The Definitive Guide to 12V Spdt Super Miniature Pcb Mount Relay: Cost, Materials &…

Introduction: Navigating the Global Market for 12v spdt super miniature pcb mount relay

In today’s fast-paced electronic landscape, sourcing reliable components like the 12V SPDT super miniature PCB mount relay is crucial for manufacturers and engineers seeking to enhance their product offerings while maximizing space efficiency. The challenge lies in navigating a diverse global market filled with varying specifications, performance standards, and supplier reliability. This guide aims to demystify the complexities associated with procuring these essential relays, providing a thorough overview of different types, applications, and critical factors to consider when selecting suppliers.

Buyers will gain insights into the relay’s specifications, such as load capacities and electrical characteristics, which are pivotal for applications ranging from automotive to telecommunications. Additionally, we delve into the nuances of supplier vetting, ensuring you can distinguish between quality manufacturers and those that may not meet your standards. Understanding cost structures and the implications of bulk purchasing will further empower you to make informed decisions that align with your budget and operational needs.

This comprehensive resource is tailored specifically for international B2B buyers from regions like Africa, South America, the Middle East, and Europe, including key markets such as Saudi Arabia and Germany. By equipping you with the necessary knowledge and tools, this guide will facilitate strategic sourcing and enhance your competitive edge in the global marketplace.

Understanding 12v spdt super miniature pcb mount relay Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard SPDT Relay | Conventional design, 2A load capacity, 12V coil voltage | General electronic applications, automotive systems | Pros: Cost-effective, reliable; Cons: Higher power consumption. |

| Low Power Consumption Relay | Energy-efficient design, reduced coil power | IoT devices, battery-operated systems | Pros: Lower energy costs; Cons: May have lower switching capacity. |

| High Sensitivity Relay | Operates effectively at lower voltages | Precision instruments, communication equipment | Pros: Enhanced reliability in low-voltage scenarios; Cons: Limited to specific applications. |

| Fully Sealed Relay | Dust and moisture resistant, suitable for harsh environments | Industrial automation, outdoor electronics | Pros: Increased durability; Cons: Higher initial cost. |

| Relay with Diode Protection | Built-in diode for circuit protection | Robotics, automotive control systems | Pros: Protects against back EMF; Cons: Slightly more complex design. |

What Are the Characteristics of Standard SPDT Relays?

Standard SPDT relays are the most common type in the market, featuring a simple design with a load capacity of 2A and a coil voltage of 12V. These relays are widely utilized in general electronic applications and automotive systems due to their reliability and affordability. B2B buyers should consider the cost-effectiveness of these relays for projects with moderate power requirements, although they may not be suitable for energy-sensitive applications due to higher power consumption.

How Do Low Power Consumption Relays Benefit B2B Buyers?

Low power consumption relays are designed to operate with minimal energy usage, making them ideal for IoT devices and battery-operated systems. They typically feature a reduced coil power requirement, which translates to lower energy costs over time. For businesses focused on sustainability and energy efficiency, these relays provide a significant advantage. However, buyers should note that these relays may have a lower switching capacity compared to standard options, limiting their use in high-load scenarios.

What Makes High Sensitivity Relays a Suitable Choice?

High sensitivity relays are engineered to function effectively at lower voltages, which is essential in precision instruments and communication equipment. Their ability to operate reliably under these conditions makes them an attractive option for B2B buyers in sectors requiring high precision and low power consumption. While these relays enhance reliability in sensitive applications, they may not be as versatile for general use, which is a consideration for potential buyers.

Why Choose Fully Sealed Relays for Harsh Environments?

Fully sealed relays are designed to withstand dust and moisture, making them suitable for industrial automation and outdoor electronics. Their robust construction ensures long-term reliability in harsh environments, which is critical for businesses operating in challenging conditions. While their durability is a significant advantage, buyers should be prepared for a higher initial investment compared to less protected relay types.

How Do Relays with Diode Protection Enhance Circuit Safety?

Relays equipped with diode protection are crucial for applications in robotics and automotive control systems, as they prevent back EMF from damaging sensitive components. This built-in protection mechanism offers peace of mind for B2B buyers concerned about circuit integrity. However, the more complex design may require additional considerations during installation and maintenance, which could be a drawback for some businesses.

Key Industrial Applications of 12v spdt super miniature pcb mount relay

| Industry/Sector | Specific Application of 12v spdt super miniature pcb mount relay | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Signal routing in 5G base stations | Ensures reliable signal integrity and efficient space utilization | Focus on high-density designs, low power consumption, and reliability |

| Automotive | Control circuits in compact vehicle electronics | Enhances safety and reliability in vehicle systems | Certifications for automotive use, temperature resilience, and size |

| Industrial Automation | Logic control in machinery and robotics | Provides cost-effective solutions for simple automation systems | Need for high cycle life, quick response times, and environment protection |

| Consumer Electronics | Power management in LED lighting systems | Enables compact designs while maintaining performance | Emphasis on compatibility with various voltage ranges and load capacities |

| Home Appliances | Switching mechanisms in smart devices | Facilitates automation and remote control functionalities | Demand for energy-efficient designs and compliance with safety standards |

How is the 12v SPDT Super Miniature PCB Mount Relay Used in Telecommunications?

In the telecommunications sector, the 12v SPDT super miniature relay is essential for signal routing within high-density equipment, such as 5G base stations. These relays help maintain reliable signal integrity while minimizing space usage, which is crucial in modern network infrastructure. Buyers in this sector should prioritize sourcing relays that offer low power consumption and high reliability to withstand the demanding operational environments typical of telecommunications applications.

What Role Does This Relay Play in Automotive Applications?

Within the automotive industry, the 12v SPDT super miniature relay is utilized in control circuits for compact electronic systems, including safety features and infotainment systems. Its design ensures that it operates effectively under varying temperature conditions while providing a reliable switching mechanism. For international buyers, especially in regions like Europe and the Middle East, ensuring that these relays meet automotive certifications is critical for compliance and safety.

How Does This Relay Enhance Industrial Automation?

In industrial automation, the 12v SPDT super miniature relay is used for basic logic control in machinery and robotics. It allows for the construction of simple automation systems without the complexity of programmable controllers, making it a cost-effective solution. Buyers in this field should consider the relay’s cycle life and response time, as these factors are vital for maintaining operational efficiency in automated processes.

What Are the Benefits of This Relay in Consumer Electronics?

For consumer electronics, particularly in LED lighting systems, the 12v SPDT super miniature relay plays a pivotal role in power management. It enables compact designs that do not compromise on performance, allowing manufacturers to create sleek, modern products. When sourcing these relays, businesses should focus on compatibility with various voltage ranges and load capacities to ensure optimal performance across different applications.

How is This Relay Used in Home Appliances?

In home appliances, the 12v SPDT super miniature relay serves as a switching mechanism in smart devices, facilitating automation and remote control functionalities. This application enhances user convenience and energy efficiency. Buyers from regions like Africa and South America should prioritize sourcing energy-efficient designs that comply with local safety standards to ensure product reliability and market acceptance.

3 Common User Pain Points for ’12v spdt super miniature pcb mount relay’ & Their Solutions

Scenario 1: Sourcing Quality Relays Amidst Global Supply Chain Issues

The Problem:

B2B buyers often face significant challenges when sourcing 12V SPDT super miniature PCB mount relays, especially in regions such as Africa and South America where supply chains can be less reliable. Issues like fluctuating availability, inconsistent quality, and longer lead times can hinder project timelines and increase costs. Buyers may find themselves frustrated when they receive inferior products that do not meet the specifications, leading to potential failures in their applications, which can damage their reputation and financial standing.

The Solution:

To mitigate these challenges, buyers should prioritize establishing relationships with reputable suppliers who offer reliable quality assurance processes. Conduct thorough research into potential vendors, focusing on their history, customer reviews, and certifications. Ensure that the supplier provides detailed technical specifications and compliance documentation for the relays. Additionally, consider sourcing from multiple suppliers to diversify the risk of supply chain disruptions. Engaging in direct communication with suppliers about your specific needs and anticipated volumes can also lead to better service and potentially favorable pricing arrangements.

Scenario 2: Ensuring Compatibility with Existing Systems

The Problem:

Another common pain point arises when B2B buyers fail to ensure that the 12V SPDT relays they purchase are compatible with their existing electronic systems. Incompatibility can stem from differences in electrical ratings, mechanical dimensions, or connection types, which can lead to operational inefficiencies or complete system failures. This oversight can result in costly redesigns or retrofitting, further extending project timelines and inflating budgets.

The Solution:

To overcome compatibility issues, it is essential to conduct a thorough analysis of the existing system’s requirements before purchasing relays. Buyers should create a checklist that includes voltage ratings, current capacities, physical dimensions, and pin configurations of the relay. Consulting with engineering teams or using simulation software can provide insights into how the new relays will interact with current systems. Furthermore, it may be beneficial to request samples from suppliers to test the relays in real-world scenarios before committing to a larger order. This proactive approach will ensure that the relays integrate seamlessly into existing designs, enhancing overall system performance.

Scenario 3: Managing Relay Longevity and Reliability

The Problem:

Reliability is a critical concern for B2B buyers, particularly when deploying 12V SPDT super miniature relays in high-density applications like IoT devices or automotive systems. Buyers may experience high failure rates due to inadequate specifications for operational environments, leading to increased maintenance costs and downtime. This issue is exacerbated in regions with extreme temperatures or conditions, where the reliability of electronic components is severely tested.

The Solution:

To enhance the longevity and reliability of relays, buyers should select models that are specifically designed for the environmental conditions in which they will operate. This includes checking for specifications such as operating temperature ranges, ingress protection ratings, and mechanical life cycles. Opting for fully sealed relays can offer superior protection against dust and moisture, making them suitable for harsh environments. Additionally, consider integrating built-in protection features, such as surge suppression and diode protection, to safeguard against voltage spikes and enhance circuit integrity. Regular maintenance checks and monitoring can also help identify potential issues before they lead to system failures, ensuring consistent performance over time.

Strategic Material Selection Guide for 12v spdt super miniature pcb mount relay

What Materials Are Commonly Used in 12V SPDT Super Miniature PCB Mount Relays?

When selecting materials for 12V SPDT super miniature PCB mount relays, it’s crucial to consider properties that directly affect performance, durability, and suitability for specific applications. Here, we analyze four common materials used in the construction of these relays: silver alloy, gold, plastic, and epoxy resin.

How Do Silver Alloy Contacts Enhance Relay Performance?

Silver alloy is a prevalent choice for contact materials in relays due to its excellent electrical conductivity and resistance to arcing. Key properties include a contact resistance typically less than 100 mΩ and a high melting point, which allows it to handle significant electrical loads.

Pros: Silver alloy contacts offer superior conductivity and are effective in high-load applications, making them ideal for controlling larger currents. They also have a good lifespan due to their resistance to wear and corrosion.

Cons: The primary drawback of silver alloy is its cost, as it is more expensive than other materials. Additionally, it may tarnish over time, which can lead to increased contact resistance if not properly maintained.

Impact on Application: Silver alloy is particularly suitable for applications requiring reliable signal transmission and high current handling, such as automotive and industrial control systems.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure that their suppliers comply with relevant standards such as DIN and IEC, particularly regarding conductivity and durability.

Why Is Gold Used in PCB Mount Relays?

Gold is often used for contacts in low-power applications due to its low contact resistance and excellent corrosion resistance.

Pros: Gold contacts provide reliable performance in low-current applications, ensuring minimal signal loss. They are also resistant to oxidation, which enhances longevity and reliability.

Cons: The primary limitation of gold is its high cost, which can significantly increase the overall price of the relay. Additionally, gold is not suitable for high-power applications due to its lower thermal conductivity compared to silver.

Impact on Application: Gold contacts are ideal for applications in telecommunications and precision instruments where low signal levels are prevalent.

Considerations for International Buyers: Buyers should consider compliance with standards like ASTM for material quality and performance, ensuring that the gold plating meets the required thickness for durability.

How Do Plastic and Epoxy Resin Contribute to Relay Durability?

Plastic and epoxy resin are commonly used for the housing and insulation of relays. These materials provide excellent electrical insulation and mechanical protection.

Pros: Both materials are lightweight, cost-effective, and resistant to moisture and chemicals, making them suitable for various environments. They also provide good thermal stability.

Cons: The main limitation is that they may not withstand extreme temperatures as well as metals, which could lead to deformation or failure in high-heat applications.

Impact on Application: Plastic housings are suitable for general-purpose applications, while epoxy resin is preferred in harsh environments due to its superior chemical resistance.

Considerations for International Buyers: Compliance with international standards for thermal and mechanical properties is essential, especially in regions with extreme climates.

Summary of Material Selection for 12V SPDT Super Miniature PCB Mount Relays

| Material | Typical Use Case for 12V SPDT Super Miniature PCB Mount Relay | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silver Alloy | High-load industrial applications | Excellent conductivity | Higher cost, potential tarnishing | High |

| Gold | Low-power telecommunications | Low contact resistance | Expensive, not for high power | High |

| Plastic | General-purpose relays | Lightweight, cost-effective | Limited temperature resistance | Low |

| Epoxy Resin | Harsh environment applications | Superior chemical resistance | May deform under extreme heat | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in 12V SPDT super miniature PCB mount relays, helping them make informed decisions that align with their specific application needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 12v spdt super miniature pcb mount relay

What Are the Main Stages of Manufacturing a 12V SPDT Super Miniature PCB Mount Relay?

The manufacturing of a 12V SPDT super miniature PCB mount relay involves several critical stages that ensure the final product meets the stringent requirements of performance and reliability. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Components Selected?

The first step in the manufacturing process is the selection and preparation of materials. High-quality raw materials are essential for ensuring electrical performance and longevity. Common materials used in these relays include high-permeability alloy for the coil, silver alloy or gold for the contacts, and durable plastics for the housing.

Before fabrication, materials undergo rigorous inspection to verify their specifications and quality. This initial quality check (Incoming Quality Control, or IQC) is crucial as it prevents defective materials from entering the production line, ultimately enhancing the reliability of the final product.

What Techniques Are Used in the Forming Process?

The forming stage involves several techniques to create the components of the relay. This includes precision stamping for the contacts and coil assembly.

Advanced techniques like laser cutting and CNC machining are often employed to ensure high precision in forming parts, which is essential given the miniature size of these relays. The coil winding process is particularly critical, as the number of turns and the tension applied can significantly affect the electromagnetic characteristics. Manufacturers often utilize automated machinery to achieve consistent results, ensuring that each relay meets the specified dimensions and performance criteria.

How Is the Assembly of the Relay Conducted?

Once the components are formed, they move to the assembly stage. Here, skilled technicians or automated systems assemble the relay parts, including the coil, contacts, and housing.

The assembly process also involves meticulous alignment of the moving parts to ensure optimal performance. During this stage, various techniques such as soldering and crimping are employed to secure connections. The assembly area is typically controlled for static electricity and other environmental factors to prevent damage to sensitive components.

What Finishing Processes Are Involved?

After assembly, the relay undergoes finishing processes, which may include cleaning, coating, and testing. Cleaning is crucial for removing any contaminants that could affect performance. Coating can provide additional protection against moisture and dust, especially for fully sealed versions of the relay designed for harsh environments.

The finishing stage also includes initial testing to verify that the relay operates correctly under specified conditions. This may involve checking for mechanical movement, contact resistance, and insulation resistance.

How Is Quality Assurance Implemented in Relay Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of 12V SPDT super miniature PCB mount relays. It encompasses various international and industry-specific standards, as well as multiple checkpoints throughout the production process.

What International Standards Are Relevant to Relay Manufacturing?

Manufacturers often adhere to international standards such as ISO 9001, which sets out criteria for a quality management system. Compliance with ISO 9001 ensures that companies consistently provide products that meet customer and regulatory requirements, enhancing customer satisfaction.

Additionally, industry-specific certifications like CE marking for compliance with European safety standards, or API certifications for specific applications, are often pursued. These certifications are crucial for B2B buyers, particularly in regions such as Europe and the Middle East, where regulatory compliance is strictly enforced.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components before they enter the production line.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, random checks are performed to ensure that assembly and production methods conform to established standards.

-

Final Quality Control (FQC): After assembly and finishing, the relay undergoes comprehensive testing to verify performance metrics, such as contact resistance, insulation resistance, and operational functionality.

What Common Testing Methods Are Used?

Testing methods for relays can include:

- Electrical Testing: To measure contact resistance, insulation resistance, and coil resistance.

- Mechanical Testing: To assess the durability of the relay under mechanical stress and repeated operations.

- Environmental Testing: To ensure reliable operation under extreme conditions, such as temperature fluctuations and humidity.

These testing methods help guarantee that the relay will perform reliably in various applications, from automotive to industrial settings.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. This can include:

-

Supplier Audits: Conducting on-site audits of the manufacturing facility to assess compliance with quality standards and the effectiveness of their QA processes.

-

Reviewing Quality Reports: Requesting detailed quality reports and certifications that demonstrate adherence to international and industry-specific standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide unbiased verification of a supplier’s quality control practices and product reliability.

What Are the Quality Control Nuances for International Buyers?

For buyers from regions such as Africa, South America, the Middle East, and Europe, it is important to consider regional regulations and standards. Different regions may have specific requirements that impact the acceptance of products.

For instance, European buyers may require CE marking for compliance with EU directives, while buyers in the Middle East might look for compliance with Gulf standards. Understanding these nuances can help buyers select suppliers who are not only capable of delivering high-quality products but also compliant with local regulations, thus minimizing the risk of supply chain disruptions.

In conclusion, the manufacturing and quality assurance processes for 12V SPDT super miniature PCB mount relays are intricate and critical for ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions and choose suppliers that align with their quality expectations and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ’12v spdt super miniature pcb mount relay’

In the competitive landscape of electronics, sourcing a reliable 12V SPDT super miniature PCB mount relay requires careful consideration. This guide provides a step-by-step checklist to help international B2B buyers make informed purchasing decisions, ensuring they select the right components for their applications.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of successful sourcing. Determine the relay’s specifications, including dimensions, electrical characteristics (such as contact rating and coil voltage), and operating conditions. Consider the application—whether it’s for automotive, telecommunications, or industrial use—since this will influence the necessary features, such as temperature tolerance and load capacity.

Step 2: Research Market Options

Conduct thorough market research to identify potential suppliers of 12V SPDT relays. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers. Pay close attention to their product offerings, technological innovations, and customer reviews to gauge their reputation in the market.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers that offer technical support and have experience with international shipping, especially if you are sourcing from regions like Africa or South America.

- Supplier certifications: Check for compliance with international standards (such as ISO 9001) to ensure product quality.

- Production capabilities: Understand their manufacturing processes and lead times to ensure they can meet your demands.

Step 4: Assess Product Quality and Testing

Quality assurance is vital for electronic components. Inquire about the testing procedures the supplier uses for their relays. Ensure they conduct reliability tests under various conditions to guarantee performance and longevity.

- Sample requests: Ask for samples to evaluate the relay’s performance firsthand.

- Documentation: Request detailed specifications, including datasheets and certifications, to understand the product better.

Step 5: Understand Pricing and Payment Terms

Pricing can vary widely based on supplier, order quantity, and shipping costs. Obtain quotes from multiple suppliers to compare prices effectively. Additionally, clarify payment terms, including deposits, payment methods, and any warranties or return policies.

- Bulk discounts: Inquire about discounts for larger orders, which can significantly reduce overall costs.

- Hidden costs: Be aware of potential additional costs, such as import duties and taxes, which can affect your total expenditure.

Step 6: Plan for Logistics and Delivery

Coordinate logistics to ensure timely delivery of your components. Discuss shipping options with your supplier, considering both speed and cost-effectiveness. Establish clear timelines and contingency plans for potential delays.

- Shipping methods: Evaluate options like air freight versus sea freight based on urgency and budget.

- Tracking systems: Ensure the supplier provides tracking information to monitor your shipment.

Step 7: Establish a Long-term Relationship

After securing your purchase, consider establishing a long-term relationship with the supplier. Consistent communication and collaboration can lead to better pricing, priority service, and access to new products.

- Feedback loop: Provide feedback on the product and service to help improve future transactions.

- Joint ventures: Explore opportunities for joint product development or exclusive agreements to enhance your competitive advantage.

By following this checklist, B2B buyers can navigate the complexities of sourcing 12V SPDT super miniature PCB mount relays, ensuring they select the right components for their projects while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for 12v spdt super miniature pcb mount relay Sourcing

When sourcing 12V SPDT super miniature PCB mount relays, understanding the cost structure and pricing dynamics is crucial for B2B buyers, especially those operating in diverse international markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in 12V SPDT Relay Manufacturing?

-

Materials: The primary materials include copper for coils, silver or gold for contacts, and various plastics for housing. The choice of materials significantly impacts the cost, with higher-grade materials providing better performance but at a premium.

-

Labor: Labor costs can vary greatly depending on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but this can sometimes lead to compromises in quality.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and administrative expenses. Efficient manufacturing processes can help reduce overhead, allowing for more competitive pricing.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs. These costs are typically amortized over production runs, making high-volume orders more cost-effective.

-

Quality Control (QC): Rigorous testing and quality assurance processes are essential for ensuring reliability. While they add to costs, they can prevent costly failures in the field, which is especially important for buyers in sectors where performance is critical.

-

Logistics: Transportation costs can fluctuate based on distance, mode of transport, and shipping terms. Incoterms play a vital role in determining who bears these costs, affecting overall pricing.

-

Margin: Manufacturers will include a profit margin in their pricing, which can vary based on market competition and the perceived value of their product.

How Do Price Influencers Affect Relay Sourcing Decisions?

-

Volume/MOQ: Minimum order quantities (MOQ) can greatly influence pricing. Bulk orders often lead to lower per-unit costs. B2B buyers should evaluate their demand to negotiate favorable terms.

-

Specifications/Customization: Custom features, such as special contact materials or additional functionalities like LED indicators or surge suppression, can increase costs. Buyers should weigh the benefits against the additional expense.

-

Quality and Certifications: Products that meet international standards or specific certifications (such as RoHS or ISO) typically command higher prices due to the assurance of quality and compliance.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more for their experience and proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is critical for international buyers. They dictate the responsibilities and costs associated with shipping, which can significantly impact the total cost of ownership.

What Are the Best Practices for Negotiating Prices and Ensuring Cost Efficiency?

-

Conduct Thorough Market Research: Understanding the competitive landscape and price benchmarks in various regions can empower buyers during negotiations.

-

Leverage Volume Discounts: If your business has the capacity, consolidating orders can lead to significant savings. Engage suppliers to explore tiered pricing based on order quantities.

-

Evaluate Total Cost of Ownership (TCO): TCO encompasses all costs associated with a product, including purchase price, maintenance, and potential failure costs. Focusing on TCO rather than just initial pricing can lead to better long-term decisions.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, exploring local suppliers can reduce logistics costs and lead times, enhancing overall efficiency.

-

Be Aware of Pricing Nuances: Fluctuations in material costs, currency exchange rates, and geopolitical factors can affect pricing. Staying informed will help you make timely purchasing decisions.

Conclusion

The sourcing of 12V SPDT super miniature PCB mount relays involves a complex interplay of various cost components and price influencers. By understanding these factors and employing strategic negotiation tactics, international B2B buyers can optimize their sourcing strategies, ensuring they receive quality products at competitive prices. Always remember that indicative prices may vary based on market conditions and supplier negotiations.

Alternatives Analysis: Comparing 12v spdt super miniature pcb mount relay With Other Solutions

Introduction to Alternative Solutions for 12V SPDT Super Miniature PCB Mount Relays

In the rapidly evolving landscape of electronics, the 12V SPDT super miniature PCB mount relay stands out for its compactness and efficiency. However, several alternative technologies can also serve similar functions in controlling circuits. Understanding these alternatives is crucial for international B2B buyers who must assess performance, cost, and suitability for their specific applications. This analysis will compare the 12V SPDT relay against two viable alternatives: Solid State Relays (SSRs) and Electromechanical Relays (EMRs).

| Comparison Aspect | 12V SPDT Super Miniature PCB Mount Relay | Solid State Relay (SSR) | Electromechanical Relay (EMR) |

|---|---|---|---|

| Performance | High performance, compact size, reliable | Fast switching, no wear | Good performance, bulkier |

| Cost | Moderate cost, competitive pricing | Higher initial investment | Generally lower cost |

| Ease of Implementation | Simple integration into PCB designs | Requires heat sinking | Standard PCB mounting |

| Maintenance | Low maintenance, high durability | Minimal maintenance | Regular checks needed |

| Best Use Case | High-density applications, IoT devices | Fast switching, high-frequency applications | General-purpose control |

Detailed Breakdown of Alternatives

What are the Advantages and Disadvantages of Solid State Relays (SSRs)?

Solid State Relays (SSRs) utilize semiconductor devices to switch circuits, offering significant advantages such as faster switching speeds and no mechanical wear. This makes them ideal for high-frequency applications, such as motor control and automation systems. However, SSRs generally come at a higher initial cost and may require additional components like heat sinks due to heat generation during operation. While they offer long-term reliability and low maintenance, their inability to handle high inrush currents effectively can be a limitation in certain scenarios.

How Do Electromechanical Relays (EMRs) Compare?

Electromechanical Relays (EMRs) are traditional relays that use electromagnetic coils to operate mechanical switches. They are typically more cost-effective than SSRs and are widely available. EMRs are suitable for a range of applications, including lighting control and HVAC systems. However, they are bulkier and slower than both the 12V SPDT super miniature relay and SSRs, which can be a disadvantage in space-constrained designs. Additionally, they may require more frequent maintenance due to mechanical wear over time.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a relay solution, B2B buyers must consider various factors, including application requirements, budget constraints, and design specifications. The 12V SPDT super miniature PCB mount relay excels in applications requiring compactness and reliability, particularly in high-density electronic systems. However, for projects demanding faster switching speeds or lower maintenance, Solid State Relays may be more suitable despite their higher cost. Conversely, Electromechanical Relays can offer a cost-effective solution for general-purpose applications but may fall short in performance and space efficiency. Understanding the specific needs of your project will guide you in choosing the most appropriate relay technology.

Essential Technical Properties and Trade Terminology for 12v spdt super miniature pcb mount relay

What Are the Key Technical Properties of a 12V SPDT Super Miniature PCB Mount Relay?

When evaluating the 12V SPDT super miniature PCB mount relay for procurement, understanding its technical specifications is essential for ensuring optimal performance in various applications. Below are several critical properties that buyers should consider:

-

Contact Rating

– Definition: This specifies the maximum load that the relay contacts can handle without failure. For instance, a common rating is 2A at 250VAC or 30VDC.

– Importance: Knowing the contact rating helps ensure that the relay can manage the electrical load of the application without risk of overheating or failure, which is crucial for maintaining system reliability. -

Coil Voltage and Resistance

– Definition: The coil voltage is the operating voltage required to energize the relay, typically 12V DC, with a coil resistance that can vary (e.g., around 180Ω).

– Importance: Understanding the coil specifications is vital for compatibility with existing systems, affecting the relay’s efficiency and energy consumption. A mismatch can lead to operational failures or increased power costs. -

Insulation Resistance

– Definition: This property measures the resistance between the relay contacts and the coil, often specified to be greater than 100MΩ.

– Importance: High insulation resistance is critical for preventing short circuits and ensuring the safety of electronic systems, particularly in environments with high humidity or dust. -

Operating Temperature Range

– Definition: The operational limits within which the relay can function effectively, typically ranging from -40°C to +85°C.

– Importance: This range is essential for applications in extreme environments, as it determines the relay’s reliability and longevity. Understanding this helps buyers select relays suited for specific climatic conditions. -

Size and Footprint

– Definition: The physical dimensions of the relay, often around 10 x 6 x 5mm for super miniature versions.

– Importance: Space constraints in modern electronic devices necessitate compact components. A smaller relay can free up valuable PCB real estate for additional functionalities. -

Switching Speed

– Definition: The time it takes for the relay to switch from one state to another, typically less than 10ms for these types of relays.

– Importance: In applications requiring quick response times, such as automotive or telecommunications systems, understanding switching speed is crucial for ensuring system performance.

What Are Common Trade Terms Related to 12V SPDT Super Miniature PCB Mount Relays?

Familiarizing yourself with industry jargon can enhance communication and negotiation with suppliers. Here are some essential terms relevant to purchasing 12V SPDT relays:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships helps buyers identify the source of components, ensuring quality and compatibility with their existing systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is crucial for budgeting and inventory management. It can affect cash flow, especially for small businesses or startups. -

RFQ (Request for Quotation)

– Definition: A standard business process where a company solicits bids from suppliers to obtain pricing for specific products.

– Importance: Submitting an RFQ enables buyers to compare prices and terms from multiple suppliers, aiding in making informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers.

– Importance: Understanding Incoterms helps buyers anticipate shipping costs, insurance, and liability, which can significantly impact total procurement costs. -

Lead Time

– Definition: The amount of time it takes from placing an order until the product is received.

– Importance: Knowing the lead time is essential for planning production schedules and managing customer expectations. -

Certification Standards

– Definition: Regulatory standards that ensure products meet specific safety and performance criteria, such as CE or UL certification.

– Importance: Certifications provide assurance of quality and compliance, which is especially important for products used in regulated industries.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing 12V SPDT super miniature PCB mount relays, ensuring they meet both technical requirements and business objectives.

Navigating Market Dynamics and Sourcing Trends in the 12v spdt super miniature pcb mount relay Sector

What Are the Key Market Dynamics and Trends Influencing the 12V SPDT Super Miniature PCB Mount Relay Sector?

The global market for 12V SPDT super miniature PCB mount relays is witnessing robust growth, driven by the increasing demand for compact electronic components in industries such as automotive, telecommunications, and consumer electronics. As devices become smaller and more integrated, the need for relays that offer high reliability while conserving space is critical. The trend towards miniaturization is not only a response to consumer preferences but also a necessity for manufacturers looking to optimize performance in densely packed electronic systems.

In terms of sourcing, buyers are increasingly seeking suppliers that can provide customizable solutions to meet specific application needs. This trend is particularly relevant in regions like Africa and South America, where local manufacturers are striving to enhance their production capabilities. Furthermore, international buyers from Europe and the Middle East are focusing on sourcing relays that not only meet performance specifications but also adhere to international quality standards, ensuring reliability and safety in their applications.

Emerging technologies, such as IoT and 5G, are also shaping market dynamics. The need for relays that can operate effectively in high-frequency environments is becoming essential, pushing manufacturers to innovate continuously. Additionally, the rise of smart automation and control systems is leading to increased demand for relay solutions that integrate seamlessly with advanced electronic architectures.

How Are Sustainability and Ethical Sourcing Impacting the 12V SPDT Relay Supply Chain?

Sustainability has become a pivotal consideration for businesses globally, influencing purchasing decisions and supplier relationships. In the realm of 12V SPDT super miniature PCB mount relays, buyers are increasingly prioritizing manufacturers that adopt environmentally friendly practices. This includes the use of recyclable materials, energy-efficient production processes, and adherence to stringent environmental regulations.

The importance of ethical sourcing is underscored by growing consumer awareness and regulatory pressures. Companies are expected to demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and that labor practices meet ethical standards. Certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous substances are becoming benchmarks for suppliers. B2B buyers should look for these certifications when sourcing relays to ensure they align with sustainability goals and can meet regulatory requirements in their respective markets.

Moreover, the incorporation of green technologies in relay manufacturing, such as the development of low-power consumption types, not only reduces environmental impact but also meets the increasing demand for energy-efficient solutions. This trend is particularly significant in regions focused on sustainable development, such as Europe and the Middle East, where governments are incentivizing green technology adoption.

How Has the 12V SPDT Relay Evolved to Meet Modern Demands?

The evolution of the 12V SPDT super miniature PCB mount relay reflects the broader trends in electronics and automation. Initially, relays were bulky components primarily used in telecommunication systems. Over the years, advancements in materials and manufacturing processes have led to the development of ultra-miniature designs that offer substantial space savings without compromising performance.

Modern relays are characterized by their sophisticated electromagnetic mechanisms and precision mechanical systems that enhance reliability and efficiency. The incorporation of advanced materials, such as silver alloy and gold plating, has improved contact performance, ensuring lower resistance and longer operational life. Additionally, features like built-in protection mechanisms and energy-saving designs are now standard, addressing both safety and sustainability concerns.

As industries increasingly adopt automation and smart technologies, the role of these relays has expanded. They now serve critical functions in smart devices, IoT applications, and automotive systems, highlighting the need for continuous innovation to meet the demands of modern electronics. This evolution not only underscores the importance of selecting the right relay for specific applications but also emphasizes the need for B2B buyers to engage with suppliers who are at the forefront of technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of 12v spdt super miniature pcb mount relay

-

How do I ensure the reliability of 12V SPDT super miniature PCB mount relays?

To ensure reliability, consider sourcing from reputable manufacturers known for their stringent quality control processes. Look for relays with certifications such as ISO 9001 or UL. Additionally, review the technical specifications, such as contact resistance, insulation resistance, and operational temperature range, to verify performance under your application conditions. Request samples to test in your specific environment and ask for third-party test reports to confirm the manufacturer’s claims. -

What factors should I consider when selecting a 12V relay for my application?

When selecting a 12V relay, consider its electrical characteristics, such as load capacity (e.g., 2A or 7A), contact configuration (SPDT), and coil voltage tolerance. Evaluate environmental factors like operating temperature and potential exposure to dust or moisture, which may necessitate sealed designs. Additionally, assess the relay’s response time and durability to ensure it meets your application’s performance requirements, especially in high-density electronic systems. -

What are the typical minimum order quantities (MOQs) for 12V SPDT relays?

MOQs for 12V SPDT relays can vary significantly among suppliers, typically ranging from 50 to 500 units. Some manufacturers may offer lower MOQs for initial trial orders, especially for customized products. It’s advisable to communicate your needs directly with suppliers to negotiate MOQs that align with your purchasing strategy. Additionally, inquire about pricing tiers as larger orders often lead to discounts. -

How can I customize my order of 12V SPDT relays?

Customization options for 12V SPDT relays may include alterations in contact materials, coil specifications, and additional features such as built-in diodes or LED indicators. To initiate customization, consult with your supplier about your specific requirements and any available options. Be prepared to provide detailed technical specifications and, if necessary, collaborate on prototyping to ensure the product meets your operational needs. -

What payment terms should I expect when sourcing 12V relays internationally?

Payment terms can vary based on supplier policies and the relationship established. Common terms include 30% upfront payment with the balance due upon shipment or delivery. For new partnerships, suppliers may request full payment in advance. It’s essential to clarify payment methods accepted, such as wire transfers, credit cards, or letters of credit, and consider using escrow services for added security in international transactions. -

What logistics considerations should I keep in mind when importing relays?

When importing 12V relays, consider shipping methods, lead times, and customs regulations in your country. Select between air freight for speed or sea freight for cost-effectiveness, depending on urgency. Ensure compliance with local import tariffs and regulations, which may involve providing documentation such as invoices and certificates of origin. Partnering with a reliable freight forwarder can streamline the logistics process and help navigate customs clearance. -

How do I vet suppliers for 12V SPDT relays?

To vet suppliers, assess their industry experience, customer reviews, and certifications. Request references from previous clients to gauge reliability and product quality. Conduct audits if possible, or use third-party inspection services to verify manufacturing practices. Additionally, ensure the supplier has a clear return policy and warranty provisions, which can provide further assurance of their commitment to quality. -

What quality assurance measures should I expect for 12V relays?

Quality assurance measures for 12V relays typically include thorough testing of electrical characteristics, mechanical reliability, and compliance with international standards. Reputable manufacturers will conduct routine inspections during production and final testing before shipment, which may involve functionality tests under various conditions. Request documentation of these QA processes to ensure the relays meet your specifications and are suitable for your applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 12V Spdt Super Miniature Pcb Mount Relay Manufacturers & Suppliers List

1. RS Components – AC Power Supply 12W

Domain: us.rs-online.com

Registered: 2001 (24 years)

Introduction: ACJ1212, 70309715, RS Components UK, Product Type: AC Power Supply, Input Voltage: 85-264V AC, Output Voltage: 12V DC, Output Current: 1A, Power Rating: 12W, Dimensions: 90 x 50 x 30mm, Weight: 0.2kg, Mounting Type: Panel Mount, Operating Temperature: -20 to +70°C, Efficiency: >85%, Safety Standards: UL, CE, RoHS Compliant.

2. Panasonic – JW2SN-12DCV Nais Miniature Power Relay

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “JW2SN-12DCV Nais Miniature Power Relay”, “Type”: “DPDT”, “Mounting Type”: “PCB Mount”, “Voltage”: “12Vdc”, “Current Rating”: “5A”, “Condition”: “New – Open box”, “Quantity Available”: “4”, “Brand”: “Panasonic”, “MPN”: “JW2SN-12DCV”, “Seller”: “manbros.export”, “Seller Feedback”: “99% positive”, “Shipping Cost”: “$17.95”, “Shipping Method”: “FedEx International Economy”, “Returns”…

3. TopFast – 12V SPDT Super Miniature Relay

Domain: topfastpcba.com

Registered: 2022 (3 years)

Introduction: {“Product Name”: “12V SPDT Super Miniature PCB Mount Relay”, “Dimensions”: “10×10×5mm (varies by model)”, “Weight”: “<10g”, “Operating Voltage”: “12VDC ±20%”, “Contact Form”: “SPDT (1 Form C)”, “Contact Resistance”: “≤50mΩ”, “Operating Temperature Range”: “-40℃ to +85℃”, “Protection Rating”: “IP67 (premium models)”, “Mechanical Life”: {“Industrial Grade”: “500,000 cycles”, “Automotive Grade”: “1M …

4. RS Delivers – Miniature PCB Mount Automotive Relays

Domain: export.rsdelivers.com

Registered: 2009 (16 years)

Introduction: This company, RS Delivers – Miniature PCB Mount Automotive Relays, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Sharvie Electronics – SPDT Relay 12V 7A PCB Mount

Domain: sharvielectronics.com

Introduction: SPDT Relay, 12V, 7A, PCB Mount

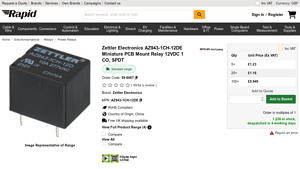

6. Zettler Electronics – AZ943-1CH-12DE Miniature PCB Mount Relay

Domain: rapidonline.com

Registered: 2002 (23 years)

Introduction: {“Product Name”: “Zettler Electronics AZ943-1CH-12DE Miniature PCB Mount Relay”, “Coil Voltage”: “12VDC”, “Contact Configuration”: “1 CO, SPDT”, “Order Code”: “59-6067”, “Brand”: “Zettler Electronics”, “MPN”: “AZ943-1CH-12DE”, “RoHS Compliant”: true, “Country of Origin”: “China”, “Stock Availability”: “1,226 in stock, despatched in 4 working days”, “Price”: {“5+ units”: “£1.23”, “25+ units”: “£1.1…

7. Gruassant Jordi – 1A 12VDC SPDT Mini Relay

Domain: gruassantjordi.com

Registered: 2000 (25 years)

Introduction: {“name”:”1A 12VDC SPDT PCB Mount Mini Relay”,”type”:”Relay”,”current_rating”:”1A”,”voltage”:”12VDC”,”contact_configuration”:”SPDT”,”mounting_type”:”PCB Mount”}

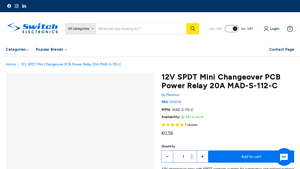

8. Switch Electronics – 12V SPDT Mini Changeover Relay

Domain: switchelectronics.co.uk

Registered: 2014 (11 years)

Introduction: {“Product Name”: “12V SPDT Mini Changeover PCB Power Relay 20A MAD-S-112-C”, “SKU”: “309008”, “MPN”: “MAD-S-112-C”, “Availability”: “283 in stock”, “Original Price”: “$0.82”, “Current Price”: “$0.66”, “Coil Voltage”: “12VDC”, “Coil Power”: “600mW”, “Maximum Switching Current”: “20A (at 16VDC)”, “Maximum Switching Voltage”: “60VDC”, “Maximum Switching Power”: “280mW”, “Dimensions”: “15.25 x 12.25 x…

Strategic Sourcing Conclusion and Outlook for 12v spdt super miniature pcb mount relay

In today’s fast-paced electronics market, the 12V SPDT super miniature PCB mount relay stands out as a vital component for various applications, from automotive to telecommunications. Its compact design not only maximizes space efficiency but also ensures reliable performance across a wide range of operating conditions. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the technical specifications and benefits of these relays is essential for making informed purchasing decisions.

Strategic sourcing of these components allows businesses to enhance their product offerings while optimizing costs. By partnering with reputable manufacturers, buyers can secure high-quality relays that meet stringent performance standards and provide long-term reliability. Additionally, leveraging suppliers with a strong presence in global markets can facilitate smoother logistics and better support services.

Looking ahead, the demand for ultra-miniature relays is expected to grow as industries increasingly prioritize compact, energy-efficient solutions. Now is the time to evaluate your sourcing strategies and consider investing in 12V SPDT super miniature PCB mount relays to stay competitive. Engage with trusted suppliers and explore innovative solutions that align with your business goals.