Choosing Your Vicks Humidifier Parts: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for vicks humidifier parts

In the ever-evolving landscape of global commerce, sourcing Vicks humidifier parts can present significant challenges for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Understanding the intricacies of the supply chain, including identifying the right models, quality assurance, and navigating regulatory requirements, is crucial for maintaining operational efficiency and customer satisfaction. This comprehensive guide delves into various aspects of Vicks humidifier parts, covering key elements such as types of parts available, their applications in different humidifier models, and essential tips for supplier vetting.

Through detailed insights on sourcing genuine parts, assessing costs, and understanding market trends, this guide empowers international buyers to make informed purchasing decisions. Whether you are a distributor in Saudi Arabia looking to enhance your product offerings or a retailer in Nigeria seeking reliable suppliers, this resource is designed to equip you with the knowledge necessary to optimize your procurement strategies. Additionally, we will explore best practices for managing inventory and ensuring timely delivery, all while emphasizing the importance of customer service in fostering long-term business relationships. By leveraging the information presented in this guide, you can confidently navigate the complexities of the global market for Vicks humidifier parts, ensuring your business remains competitive and responsive to consumer needs.

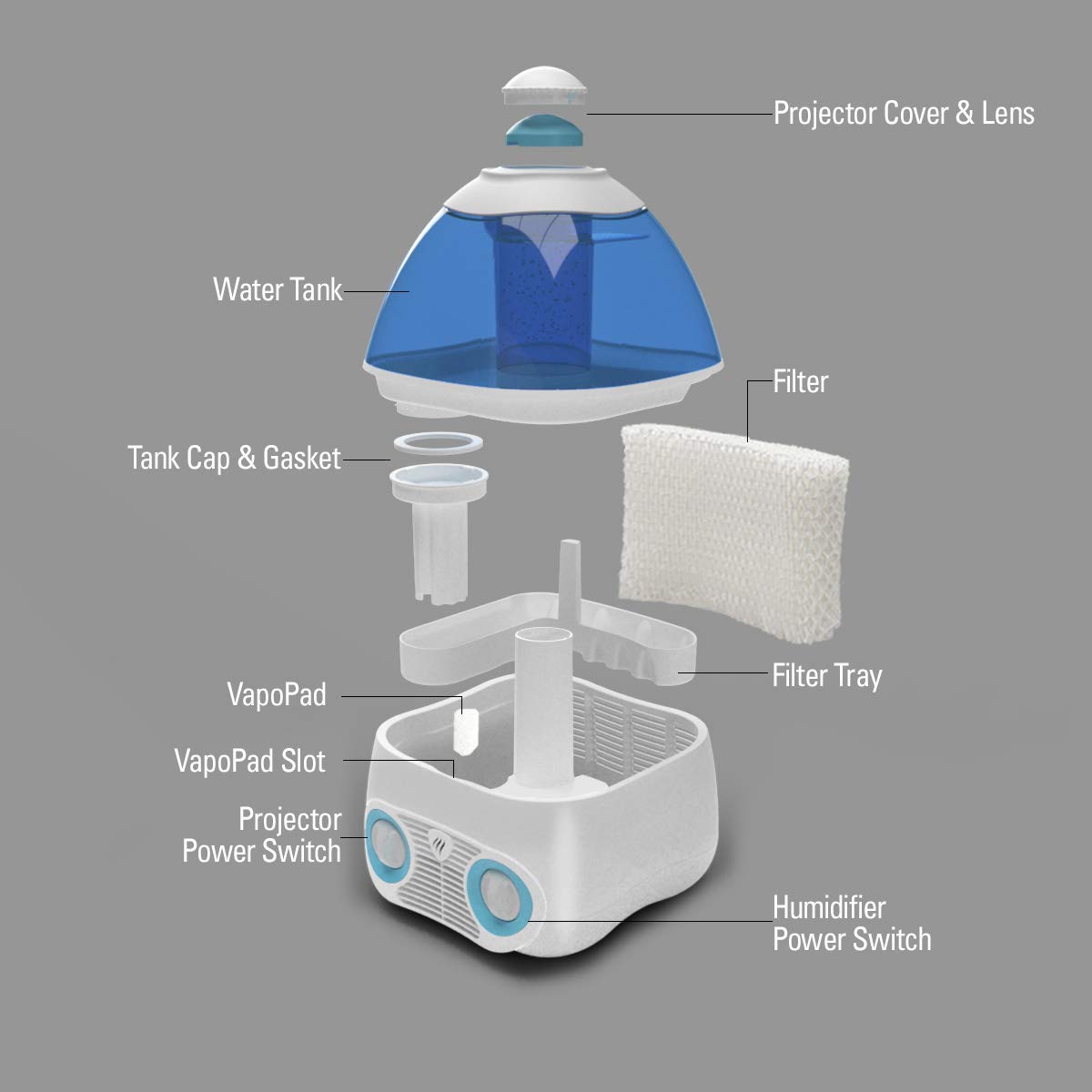

Understanding vicks humidifier parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Water Tanks | Store water for humidification; typically removable. | Replacement for various humidifier models | Pros: Essential for operation; easy to replace. Cons: May require frequent replacement depending on usage. |

| Filters | Remove impurities from water; available in various types. | Necessary for maintaining air quality | Pros: Improves air quality; enhances humidifier efficiency. Cons: Ongoing cost; requires regular replacement. |

| VapoPads® | Scented pads that enhance humidification with menthol. | Used in healthcare settings for relief | Pros: Provides soothing aroma; aids respiratory relief. Cons: Limited lifespan; additional cost for replenishment. |

| VapoSteam® | Liquid additive for warm steam humidifiers. | Ideal for medicinal applications | Pros: Enhances steam effectiveness; targeted relief for respiratory issues. Cons: Requires caution in use; may not be suitable for all models. |

| Humidity Monitors | Devices that measure and display humidity levels. | Useful in controlled environments | Pros: Helps maintain optimal humidity; prevents over-humidification. Cons: Additional investment; requires monitoring and calibration. |

What Are the Key Characteristics of Water Tanks for Vicks Humidifiers?

Water tanks are fundamental components of Vicks humidifiers, designed to hold and supply water for vaporization. Typically removable, they facilitate easy filling and cleaning, which is vital for maintaining hygiene standards in commercial settings. B2B buyers should consider the capacity and compatibility of water tanks with specific Vicks models to ensure seamless integration into their operations.

How Do Filters Enhance the Performance of Humidifiers?

Filters play a crucial role in ensuring that the air released into the environment is free from impurities and allergens. By trapping dust, pollen, and other contaminants, filters improve the overall air quality, making them essential in healthcare facilities and offices. B2B buyers must evaluate the type of filter needed for their humidifiers, as this affects the maintenance schedule and ongoing operational costs.

What Benefits Do VapoPads® Offer in Humidification?

VapoPads® are scented pads that release soothing menthol vapors, enhancing the humidification process. They are particularly beneficial in healthcare environments where patients seek relief from cold and allergy symptoms. When purchasing, B2B buyers should assess the compatibility of VapoPads® with their humidifier models and consider the frequency of replacement to manage ongoing costs effectively.

How Does VapoSteam® Contribute to Humidifier Functionality?

VapoSteam® is a liquid additive specifically designed for use in warm steam humidifiers. It enhances the steam’s effectiveness, providing targeted relief for respiratory issues. B2B buyers must be mindful of the specific requirements and safety instructions associated with VapoSteam® to ensure proper usage and compatibility with their humidifier models.

Why Are Humidity Monitors Important for Optimal Humidification?

Humidity monitors are essential tools for maintaining the right moisture levels in various environments. They help prevent over-humidification, which can lead to mold growth and other issues. For B2B buyers, investing in humidity monitors can enhance operational efficiency by ensuring that humidity levels remain within the optimal range, thereby protecting both equipment and health.

Key Industrial Applications of vicks humidifier parts

| Industry/Sector | Specific Application of Vicks Humidifier Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Replacement parts for hospital humidifiers | Ensures optimal humidity levels for patient comfort and recovery | Compliance with health regulations and availability of genuine parts |

| Hospitality | Humidifier parts for hotels and resorts | Enhances guest experience through improved air quality | Need for rapid delivery and bulk purchasing options |

| Education | Maintenance of classroom humidifiers | Supports a healthier learning environment, reducing illness spread | Cost-effectiveness and compatibility with various humidifier models |

| Agriculture | Parts for agricultural humidifiers in greenhouses | Maintains optimal humidity for plant growth and crop yield | Durability and resistance to agricultural chemicals |

| Residential Services | Parts for residential humidifiers in rental properties | Improves tenant satisfaction and reduces maintenance calls | Availability of diverse parts to cater to multiple humidifier models |

How Are Vicks Humidifier Parts Used in Healthcare Settings?

In healthcare, Vicks humidifier parts play a crucial role in maintaining ideal humidity levels in hospitals and clinics. By ensuring that the air is adequately humidified, these parts help alleviate respiratory issues and promote patient comfort during recovery. Healthcare facilities often require compliance with strict health regulations, so sourcing genuine parts is essential. Buyers from regions like Africa and the Middle East must consider local regulations and the ability to procure parts quickly to minimize downtime.

What Benefits Do Vicks Humidifier Parts Provide to the Hospitality Industry?

Hotels and resorts utilize Vicks humidifier parts to enhance the guest experience by improving indoor air quality. Proper humidity levels can prevent dryness and enhance comfort, making stays more enjoyable. For international buyers in South America and Europe, ensuring rapid delivery and the ability to purchase in bulk is vital, especially during peak seasons when guest occupancy rises.

How Do Vicks Humidifier Parts Support Educational Institutions?

In educational settings, Vicks humidifier parts are essential for maintaining a healthy environment in classrooms. Proper humidity can reduce the spread of illnesses, contributing to better attendance and learning outcomes. Buyers in this sector need to focus on cost-effectiveness while ensuring compatibility with various humidifier models used across different schools.

Why Are Vicks Humidifier Parts Important in Agriculture?

Agricultural applications, particularly in greenhouse settings, benefit significantly from Vicks humidifier parts. These parts help maintain optimal humidity levels, essential for plant growth and maximizing crop yield. Buyers in this sector, especially in regions like Africa, should prioritize sourcing durable parts that can withstand exposure to agricultural chemicals and ensure long-term reliability.

How Do Vicks Humidifier Parts Enhance Residential Services?

For residential services, maintaining humidifiers in rental properties with Vicks parts can significantly improve tenant satisfaction. Properly functioning humidifiers help prevent issues related to dry air, such as respiratory problems and discomfort. Buyers in this market should focus on the availability of diverse parts to cater to different models, ensuring they can meet the needs of various rental properties efficiently.

3 Common User Pain Points for ‘vicks humidifier parts’ & Their Solutions

Scenario 1: Difficulty in Identifying Compatible Humidifier Parts

The Problem:

B2B buyers often face challenges in identifying the correct replacement parts for specific Vicks humidifier models. This is particularly problematic for businesses in regions like Africa and South America, where access to comprehensive product catalogs may be limited. When buyers order the wrong parts, it leads to delays in repairs, increased costs, and potential dissatisfaction among end-users who rely on these humidifiers for health and comfort.

The Solution:

To mitigate this issue, buyers should utilize the manufacturer’s official resources, such as the Vicks website, which provides detailed lists of compatible parts for each humidifier model. Additionally, it is advisable to maintain a clear inventory of all humidifier models being used within their operations. Creating a database or spreadsheet that includes model numbers alongside compatible parts can streamline the ordering process. When placing orders, ensure to verify part numbers against the manufacturer’s specifications. Engaging with reputable suppliers that offer customer support can also provide assistance in confirming compatibility before purchase.

Scenario 2: Managing Inventory of Humidifier Parts Effectively

The Problem:

For businesses that use Vicks humidifiers in bulk, managing inventory can become a daunting task, particularly when it comes to replacement parts such as filters and water tanks. Buyers may find themselves running out of essential components, leading to operational downtime and impacting customer satisfaction. This is especially critical in regions where humidifiers are vital for health, particularly during dry seasons or in areas with high pollution levels.

The Solution:

Implementing a robust inventory management system is key to overcoming this pain point. Businesses should categorize humidifier parts into high, medium, and low turnover rates to prioritize stock levels accordingly. Using inventory management software that tracks usage patterns can help predict when parts need to be reordered. Additionally, establishing a relationship with suppliers that provide automatic reorder options can prevent stockouts. Regular audits of inventory can also ensure that businesses are not holding excessive stock of low-turnover items, thus optimizing storage costs and space.

Scenario 3: Ensuring Proper Maintenance of Vicks Humidifier Parts

The Problem:

B2B buyers often struggle with ensuring the proper maintenance of Vicks humidifier parts to extend their lifespan and maintain optimal performance. Neglecting maintenance can lead to decreased efficiency, increased energy costs, and potential health risks due to mold or mineral buildup, particularly in humidifiers that operate in high-use environments such as hospitals or schools.

The Solution:

Developing a comprehensive maintenance schedule is essential for ensuring the longevity of humidifier parts. This includes regular cleaning and replacement of filters as per the manufacturer’s guidelines. Buyers should train their staff on the correct maintenance procedures specific to each humidifier model, which can often be found in the user manuals available online. Investing in training sessions or workshops on proper humidifier care can also empower employees to perform regular checks and maintenance tasks. Moreover, using high-quality water, such as distilled or purified water, can minimize mineral buildup, thereby reducing the frequency of required maintenance. Regularly scheduled maintenance checks can help identify potential issues before they escalate, ensuring smooth operations and customer satisfaction.

Strategic Material Selection Guide for vicks humidifier parts

What Materials Are Commonly Used in Vicks Humidifier Parts?

When selecting materials for Vicks humidifier parts, several factors must be considered, including performance properties, durability, cost, and compliance with international standards. Here’s an analysis of four common materials used in these components.

1. Polypropylene (PP)

Key Properties:

Polypropylene is a thermoplastic polymer known for its high melting point (around 160°C) and excellent chemical resistance. It is lightweight and has a good balance of flexibility and rigidity.

Pros & Cons:

The durability of polypropylene is a significant advantage, as it can withstand repeated use without significant wear. It’s also cost-effective, making it a popular choice for mass production. However, it may not be suitable for high-temperature applications beyond its melting point, and its mechanical properties can degrade over time when exposed to UV light.

Impact on Application:

Polypropylene is compatible with water and various cleaning agents, making it ideal for water tanks and other humidifier components. However, it is essential to ensure that the specific grade of polypropylene used is suitable for humidifier applications.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure that the polypropylene used complies with relevant standards such as ASTM D638 for tensile properties. Additionally, they should consider sourcing from manufacturers that provide certifications for quality assurance.

2. Silicone Rubber

Key Properties:

Silicone rubber is known for its excellent temperature resistance (from -60°C to +200°C) and flexibility. It is also resistant to water and various chemicals.

Pros & Cons:

The primary advantage of silicone rubber is its ability to maintain performance in extreme conditions, making it suitable for seals and gaskets in humidifiers. However, it is generally more expensive than other materials, and manufacturing processes can be complex, potentially leading to higher costs.

Impact on Application:

Silicone rubber is particularly effective for applications requiring airtight seals, which is crucial for maintaining humidity levels in humidifiers. Its flexibility allows it to conform to various shapes, enhancing its usability.

Considerations for International Buyers:

International buyers must ensure that silicone rubber complies with standards such as FDA regulations for materials that come into contact with food or pharmaceuticals, especially in regions with stringent health regulations like Europe.

3. Polycarbonate (PC)

Key Properties:

Polycarbonate is a strong, transparent thermoplastic with high impact resistance and a temperature tolerance of up to 120°C. It also has good dimensional stability.

Pros & Cons:

The key advantage of polycarbonate is its durability and clarity, making it ideal for water tanks and visibility in design. However, it can be more expensive than other plastics and may require specialized processing techniques.

Impact on Application:

Polycarbonate’s clarity allows users to easily monitor water levels in humidifiers, which is a practical feature. However, it is susceptible to scratching and may require protective coatings.

Considerations for International Buyers:

Buyers should look for polycarbonate that meets international safety standards, such as ISO 11469 for material identification, especially in markets with strict import regulations.

4. Stainless Steel

Key Properties:

Stainless steel is known for its high corrosion resistance and ability to withstand high temperatures. It is durable and can last for many years with proper maintenance.

Pros & Cons:

The primary advantage of stainless steel is its longevity and resistance to rust, making it suitable for components exposed to water. However, it is heavier and more expensive than plastic alternatives, which can affect shipping costs.

Impact on Application:

Stainless steel is ideal for parts that require high durability and hygiene, such as water tanks and heating elements. Its non-reactive nature ensures that it does not leach chemicals into the water.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM A240 for stainless steel, particularly in regions like the Middle East where high-quality materials are expected.

Summary Table of Material Selection for Vicks Humidifier Parts

| Material | Typical Use Case for Vicks Humidifier Parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Water tanks, body parts | Cost-effective and durable | Limited high-temperature performance | Low |

| Silicone Rubber | Seals and gaskets | Excellent temperature resistance | Higher cost and complex manufacturing | High |

| Polycarbonate | Water tanks, visibility components | Strong and impact-resistant | More expensive and prone to scratching | Medium |

| Stainless Steel | Water tanks, heating elements | High durability and corrosion resistance | Heavier and higher shipping costs | High |

This material selection guide provides essential insights for B2B buyers looking to procure Vicks humidifier parts, ensuring they make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for vicks humidifier parts

What Are the Key Stages in the Manufacturing Process of Vicks Humidifier Parts?

The manufacturing process for Vicks humidifier parts involves several critical stages to ensure the production of high-quality components. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-grade materials that meet the specifications required for humidifier parts. Common materials include high-density polyethylene (HDPE) for water tanks, polypropylene for components like filters, and various metals for heating elements. Suppliers must adhere to stringent quality standards to ensure that the materials are free from defects and contaminants.

-

Forming: In this stage, the prepared materials are shaped into parts using various techniques. For plastic components, processes such as injection molding or blow molding are commonly employed. These methods allow for precise shaping and are essential for creating parts that fit together seamlessly. Metal parts may undergo stamping or machining, which require precision to maintain tolerances that ensure proper functionality in the final assembly.

-

Assembly: Once individual components are formed, they are assembled into the final product. This process can be manual or automated, depending on the complexity of the part and the production volume. During assembly, attention is paid to fitting parts together correctly to avoid future operational issues. Assembly lines are often equipped with quality control stations to catch any defects early in the process.

-

Finishing: The final stage involves applying coatings or treatments to enhance the durability and aesthetic appeal of the parts. This could include painting, polishing, or applying protective coatings. For humidifier parts, it is crucial that the finishing processes do not introduce any harmful substances, especially since these components are used in environments where air quality is a concern.

How Is Quality Assurance Integrated into the Manufacturing Process of Humidifier Parts?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that all parts meet both regulatory and customer expectations. The QA process for Vicks humidifier parts typically adheres to international standards such as ISO 9001 and industry-specific certifications like CE marking.

-

What International Standards Should B2B Buyers Look For?

Buyers should ensure that their suppliers are certified under ISO 9001, which outlines a framework for quality management systems. This certification indicates that the manufacturer consistently meets customer and regulatory requirements. Additionally, CE marking is essential for products sold in Europe, signifying compliance with safety and environmental standards. -

What Are the Key Quality Control Checkpoints?

Quality control is integrated at various checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival. Suppliers should provide certificates of compliance to verify that the materials meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, random samples of parts are tested for defects. This can include dimensional checks and functional testing to ensure that parts will perform as expected.

– Final Quality Control (FQC): Before shipping, finished products undergo a thorough inspection to confirm that they meet all specifications and quality standards. This may include performance testing, durability assessments, and safety checks.

What Testing Methods Are Commonly Used to Ensure the Quality of Humidifier Parts?

Testing methods for humidifier parts vary depending on the specific component and its function. Common methods include:

- Functional Testing: Ensures that parts operate as intended under normal conditions. For example, water tanks must be tested for leaks, while filters must be assessed for efficiency.

- Durability Testing: Involves subjecting parts to stress and strain to evaluate their performance over time. This is especially important for components like heating elements and water tanks, which are subject to thermal and mechanical stress.

- Chemical Analysis: Conducted to ensure that materials used in manufacturing do not release harmful substances when heated or in contact with water.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can adopt several strategies to verify the quality control practices of suppliers:

-

Conducting Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control practices. These audits should assess compliance with international standards and the effectiveness of their QA measures.

-

Requesting Quality Assurance Documentation: Suppliers should be able to provide documentation demonstrating their adherence to quality standards, including test reports, certifications, and compliance records.

-

Third-party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services can verify that products meet specified standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Regulatory Compliance: Different countries have unique regulations regarding product safety and quality. Buyers must ensure that suppliers are compliant with local regulations in their target markets.

- Supply Chain Transparency: Understanding the supply chain is crucial. Buyers should inquire about the traceability of materials and components to ensure that they are sourced from reputable suppliers.

- Cultural Considerations: Cultural differences may affect communication and quality expectations. Building strong relationships with suppliers can facilitate better understanding and adherence to quality standards.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing Vicks humidifier parts, ensuring they receive products that meet their quality expectations and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vicks humidifier parts’

To ensure a successful procurement process for Vicks humidifier parts, follow this comprehensive checklist. Each step is designed to guide you through the essential actions required for sourcing high-quality parts effectively.

Step 1: Identify Your Specific Needs

Understanding your exact requirements is crucial before initiating any procurement process. Determine which models of Vicks humidifiers you are servicing and the specific parts needed, such as filters, water tanks, or VapoPads. This clarity will streamline your search and help you communicate effectively with suppliers.

Step 2: Conduct Market Research

Research the market to identify potential suppliers that specialize in Vicks humidifier parts. Utilize online platforms, industry directories, and trade shows to gather a list of reputable suppliers. Pay attention to their product offerings, pricing, and customer reviews, as this information can provide insights into their reliability and service quality.

Step 3: Evaluate Supplier Certifications

Before entering into any agreements, verify that potential suppliers possess the necessary certifications and compliance with international standards. This ensures that the parts you are sourcing are genuine and meet quality benchmarks. Look for certifications such as ISO, CE, or any relevant local certifications that may apply in your region.

Step 4: Request Samples and Specifications

Request samples of the parts you intend to purchase, especially if you are considering bulk orders. Evaluate these samples for quality and compatibility with your humidifier models. Additionally, ask for detailed specifications and technical documentation to ensure that the parts meet your operational requirements.

Step 5: Compare Pricing and Terms

Once you have shortlisted potential suppliers, compare their pricing structures and payment terms. Consider not just the upfront costs but also shipping fees, lead times, and bulk order discounts. This will help you identify the best value for your investment while ensuring timely delivery.

Step 6: Assess Supplier Reputation and Reliability

Investigate the reputation of your shortlisted suppliers by checking customer testimonials, case studies, and references. Engage with other businesses in your network to gather feedback on their experiences. A supplier’s reliability can significantly impact your operational efficiency, making this step essential.

Step 7: Establish a Clear Communication Channel

Effective communication is key to a successful procurement process. Establish a direct line of communication with your chosen supplier to discuss order specifics, delivery schedules, and after-sales support. Ensure that both parties are aligned on expectations to avoid any misunderstandings that could affect your supply chain.

By following this checklist, you can confidently source Vicks humidifier parts that meet your quality standards and operational needs. Ensuring a systematic approach will not only save time but also enhance your procurement efficiency in the long run.

Comprehensive Cost and Pricing Analysis for vicks humidifier parts Sourcing

What Are the Key Cost Components in Sourcing Vicks Humidifier Parts?

When sourcing Vicks humidifier parts, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials directly impacts the price. For instance, components like water tanks and filters require high-quality plastics or specialized materials to ensure durability and functionality.

-

Labor: Labor costs can vary significantly based on the production location. Countries with lower labor costs can offer competitive pricing, but this must be balanced with quality assurance measures.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and indirect labor. Buyers should inquire about how these costs affect the pricing of parts.

-

Tooling: Initial tooling costs for custom parts can be substantial. This is particularly relevant for unique models or specifications not commonly produced.

-

Quality Control: Ensuring that parts meet quality standards incurs additional costs. Certifications (like ISO) can also influence pricing, as they require compliance with stringent regulations.

-

Logistics: Transportation costs, especially for international shipping, can significantly affect the final price. Factors such as distance, shipping method, and customs duties must be considered.

-

Margin: Finally, the supplier’s margin is a crucial component of the final price. Understanding typical margins in the industry can help buyers negotiate better deals.

What Influences the Pricing of Vicks Humidifier Parts?

Several factors can influence the pricing of Vicks humidifier parts, making it essential for buyers to understand their implications.

-

Volume/MOQ: Suppliers often offer better pricing for larger orders. Establishing a minimum order quantity (MOQ) can lead to significant savings, especially for businesses planning to resell parts.

-

Specifications and Customization: Custom parts or specific configurations may incur higher costs due to additional tooling and manufacturing processes.

-

Materials and Quality Certifications: High-quality materials and certifications can elevate the price but may also enhance the product’s reliability and longevity. Buyers should weigh the benefits against the costs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a proven track record may charge more but can provide better quality assurance and service.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can affect shipping costs and responsibilities. Buyers should negotiate terms that minimize their total cost.

What Are the Best Negotiation Strategies for B2B Buyers?

For B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to substantial cost savings.

-

Understanding Total Cost of Ownership (TCO): Buyers should calculate the TCO, which includes not just the purchase price but also logistics, maintenance, and potential replacements. This approach helps in making informed decisions.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs, which can lead to better pricing and reduced logistics costs.

-

Request Samples: Before committing to large orders, request samples to assess quality. This can prevent costly mistakes and ensure that the products meet expectations.

-

Build Long-Term Relationships: Establishing a reliable relationship with suppliers can lead to favorable terms and conditions over time. Suppliers are often more willing to negotiate with buyers who show loyalty.

-

Stay Informed about Market Trends: Understanding current market conditions can provide leverage in negotiations. For instance, if there’s an oversupply in the market, buyers may have more room to negotiate lower prices.

Final Thoughts for International B2B Buyers

When sourcing Vicks humidifier parts, it’s crucial to remain vigilant about pricing nuances and cost structures. Understanding the components that contribute to pricing, the factors that influence it, and effective negotiation strategies can lead to better purchasing decisions. Buyers should also be aware that prices are indicative and can fluctuate based on market conditions, supplier dynamics, and geopolitical factors.

Alternatives Analysis: Comparing vicks humidifier parts With Other Solutions

Understanding the Importance of Alternative Solutions for Humidification

In the quest for optimal air quality, particularly in regions with dry climates or during cold seasons, humidifiers are essential tools. While Vicks humidifier parts are a popular choice for many, exploring alternative solutions can provide buyers with a broader perspective on their options. This analysis compares Vicks humidifier parts against two viable alternatives: ultrasonic humidifiers and evaporative humidifiers, which serve similar purposes but employ different technologies.

Comparison Table

| Comparison Aspect | Vicks Humidifier Parts | Ultrasonic Humidifiers | Evaporative Humidifiers |

|---|---|---|---|

| Performance | Reliable for consistent moisture levels | Efficient at producing cool mist quickly | Natural evaporation, self-regulating humidity |

| Cost | Moderate; parts vary by model | Generally higher initial investment | Usually more affordable to maintain |

| Ease of Implementation | Simple replacement and installation for parts | Easy to set up, often portable | Requires regular filter replacement |

| Maintenance | Regular cleaning and part replacements needed | Minimal; occasional cleaning required | Regular filter changes needed |

| Best Use Case | Ideal for targeted relief from respiratory issues | Best for quick humidification in small spaces | Suitable for large areas, maintaining consistent humidity |

Detailed Breakdown of Alternatives

Ultrasonic Humidifiers

Ultrasonic humidifiers use high-frequency sound waves to create a fine mist from water. They are known for their ability to produce a significant amount of moisture quickly and quietly, making them ideal for home or office environments where noise may be a concern. While they tend to have a higher initial cost than Vicks humidifiers, they require less frequent maintenance and are often portable. However, they can produce white dust if hard water is used, which may necessitate the use of distilled water or demineralization cartridges.

Evaporative Humidifiers

Evaporative humidifiers work by drawing air through a moistened wick filter, allowing water to evaporate naturally into the air. This method is self-regulating; as humidity levels rise, the evaporation rate decreases. They are generally more affordable to operate since they do not require electricity for heating. However, they can be bulkier and may require regular filter changes, which could be a downside for some users. Their best use case is in larger areas where maintaining consistent humidity levels is crucial.

Conclusion: How to Choose the Right Humidification Solution

When selecting the right humidification solution, B2B buyers should consider their specific needs, including the size of the area to be humidified, budget constraints, and maintenance capabilities. Vicks humidifier parts are an excellent choice for those seeking reliable performance and targeted respiratory relief, particularly in regions where air quality is a concern. However, ultrasonic and evaporative humidifiers offer valuable alternatives that may better suit different operational environments or budgetary considerations. By evaluating the pros and cons of each option, buyers can make informed decisions that align with their operational goals and enhance indoor air quality effectively.

Essential Technical Properties and Trade Terminology for vicks humidifier parts

What Are the Essential Technical Properties of Vicks Humidifier Parts?

Understanding the technical specifications of Vicks humidifier parts is crucial for B2B buyers in ensuring compatibility, performance, and reliability. Below are several key properties that play a vital role in the selection and procurement of these components.

-

Material Grade

– The materials used in humidifier parts, such as plastics or metals, determine durability, resistance to moisture, and overall performance. For instance, high-grade polypropylene is often used for water tanks due to its resistance to corrosion and ability to withstand high humidity levels. Selecting parts made from superior materials can minimize maintenance costs and extend the lifespan of the humidifier. -

Filtration Efficiency

– Filters, particularly in evaporative humidifiers, must meet specific standards for particle retention. This efficiency is usually measured in microns. A filter with a smaller micron rating can capture more allergens and impurities, which is essential for maintaining air quality. B2B buyers should prioritize parts that guarantee high filtration efficiency to enhance customer satisfaction and product efficacy. -

Flow Rate

– The flow rate of humidifier components, especially for pumps, is measured in liters per hour (L/h). This specification indicates how much moisture the humidifier can produce. A higher flow rate can be crucial for larger spaces or in regions with dry climates. Understanding this parameter allows buyers to select the right parts that meet the operational needs of their customers. -

Operating Voltage

– Components like motors and heaters often have specific voltage requirements, typically indicated in volts (V). Compatibility with local electrical standards is essential to ensure safe and effective operation. Buyers must consider voltage ratings to avoid equipment failures and potential hazards. -

Temperature Tolerance

– Parts like water tanks and heating elements must withstand certain temperature ranges to operate effectively. This specification is crucial for warm mist humidifiers, where components can reach high temperatures. Understanding the temperature tolerance helps in selecting parts that will not degrade or fail under operational conditions.

What Are Common Trade Terms Related to Vicks Humidifier Parts?

Familiarity with industry terminology is essential for effective communication and negotiation between suppliers and buyers. Here are some common trade terms relevant to Vicks humidifier parts.

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts used in another company’s end product. For Vicks humidifier parts, sourcing OEM components ensures compatibility and quality assurance, which is vital for maintaining brand integrity. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers as it affects inventory management and initial procurement costs. Negotiating favorable MOQs can lead to cost savings and better cash flow. -

RFQ (Request for Quotation)

– An RFQ is a formal process used by buyers to solicit price quotes from suppliers. This document typically outlines the specifications, quantities, and delivery requirements for the parts needed. Crafting a detailed RFQ helps ensure that suppliers provide accurate and competitive pricing. -

Incoterms (International Commercial Terms)

– These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Knowing Incoterms is essential for understanding shipping costs, risks, and responsibilities, particularly when importing Vicks humidifier parts from different regions. -

Lead Time

– This term refers to the amount of time it takes from placing an order until the parts are delivered. Understanding lead times is vital for inventory planning and ensuring that supply meets demand. Buyers should factor in lead times when negotiating contracts to avoid stockouts.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market demands. This knowledge not only enhances purchasing efficiency but also strengthens supplier relationships and overall business performance.

Navigating Market Dynamics and Sourcing Trends in the vicks humidifier parts Sector

What Are the Current Market Dynamics and Key Trends Affecting Vicks Humidifier Parts?

The global market for Vicks humidifier parts is driven by several key factors. An increase in respiratory ailments, particularly in regions like Africa, South America, the Middle East, and Europe, has heightened the demand for humidifiers and their associated components. As consumers become more health-conscious, the need for effective humidification solutions is surging. The rise of e-commerce has also transformed how B2B buyers source these parts, allowing for quicker access to a broader range of products.

Emerging technologies such as smart humidifiers, which can be controlled remotely via mobile applications, are gaining traction. This trend towards connectivity is prompting manufacturers to innovate, creating parts that cater to these advanced models. B2B buyers should be aware of the compatibility of replacement parts with existing humidifier models, particularly as the market shifts toward multifunctional devices.

Additionally, sustainability is becoming a focal point in procurement strategies. Buyers are increasingly seeking suppliers that prioritize eco-friendly practices in their production processes. This trend not only enhances brand reputation but also aligns with the values of environmentally conscious consumers. For international buyers, understanding these dynamics is crucial for making informed sourcing decisions that meet both market demands and consumer expectations.

How Is Sustainability Influencing Sourcing Decisions in the Vicks Humidifier Parts Sector?

Sustainability and ethical sourcing are becoming integral to the procurement of Vicks humidifier parts. The environmental impact of manufacturing processes has led buyers to prioritize suppliers that adhere to sustainable practices. This includes the use of recycled materials, energy-efficient manufacturing, and minimal waste production.

Moreover, certifications such as ISO 14001 for environmental management systems are increasingly sought after by B2B buyers. These certifications not only indicate a commitment to sustainability but also provide assurance that the supplier is following best practices in environmental stewardship.

Another important aspect is the use of ‘green’ materials in the production of humidifier parts. For example, filters that utilize biodegradable materials or components that can be recycled at the end of their lifecycle are becoming more desirable. Buyers should actively seek suppliers who can demonstrate their commitment to sustainability through product design and material selection, as this will resonate well with end consumers who are increasingly concerned about their environmental footprint.

What Is the Historical Context of Vicks Humidifier Parts in the Market?

The Vicks brand has a long-standing history in the humidification sector, dating back to the early 20th century when it was primarily recognized for its vapor rubs. As the understanding of respiratory health evolved, so did Vicks’ product offerings, leading to the introduction of humidifiers designed to alleviate symptoms of colds and allergies. Over the decades, the brand has expanded its line to include a variety of humidifier models, each requiring specific parts for maintenance and repair.

As consumer needs shifted towards more advanced, efficient humidification solutions, Vicks adapted by incorporating technology into their products, such as filter-free designs and smart functionalities. This evolution has made the sourcing of Vicks humidifier parts an increasingly important consideration for international B2B buyers, as they must navigate a landscape that demands both innovation and reliability in product offerings. Understanding the historical context of these products can provide valuable insights into current trends and future developments in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of vicks humidifier parts

-

How do I source genuine Vicks humidifier parts for my business?

To source genuine Vicks humidifier parts, begin by identifying reliable suppliers who specialize in appliance parts. Look for distributors with a track record of providing authentic components and check for certifications or partnerships with Vicks or its parent company. Request product catalogs and confirm the authenticity of the parts through model numbers. Establishing relationships with manufacturers or authorized dealers can also ensure you receive genuine products, which is crucial for maintaining quality and customer satisfaction. -

What is the best way to verify the authenticity of Vicks humidifier parts?

To verify the authenticity of Vicks humidifier parts, always request detailed product specifications and certifications from your suppliers. Compare the parts against official Vicks documentation or websites to ensure they match in appearance and functionality. Additionally, consider ordering a sample before making bulk purchases. Trustworthy suppliers will provide transparent information regarding their sourcing and authenticity guarantees, which is vital for maintaining the integrity of your offerings in the market. -

What are the typical minimum order quantities (MOQs) for Vicks humidifier parts?

Minimum order quantities (MOQs) for Vicks humidifier parts can vary significantly depending on the supplier and the specific parts you need. Generally, MOQs might range from 50 to several hundred units. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are just starting or testing new products in your market. Some suppliers may offer lower MOQs for first-time orders or for certain high-demand parts, facilitating easier entry into the market. -

What payment terms should I expect when sourcing Vicks humidifier parts internationally?

When sourcing Vicks humidifier parts internationally, payment terms can vary. Common practices include advance payment, payment upon delivery, or a letter of credit. Many suppliers may require a deposit (30-50%) upfront, with the balance due upon shipping. Always clarify payment terms before finalizing orders, and consider using secure payment methods to protect your financial interests. Establishing a good rapport with your supplier can also lead to more favorable terms over time. -

How can I ensure quality assurance (QA) for Vicks humidifier parts?

To ensure quality assurance for Vicks humidifier parts, request detailed quality control procedures from your supplier. This includes information on testing methods, compliance with industry standards, and certifications that the parts meet Vicks’ specifications. Implement a quality inspection process upon receipt of goods, possibly engaging third-party inspection services to verify the condition and functionality of the parts. Regular communication with your supplier about quality expectations is crucial for maintaining standards. -

What logistics considerations should I keep in mind when importing Vicks humidifier parts?

When importing Vicks humidifier parts, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose reliable freight forwarders experienced in handling appliance parts to ensure timely delivery. Familiarize yourself with import duties and taxes in your country to avoid unexpected costs. Additionally, assess the supplier’s ability to provide documentation required for customs clearance, as this can streamline the import process and prevent delays. -

Can I customize Vicks humidifier parts for my specific market needs?

Customization of Vicks humidifier parts may be possible, depending on the supplier and the part in question. Discuss your specific market requirements with your supplier to explore options for custom branding or modifications. Some manufacturers may offer tailored solutions for unique applications or regional preferences. However, be mindful of MOQs and additional costs associated with customization, as these can impact your overall budget and pricing strategy. -

What should I do if I encounter issues with Vicks humidifier parts after purchase?

If you encounter issues with Vicks humidifier parts after purchase, first contact your supplier for support. Provide detailed information about the problem, including model numbers and the nature of the issue. Most reputable suppliers will have a return or exchange policy for defective parts. Additionally, familiarize yourself with warranty information provided by Vicks or the supplier, as this can offer guidance on resolution processes. Maintaining clear documentation of your communications can aid in resolving disputes effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Vicks Humidifier Parts Manufacturers & Suppliers List

1. Vicks – Humidifiers & Vaporizers

Domain: vickshumidifiers.com

Registered: 2012 (13 years)

Introduction: Vicks offers a variety of humidifiers and vaporizers, including:

1. Vicks CoolRelief Cool Mist Humidifier (VUL600)

2. Vicks 3-in-1 SleepyTime Humidifier (VUL500)

3. Vicks Mini Filter Free Cool Mist Humidifier (VUL520)

4. Vicks Filter Free Cool Mist Humidifier (V4600)

5. Vicks Mini Filter Free & Filter Free Humidifier (VUL525 & VUL545)

6. Vicks Dual Comfort Cool + Warm Mist Humidifier (VWC775)

7. V…

2. Vicks – Humidifier Parts

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Vicks Humidifier Parts available on eBay include various models such as Vicks UltraQuiet Cool Mist Humidifier (V5100NS) and Vicks Ultrasonic Cool Mist Humidifier. Products are listed as brand new or pre-owned, with prices ranging from $7.99 to $50.00. Some listings offer free delivery, while others have shipping costs. Ratings for products are generally high, with many listings showing 5.0 out of …

3. Vicks – Humidifier Model V745A

Domain: justanswer.com

Registered: 2004 (21 years)

Introduction: Vicks Humidifier Model V745A; issue: knob broke off; replacement options: order from Vicks or third-party suppliers; consider universal knob if unavailable; check knob stem integrity; avoid forcing knob; clean control area regularly; professional repair may be needed if internal control shaft is damaged.

4. Vicks – Humidifier Filters

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Vicks – Humidifier Filters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Discount Filters – Vicks Compatible Humidifier Wicks

Domain: discountfilters.com

Registered: 2003 (22 years)

Introduction: Vicks Compatible Humidifier Wicks & Pads Replacement Filter Wick for Honeywell Portable Humidifiers – HAC-504, WF2 6-Pack $8.95 / Filter Wick $11.19 Save 20%! 6 Pack Selected Save 20% $53.70 Save 20% 2 Pack Save 20% $27.90 $13.95 each Save 20% 4 Pack Save 20% $43.80 $10.95 each Save 20% 6 Pack Save 20% $53.70 $8.95 each Ships Free! Compatible Model/Part Numbers: V-3600, V-3500, V-3100, V-3500N, V-…

Strategic Sourcing Conclusion and Outlook for vicks humidifier parts

In the competitive landscape of humidifier parts, strategic sourcing is crucial for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By prioritizing quality and reliability, businesses can ensure they procure genuine Vicks humidifier parts that enhance product performance and customer satisfaction. Establishing partnerships with reputable suppliers not only facilitates timely access to essential components like filters, water tanks, and VapoPads but also helps mitigate risks associated with counterfeit products.

Moreover, understanding the diverse range of Vicks humidifier models allows buyers to tailor their inventory to meet regional demands effectively. By leveraging data on consumer preferences and market trends, businesses can optimize their product offerings, ensuring they remain competitive and relevant.

Looking ahead, the demand for reliable humidification solutions is set to grow, driven by increasing awareness of air quality and health. Now is the time for B2B buyers to evaluate their sourcing strategies and build robust supply chains that can adapt to market fluctuations. Engage with trusted suppliers to secure your position in this expanding market and ensure your customers receive the best in humidification technology.