Is Your Ac Compressor Scrap Price Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for ac compressor scrap price

In the ever-evolving landscape of global trade, sourcing AC compressor scrap prices has become a critical challenge for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Fluctuating prices, coupled with varying local regulations and market demands, can make it difficult for businesses to navigate this niche market effectively. This guide aims to empower buyers by providing a comprehensive overview of the AC compressor scrap market, including types of compressors, their applications, and key factors influencing pricing.

As you delve into this resource, you will gain insights into the different grades and qualities of AC compressor scrap, which can significantly impact your purchasing decisions. Additionally, we will address the importance of vetting suppliers to ensure quality and reliability in your transactions, thus minimizing risks associated with scrap procurement.

Understanding the nuances of AC compressor scrap pricing will allow you to make informed decisions that align with your business goals. Whether you are operating in Brazil, Saudi Arabia, or any other global market, this guide is designed to equip you with the knowledge needed to optimize your sourcing strategies and maximize profitability. By the end of this guide, you will be well-prepared to navigate the complexities of the AC compressor scrap market with confidence.

Understanding ac compressor scrap price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sealed Units | Heavy, difficult to open; contains an electric motor. | HVAC systems, refrigeration, and appliance repairs. | Pros: Higher copper content; Cons: Lower price than motors. |

| Aluminum Compressors | Lightweight, aluminum casing; often less valuable than steel units. | Automotive, HVAC, and recycling industries. | Pros: Easier to transport; Cons: Lower scrap value. |

| Copper Wound Compressors | Contains significant copper wire; usually requires oil removal. | Electrical contractors, HVAC maintenance. | Pros: High copper value; Cons: Requires proper disposal of oil. |

| Industrial Compressors | Larger units from industrial applications; typically heavier. | Manufacturing and heavy machinery sectors. | Pros: Higher scrap weight; Cons: Difficult to handle and transport. |

| Residential Compressors | Smaller, lightweight units from home appliances; often pre-used. | Appliance recycling, home repair services. | Pros: Easy to source; Cons: Lower individual value. |

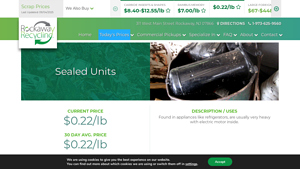

What Are Sealed Units and Their Scrap Value?

Sealed units, commonly known as compressors, are characterized by their heavy weight and challenging structure, which includes an electric motor encased in steel. These units are typically utilized in HVAC systems and refrigeration applications. B2B buyers should consider that while sealed units may offer a higher copper content, they usually command a lower price than electric motors due to their cumbersome nature and processing requirements.

How Do Aluminum Compressors Differ in Scrap Pricing?

Aluminum compressors are distinguished by their lightweight aluminum casings, making them easier to transport compared to heavier steel units. They are primarily found in the automotive and HVAC sectors. Buyers in these industries should note that while aluminum compressors are easier to handle, their scrap value tends to be lower, which may impact overall profitability in large-scale recycling operations.

What Are the Benefits of Copper Wound Compressors?

Copper wound compressors are valuable due to the significant amount of copper wire they contain. This type of compressor requires proper oil removal to maximize scrap value and is often found in HVAC maintenance and electrical contracting. B2B buyers should prioritize sourcing these units as they offer a higher return, albeit with the added responsibility of environmentally safe oil disposal.

Why Are Industrial Compressors Valuable for Scrap?

Industrial compressors are larger units commonly sourced from manufacturing and heavy machinery applications. Their substantial weight can lead to higher scrap values, making them appealing to B2B buyers in these sectors. However, the challenges of handling and transportation should be carefully considered, as they can incur additional costs and logistical complexities.

What Should Buyers Know About Residential Compressors?

Residential compressors are typically smaller and lighter, sourced from home appliances such as refrigerators and air conditioning units. They are relatively easy to find and source, making them a convenient option for appliance recycling and home repair services. However, buyers should be aware that the individual scrap value of these units is generally lower, which may affect profitability when dealing with larger quantities.

Key Industrial Applications of ac compressor scrap price

| Industry/Sector | Specific Application of ac compressor scrap price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC and Refrigeration | Recycling of old AC compressors for parts | Cost savings on new components, reduced waste, and sustainability | Ensure proper oil drainage and compliance with local regulations |

| Manufacturing | Raw material for metal fabrication | Lower raw material costs and enhanced supply chain efficiency | Assess quality and type of metal for specific manufacturing needs |

| Automotive | Production of automotive air conditioning units | Access to affordable, high-quality components for vehicle repairs | Verify compatibility with existing systems and quality standards |

| Construction | Use in HVAC systems for buildings | Improved energy efficiency and reduced installation costs | Source from reliable suppliers to ensure quality and reliability |

| Metal Recycling | Sale of scrap metal to recycling facilities | Revenue generation from scrap sales and environmental benefits | Understand market rates and demand for scrap materials in the region |

How is ‘ac compressor scrap price’ Used in HVAC and Refrigeration Industries?

In the HVAC and refrigeration sectors, the scrap price of AC compressors is pivotal for recycling old units. Businesses can dismantle compressors to recover valuable materials, such as copper and steel, which are then reused in new products. This practice not only reduces waste but also significantly lowers the costs associated with purchasing new components. International buyers must ensure that the compressors are properly drained of oil to comply with environmental regulations, particularly in regions like Africa and South America where regulations may vary.

What Role Does ‘ac compressor scrap price’ Play in Manufacturing?

Manufacturers often utilize the scrap price of AC compressors to acquire raw materials at a lower cost. The metals extracted from these units can be repurposed in various manufacturing processes, enhancing supply chain efficiency and reducing reliance on virgin materials. For businesses in Europe and the Middle East, sourcing high-quality scrap that meets specific material standards is essential to maintain product integrity and performance. Companies should prioritize suppliers who can guarantee the quality and type of metals required for their operations.

How Can the Automotive Sector Benefit from ‘ac compressor scrap price’?

In the automotive industry, the scrap price of AC compressors can provide an economical source of parts for air conditioning systems. By recycling these compressors, automotive businesses can access high-quality components for repairs at a fraction of the cost of new parts. Buyers, particularly in regions like Brazil and Saudi Arabia, should ensure that the recycled parts meet compatibility and quality standards to avoid issues in vehicle performance and safety.

What are the Advantages of Using ‘ac compressor scrap price’ in Construction?

Construction companies can leverage the scrap price of AC compressors when installing HVAC systems in new buildings. By using recycled components, these businesses can achieve better energy efficiency and lower installation costs. International buyers should consider sourcing from reputable suppliers who can provide reliable and quality components, which is crucial for maintaining the longevity and effectiveness of HVAC systems in diverse climates.

How Does ‘ac compressor scrap price’ Contribute to Metal Recycling Efforts?

The scrap price of AC compressors plays a significant role in the metal recycling industry by providing a steady stream of recyclable materials. Companies engaged in metal recycling can profit from the sale of these materials while contributing to environmental sustainability. Understanding market rates and regional demand is essential for businesses looking to maximize their revenue from scrap sales, especially in emerging markets where recycling practices are rapidly evolving.

3 Common User Pain Points for ‘ac compressor scrap price’ & Their Solutions

Scenario 1: Fluctuating Scrap Prices Create Uncertainty for Buyers

The Problem: B2B buyers often struggle with the volatility of scrap prices for AC compressors, which can vary significantly based on geographic location and market demand. This unpredictability can make it challenging for businesses to budget effectively and forecast profit margins. For example, a buyer in Brazil might find that the price for scrap AC compressors fluctuates from $0.09 to $0.20 per pound within a matter of weeks, complicating purchasing decisions and inventory management.

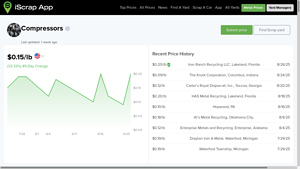

The Solution: To navigate this issue, buyers should establish relationships with multiple local scrap yards to gain insights into current market trends. Regular communication with these vendors can help buyers stay updated on price changes and negotiate better rates. Additionally, leveraging technology, such as scrap price tracking apps, can provide real-time updates on scrap values, enabling informed decision-making. By staying proactive and informed, businesses can adjust their purchasing strategies to align with price fluctuations, ensuring they maximize profitability.

Scenario 2: Environmental Regulations Complicate Disposal Processes

The Problem: Many international buyers face challenges related to environmental regulations when disposing of AC compressors, particularly concerning the proper handling and disposal of oils and refrigerants contained within these units. For instance, a company in Saudi Arabia might be unaware of local laws requiring that these substances be drained and processed by certified professionals, leading to potential fines and environmental damage.

The Solution: To mitigate this risk, buyers should invest in training and resources to understand local environmental regulations thoroughly. Establishing partnerships with certified waste management companies can ensure compliance while also facilitating the safe disposal of hazardous materials. Additionally, buyers can create standard operating procedures (SOPs) for their teams that detail the necessary steps for environmentally responsible disposal. By prioritizing compliance and environmental responsibility, businesses can not only avoid legal repercussions but also enhance their reputation in the marketplace.

Scenario 3: Difficulty in Finding Reliable Buyers for Scrap Compressors

The Problem: B2B buyers often encounter difficulties in locating reliable buyers for their scrap AC compressors, especially when dealing with large quantities. This challenge is particularly evident in regions with less developed scrap markets, such as parts of South America, where buyers might struggle to find companies willing to purchase their materials at competitive rates.

The Solution: To address this issue, buyers should consider diversifying their sales channels. Engaging with international scrap brokers or utilizing online marketplaces can expand their reach and improve their chances of finding reliable buyers. Additionally, participating in local and international trade shows can help establish connections with potential buyers and industry peers. Forming cooperative networks with other businesses facing similar challenges can also lead to collective bargaining power, allowing them to negotiate better terms and prices for their scrap materials. By broadening their approach to selling scrap, buyers can enhance their market access and achieve better financial outcomes.

Strategic Material Selection Guide for ac compressor scrap price

What Are the Key Materials Impacting AC Compressor Scrap Prices?

When considering AC compressor scrap prices, several materials play a crucial role in determining both the value and the marketability of the scrap. Below, we analyze four common materials found in AC compressors: copper, aluminum, steel, and plastic. Each material has unique properties, advantages, disadvantages, and implications for international buyers.

Copper: The Premium Scrap Material

Key Properties:

Copper is known for its excellent thermal and electrical conductivity, making it vital in compressor applications where efficient heat exchange is necessary. It also exhibits good corrosion resistance, particularly in moist environments.

Pros & Cons:

The primary advantage of copper is its high market value, which often leads to better scrap prices. However, copper can be more expensive to source and process, which may increase overall costs. Additionally, its extraction and recycling processes can be complex and energy-intensive.

Impact on Application:

Copper’s compatibility with various refrigerants and its ability to withstand high pressures make it ideal for use in AC compressors. However, its high cost may deter some manufacturers from using it in lower-end models.

International Considerations:

For buyers in regions like Africa and South America, compliance with local regulations regarding copper recycling is essential. Standards such as ASTM and DIN may apply, influencing sourcing decisions.

Aluminum: The Lightweight Alternative

Key Properties:

Aluminum is lightweight and has good thermal conductivity, although not as high as copper. It is also resistant to corrosion, particularly when anodized.

Pros & Cons:

Aluminum’s lower cost compared to copper makes it an attractive option for manufacturers looking to reduce production costs. However, it is less durable under high pressure and can be more prone to fatigue over time, potentially affecting the longevity of the compressor.

Impact on Application:

Aluminum is suitable for applications where weight reduction is essential, such as in portable or automotive air conditioning systems. However, its lower pressure ratings may limit its use in high-performance applications.

International Considerations:

Aluminum scrap is widely accepted in international markets, but buyers should be aware of varying standards for aluminum grades. Compliance with local recycling laws is also crucial, especially in Europe and the Middle East.

Steel: The Structural Backbone

Key Properties:

Steel is known for its strength and durability, making it suitable for the structural components of AC compressors. It can withstand high pressures and temperatures, which is critical for compressor performance.

Pros & Cons:

The primary advantage of steel is its low cost and availability. However, it is heavier than aluminum and copper, which may be a disadvantage in applications where weight is a concern. Additionally, steel can be prone to rust if not properly treated.

Impact on Application:

Steel is often used in the casing and support structures of compressors, providing necessary strength. Its weight can impact the overall design and efficiency of portable units.

International Considerations:

Steel scrap is generally accepted globally, but buyers should ensure that they are sourcing from compliant suppliers. Standards like JIS and ASTM are important for ensuring quality and consistency.

Plastic: The Insulating Component

Key Properties:

Plastic is used primarily for insulation and housing components in AC compressors. It is lightweight and resistant to corrosion, making it suitable for various environmental conditions.

Pros & Cons:

The advantage of plastic is its low cost and ease of manufacturing. However, it is not as durable as metals and may degrade over time, especially under high temperatures.

Impact on Application:

Plastic components are crucial for insulation and safety, but their lower durability can limit the lifespan of the compressor.

International Considerations:

Different regions have varying regulations regarding plastic recycling, particularly in Europe, where compliance with environmental standards is stringent.

Summary Table of Key Materials for AC Compressor Scrap Prices

| Material | Typical Use Case for ac compressor scrap price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical wiring and heat exchangers | High conductivity and corrosion resistance | High cost and complex recycling | High |

| Aluminum | Housing and lightweight components | Lower cost and lightweight | Lower pressure ratings and durability | Medium |

| Steel | Structural components and casings | Strength and low cost | Heavier and prone to rust | Low |

| Plastic | Insulation and housing | Lightweight and corrosion-resistant | Lower durability and temperature sensitivity | Low |

This analysis provides a comprehensive overview of the materials impacting AC compressor scrap prices, equipping international B2B buyers with the knowledge necessary for informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for ac compressor scrap price

What Are the Key Stages in the Manufacturing Process of AC Compressors?

The manufacturing process of AC compressors involves several critical stages that ensure the final product meets quality and performance standards. Understanding these stages can help B2B buyers assess potential suppliers more effectively.

Material Preparation: What Materials Are Used in AC Compressors?

The first stage is material preparation, where high-quality raw materials are sourced. Common materials include steel for the casing, copper for windings, and various alloys for internal components. The selection of materials is crucial, as they impact the durability and efficiency of the compressor. Suppliers often employ advanced sourcing strategies to ensure they use materials that meet international standards.

Forming: How Are AC Compressors Shaped?

The next stage is forming, where materials are shaped into the necessary components. Techniques such as stamping, die-casting, and machining are commonly used. For instance, steel casings may be stamped into shape, while copper windings are formed using precision winding machines. This stage requires skilled labor and sophisticated machinery to ensure accuracy and consistency in dimensions.

Assembly: What Are the Steps in Assembling AC Compressors?

Assembly is where individual components come together to form the complete compressor unit. This stage typically involves fitting the motor, connecting the electrical components, and sealing the unit to ensure no leaks occur. Assembly lines may use automated systems for efficiency, but manual checks are essential to maintain quality. Each unit is tested for proper fit and function during this phase.

Finishing: What Finishing Techniques Are Applied?

The final stage is finishing, which includes surface treatment, painting, and quality checks. Finishing techniques may involve powder coating or galvanizing to enhance corrosion resistance. This stage is crucial for aesthetic appeal and longevity. After finishing, compressors undergo rigorous testing to ensure they meet performance specifications.

What Quality Control Standards Are Relevant for AC Compressors?

Quality control (QC) is vital in ensuring that AC compressors are manufactured to high standards. B2B buyers should be familiar with the relevant international and industry-specific standards that suppliers must adhere to.

Which International Standards Should Buyers Look For?

ISO 9001 is one of the most recognized quality management standards globally, applicable across various industries, including manufacturing. It emphasizes continuous improvement and customer satisfaction. Buyers should ensure that their suppliers are certified to this standard, as it indicates a commitment to maintaining quality throughout the manufacturing process.

What Industry-Specific Certifications Should Be Considered?

In addition to ISO 9001, specific industry certifications such as CE marking (for compliance with European health and safety standards) and API (American Petroleum Institute) standards for compressors used in oil and gas applications can be significant. These certifications ensure that the products meet specific performance and safety requirements, which can be crucial for international transactions.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control is not a one-time event but a continuous process throughout manufacturing. Several checkpoints are critical in maintaining quality standards.

How Is Incoming Quality Control (IQC) Conducted?

Incoming Quality Control (IQC) involves inspecting raw materials and components before they enter the production process. This step ensures that all materials meet specified standards and are free from defects. Suppliers often employ specialized personnel and equipment for this purpose, including visual inspections and material testing.

What Is In-Process Quality Control (IPQC)?

In-Process Quality Control (IPQC) occurs during the manufacturing stages. Regular inspections and tests are conducted to monitor the production process, ensuring that each component is manufactured correctly. Techniques such as statistical process control (SPC) are often used to identify variations in the production process and correct them in real-time.

What Does Final Quality Control (FQC) Entail?

Final Quality Control (FQC) is the last checkpoint before the product is shipped. It includes comprehensive testing of the finished compressors to ensure they meet performance specifications. Common tests include pressure tests, noise level assessments, and efficiency evaluations. This stage is critical for ensuring customer satisfaction and minimizing returns.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are some effective methods to achieve this.

What Role Do Audits Play in Supplier Verification?

Conducting supplier audits is an effective way to assess quality control processes. These audits can be internal or third-party evaluations that examine the supplier’s manufacturing practices, quality control checkpoints, and adherence to standards. Audits can reveal potential weaknesses in the supplier’s processes and provide insights into their overall quality management system.

How Can Buyers Utilize Quality Reports?

Suppliers often provide quality reports detailing their QC processes and results. These reports may include information on testing methods, pass/fail rates, and corrective actions taken for any identified issues. Buyers should request these reports to gain a deeper understanding of the supplier’s commitment to quality.

What Are the Benefits of Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing and quality control processes. These inspections can be particularly beneficial for buyers in regions where local standards may differ from international expectations. Third-party inspectors can verify compliance with relevant standards and ensure that the products meet the buyer’s specifications before shipment.

What Unique QC Considerations Exist for International Buyers?

B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of specific QC nuances when engaging with suppliers.

How Do Regional Standards Impact Quality Control?

Different regions may have varying quality standards and regulations. Buyers should familiarize themselves with local regulations in the supplier’s country, as compliance with these regulations is often mandatory. Understanding these nuances can help buyers avoid potential legal issues and ensure product acceptance in their markets.

What Are the Challenges of Language and Cultural Differences?

Language barriers and cultural differences can pose challenges in communicating quality expectations. Buyers should establish clear communication channels and consider working with suppliers who have experience in international trade. This can facilitate smoother transactions and ensure that quality expectations are understood and met.

Conclusion

Understanding the manufacturing processes and quality assurance practices for AC compressors is crucial for B2B buyers aiming to make informed purchasing decisions. By focusing on material preparation, forming, assembly, finishing, and the associated quality control standards, buyers can better assess suppliers and ensure that they receive high-quality products that meet international standards. Engaging in thorough supplier verification processes, including audits and quality reports, can further enhance confidence in the purchasing decision.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ac compressor scrap price’

Introduction

Navigating the market for AC compressor scrap can be complex, especially for international B2B buyers. This checklist serves as a practical guide to help you systematically source and evaluate AC compressor scrap prices, ensuring you make informed purchasing decisions that maximize value and minimize risk.

1. Identify Your Scrap Requirements

Before engaging with suppliers, clearly outline the specifications for the AC compressor scrap you need. This includes understanding the types of compressors, their weight, and whether they need to be oil-free. Knowing your requirements will help you target the right suppliers and negotiate effectively.

2. Research Market Prices

Stay informed about the current market prices for AC compressor scrap. Prices fluctuate based on various factors, including location and demand. Use online platforms like iScrap App or Rockaway Recycling to get up-to-date pricing information, which will enable you to make competitive offers and avoid overpaying.

3. Establish Supplier Criteria

Define the criteria that potential suppliers must meet. This could include certifications, experience in the industry, and the ability to provide detailed product information. Setting these standards will streamline your selection process and ensure you work with reputable partners.

4. Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request documentation such as company profiles, references, and case studies from similar industries. This step is essential to verify their credibility and assess their capacity to meet your needs reliably.

5. Request Samples and Inspect Quality

Whenever possible, request samples of the AC compressor scrap before finalizing a deal. Inspect the samples for quality and compliance with your specifications. This step is crucial to ensure you are sourcing high-quality materials, which can significantly impact your resale value.

6. Negotiate Terms and Pricing

Once you have identified a suitable supplier, negotiate the terms of the contract. Discuss pricing, payment terms, delivery schedules, and any warranties on the quality of the scrap. Effective negotiation can lead to better pricing and terms that align with your business needs.

7. Plan for Logistics and Compliance

Finally, ensure you have a logistics plan in place for transporting the scrap. This includes understanding any regulatory requirements for importing scrap materials in your region. Compliance with local laws is vital to avoid potential fines and ensure a smooth procurement process.

By following this step-by-step checklist, B2B buyers can effectively source AC compressor scrap, ensuring they secure the best prices and maintain high standards in their procurement processes.

Comprehensive Cost and Pricing Analysis for ac compressor scrap price Sourcing

What Are the Key Cost Components Influencing AC Compressor Scrap Prices?

When sourcing AC compressor scrap, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The intrinsic value of the materials in the compressors, such as copper and steel, significantly affects pricing. Copper wire, often found inside compressors, commands high prices in the scrap market. As of late 2025, copper prices are notably fluctuating, impacting the overall scrap price.

-

Labor: Labor costs for dismantling, sorting, and processing compressors contribute to the total cost. Efficient labor practices can help reduce overall expenses.

-

Manufacturing Overhead: This includes costs related to equipment maintenance, utilities, and other indirect costs associated with the recycling process.

-

Tooling: Specialized tools may be required for the efficient extraction of valuable components from compressors, adding to the initial investment.

-

Quality Control (QC): Ensuring that the compressors are free from oil and other contaminants is crucial. Companies may incur additional costs for quality assurance measures to comply with environmental regulations.

-

Logistics: Transportation costs for moving scrap compressors to recycling facilities can vary significantly based on location and volume. International shipping may involve additional complexities, such as tariffs and customs fees.

-

Margin: Suppliers often add a margin to cover their operational risks and ensure profitability, which can vary widely based on market conditions and competition.

How Do Price Influencers Affect AC Compressor Scrap Pricing?

Several factors influence the pricing of AC compressor scrap, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically attract better pricing due to economies of scale. Buyers should consider consolidating shipments to maximize cost efficiency.

-

Specifications/Customization: Specific requirements for compressor types, sizes, or conditions can lead to price variations. Customization may incur additional costs, but it can also result in higher quality products.

-

Materials: The quality and type of materials within the compressors directly influence scrap value. Compressors with higher copper content will generally fetch better prices.

-

Quality/Certifications: Compressors that meet specific quality standards or certifications may command higher prices. Buyers should verify the certifications of suppliers to ensure compliance with their regional regulations.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer better quality and service, which can justify higher costs.

-

Incoterms: Understanding the terms of shipping and delivery is essential for calculating total costs. Incoterms dictate who is responsible for shipping, insurance, and tariffs, which can affect the final price.

What Tips Can Buyers Utilize for Cost-Efficiency in AC Compressor Scrap Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Engage in thorough negotiations with suppliers to secure the best prices. Be prepared to discuss volume, payment terms, and delivery conditions to reach a mutually beneficial agreement.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront price. Consider long-term implications, such as maintenance, processing, and potential resale value of the scrap.

-

Pricing Nuances: Be aware of seasonal fluctuations in scrap prices. Timing your purchases can lead to significant savings, especially when copper prices are lower.

-

Market Research: Regularly monitor market trends and prices through resources like scrap metal pricing platforms. This knowledge will empower buyers to make informed purchasing decisions.

-

Local Insights: Understanding local market conditions and regulations can provide a competitive edge. Engage with local scrap yards and recycling companies to gain insights on pricing and logistics.

Disclaimer on Indicative Prices

The prices referenced in this analysis are indicative and subject to change based on market fluctuations, regional differences, and supplier negotiations. Buyers should conduct due diligence and consult multiple sources to obtain accurate and current pricing information tailored to their specific needs.

Alternatives Analysis: Comparing ac compressor scrap price With Other Solutions

Introduction: Evaluating Alternatives to AC Compressor Scrap Price

In the ever-evolving landscape of industrial materials recycling, understanding the various options available to B2B buyers is critical. The price of AC compressor scrap serves as a key metric for businesses involved in HVAC and refrigeration systems. However, it is essential to consider alternative solutions that may offer similar benefits, whether they are more profitable, easier to implement, or environmentally friendly. This analysis compares AC compressor scrap price against two viable alternatives: recycling of electric motors and repurposing of used compressors for refurbishment.

Comparison Table

| Comparison Aspect | Ac Compressor Scrap Price | Electric Motor Recycling | Refurbished Compressors |

|---|---|---|---|

| Performance | Moderate (based on weight and metal content) | High (due to copper and steel content) | High (fully functional) |

| Cost | $0.15/lb to $0.40/lb | $0.30/lb to $1.20/lb | $400/MT CIF ASWP |

| Ease of Implementation | Easy (local scrap yards available) | Moderate (requires sorting) | Moderate (requires refurbishment process) |

| Maintenance | Minimal (once sold) | Low (once processed) | Moderate (depends on condition) |

| Best Use Case | Quick cash for scrap metal | Profitable for heavy scrap operations | Ideal for businesses needing cost-effective replacements |

Detailed Breakdown of Alternatives

Electric Motor Recycling

Electric motors are often made with high-value materials, such as copper wiring and steel, making their scrap value higher than that of AC compressors. The performance of electric motor recycling is typically high due to the demand for copper, which remains a significant commodity in the recycling market. While the ease of implementation is moderate—requiring proper sorting and sometimes disassembly—the potential profit margins can be significantly higher. Maintenance is low once the motors are sold, and they are best suited for businesses that generate large quantities of scrap metal.

Refurbished Compressors

Refurbished compressors present an alternative that allows businesses to obtain functional equipment at a fraction of the cost of new units. The performance of refurbished compressors is high, as they are restored to operational condition and can often serve longer than new, cheaper models. However, the cost is considerably higher than scrap prices, with rates around $400/MT CIF ASWP. The ease of implementation is moderate, as it requires sourcing from reputable refurbishers. Maintenance can be variable based on the compressor’s condition at the time of refurbishment, making this option ideal for businesses needing reliable equipment without the capital expense of new purchases.

Conclusion: Choosing the Right Solution for Your Business

For B2B buyers, the choice between AC compressor scrap price and its alternatives hinges on specific operational needs and financial objectives. If immediate cash flow is critical, selling scrap compressors may be the best option. On the other hand, businesses looking to optimize their equipment procurement might find better value in refurbished compressors. Meanwhile, electric motor recycling could offer a lucrative avenue for those with larger scrap operations. Ultimately, understanding the nuances of each option will empower buyers to make informed decisions that align with their business goals.

Essential Technical Properties and Trade Terminology for ac compressor scrap price

When navigating the complexities of the AC compressor scrap market, understanding essential technical properties and trade terminology is crucial for B2B buyers. This knowledge not only aids in making informed purchasing decisions but also enhances negotiation capabilities with suppliers.

What Are the Key Technical Properties of AC Compressor Scrap?

-

Material Grade

The material grade of AC compressor scrap primarily refers to the composition of metals, such as copper, aluminum, and steel, within the compressors. High-grade materials fetch better prices in the scrap market. For instance, compressors with a higher copper content are more valuable due to copper’s demand in various industries. B2B buyers should evaluate the material grade to ensure they are securing profitable deals. -

Weight Classification

AC compressors come in various weights, typically ranging from 2 kg to 15 kg. The weight of the compressor directly impacts its scrap value, as many scrap yards price based on weight. Buyers should consider the weight classification when sourcing compressors to maximize profitability. Ensuring accurate weight documentation can also streamline the transaction process. -

Condition of the Compressor

The condition, specifically whether the compressor is fully drained of oil, affects its marketability. Oil-free compressors are preferred because they reduce environmental risks and disposal costs. Buyers should confirm the oil drainage status before purchase to avoid potential penalties associated with improper disposal. -

Brand and Model Specifications

Different brands and models of compressors can have varying scrap values based on their popularity and demand in the recycling market. Recognizing well-known brands like Danfoss or Embraco can help buyers assess potential resale value and market interest. Familiarity with specific models can also assist in better negotiation strategies. -

Cooling Capacity

The cooling capacity, measured in watts, indicates the compressor’s efficiency and performance level. Compressors with higher cooling capacities generally yield higher scrap values. Buyers should inquire about the cooling capacity to gauge the overall worth of the compressors they intend to purchase.

What Common Trade Terms Should B2B Buyers Understand?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relevance can help buyers identify the quality and reliability of compressor brands, which can influence scrap value. -

MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units a supplier is willing to sell. Buyers should be aware of MOQs to plan their procurement strategies effectively and ensure they can meet supplier requirements for pricing and availability. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. Crafting a detailed RFQ can help buyers secure competitive pricing and better understand the suppliers’ offerings, leading to more favorable deals. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for managing shipping costs, risks, and delivery responsibilities, which can significantly impact the overall pricing of AC compressor scrap. -

CIF (Cost, Insurance, and Freight)

This term indicates that the seller covers the costs of shipping, insurance, and freight to a specified destination. Buyers should be aware of CIF terms to ensure they understand the total costs involved in their transactions and avoid unexpected expenses.

By familiarizing themselves with these essential properties and trade terms, B2B buyers in the AC compressor scrap market can enhance their negotiating power, ensure compliance with industry standards, and ultimately drive profitability in their operations.

Navigating Market Dynamics and Sourcing Trends in the ac compressor scrap price Sector

What Are the Key Market Dynamics Influencing AC Compressor Scrap Prices?

The global market for AC compressor scrap is shaped by various factors, including fluctuating demand for raw materials, advancements in recycling technologies, and environmental regulations. One significant driver is the increasing demand for recycled metals, particularly copper and aluminum, which are prevalent in compressor units. This demand is further fueled by the rise in construction and manufacturing sectors across Africa, South America, the Middle East, and Europe. For instance, countries like Brazil and Saudi Arabia are investing heavily in infrastructure projects, thereby elevating the need for sustainable sourcing of materials.

Emerging technologies are also transforming sourcing strategies. The advent of digital platforms that connect scrap sellers with buyers facilitates more transparent pricing and improved logistics. B2B buyers can leverage these platforms to access real-time market data, enabling them to make informed purchasing decisions. Moreover, the growing emphasis on circular economy principles is prompting companies to seek suppliers who can provide verified scrap materials that meet specific quality and sustainability standards.

How Does Sustainability and Ethical Sourcing Influence AC Compressor Scrap Pricing?

Sustainability has become a critical consideration in the sourcing of AC compressor scrap. As businesses worldwide face increasing pressure to minimize their environmental impact, ethical sourcing practices are gaining prominence. Buyers are now more inclined to partner with suppliers who demonstrate a commitment to responsible recycling processes and adherence to environmental regulations.

The environmental impact of compressor disposal is significant, given that improper handling can lead to hazardous waste. Therefore, companies that prioritize ethical supply chains often seek out suppliers with certifications that validate their commitment to sustainability, such as ISO 14001 for environmental management systems. These certifications not only enhance the credibility of suppliers but also assure buyers that they are sourcing from environmentally responsible entities.

Additionally, the importance of proper oil drainage and recycling methods cannot be overstated. Companies that effectively manage the environmental impact of their operations can command better pricing for their scrap. As a result, B2B buyers are increasingly focusing on the sustainability credentials of their suppliers, which in turn influences the pricing and availability of AC compressor scrap.

What is the Evolution of the AC Compressor Scrap Market?

The AC compressor scrap market has evolved significantly over the years. Initially, the market was fragmented, with local scrap yards operating independently and offering varying prices based on regional demands. However, the growth of global trade and e-commerce has led to the emergence of larger, more organized players who can offer competitive pricing and improved services.

In recent years, the introduction of technology-driven platforms has further transformed the landscape, allowing buyers to access a wider range of suppliers and compare prices with ease. This shift has made it essential for suppliers to maintain transparency and provide accurate information about their products. As the market continues to grow, the focus on sustainability and ethical sourcing will likely shape future trends, compelling businesses to adapt to changing consumer expectations and regulatory requirements.

By understanding these dynamics, international B2B buyers can better navigate the complexities of the AC compressor scrap price sector, ensuring that they make informed sourcing decisions that align with both their business goals and sustainability objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of ac compressor scrap price

-

How do I find the current market price for AC compressor scrap?

To determine the current market price for AC compressor scrap, it’s advisable to contact local scrap yards or utilize online platforms like iScrap App, which provide real-time pricing information. Prices can fluctuate based on factors such as location, scrap type, and demand. Additionally, keep an eye on market trends and reports, as they can offer insights into price changes over time. -

What factors influence the price of AC compressor scrap?

The price of AC compressor scrap is influenced by several factors, including the global demand for metals, the condition of the compressors (e.g., whether they are drained of oil), and the copper content within the compressors. Seasonal fluctuations in HVAC usage can also impact pricing, as higher demand for air conditioning during summer months may lead to increased scrap generation. -

How can I verify the credibility of a supplier for AC compressor scrap?

To vet a supplier for AC compressor scrap, consider conducting a background check by looking for reviews, testimonials, and their business history. Additionally, request references from previous clients and verify their compliance with local regulations regarding scrap metal trading. Engaging in direct communication can also help assess their responsiveness and professionalism. -

What is the typical minimum order quantity (MOQ) for AC compressor scrap?

Minimum order quantities (MOQ) for AC compressor scrap can vary significantly by supplier, but many will require orders of at least 100 metric tons to ensure efficient logistics and cost-effectiveness. Always confirm the MOQ before entering negotiations, as some suppliers may offer flexibility based on the buyer’s needs or relationship with the supplier. -

What payment terms are commonly accepted for international purchases of AC compressor scrap?

Common payment terms for international purchases of AC compressor scrap may include options like letter of credit (LC), advance payment, or net payment terms (e.g., 30, 60, or 90 days). It’s crucial to discuss and agree upon payment terms upfront to avoid any misunderstandings, especially considering currency fluctuations and international transaction fees. -

How should I handle logistics and shipping for AC compressor scrap?

When managing logistics for shipping AC compressor scrap, consider partnering with a freight forwarder experienced in handling scrap materials. They can assist with containerization, customs clearance, and compliance with international shipping regulations. Ensure that you have a clear understanding of shipping costs and timelines before finalizing any agreements. -

What quality assurance measures should be in place when sourcing AC compressor scrap?

Quality assurance measures for sourcing AC compressor scrap should include inspecting the scrap for contamination, verifying the presence of copper and other valuable metals, and ensuring proper oil drainage. Requesting certifications or inspection reports from suppliers can help ensure that the scrap meets your quality standards. -

Are there specific regulations I should be aware of when importing AC compressor scrap?

Yes, importing AC compressor scrap may be subject to specific regulations that vary by country. Importers should familiarize themselves with local environmental laws and customs regulations, including documentation requirements and any potential tariffs. Consulting with a legal expert or customs broker can provide clarity on compliance and help navigate any complexities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Ac Compressor Scrap Price Manufacturers & Suppliers List

1. iScrapApp – Compressors Scrap Price

Domain: iscrapapp.com

Registered: 2010 (15 years)

Introduction: Compressors Scrap Price: $0.15/lb (33.33% change) as of September 4, 2025. Recent prices from various yards include: $0.20/lb (Iron Ranch Recycling, Lakeland, FL, 8/26/25), $0.09/lb (The Kroot Corporation, Columbus, IN, 8/24/25), $0.12/lb (Carter’s Royal Dispos-all, Toccoa, GA, 8/20/25), $0.20/lb (HAS Metal Recycling, Lakeland, FL, 8/18/25), $0.10/lb (Hopwood, PA, 8/16/25), $0.18/lb (Al’s Metal Re…

2. ScrapMonster – AC Compressors Scrap

3. Rockaway Recycling – Sealed Units/Compressors

Domain: rockawayrecycling.com

Registered: 2007 (18 years)

Introduction: {“current_price”:”$0.22/lb”,”30_day_avg_price”:”$0.22/lb”,”description”:”Found in appliances like refrigerators, usually very heavy with electric motor inside. Sealed Units/Compressors are good to save up for scrap due to their heaviness. They typically have a blackout casing made of steel and contain copper inside the electric motor. All oil must be drained before purchase.”,”historical_prices”:”…

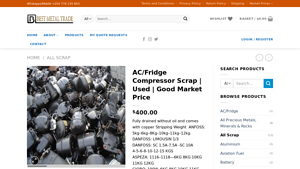

4. AC/Fridge Compressor Scrap – Used Copper Wire

Domain: bestmetaltrade.com

Registered: 2019 (6 years)

Introduction: Product Name: AC/Fridge Compressor Scrap

Condition: Used

Price: $400.00 per MT CIF ASWP

Weight Options: 5kg, 6kg, 8kg, 10kg, 11kg, 12kg (various brands)

Brands: ANFOSS, DANFOSS, ASPEZA, GIOBO, TECUMSEH, IRELEND, DENO, BOSCH

Material: Copper wire inside

Type: Electronic

Oil Status: Fully drained without oil

Packing: 20ft container holds 3000 to 3450 pcs of compressors

Minimum Order: 100 MT

Availabl…

5. Scrap Metal Forum – Air Conditioner Compressor Parts

Domain: scrapmetalforum.com

Registered: 2010 (15 years)

Introduction: Air conditioner compressors can be salvaged for parts, particularly the motor and copper. A typical window unit compressor can yield about 4-5 pounds of #2 copper and 75 pounds of steel scrap. The motor can weigh around a pound or more. Prices for scrap vary, with larger compressors fetching $3.00 each and smaller ones $1.50. The value of the copper can range from $13.00 to $18.00, making it worth…

6. ForScrap – Sealed Units Scrap

Domain: forscrap.com

Registered: 2009 (16 years)

Introduction: Buying Sealed Units – Compressors Scrap in LA. Latest price: $00.05-$00.07 per pound. Sealed units are heavy, typically made of steel, and encase electric motors. Found in home appliances (fridges, washing machines, dishwashers) and vehicles. Important to drain liquids and oils before selling. Greener Recycling offers scrap pick-up and sorting assistance for optimal recycling.

7. S S Enterprises – AC Compressor Scrap

Domain: dir.indiamart.com

Registered: 1996 (29 years)

Introduction: This company, S S Enterprises – AC Compressor Scrap, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for ac compressor scrap price

In the evolving landscape of AC compressor scrap pricing, strategic sourcing remains paramount for international buyers looking to optimize their procurement processes. The recent fluctuations in scrap prices, currently averaging around $0.15 per pound, underscore the importance of staying informed about market trends and local pricing variations. By engaging directly with scrap metal yards and utilizing platforms that provide real-time pricing updates, buyers can secure better deals and maximize their profit margins.

Moreover, the significance of sustainability cannot be overstated; responsible disposal and recycling practices not only contribute to environmental stewardship but can also enhance a company’s reputation in the global market. Buyers are encouraged to build relationships with reliable suppliers who prioritize quality and compliance with environmental regulations.

Looking ahead, the demand for scrap compressors is projected to remain robust, driven by the growing focus on recycling and resource recovery across various industries. International buyers from regions such as Africa, South America, the Middle East, and Europe should actively seek out partnerships that align with their sustainability goals and economic interests. By doing so, they can position themselves advantageously in a competitive market and contribute to a circular economy.