92 Polyester 8 Spandex Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for 92 polyester 8 spandex

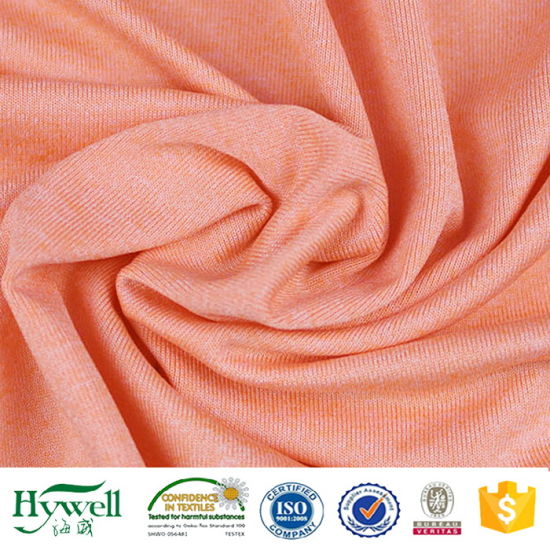

In the competitive landscape of global textile sourcing, one of the pivotal challenges faced by international B2B buyers is identifying high-quality materials that meet diverse application needs while also ensuring cost-effectiveness. Among these materials, 92 polyester 8 spandex stands out as a versatile choice, particularly prized for its comfort, durability, and exceptional stretch properties. This fabric is increasingly favored in various sectors, including activewear, athleisure, and fashion apparel, making it essential for businesses to understand its offerings and applications.

This comprehensive guide delves into the multifaceted world of 92 polyester 8 spandex, covering critical aspects such as types, applications, and supplier vetting processes. Additionally, it provides insights into pricing structures and the nuances of global market trends affecting this fabric. By equipping buyers from regions like Africa, South America, the Middle East, and Europe—particularly in markets like Brazil and Saudi Arabia—with actionable information, this guide empowers them to make informed purchasing decisions.

Navigating through this resource, buyers will gain a deeper understanding of how to select the right suppliers and negotiate favorable terms, ensuring they secure high-quality materials that align with their business objectives. With the right knowledge at hand, companies can enhance their product offerings, respond to market demands, and ultimately drive growth in their respective industries.

Understanding 92 polyester 8 spandex Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 4-Way Stretch Jersey | Excellent elasticity, soft hand-feel, 59/60″ width | Activewear, Yoga, Athleisure | Pros: Versatile, comfortable; Cons: May require specific care to maintain elasticity. |

| New Jersey Stretch | Soft touch, machine washable, available in 33 colors | Casual wear, dresses, loungewear | Pros: Wide color selection; Cons: Limited to lighter applications. |

| High-Performance Sports Fabric | High compression, UV protection, moisture-wicking | Sportswear, leggings, swimwear | Pros: Ideal for performance wear; Cons: Higher cost per yard compared to standard fabrics. |

| Stretch Denim | Durable, structured feel, 4-way stretch | Casual wear, jeans, skirts | Pros: Combines comfort with durability; Cons: Heavier weight may limit applications. |

| Specialty Knits (e.g., Spandex Velvet) | Luxurious feel, unique textures, vibrant colors | Fashion apparel, evening wear | Pros: High aesthetic appeal; Cons: May not be suitable for high-performance activities. |

What are the Key Characteristics of 4-Way Stretch Jersey Fabric?

4-Way Stretch Jersey fabric is a popular choice for activewear due to its remarkable elasticity and soft hand-feel. This fabric allows for freedom of movement, making it ideal for activities like yoga and fitness. With a width of 59/60 inches and a weight of approximately 6.25 oz, it is suitable for both casual and form-fitting garments. B2B buyers should consider the fabric’s versatility and comfort, but also be aware that it may require specific care instructions to maintain its stretch properties.

How Does New Jersey Stretch Fabric Stand Out?

New Jersey Stretch fabric features a soft touch and is machine washable, making it a practical choice for various applications, including casual wear and loungewear. Available in 33 colors, it offers B2B buyers a wide palette for product customization. Its 4-way stretch capability enhances comfort and fit. However, while it excels in softness and color variety, it may not be the best option for high-performance applications, limiting its utility for more active-focused brands.

What Makes High-Performance Sports Fabric Essential?

High-Performance Sports Fabric is designed for active use, featuring high compression and UV protection, along with moisture-wicking capabilities. This makes it ideal for sportswear, leggings, and swimwear, catering to brands that prioritize functionality. B2B buyers should note its slightly higher cost, reflecting its advanced properties. The investment is worthwhile for businesses focused on performance-driven apparel, ensuring their products meet the rigorous demands of athletic activities.

Why Choose Stretch Denim for Casual Applications?

Stretch Denim combines the durability of traditional denim with the comfort of spandex, offering a structured feel that is still flexible. This fabric is particularly suitable for casual wear, including jeans and skirts. B2B buyers will appreciate its ability to provide comfort without sacrificing style. However, its heavier weight may limit its use in lighter applications, making it essential to consider the intended end-use when selecting this fabric.

What Benefits Do Specialty Knits Like Spandex Velvet Offer?

Specialty knits, such as Spandex Velvet, are characterized by their luxurious feel and vibrant colors, making them ideal for fashion-forward applications like evening wear. These fabrics appeal to designers looking for high aesthetic value. However, while they offer unique textures and visual appeal, they may not be suitable for high-performance activities, which could limit their marketability for brands focused on functionality. B2B buyers should weigh the aesthetic benefits against performance needs when considering these specialty fabrics.

Key Industrial Applications of 92 polyester 8 spandex

| Industry/Sector | Specific Application of 92 polyester 8 spandex | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports and Activewear | Athletic apparel including leggings and tops | High durability and comfort, enhancing performance | Ensure compliance with local regulations and standards, consider fabric weight and stretch properties. |

| Fashion and Apparel | Casual and formal wear such as dresses and blouses | Versatile styling options with a soft touch | Availability of various colors and patterns, machine washability, and fabric sourcing timelines. |

| Medical and Healthcare | Scrubs and active medical wear | Comfort and functionality for healthcare professionals | Compliance with medical standards, durability against frequent washing, and resistance to stains. |

| Home Textiles | Bedding and loungewear | Soft, comfortable fabrics for enhanced consumer experience | Consider fabric weight, colorfastness, and certification for home use. |

| Swimwear and Beachwear | Swim suits and beach cover-ups | Excellent stretch and recovery for active use | UV protection capabilities, chlorine resistance, and fit customization for varying body types. |

How is 92 Polyester 8 Spandex Used in Sports and Activewear?

In the sports and activewear sector, 92 polyester 8 spandex is primarily used for creating high-performance athletic apparel such as leggings, tops, and shorts. This fabric is favored for its exceptional stretch and recovery properties, allowing athletes to perform movements with ease. Buyers in this sector must consider the fabric’s durability and moisture-wicking capabilities, especially for regions with hot climates like parts of Africa and the Middle East. Ensuring compliance with local sports regulations and standards is also crucial for international buyers.

What Role Does 92 Polyester 8 Spandex Play in Fashion and Apparel?

The fashion industry benefits from 92 polyester 8 spandex due to its versatility, making it suitable for a wide range of garments, from casual wear to formal dresses. The fabric’s soft touch and four-way stretch provide comfort without compromising style, appealing to modern consumers. For B2B buyers, sourcing this fabric requires attention to the availability of diverse colors and patterns, as well as machine washability, to meet consumer demands in markets across South America and Europe.

How is 92 Polyester 8 Spandex Utilized in Medical and Healthcare Applications?

In the medical and healthcare sector, 92 polyester 8 spandex is commonly used for scrubs and other active medical wear. The fabric’s comfort and flexibility are essential for healthcare professionals who require ease of movement throughout their shifts. Buyers must ensure that the fabric meets stringent medical standards and is durable enough to withstand frequent washing and exposure to stains. This is particularly important for international buyers looking to supply hospitals and clinics in various regions.

What Are the Benefits of Using 92 Polyester 8 Spandex in Home Textiles?

For home textiles, 92 polyester 8 spandex is utilized in products like bedding and loungewear. The fabric’s soft and comfortable nature enhances the consumer experience, making it an attractive choice for home goods manufacturers. Buyers should consider the fabric’s weight, colorfastness, and certification for home use to ensure quality and compliance with safety standards. This is especially relevant for B2B buyers in Europe and the Middle East, where consumer expectations for home textiles are high.

How Does 92 Polyester 8 Spandex Enhance Swimwear and Beachwear?

In the swimwear and beachwear sector, 92 polyester 8 spandex is ideal for creating swimsuits and cover-ups due to its excellent stretch, recovery, and UV protection properties. This fabric allows for a snug fit that accommodates various body types while providing comfort during water activities. B2B buyers should prioritize sourcing options that offer chlorine resistance and customization for fit, particularly in markets like Brazil, where beach culture is prominent.

3 Common User Pain Points for ’92 polyester 8 spandex’ & Their Solutions

Scenario 1: Sourcing Quality Fabric for Competitive Pricing

The Problem: B2B buyers often struggle to find a reliable supplier who can provide high-quality 92 polyester 8 spandex fabric at a competitive price. Many suppliers may have inconsistent quality, leading to issues with fabric performance in end products, such as clothing or activewear. This inconsistency can result in increased production costs due to returns, rework, and loss of customer trust, especially in markets like Africa and South America, where price sensitivity is high.

The Solution: To mitigate this issue, buyers should focus on establishing relationships with multiple suppliers and conducting thorough quality assessments before making bulk purchases. Request samples to evaluate the fabric’s stretch, recovery, and overall feel, ensuring it meets industry standards for the intended applications, such as activewear or athleisure. Implementing a quality control process that includes testing for durability and colorfastness will also help ensure that the fabric meets the specifications required for successful production. Buyers should also consider engaging with suppliers that offer transparency in their production processes, such as those that provide certifications or testing reports, to build confidence in their sourcing decisions.

Scenario 2: Managing Fabric Availability and Lead Times

The Problem: International buyers often face challenges with fabric availability and lead times, which can disrupt production schedules. This is particularly critical for businesses in regions like the Middle East and Europe, where timely delivery is essential to meet market demands and seasonal trends. Delays in receiving 92 polyester 8 spandex can lead to missed opportunities in launching new products, resulting in lost revenue.

The Solution: To address this issue, buyers should prioritize suppliers that maintain adequate inventory levels and offer reliable shipping options. Establishing a forecasted ordering system can help suppliers prepare for demand surges, minimizing lead times. Additionally, engaging in strategic partnerships with suppliers who have a history of prompt delivery can be beneficial. Buyers should also negotiate terms that allow for partial shipments to ensure that production can continue while waiting for the remaining fabric, thus reducing downtime and maintaining a steady workflow.

Scenario 3: Ensuring Fabric Performance Meets End-User Expectations

The Problem: Another common pain point for B2B buyers is ensuring that the 92 polyester 8 spandex fabric performs well in its intended applications, such as moisture-wicking, breathability, and comfort. Failure to meet end-user expectations can lead to poor product reviews and increased return rates, particularly in competitive markets like Brazil and Saudi Arabia, where consumers have high standards for activewear.

The Solution: To ensure that the fabric meets performance expectations, buyers should work closely with suppliers to understand the fabric’s technical specifications and performance characteristics. It is advisable to conduct field tests where samples of the fabric are used in actual product prototypes to gather feedback on their performance under real-world conditions. Collaborating with manufacturers who specialize in activewear can also provide insights into the latest fabric innovations and treatments, such as antimicrobial finishes or UV protection. By leveraging these partnerships and incorporating consumer feedback, buyers can refine their product offerings to ensure they meet the high standards expected by their target markets, ultimately enhancing brand reputation and customer loyalty.

Strategic Material Selection Guide for 92 polyester 8 spandex

What Are the Key Properties of 92 Polyester 8 Spandex?

The 92 polyester 8 spandex blend is renowned for its unique properties that cater to various applications in the textile industry. This fabric exhibits excellent four-way stretch capabilities, allowing it to conform to body movements, which is particularly beneficial for activewear and athleisure. Additionally, it offers a soft hand-feel, enhancing comfort for the wearer. The durability of polyester combined with the elasticity of spandex makes this blend resistant to wear and tear, ensuring longevity in garments.

What Are the Advantages and Disadvantages of 92 Polyester 8 Spandex?

When evaluating the advantages of 92 polyester 8 spandex, one of the most significant benefits is its versatility. This fabric is suitable for a wide range of applications, including sportswear, loungewear, and even formal attire. Its moisture-wicking properties also make it ideal for activewear, as it helps keep the wearer dry during physical activities.

However, there are some limitations to consider. The manufacturing complexity can be higher than that of pure polyester or cotton fabrics due to the need for blending and ensuring the right proportions of spandex. Additionally, while the fabric is durable, it may not be as breathable as 100% natural fibers, which could be a consideration in hotter climates.

How Does 92 Polyester 8 Spandex Impact Specific Applications?

The impact of 92 polyester 8 spandex on specific applications is profound. In activewear, for instance, the fabric’s stretch and recovery properties allow for a snug fit without compromising mobility. This makes it an excellent choice for leggings, yoga pants, and other sports apparel. In fashion, the fabric’s soft touch and drape make it suitable for dresses, blouses, and loungewear, appealing to a wide demographic.

What Should International B2B Buyers Consider When Sourcing 92 Polyester 8 Spandex?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, several factors should be taken into account. Compliance with local regulations and standards, such as ASTM, DIN, or JIS, is crucial. Buyers should also consider the fabric’s performance in different climates; for example, regions with high humidity may require fabrics with enhanced breathability. Additionally, understanding local market preferences for fabric texture, weight, and color can help in making informed purchasing decisions.

Summary Table of Material Characteristics

| Material | Typical Use Case for 92 polyester 8 spandex | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 92 Polyester 8 Spandex | Activewear, athleisure, fashion apparel | Excellent stretch and comfort | Higher manufacturing complexity | Medium |

| 100% Polyester | Casual wear, outerwear | Cost-effective and durable | Less stretch and comfort | Low |

| Cotton-Spandex Blend | Casual wear, loungewear | Breathable and soft | Less durability compared to polyester | Medium |

| Nylon-Spandex Blend | Swimwear, performance apparel | High elasticity and moisture-wicking | Can be more expensive | High |

This guide provides a comprehensive overview of the strategic material selection for 92 polyester 8 spandex. By understanding the properties, advantages, and considerations associated with this fabric, international B2B buyers can make informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 92 polyester 8 spandex

What Are the Key Stages in the Manufacturing Process of 92 Polyester 8 Spandex?

The manufacturing of 92 polyester 8 spandex fabric involves several critical stages that ensure the final product meets quality and performance standards. Understanding these stages is essential for B2B buyers looking to source high-quality materials.

Material Preparation

The manufacturing process begins with the selection and preparation of raw materials. Polyester fibers are sourced, often through a combination of virgin and recycled materials, while spandex is procured for its elasticity. The fibers are then processed through a spinning method, which may involve melting the polyester granules and extruding them to create filament yarns. The spandex is similarly produced and blended with polyester to achieve the desired fabric characteristics.

Forming Techniques

Once the fibers are prepared, they undergo various forming techniques, including knitting and weaving. For 92 polyester 8 spandex, a common approach is to use a warp or weft knitting process. This results in a four-way stretch fabric that enhances comfort and fit, essential for applications in activewear and athleisure. The knitting technique also contributes to the fabric’s breathability and moisture-wicking properties, making it suitable for high-performance garments.

Assembly and Finishing

After forming, the fabric undergoes assembly and finishing processes. This can include dyeing, printing, and applying treatments to enhance properties like UV resistance or water repellency. Dye sublimation is a popular method used for this fabric type, allowing for vibrant, long-lasting colors. Quality control at this stage is crucial, as improper finishing can lead to color inconsistencies or fabric defects.

How Is Quality Assurance Implemented in Manufacturing 92 Polyester 8 Spandex?

Quality assurance is integral to the manufacturing of 92 polyester 8 spandex fabric. Manufacturers must adhere to international and industry-specific standards to ensure product reliability and safety.

What Are the Relevant International Standards for Quality Assurance?

One of the primary standards that guide manufacturing processes is ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 helps ensure consistency in product quality and customer satisfaction. Additionally, industry-specific certifications like CE or API may be relevant depending on the intended application of the fabric, particularly in medical or safety-related uses.

What QC Checkpoints Are Critical in the Manufacturing Process?

Quality control (QC) checkpoints are established at various stages of production, including:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. Tests may include fiber strength assessments and chemical composition checks.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to monitor the quality of the fabric being produced. This may involve checking for consistent stretch properties and ensuring that the knitting or weaving process is defect-free.

-

Final Quality Control (FQC): After the fabric has been finished, a final inspection is conducted to verify that it meets all specifications. This includes checking for colorfastness, dimensional stability, and overall fabric appearance.

Which Common Testing Methods Are Used to Ensure Quality?

To ensure the fabric’s performance characteristics, various testing methods are employed, such as:

-

Stretch and Recovery Tests: These assess the fabric’s elasticity and ability to return to its original shape after being stretched, which is crucial for activewear applications.

-

Colorfastness Testing: Fabrics undergo tests to ensure that colors remain vibrant after exposure to washing, light, and perspiration.

-

Durability Tests: These include abrasion resistance tests to evaluate how well the fabric withstands wear and tear over time.

-

Moisture Management Testing: This assesses the fabric’s ability to wick moisture away from the body, an essential property for athletic wear.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure that the fabrics meet their specific requirements.

What Steps Can Buyers Take to Ensure Supplier Compliance?

-

Conduct Supplier Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This can include reviewing their compliance with international standards like ISO 9001.

-

Request Quality Reports: Suppliers should be able to provide documentation that details their quality control processes, including results from testing methods mentioned earlier.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices and the overall quality of the fabric produced.

-

Evaluate Certifications: Check for relevant certifications that the supplier holds. This can include ISO certifications, CE marks, and any other industry-specific credentials that demonstrate their commitment to quality.

What Are the QC and Certification Nuances for International Buyers?

International buyers must also be aware of the nuances that come with sourcing textiles globally. Different regions may have varying quality standards and regulations. For example, fabrics exported to the European Union may need to comply with specific safety and environmental regulations that differ from those in the Middle East or South America.

Additionally, cultural and regional preferences can influence fabric specifications, requiring buyers to communicate their needs clearly to suppliers. It is advisable for buyers to establish long-term relationships with suppliers who understand these nuances and can adapt their offerings accordingly.

Conclusion

Understanding the manufacturing processes and quality assurance measures for 92 polyester 8 spandex is critical for B2B buyers seeking reliable textile solutions. By being informed about the production stages, quality control checkpoints, and testing methods, buyers can make educated decisions when sourcing materials. Furthermore, implementing thorough verification processes will ensure that they partner with suppliers who prioritize quality and compliance, ultimately enhancing the success of their product offerings in competitive markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ’92 polyester 8 spandex’

The purpose of this guide is to provide international B2B buyers with a comprehensive checklist for sourcing 92% polyester and 8% spandex fabric. This versatile material is ideal for various applications, including activewear, athleisure, and formal garments. By following these steps, buyers can ensure they procure high-quality fabric that meets their specific requirements.

Step 1: Define Your Technical Specifications

Clearly outlining your fabric requirements is essential. Consider the end application of the fabric, such as whether it will be used for sportswear, casual wear, or formal attire. Specifics like weight (e.g., 6.25 oz.), stretch characteristics (4-way stretch), and width (usually 58/60 inches) should be documented. This will help you communicate effectively with suppliers and ensure that the fabric meets your intended use.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for manufacturers known for their expertise in polyester and spandex blends. Investigate their history, production capabilities, and customer reviews. Utilize platforms like trade shows, industry directories, and online marketplaces to gather a list of potential suppliers who can meet your sourcing needs.

Step 3: Evaluate Supplier Certifications

Verify the quality and compliance certifications of potential suppliers. Certifications such as ISO 9001, OEKO-TEX, and GOTS (if applicable) indicate that the supplier adheres to international quality standards and sustainability practices. Request copies of these certifications to ensure the supplier’s products align with your company’s ethical and quality benchmarks.

Step 4: Request Samples

Always ask for fabric samples before making large orders. This allows you to assess the texture, weight, color, and overall quality of the material firsthand. Pay attention to the fabric’s stretch and recovery, as well as its softness and durability. Request samples in various colors to evaluate how the fabric performs under different printing techniques, especially if you plan to use dye sublimation.

Step 5: Compare Pricing and Terms

Request detailed quotes from multiple suppliers to compare pricing. Ensure that quotes include all costs associated with the fabric, such as shipping, taxes, and any additional fees. Take note of minimum order quantities and payment terms. Comparing these factors will help you identify the best value while considering both price and quality.

Step 6: Review Production and Delivery Timelines

Establish clear timelines for production and delivery. Confirm how long it will take for the supplier to fulfill your order and consider their ability to meet your deadlines. This is particularly important for seasonal products or time-sensitive projects. Assessing their responsiveness and flexibility in adjusting timelines can significantly impact your supply chain efficiency.

Step 7: Build a Strong Relationship with Your Supplier

Once you choose a supplier, focus on building a long-term relationship. Regular communication can lead to better pricing, priority service, and collaboration on new product developments. Share your feedback on the fabric quality and performance, as this will help the supplier understand your needs and improve their offerings over time.

By following this checklist, B2B buyers can confidently navigate the sourcing process for 92% polyester and 8% spandex fabric, ensuring they find reliable suppliers who meet their quality and performance standards.

Comprehensive Cost and Pricing Analysis for 92 polyester 8 spandex Sourcing

What Are the Key Cost Components in Sourcing 92 Polyester 8 Spandex?

Sourcing 92 polyester 8 spandex involves various cost components that international B2B buyers must consider. The primary costs include:

-

Materials: The fabric itself is the most significant cost component, influenced by the quality of polyester and spandex used. For high-performance variants, expect a premium.

-

Labor: This includes wages for workers involved in fabric production and garment manufacturing. Labor costs can vary significantly based on the region, with lower costs in developing countries compared to developed nations.

-

Manufacturing Overhead: This encompasses the operational costs of running manufacturing facilities, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Costs associated with machinery and tools used in the production process. For specialized fabric types or custom designs, tooling costs can be higher.

-

Quality Control (QC): Implementing stringent QC measures ensures the fabric meets international standards. The cost of inspections and testing must be factored into the overall pricing.

-

Logistics: Shipping costs, including freight, insurance, and customs duties, can significantly affect the total cost. Selecting appropriate Incoterms can help manage these expenses effectively.

-

Margin: Suppliers typically add a markup to cover their costs and profit. This margin can vary based on supplier reputation and market conditions.

How Do Pricing Influencers Affect the Cost of 92 Polyester 8 Spandex?

Several factors influence the pricing of 92 polyester 8 spandex:

-

Volume/MOQ: Larger orders generally lead to better pricing due to economies of scale. Suppliers often have Minimum Order Quantities (MOQs) that can affect pricing strategies.

-

Specifications and Customization: Custom fabric specifications, such as specific stretch requirements or color matching, can raise costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Material Quality and Certifications: Fabrics with certifications (e.g., OEKO-TEX) or high-performance attributes (e.g., moisture-wicking, UV protection) may command higher prices.

-

Supplier Factors: The reputation, location, and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their experience and reliability.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) impacts logistics costs and responsibilities, affecting the overall pricing structure.

What Buyer Tips Can Enhance Cost Efficiency When Sourcing 92 Polyester 8 Spandex?

To optimize costs when sourcing 92 polyester 8 spandex, consider the following strategies:

-

Negotiate Effectively: Establish a strong relationship with suppliers and negotiate based on volume and long-term partnerships. Highlight your potential for repeat business to secure better pricing.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the initial fabric cost but the long-term implications, including durability, maintenance, and shipping costs. A higher-quality fabric may reduce overall costs over time.

-

Understand Pricing Nuances in International Markets: Be aware of regional differences in pricing and demand. For instance, fabrics may be more competitively priced in regions with established textile industries.

-

Leverage Trade Agreements: Investigate any trade agreements that may reduce tariffs on textile imports, particularly for buyers in regions like Africa and South America.

-

Stay Informed on Market Trends: Regularly review market trends in fabric sourcing to anticipate price fluctuations and adjust your purchasing strategy accordingly.

Disclaimer on Indicative Prices

Prices for 92 polyester 8 spandex can vary widely based on the factors discussed above. Buyers should seek quotes from multiple suppliers to ensure competitive pricing while considering the total cost of ownership and long-term value.

Alternatives Analysis: Comparing 92 polyester 8 spandex With Other Solutions

Introduction: Exploring Alternatives to 92 Polyester 8 Spandex

In the competitive landscape of textile manufacturing, finding the right fabric blend is crucial for meeting market demands. The 92 polyester 8 spandex blend is celebrated for its versatility and performance, particularly in activewear and athleisure applications. However, various alternatives exist that can cater to specific needs such as cost, performance, and application. This analysis explores key alternatives, providing B2B buyers with actionable insights to make informed decisions.

Comparison Table

| Comparison Aspect | 92 Polyester 8 Spandex | Alternative 1: 86 Polyester 14 Spandex | Alternative 2: 100% Cotton |

|---|---|---|---|

| Performance | Excellent stretch, durability, and moisture-wicking properties, ideal for activewear. | Good stretch and recovery, slightly more breathable, suitable for casual wear. | Natural fiber, breathable, soft touch, but lacks stretch and moisture management. |

| Cost | Moderate pricing, competitive for high-performance fabrics. | Slightly higher cost due to the increased spandex content. | Generally lower cost, but varies based on quality. |

| Ease of Implementation | Easy to work with; compatible with dye sublimation printing. | Similar ease of use, but may require adjustments in production due to higher spandex content. | Requires different handling and manufacturing processes. |

| Maintenance | Machine washable and durable, retaining shape after multiple washes. | Machine washable, but may require more careful washing to maintain elasticity. | Easy to care for but may shrink or lose shape over time. |

| Best Use Case | Best suited for high-performance activewear, leggings, and sports apparel. | Ideal for casual wear and garments requiring a softer feel. | Perfect for everyday clothing, loungewear, and non-performance applications. |

Detailed Breakdown of Alternatives

Alternative 1: 86 Polyester 14 Spandex

This alternative offers a higher spandex content, which enhances the stretch and comfort level, making it an excellent choice for garments that require a snug fit. The trade-off is a slightly higher cost, which may not be justifiable for all applications. It maintains good durability but requires careful washing to preserve the elasticity over time. This blend is particularly suitable for casual wear and activewear that demands a softer touch.

Alternative 2: 100% Cotton

Cotton is a natural fiber known for its breathability and comfort, making it a preferred choice for everyday clothing. However, it lacks the stretch and moisture-wicking properties found in polyester blends. While cotton garments are generally lower in cost, they may not withstand rigorous activities or maintain their shape as effectively as synthetic blends. This makes 100% cotton more suitable for loungewear and casual apparel, rather than performance-oriented products.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right fabric for your product line, consider the specific requirements of your target market. The 92 polyester 8 spandex blend is ideal for high-performance applications, offering excellent stretch and durability. However, if you are focusing on casual wear or need a softer fabric, alternatives like the 86 polyester 14 spandex or 100% cotton may better suit your needs. By evaluating factors such as performance, cost, and ease of implementation, B2B buyers can make informed decisions that align with their business goals and customer expectations.

Essential Technical Properties and Trade Terminology for 92 polyester 8 spandex

What Are the Key Technical Properties of 92 Polyester 8 Spandex?

Understanding the technical properties of 92 polyester 8 spandex is crucial for B2B buyers looking to procure high-performance fabrics for various applications. Here are some critical specifications to consider:

-

Composition: The fabric consists of 92% polyester and 8% spandex, providing excellent stretch and recovery. This blend ensures durability and comfort, making it ideal for activewear, athleisure, and fashion apparel. Buyers should note that the spandex content allows for flexibility, enhancing fit and mobility.

-

Weight: Typically available in weights around 6.25 oz. per square yard, this fabric strikes a balance between lightness and substance. Weight is significant for applications such as leggings and activewear, where breathability and comfort during movement are essential.

-

Width: Commonly offered in widths of 58/60 inches, the width of the fabric can affect cutting yields and overall production costs. Wider fabrics can reduce waste and improve efficiency for manufacturers, making it a preferred choice for bulk orders.

-

Stretchability: This fabric features a 4-way stretch capability, allowing it to stretch both horizontally and vertically. This property is vital for garments requiring a snug fit, as it contributes to comfort and ease of movement, essential in sportswear and active apparel.

-

Washability: Machine washability is a key property that influences the fabric’s usability in everyday clothing. Fabrics that can withstand regular washing without losing their shape or color are more appealing to consumers, thus enhancing marketability.

-

UV Protection: Some variations of this fabric offer UV protection, making them suitable for outdoor apparel. This property is increasingly important for consumers in regions with high sun exposure, adding value to the fabric for specific applications like swimwear or outdoor gear.

What Are Common Trade Terms Related to 92 Polyester 8 Spandex?

Familiarity with industry jargon is essential for smooth transactions and effective communication with suppliers and manufacturers. Here are some common terms relevant to B2B buyers in the textile industry:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce products based on the specifications provided by another company. In the context of 92 polyester 8 spandex, an OEM may manufacture finished garments or components using this fabric, allowing brands to focus on design and marketing.

-

MOQ (Minimum Order Quantity): MOQ signifies the smallest order size that a supplier is willing to accept. Understanding MOQ is crucial for buyers to manage their budgets and inventory effectively, especially when sourcing specialized fabrics like 92 polyester 8 spandex.

-

RFQ (Request for Quotation): An RFQ is a formal process where buyers solicit price quotes from suppliers for specific quantities of fabric or products. This is particularly important for B2B buyers seeking competitive pricing and ensuring they receive accurate cost estimates for their fabric needs.

-

Incoterms (International Commercial Terms): These are standardized trade terms used in international contracts to clarify the responsibilities of buyers and sellers. Key Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) help determine who bears the costs and risks during shipping, critical for international buyers sourcing 92 polyester 8 spandex from global suppliers.

-

Lead Time: This term refers to the time it takes from placing an order to the delivery of the product. Understanding lead time is vital for buyers to ensure timely delivery of fabrics, especially when working on seasonal collections or time-sensitive projects.

-

Dye Sublimation: A printing technique compatible with 92 polyester 8 spandex that allows for vibrant, long-lasting designs. This process is essential for brands looking to incorporate unique prints and patterns into their activewear lines, enhancing product appeal.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, ensuring they select the right materials for their product offerings while navigating the complexities of global trade.

Navigating Market Dynamics and Sourcing Trends in the 92 polyester 8 spandex Sector

What Are the Key Market Dynamics and Trends Affecting the 92 Polyester 8 Spandex Sector?

The 92 polyester 8 spandex fabric market is currently experiencing a robust growth trajectory, driven by the rising demand for activewear and athleisure apparel across global markets. Key trends influencing this sector include a surge in health consciousness, leading consumers to seek comfortable yet stylish clothing that supports an active lifestyle. This demand is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where the fitness culture is rapidly expanding. Additionally, the rise of e-commerce platforms has made it easier for B2B buyers to access a wide variety of fabrics, facilitating quicker sourcing and inventory management.

Technological advancements in textile manufacturing are also reshaping the market landscape. Innovations such as digital printing and dye sublimation are allowing manufacturers to create custom designs efficiently, catering to specific regional tastes and preferences. This flexibility is crucial for international buyers, enabling them to adapt to market demands swiftly. Moreover, the increasing focus on performance attributes—such as moisture-wicking, UV protection, and durability—further enhances the appeal of 92 polyester 8 spandex fabrics, making them a preferred choice for sportswear and casual clothing.

How Can B2B Buyers Embrace Sustainability and Ethical Sourcing in the 92 Polyester 8 Spandex Market?

Sustainability is becoming a central theme in the textile industry, with B2B buyers increasingly prioritizing ethical sourcing practices. The environmental impact of polyester production, particularly in terms of water usage and pollution, has prompted many companies to seek out recycled polyester options. Utilizing 92 polyester 8 spandex fabrics made from recycled materials not only addresses environmental concerns but also aligns with consumer preferences for eco-friendly products.

Ethical supply chains are also gaining traction, with buyers urged to investigate the sourcing practices of their suppliers. Certifications such as Global Recycled Standard (GRS) and OEKO-TEX® Standard 100 can serve as benchmarks for identifying environmentally responsible materials. Buyers should engage with suppliers who demonstrate transparency in their manufacturing processes and labor practices, ensuring that their supply chains uphold ethical standards. By prioritizing sustainability and ethics, B2B buyers can not only mitigate risks associated with reputational damage but also cater to a growing market segment that values corporate social responsibility.

What Is the Historical Context of 92 Polyester 8 Spandex in the Textile Industry?

The evolution of 92 polyester 8 spandex fabrics can be traced back to the broader development of synthetic textiles in the 20th century. Initially popularized in the athletic wear segment, this fabric composition has become synonymous with comfort and performance due to its excellent stretch and recovery properties. Over the decades, improvements in fiber technology have enhanced the durability and versatility of these fabrics, making them suitable for a wide array of applications—from casual loungewear to high-performance sports apparel.

As consumer preferences shifted towards athleisure and functional fashion, the demand for 92 polyester 8 spandex surged, prompting manufacturers to innovate continuously. The fabric’s compatibility with advanced printing techniques has further solidified its position in the market, allowing brands to offer diverse and customizable options to their customers. Today, the 92 polyester 8 spandex blend stands as a testament to the textile industry’s capacity for adaptation and innovation, catering to the evolving needs of both consumers and B2B partners alike.

Frequently Asked Questions (FAQs) for B2B Buyers of 92 polyester 8 spandex

-

1. How can I ensure the quality of 92 polyester 8 spandex fabric before purchasing?

To ensure quality, request samples from potential suppliers to evaluate the fabric’s texture, stretch, and durability. Additionally, inquire about the supplier’s quality assurance processes, including any certifications or standards they adhere to, such as ISO certifications. Establish clear criteria for testing, such as stretchability, colorfastness, and wear resistance, and consider third-party inspections if ordering in bulk. Engaging in direct communication about your quality expectations can also help align standards between you and the supplier. -

2. What applications are best suited for 92 polyester 8 spandex fabric?

The versatility of 92 polyester 8 spandex fabric makes it ideal for various applications, particularly in activewear, athleisure, and casual clothing. It is commonly used in leggings, yoga pants, sports bras, and performance apparel due to its excellent stretch and recovery properties. Additionally, it can be utilized in fashion garments, such as dresses and blouses, offering a comfortable fit and a soft hand feel. Its moisture-wicking capabilities further enhance its suitability for sports and leisure activities. -

3. What are the typical minimum order quantities (MOQs) for 92 polyester 8 spandex fabric?

Minimum order quantities can vary significantly among suppliers, typically ranging from 500 to 1,000 meters for custom orders. However, some manufacturers may offer lower MOQs for stock fabrics. It’s essential to clarify MOQs with potential suppliers upfront to align with your production needs. Negotiating MOQs may also be possible, especially if you are willing to establish a long-term partnership or place larger orders over time. -

4. How do I choose the right supplier for 92 polyester 8 spandex fabric?

Selecting the right supplier involves evaluating their industry reputation, product quality, and service reliability. Research potential suppliers through online reviews, industry forums, and trade shows. Request references from previous clients and assess their communication responsiveness. Consider their production capacity, lead times, and flexibility in customization. Additionally, ensure they comply with international trade regulations and quality standards relevant to your target market. -

5. What are the payment terms typically offered for international orders of 92 polyester 8 spandex?

Payment terms can vary but commonly include options like advance payment, letters of credit, or payment upon delivery. Many suppliers require a deposit (usually 30-50%) before production, with the balance due prior to shipping. Discussing payment terms upfront is crucial to establish trust and mitigate risks. Ensure that all terms are clearly documented in your purchase agreement to avoid misunderstandings later in the transaction. -

6. How can I customize 92 polyester 8 spandex fabric for my brand?

Customization options typically include color selection, weight variations, and specific performance features like UV protection or moisture-wicking properties. Many suppliers offer dyeing services to match your desired colors, while others might allow adjustments in fabric weight to meet your specifications. Discuss your needs directly with the supplier to explore available options and associated costs. It’s also advisable to request prototypes before committing to large orders to ensure the final product aligns with your vision. -

7. What logistics considerations should I keep in mind when importing 92 polyester 8 spandex fabric?

When importing, consider shipping methods, customs regulations, and potential tariffs that may apply to your order. Choose a reliable freight forwarder experienced in textile shipments to streamline the process. Ensure you have all necessary documentation, such as commercial invoices and certificates of origin, to facilitate customs clearance. It’s also wise to factor in delivery times and costs, which can vary based on your chosen shipping method (air or sea). -

8. How do I handle issues with defective fabric upon delivery?

In the event of receiving defective fabric, immediately document the issues with photographs and detailed descriptions. Contact your supplier promptly to discuss the problem and refer to the terms outlined in your purchase agreement regarding returns or exchanges. Most reputable suppliers will have a policy for addressing defects, including replacement or refunds. Maintaining clear communication and documentation throughout the process is essential for resolving disputes effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 92 Polyester 8 Spandex Manufacturers & Suppliers List

1. Etsy – Polyester Spandex Blend

2. Spechler-Vogel – New Jersey Stretch Fabric

Domain: spechlervogel.com

Introduction: {“description”:”This versatile 58/60\” New Jersey Stretch consists of 92% Polyester and 8% Spandex. Offers a soft touch and 4 way stretch. Suitable for shirting/blouses, dresses/skirts, bridal/formal wear, lingerie, bedding, loungewear and much more! Available in 33 colors.”,”specifications”:{“machine_washable”:”Yes”,”four_way_stretch”:”Yes”,”composition”:”92% Polyester, 8% Spandex”,”width”:”58/60…

3. Facebook – Multi Purpose Heat Press

4. OEM T-Shirt – Short Sleeve Shirts

Domain: oemtshirt.com

Registered: 2022 (3 years)

Introduction: {“Product Name”:”Short Sleeve Shirts”,”Material”:”92% Polyester, 8% Spandex”,”Color Options”:[“Navy”,”White”,”Light Blue”,”Gray”,”Black”],”Sizes”:”S to 6XL”,”SKU”:”TX-A6-Short Sleeve”,”Price”:”$9.42″,”Minimum Order Quantity”:”10 pieces”,”Production Time”:”7-10 working days”,”Features”:[“Eco-Friendly”,”Breathable”,”Comfortable”],”Logo Customization”:”Available”,”Printing Techniques”:[“Silk Screen P…

5. Clothes Fabrics – JN-9183 High-Performance Activewear Fabric

Domain: clothesfabrics.com

Registered: 2024 (1 years)

Introduction: 92 Polyester 8 Spandex: High-performance fabric ideal for activewear and sportswear. Key features include:

– Composition: 92% Polyester, 8% Spandex

– Model: JN-9183

– Fabric Type: Single jersey with both side peach TCD Yarn

– Customizable degree of peach (single or double peach available)

– Good stretch and recovery

– High compression

– Soft hand-feel

– UV protection

– Cuttable width: 59″

– Weight…

6. Tri-Mountain – Gold K435 Men’s Polo Shirt

Domain: apparelnbags.com

Registered: 2010 (15 years)

Introduction: Tri-Mountain Gold K435 Men’s Polo Shirt, 92% Polyester, 8% Spandex, Short Sleeve

Strategic Sourcing Conclusion and Outlook for 92 polyester 8 spandex

In conclusion, the strategic sourcing of 92% polyester and 8% spandex fabric presents significant advantages for businesses targeting activewear and athleisure markets. This versatile material offers exceptional durability, comfort, and stretchability, making it ideal for a wide range of applications, from sports apparel to casual wear. Buyers should prioritize suppliers that emphasize quality, timely delivery, and customization options, as these factors are essential for maintaining a competitive edge in the global marketplace.

As international B2B buyers from Africa, South America, the Middle East, and Europe evaluate sourcing opportunities, understanding the unique properties and applications of 92 polyester 8 spandex will be crucial. Leveraging this fabric can enhance product offerings, meet consumer demand for high-performance apparel, and drive brand loyalty.

Looking ahead, businesses are encouraged to engage with reputable suppliers who can provide innovative solutions and support tailored to their specific needs. By investing in quality materials like 92 polyester 8 spandex, companies can not only elevate their product lines but also position themselves for sustainable growth in an increasingly competitive landscape.