Is Your 4 X 8 Particle Board Price Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for 4 x 8 particle board price

In the ever-evolving landscape of global trade, sourcing 4 x 8 particle board at competitive prices presents a significant challenge for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe, including key players like Saudi Arabia and Brazil. With the demand for quality materials rising, understanding the nuances of pricing, supply chain dynamics, and product specifications is crucial for making informed purchasing decisions.

This comprehensive guide delves into various aspects of 4 x 8 particle board pricing, equipping international buyers with the knowledge needed to navigate this complex market. From different types and applications of particle board to detailed insights on supplier vetting processes, we cover all essential components that influence cost. Additionally, we will explore how regional market trends, material quality, and environmental considerations can impact pricing structures.

By providing actionable insights and a thorough understanding of the factors that contribute to price variations, this guide empowers B2B buyers to make strategic purchasing decisions. Whether you are looking to enhance your supply chain efficiencies or seeking competitive pricing options, our resource serves as a vital tool to ensure that your business remains ahead in the competitive landscape of particle board procurement.

Understanding 4 x 8 particle board price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Particle Board | Basic composition, usually 1/2″ to 3/4″ thick | Furniture, cabinetry, flooring | Pros: Cost-effective, easy to cut; Cons: Less durable, sensitive to moisture. |

| Moisture-Resistant Particle Board | Enhanced resistance to moisture and humidity | Kitchen and bathroom cabinetry | Pros: Suitable for high-moisture areas; Cons: Higher cost than standard options. |

| Fire-Retardant Particle Board | Treated to resist ignition and slow flame spread | Commercial buildings, safety applications | Pros: Increased safety compliance; Cons: More expensive and may require special handling. |

| Eco-Friendly Particle Board | Made from recycled materials, low VOC emissions | Sustainable construction projects | Pros: Environmentally friendly; Cons: Potentially higher price point. |

| High-Density Particle Board | Denser composition for better structural integrity | Heavy-duty applications, industrial use | Pros: Greater strength and durability; Cons: Heavier and may be more costly. |

What Are the Characteristics of Standard Particle Board?

Standard particle board is the most commonly used type of 4 x 8 particle board, typically available in thicknesses of 1/2″ to 3/4″. Its primary composition includes wood chips and resin, making it a cost-effective choice for various applications, including furniture and cabinetry. B2B buyers should consider its affordability and ease of handling, but also be aware of its limitations regarding moisture sensitivity and overall durability.

How Does Moisture-Resistant Particle Board Differ?

Moisture-resistant particle board is specifically designed to withstand higher humidity levels, making it ideal for environments like kitchens and bathrooms. This type of board often incorporates special additives that enhance its moisture resistance. While it offers better longevity in damp conditions, B2B buyers should factor in the higher price point compared to standard options, as well as the need for careful handling during installation.

What Makes Fire-Retardant Particle Board a Safe Choice?

Fire-retardant particle board is treated with chemicals that slow down the spread of flames, making it a suitable choice for commercial buildings and applications where safety compliance is critical. This type of board provides peace of mind for B2B buyers in industries with stringent fire safety regulations. However, buyers should be prepared for the increased cost and potential need for special handling procedures.

Why Choose Eco-Friendly Particle Board?

Eco-friendly particle board is manufactured from recycled materials and is designed to emit low levels of volatile organic compounds (VOCs). This makes it an excellent option for sustainable construction projects. B2B buyers focused on environmental impact will find this type appealing, although they may encounter a higher price point. It’s essential to assess the balance between sustainability goals and budget constraints when considering this option.

What Are the Benefits of High-Density Particle Board?

High-density particle board features a denser composition that provides superior structural integrity and durability, making it suitable for heavy-duty applications and industrial use. This type is often used in environments where strength is paramount. While it delivers enhanced performance, buyers should consider its weight and potentially higher cost, ensuring it aligns with their specific project requirements.

Key Industrial Applications of 4 x 8 particle board price

| Industry/Sector | Specific Application of 4 x 8 particle board price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Production of particle board furniture components | Cost-effective material for creating durable furniture | Quality assurance and compliance with international standards |

| Construction & Renovation | Underlayment for flooring installations | Provides a smooth, stable base for various flooring types | Moisture resistance and fire safety certifications |

| Packaging & Shipping | Use in packaging solutions for fragile items | Lightweight yet sturdy, reduces shipping costs | Custom sizing options and environmental impact assessments |

| Interior Design | Wall paneling and decorative features | Enhances aesthetic appeal while maintaining budget constraints | Availability of finishes and customization capabilities |

| DIY & Home Improvement | Crafting and home renovation projects | Versatile and easy to work with for various projects | Sourcing from reliable suppliers with competitive pricing |

How is 4 x 8 Particle Board Used in Furniture Manufacturing?

In the furniture manufacturing sector, 4 x 8 particle board is extensively used to create components like tabletops, shelving, and cabinetry. Its cost-effectiveness allows manufacturers to produce high-quality furniture without inflating production costs. International buyers, especially in regions like Africa and South America, often seek particle board that meets specific quality standards and regulations to ensure durability and safety in end products.

What Role Does 4 x 8 Particle Board Play in Construction & Renovation?

In construction and renovation, 4 x 8 particle board serves as an underlayment for flooring installations. This application is critical as it provides a smooth and stable base for various flooring types, including laminate and carpet. Buyers from the Middle East and Europe should consider moisture-resistant options, as they are essential for preventing warping and damage in humid environments.

How is 4 x 8 Particle Board Utilized in Packaging & Shipping?

The packaging and shipping industry uses 4 x 8 particle board for creating protective packaging solutions for fragile items. Its lightweight yet sturdy nature reduces shipping costs while ensuring product safety during transit. B2B buyers need to focus on custom sizing options and the environmental impact of their packaging materials, particularly in regions where sustainability is becoming increasingly important.

What Benefits Does 4 x 8 Particle Board Offer in Interior Design?

In interior design, 4 x 8 particle board is often used for wall paneling and decorative features. It provides an affordable way to enhance the aesthetic appeal of spaces while adhering to budget constraints. Buyers should pay attention to the availability of various finishes and customization capabilities to meet the design requirements of their projects, especially in competitive markets like Europe.

How is 4 x 8 Particle Board Relevant for DIY & Home Improvement Projects?

For DIY enthusiasts and home improvement projects, 4 x 8 particle board is a versatile material that can be easily cut and shaped for various applications. Its affordability makes it a popular choice for crafting furniture, shelving, and other home projects. When sourcing, buyers should look for reliable suppliers that offer competitive pricing and quality assurance to ensure successful project outcomes.

3 Common User Pain Points for ‘4 x 8 particle board price’ & Their Solutions

Scenario 1: Difficulty in Budgeting for Bulk Purchases of 4 x 8 Particle Board

The Problem:

International B2B buyers often struggle with budgeting for bulk purchases of 4 x 8 particle boards due to fluctuating prices. This can be especially challenging for businesses operating in regions like Africa and South America, where import tariffs, shipping costs, and local market volatility can lead to unexpected price surges. Buyers may find it hard to predict costs, leading to budget overruns and impacting project timelines.

The Solution:

To mitigate these budgeting issues, buyers should conduct thorough market research and establish relationships with multiple suppliers. Regularly monitoring price trends and setting up alerts for price changes can help buyers make informed purchasing decisions. Additionally, negotiating long-term contracts with suppliers can lock in prices and provide stability. Utilizing a centralized procurement system that consolidates orders across multiple projects can also lead to economies of scale, reducing overall costs. Consider using freight forwarders or local distributors who can provide insights into market conditions and help navigate additional costs associated with shipping and tariffs.

Scenario 2: Inconsistent Quality Across Suppliers

The Problem:

B2B buyers often encounter quality inconsistencies when sourcing 4 x 8 particle boards from different suppliers. Variability in density, moisture content, and thickness can lead to dissatisfaction and project delays. This is particularly problematic for businesses in the construction and furniture manufacturing sectors, where specific material properties are critical for structural integrity and end-product quality.

The Solution:

To ensure consistent quality, buyers should prioritize sourcing from reputable manufacturers that adhere to industry standards. Requesting product specifications and third-party quality assurance certifications can help verify material properties before purchase. Establishing a quality control protocol that includes inspecting samples from each shipment can also minimize risks. Additionally, collaborating with suppliers to communicate specific requirements and expectations can foster a better understanding, leading to improved consistency over time. Building long-term relationships with a select few suppliers can further ensure reliability and trust in the quality of the products received.

Scenario 3: Lack of Transparency in Pricing Structures

The Problem:

Many B2B buyers face challenges due to a lack of transparency in the pricing structures of 4 x 8 particle boards. Hidden fees, shipping costs, and variable pricing based on order volume can complicate the purchasing process. This lack of clarity often leads to confusion and mistrust between buyers and suppliers, making it difficult to make informed purchasing decisions.

The Solution:

To address this issue, buyers should demand clear and detailed pricing breakdowns from suppliers. This should include base prices, potential discounts for bulk orders, shipping fees, and any additional costs that may arise. Creating a standardized request for quotation (RFQ) template can streamline the process of comparing multiple suppliers. Additionally, utilizing e-procurement platforms can enhance transparency by providing a comprehensive view of pricing, terms, and supplier performance. Engaging in open dialogue with suppliers about pricing concerns can also foster a collaborative relationship and lead to more favorable terms. Finally, consider leveraging technology to automate procurement processes, which can help track pricing fluctuations and streamline order management.

Strategic Material Selection Guide for 4 x 8 particle board price

What Are the Key Properties of Common Materials Used in 4 x 8 Particle Board?

When selecting materials for 4 x 8 particle boards, several common options are available, each with unique properties that influence performance, cost, and suitability for various applications. Understanding these materials is crucial for international B2B buyers looking to optimize their procurement strategies.

1. Standard Particle Board

Key Properties: Standard particle board is composed of wood chips, sawmill shavings, or sawdust, bonded together with a synthetic resin or adhesive under heat and pressure. It typically has a density ranging from 600 to 800 kg/m³ and is suitable for indoor applications due to its low moisture resistance.

Pros & Cons: The primary advantage of standard particle board is its cost-effectiveness, making it an attractive option for budget-conscious projects. However, it is less durable than alternatives like MDF or plywood and can warp or swell when exposed to moisture.

Impact on Application: This material is ideal for furniture, cabinetry, and interior fixtures but is not recommended for high-moisture environments, such as kitchens or bathrooms.

Considerations for International Buyers: Buyers must ensure compliance with local regulations regarding formaldehyde emissions, particularly in regions like the EU, where strict standards (e.g., E1 or E0) are enforced.

2. Moisture-Resistant Particle Board

Key Properties: Moisture-resistant particle board is treated with additives to enhance its resistance to humidity and moisture. It typically features a higher density and improved bonding agents, allowing it to withstand more challenging environments.

Pros & Cons: The key advantage of moisture-resistant particle board is its suitability for areas prone to dampness, such as kitchens and bathrooms. However, it generally comes at a higher price point compared to standard particle board, which may impact budget considerations.

Impact on Application: This type of board is particularly beneficial for applications requiring durability in humid conditions, such as cabinetry or shelving in bathrooms.

Considerations for International Buyers: Buyers should verify that the product meets local moisture resistance standards, which can vary significantly between regions, especially in humid climates like those found in parts of Africa and South America.

3. High-Density Fiberboard (HDF)

Key Properties: HDF is made from wood fibers bonded under high pressure and temperature, resulting in a dense and durable product. It typically has a density of 800-1,200 kg/m³ and offers excellent surface smoothness.

Pros & Cons: HDF provides superior durability and is less prone to warping than traditional particle board. However, it can be more expensive and may require specialized cutting tools due to its density.

Impact on Application: This material is ideal for high-end furniture, flooring, and decorative panels, where aesthetics and durability are paramount.

Considerations for International Buyers: Compliance with international standards for emissions and durability is essential, particularly for markets in Europe and North America, where consumer preferences lean towards eco-friendly and sustainable materials.

Summary Table of Material Selection for 4 x 8 Particle Board Price

| Material | Typical Use Case for 4 x 8 Particle Board Price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Standard Particle Board | Furniture, cabinetry, interior fixtures | Cost-effective | Less durable, moisture-sensitive | Low |

| Moisture-Resistant Particle Board | Kitchen and bathroom cabinetry | Enhanced moisture resistance | Higher price point | Medium |

| High-Density Fiberboard (HDF) | High-end furniture, flooring, decorative panels | Superior durability and surface finish | More expensive, requires specialized tools | High |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on the specific needs of their projects and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 4 x 8 particle board price

What Are the Main Stages in the Manufacturing Process of 4 x 8 Particle Board?

The manufacturing of 4 x 8 particle board involves several key stages, each critical to ensuring the final product meets industry standards and customer specifications.

-

Material Preparation: This initial stage involves sourcing raw materials, primarily wood chips, sawdust, and other wood residues. These materials are selected based on their quality and suitability for particle board production. They undergo a drying process to reduce moisture content, which is vital for achieving the desired density and strength in the final product.

-

Forming: In this stage, the dried wood particles are mixed with adhesives (often urea-formaldehyde or phenol-formaldehyde) and other additives to enhance properties such as fire resistance and moisture resistance. This mixture is then formed into mats of specific dimensions. The mats are compressed under high pressure, using hot or cold pressing techniques, to bond the particles together and create a solid sheet.

-

Assembly: After pressing, the sheets are trimmed to the standard 4 x 8 dimensions. This stage may include the application of edge banding or surface finishing treatments to enhance aesthetics and durability. The sheets are then conditioned in a controlled environment to stabilize their dimensions and moisture content.

-

Finishing: Finally, the finished boards undergo surface treatments, which may include sanding and coating. This enhances their visual appeal and prepares them for various applications, such as furniture manufacturing, flooring, and cabinetry.

What Quality Control Measures Are Commonly Implemented in Particle Board Production?

Quality control (QC) is paramount in the production of 4 x 8 particle board to ensure that the final products meet international standards and customer expectations.

-

International and Industry-Specific Standards: Manufacturers often adhere to international standards such as ISO 9001 for quality management systems. In addition, regional standards like the CE marking in Europe and other certifications like the American Plywood Association (APA) standards are critical. These certifications assure buyers that the products comply with safety and environmental regulations.

-

Quality Control Checkpoints: Various checkpoints are established throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet predefined quality specifications.

– In-Process Quality Control (IPQC): During production, samples are taken to check the consistency of the mixture, adhesive application, and pressing conditions. This helps identify and rectify issues before they affect the entire production batch.

– Final Quality Control (FQC): Finished boards are tested for physical properties such as thickness, density, and moisture content. This stage also includes visual inspections for defects like warping or surface imperfections. -

Common Testing Methods: Various testing methods are employed to assess the quality of particle boards. These include:

– Mechanical Testing: Evaluating bending strength, internal bond strength, and screw holding ability.

– Moisture Content Testing: Ensuring the moisture content is within acceptable limits to prevent future warping or swelling.

– Formaldehyde Emission Testing: To comply with health regulations, particularly in markets like Europe, boards are tested for formaldehyde emissions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are several strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide firsthand insight into their manufacturing practices and quality control measures. This is an effective way to assess compliance with international standards and identify any potential risks.

-

Requesting Quality Reports: Buyers should request detailed quality assurance reports that outline the QC processes, testing results, and certifications obtained by the supplier. These documents should also include the results of any third-party inspections.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These organizations often have expertise in specific markets and can conduct comprehensive evaluations of manufacturing facilities.

-

Certification Verification: Buyers should verify that suppliers hold relevant certifications. This can often be done through the issuing bodies or industry associations that maintain databases of certified manufacturers.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

B2B buyers operating in diverse markets must navigate various quality control and certification nuances that can affect their purchasing decisions:

-

Regional Regulations: Different regions have specific regulations concerning building materials. For instance, particle boards sold in Europe must comply with the E1 standard for formaldehyde emissions, while other markets may have less stringent requirements. Understanding these regulations is crucial for compliance and market entry.

-

Cultural Expectations: Quality expectations can vary significantly across regions. Buyers in the Middle East may prioritize durability and moisture resistance due to the climate, while those in Europe may emphasize eco-friendliness and low emissions. Suppliers should be aware of these nuances to tailor their offerings accordingly.

-

Documentation and Traceability: International buyers should ensure that suppliers provide complete documentation for traceability, including raw material sources and production processes. This not only aids in compliance but also enhances transparency and trust in supplier relationships.

In conclusion, understanding the manufacturing processes and quality assurance measures for 4 x 8 particle board is vital for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring that they receive high-quality products that meet their specific needs and regional regulations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘4 x 8 particle board price’

To effectively source 4 x 8 particle board, it’s essential for B2B buyers to approach the procurement process systematically. This guide provides a step-by-step checklist to ensure that you not only find competitive pricing but also secure quality products that meet your specific needs.

Step 1: Define Your Technical Specifications

Before starting your search, clarify the specifications of the particle board you need. Consider factors such as thickness, density, and intended use (e.g., flooring, furniture, or cabinetry). Understanding these details helps you communicate effectively with suppliers and ensures you receive the right product.

Step 2: Research Market Prices

Investigate current market prices for 4 x 8 particle board across different suppliers. Check online platforms, local distributors, and industry reports to get a sense of the price range. This knowledge will empower you to negotiate better deals and identify potential overpricing from suppliers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have a proven track record in delivering quality products consistently.

- Check Certifications: Ensure the supplier meets industry standards and certifications, such as ISO or environmental regulations, which can impact product quality and safety.

- Assess Reliability: Investigate their reputation by reading reviews or seeking feedback from other businesses.

Step 4: Request Samples

Always request samples before placing a bulk order. This step allows you to assess the quality of the particle board firsthand. Evaluate the samples for properties such as durability, finish, and resistance to moisture or other environmental factors relevant to your use case.

Step 5: Negotiate Pricing and Terms

Once you have identified potential suppliers, engage in negotiations. Discuss not only the pricing but also payment terms, shipping costs, and bulk discounts. Clear communication about expectations can lead to more favorable terms and establish a solid working relationship.

Step 6: Confirm Delivery and Logistics

Ensure that you have a clear understanding of the delivery timelines and logistics involved. Discuss shipping options and potential costs upfront to avoid unexpected charges. Confirm the supplier’s ability to meet your delivery deadlines, especially if you are working on a tight project timeline.

Step 7: Establish a Long-term Relationship

After the initial purchase, consider building a long-term relationship with your supplier. Regular communication and feedback can lead to better pricing, priority service, and access to new products. Establishing trust can also facilitate smoother transactions in future orders.

By following this checklist, B2B buyers can navigate the complexities of sourcing 4 x 8 particle board effectively, ensuring quality products at competitive prices while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for 4 x 8 particle board price Sourcing

What Are the Key Cost Components for 4 x 8 Particle Board?

When sourcing 4 x 8 particle board, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The core material for particle board is typically wood chips, sawdust, or recycled wood fiber. The price can fluctuate based on the availability of raw materials and market demand. Sustainable sources may come at a premium but can enhance brand reputation.

-

Labor: Labor costs encompass the wages for workers involved in the production process. Regions with higher wage standards may see increased production costs, which can impact the final pricing for buyers.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Efficient manufacturing processes can mitigate these costs, potentially leading to lower prices for bulk purchases.

-

Tooling: Specialized tools and machinery for producing particle board can be significant investments. Buyers should consider suppliers’ capacity to scale production without incurring excessive tooling costs.

-

Quality Control (QC): Ensuring product quality is paramount. Enhanced QC processes may lead to higher prices, but they can also reduce the risk of defects and increase customer satisfaction.

-

Logistics: Transportation costs can vary significantly based on distance, mode of transport, and fuel prices. International buyers should factor in customs duties and taxes, which can further impact total costs.

-

Margin: Supplier profit margins can vary based on market competition and demand. Understanding the typical margin in your region can aid in negotiations.

How Do Price Influencers Affect 4 x 8 Particle Board Costs?

Several factors influence the pricing of 4 x 8 particle board, which buyers should consider when sourcing:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Higher volumes often lead to discounts, making bulk purchasing an attractive option for larger projects.

-

Specifications and Customization: Custom specifications, such as thickness or surface finish, can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials Quality and Certifications: Higher-quality materials and certifications (e.g., CARB compliance for formaldehyde emissions) can lead to increased costs. Buyers should weigh the benefits of these certifications against budget constraints.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers with a proven track record may command higher prices but offer greater assurance in quality and delivery.

-

Incoterms: Understanding Incoterms is essential for international transactions. They define who bears responsibility for shipping costs, insurance, and customs clearance, affecting overall pricing.

What Are the Best Tips for Negotiating 4 x 8 Particle Board Prices?

For B2B buyers, especially from diverse markets such as Africa, South America, the Middle East, and Europe, strategic negotiation can lead to more favorable pricing:

-

Conduct Market Research: Understanding the market price range for 4 x 8 particle board helps buyers negotiate effectively. Utilize industry reports and consult multiple suppliers for comparative analysis.

-

Leverage Total Cost of Ownership (TCO): Consider not just the purchase price but the TCO, including shipping, handling, and potential maintenance costs. Presenting TCO analysis can strengthen negotiation positions.

-

Build Long-Term Relationships: Establishing rapport with suppliers can lead to better terms and pricing flexibility over time. Regular communication and feedback can foster a collaborative partnership.

-

Be Clear on Specifications: Providing detailed specifications and quality requirements upfront can prevent misunderstandings and unnecessary costs later in the process.

-

Stay Informed on Pricing Trends: Keeping abreast of market fluctuations, especially regarding raw material prices, can aid in timing purchases effectively to secure better deals.

Disclaimer on Indicative Prices

Prices for 4 x 8 particle board can vary widely based on regional markets, supplier capabilities, and material sources. It is essential for buyers to obtain quotes directly from suppliers to ensure accurate pricing tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing 4 x 8 particle board price With Other Solutions

Understanding Alternatives to 4 x 8 Particle Board

In the realm of construction and manufacturing, selecting the right material is crucial for achieving desired performance and cost efficiency. While 4 x 8 particle board is a popular choice for various applications due to its affordability and versatility, there are alternative materials that may offer distinct advantages depending on the specific needs of a project. This section explores two viable alternatives to 4 x 8 particle board, comparing them across several key aspects.

Comparison Table

| Comparison Aspect | 4 x 8 Particle Board Price | Alternative 1: Oriented Strand Board (OSB) | Alternative 2: Medium Density Fiberboard (MDF) |

|---|---|---|---|

| Performance | Moderate strength; suitable for dry environments | High strength and durability; better moisture resistance | Smooth surface; ideal for detailed finishes |

| Cost | Generally lower cost; around $15-$30 per sheet | Comparable price; typically $20-$35 per sheet | Higher cost; ranges from $30-$50 per sheet |

| Ease of Implementation | Easy to cut and handle; suitable for DIY projects | Requires proper handling due to weight; easy to install | Can be heavy; requires specialized tools for cutting |

| Maintenance | Low maintenance; sensitive to moisture | Low maintenance; moisture-resistant options available | Low maintenance; can swell if exposed to moisture |

| Best Use Case | Ideal for furniture, cabinets, and interior applications | Great for flooring, sheathing, and structural applications | Best for cabinetry, moldings, and high-quality finishes |

What Are the Pros and Cons of Oriented Strand Board (OSB)?

Oriented Strand Board (OSB) is a strong, engineered wood product made from strands of wood that are oriented in specific directions and bonded with adhesives. One of the primary advantages of OSB is its superior strength and durability compared to particle board, particularly in high-moisture environments. This makes it an excellent choice for applications such as flooring and roofing. However, OSB can be heavier and may require more effort during installation. While its price is generally competitive with particle board, it may not be as readily available in all regions.

How Does Medium Density Fiberboard (MDF) Compare?

Medium Density Fiberboard (MDF) offers a smooth surface that is ideal for applications requiring detailed finishes, such as cabinetry and molding. Its fine texture allows for easy painting and veneering, making it a preferred choice for high-quality aesthetic projects. However, MDF typically comes at a higher price point compared to both particle board and OSB, which may be a consideration for budget-conscious buyers. Additionally, MDF can be susceptible to moisture damage, so it may not be the best choice for areas with high humidity.

Choosing the Right Solution for Your Needs

When selecting between 4 x 8 particle board and its alternatives, it’s essential for B2B buyers to assess the specific requirements of their projects. Factors such as performance needs, budget constraints, and installation capabilities will significantly influence the decision. For projects that prioritize cost and ease of use, particle board remains a strong contender. Conversely, if durability and moisture resistance are paramount, OSB may be the better option. Meanwhile, for projects where finish quality is critical, MDF could be the preferred choice despite its higher cost. By carefully evaluating these aspects, buyers can make informed decisions that align with their project goals.

Essential Technical Properties and Trade Terminology for 4 x 8 particle board price

What Are the Key Technical Properties of 4 x 8 Particle Board?

Understanding the technical specifications of 4 x 8 particle board is crucial for B2B buyers to ensure they select the right product for their applications. Here are some essential properties:

-

Material Grade: Particle boards are typically classified by their density and composition, which can include varying amounts of wood fibers, adhesives, and other materials. Higher-grade boards, often referred to as “premium” or “industrial” grade, offer better durability and moisture resistance. For international buyers, selecting the appropriate grade is vital to ensure compliance with local building regulations and standards.

-

Thickness: The most common thicknesses for 4 x 8 particle board are 1/2 inch, 5/8 inch, and 3/4 inch. The choice of thickness affects the board’s strength, weight, and suitability for different applications, such as cabinetry or flooring. Understanding the load-bearing requirements of the intended use can help buyers choose the correct thickness.

-

Moisture Resistance: Some particle boards are treated to be moisture-resistant, which is particularly important in humid climates or environments where the board may be exposed to water. This property can significantly impact the longevity and performance of the board, making it a critical factor for buyers in regions with high humidity, such as parts of Africa and South America.

-

Formaldehyde Emissions: Many particle boards are now manufactured to meet low-emission standards, which is important for health and safety compliance. Products that adhere to regulations like CARB (California Air Resources Board) or EPA (Environmental Protection Agency) standards are preferable for buyers concerned about indoor air quality.

-

Tolerance: Tolerance refers to the allowable deviation from the nominal dimensions of the board. Understanding tolerance is essential for ensuring that the particle board will fit correctly in its intended application, especially in precision installations.

-

Finish: Particle boards can come with various finishes, such as melamine or laminate, which enhance their aesthetic appeal and durability. Buyers should consider the finish based on the intended use, whether for visible surfaces or hidden applications.

What Are Common Trade Terms Related to 4 x 8 Particle Board Pricing?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of particle board, OEMs might supply the boards to furniture manufacturers or construction companies.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is critical for buyers to assess whether they can meet the supplier’s requirements without overcommitting to inventory.

-

RFQ (Request for Quotation): An RFQ is a document sent by a buyer to suppliers requesting pricing and other terms for a specific quantity of goods. It’s an essential tool for buyers to gather competitive pricing on particle boards and to understand lead times and payment terms.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for understanding shipping costs, risk management, and delivery obligations when sourcing particle boards from overseas suppliers.

-

Lead Time: This term refers to the time taken from placing an order until the product is delivered. For international buyers, understanding lead times is vital for planning and inventory management, especially in markets with longer shipping routes.

-

Sustainability Certifications: Many buyers are increasingly concerned about environmental impact. Terms like FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) indicate that the particle board is sourced from sustainably managed forests. Buyers should consider these certifications as part of their purchasing criteria.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 4 x 8 particle board, ensuring they meet both their operational needs and compliance requirements.

Navigating Market Dynamics and Sourcing Trends in the 4 x 8 particle board price Sector

What Are the Current Market Dynamics and Key Trends Influencing the 4 x 8 Particle Board Price Sector?

The market for 4 x 8 particle board is driven by several global factors, including the increasing demand for affordable and versatile building materials in the construction and furniture sectors. Emerging economies in Africa and South America are seeing a surge in infrastructure projects, while European nations are focusing on sustainable building practices, creating a robust demand for particle boards. Technological advancements in production processes, such as enhanced manufacturing techniques and automation, are also optimizing supply chains and reducing costs, further influencing pricing structures.

International B2B buyers should be aware of current sourcing trends, including the rise of online marketplaces which facilitate direct procurement from manufacturers. This shift is empowering buyers to negotiate better prices and access a wider array of products. Additionally, as the industry grapples with fluctuating raw material costs and supply chain disruptions, buyers must develop agile sourcing strategies that accommodate these market dynamics. Countries like Saudi Arabia and Brazil are investing heavily in local manufacturing capabilities, which could offer buyers cost-effective options in the near future.

How Does Sustainability and Ethical Sourcing Impact the 4 x 8 Particle Board Price?

Sustainability has become a crucial consideration in the sourcing of 4 x 8 particle board, influencing both pricing and procurement strategies. The environmental impact of wood sourcing is significant, as deforestation and unsustainable practices can lead to increased regulatory scrutiny and potential supply shortages. As such, B2B buyers are increasingly prioritizing suppliers who adhere to sustainable practices and can provide certifications such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification).

Moreover, the demand for eco-friendly products is reshaping the market landscape. Buyers are looking for particle boards that utilize recycled materials or are manufactured with low-emission processes. This trend not only satisfies the growing consumer preference for green products but also aligns with corporate social responsibility (CSR) goals. Consequently, while sustainably sourced particle boards may come at a premium, the long-term benefits—such as enhanced brand reputation and compliance with regulations—often justify the investment.

What is the Historical Context of the 4 x 8 Particle Board Price Sector?

The particle board market has evolved significantly over the past few decades. Initially developed in the 1940s as an alternative to solid wood, particle board quickly gained popularity due to its cost-effectiveness and versatility. The standardized 4 x 8 size became a staple in various applications, from cabinetry to flooring. As technology advanced, the production of particle board improved, leading to better quality and performance characteristics, which in turn influenced pricing structures.

The late 20th century saw a growing emphasis on sustainability, prompting manufacturers to explore eco-friendly materials and processes. This historical shift laid the groundwork for today’s market, where ethical sourcing and environmental responsibility are paramount. As international B2B buyers navigate this landscape, understanding the evolution of particle board pricing and the factors influencing it can provide valuable insights for strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of 4 x 8 particle board price

-

How do I determine the price of 4 x 8 particle board in my region?

To ascertain the price of 4 x 8 particle board, consider reaching out to multiple suppliers in your region for quotes. Prices can vary significantly based on factors such as local demand, material quality, and shipping costs. Additionally, check online platforms and regional building material distributors to gather a comprehensive understanding of current market rates. Always inquire about bulk pricing as well, which can lead to significant savings for larger orders. -

What factors influence the price of 4 x 8 particle board?

The price of 4 x 8 particle board is influenced by various factors, including material quality, thickness, manufacturing processes, and regional market conditions. Additionally, fluctuations in raw material costs, shipping expenses, and tariffs can affect final pricing, especially for international buyers. It’s also important to consider any added features such as moisture resistance or eco-friendliness, which may come at a premium but provide long-term benefits. -

How can I vet suppliers for 4 x 8 particle board?

When vetting suppliers, assess their reputation through reviews and testimonials from previous clients. Request samples to evaluate product quality and ensure they meet your specifications. Additionally, verify their compliance with international standards and certifications. Establish communication regarding their production capacity, lead times, and after-sales support to ensure they can meet your business needs consistently. -

What are the typical minimum order quantities (MOQs) for 4 x 8 particle board?

MOQs for 4 x 8 particle board can vary widely among suppliers, typically ranging from 50 to 500 sheets, depending on the manufacturer and your location. Larger manufacturers often have higher MOQs, while smaller companies may be more flexible. When negotiating, consider your storage capabilities and long-term usage to avoid excess inventory. Always confirm if the supplier offers discounts for larger orders. -

What payment terms should I expect when ordering 4 x 8 particle board?

Payment terms can differ significantly among suppliers. Common arrangements include a deposit upon order confirmation with the balance due upon delivery or a net 30-day term after receipt of goods. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your interests. Ensure clarity on any applicable taxes, duties, and fees that may impact the total cost. -

How can I ensure the quality of 4 x 8 particle board?

To ensure quality, request certifications from suppliers that verify compliance with industry standards, such as ISO or ANSI. Conduct regular quality checks on shipments and consider third-party inspections, especially for larger orders. If possible, establish a long-term relationship with a reliable supplier who understands your quality requirements and can consistently deliver products that meet your specifications. -

What are the shipping options for 4 x 8 particle board?

Shipping options for 4 x 8 particle board depend on your location and the supplier’s capabilities. Common methods include freight shipping for larger orders, which can be cost-effective, and express shipping for urgent needs. Ensure to discuss shipping terms, costs, and estimated delivery times upfront. It’s also wise to confirm whether the supplier can handle customs clearance if importing the boards internationally. -

Can I customize the particle board specifications for my project?

Many suppliers offer customization options for particle board, including variations in thickness, density, and surface finish. When reaching out to suppliers, clearly communicate your specific requirements and project needs. Custom orders may have different lead times and pricing structures, so be prepared for potential adjustments in your budget and timeline. Always request samples of customized products to ensure they meet your expectations before placing a larger order.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

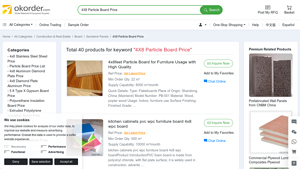

Top 1 4 X 8 Particle Board Price Manufacturers & Suppliers List

1. Okorder – 4×8 Particle Board for Furniture

Domain: okorder.com

Registered: 2007 (18 years)

Introduction: 4×8 Particle Board for Furniture Usage

– Ref Price: Min Order Qty: 22 m³

– Supply Capability: 8000 m³/month

– Type: Flakeboards

– Place of Origin: Shandong, China (Mainland)

– Model Number: PB-001

– Material: Wood, poplar wood

– Usage: Indoor, furniture use

– Surface Finishing: Finished

3/4 Particle Board OSB Board

– Ref Price: Min Order Qty: 1000 pc

– Supply Capability: 1000000 pc/month

– Size: …

Strategic Sourcing Conclusion and Outlook for 4 x 8 particle board price

In today’s competitive landscape, strategic sourcing of 4 x 8 particle board is crucial for maximizing value and ensuring supply chain resilience. As highlighted throughout this guide, understanding the various pricing dynamics and sourcing options is essential for international B2B buyers. Factors such as material quality, regional availability, and market demand significantly influence pricing, making it imperative to establish strong relationships with suppliers across key regions, including Africa, South America, the Middle East, and Europe.

Buyers should prioritize sourcing strategies that emphasize sustainability and compliance with international standards, which not only enhance product quality but also align with growing global eco-consciousness. By leveraging local suppliers and exploring bulk purchasing agreements, businesses can mitigate risks associated with fluctuating prices and ensure a steady supply of particle board.

Looking ahead, the market for 4 x 8 particle board is expected to evolve, driven by advancements in manufacturing technologies and shifting consumer preferences. International buyers are encouraged to stay informed about market trends and engage actively with suppliers to negotiate favorable terms. By adopting a proactive sourcing approach, companies can secure competitive advantages and foster long-term growth in their respective markets.