How to Source 2 Core Wire 3/29 Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for 2 core wire 3/29

Navigating the global market for 2 core wire 3/29 can be a daunting task for international B2B buyers, particularly when faced with challenges such as varying supplier quality, fluctuating prices, and compliance with regional standards. This guide is designed to equip you with the knowledge necessary to make informed sourcing decisions, ensuring that you procure high-quality electrical wiring that meets your specific needs.

Within these pages, we will explore a comprehensive range of topics, including the types of 2 core wire 3/29 available, their diverse applications across industries, and critical factors to consider when vetting suppliers. Understanding the nuances of pricing structures and the impact of local market conditions on costs will also be covered, enabling you to negotiate effectively and secure the best deals.

This resource is particularly beneficial for buyers in regions such as Africa, South America, the Middle East, and Europe, including emerging markets like Vietnam and established ones like Saudi Arabia. By addressing the key challenges you face in sourcing 2 core wire 3/29, this guide empowers you to streamline your purchasing process, mitigate risks, and ultimately enhance the efficiency and safety of your electrical projects. With the right information at your fingertips, you can navigate the complexities of the global market with confidence and precision.

Understanding 2 core wire 3/29 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Insulated 2 Core Wire | Durable PVC insulation, various gauge options | Residential wiring, light industrial use | Pros: Cost-effective, flexible; Cons: Limited heat resistance. |

| Armored 2 Core Cable | Enhanced protection with metallic armor | Heavy-duty industrial applications | Pros: High durability, resistant to physical damage; Cons: Higher cost. |

| Low Voltage 2 Core Wire | Specifically designed for low voltage applications | Solar installations, LED lighting | Pros: Lightweight, easy to install; Cons: Not suitable for high voltage. |

| High Temperature 2 Core Wire | Rated for high-temperature environments | Automotive and aerospace industries | Pros: Excellent heat resistance; Cons: Generally more expensive. |

| Shielded 2 Core Cable | Provides electromagnetic interference protection | Data transmission, sensitive equipment | Pros: Reduces signal interference; Cons: Higher complexity in installation. |

What Are the Characteristics and Suitability of PVC Insulated 2 Core Wire?

PVC insulated 2 core wire is widely used in residential and light industrial applications due to its flexibility and cost-effectiveness. The insulation provides a good balance of durability and electrical safety, making it suitable for general wiring tasks. When purchasing, buyers should consider the wire’s gauge, as it directly impacts the current-carrying capacity, ensuring it aligns with their specific project requirements.

How Does Armored 2 Core Cable Stand Out in Heavy-Duty Applications?

Armored 2 core cable is designed for environments that require enhanced protection against mechanical damage. The metallic armor provides additional strength, making it ideal for heavy-duty industrial applications such as manufacturing and construction sites. Buyers should evaluate the cable’s armor material and thickness to ensure it meets the specific demands of their operational environment, balancing cost against the required durability.

Why Choose Low Voltage 2 Core Wire for Solar Installations?

Low voltage 2 core wire is particularly suited for solar installations and LED lighting projects. Its lightweight design facilitates easier handling and installation, while the insulation is engineered to withstand outdoor conditions. When sourcing this wire, B2B buyers should focus on the cable’s voltage rating and environmental resistance to ensure optimal performance in their energy solutions.

What Are the Benefits of High Temperature 2 Core Wire in Specialized Industries?

High temperature 2 core wire is essential in sectors like automotive and aerospace, where components are exposed to elevated temperatures. This wire type is built to resist heat degradation, ensuring long-term reliability in demanding applications. Buyers should assess the temperature rating and compliance with industry standards to ensure the wire’s suitability for their specific applications.

What Advantages Does Shielded 2 Core Cable Offer for Sensitive Equipment?

Shielded 2 core cable is designed to protect sensitive electronic equipment from electromagnetic interference, making it ideal for data transmission applications. This type of cable is crucial in environments where signal integrity is paramount, such as telecommunications and medical devices. Buyers should consider the level of shielding required based on their operational environment and the potential for interference, ensuring their investment supports uninterrupted performance.

Key Industrial Applications of 2 core wire 3/29

| Industry/Sector | Specific Application of 2 core wire 3/29 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Power supply for lighting and electrical systems | Ensures reliable power distribution, enhancing safety and efficiency on-site | Compliance with local electrical standards and certifications |

| Automotive | Wiring for vehicle electrical systems | Supports critical functions, improving vehicle reliability and performance | High-temperature insulation and durability for harsh conditions |

| Renewable Energy | Connection for solar panel installations | Facilitates efficient energy transfer, maximizing solar output | UV resistance and weatherproofing for outdoor applications |

| Industrial Equipment | Control and power wiring for machinery | Enhances operational efficiency and minimizes downtime | Ability to withstand high current loads and mechanical stress |

| Home Appliances | Internal wiring for electrical devices | Ensures safety and compliance with appliance regulations | Quality insulation materials to prevent electrical hazards |

How is 2 Core Wire 3/29 Used in the Construction Industry?

In the construction sector, 2 core wire 3/29 is pivotal for powering lighting and electrical systems within buildings. It provides a reliable conduit for electricity, which is essential for the functionality of tools, safety systems, and communication devices. The wire’s robustness allows it to endure the rigors of construction environments, addressing challenges such as exposure to moisture and physical wear. For international buyers, particularly in regions like Africa and South America, it’s crucial to source wires that meet local electrical standards to ensure safety and compliance.

What Role Does 2 Core Wire 3/29 Play in Automotive Applications?

In the automotive industry, 2 core wire 3/29 is used extensively for wiring vehicle electrical systems, including lighting, ignition, and control circuits. Its high conductivity and durability make it suitable for the demanding conditions of automotive environments, where resistance to heat and vibration is critical. For buyers in the Middle East and Europe, it’s essential to consider suppliers that offer wires with high-temperature insulation to ensure long-term reliability in vehicles operating under extreme conditions.

How is 2 Core Wire 3/29 Beneficial for Renewable Energy Projects?

For renewable energy applications, particularly solar installations, 2 core wire 3/29 facilitates effective connections between solar panels and inverters, ensuring optimal energy transfer. This wire’s ability to withstand UV exposure and harsh weather conditions is vital for outdoor installations. Buyers from regions like Africa, where solar energy is rapidly growing, should prioritize sourcing wires that are specifically designed for outdoor use to maximize the efficiency and lifespan of their solar systems.

In What Ways Does 2 Core Wire 3/29 Enhance Industrial Equipment Operations?

In industrial settings, 2 core wire 3/29 is commonly used for control and power wiring in machinery and equipment. Its capacity to handle high current loads is crucial for the operational efficiency of manufacturing processes. This wire helps minimize downtime by ensuring reliable connections in critical systems. International buyers should focus on sourcing high-quality wires that can endure mechanical stress and comply with industry standards to enhance productivity.

Why is 2 Core Wire 3/29 Important for Home Appliance Manufacturing?

Within the home appliance sector, 2 core wire 3/29 is integral for internal wiring, connecting various electrical components safely and efficiently. Its insulation properties are essential to prevent electrical hazards, ensuring that appliances meet safety regulations. For buyers in Europe and South America, it is vital to select wires that adhere to local safety standards, as this not only guarantees compliance but also enhances consumer trust in the products.

3 Common User Pain Points for ‘2 core wire 3/29’ & Their Solutions

Scenario 1: Quality Assurance in Sourcing 2 Core Wire 3/29

The Problem: B2B buyers often face challenges when it comes to ensuring the quality of the 2 core wire 3/29 they source. In regions like Africa and South America, where suppliers may vary significantly in reliability, buyers are concerned about receiving substandard products that do not meet international safety standards. This can lead to operational inefficiencies, increased project costs, and even safety hazards if the wiring fails during use.

The Solution: To mitigate quality concerns, B2B buyers should prioritize sourcing from established manufacturers that provide certifications for their products, such as IEC or UL approvals. Conduct thorough due diligence by requesting samples and conducting quality tests before placing bulk orders. Additionally, consider leveraging online platforms that aggregate supplier ratings and reviews, such as Alibaba or TradeIndia, to identify reputable suppliers. Establishing a direct line of communication with manufacturers can also help clarify specifications and quality standards, ensuring that the sourced wire meets your project requirements.

Scenario 2: Managing Costs and Budget Constraints

The Problem: Another prevalent issue for B2B buyers is the fluctuation in costs associated with purchasing 2 core wire 3/29. Unexpected price increases can disrupt budgets, especially for projects that rely on precise cost estimations. Buyers in regions like the Middle East and Europe may also face additional challenges such as import tariffs or fluctuating currency rates, which can further complicate pricing.

The Solution: To effectively manage costs, buyers should consider negotiating bulk pricing with suppliers and exploring long-term contracts that secure fixed rates over time. It’s essential to compare multiple quotes from different suppliers to ensure competitive pricing. Additionally, buyers can minimize costs by consolidating their orders to reduce shipping fees and taking advantage of local suppliers where feasible. Regularly analyzing the market for trends in material costs can also help buyers anticipate price changes and adjust their procurement strategies accordingly.

Scenario 3: Technical Specifications and Compatibility Issues

The Problem: B2B buyers often struggle with understanding the technical specifications of 2 core wire 3/29, leading to compatibility issues with existing electrical systems. This is especially problematic in industries such as construction or manufacturing, where precise electrical requirements are critical. Misunderstandings regarding gauge sizes, insulation types, or conductor materials can result in delays and increased costs due to the need for replacements or modifications.

The Solution: To avoid technical pitfalls, buyers should invest in a comprehensive understanding of the electrical requirements specific to their projects. This includes consulting with electrical engineers or technicians who can provide insights into the necessary specifications for the 2 core wire 3/29. Buyers should also request detailed product datasheets from suppliers, which outline the technical characteristics of the wire, including voltage ratings and thermal limits. Utilizing software tools for electrical design can help in verifying compatibility before purchasing, ensuring that the selected wire meets all operational requirements. Establishing a checklist of specifications can streamline the purchasing process, reducing the risk of errors and ensuring project success.

Strategic Material Selection Guide for 2 core wire 3/29

What Are the Key Materials for 2 Core Wire 3/29?

When selecting materials for 2 core wire 3/29, understanding the properties, advantages, and limitations of each material is crucial for ensuring optimal performance in various applications. Below are analyses of four common materials used in the production of 2 core wire 3/29.

1. Copper

Key Properties: Copper is known for its excellent electrical conductivity, thermal conductivity, and resistance to corrosion. It typically operates efficiently at temperatures up to 200°C and can handle high current loads without significant heat generation.

Pros & Cons: The primary advantage of copper is its superior conductivity, which allows for smaller wire sizes and reduced energy losses. However, copper is more expensive than alternatives like aluminum, and its susceptibility to oxidation can lead to performance issues if not properly insulated.

Impact on Application: Copper wires are ideal for applications requiring high reliability and performance, such as in industrial machinery and high-end electrical systems. They are compatible with various media and environments, making them a versatile choice.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B3 or DIN 48201 for copper wires. In regions like Africa and the Middle East, where humidity can be high, selecting copper with adequate insulation is essential.

2. Aluminum

Key Properties: Aluminum has a lower density than copper, making it lighter and easier to handle. It has good conductivity, though not as high as copper, and can operate effectively at temperatures up to 150°C.

Pros & Cons: Aluminum is generally more cost-effective than copper, making it an attractive option for large-scale projects. However, it has a higher thermal expansion coefficient, which can lead to joint failures if not properly managed.

Impact on Application: Aluminum is often used in overhead power lines and large-scale electrical installations due to its weight advantages. It is suitable for applications where weight is a critical factor, such as in transportation.

Considerations for International Buyers: Buyers must be aware of standards such as ASTM B800 for aluminum conductors. In regions like South America, where environmental factors can vary, ensuring proper insulation and protection against corrosion is vital.

3. PVC (Polyvinyl Chloride)

Key Properties: PVC is a widely used insulating material due to its excellent electrical insulation properties and resistance to moisture, chemicals, and abrasion. It can withstand temperatures up to 70°C, making it suitable for many applications.

Pros & Cons: The main advantage of PVC is its cost-effectiveness and ease of manufacturing. However, it has limitations in high-temperature applications and can degrade under UV exposure.

Impact on Application: PVC insulation is commonly used in residential and commercial wiring due to its affordability and versatility. It is suitable for indoor applications but may not be ideal for outdoor or high-temperature environments.

Considerations for International Buyers: Compliance with standards such as UL 83 or IEC 60227 is essential. Buyers in Europe and the Middle East should also consider the environmental regulations regarding PVC use and disposal.

4. XLPE (Cross-Linked Polyethylene)

Key Properties: XLPE offers superior thermal resistance, allowing it to operate at temperatures up to 90°C continuously. It also has excellent dielectric properties and is resistant to chemicals and moisture.

Pros & Cons: XLPE is highly durable and suitable for high-voltage applications. However, it is more expensive than PVC and can be more complex to manufacture.

Impact on Application: XLPE is often used in industrial applications and power distribution systems where high performance and durability are required. Its resistance to harsh conditions makes it suitable for outdoor applications.

Considerations for International Buyers: Buyers should ensure compliance with standards such as IEC 60502. In regions like Africa and Europe, where environmental conditions can be challenging, XLPE is an excellent choice for long-lasting performance.

Summary Table of Material Selection for 2 Core Wire 3/29

| Material | Typical Use Case for 2 core wire 3/29 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Industrial machinery, high-end electrical systems | Superior conductivity and reliability | Higher cost, oxidation issues | High |

| Aluminum | Overhead power lines, large-scale installations | Cost-effective and lightweight | Lower conductivity, thermal expansion issues | Medium |

| PVC | Residential and commercial wiring | Cost-effective and versatile | Limited temperature range, UV degradation | Low |

| XLPE | Industrial applications, power distribution | High durability and thermal resistance | More expensive, complex manufacturing | High |

This guide provides a comprehensive overview of the materials used in 2 core wire 3/29, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 2 core wire 3/29

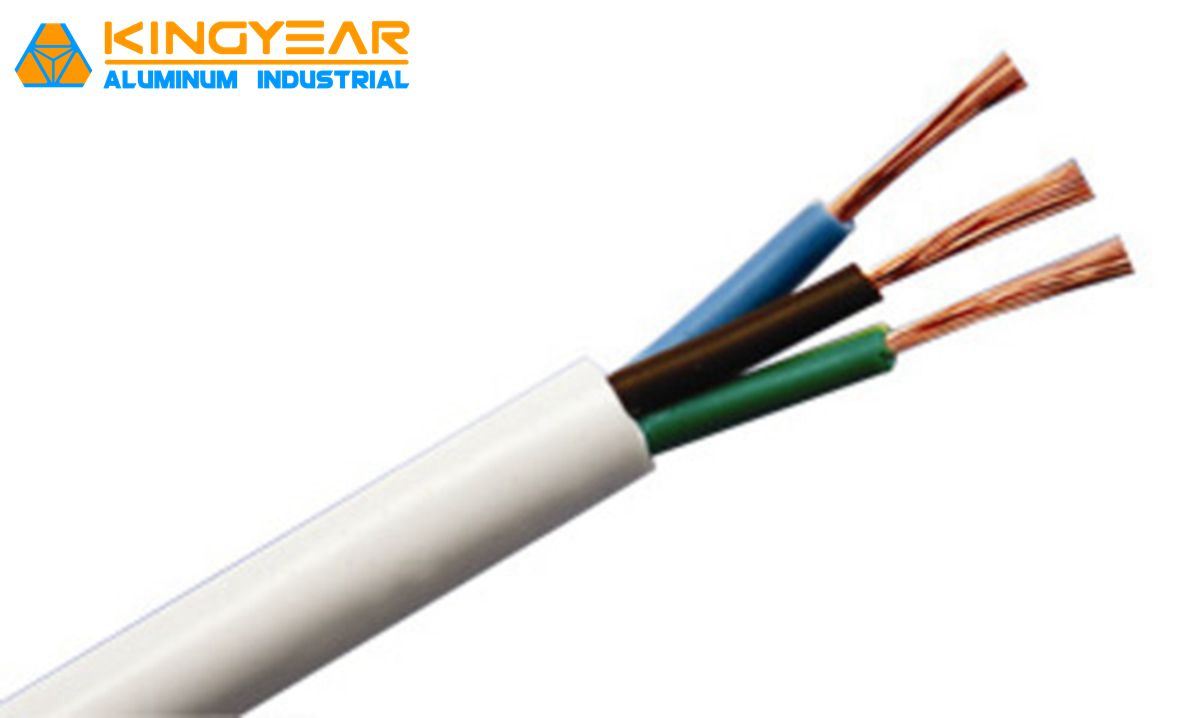

What Are the Key Stages in the Manufacturing Process of 2 Core Wire 3/29?

The manufacturing process for 2 core wire 3/29 involves several critical stages that ensure the production of high-quality electrical cables. Understanding these stages can help international B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation

The manufacturing process begins with the selection of raw materials. For 2 core wire 3/29, the primary component is copper, known for its excellent conductivity and reliability. The copper is sourced from reputable suppliers, ensuring it meets industry standards. Once procured, the copper undergoes a cleaning process to remove impurities that could affect conductivity.

Additionally, insulation materials, often made from PVC or other flame-retardant materials, are prepared. These materials are crucial for protecting the copper from environmental factors and preventing electrical hazards.

2. Forming and Stranding

Once the materials are ready, the next stage involves forming the wires. The copper is drawn through a series of dies to achieve the desired gauge, typically 2.5 mm for 3/29 applications. This process increases the wire’s length while reducing its diameter.

In the stranding process, multiple strands of copper are twisted together to form a single core. This technique enhances flexibility and improves the wire’s ability to handle mechanical stress without breaking. The number of strands and their arrangement can vary based on specific product requirements.

3. Insulation and Assembly

After forming the cores, the next step is to apply insulation. The copper cores are coated with the insulating material, which is extruded over the wire. This process ensures a uniform thickness of insulation, which is critical for electrical safety and performance.

Following insulation, the assembly process occurs, where two insulated cores are combined to create the final product—2 core wire 3/29. Additional features, such as color coding and marking for easy identification, may also be incorporated during this phase.

4. Finishing Touches

The final stage in the manufacturing process involves various finishing steps, such as cutting the wire to specified lengths and applying outer sheathing. The outer sheath provides additional protection against environmental factors and mechanical wear. It also enhances the cable’s aesthetic appeal, which can be important for certain applications.

How is Quality Assurance Implemented in the Manufacturing of 2 Core Wire 3/29?

Quality assurance is a vital aspect of the manufacturing process, ensuring that products meet international and industry-specific standards. For B2B buyers, understanding these quality control measures can enhance their confidence in the products they procure.

Relevant International Standards

Manufacturers of 2 core wire 3/29 typically adhere to several international quality standards. ISO 9001 is a widely recognized standard that outlines criteria for quality management systems. Compliance with ISO 9001 indicates a commitment to continuous improvement and customer satisfaction.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for European markets and UL (Underwriters Laboratories) for North American markets may apply. These certifications ensure that the products are safe for use and meet regulatory requirements.

Key Quality Control Checkpoints

Quality control is integrated into multiple stages of the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection phase verifies the quality of raw materials before production begins. Any materials that do not meet specifications are rejected.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, samples are taken to ensure that the production methods are yielding products that meet quality standards. This includes monitoring the forming and insulation processes.

-

Final Quality Control (FQC): Once the cables are assembled, a final inspection is conducted. This includes testing for electrical conductivity, insulation resistance, and physical integrity to ensure compliance with specifications.

What Testing Methods Are Commonly Used for 2 Core Wire 3/29?

Testing methods play a crucial role in verifying the quality and safety of 2 core wire 3/29. Here are some of the most common testing techniques employed:

-

Electrical Testing: This involves measuring the resistance and conductivity of the wire to ensure it meets specified electrical performance criteria.

-

Insulation Testing: Insulation resistance tests are performed to verify that the insulation effectively prevents electrical leakage, which is critical for safety.

-

Mechanical Testing: Tests such as tensile strength and flexibility are conducted to ensure that the wire can withstand mechanical stress during installation and use.

-

Thermal Testing: This assesses the wire’s performance under elevated temperatures, ensuring that the insulation material can withstand the heat generated during operation.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several approaches to consider:

-

Supplier Audits: Conducting on-site audits of the manufacturing facilities allows buyers to assess the quality control measures in place. This includes reviewing documentation, observing production processes, and assessing compliance with international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their testing methods, inspection results, and overall quality performance. This information is crucial for evaluating reliability.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control processes and product quality. This additional layer of verification can enhance confidence in procurement decisions.

What Quality Control Nuances Should International Buyers Consider?

International buyers must be aware of specific nuances when dealing with quality control in different markets. Variations in standards, regulations, and cultural approaches to quality can impact procurement decisions.

For instance, buyers from Europe may prioritize CE marking, while those in the Middle East may focus on specific local certifications. Understanding these distinctions can help buyers navigate the complexities of international trade and ensure compliance with regional regulations.

Additionally, factors such as language barriers and differing business practices may influence communication with suppliers. Establishing clear expectations and maintaining open lines of communication can mitigate potential misunderstandings and ensure a smooth procurement process.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for 2 core wire 3/29 empowers B2B buyers to make informed decisions. By focusing on supplier quality, international standards, and effective testing methods, buyers can enhance their procurement strategies and ensure they receive reliable and safe electrical cables for their projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2 core wire 3/29’

When sourcing ‘2 core wire 3/29’, a structured approach ensures that your procurement process is efficient and effective. This guide serves as a practical checklist for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe. By following these steps, you can secure high-quality products that meet your specifications while fostering strong supplier relationships.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications for the 2 core wire 3/29 you require. This includes parameters such as wire gauge, insulation type, and voltage rating. Having precise specifications helps in communicating your needs to suppliers and ensures that the products you receive will meet your operational requirements.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify potential suppliers with a solid reputation in the market. Look for manufacturers with positive reviews, extensive experience, and a history of supplying similar products. Utilize platforms like industry trade shows, online marketplaces, and B2B directories to find reliable partners.

Step 3: Verify Supplier Certifications

Before proceeding with any supplier, it’s essential to verify their certifications. Check for compliance with international standards such as ISO, UL, or CE, which indicate that the products meet safety and quality benchmarks. This step helps mitigate risks associated with product failures and ensures that you are sourcing from a legitimate manufacturer.

Step 4: Request Product Samples

Always request product samples before placing a bulk order. Testing samples allows you to assess the quality, flexibility, and durability of the 2 core wire 3/29. Additionally, it gives you an opportunity to evaluate the supplier’s responsiveness and willingness to accommodate your needs.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing and payment terms. Look beyond the base price; consider factors such as minimum order quantities, shipping costs, and payment options. This ensures you are getting the best overall value and helps you negotiate favorable terms.

Step 6: Evaluate Logistics and Delivery Options

Understand the logistics involved in your order. Discuss delivery timelines, shipping methods, and potential customs issues with your supplier. Efficient logistics are crucial to maintaining your project schedules, especially when sourcing from international suppliers.

Step 7: Establish a Communication Plan

Maintain open lines of communication with your supplier throughout the procurement process. Set clear expectations regarding updates, delivery schedules, and any potential issues. Effective communication fosters a strong partnership and ensures that any problems can be addressed promptly.

By adhering to this checklist, B2B buyers can streamline their sourcing process for 2 core wire 3/29, ensuring they secure high-quality materials while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for 2 core wire 3/29 Sourcing

What Are the Key Cost Components for 2 Core Wire 3/29?

When sourcing 2 core wire 3/29, it is essential to understand the cost structure involved. The primary cost components include:

-

Materials: The core of the wire is typically made from high-quality copper, which is a significant cost driver. The insulation material, often PVC or other flame-retardant materials, also contributes to the overall cost.

-

Labor: Manufacturing labor costs can vary based on the region and the specific supplier. Skilled labor is needed for precise wire production, including the winding and insulation processes.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can help in keeping these costs lower.

-

Tooling: Initial setup costs for specialized machinery and tools can be substantial, especially for custom wire specifications. These costs are amortized over the production run.

-

Quality Control (QC): Investing in quality assurance is crucial to meet international standards. QC processes ensure that the wires are safe and reliable, which can add to the overall cost but is necessary for compliance.

-

Logistics: Transportation costs vary based on the supplier’s location and the destination market. International shipping can significantly impact the total cost, especially for bulk orders.

-

Margin: Suppliers will add a profit margin to cover their business risks and operational costs. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Impact 2 Core Wire 3/29 Pricing?

Several factors can influence the pricing of 2 core wire 3/29, making it crucial for buyers to consider these elements:

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Larger orders often lead to bulk discounts, significantly reducing the per-unit cost.

-

Specifications and Customization: Custom specifications or unique features (e.g., length, insulation type) can increase the price. Standardized products generally offer more competitive pricing.

-

Materials and Quality Certifications: High-quality materials and specific certifications (such as UL or IEC standards) can drive up costs. Buyers should weigh the benefits of certified products against their budget constraints.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established manufacturers may charge a premium for their reliability and product quality.

-

Incoterms: Understanding Incoterms is vital for international purchases. They define the responsibilities of buyers and sellers regarding shipping costs, insurance, and liability, which can affect the total landed cost.

What Are Effective Buyer Tips for Negotiating 2 Core Wire 3/29 Prices?

To secure the best pricing and terms when sourcing 2 core wire 3/29, consider the following strategies:

-

Negotiate Terms: Engage in discussions about pricing, payment terms, and delivery schedules. Building a rapport with suppliers can lead to better deals and flexibility.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors like installation costs, potential downtime, and the lifespan of the wire, as these can impact overall expenditures.

-

Stay Informed About Market Trends: Understanding fluctuations in copper prices and international supply chain dynamics can provide leverage during negotiations.

-

Explore Multiple Suppliers: Request quotes from various suppliers to compare pricing and quality. This competitive approach can reveal the best options available in the market.

-

Leverage Quality and Certifications: Emphasize the importance of quality and certifications when negotiating. Suppliers that prioritize compliance may justify higher prices but provide long-term value through reliability and safety.

Disclaimer on Indicative Prices

Prices for 2 core wire 3/29 can vary significantly based on the factors mentioned above. The indicative prices range from approximately $0.06 to $5.00 per meter, depending on the specifications and supplier. Buyers should conduct thorough due diligence and request specific quotes based on their requirements to ensure accurate budgeting.

Alternatives Analysis: Comparing 2 core wire 3/29 With Other Solutions

Exploring Alternatives to 2 Core Wire 3/29: A Comparative Analysis

When considering electrical wiring solutions, the 2 Core Wire 3/29 stands out due to its robust performance and versatility. However, various alternatives exist that may better suit specific applications or budgets. This analysis compares the 2 Core Wire 3/29 with two viable alternatives: Multi-Core Flexible Cable and Aluminum Conductor Cable. By understanding the strengths and weaknesses of each option, international B2B buyers can make informed decisions tailored to their unique requirements.

Comparison Table

| Comparison Aspect | 2 Core Wire 3/29 | Multi-Core Flexible Cable | Aluminum Conductor Cable |

|---|---|---|---|

| Performance | High conductivity, durable | Flexible, good for tight spaces | Lightweight, excellent conductivity |

| Cost | Moderate (bulk pricing available) | Generally higher than 2 Core | Lower initial cost |

| Ease of Implementation | Straightforward installation | Requires careful handling | Easier to work with in large projects |

| Maintenance | Low maintenance | Moderate (may need replacements) | Low, but sensitive to corrosion |

| Best Use Case | General electrical applications | Tight spaces, mobile equipment | Overhead power lines, large installations |

Detailed Breakdown of Alternatives

Multi-Core Flexible Cable

Multi-Core Flexible Cable is designed for applications where flexibility is paramount. This type of cable is ideal for scenarios involving tight bends or mobile equipment, such as in robotics or portable power tools. While it offers superior flexibility, it is generally more expensive than the 2 Core Wire 3/29. Additionally, the installation requires careful handling to avoid damage to the cores. Maintenance can be moderate, as wear and tear may necessitate periodic replacements.

Aluminum Conductor Cable

Aluminum Conductor Cable is a cost-effective alternative, especially in large-scale installations. Its lightweight nature makes it easier to handle and install, particularly in overhead power line applications. While it provides excellent conductivity, it can be more prone to corrosion compared to copper alternatives. This means maintenance may be lower, but careful consideration of environmental factors is essential to ensure longevity. The lower initial cost may appeal to budget-conscious buyers, but the trade-off may include reduced durability over time.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right electrical cable depends on a variety of factors, including performance requirements, budget constraints, and specific application needs. The 2 Core Wire 3/29 excels in providing reliable power transmission in general applications, while alternatives like Multi-Core Flexible Cable and Aluminum Conductor Cable offer unique benefits for specialized use cases. B2B buyers should assess their project requirements, considering factors such as installation environment and long-term maintenance costs, to determine the best wiring solution for their operations. Making an informed choice will ultimately enhance efficiency and reduce operational risks in their electrical projects.

Essential Technical Properties and Trade Terminology for 2 core wire 3/29

What Are the Key Technical Properties of 2 Core Wire 3/29?

Understanding the essential technical properties of 2 core wire 3/29 is crucial for B2B buyers, particularly those engaged in industries requiring reliable electrical solutions. Here are some of the critical specifications:

-

Material Grade

The core of 2 core wire 3/29 is typically made of high-quality copper, which offers excellent conductivity and durability. Copper’s ability to carry high current loads makes it suitable for various applications, from residential to industrial settings. Buyers should prioritize wires with a high purity level to ensure optimal performance. -

Cross-Sectional Area

The term “3/29” refers to the gauge of the wire, indicating a specific cross-sectional area. This dimension is essential as it directly influences the wire’s current-carrying capacity and resistance. A larger cross-sectional area results in lower resistance and better heat dissipation, making it vital for applications that require significant power transmission. -

Insulation Type

The insulation material used in 2 core wire 3/29 is often PVC or flame-retardant compounds. The choice of insulation affects not only the wire’s safety but also its longevity in various environments. For instance, flame-retardant insulation is critical in industrial applications to prevent electrical fires and ensure compliance with safety standards. -

Voltage Rating

Voltage ratings for 2 core wire 3/29 typically range from 300/500V to higher specifications depending on the application. Understanding the voltage rating is essential for ensuring that the wire can handle the required electrical load without risk of insulation breakdown or overheating. -

Temperature Rating

The wire’s temperature rating, often indicated as 70°C or 90°C, is another critical property. This rating determines the maximum operating temperature the wire can withstand without degrading. B2B buyers must consider this specification to ensure the wire performs effectively in various thermal environments. -

Flexibility and Bend Radius

Flexibility is an important aspect, especially for applications requiring intricate installations. Wires designed with a softer PVC or rubber insulation can bend without damage, making them ideal for tight spaces. Buyers should inquire about the minimum bend radius to ensure compatibility with their specific installation needs.

What Are Common Trade Terms Related to 2 Core Wire 3/29?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms associated with 2 core wire 3/29:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end products. In the context of electrical wiring, buyers may work with OEMs for custom wire solutions tailored to specific applications, ensuring compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers plan their purchases and manage inventory effectively. It can be a critical factor when sourcing 2 core wire 3/29, especially for businesses looking to reduce costs. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price bids from suppliers. It typically includes specifications and quantities. For B2B buyers, submitting an RFQ for 2 core wire 3/29 allows for comparison among suppliers and aids in making informed purchasing decisions. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in a transaction. They clarify aspects like delivery points and shipping costs. Familiarity with Incoterms is essential for international buyers of 2 core wire 3/29 to ensure smooth logistics and compliance with trade regulations. -

Certification Standards

Certification standards, such as UL, IEC, or RoHS, indicate that the wire meets specific safety and performance criteria. These certifications are essential for B2B buyers to ensure that the products they source are reliable and compliant with international regulations. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times is crucial for buyers to manage project timelines effectively and avoid delays in electrical installations or manufacturing processes.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 2 core wire 3/29, ensuring they meet both quality and regulatory standards while optimizing costs and efficiency.

Navigating Market Dynamics and Sourcing Trends in the 2 core wire 3/29 Sector

What Are the Key Market Trends Influencing the 2 Core Wire 3/29 Sector?

The global market for 2 core wire 3/29 is witnessing significant growth driven by increasing demand for reliable electrical infrastructure across various sectors, including construction, renewable energy, and automotive. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to enhance their electrical systems, the emphasis on high-quality materials has intensified. Notably, the rise of smart technologies and automation is pushing manufacturers to innovate, leading to the introduction of cables with enhanced conductivity and durability.

Emerging trends include the digitalization of supply chains, where buyers are leveraging e-commerce platforms to streamline procurement processes. This shift enables greater access to a diverse range of suppliers, facilitating competitive pricing and improved product quality. Additionally, the emphasis on customization is growing, as buyers increasingly seek tailored solutions to meet specific project requirements. The integration of advanced technologies, such as IoT and AI, is further transforming the sourcing landscape, enabling real-time tracking of shipments and inventory levels.

Moreover, geopolitical factors and trade regulations are influencing sourcing strategies. Buyers must remain vigilant about changes in tariffs and trade agreements, particularly in regions like the Middle East and Africa, where local content requirements are becoming more stringent. Understanding these dynamics is crucial for B2B buyers aiming to navigate the complexities of the 2 core wire 3/29 market effectively.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the 2 Core Wire 3/29 Sector?

Sustainability is becoming a pivotal consideration for B2B buyers in the 2 core wire 3/29 sector. The environmental impact of manufacturing processes, particularly in terms of resource extraction and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, including the use of recycled materials and energy-efficient production methods.

Ethical sourcing has also gained prominence, with businesses aiming to ensure that their supply chains are free from unethical labor practices and environmental degradation. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential indicators of a supplier’s commitment to sustainability. Buyers should actively seek partnerships with manufacturers who hold these certifications, as they signify adherence to international standards and best practices.

Moreover, the demand for ‘green’ materials is rising. Products like flame-retardant insulation and low-emission cables are now preferred choices for projects aiming to minimize their carbon footprint. By choosing suppliers who prioritize sustainable and ethical practices, B2B buyers not only enhance their corporate responsibility profile but also align themselves with the growing consumer demand for eco-friendly products.

What Is the Historical Context of 2 Core Wire 3/29 Development?

The evolution of 2 core wire 3/29 can be traced back to the industrial revolution, when the demand for efficient electrical transmission systems surged. Initially, electrical wiring was rudimentary, often using basic materials that lacked the durability and safety features required for modern applications. Over the decades, advancements in materials science have led to the development of high-quality copper cores and advanced insulation technologies, significantly improving performance and safety.

As global electrical standards evolved, the 2 core wire 3/29 has adapted to meet stringent regulations and consumer expectations. Today, it is recognized for its versatility in various applications, from residential wiring to complex industrial systems. This evolution reflects the broader trends in electrical engineering towards increased efficiency, safety, and sustainability, making it a cornerstone in modern electrical infrastructure.

In conclusion, understanding the market dynamics, sustainability imperatives, and historical context of 2 core wire 3/29 provides B2B buyers with valuable insights to make informed purchasing decisions that align with both business objectives and ethical considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of 2 core wire 3/29

-

How do I ensure the quality of 2 core wire 3/29 before purchasing?

To ensure quality, first verify that the supplier adheres to international standards such as ISO or IEC certifications. Request product samples to evaluate the materials used, such as the copper core and insulation quality. Additionally, check for customer reviews and references to gauge the supplier’s reliability. Finally, consider visiting the manufacturing facility if feasible, or utilize third-party inspection services for quality assurance before placing a bulk order. -

What are the typical applications for 2 core wire 3/29?

2 core wire 3/29 is commonly used in various electrical applications, including residential wiring, commercial installations, and industrial machinery. Its robust construction makes it suitable for high current loads and environments that require durable wiring solutions. It is also ideal for powering appliances, lighting systems, and in renewable energy setups, such as solar panel installations, ensuring safe and efficient electricity transmission. -

What should I consider when comparing suppliers for 2 core wire 3/29?

When comparing suppliers, consider factors such as product quality, pricing, minimum order quantities (MOQs), and delivery times. Evaluate their experience and reputation in the industry, including customer feedback and case studies. Additionally, assess their capacity for customization to meet specific project requirements and their adherence to international compliance standards. Finally, inquire about their after-sales support and warranty policies for added assurance. -

What are the minimum order quantities (MOQs) for 2 core wire 3/29?

MOQs for 2 core wire 3/29 can vary significantly between suppliers. Typically, MOQs range from a few hundred meters to several thousand meters, depending on the manufacturer’s production capabilities and your specific requirements. It’s essential to discuss your needs with potential suppliers to negotiate favorable terms, especially if you are looking for smaller quantities for initial projects or testing. -

What payment terms are commonly accepted by suppliers of 2 core wire 3/29?

Payment terms can differ widely among suppliers. Common options include advance payment, letters of credit, and payment upon delivery. Many suppliers may also offer net payment terms, allowing you to pay within a specified period after receiving the goods. It’s advisable to clarify these terms upfront and ensure they align with your financial policies to avoid any complications during the transaction. -

How can I customize 2 core wire 3/29 for specific projects?

Customization options for 2 core wire 3/29 typically include variations in wire gauge, insulation types, and color coding. To initiate customization, discuss your project specifications with the supplier, including any regulatory requirements or environmental conditions the cable must withstand. Many manufacturers are equipped to tailor their products to meet unique demands, so be clear about your needs to ensure the final product aligns with your expectations. -

What logistics considerations should I keep in mind when sourcing 2 core wire 3/29 internationally?

When sourcing internationally, consider shipping methods, delivery times, and customs regulations for your target market. Engage with logistics experts or freight forwarders to navigate these complexities efficiently. Additionally, factor in potential tariffs, import duties, and packaging requirements to ensure compliance with local laws. Establishing a reliable supply chain is crucial for timely project execution and avoiding unexpected delays. -

What quality assurance measures should I expect from a reputable supplier?

A reputable supplier of 2 core wire 3/29 should implement robust quality assurance measures, including routine testing of materials and finished products for compliance with international standards. They should provide documentation, such as test reports and certification, to validate their claims. Additionally, inquire about their production processes, including inspection protocols and traceability systems, to ensure that every batch meets quality expectations before shipment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 2 Core Wire 3/29 Manufacturers & Suppliers List

1. Danyang Winpower – Electric Cable Wire Roll 3 29

Domain: whxcable.com

Registered: 2023 (2 years)

Introduction: Electric Cable Wire Roll 3 29, manufactured by Danyang Winpower Wire & Cable MFG Co., Ltd. Features include: solid copper core, flame-retardant insulation, high conductivity, low resistance, excellent heat dissipation, designed for high current loads, suitable for industrial and domestic conditions, meets international standards.

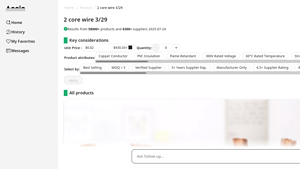

2. Accio – 2 Core Wire 3/29

Domain: accio.com

Registered: 1997 (28 years)

Introduction: {“Product Name”: “2 Core Wire 3/29”, “Unit Price”: “$0.02 – $430.03”, “Quantity”: “Customizable”, “Product Attributes”: {“Conductor Material”: “Copper”, “Insulation Material”: “PVC”, “Flame Retardant”: true, “Rated Voltage”: “300V”, “Rated Temperature”: “60°C”, “Wire Type”: “Stranded”, “UL Listed”: true, “RoHS Compliant”: true, “Cross Section”: “2.5mm²”, “Features”: [“Low Smoke”, “Zero Halogen”, “…

3. Million Elyas – Wire 3/29 2Core

Domain: royalelectric.pk

Registered: 2017 (8 years)

Introduction: MILLION ELYAS WIRE 3/29 2Core, Price: ₨ 9,430, Category: Million Elyas, Note: Product color may slightly vary due to photographic lighting sources or your screen setting.

4. MCI – 3.29 Standard Cable

Domain: shop.mcipak.com

Registered: 2018 (7 years)

Introduction: {“Product Name”: “3.29 STANDARD CABLE”, “SKU”: “1.044 Standard Electric Wire-1”, “Category”: “Standard Cables”, “Price”: “₨ 5,350”, “Type”: “Single Core Electrical Cable”, “Material”: “99.99% Copper Wire”, “Standards”: [“ISO Standard”, “Tested by PCSIR”, “Approved by PSQCA”], “Electrical Performance”: {“Rated Voltage”: [“200/450V”, “300/500V”, “450/750V”]}, “Thermal Performance”: {“Operating Tempe…

Strategic Sourcing Conclusion and Outlook for 2 core wire 3/29

In the ever-evolving landscape of electrical supply, the strategic sourcing of 2 core wire 3/29 stands out as a vital element for international buyers. This cable, known for its superior conductivity and durability, is engineered to meet the demands of both industrial and domestic applications. By prioritizing quality from reputable manufacturers, such as those found in China, buyers can ensure compliance with international standards while optimizing their procurement processes.

The strategic sourcing approach not only minimizes risks associated with supply chain disruptions but also enhances cost efficiency through bulk purchasing options. As markets expand in Africa, South America, the Middle East, and Europe, the ability to leverage relationships with trusted suppliers will provide a competitive edge.

Looking ahead, the demand for reliable electrical infrastructure will continue to grow, driven by advancements in technology and an increased focus on sustainable energy solutions. International buyers are encouraged to actively engage with suppliers, explore innovative products, and seize opportunities for collaboration. By doing so, they can secure the best quality 2 core wire 3/29, ensuring their projects are powered by the most reliable electrical solutions available.