How to Source Tablet Press Molds Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for tablet press molds

In today’s competitive pharmaceutical landscape, sourcing high-quality tablet press molds is a critical challenge for international B2B buyers. With the increasing demand for customized medications and supplements, businesses must navigate a complex market to find reliable suppliers who offer molds that meet specific production needs. This guide serves as a comprehensive resource, detailing various types of tablet press molds, their applications, and essential factors to consider when selecting suppliers, such as quality assurance, customization options, and pricing structures.

By exploring the intricacies of the tablet press mold market, this guide empowers buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Brazil—to make informed purchasing decisions. Each section is designed to address common pain points, such as ensuring mold durability, understanding the costs involved, and identifying trustworthy suppliers.

Armed with actionable insights and practical tips, B2B buyers can streamline their sourcing process, reduce operational risks, and ultimately enhance their product offerings. Whether you’re a small business owner seeking cost-effective solutions or a large pharmaceutical manufacturer looking for precision-engineered molds, this guide provides the knowledge necessary to succeed in today’s global marketplace.

Understanding tablet press molds Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Punch Molds | Simple design, suitable for low-volume production | Small-scale pharmaceuticals, herbal products | Pros: Cost-effective, easy to use. Cons: Limited output capacity. |

| Rotary Press Molds | Multiple punches for high-speed production | Mass production of tablets | Pros: High efficiency, consistent quality. Cons: Higher initial investment. |

| Custom Molds | Tailored designs to meet specific product needs | Niche pharmaceuticals, specialty supplements | Pros: Perfect fit for unique requirements. Cons: Longer lead times, potentially higher costs. |

| Multi-tip Molds | Multiple shapes in one mold | Confectionery, varied pharmaceutical forms | Pros: Versatile, reduces tooling costs. Cons: Complexity in design may lead to higher failure rates. |

| Candy Molds | Designed specifically for confectionery products | Candy manufacturing, dietary supplements | Pros: Optimized for candy production. Cons: Limited to softer formulations. |

What Are the Characteristics of Single Punch Molds?

Single punch molds are characterized by their straightforward design, which allows for easy operation and maintenance. They are ideal for small-scale production, making them suitable for businesses that require flexibility in their manufacturing process. When considering a purchase, B2B buyers should evaluate their production volume needs, as these molds are more cost-effective for lower output but can become a bottleneck for larger operations.

How Do Rotary Press Molds Enhance Production Efficiency?

Rotary press molds are designed for high-speed production, utilizing multiple punches to create tablets simultaneously. This type of mold is essential for businesses aiming for mass production, as it significantly increases output while maintaining consistent tablet quality. Buyers should consider the initial investment cost and the complexity of the machinery required to operate rotary molds, as these factors can influence overall profitability.

Why Consider Custom Molds for Unique Product Needs?

Custom molds offer tailored solutions for businesses with specific product requirements. These molds can be designed to create unique tablet shapes or sizes, catering to niche markets such as specialty pharmaceuticals or dietary supplements. While they provide an excellent fit for unique applications, B2B buyers must be prepared for longer lead times and potentially higher costs, which can impact cash flow.

What Are the Advantages of Multi-tip Molds in Production?

Multi-tip molds allow manufacturers to produce various tablet shapes from a single mold, offering versatility in product offerings. This is particularly beneficial for businesses in the confectionery and pharmaceutical industries that require a range of products. However, the complexity of these molds can lead to higher failure rates, so buyers should assess their quality control measures and production capabilities to ensure reliability.

How Are Candy Molds Specifically Designed for Confectionery?

Candy molds are specifically engineered for the production of confectionery items, allowing for the creation of intricate shapes and designs. These molds are optimized for softer formulations, making them ideal for candy manufacturers and dietary supplement producers. B2B buyers should consider the material compatibility and design intricacies to ensure that the molds meet their production requirements while adhering to food safety standards.

Key Industrial Applications of tablet press molds

| Industry/Sector | Specific Application of tablet press molds | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceutical Industry | Production of generic and branded tablets | Cost-effective manufacturing of high-quality medications | Compliance with regulatory standards, material durability |

| Nutraceuticals | Custom vitamin and supplement tablet formulation | Enhanced customer satisfaction with tailored products | Customization options, quick turnaround times |

| Food Industry | Creation of functional food tablets (e.g., energy bars) | Diversification of product offerings | Food-grade materials, adherence to food safety regulations |

| Veterinary Medicine | Production of animal health tablets | Improved animal health solutions, meeting market demand | Size and shape customization for different species |

| Laboratory Research | Development of experimental tablets for research purposes | Innovation in drug formulation and testing | Precision in mold design, compatibility with various substances |

How Are Tablet Press Molds Used in the Pharmaceutical Industry?

In the pharmaceutical sector, tablet press molds are crucial for producing both generic and branded medications. These molds ensure that tablets are manufactured with precision, maintaining the correct dosage and consistency. International buyers, particularly from regions like Africa and the Middle East, must consider sourcing molds that meet local regulatory standards to ensure compliance and quality assurance. Additionally, the durability of the molds is vital for sustaining high-volume production without compromising quality.

What Role Do Tablet Press Molds Play in Nutraceuticals?

Tablet press molds are extensively used in the nutraceutical industry for creating custom vitamins and dietary supplements. This application allows businesses to cater to specific health needs and preferences, enhancing customer satisfaction. For B2B buyers in South America and Europe, it is essential to evaluate customization options and the turnaround time for mold production, as these factors can significantly impact market responsiveness and product offerings.

How Are Tablet Press Molds Beneficial for the Food Industry?

In the food industry, tablet press molds are employed to produce functional food tablets, such as energy bars or meal replacements. This innovative approach helps businesses diversify their product lines and appeal to health-conscious consumers. Sourcing molds made from food-grade materials is crucial for compliance with safety regulations, especially for buyers in regions with stringent food safety standards.

Why Are Tablet Press Molds Important for Veterinary Medicine?

Tablet press molds are also vital in the veterinary medicine sector, where they are used to manufacture tablets for animal health. These molds allow for the creation of pills tailored to different animal sizes and species, addressing specific health needs. B2B buyers must focus on the customization capabilities of molds to ensure they meet the diverse requirements of animal health products, especially in markets with a high demand for veterinary solutions.

How Do Tablet Press Molds Facilitate Laboratory Research?

In laboratory research, tablet press molds are utilized to develop experimental tablets for drug formulation studies. This application fosters innovation in pharmaceutical research, enabling scientists to test new compounds and delivery methods. Buyers in the research sector should prioritize precision in mold design and compatibility with various substances to ensure successful outcomes in their experiments.

3 Common User Pain Points for ‘tablet press molds’ & Their Solutions

Scenario 1: High Variation in Product Quality

The Problem: B2B buyers often face inconsistencies in the quality of tablets produced using tablet press molds. These inconsistencies can arise from poor mold quality, improper maintenance, or incorrect specifications. For pharmaceutical companies in Africa or South America, where regulatory standards are stringent, even minor variations can lead to significant compliance issues and financial losses. Buyers may find themselves receiving complaints from customers or facing costly recalls due to subpar products.

The Solution: To mitigate quality issues, it is crucial to invest in high-quality molds from reputable manufacturers. Buyers should prioritize sourcing molds that are made from durable materials, such as high-grade stainless steel, which can withstand repeated use without losing integrity. Furthermore, implementing a routine maintenance schedule for molds is essential. Regular inspections and cleaning can prevent degradation and ensure consistent performance. Additionally, buyers should collaborate closely with suppliers to ensure that the molds meet specific production requirements, such as tablet dimensions and hardness levels, which are vital for maintaining product consistency.

Scenario 2: Difficulty in Customization

The Problem: Many B2B buyers struggle with the need for customized tablet shapes and sizes that align with their unique branding or formulation needs. For instance, companies in the Middle East and Europe may require molds that not only produce functional tablets but also feature specific logos or designs to enhance marketability. The inability to easily obtain customized molds can delay product launches and lead to missed market opportunities.

The Solution: To address customization challenges, buyers should seek suppliers that offer flexible mold customization services. When engaging with manufacturers, it is important to clearly communicate design requirements, including dimensions, shapes, and any specific branding elements. Some suppliers provide a rapid prototyping service, allowing buyers to visualize and test their designs before full production. Buyers should also consider suppliers with a track record of successful custom projects, as this can provide reassurance of their capability to deliver on specific requests. Additionally, establishing a strong relationship with the supplier can facilitate easier adjustments to mold designs in the future as market needs evolve.

Scenario 3: Slow Lead Times and Delivery Issues

The Problem: In today’s fast-paced market, delays in receiving tablet press molds can have dire consequences for production schedules and overall business operations. B2B buyers, especially in regions such as South America and Africa, may experience longer lead times due to logistical challenges or supplier inefficiencies. Such delays can cause production bottlenecks, impacting the ability to meet customer demands and potentially resulting in lost sales.

The Solution: To combat lead time issues, buyers should evaluate the logistics and delivery capabilities of potential suppliers before making a purchase. It is beneficial to select manufacturers that have established distribution networks and can provide clear timelines for delivery. Buyers should also consider placing orders well in advance and maintaining a buffer stock of essential molds to prevent disruptions. Another effective strategy is to collaborate with suppliers who offer expedited shipping options for urgent orders. Additionally, buyers can explore local suppliers within their regions to reduce shipping times and costs, thereby ensuring a more reliable and efficient supply chain.

Strategic Material Selection Guide for tablet press molds

What Are the Most Common Materials Used for Tablet Press Molds?

When selecting materials for tablet press molds, it is essential to consider various factors, including performance characteristics, manufacturing complexities, and compliance with international standards. Here, we analyze four common materials used in the production of tablet press molds: stainless steel, aluminum, carbide, and plastic composites. Each material has unique properties that can significantly impact the efficiency and quality of the tablet manufacturing process.

How Does Stainless Steel Perform in Tablet Press Molds?

Stainless steel is widely regarded as the industry standard for tablet press molds due to its excellent mechanical properties. It offers high corrosion resistance, making it suitable for various pharmaceutical applications. Stainless steel can withstand high temperatures and pressures, which is crucial during the tablet compression process.

Pros:

– Exceptional durability and longevity.

– High resistance to corrosion and chemical wear.

– Can be easily polished to achieve a smooth finish, enhancing tablet quality.

Cons:

– Higher manufacturing costs compared to other materials.

– Heavier, which may complicate handling and installation.

– Requires specialized tooling for precision machining.

Impact on Application:

Stainless steel molds are compatible with a wide range of media, including both wet and dry granulations. They are particularly favored in environments where hygiene and contamination control are paramount.

Considerations for International Buyers:

Compliance with standards such as ASTM and DIN is critical. Buyers from regions like Europe and the Middle East often prioritize suppliers who can provide certifications for material quality.

What Advantages Do Aluminum Molds Offer for Tablet Pressing?

Aluminum is another popular choice for tablet press molds, especially in applications where weight and cost are significant factors. It is lightweight and offers good thermal conductivity, which can be beneficial during the cooling process of tablets.

Pros:

– Lower cost compared to stainless steel.

– Lightweight, making it easier to handle and install.

– Good thermal properties facilitate faster cooling.

Cons:

– Less durable than stainless steel, leading to a shorter lifespan.

– Prone to corrosion, especially in humid environments.

– May require more frequent replacements, increasing long-term costs.

Impact on Application:

Aluminum molds are best suited for low-volume production runs or for applications where cost is a critical factor. They are less ideal for high-pressure applications due to their lower strength.

Considerations for International Buyers:

Buyers should ensure that aluminum molds meet local regulations regarding material safety and performance standards, particularly in regions with stringent pharmaceutical regulations.

Why Choose Carbide for Tablet Press Molds?

Carbide is a hard material that offers exceptional wear resistance, making it ideal for high-volume tablet production. Its ability to maintain sharp edges over extended use makes it a preferred choice for precision applications.

Pros:

– Extremely durable and wear-resistant.

– Maintains dimensional stability under high pressure.

– Reduces the frequency of mold replacements.

Cons:

– Higher initial cost due to complex manufacturing processes.

– More brittle than other materials, increasing the risk of chipping.

– Requires specialized handling and storage to prevent damage.

Impact on Application:

Carbide molds are particularly effective for high-speed tablet production, where wear and tear can significantly impact output quality.

Considerations for International Buyers:

Buyers should verify that carbide molds comply with international quality standards, such as JIS, to ensure product reliability and performance.

How Do Plastic Composites Fit into Tablet Press Mold Selection?

Plastic composites are gaining traction in the industry due to their versatility and lower cost. They can be engineered to meet specific performance requirements, making them suitable for various applications.

Pros:

– Lightweight and easy to handle.

– Lower cost compared to metal molds.

– Can be customized for specific applications.

Cons:

– Generally less durable and may wear out faster.

– Limited temperature and pressure tolerance.

– May not be suitable for all pharmaceutical applications.

Impact on Application:

Plastic composite molds are often used in pilot studies or low-volume production, where flexibility and cost are more critical than durability.

Considerations for International Buyers:

It is vital to ensure that plastic composites meet relevant safety and performance standards, particularly in regions with strict regulatory frameworks.

Summary Table of Material Properties for Tablet Press Molds

| Material | Typical Use Case for tablet press molds | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-volume pharmaceutical production | Exceptional durability and hygiene | Higher manufacturing costs | High |

| Aluminum | Low to medium-volume production | Lightweight and cost-effective | Less durable and prone to corrosion | Medium |

| Carbide | High-speed tablet production | Extremely wear-resistant | Higher initial cost and brittleness | High |

| Plastic Composites | Pilot studies and low-volume runs | Customizable and cost-effective | Limited durability and tolerance | Low |

This guide provides a comprehensive overview of the strategic material selection for tablet press molds, offering valuable insights for international B2B buyers navigating the complexities of material properties and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for tablet press molds

What Are the Main Stages in Manufacturing Tablet Press Molds?

The manufacturing of tablet press molds involves several critical stages that ensure the molds meet the high standards required in the pharmaceutical and dietary supplement industries.

-

Material Preparation: The first step in the manufacturing process is selecting the appropriate materials. High-quality steel, such as stainless steel or tool steel, is commonly used for its durability and resistance to wear. The selected materials undergo rigorous testing to verify their properties, including hardness and tensile strength, ensuring they can withstand the pressures of tablet formation.

-

Forming: In this stage, the prepared materials are shaped into the desired mold configurations using techniques such as CNC machining, forging, or EDM (Electrical Discharge Machining). CNC machining allows for precision shaping, enabling manufacturers to create complex designs that meet specific customer requirements.

-

Assembly: Once the individual components are formed, they are assembled into the final mold structure. This process may involve aligning and fastening different parts, ensuring they fit together accurately. Precision is crucial here, as any misalignment can affect the tablet’s quality.

-

Finishing: The final stage involves surface treatments and coatings to enhance the molds’ durability and performance. Processes such as polishing, hardening, or applying protective coatings can significantly extend the lifespan of the molds and improve their ability to produce high-quality tablets.

What Key Techniques Are Employed in Tablet Press Mold Manufacturing?

Several advanced techniques are employed during the manufacturing of tablet press molds to ensure efficiency and quality:

-

CNC Machining: This technique provides high precision and flexibility in mold design, allowing for intricate shapes and sizes that meet diverse product needs.

-

EDM (Electrical Discharge Machining): EDM is particularly useful for creating complex geometries that are difficult to achieve with traditional machining methods. It utilizes electrical discharges to remove material from the workpiece, resulting in high precision.

-

Surface Hardening: This process enhances the wear resistance of the molds, which is critical given the high pressures involved in tablet pressing. Techniques such as nitriding or hard chrome plating are often used.

-

Quality Control Techniques: Integrating quality control measures throughout the manufacturing process ensures that each mold meets the required specifications. This includes in-process inspections and final testing before shipment.

How Do Quality Assurance Standards Impact Tablet Press Mold Production?

Quality assurance is paramount in the manufacturing of tablet press molds, particularly for international B2B buyers who must comply with various regulatory standards.

-

International Standards: Adhering to ISO 9001 is essential for ensuring consistent quality management systems. This certification indicates that a manufacturer has established processes to consistently provide products that meet customer and regulatory requirements.

-

Industry-Specific Standards: Compliance with CE marking and API (Active Pharmaceutical Ingredient) standards is crucial for manufacturers targeting the pharmaceutical market. These certifications ensure that the molds are safe, effective, and suitable for use in drug production.

What Are the Key Quality Control Checkpoints in Tablet Press Mold Manufacturing?

Quality control checkpoints throughout the manufacturing process help ensure that the molds produced are of the highest quality.

-

Incoming Quality Control (IQC): This initial step involves inspecting raw materials upon arrival to ensure they meet predefined specifications. Any substandard materials are rejected, reducing the risk of defects in the final product.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, regular inspections are conducted to monitor the production process. This includes checking dimensions, surface finishes, and other critical parameters to ensure compliance with quality standards.

-

Final Quality Control (FQC): Before molds are shipped, a final inspection is performed to verify that all molds meet the required specifications and standards. This includes functional testing to ensure that the molds operate correctly under real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

-

Conducting Audits: Regular audits of suppliers can provide insight into their manufacturing processes and quality control measures. This allows buyers to assess compliance with international standards and the effectiveness of the supplier’s quality management system.

-

Requesting Quality Assurance Documentation: Suppliers should be able to provide quality assurance documentation, including inspection reports, certifications (ISO, CE, API), and records of any quality control checks performed during production.

-

Third-Party Inspections: Engaging third-party inspection agencies can add an extra layer of assurance. These independent organizations can conduct thorough assessments of the manufacturing processes and quality control practices of suppliers.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

-

Cultural and Regulatory Differences: Different regions may have varying regulatory requirements and cultural expectations regarding quality. Buyers must familiarize themselves with these differences to ensure compliance and avoid potential issues.

-

Logistics and Supply Chain Considerations: International shipping and logistics can introduce challenges that affect the quality of the molds. Buyers should discuss shipping methods and storage conditions with suppliers to ensure that quality is maintained throughout the supply chain.

-

Communication and Transparency: Clear communication with suppliers about quality expectations and standards is vital. Establishing a transparent relationship can help mitigate risks and foster trust, leading to more successful partnerships.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices for tablet press molds is crucial for B2B buyers. By focusing on these aspects, businesses can make informed decisions, ensuring they procure high-quality molds that meet their specific needs and regulatory standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tablet press molds’

When sourcing tablet press molds, it’s essential for B2B buyers to follow a systematic approach to ensure they procure high-quality products that meet their specific needs. This guide outlines critical steps to help you navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. Consider factors such as the size, shape, and material of the molds you need. This step is crucial because precise specifications will help you avoid costly mistakes and ensure compatibility with your tablet press machinery.

- Material Considerations: Look for durable materials that can withstand repeated use, such as stainless steel or hard chrome.

- Mold Dimensions: Ensure the molds are designed for the specific tablet sizes you intend to produce.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in tablet press molds. Utilize online directories, industry forums, and trade shows to gather a list of manufacturers. This step is vital as the quality of your molds will directly impact your production efficiency and product quality.

- Supplier Reputation: Check for reviews and testimonials from other businesses in your industry.

- Product Range: Ensure that the supplier offers a variety of molds to accommodate future needs.

Step 3: Evaluate Supplier Certifications

Verify that your potential suppliers hold relevant industry certifications. Certifications such as ISO 9001 can indicate adherence to quality management standards. This step ensures that you are partnering with a supplier committed to maintaining high-quality production processes.

- Quality Assurance: Ask for documentation that demonstrates the supplier’s quality control measures.

- Compliance: Ensure the supplier complies with regional regulations, particularly if you are sourcing from international suppliers.

Step 4: Request Samples

Before making a bulk order, request samples of the tablet press molds. Testing samples will allow you to evaluate the quality and compatibility of the molds with your equipment. This step is critical to ensure that the molds perform as expected in real-world applications.

- Testing Procedure: Establish a clear procedure for testing the samples, including metrics for performance evaluation.

- Feedback Loop: Share findings with your team to gather insights and make informed decisions.

Step 5: Negotiate Terms and Pricing

Engage in negotiations with your shortlisted suppliers regarding pricing, lead times, and payment terms. This step is essential to ensure that you receive the best value for your investment while establishing a mutually beneficial relationship.

- Bulk Discounts: Inquire about discounts for larger orders.

- Shipping Costs: Clarify shipping arrangements to avoid unexpected expenses.

Step 6: Finalize the Order and Confirm Delivery Schedules

Once you’ve selected a supplier and agreed on terms, finalize your order and confirm delivery schedules. Clear communication is vital to ensure timely delivery, which is critical for maintaining your production timelines.

- Order Confirmation: Ensure that all details, including quantities and specifications, are documented in the order confirmation.

- Tracking Information: Request tracking details to monitor your shipment.

Step 7: Establish a Quality Control Process

After receiving the molds, implement a quality control process to verify their condition and functionality. This step ensures that you maintain high production standards and can address any issues promptly.

- Inspection Checklist: Create a checklist to evaluate the molds upon receipt.

- Feedback Mechanism: Establish a process for reporting any defects or issues to the supplier for resolution.

By following these steps, B2B buyers can confidently navigate the procurement process for tablet press molds, ensuring they select the right suppliers and products to meet their operational needs.

Comprehensive Cost and Pricing Analysis for tablet press molds Sourcing

What Are the Key Cost Components in Sourcing Tablet Press Molds?

When sourcing tablet press molds, understanding the cost structure is essential for making informed purchasing decisions. The cost components typically include:

-

Materials: The primary cost driver is the quality and type of materials used. Common materials include stainless steel and specialized alloys, which ensure durability and resistance to wear. Higher quality materials may lead to increased upfront costs but can reduce long-term expenses related to maintenance and replacement.

-

Labor: Labor costs encompass the wages of skilled workers involved in mold fabrication. Countries with lower labor costs may offer competitive pricing, but it’s important to evaluate the trade-off between cost and quality.

-

Manufacturing Overhead: This includes expenses related to production facilities, utilities, and equipment depreciation. Efficient manufacturing processes can help minimize overhead costs, which ultimately affects pricing.

-

Tooling: Tooling costs refer to the initial expenses associated with creating the mold itself. This can be significant for custom molds, as they require specific designs and precision engineering.

-

Quality Control (QC): Ensuring that molds meet industry standards involves rigorous testing and inspection processes. Implementing comprehensive QC measures might increase costs but is crucial for maintaining product integrity.

-

Logistics: Shipping and handling costs can vary widely depending on the supplier’s location and the destination. International buyers should consider freight, customs duties, and potential delays that can impact the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market conditions, competition, and perceived value.

How Do Price Influencers Affect Tablet Press Mold Costs?

Several factors influence the pricing of tablet press molds, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to significant discounts. Buyers should negotiate MOQs to achieve cost savings while balancing their production needs.

-

Specifications and Customization: Customized molds tailored to specific products or designs generally incur higher costs due to the additional engineering and production requirements. Standard molds are typically more affordable.

-

Material Quality and Certifications: Molds made from premium materials or those that meet international certifications (like ISO or GMP) may command higher prices. However, they often provide better performance and longer lifespan, translating to lower Total Cost of Ownership (TCO).

-

Supplier Factors: The reputation and reliability of suppliers play a critical role in pricing. Established suppliers may charge more due to their proven quality and service levels, while newer suppliers may offer lower prices to penetrate the market.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international buyers. These terms dictate shipping responsibilities and costs, which can significantly affect the final price.

What Buyer Tips Can Enhance Cost Efficiency in Tablet Press Mold Sourcing?

To maximize cost efficiency in sourcing tablet press molds, consider the following strategies:

-

Negotiate Effectively: Engage in discussions with suppliers to negotiate better terms. Leverage your purchasing power, especially if you’re committing to larger orders.

-

Focus on Total Cost of Ownership (TCO): Rather than solely considering upfront costs, evaluate the TCO, which includes maintenance, operational efficiency, and potential downtime costs. Investing in higher-quality molds may yield savings in the long run.

-

Research and Compare Suppliers: Conduct thorough research on various suppliers from different regions, such as Europe or Asia, to compare pricing, quality, and service levels. This can provide insights into market pricing dynamics.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, import taxes, and tariffs that can affect overall costs when sourcing from international suppliers.

-

Leverage Local Resources: For buyers in regions like Africa or South America, consider sourcing from local suppliers to reduce logistics costs and facilitate easier communication.

By considering these factors and strategies, international B2B buyers can navigate the complexities of tablet press mold sourcing and make well-informed purchasing decisions. Always keep in mind that pricing may vary based on market conditions, so it’s advisable to seek indicative prices and conduct regular market assessments.

Alternatives Analysis: Comparing tablet press molds With Other Solutions

Introduction: Exploring Alternatives to Tablet Press Molds

When it comes to manufacturing tablets, selecting the right production method is crucial for efficiency, quality, and cost-effectiveness. While tablet press molds are a widely used solution in the pharmaceutical and nutraceutical industries, there are alternative technologies and methods that may also serve the needs of B2B buyers. Understanding these alternatives can help businesses make informed decisions based on their specific production requirements and operational capabilities.

Comparison Table

| Comparison Aspect | Tablet Press Molds | Handheld Pill Press | Rotary Tablet Press |

|---|---|---|---|

| Performance | High precision and consistency; suitable for mass production. | Lower throughput; ideal for small batches. | High speed and efficiency; great for large-scale operations. |

| Cost | Moderate initial investment; long-term cost-effective. | Low initial cost; limited scalability. | Higher upfront cost; designed for high-volume production. |

| Ease of Implementation | Requires specific machinery setup; moderate complexity. | Simple setup; user-friendly. | Complex installation; requires skilled operators. |

| Maintenance | Regular maintenance needed for molds and machinery. | Minimal maintenance; easy to clean. | Higher maintenance due to complexity and moving parts. |

| Best Use Case | Ideal for pharmaceutical manufacturing and large-scale production. | Suitable for small businesses or individual users producing custom pills. | Best for large pharmaceutical companies focusing on mass production. |

Detailed Breakdown of Alternatives

Handheld Pill Press

Handheld pill presses are compact, cost-effective devices that allow users to produce small batches of tablets. They are particularly advantageous for small businesses or individuals looking to create custom formulations without the need for extensive machinery. However, the performance is limited compared to tablet press molds, as they generally produce fewer tablets per hour, making them unsuitable for large-scale operations. The simplicity of their design means they require minimal maintenance, making them an attractive option for startups or niche markets.

Rotary Tablet Press

Rotary tablet presses are advanced machines designed for high-volume tablet production. They are capable of producing thousands of tablets per hour, making them ideal for large pharmaceutical companies. The cost of rotary tablet presses is significantly higher than that of tablet press molds, but the investment can be justified by the increased output and efficiency. Installation and operation can be complex, requiring skilled personnel for maintenance and operation. This makes rotary presses less accessible for smaller businesses but an excellent choice for enterprises focused on mass production.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right tablet production method hinges on various factors, including production scale, budget, and operational capabilities. For businesses focused on high-volume output, rotary tablet presses may be the best fit despite their higher costs and complexity. Conversely, for smaller operations or those requiring custom formulations, handheld pill presses offer a practical and cost-effective solution. Tablet press molds remain a robust option for medium to large-scale pharmaceutical production, balancing performance and cost. B2B buyers should carefully evaluate their specific needs and operational constraints to determine which solution aligns best with their strategic goals.

Essential Technical Properties and Trade Terminology for tablet press molds

What Are the Key Technical Properties of Tablet Press Molds?

Understanding the essential specifications of tablet press molds is critical for businesses aiming to optimize their production processes and ensure high-quality output. Here are several key technical properties to consider:

-

Material Grade

The material used in tablet press molds is crucial for durability and performance. Common materials include stainless steel and hardened tool steel, which provide resistance to wear and corrosion. High-grade materials ensure that molds can withstand repeated use without degrading, reducing the risk of contamination and maintaining product integrity. For B2B buyers, investing in higher-grade materials can lead to long-term cost savings through reduced maintenance and replacement needs. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In tablet press molds, tight tolerances are essential for ensuring that tablets are uniformly shaped and sized, which directly impacts dosage accuracy and consumer satisfaction. For pharmaceutical applications, where precision is paramount, understanding and specifying tolerances during the procurement process can help avoid costly production errors and regulatory issues. -

Surface Finish

The surface finish of a mold affects the quality of the tablets produced. A smoother finish can reduce friction and wear, leading to less sticking and easier ejection of the tablets. Additionally, a high-quality surface finish minimizes the risk of contamination and improves the overall aesthetic of the final product. For businesses, selecting molds with the appropriate surface finish can enhance production efficiency and product quality. -

Die Configuration

The configuration of the die, including its shape and size, is critical for producing tablets with specific characteristics. Custom die configurations allow businesses to create unique tablet shapes that can differentiate their products in a competitive market. Understanding the capabilities and limitations of die configurations is essential for businesses looking to innovate and meet specific customer demands. -

Heat Treatment

Heat treatment processes can enhance the physical properties of the mold material, such as hardness and toughness. This treatment is vital for extending the lifespan of tablet press molds, especially in high-volume production environments. For B2B buyers, knowing whether a mold has undergone heat treatment can inform decisions about its suitability for specific applications. -

Compatibility with Equipment

Ensuring that tablet press molds are compatible with existing machinery is crucial for seamless integration into production lines. Different machines may require specific mold designs or configurations, so understanding the compatibility can prevent costly downtime and adjustments. B2B buyers should confirm compatibility with manufacturers to streamline operations.

What Are Common Trade Terms Related to Tablet Press Molds?

Navigating the procurement landscape for tablet press molds involves understanding various industry-specific terms. Here are some common jargon and trade terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of tablet press molds, understanding OEM relationships can help businesses ensure they are sourcing high-quality components that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of products that a supplier is willing to sell. This term is crucial for B2B buyers as it can significantly affect inventory management and cash flow. Knowing the MOQ can help businesses plan their purchasing strategies accordingly. -

RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests price quotes from suppliers for specific products or services. When sourcing tablet press molds, submitting an RFQ can help businesses compare pricing, specifications, and lead times to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, particularly regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B transactions involving tablet press molds, as it clarifies the risks and costs involved in the shipping process. -

Lead Time

Lead time is the duration between placing an order and receiving the product. For tablet press molds, understanding lead times is critical for project planning and ensuring that production schedules are met. Effective communication with suppliers regarding lead times can help avoid delays. -

Custom Molds

Custom molds are specifically designed to meet unique product specifications. This term is vital for businesses looking to produce specialized tablets. Understanding the process and costs associated with custom molds can enable companies to innovate and meet specific market demands effectively.

By grasping these technical properties and trade terminologies, international B2B buyers can make more informed decisions, ensuring they select the right tablet press molds for their production needs.

Navigating Market Dynamics and Sourcing Trends in the tablet press molds Sector

What Are the Current Market Dynamics and Key Trends in the Tablet Press Molds Sector?

The global tablet press molds market is witnessing significant transformation, driven by advancements in technology and increasing demand for personalized pharmaceuticals. Key trends include the rise of automation in manufacturing processes, which enhances efficiency and reduces human error. Additionally, the customization of molds is gaining traction, allowing manufacturers to produce specific tablet shapes and sizes tailored to unique market needs. This trend is particularly relevant for international buyers from regions such as Africa, South America, and the Middle East, where localized production can significantly reduce logistics costs and improve supply chain efficiency.

Furthermore, the shift towards compact and portable tablet press machines, such as handheld models, is shaping sourcing strategies. These machines not only save space but also cater to small businesses and startups looking to enter the pharmaceutical market without heavy capital investment. Buyers in emerging markets, particularly in Saudi Arabia and Brazil, are increasingly interested in cost-effective, reliable solutions that do not compromise on quality.

In terms of market dynamics, the growing emphasis on regulatory compliance and quality assurance is pushing manufacturers to adopt higher standards in mold production. Buyers must prioritize suppliers who demonstrate robust quality control processes and certifications, ensuring that molds can withstand rigorous production demands while maintaining product integrity.

How Is Sustainability and Ethical Sourcing Impacting the Tablet Press Molds Market?

Sustainability has become a critical consideration in the sourcing of tablet press molds. The environmental impact of manufacturing processes is under scrutiny, with buyers increasingly favoring suppliers who prioritize eco-friendly practices. This includes the use of sustainable materials and processes that minimize waste and energy consumption. For instance, molds made from recyclable materials or those produced using energy-efficient techniques are gaining popularity.

Moreover, ethical sourcing is becoming a vital aspect of procurement strategies. International buyers are seeking suppliers who adhere to fair labor practices and maintain transparency in their supply chains. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential indicators of a supplier’s commitment to sustainability.

Investing in suppliers that prioritize green certifications not only aligns with corporate social responsibility goals but also enhances brand reputation in increasingly eco-conscious markets. Buyers must conduct thorough due diligence to ensure their suppliers meet these standards, thereby contributing to a more sustainable and ethical pharmaceutical industry.

What Is the Historical Context of Tablet Press Molds and Their Evolution?

The evolution of tablet press molds can be traced back to the early 20th century, when the pharmaceutical industry began to embrace mechanized production. Initially, molds were rudimentary and primarily designed for simple tablet shapes. However, as the demand for diverse pharmaceutical products grew, so did the complexity and sophistication of tablet press molds.

The introduction of rotary tablet presses in the 1950s marked a significant advancement in the field, allowing for mass production of tablets with greater precision and consistency. Over the decades, innovations in materials science have led to the development of durable and high-performance molds, enhancing their lifespan and effectiveness in various manufacturing settings. Today, the market is characterized by a focus on customization, automation, and sustainability, reflecting the dynamic needs of a globalized pharmaceutical landscape.

This historical context provides valuable insights for B2B buyers, highlighting the importance of choosing suppliers with a proven track record of innovation and reliability in mold production. Understanding these trends enables buyers to make informed decisions that align with current market demands and future growth opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of tablet press molds

-

How do I choose the right tablet press mold for my production needs?

Selecting the appropriate tablet press mold hinges on your specific production requirements. Consider factors such as the type of tablets you are manufacturing (e.g., size, shape, and composition), the machine compatibility, and the expected production volume. Additionally, consult with suppliers who offer customization options; this allows you to create molds tailored to your exact specifications. Evaluating samples and past customer reviews can also provide insights into the quality and performance of the molds you are considering. -

What is the best material for tablet press molds?

The best material for tablet press molds typically includes high-grade steel, such as stainless steel or tool steel, due to their durability, corrosion resistance, and ability to withstand high pressure during the tablet formation process. Some manufacturers may also offer molds made from specialized alloys to enhance performance. When choosing a material, consider the specific requirements of your production process, including the types of active pharmaceutical ingredients (APIs) you will be using and any environmental factors that may affect mold integrity. -

What are the common customization options for tablet press molds?

Customization options for tablet press molds can include variations in shape, size, and design to meet specific product requirements. Suppliers often provide services to engrave logos or unique designs onto the molds, which can enhance branding. Additionally, you can request specific dimensions, punch types, and die configurations based on your production needs. It’s crucial to communicate clearly with your supplier about your customization needs and to review prototypes when possible to ensure they meet your expectations. -

What should I consider regarding minimum order quantities (MOQ) when sourcing molds?

Minimum order quantities (MOQ) can vary significantly among suppliers and may depend on the complexity of the mold design and production processes. When sourcing tablet press molds, inquire about the MOQ to ensure it aligns with your production scale. For smaller operations, look for suppliers that accommodate lower MOQs or offer stock molds. Additionally, consider the potential for future orders, as establishing a relationship with a supplier may lead to more favorable terms over time. -

What payment terms are typically offered by suppliers for tablet press molds?

Payment terms for tablet press molds can vary widely depending on the supplier and the size of the order. Common practices include upfront deposits ranging from 30% to 50% of the total cost, with the remaining balance due upon completion or prior to shipping. It’s advisable to negotiate terms that align with your cash flow needs and to ensure that payment methods (such as wire transfer, credit card, or letter of credit) are secure and acceptable to both parties. Always request a formal invoice detailing the payment structure. -

How can I ensure quality assurance (QA) when sourcing tablet press molds?

To ensure quality assurance when sourcing tablet press molds, start by researching the supplier’s certifications and compliance with international standards, such as ISO 9001. Request detailed information about their manufacturing processes, including materials used and testing protocols. Conducting a factory visit or requesting third-party audits can provide deeper insights into their operations. Additionally, consider requesting samples or prototypes to evaluate mold performance before committing to a larger order. -

What logistics considerations should I keep in mind when importing tablet press molds?

Logistics play a crucial role in the timely and cost-effective import of tablet press molds. Be aware of shipping options, estimated delivery times, and associated costs, including customs duties and taxes. Collaborating with a freight forwarder can help navigate international shipping regulations and streamline the import process. Also, ensure that the supplier provides accurate documentation to facilitate customs clearance and consider the option of local warehousing if you anticipate ongoing orders. -

How do I vet suppliers for tablet press molds in international markets?

When vetting suppliers for tablet press molds in international markets, start by checking their industry reputation through online reviews and testimonials. Look for suppliers with a proven track record in your specific region, especially those who have experience exporting to countries like those in Africa, South America, the Middle East, and Europe. Request references from previous clients and verify their manufacturing capabilities and quality certifications. Engaging with suppliers at trade shows or industry exhibitions can also provide valuable face-to-face interaction to gauge reliability and professionalism.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Tablet Press Molds Manufacturers & Suppliers List

1. TOPTDP – Pill Press Machines

Domain: toptdp.com

Registered: 2021 (4 years)

Introduction: TOPTDP offers a range of pill press machines and molds, including the handheld TDP pill press, TDP-5L lightweight electric tablet press, TDP-5 electric drive tablet press, and TDP-0 manual pill press. The machines are designed for easy use and customization, allowing users to create pills, supplements, and vitamins at home. Custom pill press dies are available for both desktop single punch and rot…

2. Shanghai Tianhe – Key Product

Domain: automatictabletpressmachine.com

Registered: 2016 (9 years)

Introduction: Key product details for pill press molds include: 1. Manufacturer: Shanghai Tianhe Pharmaceutical Machinery Co., Ltd. 2. Types of molds: Customized Pill Stamp Mold, 3-Head Multiple Punch Die Tooling, Tablet Pill mold Punches & Dies, Multi-tips Punch Pressing Stamping Mold, EU B / TDP / ZP 10 Tablet Press Tooling, Multi-tip Punch Press Tooling, Tablet Dies & Punches, Steel Any Shape Tablet Press To…

3. SZ Pharma – ZP-9 Pill Press Molds

Domain: sz-pharma.com

Registered: 2016 (9 years)

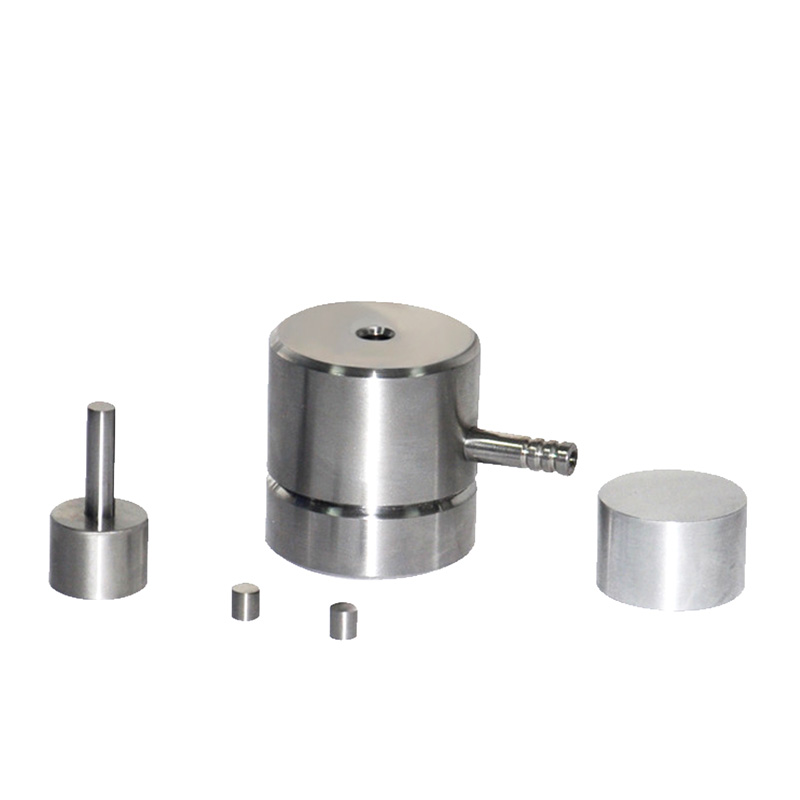

Introduction: Product Name: ZP-9 Pill Press Molds Shaped Mould

Material: Carbon steel, bearing steel, and chrome 12

Components: 1 top punch, 1 bottom punch, 1 center ring die

Compatibility: Suitable for ZP series tablet press

Applications: Compressing various types of tablets including Chinese and Western medicine tablets, nutrient tablets, lozenges, spirulina tablets, milk tablets, vitamin C effervescent table…

4. Etsy – Pill Press Mold

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Pill Press Mold – 1,000+ items available, Free shipping, Arrives within 7 days, Star Seller, Ships from United States, Various sellers and products including:

– ATH01, ATHPRO bath bomb mold press, shampoo bar mold press – Sale Price: $112.00 (Original Price: $140.00, 20% off)

– 5″ Aluminum Cigar Mold / Press – Cannagar Mold – Price: $145.00

– Duty Free/Bath Bomb Mold Press and Shampoo Bar Mold Pre…

5. TabletPress – Customized Tablet Press Molds

Domain: tp-tabletpress.com

Registered: 2019 (6 years)

Introduction: China Customized tablet press molds. Specializes in manufacturing tablet press die and customizing pill press stamps according to customer demands. Production starts upon receiving tablet drawings, physical tablet samples, or existing tablet press mold sets. Capable of producing around 4000 sets of tablet press punch die sets monthly.

6. Micro-Tec – Tablet Press and Punch Die Kit

Domain: microtonano.com

Registered: 2008 (17 years)

Introduction: Micro-Tec Tablet Press and Tablet Punch Die Kit

Tablet Press Models:

– Micro-Tec MTB3 tablet press for Ø3mm tablets, carbon steel

– Micro-Tec MTB6 manual tablet press for Ø6mm tablets, carbon steel

– Micro-Tec MTB8 tablet press for Ø8mm tablets, carbon steel

– Micro-Tec MTB10 manual tablet press for Ø10mm tablets, carbon steel

– Micro-Tec MTB12 manual tablet press for Ø12mm tablets, carbon steel

…

7. Kindle Tech – Tablet Press Molds

Domain: kindle-tech.com

Registered: 2017 (8 years)

Introduction: Classification of tablet press molds includes various shapes for the end face of a punch, such as flat, hypotenuse, shallow concave, deep concave, and integrated shapes. Each shape serves a specific purpose in tablet compression. The stamping die consists of three parts: the upper punch, middle die, and lower punch, with the middle die being the main working element. Precautions for use include en…

Strategic Sourcing Conclusion and Outlook for tablet press molds

In the dynamic landscape of pharmaceutical manufacturing, strategic sourcing of tablet press molds is paramount for international B2B buyers. By leveraging customized solutions, companies can ensure high-quality production while optimizing costs. The ability to select molds that meet specific requirements—such as durability, shape, and size—enables businesses to maintain a competitive edge in their markets.

Buyers from regions like Africa, South America, the Middle East, and Europe must prioritize partnerships with reliable suppliers that offer both standard and custom molds, ensuring flexibility and responsiveness to market demands. Investing in high-quality molds will not only enhance product quality but also streamline production processes, reducing downtime and increasing efficiency.

Looking ahead, the trend towards personalized medicine and tailored pharmaceutical solutions will only amplify the need for innovative tablet press molds. As the industry evolves, embracing these strategic sourcing opportunities will empower businesses to meet growing consumer expectations. Now is the time for international buyers to engage with reputable manufacturers and secure the molds that will drive their success in the future.