A B2B Buyer’s Guide to Replacement Bar Stool Legs: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for replacement bar stool legs

In the ever-evolving landscape of the hospitality and furniture industries, sourcing high-quality replacement bar stool legs is a critical challenge for international B2B buyers. As establishments across Africa, South America, the Middle East, and Europe seek to maintain their aesthetic appeal while ensuring functionality, the demand for durable and stylish replacement legs has surged. This guide is designed to navigate you through the complexities of the global market for replacement bar stool legs, providing insights into various styles, applications, and materials available.

From identifying the right types of legs suited for specific bar stool designs to understanding the nuances of supplier vetting, this comprehensive resource equips you with the knowledge necessary to make informed purchasing decisions. You’ll discover how to evaluate costs effectively and assess the quality of products, ensuring that your investments yield long-term benefits.

Whether you’re based in bustling cities like Lagos or Frankfurt, the insights provided here are tailored to meet the unique needs of international buyers. By leveraging this guide, you can confidently source the right replacement bar stool legs that not only enhance your furniture’s longevity but also elevate your establishment’s overall ambiance and customer experience. Engage with this essential resource to transform your procurement process and stay ahead in a competitive market.

Understanding replacement bar stool legs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Chrome Base | Sleek chrome finish, versatile design | Bars, restaurants, cafes | Pros: Timeless look, easy to clean. Cons: Can scratch easily. |

| Retro Double Ring Base | Double ring support, vintage aesthetic | Diners, themed establishments | Pros: Unique style, sturdy support. Cons: Limited modern appeal. |

| Adjustable Height Base | Height adjustable mechanism, often hydraulic | Multi-purpose venues | Pros: Versatility for different customer heights. Cons: Mechanism can wear out. |

| Backless Metal Base | Minimalist design, lightweight and stackable | Outdoor venues, events | Pros: Space-saving, easy to move. Cons: Less comfort without back support. |

| Tulip Base | Rounded base, often paired with modern styles | Upscale restaurants, lounges | Pros: Stylish appearance, stability. Cons: Higher price point. |

What are the Characteristics of Classic Chrome Bases?

Classic chrome bases feature a polished finish and a simple, elegant design that complements various decor styles. They are particularly suited for environments such as bars and restaurants where aesthetics and functionality are key. When purchasing, consider the base’s durability against scratches and the maintenance required to keep the chrome looking pristine. Buyers should also evaluate the compatibility of these bases with existing bar stools to ensure a seamless integration.

How Do Retro Double Ring Bases Stand Out?

Retro double ring bases are characterized by their vintage design, providing a nostalgic feel to any establishment. These bases are often found in diners and themed restaurants, appealing to customers seeking a unique dining experience. When selecting this type, buyers should assess the weight capacity and stability, as the double ring design offers enhanced support. However, it’s essential to note that their retro appeal may not suit all modern venues.

Why Choose Adjustable Height Bases?

Adjustable height bases are designed with a hydraulic mechanism, allowing users to modify the seat height easily. This feature is particularly beneficial in multi-purpose venues that cater to diverse clientele. Buyers should consider the reliability of the adjustment mechanism and the ease of use. While these bases offer great versatility, potential buyers must be aware of the maintenance required to ensure longevity and functionality.

What Advantages Do Backless Metal Bases Offer?

Backless metal bases are designed for minimalism and portability, making them ideal for outdoor venues and events. Their lightweight nature allows for easy rearrangement, while their stackable design saves space during storage. When purchasing, it’s crucial to consider the comfort level for patrons, as the lack of back support may deter some customers. Additionally, buyers should evaluate the materials used to ensure they withstand outdoor conditions.

How Do Tulip Bases Enhance Upscale Settings?

Tulip bases provide a modern aesthetic with their rounded shapes, making them a popular choice for upscale restaurants and lounges. Their design not only adds elegance but also offers stability, accommodating various seat styles. Buyers should weigh the cost against the potential for increased customer appeal and satisfaction. While tulip bases are generally more expensive, their visual impact and durability can justify the investment in high-end settings.

Key Industrial Applications of replacement bar stool legs

| Industry/Sector | Specific Application of Replacement Bar Stool Legs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Replacement in Restaurants and Bars | Enhances customer comfort and seating stability, prolonging furniture life | Quality of materials, compatibility with existing furniture styles, local availability |

| Retail | Upgrading Display and Sampling Stools | Improves aesthetics and functionality, attracting more customers | Design options, ease of assembly, compliance with local regulations |

| Education | Refurbishing Cafeteria and Student Lounge Furniture | Provides durable and safe seating options for students | Safety standards, durability under heavy use, ease of maintenance |

| Event Management | Customizing Event Seating for Weddings and Conferences | Offers flexibility and adaptability to various event themes | Variety of styles, transportability, and quick assembly features |

| Residential | DIY Home Bar and Kitchen Stool Upgrades | Allows homeowners to personalize their space economically | Design compatibility, material choices, and cost-effectiveness |

How Are Replacement Bar Stool Legs Used in the Hospitality Industry?

In the hospitality sector, particularly in restaurants and bars, replacement bar stool legs are essential for maintaining customer satisfaction. As furniture endures heavy daily use, legs can wear out or become unstable, leading to safety concerns. By replacing these legs, businesses can enhance the overall aesthetic and comfort of their seating, ensuring that patrons enjoy their dining experience. For international buyers, sourcing durable and stylish legs that match existing decor is crucial, alongside considering local shipping options to minimize downtime.

What Role Do Replacement Bar Stool Legs Play in Retail Environments?

In retail settings, replacement bar stool legs are often used to upgrade display and sampling stools. These stools need to be visually appealing and sturdy to withstand frequent use as customers interact with products. By investing in high-quality replacement legs, retailers can create an inviting atmosphere that encourages customer engagement. Buyers from regions like Africa and South America should focus on sourcing options that align with their brand identity while ensuring compliance with local safety standards.

Why Are Replacement Bar Stool Legs Important for Educational Institutions?

Educational institutions, such as schools and universities, frequently refurbish cafeteria and student lounge furniture. Replacement bar stool legs provide a cost-effective solution to enhance seating durability and safety, which is particularly important in high-traffic areas. For international buyers, it is vital to consider the durability of materials, as well as the ease of maintenance, to accommodate diverse student populations while adhering to safety regulations.

How Do Replacement Bar Stool Legs Benefit Event Management?

In the event management industry, customization of seating is key to creating memorable experiences for guests. Replacement bar stool legs allow for the adaptation of seating arrangements for various events, from weddings to corporate conferences. The ability to quickly assemble and disassemble furniture is crucial in this sector. Buyers should prioritize sourcing options that offer a range of styles, ensuring they can cater to different themes and settings while maintaining quality and comfort.

What Advantages Do Replacement Bar Stool Legs Offer Homeowners?

For residential applications, homeowners often seek to upgrade their home bars or kitchen seating with replacement bar stool legs. This allows for personalization without the expense of entirely new furniture. Buyers can choose legs that match their existing decor, offering a unique touch to their space. When sourcing, considerations such as design compatibility, material quality, and cost-effectiveness are essential, particularly for international buyers looking to optimize their home environments economically.

3 Common User Pain Points for ‘replacement bar stool legs’ & Their Solutions

Scenario 1: Difficulty in Finding Compatible Replacement Bar Stool Legs

The Problem: One of the primary challenges faced by B2B buyers when sourcing replacement bar stool legs is ensuring compatibility with existing furniture. Many businesses, especially those in the hospitality sector, have unique bar stool designs that require specific leg dimensions and fittings. If a buyer orders the wrong size or style, it can result in wasted time and resources, not to mention potential safety hazards if stools are unstable.

The Solution: To avoid compatibility issues, buyers should first take precise measurements of their current bar stools, including leg height, width, and fitting specifications. This data should be cross-referenced with product listings from suppliers. Utilizing manufacturers’ catalogs or websites that provide detailed specifications can also be beneficial. Additionally, engaging directly with suppliers to discuss specific needs or even requesting samples can ensure that the replacement legs will fit seamlessly with existing furniture. Establishing a close working relationship with a reliable supplier can also facilitate easier returns or exchanges if needed.

Scenario 2: The Challenge of Durability and Material Quality

The Problem: Another common pain point for B2B buyers is the durability of replacement bar stool legs. Many businesses invest in high-quality furniture, but when it comes to replacement parts, there can be a tendency to compromise on material quality due to cost constraints. This can lead to frequent replacements, impacting both budget and customer satisfaction, especially in high-traffic areas like bars and restaurants.

The Solution: To ensure longevity, buyers should prioritize sourcing replacement legs made from robust materials such as stainless steel or high-grade aluminum, which offer superior resistance to wear and tear. It’s advisable to request material certifications and test reports from suppliers to validate quality claims. Additionally, buyers can look for legs that come with warranties, indicating confidence from manufacturers in their products’ durability. When budgeting, consider the long-term cost savings associated with investing in higher-quality components, which can reduce the frequency of replacements and maintenance.

Scenario 3: Managing Lead Times and Delivery Expectations

The Problem: B2B buyers often face challenges with lead times and delivery when sourcing replacement bar stool legs, especially in international markets. Delays in receiving essential components can hinder operations, leading to dissatisfied customers and lost revenue, particularly for businesses that depend on quick turnarounds for repairs or replacements.

The Solution: To effectively manage lead times, buyers should conduct thorough research on suppliers’ shipping policies and average delivery times. When placing orders, it’s essential to communicate urgency and confirm expected delivery dates. Consider building relationships with multiple suppliers to create a backup plan in case of unforeseen delays. Additionally, exploring local suppliers can reduce shipping times and costs. For critical situations, buyers might also consider keeping a small inventory of commonly used replacement legs on hand to mitigate disruptions in service. Implementing a just-in-time inventory system could further streamline operations and enhance customer satisfaction.

By addressing these common pain points with strategic solutions, B2B buyers can ensure a smoother purchasing process and better overall experience with replacement bar stool legs.

Strategic Material Selection Guide for replacement bar stool legs

What Are the Key Materials for Replacement Bar Stool Legs?

When selecting replacement bar stool legs, understanding the properties and implications of various materials is essential for B2B buyers. The choice of material can significantly impact durability, cost, and suitability for specific applications, particularly in diverse markets across Africa, South America, the Middle East, and Europe.

How Do Metal Bar Stool Legs Perform in Various Environments?

Key Properties: Metal legs, typically made from steel or aluminum, offer high strength and excellent load-bearing capabilities. They can withstand significant pressure and are often treated for corrosion resistance, making them suitable for both indoor and outdoor use.

Pros & Cons: Metal legs are highly durable and can last for many years with proper maintenance. However, they can be heavier than other materials, which may complicate shipping and assembly. The cost can vary; while aluminum is generally less expensive, steel may require additional treatments to prevent rust, increasing overall costs.

Impact on Application: Metal legs are compatible with various seating styles and can support a wide range of weight capacities, making them ideal for commercial settings such as restaurants and bars.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers should also consider local preferences for finishes and styles, which can vary significantly across regions like Nigeria and Germany.

What Advantages Do Wooden Bar Stool Legs Offer?

Key Properties: Wooden legs provide natural aesthetics and are often made from hardwoods like oak or maple. They offer good strength and can be treated for moisture resistance, enhancing their durability.

Pros & Cons: The primary advantage of wooden legs is their visual appeal, which can enhance the overall design of a bar stool. However, they may be less durable than metal counterparts, particularly in humid environments. The cost of high-quality hardwood can also be significant, making them a more premium option.

Impact on Application: Wooden legs are suitable for upscale environments where aesthetics are a priority, but they may not perform well in high-traffic areas without proper care.

Considerations for International Buyers: Buyers should be aware of local wood sourcing regulations and sustainability practices, especially in regions with strict environmental standards.

How Do Plastic Bar Stool Legs Compare in Terms of Practicality?

Key Properties: Plastic legs are lightweight and often made from high-density polyethylene (HDPE) or polypropylene. They are resistant to moisture and corrosion, making them suitable for various environments.

Pros & Cons: The primary advantage of plastic legs is their affordability and ease of maintenance. However, they may not be as strong as metal or wood, limiting their use in high-capacity settings.

Impact on Application: Plastic legs are ideal for casual settings or outdoor use, where weight and ease of transport are priorities.

Considerations for International Buyers: Compliance with safety standards is essential, particularly in regions like Europe, where regulations on materials can be stringent.

What Role Do Composite Materials Play in Replacement Bar Stool Legs?

Key Properties: Composite materials, such as fiberglass-reinforced plastics, combine the benefits of both plastic and metal. They offer excellent strength-to-weight ratios and are resistant to various environmental factors.

Pros & Cons: Composite legs provide a balance of durability and aesthetic appeal, making them versatile for different applications. However, they can be more expensive to manufacture, impacting overall costs.

Impact on Application: These materials are suitable for modern designs and can withstand various conditions, making them ideal for both indoor and outdoor settings.

Considerations for International Buyers: Buyers should ensure that composite materials meet local safety and environmental standards, as regulations can vary widely across regions.

Summary of Material Selection for Replacement Bar Stool Legs

| Material | Typical Use Case for Replacement Bar Stool Legs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Metal | High-traffic commercial settings | High durability and load capacity | Heavier, potential rust issues | Medium |

| Wood | Upscale restaurants and bars | Aesthetic appeal | Less durable in humid environments | High |

| Plastic | Casual and outdoor settings | Lightweight and affordable | Limited strength for heavy use | Low |

| Composite | Modern designs in various environments | Excellent strength-to-weight ratio | Higher manufacturing costs | Medium to High |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for replacement bar stool legs, ensuring informed purchasing decisions tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for replacement bar stool legs

What Are the Key Stages in the Manufacturing Process for Replacement Bar Stool Legs?

The manufacturing process of replacement bar stool legs involves several critical stages that ensure the final product meets quality and durability standards. Understanding these stages is essential for B2B buyers seeking reliable suppliers.

-

Material Preparation: This initial stage involves sourcing high-quality materials, typically metals such as steel or aluminum, which are favored for their strength and durability. Materials are often subjected to a chemical treatment process to prevent corrosion, especially important for products intended for bars and restaurants where moisture exposure is common. Suppliers may offer options for different finishes, such as powder coating or chrome plating, to enhance aesthetic appeal and longevity.

-

Forming: In this stage, the prepared materials are shaped into the desired form through processes like welding, bending, or stamping. Advanced techniques such as CNC (Computer Numerical Control) machining are often employed for precision and consistency. The forming process should adhere to specified dimensions and designs, which are critical for compatibility with various stool types.

-

Assembly: Once the individual components are formed, they undergo assembly. This may include attaching legs to bases, integrating swivel mechanisms, or adding footrests. Automation is increasingly utilized in this stage to enhance efficiency and reduce labor costs. However, skilled labor remains essential for quality assurance during assembly, particularly for custom or intricate designs.

-

Finishing: The finishing stage involves applying protective coatings and aesthetic treatments. This can include painting, powder coating, or plating, depending on the desired look and durability requirements. Quality in this phase is crucial, as it impacts both the visual appeal and the longevity of the product. Proper curing processes must be followed to ensure coatings adhere effectively and resist chipping or peeling.

How Is Quality Assurance Implemented in the Manufacturing of Replacement Bar Stool Legs?

Quality assurance (QA) is a pivotal aspect of the manufacturing process, ensuring that replacement bar stool legs meet international standards and customer expectations.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, an internationally recognized quality management system standard that emphasizes a consistent approach to quality and continuous improvement. Compliance with CE marking is also critical for products sold in the European market, indicating conformity with health, safety, and environmental protection standards.

-

Quality Control Checkpoints: Quality control is integrated at various stages of production:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps catch defects early. This includes checking dimensions, weld quality, and assembly integrity.

– Final Quality Control (FQC): Before products are shipped, a thorough inspection is conducted to verify that they meet design specifications and quality standards. Testing may include load tests to assess durability and stability. -

Testing Methods: Common testing methods include tensile strength tests, corrosion resistance tests, and dimensional inspections. These tests ensure that the final products can withstand the rigors of use in commercial environments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring the reliability of replacement bar stool legs.

-

Supplier Audits: Conducting on-site audits provides insight into the supplier’s manufacturing processes and quality assurance measures. Buyers can assess compliance with international standards and observe the operational environment firsthand.

-

Quality Reports: Requesting detailed quality reports can offer transparency into a supplier’s QA processes. These reports should outline testing methods, results, and corrective actions taken for any identified issues.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These independent entities evaluate the manufacturing processes and final products, providing an unbiased assessment of quality.

-

Certifications and Compliance Documentation: Buyers should seek suppliers who can provide documentation of compliance with relevant standards, such as ISO certifications or CE marking. This documentation serves as a testament to the supplier’s commitment to quality.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers face specific challenges and considerations when it comes to quality control in the procurement of replacement bar stool legs.

-

Cultural and Regulatory Differences: Understanding the regulatory landscape in the supplier’s country is essential. Different regions may have varying standards for materials and manufacturing processes. Buyers should be familiar with these regulations to ensure compliance.

-

Supply Chain Transparency: Ensuring transparency throughout the supply chain can mitigate risks associated with quality. Buyers should inquire about the sourcing of materials and the reputation of component suppliers.

-

Communication and Support: Establishing clear lines of communication with suppliers is vital. This includes discussing quality expectations, timelines, and addressing any concerns promptly. Language barriers can pose challenges, so utilizing multilingual staff or translation services can enhance clarity.

-

Flexibility and Responsiveness: The ability of a supplier to adapt to changing requirements is crucial. Buyers should assess the responsiveness of suppliers to quality issues or changes in order specifications, which can impact project timelines and overall satisfaction.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing replacement bar stool legs, ensuring they invest in products that meet high standards of quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘replacement bar stool legs’

Introduction

Sourcing replacement bar stool legs is a critical task for businesses in the hospitality and furniture sectors. This guide provides a comprehensive checklist to streamline your procurement process, ensuring you select the right products for your needs while maximizing quality and cost-effectiveness. Whether you’re a restaurant owner, furniture retailer, or an interior designer, following these steps will facilitate informed purchasing decisions.

Step 1: Define Your Technical Specifications

Establishing clear specifications is essential before initiating your search. Consider factors such as material (metal, wood, plastic), weight capacity, height, and design style. This clarity helps narrow down options and ensures compatibility with existing bar stools.

- Material Considerations: Different materials offer varying durability and aesthetics. For instance, metal legs may provide a modern look and greater strength, while wooden legs can enhance a rustic appeal.

- Height Requirements: Ensure that the legs match the height of your bar stools to maintain comfort and usability.

Step 2: Research Market Trends and Styles

Understanding current market trends can guide you in selecting popular and functional designs. Investigate what styles are trending in your target market, as preferences can vary significantly across regions.

- Regional Preferences: For instance, European buyers may favor sleek, minimalist designs, while South American customers might lean towards vibrant, colorful options.

- Functional Innovations: Look for features like swivel bases or adjustable heights that can enhance the functionality of your bar stools.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is crucial. Request detailed company profiles, product catalogs, and references from businesses in similar industries or regions.

- Supplier Reputation: Check online reviews and testimonials to gauge the supplier’s reliability and product quality.

- Certifications and Standards: Verify that suppliers adhere to relevant industry standards and certifications, which can be critical for quality assurance.

Step 4: Request Samples

Always request samples before making bulk purchases. This allows you to assess the quality, finish, and durability of the replacement legs firsthand.

- Quality Control: Inspect samples for craftsmanship and material integrity to ensure they meet your specifications.

- Fit and Compatibility: Test samples with existing bar stools to confirm compatibility in terms of design and functional performance.

Step 5: Negotiate Terms and Conditions

Once you have identified potential suppliers and are satisfied with the samples, engage in negotiations regarding pricing, delivery timelines, and payment terms.

- Volume Discounts: Inquire about pricing structures for bulk orders, which can significantly reduce costs.

- Return Policies: Understand the return and exchange policies in case the products do not meet your expectations upon delivery.

Step 6: Confirm Logistics and Shipping Details

Before finalizing your order, confirm shipping logistics and timelines. This step ensures that you receive your products on time, minimizing disruptions to your business operations.

- Shipping Costs: Assess the total shipping costs and compare them across suppliers to find the most economical option.

- Delivery Times: Ensure that the delivery schedule aligns with your project timelines to avoid delays.

Step 7: Establish a Long-term Relationship

After your initial purchase, consider building a long-term relationship with your supplier. This can lead to better pricing, priority service, and access to new products.

- Feedback Loop: Provide feedback on your experience to help suppliers improve their offerings and service.

- Future Orders: Discuss potential future orders and how you can work together to meet evolving needs.

By following these steps, B2B buyers can effectively navigate the sourcing process for replacement bar stool legs, ensuring they make informed decisions that align with their business objectives.

Comprehensive Cost and Pricing Analysis for replacement bar stool legs Sourcing

What Are the Key Cost Components in Sourcing Replacement Bar Stool Legs?

When sourcing replacement bar stool legs, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly influences the cost. Common materials include metal, wood, and plastic. High-quality metals like stainless steel can drive up costs but offer better durability and aesthetic appeal.

-

Labor: Labor costs vary by region and production methods. In regions with lower labor costs, such as parts of Africa and South America, sourcing may be more economical. However, the skill level required for manufacturing certain designs may impact labor costs.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and factory operations. Efficient manufacturing processes can reduce these costs, making it essential to evaluate potential suppliers on their production efficiency.

-

Tooling: Custom designs require specialized tooling, which can add to the initial costs. Understanding the tooling requirements for specific designs helps in negotiating better pricing.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the final products meet quality standards, which can add to the overall cost. Buyers should inquire about the QC measures employed by suppliers to avoid future issues.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors such as distance, mode of transportation, and import duties can significantly impact the overall cost.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on the supplier’s market positioning and the perceived value of the product.

How Do Price Influencers Affect Replacement Bar Stool Leg Costs?

Several factors influence pricing in the replacement bar stool leg market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts. Buyers should negotiate MOQs to achieve better pricing, especially when dealing with multiple suppliers.

-

Specifications and Customization: Custom designs or specific specifications can lead to higher costs. Buyers should balance their need for unique features with their budget constraints.

-

Material Quality and Certifications: Higher-quality materials often come with certifications (e.g., ISO, ANSI) that may be required by certain markets. Understanding these requirements can help in selecting the right supplier.

-

Supplier Factors: The supplier’s reputation, production capabilities, and location can all influence pricing. Established suppliers may charge more but offer reliability and better service.

-

Incoterms: Understanding international shipping terms is vital for cost management. Terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) dictate who bears the costs at various stages of shipping, impacting total pricing.

What Buyer Tips Should Be Considered for Cost-Efficiency?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Effectively: Leverage your purchasing power by negotiating terms with suppliers. Discussing volume discounts and payment terms can lead to substantial savings.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the costs associated with shipping, tariffs, and potential maintenance. A lower upfront cost may not always equate to lower overall expenses.

-

Understand Pricing Nuances: Be aware of currency fluctuations and their impact on pricing. Establishing contracts in stable currencies can mitigate risks.

-

Research Local Suppliers: Investigate local suppliers to reduce shipping costs and lead times. Local sourcing can also simplify logistics and improve communication.

-

Request Samples: Before committing to large orders, request samples to evaluate quality. This can prevent costly mistakes related to poor-quality products.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always seek updated quotes and conduct thorough market research before making purchasing decisions.

Alternatives Analysis: Comparing replacement bar stool legs With Other Solutions

Exploring Alternatives to Replacement Bar Stool Legs

When it comes to maintaining or upgrading bar stools, replacement legs are a common solution. However, businesses may want to consider various alternatives that can also enhance the functionality and aesthetics of their seating arrangements. This section evaluates replacement bar stool legs against two viable alternatives: complete bar stool replacement and adjustable height bar stools. Each option presents unique advantages and considerations that can impact purchasing decisions.

| Comparison Aspect | Replacement Bar Stool Legs | Complete Bar Stool Replacement | Adjustable Height Bar Stools |

|---|---|---|---|

| Performance | Restores original stability and function | Offers new designs and improved comfort | Versatile for different seating heights |

| Cost | Generally low-cost option (e.g., $70-$300) | Higher initial investment (e.g., $150-$500) | Moderate cost (e.g., $100-$400) |

| Ease of Implementation | Simple to install, often DIY | Requires disposal of old stools and new assembly | Easy to adjust but may require maintenance |

| Maintenance | Minimal; occasional checks needed | Varies based on materials and usage | Regular checks needed for height adjustment mechanisms |

| Best Use Case | Ideal for businesses with durable seats needing minor repairs | Suitable for establishments wanting a complete aesthetic overhaul | Perfect for environments with varying customer preferences |

What Are the Benefits and Drawbacks of Complete Bar Stool Replacement?

Complete bar stool replacement involves acquiring entirely new stools rather than just replacing the legs. This option allows businesses to select contemporary designs that align with current trends and customer preferences. The primary advantage is the opportunity to enhance the overall look and comfort of the seating area. However, this method can be significantly more costly, and disposal of old furniture can be an additional hassle. Moreover, businesses may face longer lead times to receive new stools.

Why Consider Adjustable Height Bar Stools?

Adjustable height bar stools provide flexibility, allowing users to modify the stool’s height to suit various settings or personal preferences. This adaptability makes them an excellent option for restaurants and bars that cater to diverse clientele. The primary drawback is the potential for mechanical issues over time, which may require maintenance to ensure proper function. Additionally, while these stools can be cost-effective compared to full replacements, they may still represent a higher investment than simply replacing legs.

How to Choose the Right Solution for Your Bar Stool Needs

When selecting between replacement bar stool legs and alternatives, B2B buyers should assess their specific needs, including budget constraints, desired aesthetics, and functional requirements. If the existing seats are in good condition and simply need a refresh, replacement legs are often the most economical and straightforward choice. Conversely, if a business aims to modernize its appearance or accommodate a wider range of customer preferences, investing in new stools or adjustable options may yield better long-term value. Evaluating these factors will lead to informed decisions that align with operational goals and customer satisfaction.

Essential Technical Properties and Trade Terminology for replacement bar stool legs

What Are the Key Technical Properties of Replacement Bar Stool Legs?

When sourcing replacement bar stool legs, understanding the technical specifications is crucial for ensuring durability, safety, and compatibility. Here are some essential properties to consider:

-

Material Grade

The material used for bar stool legs significantly impacts strength and durability. Common materials include steel, aluminum, and wood. Steel, for instance, offers high tensile strength, making it ideal for heavy-use environments like restaurants and bars. Aluminum is lightweight and resistant to corrosion, while wood provides aesthetic appeal but may require additional maintenance. Selecting the appropriate material grade ensures that the legs can withstand the intended load and usage conditions. -

Weight Capacity

Each bar stool leg or base has a defined weight capacity, which is crucial for safety and functionality. This specification indicates the maximum weight that the stool can support without compromising structural integrity. For B2B buyers, understanding this capacity is essential when matching replacement legs to existing stools, especially in high-traffic areas. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. For replacement bar stool legs, this includes measurements such as height, width, and attachment points. A tight tolerance ensures that the legs fit securely with the stool seat and bases, minimizing wobble and enhancing user comfort. Poor tolerance can lead to instability and increased wear over time. -

Finish Type

The finish on replacement bar stool legs not only affects aesthetics but also durability. Common finishes include powder coating, chrome plating, and varnishing for wood. A high-quality finish provides resistance to scratches, rust, and fading, which is particularly important for maintaining the appearance of bar stools in commercial settings. Buyers should consider the environment in which the stools will be used to select the most appropriate finish. -

Height Adjustability

Some replacement bar stool legs offer height adjustability, which can be a valuable feature for versatility in seating arrangements. This property allows stools to be modified for different user preferences or table heights, making them suitable for various settings. For B2B buyers, investing in adjustable options can enhance customer satisfaction and usability. -

Base Design

The design of the stool base, such as a four-legged pyramid or a swivel base, influences stability and functionality. Different designs cater to specific applications; for instance, swivel bases are ideal for dynamic environments where users frequently move in and out of their seats. Understanding the implications of base design helps in selecting suitable replacements that align with operational needs.

What Are Common Trade Terms Used in Replacement Bar Stool Legs?

Understanding industry jargon is vital for effective communication and negotiation in the B2B space. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of bar stool legs, buyers may seek OEM parts to ensure compatibility with existing furniture. This term is essential for maintaining brand integrity and product quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers, as it impacts inventory management and cost efficiency. Buyers must evaluate their needs against the supplier’s MOQ to make informed purchasing decisions. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products or services. For replacement bar stool legs, issuing an RFQ helps buyers gather multiple quotes, enabling them to compare prices and terms effectively. This process is essential for making cost-effective sourcing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping responsibilities, insurance, and risk management, which are vital for cross-border purchases of replacement bar stool legs. -

Lead Time

Lead time refers to the amount of time from the placement of an order until the delivery of the product. Understanding lead times is critical for inventory planning and ensuring that replacement legs are available when needed. Buyers should discuss lead times upfront to avoid disruptions in their supply chain. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and longevity of the product. For replacement bar stool legs, a warranty can provide buyers with assurance regarding the durability and performance of their purchase, making it an important consideration during sourcing.

By familiarizing yourself with these technical properties and industry terms, you can make more informed purchasing decisions, ensuring that your replacement bar stool legs meet the required specifications for quality and functionality.

Navigating Market Dynamics and Sourcing Trends in the replacement bar stool legs Sector

What Are the Key Trends Shaping the Global Replacement Bar Stool Legs Market?

The global replacement bar stool legs market is experiencing a dynamic shift driven by several key factors. Increasing consumer demand for customization and personalization in furniture is pushing manufacturers to innovate and offer a variety of designs and styles. In regions such as Africa and South America, there is a growing trend towards locally-sourced materials, which not only supports local economies but also reduces transportation costs. Meanwhile, in Europe and the Middle East, buyers are leaning towards premium materials that offer both aesthetic appeal and durability, reflecting a broader trend of investing in high-quality furnishings that can withstand heavy usage.

Emerging technologies are also reshaping sourcing strategies. The integration of e-commerce platforms allows B2B buyers to easily compare products, prices, and suppliers, enhancing transparency and efficiency in the procurement process. Additionally, the use of 3D printing technology is on the rise, enabling manufacturers to produce custom replacement legs quickly and cost-effectively. This trend is particularly advantageous for international buyers who require specific designs or sizes not readily available in standard inventories.

How Is Sustainability Influencing the Sourcing of Replacement Bar Stool Legs?

Sustainability is becoming increasingly important in the replacement bar stool legs sector, as both buyers and manufacturers recognize the environmental impact of their choices. The furniture industry is notorious for its carbon footprint, prompting a shift towards more sustainable practices. Many manufacturers are adopting eco-friendly materials such as reclaimed wood, recycled metals, and non-toxic finishes to minimize environmental harm.

Moreover, ethical sourcing is paramount for international B2B buyers, particularly those operating in markets with stringent regulations around sustainability. Certifications such as Forest Stewardship Council (FSC) and Global Organic Textile Standard (GOTS) are becoming essential in ensuring that suppliers adhere to responsible practices. Buyers are encouraged to engage with suppliers who prioritize transparency in their supply chains, as this not only enhances brand reputation but also appeals to environmentally-conscious consumers.

What Is the Historical Context of Replacement Bar Stool Legs in B2B Markets?

The concept of replacement bar stool legs has evolved significantly over the past few decades. Initially, the focus was predominantly on functionality, with basic designs that catered to the commercial sector, particularly bars and restaurants. However, as consumer preferences shifted towards aesthetics and personalization, manufacturers began to innovate, introducing various styles, materials, and finishes that cater to diverse markets.

This evolution reflects broader trends in the furniture industry, where the emphasis on quality, sustainability, and design is reshaping how products are sourced and marketed. Today, replacement bar stool legs are not just functional components; they are integral to creating cohesive and appealing dining environments that resonate with modern consumers across various regions. International B2B buyers are now more discerning, seeking out suppliers who can provide not only quality products but also align with their values and business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of replacement bar stool legs

-

How do I solve the issue of finding the right replacement bar stool legs for my business?

To effectively find the right replacement bar stool legs, start by assessing the specific needs of your establishment, including style, material, and dimensions. Measure the existing legs and note their mounting style to ensure compatibility. Research suppliers that offer a variety of styles and customization options to meet your aesthetic preferences. Additionally, reaching out to manufacturers directly can provide insights into their product range and help you make informed decisions based on your unique requirements. -

What is the best material for replacement bar stool legs?

The best material for replacement bar stool legs largely depends on your intended use and desired aesthetic. Metal legs are durable and offer a modern look, ideal for high-traffic environments. Wooden legs, while traditionally styled, can provide warmth and comfort, making them suitable for cafes and restaurants. Consider factors such as weight capacity, maintenance, and resistance to wear and tear when selecting the material that best fits your operational needs. -

What are the advantages of customizing replacement bar stool legs?

Customizing replacement bar stool legs allows you to match your existing furniture, enhance branding, and cater to specific design themes. Custom options can include unique finishes, colors, and sizes that align with your overall décor. This not only improves the visual appeal of your seating but can also improve customer comfort and satisfaction. Additionally, custom solutions can help differentiate your establishment in a competitive market, making it more attractive to potential customers. -

What should I consider regarding minimum order quantities (MOQ) when sourcing replacement bar stool legs?

When sourcing replacement bar stool legs, it’s crucial to inquire about the supplier’s minimum order quantity (MOQ). MOQs can vary significantly based on the supplier, material, and customization options. Determine your current and future needs to avoid overcommitting to a large order that may exceed your requirements. Some suppliers may offer flexibility for smaller orders, especially for first-time buyers, which can be advantageous for businesses testing new designs or styles. -

How can I vet suppliers for replacement bar stool legs?

Vetting suppliers involves assessing their reputation, product quality, and customer service. Start by reviewing online testimonials, case studies, and references from other businesses in your region. Request samples to evaluate the quality of materials and craftsmanship. Additionally, check for certifications that indicate adherence to industry standards. Establish communication to gauge responsiveness and willingness to address any queries or concerns, which can be indicative of their overall reliability. -

What payment terms are commonly offered by suppliers of replacement bar stool legs?

Payment terms can vary widely among suppliers, so it’s essential to clarify these details upfront. Common arrangements include upfront payments, partial deposits, or net payment terms (e.g., net 30 or net 60). International buyers should also be aware of currency fluctuations and potential transaction fees. Establishing clear payment terms can help manage cash flow effectively and build a trustworthy relationship with your supplier. -

How do I ensure quality assurance for replacement bar stool legs?

To ensure quality assurance, collaborate with suppliers that have established quality control processes. Request information about their testing methods and certifications for materials used in the production of bar stool legs. Consider conducting third-party inspections, especially for bulk orders, to verify compliance with your quality standards before shipment. Regular communication and feedback loops with your supplier can also foster continuous improvement in product quality. -

What logistics considerations should I keep in mind when importing replacement bar stool legs?

When importing replacement bar stool legs, logistics considerations such as shipping costs, lead times, and customs regulations are critical. Work with suppliers who provide transparent shipping options and timelines, as delays can impact your business operations. Familiarize yourself with the import duties and taxes applicable in your region to avoid unexpected expenses. Partnering with experienced freight forwarders can also streamline the process, ensuring efficient delivery and compliance with international trade regulations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Replacement Bar Stool Legs Manufacturers & Suppliers List

1. Reddit – Replacement Leg for Barstool

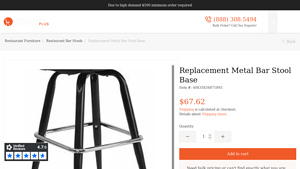

2. Restaurant Furniture Plus – Replacement Metal Bar Stool Base

Domain: restaurantfurnitureplus.com

Registered: 2016 (9 years)

Introduction: Replacement Metal Bar Stool Base

3. American Chairs – Replacement Parts for Bar Stools and Diner Chairs

Domain: americanchairs.com

Registered: 2002 (23 years)

Introduction: Replacement Parts for bar stools and diner chairs including: Set of 2 Replacement Seats & Backs – $279.95, Diner Chair Foot Glides (Set of 24) – $69.99, Laminate Sheets – $399.95, Vinyl Yardage – $49.99, 1.25″ Aluminum Edging – $169.95, 2.25″ Aluminum Edging – $199.95, Bar Stool Foot Caps (Set of 24) – $42.99, 1-Ring Bar Stool Frame – $59.95, Diner Chair Frame – $129.95, 797 Art Deco Legs (Set of …

4. Etsy – Replacement Stool Legs

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Replacement Stool Legs available on Etsy with over 1,000 items listed. Features include free shipping, delivery within 7 days, and options to sort by relevancy, price, customer reviews, and recency. Notable products include: 1) Rebar Hair Pin Legs Set of 4 – $128.49, 2) U-Shape Table Leg – Sale Price $68.95 (originally $114.92), 3) Solid Beech Wood Spider Legs – Sale Price $217.70 (originally $311…

5. Central Seating – Bolt Down Bar Stool Replacement Base Leg Column Set

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Bolt Down Bar Stool Replacement Base Leg Column Set”, “Height”: “26 inches”, “Condition”: “New”, “Price”: “$149.99”, “Shipping”: “Free USPS Priority Mail”, “Returns”: “14 days returns, buyer pays for return shipping”, “Quantity Available”: “More than 10”, “Seller”: “centralseating”, “Item Number”: “114662249650”, “Model”: “BBDR301-28\”H”, “Category”: “Business & Industrial > Rest…

Strategic Sourcing Conclusion and Outlook for replacement bar stool legs

In the competitive landscape of the bar stool industry, strategic sourcing of replacement legs and bases is essential for maintaining product quality and customer satisfaction. By prioritizing high-quality materials and reliable suppliers, international B2B buyers can ensure that their offerings stand out in markets across Africa, South America, the Middle East, and Europe. Understanding the diverse styles and construction options available, from retro designs to modern aesthetics, allows businesses to cater to various customer preferences while also improving their brand image.

Moreover, focusing on cost-effective solutions without compromising on quality can significantly enhance profitability. Leveraging partnerships with manufacturers that offer customization and rapid delivery can streamline operations and reduce lead times, ultimately benefiting end-users.

Looking ahead, businesses must remain agile and responsive to market trends, which may include sustainable materials and innovative designs. As the demand for stylish and functional seating continues to grow, now is the time for buyers to align their sourcing strategies with these evolving consumer needs. Engage with suppliers who understand your market to secure the best deals and maintain a competitive edge in your region.