The Definitive Guide to Gas Powered Surfboard: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for gas powered surfboard

In the rapidly evolving landscape of water sports, sourcing gas-powered surfboards presents unique challenges and opportunities for B2B buyers globally. As the demand for innovative recreational products increases, understanding the specifications, performance capabilities, and market trends of these motorized surfboards becomes crucial. This guide serves as a comprehensive resource for international buyers, delving into various types of gas-powered surfboards, their diverse applications, and essential considerations for supplier vetting and cost evaluation.

Navigating the global market means recognizing the distinct preferences and purchasing behaviors of buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Brazil and Saudi Arabia. Each market presents unique challenges, from regulatory compliance to cultural preferences in water sports. By offering insights into key product features, maintenance requirements, and warranty considerations, this guide empowers businesses to make informed purchasing decisions that align with their specific needs and market dynamics.

In addition, we provide actionable strategies for assessing supplier reliability and product quality, ensuring that buyers can confidently invest in gas-powered surfboards that meet both performance and safety standards. With this guide, international B2B buyers can navigate the complexities of the gas-powered surfboard market, ultimately enhancing their offerings and customer satisfaction in the competitive water sports arena.

Understanding gas powered surfboard Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Adventure DFI | High-performance design, carbon construction, multiple color options | Rental services, adventure tourism | Pros: Versatile for various water conditions; Cons: Higher price point may deter budget buyers. |

| Cruiser DFI | Designed for comfort and stability, larger size | Leisure activities, family outings | Pros: User-friendly for beginners; Cons: Less speed compared to race models. |

| Race DFI SL | Lightweight, optimized for speed, competitive design | Competitive events, sports clubs | Pros: High speed and agility; Cons: Requires more skill to handle effectively. |

| KOOTU P1 | Affordable, two-stroke engine, portable | Personal use, recreational rentals | Pros: Cost-effective option for entry-level users; Cons: Limited advanced features. |

| Raptor EFI 02 | Advanced engine technology, custom design options | High-end rental markets, professional use | Pros: Superior performance and customization; Cons: Premium price may limit accessibility. |

What are the Key Characteristics of Adventure DFI Surfboards?

The Adventure DFI surfboard is engineered for high performance, featuring a carbon fiber construction that enhances durability and reduces weight. This type is ideal for rental services and adventure tourism, as it can handle various water conditions. Buyers should consider the higher price point, which reflects its advanced features and versatility, making it suitable for a range of users from beginners to experienced surfers.

How Does the Cruiser DFI Differ from Other Models?

The Cruiser DFI stands out with its focus on comfort and stability, making it larger and more user-friendly. It is particularly suitable for leisure activities and family outings, appealing to those looking for a relaxed surfing experience. While it is excellent for beginners, its lower speed compared to racing models may not attract thrill-seekers. B2B buyers should weigh its stability against the desire for speed when making purchasing decisions.

What Makes Race DFI SL Ideal for Competitive Use?

Designed for speed and agility, the Race DFI SL is a lightweight surfboard that caters specifically to competitive events and sports clubs. Its advanced engineering allows for quick maneuverability, which is essential in racing scenarios. However, this model requires a higher skill level to operate effectively, making it less suitable for beginners. B2B buyers in competitive markets should consider the training and skill development necessary for optimal use.

Why Choose the KOOTU P1 for Entry-Level Markets?

The KOOTU P1 is an affordable option featuring a two-stroke engine, making it accessible for personal use and recreational rentals. Its portability and ease of use cater to entry-level users, providing a solid introduction to gas-powered surfing. However, its limited advanced features may not satisfy more experienced surfers. B2B buyers focusing on entry-level markets should prioritize affordability while ensuring quality and reliability.

How Does Raptor EFI 02 Stand Out in the Premium Market?

The Raptor EFI 02 incorporates advanced engine technology and offers customizable design options, positioning it as a high-end choice for professional use and premium rental markets. Its superior performance and agility make it an attractive option for serious surfers. However, the premium price may limit its accessibility for broader markets. B2B buyers targeting high-end clientele should consider the balance between performance and cost when evaluating this model.

Key Industrial Applications of gas powered surfboard

| Industry/Sector | Specific Application of Gas Powered Surfboard | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Sports Recreation | Rental Services for Tourists | Attracts adventure-seeking tourists, enhancing revenue streams. | Durability, ease of maintenance, and customer support. |

| Marine Research | Environmental Monitoring and Surveying | Provides access to remote areas for data collection on marine ecosystems. | Stability, speed, and payload capacity for equipment. |

| Film and Media Production | Action Sports Filming | Enables dynamic filming of water sports scenes with high mobility. | Lightweight design, maneuverability, and rental options. |

| Event Management | Water Sports Competitions | Enhances spectator engagement and provides a unique experience for participants. | Custom branding options and reliable performance. |

| Emergency Services | Rescue Operations on Water | Offers rapid response capabilities in emergency situations. | Reliability, speed, and ease of operation under pressure. |

How is Gas Powered Surfboard Used in Water Sports Recreation?

In the water sports recreation industry, gas-powered surfboards are increasingly used in rental services targeted at tourists. These surfboards allow operators to offer thrilling experiences that are not dependent on wave conditions, thus attracting adventure-seeking customers. The primary requirement for businesses in this sector includes ensuring the durability of the boards, as they will be used frequently and by various individuals. Additionally, having robust customer support for maintenance and repairs is crucial to minimize downtime and maximize rental income.

What Role Does Gas Powered Surfboard Play in Marine Research?

Marine research institutions utilize gas-powered surfboards to access remote locations for environmental monitoring and surveying. These boards provide a unique advantage by allowing researchers to collect data in areas that may be difficult to reach using traditional vessels. The speed and stability of the surfboards are essential for transporting equipment and personnel safely. For international buyers, especially in regions with vast coastlines like Africa and South America, sourcing boards that can handle rough conditions and support necessary payloads becomes a critical consideration.

How Do Gas Powered Surfboards Benefit Film and Media Production?

In the film and media production sector, gas-powered surfboards are employed for action sports filming, providing filmmakers with a versatile tool for capturing dynamic water sports scenes. The boards’ lightweight design and maneuverability allow for close-up shots and unique angles that enhance the visual storytelling of water sports. Businesses in this field should focus on sourcing boards that offer reliable performance and can be easily rented or purchased, ensuring they meet the specific filming requirements.

How Are Gas Powered Surfboards Used in Event Management?

Event management companies leverage gas-powered surfboards during water sports competitions to enhance spectator engagement and provide participants with an exhilarating experience. These boards can be used for promotional activities or as part of the event’s entertainment offerings. Key considerations for sourcing include the ability to customize boards for branding purposes and ensuring they can withstand the rigors of competitive use while providing reliable performance throughout the event.

In What Ways Do Gas Powered Surfboards Assist Emergency Services?

Gas-powered surfboards can significantly aid emergency services in rescue operations on water. Their speed and agility allow for rapid response in critical situations, providing first responders with an effective means to reach individuals in distress. For international buyers in regions prone to water-related emergencies, sourcing boards that are not only reliable but also easy to operate under pressure is paramount. Ensuring that these boards are equipped with safety features and can accommodate rescue equipment further enhances their utility in emergency scenarios.

3 Common User Pain Points for ‘gas powered surfboard’ & Their Solutions

Scenario 1: Limited Access to Reliable Maintenance and Repairs

The Problem: B2B buyers often face significant challenges in maintaining gas-powered surfboards, especially in regions with limited service infrastructure. This issue is exacerbated in countries across Africa and South America, where expertise in specialized equipment can be scarce. Buyers may find themselves without local support for repairs or maintenance, leading to extended downtimes and financial losses. This lack of reliable service can deter businesses from investing in gas-powered surfboards, as the risk of equipment failure can impact operational efficiency.

The Solution: To mitigate these challenges, it is crucial for buyers to establish partnerships with manufacturers or distributors who offer robust after-sales support. When sourcing gas-powered surfboards, inquire about warranty services and the availability of spare parts. Opt for brands that provide comprehensive maintenance guides and access to customer service representatives who can assist remotely. Additionally, consider investing in training programs for local technicians, which can create a sustainable maintenance ecosystem. This proactive approach ensures that businesses can keep their surfboards operational, thus maximizing their investment and minimizing downtime.

Scenario 2: High Operational Costs Due to Fuel Inefficiency

The Problem: The operational costs associated with gas-powered surfboards can be a significant concern for B2B buyers, particularly in markets where fuel prices are volatile. Businesses that rely on these surfboards for commercial activities, such as rentals or guided tours, may struggle with unpredictable fuel expenses, impacting profit margins. This situation is particularly acute in regions like the Middle East, where fuel prices can fluctuate dramatically, making it difficult for businesses to budget effectively.

The Solution: To address fuel efficiency concerns, buyers should prioritize the selection of surfboards equipped with advanced engine technologies, such as Direct Fuel Injection (DFI). These engines optimize fuel usage, resulting in longer ride times and reduced operational costs. Conduct thorough research on different models and their fuel consumption rates before making a purchase. Additionally, consider implementing operational strategies that maximize fuel efficiency, such as optimizing ride patterns and training users on best practices for speed and throttle management. By investing in more fuel-efficient models and adopting strategic operational practices, businesses can significantly reduce their overall costs.

Scenario 3: Navigating Regulatory Compliance and Environmental Concerns

The Problem: B2B buyers in various regions face regulatory hurdles related to environmental compliance when operating gas-powered surfboards. Countries in Europe and parts of South America are increasingly enforcing stricter emissions regulations, which can pose challenges for businesses seeking to operate these motorized watercraft. Buyers may worry about potential fines, legal liabilities, or the need to upgrade their fleet to comply with new laws, which can be a costly and complex process.

The Solution: To navigate these regulatory challenges, businesses should proactively research the specific regulations governing gas-powered surfboards in their operational regions. Engage with local authorities or industry associations to gain insights into compliance requirements and upcoming regulatory changes. Additionally, consider investing in surfboards that feature low-emission engines, as these models may not only comply with current regulations but also position your business as environmentally responsible. Developing an environmental management plan that includes regular assessments of your fleet’s compliance can also be beneficial. This forward-thinking approach not only helps mitigate risks associated with regulatory non-compliance but also enhances the company’s reputation in an increasingly eco-conscious market.

Strategic Material Selection Guide for gas powered surfboard

What Are the Key Materials for Gas Powered Surfboards?

When considering the construction of gas-powered surfboards, material selection plays a crucial role in determining performance, durability, and overall user satisfaction. Below, we analyze four common materials used in the manufacturing of these surfboards, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Carbon Fiber Enhance Performance in Gas Powered Surfboards?

Key Properties: Carbon fiber is renowned for its high strength-to-weight ratio, enabling surfboards to be both lightweight and sturdy. It offers excellent tensile strength and rigidity, making it ideal for high-performance applications. Additionally, it has good resistance to corrosion and fatigue, which is essential for enduring harsh marine environments.

Pros & Cons: The primary advantage of carbon fiber is its exceptional durability and performance, allowing for faster speeds and better maneuverability. However, it is relatively expensive compared to other materials, which may impact the overall cost of the surfboard. Manufacturing complexity is also higher, requiring specialized techniques and equipment.

Impact on Application: Carbon fiber surfboards are particularly suitable for high-speed applications and competitive use, where performance is paramount. They can withstand the dynamic pressures of waves and provide a responsive riding experience.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM for material safety and performance. In regions like Europe and the Middle East, where high-performance water sports are popular, carbon fiber surfboards may attract a premium market segment.

What Role Does Fiberglass Play in Gas Powered Surfboard Construction?

Key Properties: Fiberglass is a composite material made from glass fibers and resin, offering good tensile strength and flexibility. It is resistant to corrosion and UV damage, making it suitable for prolonged exposure to water and sunlight.

Pros & Cons: Fiberglass surfboards are generally more affordable than carbon fiber options and easier to manufacture. However, they are heavier and less rigid, which can affect performance at high speeds. They may also be more prone to flexing under stress, potentially leading to quicker wear and tear.

Impact on Application: Fiberglass is ideal for recreational surfboards where cost-effectiveness is a priority. It provides adequate performance for casual users but may not meet the demands of competitive surfing.

Considerations for International Buyers: Buyers in regions with cost-sensitive markets, such as parts of South America and Africa, may find fiberglass surfboards appealing. Compliance with local manufacturing standards is essential to ensure product safety and reliability.

How Does Aluminum Alloy Contribute to Gas Powered Surfboard Durability?

Key Properties: Aluminum alloys are known for their lightweight and high corrosion resistance. They can withstand significant impacts and are less likely to deform under stress compared to plastic materials.

Pros & Cons: The main advantage of aluminum is its durability and strength, making it suitable for components like engine mounts and structural reinforcements. However, aluminum can be more expensive than plastics and may require additional treatments to prevent corrosion in saltwater environments.

Impact on Application: Aluminum is often used in the construction of surfboard frames and support structures, enhancing overall stability and safety. It is particularly beneficial in regions with rough water conditions.

Considerations for International Buyers: Buyers should consider the availability of aluminum in their region and any associated import costs. Compliance with material specifications and corrosion resistance standards is crucial, especially in coastal areas.

What Advantages Do High-Density Polyethylene (HDPE) Offer for Gas Powered Surfboards?

Key Properties: HDPE is a thermoplastic known for its high impact resistance and durability. It is lightweight, flexible, and resistant to various chemicals, making it suitable for marine applications.

Pros & Cons: The primary advantage of HDPE is its cost-effectiveness and ease of manufacturing. It can be molded into complex shapes, allowing for innovative designs. However, it may not provide the same level of performance as fiberglass or carbon fiber, particularly in high-speed scenarios.

Impact on Application: HDPE is often used for surfboard fins and other non-structural components, where flexibility and impact resistance are more critical than high-speed performance.

Considerations for International Buyers: HDPE is widely available and cost-effective, making it a popular choice in emerging markets. Buyers should ensure compliance with environmental regulations regarding plastic use and disposal.

Summary of Material Selection for Gas Powered Surfboards

| Material | Typical Use Case for gas powered surfboard | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Fiber | High-performance surfboards | Exceptional strength-to-weight ratio | High cost, complex manufacturing | High |

| Fiberglass | Recreational surfboards | Cost-effective, easier to manufacture | Heavier, less rigid performance | Medium |

| Aluminum Alloy | Structural components | Durable and corrosion-resistant | Higher cost, requires treatments | Medium |

| High-Density Polyethylene (HDPE) | Non-structural components | Cost-effective, easy to mold | Lower performance in high-speed use | Low |

This strategic material selection guide provides valuable insights for B2B buyers in the gas-powered surfboard market, enabling informed decisions that align with performance requirements and regional market dynamics.

In-depth Look: Manufacturing Processes and Quality Assurance for gas powered surfboard

What Are the Key Stages in the Manufacturing Process of Gas-Powered Surfboards?

The manufacturing of gas-powered surfboards involves several critical stages that ensure the final product meets performance and safety standards. The process typically includes material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and Why?

The choice of materials is paramount in the construction of gas-powered surfboards. Common materials include high-strength carbon fiber, which is lightweight yet durable, and various composites that enhance performance. Before manufacturing begins, these materials undergo rigorous inspection to ensure they meet specified quality standards. This includes checking for defects, structural integrity, and compliance with international standards.

How Are Gas-Powered Surfboards Formed?

The forming stage involves shaping the materials into the desired surfboard design. Techniques such as vacuum infusion and molding are commonly employed. Vacuum infusion allows for a more efficient distribution of resin, which results in a lighter and stronger final product. Additionally, CNC machining is often used for precision cutting of components, ensuring a high level of accuracy in the surfboard’s design.

What Are the Assembly Techniques Used in Gas-Powered Surfboards?

Assembly is a crucial phase where all components come together. This includes installing the engine, fuel system, and electronic controls. Each component must be aligned perfectly to ensure optimal performance. Adhesives and fasteners are selected based on their ability to withstand the stresses encountered during use.

During this stage, manufacturers may also implement advanced techniques such as automated assembly lines to enhance efficiency and reduce human error. This not only speeds up the production process but also ensures consistency in quality.

What Finishing Processes Are Essential for Gas-Powered Surfboards?

Finishing processes are the final steps that enhance the aesthetic and functional properties of the surfboard. This includes sanding, painting, and applying protective coatings. A thorough finishing process not only improves appearance but also adds layers of protection against water damage and UV radiation.

Quality control during this stage is vital. Manufacturers often employ automated inspection systems to detect any imperfections in the surface finish, ensuring that only the best products reach the market.

What International Standards Should B2B Buyers Be Aware Of?

For international buyers, understanding the relevant quality assurance standards is critical. ISO 9001 is a well-recognized standard that outlines quality management principles applicable across industries. Compliance with this standard indicates that the manufacturer has a robust quality management system in place.

Additionally, gas-powered surfboards may need to comply with specific industry standards such as CE marking in Europe and API standards in the oil and gas sector. These certifications ensure that the products meet safety, health, and environmental protection standards.

How Is Quality Control Implemented Throughout the Manufacturing Process?

Quality control (QC) is integrated at multiple stages of the manufacturing process, often categorized into three checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

IQC involves inspecting raw materials before production begins. This ensures that only high-quality materials are used, reducing the risk of defects in the final product.

-

IPQC takes place during the manufacturing process. Regular checks are performed to monitor the quality of the work being done, identifying any issues early on. This can include measuring component dimensions and testing the functionality of assembled parts.

-

FQC is the final inspection conducted once the surfboard is fully assembled. This includes tests for performance, safety, and compliance with regulatory standards.

What Testing Methods Are Commonly Used for Gas-Powered Surfboards?

To ensure the durability and performance of gas-powered surfboards, various testing methods are employed. These may include:

- Performance Testing: Assessing the surfboard’s speed, maneuverability, and stability in different water conditions.

- Durability Testing: Subjecting the surfboard to extreme conditions to evaluate its resilience against impacts and weather elements.

- Safety Testing: Ensuring that safety features such as emergency shut-off mechanisms function correctly.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are some actionable steps:

-

Conduct Supplier Audits: Regularly auditing potential suppliers can provide insights into their manufacturing processes and quality control measures.

-

Request Quality Assurance Reports: Suppliers should be able to provide documentation that outlines their quality control procedures, testing methods, and certifications.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices.

-

Review Certifications: Verify that the supplier holds relevant certifications such as ISO 9001, CE, or API, which can be indicative of their commitment to quality.

What Are the QC Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances in quality control when sourcing gas-powered surfboards. Different regions may have varying regulatory requirements, which could affect compliance. For example, the CE marking is mandatory for products sold in Europe, while similar certifications may exist in other regions.

Additionally, understanding cultural differences in business practices can aid in smoother negotiations and partnerships. Buyers should be prepared to engage in discussions about quality expectations and standards specific to their region.

Conclusion: Ensuring Quality in Gas-Powered Surfboard Manufacturing

In summary, the manufacturing and quality assurance processes for gas-powered surfboards are intricate and multifaceted. By understanding the key stages of production, relevant international standards, and effective quality control measures, B2B buyers can make informed decisions. Engaging with suppliers who prioritize quality assurance will ultimately lead to better products and enhanced customer satisfaction in the competitive watersports market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gas powered surfboard’

In the competitive market of gas-powered surfboards, B2B buyers must approach procurement with a clear, strategic framework. This guide provides a structured checklist to facilitate informed purchasing decisions that align with business objectives and customer needs.

Step 1: Define Your Technical Specifications

Understanding the precise technical requirements of the gas-powered surfboard is critical. Consider the intended use, such as recreational versus competitive surfing, and determine the necessary specifications, including engine type, power output, and materials. For instance, carbon fiber construction may offer superior performance and durability, while engine specifications will influence speed and handling.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends and technological advancements in the gas-powered surfboard market. This includes understanding the benefits of features such as two-stroke engines for efficiency and speed, or the integration of advanced technologies like Direct Fuel Injection (DFI) for improved performance. Keeping abreast of these innovations can help you select products that meet evolving consumer demands and set your offerings apart from competitors.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s vital to thoroughly vet potential suppliers. Look for established manufacturers with a solid reputation in the industry, and request their company profiles, product catalogs, and case studies. Additionally, consider customer testimonials and reviews to gauge their reliability and customer service quality. Engaging with suppliers who have experience in your target regions, such as Africa, South America, or Europe, can provide insights into localized market needs.

Step 4: Verify Compliance and Certifications

Ensure that the suppliers you consider adhere to relevant industry standards and regulations. Compliance with safety standards and certifications is essential for minimizing legal risks and ensuring the quality of the products you purchase. Check for certifications specific to your region, as regulations may vary significantly between markets, especially in the Middle East and Europe.

Step 5: Assess Pricing and Payment Terms

Analyze the pricing structures of potential suppliers to ensure they align with your budget and financial strategy. Be mindful of the total cost of ownership, which includes shipping, taxes, and potential import duties. Additionally, negotiate payment terms that are favorable for your business, such as discounts for bulk purchases or flexible payment plans that can enhance cash flow.

Step 6: Plan for After-Sales Support and Maintenance

After-sales support is a crucial aspect of your procurement strategy. Ensure that suppliers offer comprehensive warranties, maintenance services, and readily available spare parts. This not only enhances customer satisfaction but also helps maintain the longevity and performance of the surfboards, which is critical for repeat business and brand loyalty.

Step 7: Develop a Logistics Strategy

Finally, create a robust logistics strategy for importing and distributing the gas-powered surfboards. Consider factors such as shipping methods, lead times, and storage solutions. Efficient logistics planning can significantly reduce costs and improve your ability to respond to market demand swiftly.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing gas-powered surfboards effectively, ensuring they make informed decisions that drive business success.

Comprehensive Cost and Pricing Analysis for gas powered surfboard Sourcing

What Are the Key Cost Components in Gas Powered Surfboard Manufacturing?

The cost structure for gas powered surfboards is influenced by several critical components. The primary material used in construction is often carbon fiber, known for its lightweight and durable properties, which typically drives up the material costs. Other materials, such as high-performance engines, propulsion systems, and water-cooling mechanisms, also contribute significantly to the overall expenditure. Labor costs vary based on the complexity of the manufacturing process and the region in which production takes place. Manufacturing overhead, including utilities, factory maintenance, and administrative expenses, must also be factored in.

Tooling and quality control (QC) are essential elements that can further increase costs. High-quality surfboards require advanced tooling for precision, while rigorous QC processes ensure safety and performance, necessitating additional investment. Logistics, including shipping and handling, also play a vital role in the total cost, particularly for international transactions where tariffs and import duties may apply.

How Do Pricing Influencers Affect the Cost of Gas Powered Surfboards?

Several factors influence pricing in the gas powered surfboard market. Volume and minimum order quantities (MOQs) can significantly impact unit costs; larger orders typically yield discounts. The specifications and customization options requested by buyers can also lead to variations in pricing. For example, boards with advanced features, such as enhanced engines or personalized designs, will command higher prices.

Material quality and certifications are essential considerations. Boards that meet international safety and quality standards may incur additional costs but will likely appeal to discerning buyers in markets like Europe and North America. Supplier factors, including reputation and reliability, also affect pricing. Companies with a proven track record may charge premium prices due to their perceived value.

Lastly, Incoterms will influence pricing and logistics costs. Buyers should be aware of the terms of sale, as they dictate who bears responsibility for shipping, insurance, and tariffs, which can significantly affect the total cost.

What Buyer Tips Can Help Optimize Costs in Gas Powered Surfboard Sourcing?

For B2B buyers, negotiating effectively can lead to substantial savings. Establishing long-term relationships with suppliers can often yield better terms, including lower prices and improved service levels. It is advisable to compare multiple suppliers to gauge market rates and leverage competitive pricing during negotiations.

Understanding the total cost of ownership (TCO) is crucial. This includes not just the purchase price but also maintenance, parts availability, and operational costs over the board’s lifespan. Buyers should inquire about warranty coverage and parts availability, as reliable support can reduce long-term costs.

Pricing nuances are particularly important for international buyers, especially from regions like Africa, South America, the Middle East, and Europe. Factors such as currency fluctuations, shipping times, and local regulations can affect pricing and should be considered when making purchasing decisions. Engaging with suppliers who have experience in international trade can simplify the process and help mitigate potential risks.

Disclaimer on Indicative Prices for Gas Powered Surfboards

Prices for gas powered surfboards can vary significantly based on specifications, materials, and supplier factors. As of the latest data, prices range from approximately $4,699 for entry-level models to upwards of $12,990 for high-end options. These prices are indicative and subject to change based on market conditions, so it is advisable for buyers to conduct thorough research and engage directly with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing gas powered surfboard With Other Solutions

When considering the acquisition of a gas-powered surfboard, it is essential for B2B buyers to explore alternative solutions that offer similar functionalities. Understanding these alternatives can help businesses make informed decisions that align with their operational needs, budget constraints, and customer expectations.

| Comparison Aspect | Gas Powered Surfboard | Electric Surfboard | Stand-Up Paddleboard (SUP) |

|---|---|---|---|

| Performance | High speed (up to 55 km/h) | Moderate speed (up to 30 km/h) | Variable (depends on paddler) |

| Cost | €5,599 – €12,990 | €4,000 – €10,000 | €300 – €1,500 |

| Ease of Implementation | Moderate (requires fuel) | High (charging required) | Easy (no setup needed) |

| Maintenance | Moderate (engine upkeep) | Low (fewer mechanical parts) | Low (minimal upkeep) |

| Best Use Case | High-speed water sports | Recreational use, lakes | Fitness, calm waters |

What Are the Pros and Cons of Electric Surfboards Compared to Gas-Powered Surfboards?

Electric surfboards represent a viable alternative to gas-powered models, particularly for those looking for a quieter and environmentally friendly option. They typically have lower operating costs since they do not require fuel and have fewer mechanical components, leading to lower maintenance demands. However, they may be limited by battery life, which can restrict the duration of use and may require more frequent charging, especially during long sessions on the water.

How Do Stand-Up Paddleboards Compare to Gas-Powered Surfboards?

Stand-up paddleboards (SUPs) offer a much more cost-effective solution for water sports enthusiasts. They require minimal investment and maintenance, making them accessible for a broader audience. SUPs are excellent for fitness and leisurely activities, but they lack the speed and thrill that a gas-powered surfboard provides. They are best suited for calm waters and do not deliver the same adrenaline rush as motorized options.

Conclusion: How Should B2B Buyers Choose the Right Watercraft Solution?

When deciding between a gas-powered surfboard and its alternatives, B2B buyers should carefully evaluate their target market’s needs, budget, and operational requirements. For businesses focused on high-speed, adrenaline-pumping experiences, gas-powered surfboards are ideal. Conversely, for those emphasizing recreational use or fitness, electric surfboards or SUPs may be more appropriate. Ultimately, understanding the unique advantages and limitations of each option will empower businesses to select the watercraft solution that best aligns with their strategic goals.

Essential Technical Properties and Trade Terminology for gas powered surfboard

What Are the Key Technical Properties of Gas Powered Surfboards?

When considering the purchase of gas-powered surfboards, understanding their technical specifications is crucial for making informed decisions. Here are some of the essential properties:

-

Material Composition: Most gas-powered surfboards are constructed from high-grade materials such as carbon fiber and fiberglass. Carbon fiber is preferred for its lightweight yet durable properties, providing better performance and agility on the water. B2B buyers should prioritize suppliers who utilize advanced materials to ensure longevity and performance.

-

Engine Type and Specifications: The type of engine significantly influences the performance of a gas-powered surfboard. Common configurations include two-stroke and four-stroke engines, with varying horsepower ratings. For instance, a surfboard with a 110cc engine can reach speeds of up to 62 km/h. Buyers should assess engine specifications to align with their target market’s needs, especially in regions with varying water conditions.

-

Ride Time and Fuel Efficiency: The ride time, typically expressed in minutes, indicates how long the surfboard can operate on a full tank of fuel. Many models offer ride times ranging from 90 minutes to several hours, depending on engine efficiency and fuel capacity. B2B buyers should evaluate fuel efficiency to cater to markets where refueling options may be limited.

-

Speed Capabilities: Speed is a significant selling point for gas-powered surfboards. Models can vary widely, with some capable of reaching speeds of 50 km/h or more. Understanding the speed capabilities is essential for targeting specific customer segments, such as thrill-seekers or casual riders.

-

Weight Capacity and Dimensions: Each surfboard has a specified weight capacity, typically accommodating riders of various sizes. Dimensions, including length and width, affect maneuverability and stability. B2B buyers should consider the demographics of their target audience to select models that cater to diverse rider profiles.

-

Safety Features: Safety is paramount in water sports. Gas-powered surfboards may include features such as emergency shut-off switches, safety lanyards, and reinforced hull designs. B2B buyers should prioritize suppliers that emphasize safety to enhance customer satisfaction and reduce liability.

Which Trade Terms Should B2B Buyers Know When Sourcing Gas Powered Surfboards?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some common terms relevant to gas-powered surfboard procurement:

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products based on specifications provided by another company. For gas-powered surfboards, B2B buyers may engage with OEMs to customize boards that meet specific market demands.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory effectively and ensure that they can meet market demand without overcommitting resources.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing and terms for specific products. B2B buyers should use RFQs to obtain competitive pricing and ensure they are sourcing from reliable manufacturers.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, insurance, and liability, which are crucial when importing gas-powered surfboards from different regions.

-

Lead Time: This refers to the time it takes from placing an order until the product is delivered. Understanding lead times is essential for B2B buyers to plan inventory and meet market demands effectively.

-

Warranty and After-Sales Service: Warranties provide buyers with assurance regarding the product’s quality and reliability. B2B buyers should inquire about warranty terms and after-sales services to ensure long-term customer satisfaction and support.

By mastering these technical specifications and industry terms, B2B buyers can navigate the gas-powered surfboard market more effectively, ensuring they select the best products for their customers and maintain competitive advantages in their respective regions.

Navigating Market Dynamics and Sourcing Trends in the gas powered surfboard Sector

What Are the Key Trends Shaping the Global Gas Powered Surfboard Market?

The gas powered surfboard market is witnessing a surge in popularity driven by a growing consumer interest in adventure sports and water-based activities. Key global drivers include increasing disposable incomes in emerging markets such as Brazil and Saudi Arabia, where water sports are becoming more accessible. Additionally, advancements in technology are making these surfboards lighter, more efficient, and easier to operate, thereby enhancing user experience.

B2B buyers should note that the market is increasingly leaning towards customization options, with manufacturers offering personalized designs and features that cater to specific consumer preferences. This trend aligns with the growing demand for unique products in both leisure and competitive settings. Another emerging trend is the integration of smart technology into surfboards, allowing for real-time performance tracking and enhanced user safety, which can be a selling point in commercial applications like rental fleets and surf schools.

Moreover, sustainability is becoming a focal point in sourcing practices. Buyers should be aware of manufacturers who are adopting environmentally friendly practices, such as using recyclable materials in their boards and efficient engine technologies that reduce emissions. This shift not only appeals to environmentally conscious consumers but also prepares businesses to meet stricter regulations in various regions.

How Is Sustainability and Ethical Sourcing Influencing Gas Powered Surfboard Production?

The environmental impact of gas powered surfboards is an increasingly critical concern for both manufacturers and consumers. Traditional gas engines have been scrutinized for their emissions; hence, the industry is moving towards more efficient and cleaner technologies. B2B buyers should prioritize suppliers who are adopting eco-friendly practices, such as using two-stroke water-cooled engines that minimize environmental footprints.

Ethical sourcing is also gaining traction, with suppliers expected to maintain transparent supply chains. This includes using responsibly sourced materials, such as carbon fiber, which is both lightweight and durable, reducing the overall carbon footprint of the product. Green certifications, such as ISO 14001 for environmental management, are becoming a standard for reputable manufacturers, offering assurance to B2B buyers about their commitment to sustainability.

Furthermore, the importance of recycling and end-of-life management is being recognized, with some manufacturers beginning to implement take-back programs for old surfboards. This not only enhances their sustainability credentials but also aligns with the growing consumer demand for responsible products.

What Is the Evolution of Gas Powered Surfboards in the B2B Context?

The gas powered surfboard has evolved significantly since its inception, transforming from a niche recreational product into a viable business opportunity for various stakeholders. Initially, these boards were primarily utilized by extreme sports enthusiasts. However, technological advancements and market diversification have broadened their appeal, with manufacturers now catering to leisure riders, rental businesses, and competitive sports sectors.

The introduction of lightweight materials and efficient engine designs has made gas powered surfboards more accessible and user-friendly, opening new markets in regions like Africa and South America, where water sports are on the rise. As companies continue to innovate, the potential for growth in this sector remains robust, with B2B buyers positioned to leverage this evolution for competitive advantage.

In conclusion, navigating the dynamics of the gas powered surfboard market requires a keen understanding of emerging trends, sustainability practices, and the historical context that shapes current offerings. By aligning with manufacturers who prioritize innovation and environmental responsibility, B2B buyers can enhance their market positioning and contribute to a more sustainable future in water sports.

Frequently Asked Questions (FAQs) for B2B Buyers of gas powered surfboard

-

How do I ensure the quality of gas powered surfboards when sourcing internationally?

To ensure quality, start by vetting suppliers thoroughly. Request samples and check for certifications that guarantee adherence to international quality standards. Engage in direct communication to understand their manufacturing processes and quality control measures. It’s also beneficial to read reviews and seek testimonials from other buyers. Consider visiting the manufacturer if possible, or hiring a third-party inspection service to assess product quality before shipment. -

What are the best features to look for in a gas powered surfboard for commercial use?

When sourcing gas powered surfboards for commercial use, prioritize features such as engine performance, durability of materials (like carbon fiber), and ease of maintenance. Look for boards with high speed and long ride times, as these will enhance user experience. Additionally, consider the board’s weight and portability for easier transportation. Customization options can also be valuable for branding purposes, so ensure suppliers offer these. -

What is the typical minimum order quantity (MOQ) for gas powered surfboards?

The MOQ for gas powered surfboards can vary significantly between suppliers, often ranging from 5 to 50 units. This depends on the manufacturer’s production capacity and the specific model of surfboard. When negotiating, inquire about the possibility of lower MOQs for first-time orders or trial runs. Establishing a solid relationship with suppliers may also allow for more flexibility in future orders. -

How can I customize gas powered surfboards for my brand?

Customization options typically include color schemes, branding logos, and specific design features. Discuss your requirements with potential suppliers to understand their capabilities. Many manufacturers can provide tailored solutions, but it’s crucial to confirm the timelines and costs associated with customization. Request prototypes to evaluate the final product before committing to a larger order. -

What payment terms should I expect when sourcing gas powered surfboards?

Payment terms can vary widely among suppliers but generally include options like a deposit upfront (often 30-50%) with the balance due before shipment. Some suppliers may offer payment upon delivery or through letters of credit for larger orders. It’s essential to clarify these terms before finalizing any agreements to avoid misunderstandings and ensure smooth transactions. -

What logistics considerations should I keep in mind when importing gas powered surfboards?

Logistics plays a crucial role in international sourcing. Consider shipping methods (air vs. sea) based on urgency and cost-effectiveness. Ensure compliance with customs regulations in your country, including import duties and taxes. Work with a reliable freight forwarder to handle documentation and shipping logistics. Also, factor in the lead time for production and shipping to plan your inventory accordingly. -

How can I assess the reliability of a supplier for gas powered surfboards?

To assess supplier reliability, start by checking their business credentials, such as registration and manufacturing licenses. Look for reviews from other B2B buyers and request references. Conduct a background check to learn about their industry experience and financial stability. Engaging in direct conversations about their production capabilities and after-sales support can also provide insights into their reliability. -

What kind of warranty should I expect for gas powered surfboards?

Most reputable manufacturers offer warranties ranging from one to three years, covering defects in materials and workmanship. Ensure you read the warranty terms carefully, as some may exclude certain parts or require specific maintenance practices to remain valid. Ask suppliers about their warranty claims process to understand how they handle repairs or replacements, which is crucial for maintaining customer satisfaction in your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Gas Powered Surfboard Manufacturers & Suppliers List

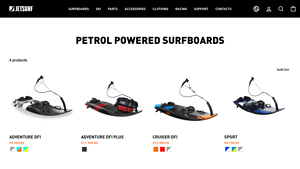

1. Jetsurf – Petrol Powered Surfboards

Domain: jetsurf.com

Registered: 2000 (25 years)

Introduction: Petrol Powered Surfboards: 1. ADVENTURE DFI – Price: €9.990,00, Colors: White / Grey, Fluo Orange / Mint, Fluo Yellow / Mint 2. ADVENTURE DFI Plus – Price: €11.990,00, Color: Carbon 3. CRUISER DFI – Price: €12.490,00, Colors: Fluo orange, Fluo red, White / Grey (Sold Out) 4. SPORT – Price: €8.790,00, Colors: Perfect Blue / White, Fluo Yellow / Blue, White / Grey 5. TITANIUM DFI SL – Price: €12.990…

2. DLEsurf – Gas Powered Jet Surf Board

Domain: jetboardsamerica.com

Registered: 2022 (3 years)

Introduction: DLEsurf: Gas Powered Jet Surf Board; motorized surfboard for all water conditions; affordable and sleek design; portable; suitable for lakes and ocean; warranty provided by DLE engines; parts available for repairs and maintenance; customer support and service emphasized.

3. KOOTU – P1 Motorized Surfboard

Domain: kootubike.com

Registered: 2021 (4 years)

Introduction: {“product_name”: “KOOTU P1 Motorized Surfboard”, “type”: “Gas Powered Surfboard”, “engine”: “Two-stroke water-cooled engine”, “max_speed”: “55 km/h”, “ride_time”: “90 minutes”, “regular_price”: “$5,599.00”, “sale_price”: “$4,699.00”, “savings”: “$900.00”, “colors_available”: [“Black Red”, “White”], “availability”: “In stock”}

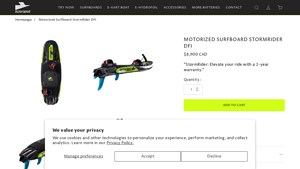

4. Rushwave – Motorized Surfboard StormRider DFI

Domain: rushwave.ca

Registered: 2023 (2 years)

Introduction: {“name”: “Motorized Surfboard StormRider DFI”, “price”: “8,900 CAD”, “warranty”: “2 years”, “key_features”: {“material”: “Carbon Fiber”, “engine”: “110cc 2-Stroke Engine”, “max_speed”: “63 km/h (39 mph)”, “design”: “Ergonomic platform and intuitive controls”, “max_load”: “120 kg (265 lbs)”, “plate_weight”: “21 kg (46 lbs)”, “dimensions”: {“surfboard_size”: “1800x600x150mm”, “package_size”: “1920×7…

5. The Inertia – The Surf Jet

Domain: theinertia.com

Registered: 2008 (17 years)

Introduction: The Surf Jet is a vintage, gas-powered surfboard made in the 1980s. It features a 255cc, two-stroke engine and razor-sharp metal fins. The design combines elements of a motorcycle and a surfboard, making it a unique personal watercraft.

Strategic Sourcing Conclusion and Outlook for gas powered surfboard

In the rapidly evolving market of gas-powered surfboards, strategic sourcing emerges as a crucial factor for international B2B buyers. By focusing on quality, performance, and customer support, businesses can differentiate themselves in a competitive landscape. Key takeaways include the importance of selecting suppliers that offer innovative technology—like DFI engines for enhanced performance—and superior materials such as carbon fiber for durability and agility.

Additionally, fostering relationships with manufacturers who provide comprehensive after-sales service, including warranties and easy access to replacement parts, can significantly enhance customer satisfaction and loyalty. With the growing popularity of motorized water sports, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for reliable and high-performance surfboards is set to rise.

As you navigate the opportunities in this dynamic sector, consider how strategic sourcing can not only streamline your procurement processes but also position your business for long-term success. Engage with reputable suppliers today to secure your place in this thrilling market and meet the demands of adventurous consumers eager for new experiences on the water.