A Deep Dive into Carbon Monoxide Detector Manual Solution

Introduction: Navigating the Global Market for carbon monoxide detector manual

As international B2B buyers increasingly recognize the critical importance of safety in various environments, sourcing reliable carbon monoxide detector manuals becomes a paramount concern. These manuals not only guide the installation and maintenance of detectors but also ensure compliance with safety regulations across diverse markets. In this comprehensive guide, we delve into the various types of carbon monoxide detectors, their applications in both residential and commercial settings, and strategies for effectively vetting suppliers.

Understanding the nuances of cost structures, certification requirements, and local regulations in regions such as Africa, South America, the Middle East, and Europe—particularly in key markets like Brazil and Germany—can be overwhelming. This guide is designed to empower buyers with actionable insights that facilitate informed purchasing decisions. By equipping stakeholders with knowledge about product specifications, market trends, and supplier reliability, we aim to simplify the often complex landscape of carbon monoxide detection solutions.

Our exploration will not only enhance your understanding of the technical aspects of carbon monoxide detectors but also provide essential information on navigating the global supply chain, ensuring that your organization can maintain a safe environment while meeting regulatory standards. Whether you are a procurement manager, safety officer, or business owner, this guide serves as a valuable resource for fostering safer workplaces and communities.

Understanding carbon monoxide detector manual Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard CO Alarm Manual | Basic installation and operational guidelines | Residential, small commercial spaces | Pros: Cost-effective, easy to use. Cons: Limited features, may not suit larger operations. |

| Low-Level CO Monitor Manual | Specialized for detecting lower levels of CO | Healthcare, laboratories | Pros: Early detection of low-level CO exposure. Cons: Higher initial investment. |

| Smart CO Detector Manual | Integration with smart home systems | Hospitality, property management | Pros: Remote monitoring, alerts via mobile apps. Cons: Requires Wi-Fi; potential connectivity issues. |

| Industrial CO Detector Manual | Heavy-duty, designed for industrial environments | Manufacturing, mining | Pros: Robust, can handle harsh conditions. Cons: More complex installation, higher maintenance needs. |

| Multi-Gas Detector Manual | Detects multiple gases including CO | Oil & gas, chemical processing | Pros: Versatile, comprehensive safety monitoring. Cons: Higher cost, more complex operation. |

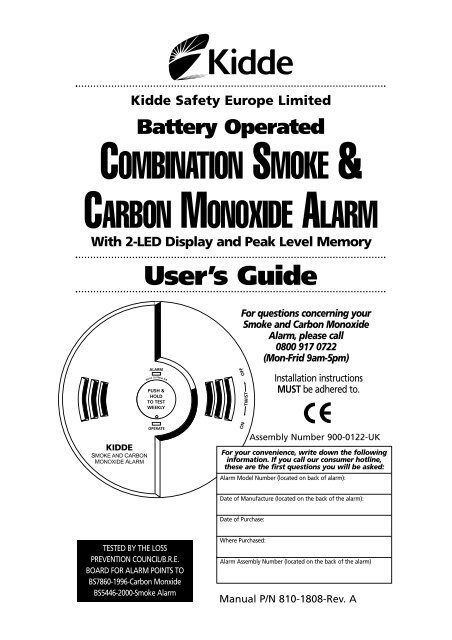

What are the Characteristics of Standard CO Alarm Manuals?

Standard CO alarm manuals provide essential information on installation, maintenance, and operation of basic carbon monoxide detectors. These manuals typically include diagrams, troubleshooting tips, and safety guidelines. They are suitable for residential properties and small commercial spaces, where straightforward detection is required. When purchasing, B2B buyers should consider the simplicity of the manual and whether it meets regulatory compliance for their region.

How Do Low-Level CO Monitor Manuals Differ from Standard Manuals?

Low-level CO monitor manuals focus on devices that detect carbon monoxide at much lower concentrations than standard alarms. These monitors are critical in environments like healthcare facilities and laboratories, where even minimal exposure can pose health risks. Buyers in these sectors should evaluate the sensitivity and calibration details provided in the manual, as well as the monitoring frequency to ensure compliance with health and safety regulations.

What are the Advantages of Smart CO Detector Manuals?

Smart CO detector manuals guide users on integrating carbon monoxide detection systems with smart home technology. These devices can send alerts to mobile devices and allow remote monitoring, making them ideal for hospitality and property management sectors. B2B buyers should consider the connectivity requirements and potential cybersecurity implications when investing in these advanced systems, as well as the ease of use for staff.

Why Choose Industrial CO Detector Manuals for Heavy-Duty Applications?

Industrial CO detector manuals cater to the needs of high-risk environments, such as manufacturing and mining. These manuals often cover installation in harsh conditions and emphasize durability and reliability. Buyers in these sectors must assess the manual for details on ruggedness, maintenance schedules, and compliance with industrial safety standards, ensuring the devices can withstand the operational environment.

What Should Buyers Know About Multi-Gas Detector Manuals?

Multi-gas detector manuals provide comprehensive guidelines for devices that monitor various gases, including carbon monoxide. These are particularly valuable in industries like oil and gas and chemical processing, where multiple hazards exist. B2B buyers should focus on the range of gases detected, calibration requirements, and the complexity of operation outlined in the manual, which can influence training and operational costs.

Key Industrial Applications of carbon monoxide detector manual

| Industry/Sector | Specific Application of Carbon Monoxide Detector Manual | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Ensuring worker safety in enclosed spaces | Reduces risk of CO poisoning, enhancing employee safety | Compliance with local safety regulations, durability |

| Hospitality | Protecting guests in hotels and restaurants | Enhances guest safety and brand reputation | Multi-language manuals for diverse clientele |

| Residential Construction | Installation guidelines for residential CO detectors | Increases safety standards in new builds | Compatibility with various building codes |

| Oil & Gas | Monitoring CO levels in drilling operations | Prevents hazardous conditions, ensuring operational safety | Robust sensors for harsh environments, maintenance ease |

| Automotive | Integration of CO detectors in vehicle manufacturing | Enhances vehicle safety features, meeting regulatory standards | Supplier reliability, certification compliance |

How Can Carbon Monoxide Detector Manuals Enhance Safety in Manufacturing?

In the manufacturing sector, carbon monoxide detectors are crucial for ensuring worker safety, particularly in enclosed spaces such as factories and warehouses. The manual provides detailed installation and maintenance guidelines that help companies comply with occupational safety regulations. By implementing these detectors, businesses can significantly reduce the risk of carbon monoxide poisoning, thereby protecting their workforce and minimizing liability. International buyers should consider sourcing detectors that meet specific local safety standards and ensure the manuals are available in relevant languages for their teams.

Why Is Carbon Monoxide Detection Essential in the Hospitality Industry?

In hotels and restaurants, the safety of guests is paramount. Carbon monoxide detector manuals guide the proper installation and maintenance of devices that monitor CO levels, ensuring a safe environment. This not only protects guests but also enhances the establishment’s reputation, as safety is a key concern for travelers. For international buyers, it’s essential to select detectors that come with multilingual manuals to cater to diverse clientele, as well as ensuring compliance with local hospitality regulations.

What Role Do Carbon Monoxide Detectors Play in Residential Construction?

In the residential construction sector, carbon monoxide detectors are integral to meeting safety standards in new buildings. The manual offers essential instructions for proper installation, ensuring that homes are equipped to protect occupants from CO exposure. This compliance not only enhances the safety of the property but also adds value for potential buyers. When sourcing detectors, international buyers should pay attention to compatibility with local building codes and consider the availability of detailed manuals for construction teams.

How Are Carbon Monoxide Detectors Used in Oil & Gas Operations?

The oil and gas industry faces unique challenges regarding safety, particularly in monitoring hazardous gases like carbon monoxide during drilling operations. Carbon monoxide detector manuals provide vital information on the installation and calibration of these devices to ensure they function effectively in harsh environments. By preventing hazardous conditions, companies can safeguard their workforce and maintain uninterrupted operations. Buyers in this sector should prioritize sourcing robust detectors that withstand extreme conditions and require minimal maintenance.

What Benefits Do Carbon Monoxide Detectors Bring to Automotive Manufacturing?

In automotive manufacturing, integrating carbon monoxide detectors into vehicles is becoming increasingly important for enhancing safety features. The manuals detail how to install and maintain these systems effectively, ensuring compliance with regulatory standards. This not only protects drivers and passengers but also boosts the manufacturer’s credibility in the market. When sourcing these detectors, international buyers should evaluate supplier reliability and ensure that the products meet stringent certification requirements for automotive safety.

3 Common User Pain Points for ‘carbon monoxide detector manual’ & Their Solutions

Scenario 1: Misunderstanding Alarm Signals and Maintenance Requirements

The Problem: B2B buyers often face confusion regarding the different alarm signals emitted by carbon monoxide detectors. Misinterpretation of these signals can lead to inadequate responses, putting lives and property at risk. Additionally, many users struggle to comprehend the maintenance schedules detailed in the manuals, leading to neglect and potential malfunction of the detectors. This situation is exacerbated in diverse markets where language barriers or varying regulatory standards may complicate understanding.

The Solution: To address this issue, it is crucial for buyers to prioritize comprehensive training for their staff on how to interpret alarm signals correctly. This can be achieved through the creation of a detailed training program that includes visual aids and simulations. Furthermore, buyers should ensure that the manuals provided with the detectors are accessible in multiple languages and formats, catering to the specific needs of their workforce. Regularly scheduled maintenance checks should be documented in a maintenance log, which can be referenced during training sessions to reinforce the importance of compliance with maintenance schedules outlined in the manual. This proactive approach not only enhances safety but also extends the life of the detectors.

Scenario 2: Difficulty in Navigating Installation Procedures

The Problem: A common pain point for international B2B buyers is the complexity of installation procedures detailed in carbon monoxide detector manuals. Inconsistent terminology, lack of visual aids, and inadequate step-by-step instructions can lead to improper installations. This is particularly problematic in regions with varying building codes and installation standards, which may not align with the guidelines provided in the manuals.

The Solution: To mitigate installation issues, buyers should consider partnering with manufacturers that provide comprehensive installation support, including detailed video tutorials and interactive guides. Additionally, they can create an installation checklist based on the specific requirements of their local regulations to ensure compliance. Engaging certified local contractors who are familiar with both the product and local codes can also facilitate smoother installations. By ensuring that the installation process is straightforward and compliant, companies can reduce the risk of detector failure and enhance overall safety.

Scenario 3: Inadequate Understanding of Sensor Technology and Performance

The Problem: Many B2B buyers may not fully grasp the differences in sensor technologies used in carbon monoxide detectors, such as electrochemical vs. metal oxide semiconductor sensors. This lack of understanding can lead to poor product selection that fails to meet specific environmental or operational needs. Furthermore, buyers often overlook the performance specifications detailed in the manuals, resulting in the procurement of detectors that do not perform optimally in their intended settings.

The Solution: To overcome this challenge, it is essential for buyers to invest time in understanding the various sensor technologies available in the market. They should request detailed product specifications from manufacturers and engage in discussions about the performance metrics relevant to their specific applications. Additionally, creating a comparative analysis of different detectors based on sensor technology and performance can empower buyers to make informed decisions. Regular training sessions focusing on technology updates and performance evaluations should be integrated into their operational protocols, ensuring that all stakeholders are aware of the latest advancements in carbon monoxide detection technology. This strategic approach will lead to better product selection and enhanced safety in their facilities.

Strategic Material Selection Guide for carbon monoxide detector manual

What Are the Key Materials for Carbon Monoxide Detectors?

When selecting materials for carbon monoxide (CO) detectors, it is essential to consider their properties, advantages, disadvantages, and compliance with international standards. Below are analyses of four common materials used in the manufacturing of CO detectors.

1. Polycarbonate

Key Properties:

Polycarbonate is a high-performance thermoplastic known for its impact resistance and transparency. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for various environments.

Pros & Cons:

The durability of polycarbonate is a significant advantage; it is resistant to shattering and can endure harsh conditions. However, it can be more expensive than other plastics and may require specialized manufacturing processes.

Impact on Application:

Polycarbonate is compatible with electronic components and offers good insulation properties, which is crucial for CO detectors that need to operate reliably in various climates.

Considerations for International Buyers:

Buyers in regions like Europe and South America should ensure that the polycarbonate used meets relevant safety standards, such as EN 50291 for CO detectors. Additionally, the availability of polycarbonate may vary by region, impacting lead times.

2. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance and strength. It can withstand high temperatures and pressures, making it suitable for industrial applications.

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to corrosion, which extends the lifespan of CO detectors in harsh environments. However, it is heavier and more expensive than plastic options, which may not be suitable for all applications.

Impact on Application:

Stainless steel is ideal for environments with high humidity or exposure to chemicals, ensuring that the detector remains functional over time.

Considerations for International Buyers:

Buyers in the Middle East and Africa should consider the specific grades of stainless steel that comply with local standards, such as ASTM or ISO certifications, to ensure product reliability and safety.

3. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can handle temperatures up to 600°C, making it suitable for various applications.

Pros & Cons:

The lightweight nature of aluminum makes it easy to transport and install. However, it may not be as durable as stainless steel and can be prone to scratches and dents.

Impact on Application:

Aluminum is suitable for outdoor applications where weight is a concern, but it may require additional coatings for enhanced durability.

Considerations for International Buyers:

In Europe, compliance with the RoHS directive regarding hazardous substances is crucial for aluminum components. Buyers should also consider local preferences for materials based on climate and environmental conditions.

4. ABS Plastic

Key Properties:

Acrylonitrile Butadiene Styrene (ABS) is a common thermoplastic known for its toughness and impact resistance. It can operate effectively in temperatures ranging from -20°C to 80°C.

Pros & Cons:

ABS is cost-effective and easy to mold, making it a popular choice for mass production. However, it has lower heat resistance compared to polycarbonate and may not perform well in extreme temperatures.

Impact on Application:

ABS is suitable for indoor applications where environmental extremes are not a concern, but its limitations in high-temperature settings should be noted.

Considerations for International Buyers:

Buyers should ensure that ABS materials comply with local regulations, particularly regarding fire safety standards, which can vary significantly across regions.

Summary Table of Material Selection for Carbon Monoxide Detectors

| Material | Typical Use Case for carbon monoxide detector manual | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Housing for indoor CO detectors | High impact resistance | Higher cost and manufacturing complexity | Medium |

| Stainless Steel | Industrial CO detectors in humid environments | Excellent corrosion resistance | Heavier and more expensive | High |

| Aluminum | Lightweight outdoor CO detectors | Lightweight and easy to transport | Less durable than stainless steel | Medium |

| ABS Plastic | Indoor CO detectors | Cost-effective and easy to mold | Lower heat resistance | Low |

This guide provides a comprehensive overview of material options for carbon monoxide detectors, aiding international B2B buyers in making informed decisions aligned with their specific market needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for carbon monoxide detector manual

What Are the Key Stages in the Manufacturing Process of Carbon Monoxide Detectors?

The manufacturing of carbon monoxide detectors involves a series of critical stages that ensure the final product meets stringent safety and performance standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Is Quality Assurance Initiated?

The manufacturing process begins with the careful selection and preparation of raw materials. High-quality components such as electrochemical sensors, circuit boards, and plastic housings are sourced from reputable suppliers. Quality assurance (QA) starts here, with incoming quality control (IQC) checks to verify that materials meet predefined specifications. This step is crucial as substandard materials can lead to product failures.

What Techniques Are Used in Forming Carbon Monoxide Detectors?

The forming stage involves shaping the prepared materials into functional components. Techniques such as injection molding for plastic parts and surface mount technology (SMT) for circuit boards are commonly employed. Each process requires precise machinery and skilled operators to ensure consistency and accuracy. Quality checkpoints during this phase often include in-process quality control (IPQC), where random sampling of components is tested for adherence to specifications.

How Is Assembly Conducted to Ensure Reliability?

During the assembly stage, components are integrated into the final product. This involves soldering circuit boards, installing sensors, and assembling the outer casing. Automated assembly lines are frequently utilized for efficiency, but manual assembly may also play a role in complex products. Quality assurance during assembly includes functional testing to ensure all components work together seamlessly. Regular audits of the assembly process help maintain high standards.

What Finishing Processes Are Important for Carbon Monoxide Detectors?

The finishing stage focuses on final touches such as labeling, packaging, and quality testing. Detectors undergo rigorous inspections to ensure they meet all regulatory requirements. This includes verifying that the product is compliant with international standards such as ISO 9001 and regional certifications like CE in Europe. Proper documentation of these processes is essential for transparency and traceability.

What International Standards Should B2B Buyers Be Aware of?

International standards play a pivotal role in the manufacturing and quality assurance of carbon monoxide detectors. Key standards include:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers maintain consistent quality in their processes.

- CE Marking: A mandatory conformity mark for products sold within the European Economic Area, indicating compliance with safety, health, and environmental protection standards.

- API Standards: These apply to products used in the oil and gas industry, ensuring that detectors meet specific performance and safety criteria.

Understanding these standards is crucial for B2B buyers, as they indicate a manufacturer’s commitment to quality and safety.

What Are the Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integral to the manufacturing process, ensuring that products meet quality standards at various stages. Common checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to verify functionality and compliance with specifications.

These checkpoints help mitigate risks and ensure that only high-quality products reach the market.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Key methods include:

- Conducting Audits: Regularly auditing suppliers can provide insights into their manufacturing processes and quality control measures. This helps ensure that they adhere to international standards.

- Requesting Quality Reports: Suppliers should provide documentation that outlines their quality control processes, including test results and compliance certifications.

- Engaging Third-Party Inspectors: Hiring independent inspectors to evaluate suppliers can provide an unbiased assessment of their quality assurance practices.

What Testing Methods Are Commonly Used in Carbon Monoxide Detector Manufacturing?

Testing methods vary depending on the specific features of the carbon monoxide detector but generally include:

- Functional Testing: Verifying that the detector operates correctly under various conditions.

- Endurance Testing: Assessing the product’s performance over an extended period to ensure reliability.

- Environmental Testing: Evaluating the product’s performance in extreme temperatures and humidity levels to ensure it can withstand various conditions.

These methods are essential for ensuring that the detectors are not only functional but also durable and reliable.

What Are the Quality Control and Certification Nuances for International Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is critical. Different regions may have varying regulations and standards that products must meet. For instance, while CE marking is essential for products sold in Europe, similar certifications may exist in other regions, such as INMETRO in Brazil or SANS in South Africa.

Additionally, B2B buyers must ensure that suppliers can navigate these regulations effectively. This may involve reviewing a supplier’s track record in obtaining necessary certifications and their ability to adapt to changing regulations.

Conclusion: Why Is Quality Assurance Vital for Carbon Monoxide Detectors?

In summary, the manufacturing processes and quality assurance for carbon monoxide detectors are complex and multifaceted. For international B2B buyers, understanding these processes is essential for making informed purchasing decisions. By prioritizing suppliers that adhere to international standards and demonstrate robust quality control practices, buyers can ensure they invest in reliable and safe products that protect lives and property.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘carbon monoxide detector manual’

In the process of procuring carbon monoxide detector manuals, a structured approach ensures that you obtain the most relevant, high-quality resources for your organization. This guide outlines essential steps for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, to effectively source these critical safety documents.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the carbon monoxide detectors you require manuals for. This includes understanding the types of detectors (e.g., battery-operated, hardwired), features (e.g., digital displays, connectivity), and compliance with local regulations. Knowing these details will help streamline your search for manuals that meet your specific needs.

Step 2: Identify Reliable Suppliers

Research and compile a list of suppliers known for producing high-quality carbon monoxide detectors. Look for suppliers with established reputations in your target regions, as well as those who have experience dealing with international clients. Prioritize suppliers who provide comprehensive documentation and support for their products.

Step 3: Evaluate Supplier Credentials and Certifications

Before proceeding, verify the credentials and certifications of your potential suppliers. Ensure they comply with relevant safety standards, such as ISO certification or compliance with local regulatory bodies. This step is critical to mitigate risks associated with substandard products and ensure that the manuals are trustworthy.

Step 4: Request Samples of Manuals

Request samples of the carbon monoxide detector manuals from shortlisted suppliers. Reviewing these samples will give you insight into the clarity, comprehensiveness, and usability of the manuals. Pay attention to the organization of information, language options, and the inclusion of troubleshooting sections, which can be vital for end-users.

Step 5: Assess Language Availability and Localization

Given the international nature of your audience, it’s essential to ensure that the manuals are available in multiple languages. Check if the supplier provides localization options to cater to regional dialects and terminologies. This will enhance user understanding and compliance with safety protocols.

Step 6: Confirm After-Sales Support and Documentation Updates

Inquire about the supplier’s after-sales support and their process for updating manuals. Good suppliers will offer ongoing support and periodically revise manuals to reflect product updates or changes in safety regulations. This aspect is vital for maintaining compliance and ensuring that users have access to the most current information.

Step 7: Negotiate Terms and Finalize Procurement

Once you have gathered all the necessary information, negotiate the terms of procurement, including pricing, payment terms, and delivery timelines. Ensure that you clarify the conditions regarding returns or replacements of manuals in case they do not meet your expectations. This step is crucial for establishing a solid partnership with your supplier.

By following these steps, B2B buyers can efficiently navigate the procurement process for carbon monoxide detector manuals, ensuring that they receive high-quality resources that enhance safety and compliance in their operations.

Comprehensive Cost and Pricing Analysis for carbon monoxide detector manual Sourcing

What Are the Key Cost Components Involved in Sourcing Carbon Monoxide Detector Manuals?

When sourcing carbon monoxide detector manuals, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: This encompasses the paper quality, ink, and any additional materials used for binding or packaging. High-quality, durable materials increase production costs but can enhance the product’s perceived value.

-

Labor: The cost of labor varies significantly by region. In countries with higher wage standards, labor costs for graphic designers, technical writers, and print workers will be higher. Understanding local labor markets can help buyers negotiate better terms.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient manufacturers will have lower overhead costs, which can translate to more competitive pricing for buyers.

-

Tooling: This refers to the costs associated with the creation of molds and templates necessary for production. For customized manuals, these costs can be significant, especially if unique designs or formats are required.

-

Quality Control (QC): Ensuring that the manuals meet specific standards is vital, especially for safety products like carbon monoxide detectors. QC processes can add to the cost but are essential for maintaining quality and compliance with international standards.

-

Logistics: Shipping costs can vary based on the volume of the order, distance from the manufacturer, and chosen Incoterms. Buyers should factor in these expenses when assessing the total cost.

-

Margin: Suppliers typically mark up their prices to cover costs and ensure profit. Understanding a supplier’s margin can provide insight into their pricing flexibility during negotiations.

How Do Price Influencers Affect the Cost of Carbon Monoxide Detector Manuals?

Several factors can influence the pricing of carbon monoxide detector manuals:

-

Volume/MOQ: Bulk orders typically lead to lower per-unit costs. Suppliers often have minimum order quantities (MOQs), and negotiating these can yield significant savings.

-

Specifications and Customization: Custom features, such as language translations or unique formatting, can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials and whether the manuals comply with specific certifications can affect the price. Manuals that meet higher safety or quality standards may come at a premium.

-

Supplier Factors: The reputation and reliability of the supplier play a significant role in pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: Understanding shipping terms can help buyers manage costs effectively. Different Incoterms (like FOB or CIF) can impact the final price based on who bears the cost of shipping and insurance.

What Negotiation Strategies Can Help Buyers Achieve Cost Efficiency?

For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, implementing effective negotiation strategies can lead to cost savings:

-

Research and Benchmarking: Gather data on market prices and competitor offerings to strengthen your negotiating position. Knowing the average costs can help identify unreasonable pricing.

-

Discuss Long-Term Partnerships: Suppliers may offer discounts for long-term contracts or consistent orders. Establishing a reliable partnership can lead to better pricing over time.

-

Focus on Total Cost of Ownership (TCO): Emphasize the long-term value of quality manuals over upfront costs. Investing in higher-quality manuals can reduce the need for replacements and enhance customer safety.

-

Be Flexible with Specifications: If possible, consider standardizing manual formats or features to reduce costs. Flexibility can lead to significant savings in production.

What Pricing Nuances Should International B2B Buyers Consider?

International buyers must navigate various pricing nuances that can affect overall costs:

-

Currency Fluctuations: Exchange rates can impact the final price when purchasing from foreign suppliers. Consider locking in prices when favorable rates are available.

-

Import Duties and Taxes: Be aware of any tariffs or taxes that may apply when importing manuals. These can significantly increase the total cost.

-

Cultural and Regional Considerations: Understanding regional market dynamics can help tailor negotiations and pricing strategies effectively. For example, what works in Europe may not resonate in Africa or South America.

Disclaimer on Indicative Prices

The prices discussed in this analysis are indicative and can fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and consult multiple suppliers to ensure competitive pricing tailored to your needs.

Alternatives Analysis: Comparing carbon monoxide detector manual With Other Solutions

In the realm of safety equipment, particularly for detecting carbon monoxide (CO), it is essential to explore various solutions that meet specific needs. While carbon monoxide detector manuals provide crucial guidelines for using these devices effectively, alternative solutions may offer different advantages in terms of technology, functionality, and cost. This analysis delves into how the traditional manual compares to advanced monitoring systems and other detection technologies.

| Comparison Aspect | Carbon Monoxide Detector Manual | Smart CO Monitoring System | Portable CO Detector |

|---|---|---|---|

| Performance | Basic usage instructions; reliability depends on the device | Real-time monitoring with alerts and data logging | Effective for immediate detection in various environments |

| Cost | Generally low cost, but varies by brand | Higher initial investment; may include subscription fees | Moderate cost; often more affordable than smart systems |

| Ease of Implementation | Requires basic installation knowledge | Requires professional setup for optimal performance | Simple to use; often battery-operated with no installation needed |

| Maintenance | Minimal; primarily battery checks and manual updates | Regular software updates and battery replacements required | Low maintenance; check battery and functionality regularly |

| Best Use Case | Residential or small-scale applications | Commercial buildings, large facilities, and smart homes | Temporary or fieldwork situations, such as construction sites |

What are the Advantages and Disadvantages of Smart CO Monitoring Systems?

Smart CO monitoring systems integrate advanced technology to provide real-time data and alerts, enhancing safety in environments where carbon monoxide exposure is a risk. These systems often connect to mobile apps or building management systems, allowing for remote monitoring and data analysis. However, the initial setup cost can be significant, and ongoing subscription fees may deter some buyers. Additionally, the complexity of installation might require professional assistance, making it less accessible for smaller operations.

How Do Portable CO Detectors Compare?

Portable CO detectors are designed for flexibility and immediate detection in various settings, making them ideal for transient work environments or for individuals on the go. These devices typically require minimal setup—often just battery insertion—and are user-friendly. While they offer a practical solution for immediate safety needs, they may not provide the comprehensive monitoring features available in smart systems or the detailed guidance found in traditional manuals. Their effectiveness can also be limited by battery life and environmental conditions.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When deciding on a carbon monoxide detection solution, B2B buyers should assess their specific operational requirements, budget constraints, and the environment in which the detection system will be deployed. For instance, businesses operating in high-risk areas may benefit from smart monitoring systems that offer extensive data and alerts. In contrast, companies with less frequent exposure risks might find traditional manuals and portable detectors sufficient for their needs. Evaluating the total cost of ownership, including maintenance and potential upgrades, will further guide buyers in selecting the most suitable solution for their organization.

Essential Technical Properties and Trade Terminology for carbon monoxide detector manual

What Are the Essential Technical Properties of Carbon Monoxide Detectors?

When evaluating carbon monoxide detectors, understanding the technical specifications is crucial for making informed purchasing decisions. Here are some critical properties to consider:

-

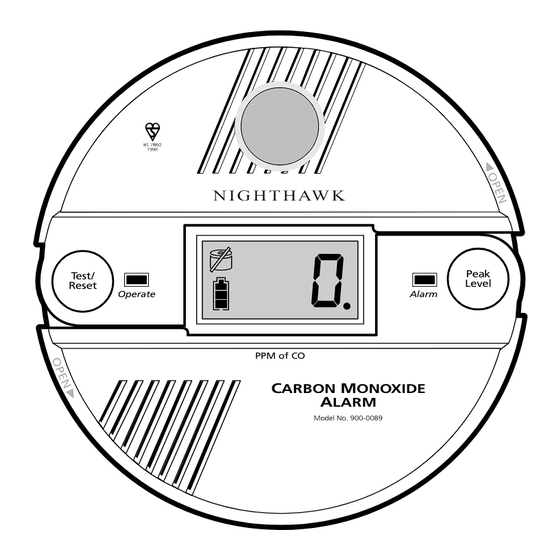

Detection Technology

Carbon monoxide detectors utilize various technologies, including electrochemical sensors, metal oxide semiconductors, and biomimetic sensors. Electrochemical sensors are widely regarded for their accuracy and response time, making them suitable for environments where CO exposure risk is high. B2B buyers should prioritize detectors with proven sensor technology to ensure reliable performance and compliance with safety regulations. -

Sensitivity Range

This specification indicates the lowest concentration of carbon monoxide that the detector can sense, typically measured in parts per million (ppm). A detector with a sensitivity range of 30 ppm or lower is essential for early warning in residential and commercial settings. Understanding sensitivity helps buyers select devices that minimize false alarms while ensuring safety. -

Power Supply

Carbon monoxide detectors can be powered by battery, hardwired, or a combination of both. Battery-operated units offer flexibility and ease of installation, while hardwired detectors provide continuous power. Knowing the power supply options allows B2B buyers to choose detectors that align with their installation capabilities and maintenance preferences. -

Alarm Features

Look for detectors equipped with visual and audible alarms. The decibel level of the alarm (usually between 85-100 dB) is critical for alerting occupants in noisy environments. Additionally, some models feature interconnected alarms, enabling multiple units to signal each other. This functionality is particularly valuable in larger facilities or homes, enhancing overall safety. -

Warranty and Compliance Standards

A robust warranty indicates the manufacturer’s confidence in their product, while compliance with international standards (such as UL 2034 or EN 50291) assures buyers of the detector’s reliability and performance. Understanding these aspects can help businesses mitigate risk and ensure they are investing in quality products.

Which Trade Terminology Should B2B Buyers Know When Purchasing Carbon Monoxide Detectors?

Familiarity with industry-specific terminology can significantly enhance the purchasing process. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are then marketed by another company. In the context of carbon monoxide detectors, knowing the OEM can help buyers assess product quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers as it impacts inventory management and cash flow. Negotiating lower MOQs can be beneficial for smaller companies or those testing new products. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing for specific products or services. This process is essential for obtaining competitive pricing and understanding the full scope of costs involved in purchasing carbon monoxide detectors. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers navigate logistics and ensure clarity in the procurement process. -

Lead Time

Lead time refers to the duration from placing an order to receiving the product. Understanding lead times is crucial for effective inventory management and planning, especially for companies operating in regions with variable shipping times. -

Certification

Certification indicates that a product meets specific safety and performance standards. For carbon monoxide detectors, certifications from recognized bodies (like UL or CE) ensure compliance with local regulations, providing peace of mind for buyers.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that they invest in reliable carbon monoxide detection solutions that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the carbon monoxide detector manual Sector

What Are the Current Market Dynamics and Key Trends in the Carbon Monoxide Detector Manual Sector?

The global market for carbon monoxide detectors is witnessing a significant transformation driven by a combination of regulatory requirements, technological advancements, and heightened awareness of safety standards. Key drivers include increasing urbanization, industrialization, and a growing emphasis on occupational safety in various sectors such as construction, manufacturing, and hospitality. Countries in Africa, South America, the Middle East, and Europe, particularly Brazil and Germany, are experiencing a surge in demand for reliable carbon monoxide detection systems, fueled by stringent safety regulations and a proactive approach to health and safety compliance.

Emerging B2B trends include the integration of smart technologies into carbon monoxide detectors, enabling real-time monitoring and alerts through mobile applications and IoT connectivity. This trend not only enhances safety but also provides valuable data analytics for organizations to optimize their safety protocols. Additionally, there is a growing preference for comprehensive manuals and guides that facilitate easy installation, maintenance, and troubleshooting of carbon monoxide detectors. B2B buyers are increasingly seeking suppliers that offer robust technical documentation, including multilingual manuals and quick-start guides, to cater to diverse markets.

How Is Sustainability Influencing Sourcing Trends in the Carbon Monoxide Detector Manual Sector?

Sustainability is becoming a pivotal consideration in the sourcing of carbon monoxide detectors and their manuals. The environmental impact of manufacturing processes and materials used in these products is under scrutiny, prompting buyers to prioritize suppliers who demonstrate a commitment to sustainable practices. This includes the use of recyclable materials in packaging and the adoption of eco-friendly manufacturing processes that minimize waste and emissions.

Moreover, ethical sourcing is gaining importance as international buyers seek to align their procurement strategies with corporate social responsibility (CSR) objectives. This focus on ethical supply chains not only mitigates risks associated with labor practices and environmental compliance but also enhances brand reputation. Suppliers who possess ‘green’ certifications, such as ISO 14001 for environmental management, are increasingly favored in the procurement process. This trend underscores the importance of transparency and accountability in the supply chain, as B2B buyers demand assurances that their products are sourced responsibly.

What Is the Historical Context of the Carbon Monoxide Detector Manual Sector?

The carbon monoxide detector sector has evolved significantly since its inception in the late 20th century. Initially, these devices were primarily mechanical, relying on simple detection mechanisms. Over the years, advancements in technology have led to the development of electrochemical sensors, which offer greater accuracy and reliability in detecting carbon monoxide levels. The evolution of user manuals has paralleled this technological progression, shifting from basic operational guidelines to comprehensive resources that include troubleshooting, maintenance, and safety compliance information.

As regulatory standards have tightened globally, the demand for detailed and accessible manuals has grown, reflecting the need for users to understand the operational and safety features of these devices. Today, B2B buyers expect manuals to not only be informative but also user-friendly, catering to a diverse audience that includes end-users, technicians, and safety officers. This shift highlights the importance of clear communication and effective documentation in fostering safe and compliant use of carbon monoxide detectors across various industries.

Frequently Asked Questions (FAQs) for B2B Buyers of carbon monoxide detector manual

-

1. How do I ensure the carbon monoxide detectors I source meet international safety standards?

To ensure compliance with international safety standards, request certifications such as UL, CE, or ISO from your supplier. Conduct thorough due diligence by reviewing their quality assurance processes and previous audits. Additionally, consider third-party testing for the products to validate compliance with the relevant regulations in your region, as standards may vary across Africa, South America, the Middle East, and Europe. -

2. What is the best carbon monoxide detector for commercial applications?

The best carbon monoxide detector for commercial applications typically features advanced sensors with low-level monitoring capabilities, high reliability, and ease of integration into existing safety systems. Models like the Defender LL6270 are designed for such environments, offering robust performance and user-friendly interfaces. When selecting a detector, consider factors like installation requirements, maintenance needs, and compatibility with other safety equipment. -

3. How can I verify the reliability of a carbon monoxide detector supplier?

Start by researching the supplier’s reputation through customer reviews and industry references. Request case studies or testimonials from businesses in your sector that have utilized their products. Additionally, evaluate their manufacturing processes, warranty policies, and customer support services. Conducting site visits or audits can further substantiate their reliability and commitment to quality. -

4. What are the minimum order quantities (MOQ) for carbon monoxide detectors?

Minimum order quantities for carbon monoxide detectors can vary significantly between suppliers. Typically, MOQs range from 100 to 1,000 units, depending on the model and supplier’s production capabilities. It’s advisable to discuss your requirements with potential suppliers to negotiate favorable terms that align with your purchasing strategy while ensuring you meet your operational needs. -

5. What payment terms should I expect when purchasing carbon monoxide detectors internationally?

Payment terms can vary widely by supplier and region. Common terms include a 30% deposit upfront, with the balance payable upon shipment or delivery. For larger orders, you might negotiate more favorable terms, such as extended payment periods or letter of credit arrangements. Always clarify payment methods (e.g., bank transfer, credit card) and potential currency fluctuations to avoid financial discrepancies. -

6. How can I customize carbon monoxide detectors for my specific needs?

Customization options can include branding, specific sensor technology, or features tailored to your industry requirements. When approaching suppliers, clearly outline your specifications and inquire about their customization capabilities. Many manufacturers offer flexible solutions, but be prepared for potential minimum order quantities and longer lead times due to bespoke manufacturing processes. -

7. What are the logistics considerations for importing carbon monoxide detectors?

Logistics considerations include shipping methods, customs regulations, and import duties specific to your country. Ensure you work with a logistics partner experienced in handling hazardous materials, as carbon monoxide detectors may fall under such categories. It’s crucial to factor in lead times for shipping, as well as the potential for delays at customs, to maintain your supply chain efficiency. -

8. How do I conduct quality assurance for carbon monoxide detectors upon receipt?

Upon receiving your order, perform a detailed inspection of the detectors, checking for physical damage and ensuring they match the specifications outlined in your purchase agreement. Conduct functional tests to verify performance, and maintain records of these inspections for future reference. Establish a quality assurance protocol that includes periodic checks to ensure ongoing compliance with safety standards throughout the product lifecycle.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

A Look at Carbon Monoxide Detector Manual Manufacturers & Suppliers

Could not verify enough suppliers for carbon monoxide detector manual to create a list at this time.

Strategic Sourcing Conclusion and Outlook for carbon monoxide detector manual

In conclusion, the strategic sourcing of carbon monoxide detectors is pivotal for ensuring safety and compliance in various industries across international markets. As highlighted throughout this guide, understanding the nuances of product specifications, regulatory standards, and regional preferences is essential for B2B buyers aiming to make informed purchasing decisions. The availability of comprehensive manuals and quick-start guides, such as those offered by manufacturers like Defender, underscores the importance of accessible information for effective installation and maintenance.

Investing in high-quality carbon monoxide detection technology not only enhances workplace safety but also mitigates the risks associated with carbon monoxide exposure. B2B buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize suppliers that provide robust product support and detailed documentation, ensuring that their teams are well-equipped to handle these critical devices.

As the global market continues to evolve, staying ahead of emerging trends and technological advancements in carbon monoxide detection will be crucial. We encourage international buyers to actively seek partnerships with reputable manufacturers and engage in continuous learning to enhance their sourcing strategies. Together, let’s foster a safer future by prioritizing effective carbon monoxide detection solutions.