Is Your Gas Surfboard Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for gas surfboard

In the ever-evolving landscape of water sports, sourcing the right gas surfboard presents a unique challenge for international B2B buyers. As the demand for high-performance motorized surfboards rises, understanding the nuances of this market is essential for making informed purchasing decisions. This comprehensive guide delves into various aspects of gas surfboards, including different types, applications, and key features that set them apart in the competitive arena. From racing models designed for adrenaline junkies to versatile boards suitable for various water conditions, we cover it all.

For buyers in Africa, South America, the Middle East, and Europe—particularly in regions like Brazil and Germany—this guide serves as an invaluable resource. It provides insights into supplier vetting processes, helping you identify reputable manufacturers and distributors while understanding pricing structures and warranty considerations. By equipping you with the knowledge to navigate the global gas surfboard market, this guide empowers your business to capitalize on emerging opportunities in water sports, ensuring you invest wisely in products that meet your specific needs and those of your customers. As you explore the information within, you’ll be better positioned to enhance your product offerings and drive sales in this exciting segment of the leisure industry.

Understanding gas surfboard Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fuel-Powered Surfboards | Two-stroke engines, speeds up to 63 km/h, carbon fiber build | Rental services, adventure sports | Pros: High speed, long range. Cons: Higher maintenance costs, fuel dependency. |

| Electric Surfboards | Battery-powered, quieter operation, eco-friendly options | Recreational rentals, eco-tourism | Pros: Low maintenance, environmentally friendly. Cons: Limited range, longer charging times. |

| Racing Surfboards | Streamlined designs, enhanced aerodynamics, competitive specs | Professional racing, events | Pros: High performance, lightweight. Cons: Specialized use, may require advanced skills. |

| Cruiser Surfboards | Designed for stability, user-friendly controls, versatile use | Leisure rentals, family outings | Pros: Easy to ride, suitable for all levels. Cons: Slower speeds, less thrilling experience. |

| Adventure Surfboards | Built for rugged conditions, enhanced durability, multi-terrain | Expedition rentals, extreme sports | Pros: Robust design, versatile use. Cons: Heavier, potentially less maneuverable. |

What Are Fuel-Powered Surfboards and Their Applications in B2B Markets?

Fuel-powered surfboards are characterized by their two-stroke engines and carbon fiber construction, allowing speeds of up to 63 km/h. They are particularly suitable for rental services and adventure sports companies looking to provide high-speed experiences. B2B buyers should consider the balance between performance and maintenance costs, as these boards may require more upkeep due to their engine components and fuel needs.

How Do Electric Surfboards Fit into Eco-Friendly Business Models?

Electric surfboards represent a growing segment in the surfing industry, offering battery-powered operation that promotes quieter and more environmentally friendly experiences. Ideal for recreational rentals and eco-tourism ventures, these boards have lower maintenance requirements compared to their gas counterparts. B2B buyers should weigh the benefits of eco-friendliness against limitations in range and charging times, especially in regions where access to power sources may be limited.

What Are the Key Features of Racing Surfboards for Competitive Use?

Racing surfboards are designed with aerodynamics and performance in mind, making them suitable for professional racing and events. Their lightweight and streamlined design allow for superior speed and agility on the water. B2B buyers in the competitive sports sector should focus on the specifications that enhance performance while considering the need for skilled operators, as these boards may not be suitable for beginners.

Why Choose Cruiser Surfboards for Family and Leisure Rentals?

Cruiser surfboards prioritize stability and ease of use, making them perfect for leisure rentals and family outings. Their user-friendly controls allow riders of all skill levels to enjoy the experience without the steep learning curve associated with high-performance boards. For B2B buyers, the appeal lies in their versatility and broad market appeal, although the trade-off is generally lower speeds compared to racing or fuel-powered options.

What Makes Adventure Surfboards Ideal for Extreme Conditions?

Adventure surfboards are built to withstand rugged conditions and are ideal for expedition rentals and extreme sports. Their durability allows them to perform well in various terrains, appealing to thrill-seekers. Buyers should consider the robustness and weight of these boards, as they may be less maneuverable than other types but offer unmatched versatility for challenging environments.

Key Industrial Applications of gas surfboard

| Industry/Sector | Specific Application of Gas Surfboard | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Sports & Recreation | Rental Services for Motorized Surfing | Attracts adventure-seekers, enhancing customer experience and revenue | Durability, ease of maintenance, and customer support services |

| Tourism & Hospitality | Guided Surfing Tours | Unique offerings that enhance customer satisfaction and engagement | Customization options, safety features, and local regulations |

| Film & Media Production | Action Sports Filming | Provides dynamic footage and unique angles for films and commercials | Performance reliability, portability, and production timelines |

| Maritime Training | Training Simulators for Watercraft Operations | Improves skill development for maritime professionals | Engine performance, safety measures, and training support |

| Event Management | Water Sport Events and Competitions | Attracts participants and spectators, boosting local tourism | Regulatory compliance, sponsorship opportunities, and logistics |

How Are Gas Surfboards Utilized in Water Sports and Recreation?

Gas surfboards serve as a thrilling addition to water sports rental services, allowing businesses to offer unique experiences to customers. With their ability to operate in various water conditions, these boards attract adventure-seekers looking for excitement. B2B buyers in this sector should prioritize durability and ease of maintenance to ensure high availability and performance. Additionally, reliable customer support is essential for addressing any issues that may arise during rentals.

What Role Do Gas Surfboards Play in Tourism and Hospitality?

In the tourism and hospitality sector, gas surfboards can enhance guided surfing tours by providing guests with an exhilarating experience. These boards allow for exploration in calmer waters, making them accessible to a broader audience. Businesses must consider customization options to tailor experiences to different skill levels, as well as compliance with local safety regulations to ensure a secure environment for tourists.

How Are Gas Surfboards Used in Film and Media Production?

Film and media production companies leverage gas surfboards to capture dynamic action shots and unique angles during water sports scenes. These boards enable filmmakers to create visually stunning content, appealing to audiences and enhancing production quality. When sourcing gas surfboards for this application, buyers should focus on performance reliability and portability to meet tight production schedules and logistics requirements.

What Are the Applications of Gas Surfboards in Maritime Training?

Gas surfboards are increasingly utilized in maritime training programs, serving as simulators for watercraft operations. These boards help trainees develop essential skills in a controlled environment, enhancing their readiness for real-world scenarios. Buyers in this sector should prioritize engine performance and safety features to ensure effective training outcomes. Additionally, comprehensive training support can significantly enhance the learning experience for participants.

How Do Gas Surfboards Contribute to Event Management?

In event management, gas surfboards can be pivotal in organizing water sport events and competitions. They attract participants and spectators alike, boosting local tourism and community engagement. Businesses should pay attention to regulatory compliance and sponsorship opportunities to ensure successful event execution. Furthermore, logistical considerations, such as transportation and setup, are crucial for a seamless event experience.

3 Common User Pain Points for ‘gas surfboard’ & Their Solutions

Scenario 1: Navigating High Initial Costs of Gas Surfboards

The Problem: For many B2B buyers, particularly those in emerging markets like Africa or South America, the upfront cost of gas surfboards can be prohibitive. Prices for high-quality boards can range from $5,000 to over $15,000, depending on the specifications and brand. This poses a significant challenge for businesses looking to incorporate gas surfboards into their rental fleets or as part of a water sports experience, especially when budgets are tight. Additionally, potential buyers may worry about the return on investment, given the niche nature of the product and the competition from other recreational water activities.

The Solution: To mitigate these high initial costs, businesses should consider establishing partnerships with manufacturers for bulk purchasing agreements. By negotiating directly with manufacturers, such as JETSURF or Kootubike, buyers can secure lower prices per unit. Additionally, exploring financing options or payment plans can ease the financial burden. When planning the fleet, it is essential to conduct a thorough market analysis to identify the best-selling models and features that align with customer preferences. Investing in models that have proven popularity can enhance rental profitability and ensure a quicker return on investment. Lastly, offering customer loyalty programs or packages that bundle equipment rentals with lessons can help attract more customers and generate additional revenue streams.

Scenario 2: Understanding Maintenance and Operational Challenges

The Problem: Another common pain point for B2B buyers is the maintenance and operational intricacies of gas-powered surfboards. Unlike traditional surfboards, gas surfboards require regular maintenance, including engine checks, fuel management, and parts replacement. Buyers may struggle with a lack of knowledge about proper care and the availability of spare parts, which can lead to increased downtime and operational inefficiencies. This is particularly challenging in regions where access to qualified technicians or replacement parts may be limited.

The Solution: To address these maintenance concerns, buyers should prioritize sourcing from reputable brands that offer comprehensive warranties and support services. Companies like Jetboards America provide customer service that includes maintenance advice and parts availability, which can be invaluable for new operators. Additionally, establishing a relationship with local service providers who specialize in marine equipment can facilitate timely repairs and maintenance. Buyers should also invest in staff training programs focused on the technical aspects of gas surfboard operation and maintenance. This ensures that personnel are equipped with the skills needed to handle routine maintenance and minor repairs, reducing reliance on external service providers and enhancing operational efficiency.

Scenario 3: Adapting to Regional Regulatory Compliance

The Problem: In various regions, particularly in Europe and the Middle East, regulatory compliance regarding the use of gas-powered surfboards can be complex and varies significantly by location. B2B buyers may face challenges in understanding local laws related to emissions, safety standards, and operational licenses. This uncertainty can lead to potential fines or restrictions on operations, creating a significant barrier to entry for businesses looking to offer gas surfboards as part of their services.

The Solution: To navigate these regulatory challenges, it is crucial for buyers to conduct thorough research on local laws and engage with legal experts who specialize in maritime regulations. Joining industry associations can provide access to valuable resources, including updates on regulatory changes and best practices for compliance. Additionally, buyers should consider investing in eco-friendly gas surfboards that meet stringent emissions standards, thereby enhancing their marketability and compliance with local regulations. Regularly reviewing and updating operational practices in line with regulatory changes can also position businesses as responsible operators in the market, ultimately leading to better customer trust and satisfaction.

Strategic Material Selection Guide for gas surfboard

What Materials Are Commonly Used in Gas Surfboards?

When selecting materials for gas surfboards, several factors come into play, including performance characteristics, durability, and cost. Here, we explore four common materials used in the construction of gas surfboards: fiberglass, carbon fiber, aluminum, and high-density polyethylene (HDPE). Each material has unique properties that cater to different performance needs and market preferences.

How Does Fiberglass Perform in Gas Surfboards?

Fiberglass is a traditional material used in surfboard manufacturing due to its excellent balance of strength and weight. It has a good temperature rating and can withstand moderate pressures, making it suitable for various water conditions. However, fiberglass is less resistant to impact and can be prone to cracking under extreme conditions.

Pros: Fiberglass is relatively inexpensive and easy to manufacture, making it a popular choice for entry-level models. It offers decent durability and can be molded into various shapes.

Cons: Its susceptibility to damage can lead to higher maintenance costs. Additionally, fiberglass is heavier than alternatives like carbon fiber, which may affect performance.

Impact on Application: Fiberglass surfboards are compatible with a wide range of water conditions but may not perform optimally in extreme environments.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding material safety and environmental impact, particularly in regions like Europe where stricter standards exist.

What Are the Advantages of Carbon Fiber in Gas Surfboards?

Carbon fiber is increasingly popular in high-performance gas surfboards due to its superior strength-to-weight ratio. It provides excellent temperature and pressure resistance, making it ideal for high-speed applications. Carbon fiber boards can reach impressive speeds while maintaining stability.

Pros: Carbon fiber is lightweight and durable, allowing for better maneuverability and performance. Its resistance to corrosion makes it suitable for saltwater environments.

Cons: The manufacturing process is complex and costly, which can elevate the price of the final product. Additionally, repairs can be challenging and expensive.

Impact on Application: Carbon fiber surfboards are well-suited for competitive racing and high-performance recreational use, providing an exhilarating experience.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial, especially for buyers in Europe and North America, where safety regulations are stringent.

How Does Aluminum Contribute to Gas Surfboard Design?

Aluminum is sometimes used in the construction of gas surfboards, particularly for components like the engine casing or structural reinforcements. It offers excellent corrosion resistance and can withstand high temperatures, making it suitable for marine environments.

Pros: Aluminum is lightweight and strong, providing a good balance of durability and performance. Its corrosion resistance is particularly advantageous in saltwater conditions.

Cons: While aluminum is durable, it may not provide the same level of impact resistance as fiberglass or carbon fiber. Additionally, it can be more expensive than traditional materials.

Impact on Application: Aluminum components can enhance the overall durability of gas surfboards, particularly in rugged conditions.

Considerations for International Buyers: Buyers should verify that aluminum components meet relevant standards for marine applications, especially in regions with specific material compliance regulations.

What Role Does High-Density Polyethylene (HDPE) Play in Gas Surfboards?

HDPE is often used for the outer shell of gas surfboards due to its excellent impact resistance and durability. It is lightweight and can withstand various environmental conditions, making it a versatile choice.

Pros: HDPE is cost-effective and easy to manufacture, providing a good balance of performance and affordability. Its impact resistance makes it ideal for recreational use.

Cons: While HDPE is durable, it may not offer the same performance characteristics as fiberglass or carbon fiber in high-speed applications.

Impact on Application: HDPE surfboards are well-suited for casual use and can withstand rough handling, making them ideal for rental operations.

Considerations for International Buyers: Buyers should consider the environmental impact of HDPE and its recyclability, especially in regions that prioritize sustainable practices.

Summary Table of Material Properties

| Material | Typical Use Case for gas surfboard | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fiberglass | Entry-level and recreational boards | Cost-effective and easy to mold | Prone to cracking and heavy | Low |

| Carbon Fiber | High-performance and racing boards | Lightweight with excellent performance | Expensive and complex to repair | High |

| Aluminum | Structural components and reinforcements | Corrosion-resistant and strong | Less impact resistance | Medium |

| High-Density Polyethylene (HDPE) | Casual and rental boards | Impact-resistant and affordable | Limited high-speed performance | Low |

This strategic material selection guide provides B2B buyers with essential insights into the advantages and limitations of various materials used in gas surfboards, enabling informed purchasing decisions tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for gas surfboard

What Are the Main Stages of Manufacturing a Gas Surfboard?

The manufacturing process of gas surfboards is intricate and involves several crucial stages to ensure high performance and durability. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing gas surfboards involves selecting high-quality materials that can withstand the rigors of water sports. Carbon fiber is commonly used for its lightweight and robust characteristics, providing a favorable strength-to-weight ratio. Manufacturers typically source materials from certified suppliers to ensure consistency and reliability.

During material preparation, raw materials are inspected for defects and tested for compliance with industry standards. This step is vital to avoid issues later in the production process, ensuring that only the best materials are utilized in the final product.

What Techniques Are Used in Forming Gas Surfboards?

The forming stage utilizes advanced techniques to shape the surfboard. Common methods include:

-

Molding: This involves creating a mold of the desired surfboard shape and then layering carbon fiber and resin to form the board. Vacuum infusion is often used to ensure a strong bond and eliminate air pockets, which can weaken the structure.

-

CNC Machining: Computer Numerical Control (CNC) machines are employed to achieve precise shapes and dimensions. This technology enhances consistency and reduces production errors, ensuring each board meets exact specifications.

-

Hand Layup: For specialized or custom boards, skilled craftsmen may employ hand layup techniques. This method allows for greater customization but requires more time and labor.

How Is Assembly of Gas Surfboards Conducted?

Once the individual components are formed, assembly takes place. This stage includes integrating the gas engine, fuel system, and control mechanisms into the surfboard. Attention to detail is critical here, as proper alignment and secure fastening are essential for safe operation.

Quality control checkpoints are established throughout the assembly process. Each board is subjected to inspections to verify that all components are installed correctly and functioning as intended. Any discrepancies are addressed immediately to prevent potential issues in the finished product.

What Finishing Processes Are Used for Gas Surfboards?

The finishing stage includes surface treatment and aesthetic enhancements. Manufacturers often apply a protective gel coat to prevent damage from UV rays and water exposure. Additionally, graphics and branding elements are added during this phase, allowing for customization that appeals to various markets.

Final inspections are conducted to ensure that the surfboards meet aesthetic and functional standards. This includes checking for any surface imperfections, ensuring proper weight distribution, and confirming that all controls operate smoothly.

What Quality Assurance Standards Are Relevant for Gas Surfboards?

Quality assurance is paramount in the gas surfboard manufacturing process, particularly for international B2B buyers. Compliance with international standards such as ISO 9001 ensures that manufacturers maintain consistent quality management systems. Specific industry standards, such as CE marking for products sold in Europe, further validate the safety and quality of the surfboards.

Which Quality Control Checkpoints Are Critical?

Quality control checkpoints typically include:

-

Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor the production process and detect any deviations from quality standards.

-

Final Quality Control (FQC): At this stage, finished products undergo comprehensive testing to verify their performance and safety before shipment.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. Key methods include:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and adherence to industry standards firsthand.

-

Quality Reports: Requesting detailed quality assurance reports can provide insights into the supplier’s compliance with ISO and other relevant standards.

-

Third-Party Inspections: Engaging independent inspection services can further validate the quality and safety of the products prior to shipping, ensuring they meet the buyer’s requirements.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific certification requirements that may vary by market. For instance, CE marking is essential for products sold within the European Union, while other regions may have different regulatory standards.

Understanding these nuances is crucial for ensuring that the imported gas surfboards comply with local laws and regulations. Buyers should also consider the implications of tariffs and import duties, which can affect overall costs and pricing strategies.

Conclusion

In summary, the manufacturing processes and quality assurance protocols for gas surfboards are designed to ensure high performance, safety, and durability. B2B buyers must remain vigilant in assessing supplier capabilities, verifying quality control measures, and ensuring compliance with relevant international standards. By prioritizing these elements, businesses can secure reliable partnerships and deliver superior products to their customers, ultimately driving success in the competitive water sports market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gas surfboard’

Introduction

This guide serves as a practical checklist for B2B buyers interested in sourcing gas surfboards. With the rise of motorized water sports, understanding the key factors in selecting the right gas surfboard can significantly enhance your procurement process and ensure you make an informed investment.

Step 1: Define Your Technical Specifications

Establish clear technical specifications based on your target market and intended use. This includes considerations like engine type, maximum speed, and fuel efficiency. Understanding these factors ensures you select a surfboard that meets performance expectations and customer needs.

- Engine Type: Consider whether a two-stroke or four-stroke engine is more suitable for your requirements.

- Performance Metrics: Assess the maximum speed and ride time to ensure they align with your market’s demands.

Step 2: Research Available Models

Conduct thorough research on the various models available in the market. Different brands offer unique features and specifications, which can significantly impact performance and user experience. This step is crucial for identifying boards that stand out in terms of quality and technology.

- Compare Features: Look for boards with advanced materials like carbon fiber for durability and lightweight performance.

- User Reviews: Analyze customer feedback to gauge satisfaction and performance in real-world conditions.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to vet potential suppliers thoroughly. Request detailed company profiles, case studies, and references from other buyers in similar industries or regions. A well-established supplier can provide not only quality products but also reliable customer service.

- Certifications and Compliance: Verify that suppliers meet international safety and quality standards relevant to your market.

- Warranty and Support: Assess the warranty offered and the availability of customer support for maintenance and repairs.

Step 4: Verify Production Capabilities

Understanding the production capabilities of your supplier is critical. Ensure they can meet your volume requirements without compromising quality. This is particularly important if you are planning to enter a competitive market.

- Lead Times: Confirm the lead times for production and shipping to avoid disruptions in your supply chain.

- Quality Control: Inquire about their quality control processes to ensure consistent product standards.

Step 5: Assess Pricing Structures

Pricing is a vital factor in the sourcing process. Request detailed quotes from multiple suppliers and compare them against the technical specifications and features of the gas surfboards offered. This will help you identify the best value for your investment.

- Bulk Discounts: Explore if suppliers offer discounts for bulk purchases, which can significantly reduce your overall costs.

- Hidden Costs: Be aware of any additional costs such as shipping, taxes, and import duties that may affect your budget.

Step 6: Conduct a Trial or Demo

If possible, arrange a trial or demo of the gas surfboards you are considering. This hands-on experience allows you to assess performance, handling, and user-friendliness. It also provides an opportunity to gather feedback from potential customers or team members.

- User Experience: Evaluate how easy the boards are to operate and whether they meet your expectations in terms of performance.

- Durability Testing: Look for signs of durability and robustness during the demo to ensure they can withstand various conditions.

Step 7: Finalize Contracts and Agreements

Once you have selected a supplier and product, it’s time to finalize contracts and agreements. Ensure that all terms, including pricing, delivery schedules, and warranty conditions, are clearly outlined and agreed upon.

- Legal Review: Consider having a legal expert review contracts to protect your interests.

- Payment Terms: Negotiate favorable payment terms that align with your cash flow and financial strategy.

Following this checklist will streamline your sourcing process and help you make informed decisions when procuring gas surfboards for your business.

Comprehensive Cost and Pricing Analysis for gas surfboard Sourcing

What Are the Key Cost Components in Gas Surfboard Manufacturing?

When sourcing gas surfboards, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: High-quality materials such as carbon fiber and specialized resins significantly contribute to the overall cost. These materials not only enhance performance but also durability, which is critical for extreme water conditions.

-

Labor: Skilled labor is essential for the precise manufacturing processes involved in creating gas surfboards. This includes assembly, quality control, and final adjustments to ensure optimal performance and safety.

-

Manufacturing Overhead: This encompasses the costs of maintaining production facilities, utilities, and equipment. Efficient manufacturing processes can help reduce these overhead costs, directly influencing the final price of the surfboards.

-

Tooling: Custom molds and tools for surfboard production can be expensive. However, investing in high-quality tooling can lead to better product consistency and lower long-term costs.

-

Quality Control (QC): Stringent QC processes are necessary to ensure that each board meets safety and performance standards. The costs associated with QC can be significant but are crucial for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping costs can vary widely based on the destination, the volume of the order, and the shipping method. International buyers should account for duties and taxes, which can add to the overall expense.

-

Margin: Manufacturers typically add a margin to cover their costs and ensure profitability. This margin can vary based on market demand and competition.

What Price Influencers Should Buyers Consider When Sourcing Gas Surfboards?

Several factors influence the pricing of gas surfboards:

-

Volume/MOQ: Larger orders often attract discounts. Establishing a minimum order quantity (MOQ) can lead to better pricing and more favorable terms.

-

Specifications and Customization: Custom features can raise costs significantly. Buyers should balance their desire for unique specifications with budget constraints.

-

Materials and Quality Certifications: Premium materials and certifications (like ISO standards) can increase the price but often result in better performance and safety. Buyers should consider these factors when assessing the total cost of ownership.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge more but often provide superior products and customer service.

-

Incoterms: Understanding Incoterms is essential for international transactions. These terms define responsibilities regarding shipping, insurance, and tariffs, impacting the final price.

What Are the Best Practices for Negotiating Gas Surfboard Prices?

To ensure cost-efficiency when sourcing gas surfboards, consider the following tips:

-

Research Market Prices: Familiarize yourself with the market to understand the average prices for different models. This knowledge will empower you during negotiations.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication can foster trust and mutual benefits.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, repairs, and operational costs. A slightly higher upfront cost may yield savings in the long run if the board is more durable and requires less maintenance.

-

Be Clear About Requirements: Clearly communicate your needs regarding specifications and quantity to avoid misunderstandings that could lead to unexpected costs.

-

Explore Financing Options: Some suppliers may offer financing plans or leasing options, which can make the upfront costs more manageable.

How Can International Buyers Navigate Pricing Nuances?

For B2B buyers from regions like Africa, South America, the Middle East, and Europe, there are specific nuances to consider:

-

Currency Fluctuations: Be aware of exchange rates, as they can significantly impact the final cost. Consider negotiating prices in a stable currency or locking in rates where possible.

-

Cultural Considerations: Understanding the cultural context of your supplier can enhance negotiations. This includes recognizing local holidays, business practices, and communication styles.

-

Compliance and Regulations: Familiarize yourself with import regulations and compliance standards in your country. This knowledge can prevent costly delays and ensure that the products meet necessary legal requirements.

Disclaimer

The prices referenced in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific order details. Always consult with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing gas surfboard With Other Solutions

When evaluating options for motorized surfing experiences, it’s essential to explore alternatives to gas surfboards. The market offers various solutions that can cater to different needs and preferences, including electric surfboards and traditional paddle boards. This analysis will compare these alternatives based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Gas Surfboard | Electric Surfboard | Traditional Paddle Board |

|---|---|---|---|

| Performance | High speeds (up to 63 km/h) | Moderate speeds (up to 30 km/h) | Variable, depends on user’s strength |

| Cost | $4,700 – $15,990 USD | $2,000 – $12,000 USD | $300 – $2,000 USD |

| Ease of Implementation | Requires fuel and maintenance | Simple charging; minimal setup | Easy to use; no setup required |

| Maintenance | Regular maintenance needed; parts availability can be an issue | Low maintenance; battery replacement needed | Minimal maintenance; typically durable |

| Best Use Case | Adventure seekers in varied water conditions | Casual riders, lakes, and calm waters | Fitness enthusiasts and casual users |

What Are the Pros and Cons of Electric Surfboards as an Alternative to Gas Surfboards?

Electric surfboards provide a quieter and more environmentally friendly option compared to gas surfboards. They are ideal for users who may not want to deal with the noise and emissions of a gas engine. Furthermore, they typically require less maintenance, as there are no fuel components to manage. However, the trade-off is that electric surfboards often have lower top speeds and limited riding time due to battery life, making them less suitable for high-adrenaline adventures.

How Do Traditional Paddle Boards Compare with Gas Surfboards?

Traditional paddle boards are the most cost-effective option and are accessible to a wide range of users. They require no fuel or battery, making them easy to use and maintain. Paddle boarding also promotes physical fitness and can be enjoyed in various water conditions. However, they lack the speed and thrill offered by gas surfboards, making them less appealing to those seeking an adrenaline rush. Additionally, they require physical exertion, which may deter some potential users.

Conclusion: Which Surfboard Solution Is Right for Your Business Needs?

When selecting the best surfboard solution for your business, consider your target audience and their preferences. If your clientele is composed of thrill-seekers looking for high-speed experiences, gas surfboards may be the best fit despite higher costs and maintenance needs. Conversely, if you are targeting casual users or eco-conscious consumers, electric surfboards could provide an attractive option with lower operational costs. For businesses focused on fitness or wellness, traditional paddle boards could be an ideal, budget-friendly solution. Ultimately, understanding the unique needs of your market will guide you in choosing the right product to maximize customer satisfaction and business success.

Essential Technical Properties and Trade Terminology for gas surfboard

What Are the Key Technical Properties of Gas Surfboards?

Gas surfboards, also known as motorized surfboards, are designed for performance and durability in various water conditions. Understanding their technical properties is crucial for B2B buyers looking to invest in these innovative products.

1. Material Composition: Why Does It Matter?

The most common materials used in gas surfboard construction are carbon fiber and fiberglass. Carbon fiber offers a superior strength-to-weight ratio, making the boards lightweight yet robust. This is critical for performance, as lighter boards are easier to maneuver and accelerate faster. For B2B buyers, selecting a board with high-quality materials ensures longevity and reduced maintenance costs, which are significant factors for operational efficiency.

2. Engine Specifications: What Should Buyers Know?

Gas surfboards typically feature two-stroke or four-stroke engines. The engine displacement, often measured in cubic centimeters (cc), indicates the power output. For example, a 110cc engine can deliver speeds up to 63 km/h, making it essential for thrill-seekers. Buyers should evaluate engine performance in relation to their target market’s needs, such as recreational use or competitive racing, to ensure they are meeting customer expectations.

3. Fuel Efficiency and Range: How Do They Impact Usage?

Fuel tank capacity and fuel efficiency directly affect the riding range of a gas surfboard. For instance, a board with a 3.5-liter fuel tank may provide an extended ride time of up to 90 minutes. Understanding these specifications is vital for B2B buyers, as they can influence customer satisfaction and repeat purchases. Boards with higher fuel efficiency can appeal to environmentally conscious consumers and those looking to reduce operational costs.

4. Weight Capacity: Why Is It Important for Performance?

Weight capacity is another critical property, usually ranging from 120 kg to 265 lbs. This specification determines how many users can ride the board and the types of riders it can accommodate. Buyers should consider their target demographic when selecting boards, as a higher weight capacity allows for more versatile use, appealing to a broader audience.

5. Speed and Acceleration: How Do They Enhance Experience?

Maximum speed capabilities, often indicated in km/h or mph, are vital for performance-oriented buyers. A gas surfboard that can reach speeds of 50 km/h or more offers an adrenaline-fueled experience, attracting thrill-seekers. Understanding speed specifications allows B2B buyers to market their products effectively, targeting specific consumer segments such as extreme sports enthusiasts.

What Trade Terms Should B2B Buyers Understand?

Navigating the gas surfboard market involves familiarizing oneself with industry-specific terminology that can significantly impact purchasing decisions.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of gas surfboards, understanding OEM relationships can be crucial for buyers looking to source high-quality components or collaborate with established brands.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential for B2B buyers as it influences inventory management and pricing strategies. Understanding MOQ helps buyers gauge their investment and aligns their purchasing strategy with market demand.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. For B2B buyers, utilizing RFQs can streamline the procurement process, ensuring they receive competitive pricing and terms from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for B2B buyers operating across borders, as they define shipping, insurance, and delivery responsibilities.

5. Warranty and Service Agreements

Warranty refers to the manufacturer’s promise regarding the quality and longevity of the product. Understanding warranty terms is essential for B2B buyers, as they can impact customer satisfaction and brand reputation. Service agreements often accompany warranties, outlining the support provided for maintenance and repairs.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they select the right gas surfboards to meet market demands and enhance customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the gas surfboard Sector

What Are the Key Market Trends Influencing the Gas Surfboard Sector?

The gas surfboard market is experiencing a notable surge, driven primarily by increasing interest in water sports and recreational activities globally. Key drivers include advancements in technology, which have led to lighter, more powerful boards, and a growing consumer base that values unique, adrenaline-inducing experiences. Notably, the demand for gas-powered surfboards is rising in regions like Africa, South America, the Middle East, and Europe, where access to diverse water bodies promotes recreational activities. Countries such as Brazil and Germany are leading markets, with emerging players in the Middle East capitalizing on the growing luxury and adventure sports sectors.

Current trends indicate a shift towards enhanced performance features, such as improved speed capabilities and longer ride times. For instance, surfboards equipped with two-stroke water-cooled engines can reach speeds of up to 63 km/h, catering to thrill-seekers. Moreover, the integration of advanced materials like carbon fiber is becoming commonplace, appealing to buyers seeking durability and lightweight options. B2B buyers are also increasingly focused on customization options, allowing them to cater to niche markets or specific consumer preferences.

How Is Sustainability Shaping the Sourcing of Gas Surfboards?

Sustainability is becoming a pivotal concern in the gas surfboard sector, influencing sourcing decisions for B2B buyers. Environmental impact assessments are essential as manufacturers face scrutiny over emissions and waste management associated with gas-powered engines. Ethical sourcing practices are gaining traction, with companies increasingly seeking suppliers who demonstrate a commitment to minimizing their carbon footprint and utilizing sustainable materials.

Additionally, the demand for ‘green’ certifications is rising among buyers. This includes the use of eco-friendly manufacturing processes and materials, such as recyclable composites and low-emission engines. B2B buyers are urged to vet suppliers for their sustainability credentials, which not only align with growing consumer expectations but also mitigate risks associated with regulatory compliance and brand reputation. By prioritizing ethical supply chains, buyers can enhance their market positioning and appeal to environmentally-conscious consumers.

What Is the Evolution of the Gas Surfboard Market?

The gas surfboard market has evolved significantly over the past few decades. Initially, surfboards were simple designs focused purely on buoyancy and maneuverability. The introduction of motorization marked a transformative phase, allowing surfers to ride in conditions previously deemed unsuitable. This evolution was propelled by technological advancements in engine design and materials, enabling boards to become lighter, faster, and more efficient.

As interest in motorized water sports surged, manufacturers began to innovate, leading to the development of specialized models that cater to various skill levels and preferences. Today, gas surfboards not only offer thrilling experiences but also represent a blend of performance and luxury, appealing to a diverse range of international buyers. This rich history provides valuable insights into current trends and future potential, particularly for B2B buyers looking to invest in high-quality, state-of-the-art surfboards.

Frequently Asked Questions (FAQs) for B2B Buyers of gas surfboard

-

How do I ensure the quality of gas surfboards when sourcing from international suppliers?

To ensure quality, conduct thorough research on potential suppliers. Request product samples to evaluate materials and craftsmanship. Look for certifications that demonstrate compliance with industry standards. Additionally, consider visiting manufacturing facilities if possible or using third-party inspection services to verify quality before bulk orders. Establish clear quality assurance protocols and maintain open communication with suppliers to address any concerns promptly. -

What are the key features to look for in a gas surfboard for commercial use?

When sourcing gas surfboards, prioritize features such as engine performance, weight capacity, and material durability. Boards made from lightweight yet strong materials like carbon fiber enhance maneuverability and longevity. Additionally, consider the maximum speed and ride time to meet your business needs. It’s essential to assess the board’s adaptability to various water conditions, ensuring it can perform well in diverse environments. -

What is the average lead time for bulk orders of gas surfboards from international suppliers?

The lead time for bulk orders can vary significantly based on the supplier’s location and production capacity. Typically, expect 4 to 12 weeks for production and shipping. Factors such as order size, customization options, and seasonal demand can also influence delivery times. To avoid delays, establish timelines with suppliers upfront and factor in additional time for customs clearance, particularly for international shipments. -

What are the minimum order quantities (MOQ) when purchasing gas surfboards?

MOQs for gas surfboards can range from as low as 5 units to over 50 units, depending on the manufacturer. Some suppliers may offer lower MOQs for new customers or trial orders, while established brands might require higher quantities to justify production costs. It’s advisable to discuss your specific needs with suppliers to negotiate favorable terms that align with your business strategy. -

How can I customize gas surfboards to suit my brand’s needs?

Customization options typically include branding elements like logos, color schemes, and specific performance features. Discuss your requirements with suppliers to explore available customization options, which may also involve alterations to design or technical specifications. Ensure that the supplier has experience with custom orders and can provide samples or mock-ups to visualize your branding before finalizing the order. -

What payment terms should I expect when sourcing gas surfboards internationally?

Payment terms can vary by supplier but typically include options such as a deposit (often 30-50%) with the balance due before shipping. Some suppliers may offer letters of credit or payment through escrow services for added security. It’s crucial to clarify these terms upfront and ensure they align with your cash flow management. Additionally, consider discussing potential discounts for upfront payments or larger orders. -

What logistics considerations should I keep in mind when importing gas surfboards?

When importing gas surfboards, account for shipping methods, customs duties, and insurance. Choose a reliable freight forwarder experienced with handling sporting goods to navigate logistics smoothly. Understand the import regulations specific to your country, including safety and environmental standards for motorized equipment. Additionally, plan for potential delays in customs and ensure all documentation is in order to expedite the process. -

How do I vet suppliers to ensure reliability and quality in gas surfboard production?

Begin by researching suppliers’ backgrounds, including their production history and customer reviews. Request references from previous clients to gauge reliability. Use platforms like Alibaba or Global Sources to find verified suppliers and check for certifications such as ISO standards. Additionally, engage in direct communication to assess responsiveness and willingness to provide information, which can indicate their commitment to customer service and quality assurance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Gas Surfboard Manufacturers & Suppliers List

1. JETSURF – Adventure DFI

Domain: jetsurfusa.com

Registered: 2017 (8 years)

Introduction: {“products”:[{“name”:”JETSURF Adventure DFI”,”price”:”$12,490.00 USD”},{“name”:”JETSURF Adventure DFI PLUS”,”price”:”$14,490.00 USD”,”original_price”:”$15,490.00 USD”},{“name”:”JETSURF Cruiser DFI”,”price”:”$15,490.00 USD”},{“name”:”JETSURF Titanium DFI SL”,”price”:”$15,990.00 USD”},{“name”:”JETSURF Race DFI SL”,”price”:”$13,490.00 USD”}]}

2. KOOTU – P1 Motorized Surfboard

Domain: kootubike.com

Registered: 2021 (4 years)

Introduction: {“product_name”:”KOOTU P1 Motorized Surfboard”,”type”:”Gas Powered Surfboard”,”price”:”Regular price: $5,599.00, Sale price: $4,699.00, Save: $900.00″,”color_options”:[“Black red”,”White”],”features”:{“engine_type”:”Two-stroke water-cooled engine”,”max_speed”:”Up to 55 km/h”,”ride_time”:”90 minutes”,”material”:”Carbon fiber”},”availability”:”In stock”}

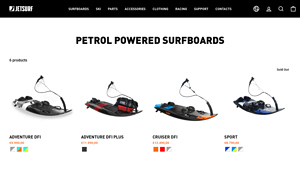

3. Jetsurf – Adventure DFI

Domain: jetsurf.com

Registered: 2000 (25 years)

Introduction: {“products”:[{“name”:”ADVENTURE DFI”,”price”:”€9.990,00″,”colors”:[“White”,”Grey”,”Fluo Orange”,”Mint”,”Fluo Yellow”]},{“name”:”ADVENTURE DFI Plus”,”price”:”€11.990,00″,”colors”:[“Carbon”]},{“name”:”CRUISER DFI”,”price”:”€12.490,00″,”colors”:[“Fluo orange”,”Fluo red”,”White”,”Grey”]},{“name”:”SPORT”,”price”:”€8.790,00″,”colors”:[“Perfect Blue”,”White”,”Fluo Yellow”,”Blue”,”White”,”Grey”]},{“name”:…

Strategic Sourcing Conclusion and Outlook for gas surfboard

In the rapidly evolving market for gas surfboards, strategic sourcing plays a pivotal role in ensuring that international B2B buyers can capitalize on the unique advantages these products offer. With a range of options available, from high-performance racing boards to versatile recreational models, buyers must prioritize quality, durability, and after-sales support when selecting suppliers. The increasing popularity of gas-powered surfboards across diverse regions—including Africa, South America, the Middle East, and Europe—highlights the growing demand for innovative water sports equipment.

Investing in gas surfboards not only enhances recreational offerings but also taps into a lucrative niche in the outdoor adventure market. As manufacturers continue to innovate with lightweight materials and efficient engines, buyers should stay attuned to emerging trends and technologies that can elevate their product offerings.

Looking ahead, international buyers are encouraged to forge partnerships with reliable suppliers who provide comprehensive support, including maintenance and warranty services. By leveraging strategic sourcing, businesses can secure a competitive edge in this exciting market. Now is the time to explore the potential of gas surfboards and position your company as a leader in the water sports industry.