Sourcing Trends in the plastic yard glass Sector

What Are the Current Market Dynamics and Key Trends Influencing the Plastic Yard Glass Sector?

The plastic yard glass sector is experiencing significant growth driven by various global factors. As outdoor events and social gatherings become more popular, especially in regions like Africa, South America, the Middle East, and Europe, the demand for vibrant, durable, and reusable drinkware is on the rise. International B2B buyers are increasingly sourcing plastic yard glasses for promotional events, festivals, and entertainment venues due to their eye-catching designs and practicality.

Emerging technologies are also shaping sourcing trends. Innovations in manufacturing processes, such as 3D printing and advanced molding techniques, allow for more customization options, enabling businesses to create unique products that resonate with their target audiences. Moreover, the rise of e-commerce platforms simplifies procurement, allowing buyers to access a broader range of suppliers and negotiate better prices.

Market dynamics are influenced by fluctuating raw material costs and supply chain disruptions, particularly for imports from Asia. Buyers should stay informed about these factors to mitigate risks associated with sourcing and pricing. Additionally, as consumer preferences shift towards personalized products, suppliers offering customizable options, such as imprinted logos or special designs, are likely to thrive.

How Is Sustainability and Ethical Sourcing Shaping the Plastic Yard Glass Market?

In today’s environmentally-conscious market, sustainability and ethical sourcing have become paramount for B2B buyers in the plastic yard glass sector. The environmental impact of single-use plastics has led to increased scrutiny from consumers and regulatory bodies alike. As a result, businesses are prioritizing the sourcing of yard glasses made from recyclable or biodegradable materials. Suppliers who can demonstrate commitment to sustainability, such as offering products made from recycled plastics or utilizing eco-friendly manufacturing processes, gain a competitive edge in this market.

Ethical supply chains are also gaining importance. Buyers are increasingly interested in knowing the origins of their products and the labor practices of their suppliers. Certifications that indicate adherence to environmental standards or fair labor practices can enhance a supplier’s credibility and attract discerning buyers. For instance, obtaining certifications like ISO 14001 for environmental management or Fair Trade certification can significantly influence purchasing decisions.

Furthermore, the shift towards sustainable practices is not only beneficial for the environment but also opens new market opportunities. Businesses that align with these values can differentiate themselves, appeal to eco-conscious consumers, and enhance brand loyalty.

What Is the Evolution and Historical Context of Plastic Yard Glasses?

The plastic yard glass, first introduced in the late 20th century, has transformed from a novelty item into a staple for outdoor social events and promotional gatherings. Initially designed for amusement parks and bars, these glasses quickly gained popularity due to their capacity and fun, vibrant designs. As consumer preferences evolved, manufacturers began to innovate, introducing customizable options that allowed businesses to imprint logos and event details, further enhancing their appeal.

Over the years, advancements in materials science have improved the durability and aesthetic qualities of plastic yard glasses, making them a preferred choice over traditional glassware in many settings. Today, the market is not only focused on functionality but also on sustainability, reflecting broader trends in consumer behavior and corporate responsibility. Understanding this evolution helps B2B buyers appreciate the significance of sourcing decisions in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic yard glass

-

How do I choose the right supplier for plastic yard glasses?

Choosing the right supplier involves several key considerations. First, evaluate their reputation by checking reviews and client testimonials. It’s essential to assess their production capacity and quality control processes to ensure they can meet your demand. Additionally, inquire about their experience with international shipping, especially to your region, and their compliance with local regulations. Request samples to inspect product quality and discuss customization options to align with your branding needs. Building a relationship with your supplier can also lead to better terms and reliability. -

What customization options are available for plastic yard glasses?

Customization options for plastic yard glasses typically include printing your logo, event details, or unique designs on the glass. Most suppliers offer various printing methods, such as silk screening or pad printing, and may allow for different colors and sizes. When placing a bulk order, confirm the minimum order quantity (MOQ) for custom designs, as this can vary by supplier. It’s also advisable to request a virtual proof of your design to ensure it meets your expectations before production begins. -

What are the minimum order quantities (MOQs) for plastic yard glasses?

Minimum order quantities for plastic yard glasses can vary significantly depending on the supplier and the customization options chosen. Generally, MOQs can range from as low as 12 pieces for unbranded glasses to several hundred for custom imprinted items. It’s essential to discuss your needs with the supplier upfront to ensure they can accommodate your order size and to negotiate terms if you require a smaller quantity. -

How do I ensure the quality of plastic yard glasses before purchasing?

To ensure quality, request samples from potential suppliers before placing a bulk order. This allows you to assess the material, weight, and overall design. Additionally, inquire about their quality assurance processes, such as inspections during production and final checks before shipping. Familiarize yourself with the specifications of the plastic used, ensuring it is BPA-free and meets food safety standards. Establishing a clear communication line for quality concerns can also help address issues proactively. -

What are the typical payment terms for international orders of plastic yard glasses?

Payment terms can vary by supplier and region, but common practices include upfront payment for first-time buyers, partial payment upon order confirmation, and the balance before shipment. Some suppliers may offer credit terms for established customers. Always clarify payment methods accepted (e.g., bank transfer, credit card) and discuss any additional fees related to international transactions. It’s advisable to use secure payment methods to protect your financial interests. -

What logistics considerations should I be aware of when importing plastic yard glasses?

When importing plastic yard glasses, consider shipping costs, customs duties, and delivery timelines. It’s important to understand the logistics process, including the supplier’s shipping methods and whether they provide tracking. Ensure that your supplier is experienced with international shipping to your region, as this can affect delivery times and reliability. Additionally, confirm any necessary import permits or compliance with local regulations in your country to avoid delays. -

How can I address potential issues with damaged or defective plastic yard glasses upon arrival?

To mitigate risks associated with damaged or defective products, inspect the shipment immediately upon arrival. Document any damages with photographs and keep a record of the packing list. Most reputable suppliers will have a policy for handling defects or damages, typically requiring you to report issues within a specific timeframe. Discuss return or exchange policies upfront with your supplier to ensure a clear understanding of how such situations will be managed. -

What are the advantages of using plastic yard glasses for events and promotions?

Plastic yard glasses offer several advantages for events and promotions. They are lightweight, making them easy to transport and distribute. Their large capacity is perfect for serving beverages at parties, festivals, or sporting events, enhancing customer experience. Additionally, they can be customized with branding, serving as effective promotional tools that guests can take home as souvenirs. Being reusable and durable, they are also a more sustainable option compared to disposable cups, aligning with eco-friendly initiatives.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Plastic Yard Glass Manufacturers & Suppliers List

1. Barconic® – Party Yard Cups

Domain: barproducts.com

Registered: 1997 (28 years)

Introduction: Barconic® Party Yard Cups with Lid & Straw, available in multiple color options.

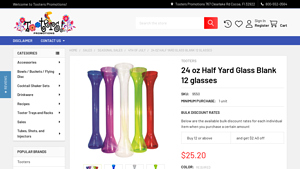

2. Tooters – 24 oz Half Yard Glass

Domain: tooters.com

Registered: 1996 (29 years)

Introduction: {“name”:”24 oz Half Yard Glass”,”pack_size”:”12 glasses”,”SKU”:”9550″,”UPC”:”N/A”,”MPN”:”N/A”,”minimum_purchase”:”1 unit”,”bulk_discount_rates”:{“1-11″:”$25.20 dz”,”12+”:”$22.80 dz”},”color”:”Available in clear vibrant colors”,”dimensions”:{“height”:”16 inches”,”diameter”:”3 inches”},”description”:”24 ounce plastic beer yard glass, perfect for serving beer, frozen drinks, or any beverage. Ideal fo…

3. Yardglass – Custom Plastic Drinkware

Domain: yardglass.com

Registered: 1997 (28 years)

Introduction: Minion Plastic Yards, Test tubes, Eco-friendly Glasses, Bottles, Beer mugs, Cans. Customization options available for names, logos, dates, and events. Supplies for large orders from brands like Bud Light, Budweiser, and Red Lobster, as well as small chain restaurants, bars, colleges, fraternities, sororities, and events like Sweet 16 parties.

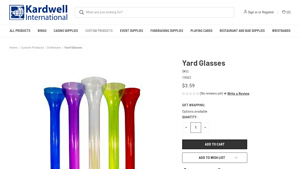

4. Kardwell – Yard Glasses

Domain: kardwell.com

Registered: 1996 (29 years)

Introduction: Yard Glasses SKU: 19501, Price: $3.59, Capacity: 24 oz, Height: 18″, Width: 3.00″, Depth: 3.00″, Available Colors: Clear, Blue, Green, Purple, Red, Material: Durable plastic, Options: Imprinted or blank.

5. S Sumtasa – Plastic Yard of Ale Glass with Lid

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Plastic Yard of Ale Glass with Lid”, “Volume”: “48oz”, “Type”: “Slush yard cup”, “Condition”: “New”, “Seller”: “S Sumtasa”, “Seller Rating”: “99.7% positive”, “Price”: “GBP 16.95 (approx US $22.77)”, “Shipping Cost”: “GBP 47.12 (approx US $63.30)”, “Shipping Method”: “International Priority Shipping via eBay’s Global Shipping Program”, “Quantity Available”: “More than 10 availabl…

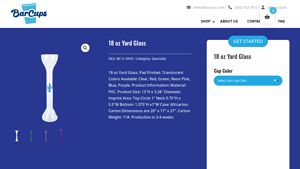

6. Bar Cups – 18 oz Yard Glass

Domain: barcups.com

Registered: 2022 (3 years)

Introduction: {“Product Name”: “18 oz Yard Glass”, “SKU”: “BC-S-18YD”, “Category”: “Specialty”, “Material”: “PVC”, “Product Size”: “13’H x 3.28′ Diameter”, “Imprint Area”: {“Top Circle”: “1′”, “Neck”: “0.75’H x 5.5’W”, “Bottom”: “1.375’H x 1’W”}, “Colors Available”: [“Clear”, “Red”, “Green”, “Neon Pink”, “Blue”, “Purple”], “Case Quantity”: “60/carton”, “Carton Dimensions”: “20′ x 17′ x 27′”, “Carton Weight”: “1…

Strategic Sourcing Conclusion and Outlook for plastic yard glass

How Can Strategic Sourcing Enhance Your Plastic Yard Glass Procurement?

In conclusion, strategic sourcing of plastic yard glasses presents a unique opportunity for international B2B buyers to capitalize on market trends and consumer preferences. By understanding the diverse range of product options—from customizable designs to various sizes and colors—businesses can effectively cater to their target demographics, whether for outdoor events, promotional activities, or hospitality settings.

The importance of strategic sourcing cannot be overstated; it allows companies to negotiate better pricing, ensure quality control, and streamline supply chains. By leveraging bulk purchasing options and exploring partnerships with reliable manufacturers, businesses can enhance their profit margins while delivering value to their customers.

As you navigate the global market, consider the growing demand for sustainable and innovative drinkware solutions. Engage with suppliers who prioritize eco-friendly materials and practices, as this aligns with the increasing consumer focus on sustainability.

Now is the time to take action—evaluate your sourcing strategies and explore the vibrant possibilities that plastic yard glasses can offer. Connect with reputable suppliers to secure your orders and position your business for success in this dynamic market.