Ac Input Isolator 1440 Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for ac input isolator 1440

In the rapidly evolving landscape of global commerce, sourcing reliable AC input isolators, particularly the AC input isolator 1440, presents a significant challenge for international B2B buyers. With the increasing demand for high-quality power solutions across various sectors—ranging from telecommunications to healthcare—businesses must navigate a complex array of products, specifications, and suppliers. This guide aims to demystify the procurement process for the AC input isolator 1440 by providing a comprehensive overview of types, applications, supplier vetting strategies, and cost considerations.

Through this resource, international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—will gain actionable insights into making informed purchasing decisions. We will delve into the nuances of different isolator configurations, explore the critical applications that demand these products, and outline best practices for evaluating suppliers to ensure quality and reliability. Furthermore, this guide will highlight cost factors that influence procurement, equipping buyers with the knowledge needed to negotiate favorable terms.

By leveraging the information presented, B2B buyers can enhance their procurement strategies, mitigate risks associated with power supply disruptions, and ultimately drive operational efficiency in their organizations. This guide serves as a vital tool for navigating the global market for the AC input isolator 1440, empowering businesses to secure the power solutions they need for sustainable growth.

Understanding ac input isolator 1440 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Line Interactive UPS | Built-in isolation transformer, true sine wave output | AV systems, IT infrastructure, control systems | Pros: Reliable power backup; Cons: Higher upfront cost. |

| Digital Isolators (ADUM1440) | 2.5kVrms isolation, 4-channel, unidirectional | Industrial automation, data acquisition | Pros: Fast data transfer; Cons: Limited to specific applications. |

| AC Opto-Isolated Input Boards | Opto-isolated for safety, LED status indicators | Monitoring systems, switch status checking | Pros: Simple integration; Cons: May require additional components. |

| Isolation Transformers | Dual voltage support, EMI/RFI protection | Healthcare, sensitive electronic applications | Pros: Reduces electrical noise; Cons: Bulkier design. |

| Rack-Mount UPS Systems | Compact design, hot-swappable batteries | Data centers, telecom equipment | Pros: Space-efficient; Cons: Limited to rack-mounted setups. |

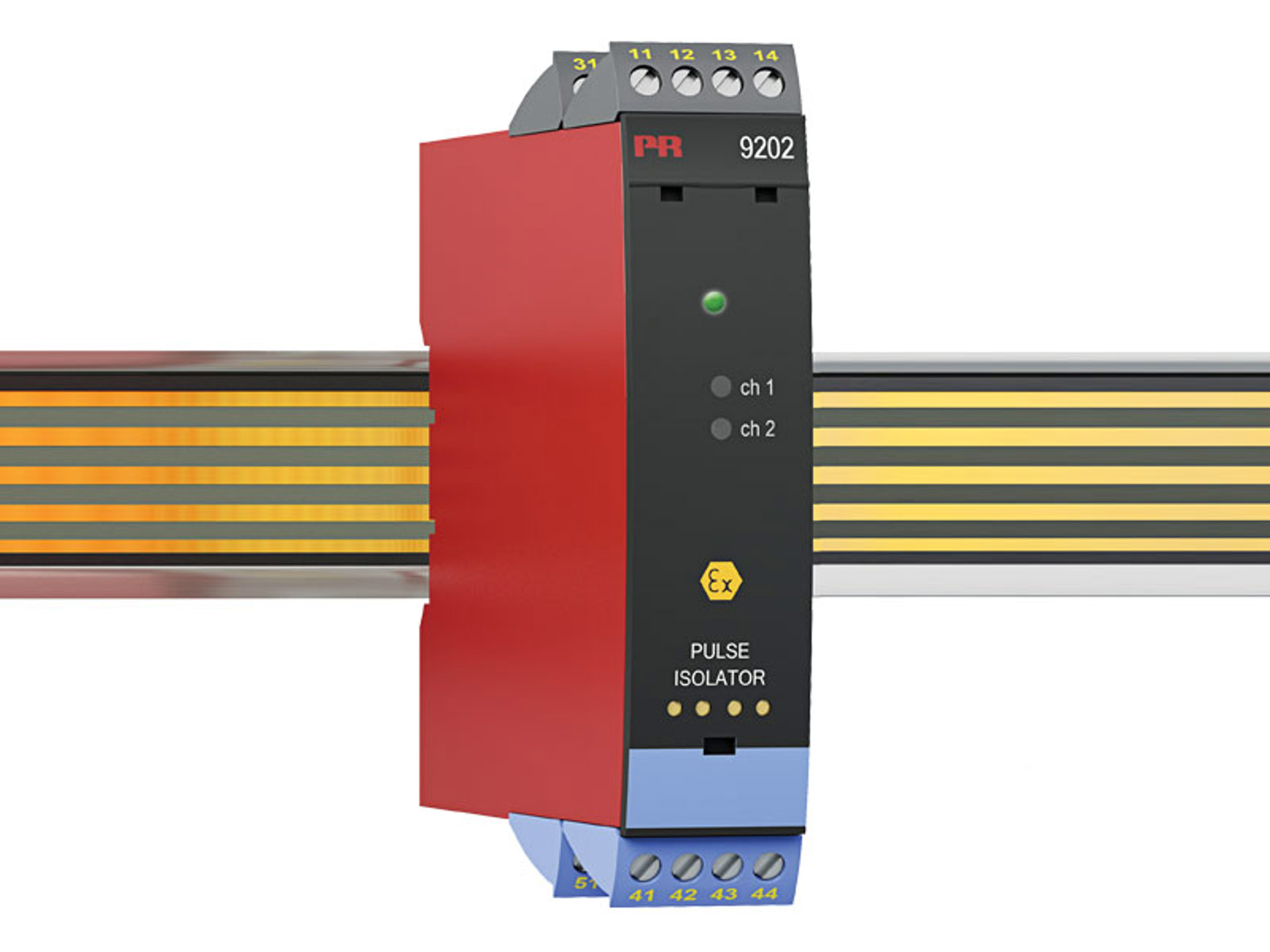

What are the key characteristics of Line Interactive UPS systems?

Line Interactive UPS systems, such as the SurgeX 1440VA model, are designed to provide consistent and clean power, particularly in mission-critical environments. They feature a built-in isolation transformer that filters out electrical noise, ensuring the safety and reliability of sensitive equipment. The true sine wave output guarantees compatibility with a wide range of devices, making them ideal for AV systems, IT infrastructure, and control systems. When considering this option, buyers should evaluate the total cost of ownership, including maintenance and battery replacement, while also factoring in the potential for downtime during power failures.

How do Digital Isolators like the ADUM1440 enhance industrial applications?

Digital isolators such as the ADUM1440 offer robust isolation capabilities with a voltage rating of 2.5kVrms. They are particularly suited for industrial automation and data acquisition applications where high-speed data transfer is critical. The four-channel configuration allows for simultaneous monitoring of multiple signals, enhancing system efficiency. Buyers should consider the specific data rate requirements and environmental conditions, as these isolators operate effectively within a temperature range of -40°C to 125°C. Their compact design also aids in space-constrained setups.

Why are AC Opto-Isolated Input Boards favored in monitoring systems?

AC Opto-Isolated Input Boards are designed to safely check the status of switches and monitor mains voltage, making them a popular choice in monitoring systems. Their opto-isolation feature ensures effective separation between input and output circuits, enhancing safety and reliability. With integrated LED status indicators, they provide immediate visual feedback on system status. While they are easy to integrate with existing setups, buyers should consider the need for additional components for complete functionality, as well as the board’s compatibility with their control systems.

What advantages do Isolation Transformers provide in sensitive applications?

Isolation transformers are essential in environments requiring reduced electrical noise and enhanced safety, such as healthcare and sensitive electronic applications. They support dual voltage options and are effective at mitigating EMI/RFI interference. This feature is particularly beneficial in applications where equipment must operate reliably without disturbances from electrical noise. However, the bulkiness of these transformers can be a drawback, especially in space-limited installations. Buyers should weigh the benefits of improved equipment protection against the physical space and installation costs.

How do Rack-Mount UPS Systems optimize space in data centers?

Rack-Mount UPS systems, such as those with a 1440VA capacity, are designed for efficient use of space in data centers and telecom environments. Their compact design allows for seamless integration into standard server racks, and features like hot-swappable batteries enable maintenance without downtime. These systems are particularly advantageous for organizations looking to maximize their rack space while ensuring reliable power backup. When purchasing, businesses should assess their specific power requirements and the overall capacity of their infrastructure to avoid overloading the system.

Key Industrial Applications of ac input isolator 1440

| Industry/Sector | Specific Application of ac input isolator 1440 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Power supply for communication equipment | Ensures uninterrupted service and protects sensitive gear | Compliance with local electrical standards and ratings |

| Industrial Automation | Isolation in control systems and PLCs | Enhances reliability and safety in high-voltage environments | Compatibility with existing systems and scalability |

| Healthcare | Power backup for critical medical devices | Guarantees continuous operation of essential equipment | Regulatory certifications and reliability assessments |

| Renewable Energy | Integration with solar inverters and wind turbines | Maximizes energy efficiency and protects against surges | Adaptability to various energy sources and voltage levels |

| Data Centers | Protection for servers and network devices | Reduces downtime and prevents equipment damage | Temperature control and monitoring capabilities |

How is the ac input isolator 1440 utilized in Telecommunications?

In the telecommunications sector, the ac input isolator 1440 is crucial for powering communication equipment, ensuring that devices remain operational even during power fluctuations. It helps in filtering electrical noise and preventing damage to sensitive electronics. For B2B buyers in regions like Africa and South America, sourcing solutions that comply with local electrical standards is vital to ensure safety and reliability in their operations.

What role does the ac input isolator 1440 play in Industrial Automation?

In industrial automation, the ac input isolator 1440 is utilized for providing isolation in control systems and Programmable Logic Controllers (PLCs). This isolation is essential for enhancing reliability and safety, especially in environments with high voltage or potential electrical interference. Buyers should consider compatibility with existing systems and the ability to scale the solution as their operations grow, particularly in emerging markets where industrial infrastructure is rapidly developing.

Why is the ac input isolator 1440 important in Healthcare?

The healthcare industry relies on the ac input isolator 1440 for providing backup power to critical medical devices, such as imaging equipment and life-support systems. This ensures that essential equipment operates continuously, even during power outages. Buyers in the healthcare sector must prioritize regulatory certifications and reliability assessments to meet stringent health and safety standards, particularly in Europe and the Middle East where regulations can be strict.

How does the ac input isolator 1440 enhance Renewable Energy systems?

The ac input isolator 1440 is integral to renewable energy applications, particularly in solar and wind energy systems, where it facilitates integration with inverters. It maximizes energy efficiency and protects against voltage surges that can damage equipment. International buyers, especially in regions with developing renewable sectors, should focus on the adaptability of these isolators to various energy sources and voltage levels to ensure optimal performance.

What benefits does the ac input isolator 1440 provide in Data Centers?

In data centers, the ac input isolator 1440 protects servers and network devices from electrical disturbances, significantly reducing downtime and preventing equipment damage. This is crucial for maintaining operational integrity in data-sensitive environments. Buyers should prioritize features like temperature control and monitoring capabilities, as these factors are essential for ensuring that equipment operates within safe parameters, especially in high-demand regions like Germany and Nigeria.

3 Common User Pain Points for ‘ac input isolator 1440’ & Their Solutions

Scenario 1: Inconsistent Power Supply Affecting Equipment Performance

The Problem: Many B2B buyers in industries like IT, telecommunications, and manufacturing face challenges with inconsistent power supply, which can lead to equipment malfunction or failure. For instance, organizations that rely on sensitive electronic systems may experience disruptions due to voltage fluctuations or electrical noise, impacting operational efficiency and risking data loss. This inconsistency can be especially detrimental in regions with unstable electrical infrastructure, common in parts of Africa and South America.

The Solution: To mitigate these risks, sourcing a high-quality AC Input Isolator 1440, such as the SurgeX UPS-1440-LI-ISO, is essential. This device features a built-in isolation transformer that filters electrical noise and stabilizes power delivery. Buyers should prioritize units that offer true sine wave output and low impedance isolation to ensure compatibility with sensitive equipment. When specifying the isolator, it’s crucial to assess the load capacity (1440 VA) to match your operational needs, ensuring that the device can handle peak demands without compromising performance. Additionally, implementing regular maintenance checks and monitoring the UPS’s performance through its graphical user interface can further enhance reliability.

Scenario 2: Complexity in Integration with Existing Systems

The Problem: Integrating new technology into existing systems can be a daunting task for B2B buyers, especially when dealing with legacy equipment. For instance, companies that operate with outdated infrastructure may find it challenging to incorporate modern AC input isolators without extensive modifications, leading to increased costs and project delays. This scenario is particularly prevalent in sectors such as manufacturing and healthcare, where operational continuity is paramount.

The Solution: To streamline integration, buyers should look for AC Input Isolator 1440 models that offer flexible mounting options and compatibility with existing systems. The SurgeX model, for instance, is designed for rack mounting, allowing for seamless integration into current setups. It’s advisable to engage with technical support from manufacturers during the procurement process to ensure that the chosen isolator meets specific compatibility requirements. Conducting a comprehensive site assessment prior to installation can also help identify any necessary adjustments or additional equipment needed to facilitate a smooth integration process, thereby minimizing downtime.

Scenario 3: High Operational Costs Due to Energy Inefficiency

The Problem: Companies are increasingly focused on reducing operational costs, and inefficient power systems can significantly contribute to higher electricity bills. Businesses using outdated or poorly specified power solutions may find themselves facing excessive energy consumption, which not only impacts their bottom line but also raises sustainability concerns. This issue is particularly pronounced in regions with high energy costs, such as parts of Europe and the Middle East.

The Solution: Investing in an AC Input Isolator 1440 that features advanced line-interactive topology can significantly improve energy efficiency. For example, models that provide a power factor of 0.9, like the SurgeX UPS-1440-LI-ISO, can optimize power consumption while ensuring reliable performance. Buyers should evaluate the energy efficiency ratings of potential isolators and consider options that include auto battery testing and hot-swappable batteries for enhanced operational efficiency. Additionally, conducting a cost-benefit analysis to compare potential savings on energy bills against the initial investment in modern isolators will provide a clearer financial picture and justify the upgrade. Engaging with energy consultants or specialists can further aid in identifying the best solutions tailored to specific operational needs.

Strategic Material Selection Guide for ac input isolator 1440

What Materials Are Commonly Used for AC Input Isolators?

When selecting materials for AC input isolators, particularly the 1440 model, it is crucial to consider properties that affect performance, durability, and compliance with international standards. Here, we analyze four common materials: plastic, aluminum, copper, and silicone.

How Does Plastic Perform in AC Input Isolators?

Plastic, particularly high-grade thermoplastics like polycarbonate and nylon, is often used in the casing and insulation of AC input isolators. These materials exhibit excellent electrical insulation properties, making them suitable for high-voltage applications. They typically have a temperature rating of up to 120°C and offer good resistance to chemicals and corrosion.

Pros: Plastic is lightweight, cost-effective, and easy to mold into complex shapes, facilitating mass production. It also provides good dielectric strength, which is essential for isolators.

Cons: However, plastics may not withstand extreme temperatures or mechanical stress as well as metals, potentially leading to reduced durability over time.

Impact on Application: Plastic is compatible with a variety of media, but its limitations in high-temperature environments may restrict its use in industrial settings.

Considerations for International Buyers: Compliance with standards such as ASTM D638 for tensile properties and IEC 60695 for fire safety is essential for buyers in regions like Europe and the Middle East.

What Role Does Aluminum Play in AC Input Isolators?

Aluminum is frequently utilized for the structural components of AC input isolators due to its lightweight and high strength-to-weight ratio. It has a melting point of about 660°C and excellent corrosion resistance when anodized.

Pros: Its durability and ability to dissipate heat effectively make aluminum an excellent choice for high-performance applications.

Cons: The primary drawback is its higher cost compared to plastics, and it may require additional treatments to enhance its corrosion resistance.

Impact on Application: Aluminum is particularly well-suited for outdoor applications where exposure to the elements is a concern.

Considerations for International Buyers: Buyers should ensure that the aluminum used meets standards such as ASTM B221 for extruded aluminum and DIN 1725 for mechanical properties.

How Does Copper Contribute to AC Input Isolators?

Copper is primarily used in the conductive components of AC input isolators due to its exceptional electrical conductivity and thermal properties. It has a melting point of approximately 1,085°C and is highly resistant to corrosion.

Pros: The high conductivity of copper ensures efficient power transfer, making it ideal for isolators that require minimal energy loss.

Cons: Copper is more expensive than both plastic and aluminum and can be prone to oxidation if not properly coated.

Impact on Application: It is essential for applications requiring high-frequency signals or low resistance, such as in telecommunications.

Considerations for International Buyers: Compliance with standards like ASTM B170 for copper wire and IEC 60068 for environmental testing is crucial for buyers in Africa and South America.

What Benefits Does Silicone Provide in AC Input Isolators?

Silicone is often used for sealing and insulating components in AC input isolators due to its flexibility and resistance to extreme temperatures, ranging from -60°C to 200°C.

Pros: Silicone provides excellent thermal stability and is resistant to UV light, making it suitable for outdoor applications.

Cons: The primary limitation is its cost, which can be higher than traditional insulating materials.

Impact on Application: Silicone is particularly effective in environments with significant temperature fluctuations.

Considerations for International Buyers: Buyers should ensure that silicone materials comply with standards such as ASTM D412 for tensile strength and IEC 60587 for electrical insulation.

Summary Table of Material Properties for AC Input Isolators

| Material | Typical Use Case for ac input isolator 1440 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Insulation and casing | Lightweight and cost-effective | Limited durability in extreme temps | Low |

| Aluminum | Structural components | High strength and heat dissipation | Higher cost and requires treatment | Medium |

| Copper | Conductive components | Excellent electrical conductivity | Expensive and oxidation-prone | High |

| Silicone | Sealing and insulation | Exceptional thermal stability | Higher cost than traditional insulators | High |

This material selection guide provides essential insights for B2B buyers, helping them make informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for ac input isolator 1440

What Are the Main Stages of Manufacturing an AC Input Isolator 1440?

The manufacturing process for an AC input isolator, such as the AC Input Isolator 1440, involves several critical stages that ensure the final product meets high performance and safety standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials, such as copper for windings, insulation materials, and electronic components. Suppliers should provide certifications confirming the quality and compliance of materials with international standards. It is essential for B2B buyers to inquire about the material specifications and any testing conducted prior to production.

-

Forming: During this stage, components such as transformers and circuit boards are fabricated. Techniques such as precision winding for transformers and surface-mount technology (SMT) for circuit boards are commonly employed. Advanced machinery, including CNC machines and automated pick-and-place systems, are used to enhance accuracy and efficiency.

-

Assembly: The assembly process combines all individual components into a complete unit. This may involve soldering, wiring, and integrating various parts like the isolation transformer and circuit boards. Manufacturers often employ skilled technicians to ensure that each unit is assembled correctly and safely.

-

Finishing: This stage includes quality checks, packaging, and labeling. The final product undergoes tests to ensure it meets electrical and safety standards. Proper finishing not only enhances the product’s reliability but also its marketability.

Which Key Techniques Are Used in the Manufacturing of AC Input Isolators?

Manufacturers utilize several key techniques to enhance the quality and functionality of AC input isolators:

-

Magnetic Coupling: This technology is pivotal in isolators, enabling effective signal transmission while providing electrical isolation. It minimizes noise and enhances performance, particularly in sensitive electronic applications.

-

Opto-Isolation: Opto-isolators are used to separate different sections of a circuit, protecting sensitive components from high voltages and transients. This technique is vital for ensuring the durability and reliability of the isolator.

-

Automated Testing: Automated testing systems are employed during production to conduct various electrical tests, ensuring that each unit meets performance specifications. This includes testing for voltage isolation, current ratings, and thermal stability.

What Are the International Standards Relevant to AC Input Isolators?

Quality assurance for AC input isolators is guided by several international standards that ensure safety, reliability, and performance:

-

ISO 9001: This standard focuses on quality management systems and is essential for manufacturers aiming to ensure consistent quality in their products. B2B buyers should verify that their suppliers hold ISO 9001 certification.

-

CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards. This is crucial for ensuring that the product is legally compliant in European markets.

-

UL and CSA Certifications: In North America, Underwriters Laboratories (UL) and the Canadian Standards Association (CSA) provide safety certifications that are often required for electrical products. Buyers should look for these certifications to ensure product safety.

How Do Quality Control Checkpoints Ensure Reliability in AC Input Isolators?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. The following checkpoints are commonly implemented:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins. This step is crucial for identifying any defects early in the process.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process allows for immediate identification and correction of any issues. This includes checking assembly practices and testing components at various stages.

-

Final Quality Control (FQC): After assembly, each isolator undergoes comprehensive testing to confirm that it meets all performance and safety standards. This may include electrical testing, thermal testing, and functional testing.

What Common Testing Methods Are Used for AC Input Isolators?

Several testing methods are employed to ensure the quality and reliability of AC input isolators:

-

Dielectric Strength Testing: This test assesses the isolator’s ability to withstand high voltage without breaking down, ensuring that it provides adequate isolation.

-

Thermal Testing: Evaluating how the isolator performs under different temperature conditions helps identify potential failure points and ensures reliable operation in various environments.

-

Functional Testing: This involves simulating operational conditions to confirm that the isolator performs as intended. This includes checking for signal integrity and response times.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers:

-

Audits: Conducting supplier audits allows buyers to assess the manufacturing processes and quality control practices firsthand. This can include reviewing documentation, inspecting facilities, and evaluating compliance with international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes, including results from testing and certifications obtained.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. This is particularly useful for international buyers who may face language and regulatory barriers.

What Are the QC/Certifications Nuances for International B2B Buyers?

International B2B buyers must navigate various certification and quality assurance nuances:

-

Regional Regulations: Different regions have specific regulations and standards that must be adhered to. For example, products sold in Europe must comply with CE marking, while those in North America may require UL certification.

-

Documentation Requirements: Buyers should be aware of the documentation required for importation, which may include certificates of conformity, test reports, and customs declarations.

-

Cultural Considerations: Understanding cultural differences in business practices and communication styles can enhance negotiations and establish better relationships with suppliers across different regions.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing AC input isolators, ensuring they obtain high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ac input isolator 1440’

When sourcing an AC input isolator 1440, it is essential to follow a structured approach to ensure that you make informed decisions that align with your business needs. This guide serves as a practical checklist for B2B buyers, helping you navigate the complexities of procurement in a global marketplace.

Step 1: Define Your Technical Specifications

Start by identifying the specific technical requirements of the AC input isolator you need. Consider factors such as voltage ratings, isolation voltage, and the number of channels required. This clarity will help you narrow down your options and ensure compatibility with your existing systems.

- Voltage Ratings: Ensure the isolator can handle the input voltage of your application.

- Number of Channels: Determine how many channels you need based on your operational requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in AC input isolators. Look for manufacturers with a proven track record and positive reviews from other businesses.

- Industry Reputation: Check online platforms and forums for supplier ratings.

- Local vs. International: Consider suppliers that are strategically located to reduce shipping costs and times.

Step 3: Evaluate Supplier Certifications

Verify the certifications and compliance of potential suppliers. This is critical to ensure that their products meet international standards and regulations, which can vary by region.

- Quality Standards: Look for ISO certifications or similar quality assurance measures.

- Safety Compliance: Ensure the products comply with regional safety regulations, such as UL or CE certifications.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples to evaluate the product’s quality and performance. Testing samples can help you confirm that the isolators meet your specifications.

- Functionality Testing: Assess the isolator’s performance under different operating conditions.

- Compatibility Check: Ensure the sample works seamlessly with your current systems.

Step 5: Negotiate Terms and Pricing

Once you have selected a supplier, enter into negotiations regarding pricing, delivery timelines, and payment terms. Establish clear agreements to avoid misunderstandings later.

- Bulk Discounts: Inquire about pricing for larger orders to maximize cost efficiency.

- Payment Flexibility: Discuss payment terms that suit your company’s cash flow needs.

Step 6: Confirm After-Sales Support and Warranty

Ensure that the supplier offers comprehensive after-sales support and warranty for the product. This is crucial for maintaining operational efficiency and addressing any potential issues post-purchase.

- Technical Support: Check if the supplier provides technical assistance for installation and troubleshooting.

- Warranty Terms: Understand the warranty coverage and conditions for claims.

Step 7: Plan for Logistics and Delivery

Finally, coordinate logistics for the delivery of the isolators. Consider the shipping methods, potential customs duties, and lead times to ensure a smooth procurement process.

- Shipping Options: Evaluate various shipping methods for cost-effectiveness and speed.

- Customs Regulations: Familiarize yourself with the import regulations in your country to avoid delays.

Following this checklist will help you make informed decisions when sourcing an AC input isolator 1440, ensuring that your procurement aligns with your operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for ac input isolator 1440 Sourcing

What Are the Key Cost Components in Ac Input Isolator 1440 Sourcing?

The cost structure of sourcing an AC input isolator 1440 involves several critical components. Materials represent a significant portion of the total cost, including the price of electronic components, isolation transformers, and any additional circuitry required for optimal performance. Labor costs reflect the expenses associated with manufacturing and assembly, which can vary based on regional labor rates and skill levels.

Manufacturing overhead encompasses utilities, facility costs, and equipment maintenance, which also contribute to the overall price. Tooling costs are relevant for custom or specialized designs, particularly if a unique molding or fabrication process is needed. Quality Control (QC) measures ensure that products meet specific standards and certifications, impacting both cost and reliability. Lastly, logistics costs, including shipping, customs, and warehousing, can significantly affect the final price, especially for international transactions.

How Do Price Influencers Affect the Cost of Ac Input Isolators?

Several factors can influence the pricing of AC input isolators. Volume and Minimum Order Quantity (MOQ) play a crucial role; larger orders typically yield lower per-unit costs due to economies of scale. Specifications and customization also impact pricing, as tailored solutions may require additional engineering and materials, raising the overall cost.

The choice of materials directly correlates with product quality and longevity, with higher-grade components generally commanding a premium. Certifications such as UL or CE can also affect pricing, as compliance with international safety and quality standards can necessitate additional testing and documentation processes.

Supplier factors, including reputation and reliability, can influence pricing strategies. Established suppliers may offer premium pricing due to their perceived value, while newer entrants might compete on cost. Finally, Incoterms can dictate logistical expenses and risk allocation, impacting the total landed cost.

What Buyer Tips Can Help Negotiate Better Pricing for Ac Input Isolators?

For B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings. Start by conducting thorough market research to understand baseline pricing and competitor offerings. This knowledge empowers you during negotiations, enabling you to advocate for fair pricing based on market standards.

Understanding the Total Cost of Ownership (TCO) is crucial. TCO encompasses not only the initial purchase price but also installation, maintenance, and potential downtime costs. Buyers should evaluate the long-term implications of their purchase decisions, seeking suppliers that offer robust support and warranty options.

Flexibility in payment terms and delivery schedules can also provide leverage during negotiations. Offering to commit to larger quantities or longer-term contracts may lead suppliers to provide discounts or more favorable conditions. Additionally, consider alternative suppliers or regional options that might offer competitive pricing without compromising quality.

Lastly, be aware of pricing nuances in international transactions, including currency fluctuations, tariffs, and additional fees that may arise. Opting for suppliers familiar with your region’s import regulations can streamline the process and minimize unexpected costs.

Conclusion

Understanding the cost structure and pricing dynamics of AC input isolators is essential for international B2B buyers. By considering key cost components, price influencers, and effective negotiation strategies, businesses can secure favorable terms and ensure that they are making informed purchasing decisions. Always remember to verify the indicative prices and confirm details directly with suppliers to avoid unexpected discrepancies.

Alternatives Analysis: Comparing ac input isolator 1440 With Other Solutions

Understanding Alternatives to AC Input Isolator 1440

When considering power isolation solutions, the AC Input Isolator 1440 stands out for its robust features. However, various alternatives may also meet the needs of businesses, especially in diverse markets across Africa, South America, the Middle East, and Europe. This analysis compares the AC Input Isolator 1440 with two viable alternatives: the SurgeX UPS-1440 and the Eaton Tripp Lite Isolation Transformer. Each option is evaluated across critical dimensions to aid international B2B buyers in making informed decisions.

| Comparison Aspect | AC Input Isolator 1440 | SurgeX UPS-1440 | Eaton Tripp Lite Isolation Transformer |

|---|---|---|---|

| Performance | High isolation voltage (2500Vrms) | True sine wave output, 0.9 power factor | Efficient dual voltage operation (115/230V) |

| Cost | Moderate (market-dependent) | Higher ($3,929) | Moderate (varies by configuration) |

| Ease of Implementation | Requires integration with systems | Rack-mountable, user-friendly setup | Simple installation for dual voltage systems |

| Maintenance | Low, minimal upkeep required | Hot-swappable batteries | Generally low, but requires periodic checks |

| Best Use Case | Industrial applications requiring high isolation | AV and IT systems needing uninterrupted power | Hospital and sensitive equipment environments |

In-Depth Analysis of Alternatives

SurgeX UPS-1440

The SurgeX UPS-1440 is a premium line-interactive uninterruptible power supply designed specifically for environments that require consistent and clean power. It features a built-in isolation transformer that filters out electrical noise, making it ideal for sensitive electronic systems. While the higher price point may be a consideration, the benefits of true sine wave output and excellent power factor (0.9) justify the investment for businesses that cannot afford downtime. The hot-swappable battery design also enhances usability, allowing for battery replacement without disrupting operations.

Eaton Tripp Lite Isolation Transformer

The Eaton Tripp Lite Isolation Transformer provides an efficient solution for environments requiring dual voltage support (115/230V). Its design is particularly suited for hospitals and other critical applications where power consistency is paramount. This transformer effectively isolates equipment from power line disturbances and offers a straightforward installation process. However, while the cost is moderate, users should plan for periodic maintenance checks to ensure optimal performance. This transformer excels in applications where operational reliability and safety are non-negotiable.

Selecting the Right Solution for Your Business Needs

When choosing between the AC Input Isolator 1440 and its alternatives, businesses must consider several factors, including performance requirements, budget constraints, and the specific environment in which the solution will operate. The AC Input Isolator 1440 is an excellent choice for industrial applications needing high isolation levels, while the SurgeX UPS-1440 is ideal for those requiring robust power backup with minimal downtime. In contrast, the Eaton Tripp Lite is best suited for environments with dual voltage needs, such as healthcare facilities. Ultimately, understanding your operational priorities and the unique demands of your industry will guide you in selecting the most suitable power isolation solution.

Essential Technical Properties and Trade Terminology for ac input isolator 1440

What Are the Key Technical Properties of the AC Input Isolator 1440?

When considering an AC input isolator, especially the 1440 model, several technical specifications are crucial for ensuring compatibility, safety, and performance in various applications.

-

Voltage Isolation

This specification indicates the maximum voltage that the isolator can withstand between its input and output without breaking down. The 1440 model typically offers around 2500Vrms of isolation. This is critical in protecting sensitive electronics from surges and transients, making it vital for industries such as telecommunications and healthcare. -

Common Mode Transient Immunity (CMTI)

Measured in kV/µs, CMTI represents the ability of the isolator to withstand fast voltage transients without failure. A high CMTI rating, like 25kV/µs, ensures that the isolator can operate effectively in environments with significant electrical noise, such as industrial settings. This is essential for maintaining the integrity of data communication in control systems. -

Data Rate

The data rate, typically expressed in Mbps, indicates how quickly data can be transmitted through the isolator. The 1440 model supports data rates of up to 2Mbps, making it suitable for real-time applications where quick response times are necessary, such as in automation and robotics. -

Operating Temperature Range

The ability to function across a range of temperatures, often from -40°C to 125°C, ensures that the isolator can be deployed in diverse environments. This durability is particularly important in regions with extreme climates, providing assurance to buyers that the product will perform consistently. -

Power Factor

A power factor of 0.9 indicates the efficiency of the isolator in converting electrical power into usable output. This specification is crucial for B2B buyers looking to optimize energy consumption and reduce operational costs, especially in facilities with high power demands. -

Form Factor

The 1440 model often comes in a 2U rack mount configuration, facilitating easier integration into existing systems. A well-defined form factor is crucial for space management in data centers and industrial applications.

What Are Common Trade Terminology and Their Importance in B2B Transactions?

Understanding industry-specific terminology is vital for effective communication and negotiation in B2B transactions.

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end product. For buyers, knowing whether a component is from an OEM can assure quality and compatibility with existing systems, which is particularly important when sourcing critical components like the AC input isolator. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This is important for buyers to consider as it affects inventory costs and cash flow. Understanding MOQ helps in planning purchases and managing stock levels effectively. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers invite suppliers to provide price quotes for specific products or services. This is essential for buyers looking to compare costs and negotiate better deals, ensuring they get value for their investment. -

Incoterms (International Commercial Terms)

These are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms helps in understanding shipping costs, risks, and responsibilities, which is crucial for buyers sourcing products from global suppliers. -

Lead Time

Lead time refers to the amount of time between placing an order and receiving the product. Understanding lead times is vital for project planning and inventory management, helping businesses avoid delays in production or project execution. -

Certifications

Certifications such as UL, CE, or ISO signify that a product meets specific safety and quality standards. Buyers should prioritize products with relevant certifications to ensure compliance with industry regulations and enhance their operational reliability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their investments in products like the AC input isolator 1440 are sound and beneficial for their operations.

Navigating Market Dynamics and Sourcing Trends in the ac input isolator 1440 Sector

What Are the Current Market Dynamics for AC Input Isolator 1440?

The AC input isolator 1440 sector is witnessing substantial growth driven by increasing demand for reliable power management solutions across various industries. Key global drivers include the rising adoption of renewable energy sources, the need for efficient power conversion, and stringent regulations regarding power quality and safety. In regions like Africa and South America, the expansion of infrastructure and industrialization fuels the demand for robust electrical components, including input isolators. Moreover, the Middle East and Europe are seeing a shift towards smart grid technologies, necessitating advanced isolators that provide enhanced protection against electrical noise and transients.

Emerging trends within the B2B sourcing landscape include a focus on integrated solutions that combine multiple functionalities, such as surge protection and energy efficiency. Buyers are increasingly looking for suppliers that offer not only products but also comprehensive support and customization options to meet specific operational needs. Additionally, the digital transformation of procurement processes is gaining traction, with businesses leveraging e-commerce platforms to streamline sourcing activities and optimize inventory management.

How Can Sustainability and Ethical Sourcing Be Integrated in the AC Input Isolator 1440 Market?

Sustainability is becoming a cornerstone of B2B purchasing decisions, particularly in the AC input isolator 1440 sector. The environmental impact of manufacturing processes and product lifecycle is under scrutiny, prompting buyers to seek suppliers that prioritize eco-friendly practices. This includes utilizing recyclable materials, reducing waste, and implementing energy-efficient manufacturing processes.

Ethical sourcing is equally vital. Companies are increasingly held accountable for their supply chains, emphasizing the need for transparency and adherence to ethical standards. Certifications such as ISO 14001 for environmental management and RoHS for hazardous substances are becoming essential for suppliers to demonstrate their commitment to sustainable practices. By choosing suppliers with these certifications, businesses can mitigate risks associated with regulatory compliance and enhance their corporate reputation.

What Has Been the Evolution of AC Input Isolators?

The evolution of AC input isolators has been marked by significant technological advancements aimed at improving performance and safety. Initially, these devices served basic functions of electrical isolation and noise reduction. However, with the advent of digital technology and the increasing complexity of electrical systems, modern isolators now incorporate advanced features such as high-speed data transmission and integrated monitoring capabilities.

Historically, the development of isolation transformers and opto-isolators paved the way for more sophisticated solutions. The introduction of digital isolators, such as those based on magnetic coupling technologies, has further enhanced reliability and efficiency. Today, manufacturers are focusing on designing isolators that not only meet the demands of high-performance applications but also align with sustainability goals, reflecting a broader trend towards responsible manufacturing in the electrical components industry.

Frequently Asked Questions (FAQs) for B2B Buyers of ac input isolator 1440

-

How do I choose the right AC input isolator for my application?

Choosing the right AC input isolator involves evaluating your specific needs, including voltage requirements, load capacity, and the environment where it will be used. Consider factors such as the presence of electrical noise, sensitivity of connected devices, and whether you need additional features like surge protection or remote monitoring. Always check the specifications, such as the isolation voltage and number of channels, to ensure compatibility with your equipment. Consulting with technical experts from suppliers can also provide tailored recommendations based on your operational demands. -

What are the key features to look for in an AC input isolator?

When sourcing an AC input isolator, focus on features like voltage isolation level, channel count, and data transfer rates. A high isolation voltage, such as 2500Vrms, is crucial for protecting sensitive electronics. Other important features include the type of isolation technology (e.g., magnetic coupling), compatibility with various supply voltages, and certifications like UL or CE for quality assurance. Additionally, assess the physical form factor, ease of installation, and whether the isolator supports your specific application needs, such as industrial automation or telecommunication systems. -

What is the typical lead time for ordering AC input isolators?

Lead times for AC input isolators can vary significantly based on the supplier, the complexity of the product, and your location. Generally, expect a lead time of around 10 weeks for specialized components or customizations. For off-the-shelf products, the lead time may be shorter, typically ranging from 1 to 4 weeks. It’s advisable to communicate directly with suppliers to get accurate estimates and plan your procurement strategy accordingly, especially if you are operating under tight deadlines. -

What minimum order quantities (MOQ) should I expect when sourcing AC input isolators?

Minimum order quantities (MOQ) for AC input isolators often depend on the supplier and the specific model. Common MOQs range from 10 to 100 units, particularly for standard products. However, custom or specialized units may have higher MOQs due to production costs. It’s essential to discuss MOQs with potential suppliers to understand their policies and negotiate terms that align with your purchasing needs, especially if you are a smaller business or are testing a new application. -

How can I verify the reliability of a supplier for AC input isolators?

To verify a supplier’s reliability, conduct thorough research that includes checking customer reviews, industry certifications, and the supplier’s track record in delivering quality products. Requesting references from previous clients can provide insights into their experiences. Additionally, assess the supplier’s manufacturing processes and quality assurance measures, such as adherence to international standards. Engaging in direct communication with the supplier and visiting their facilities, if possible, can further establish trust and confidence in their capabilities. -

What payment terms are typically available for international orders of AC input isolators?

Payment terms for international orders of AC input isolators can vary widely among suppliers. Common options include advance payment, 30 to 60 days net payment terms, or letters of credit for larger orders. It’s important to clarify these terms upfront to avoid any misunderstandings. Discussing payment flexibility based on order size and establishing a good relationship with the supplier can lead to more favorable terms. Always ensure that the payment method chosen is secure and provides adequate protection against fraud. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers of AC input isolators should implement strict quality assurance measures to ensure product reliability and safety. Expect to see certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, inquire about testing procedures that products undergo, including electrical performance tests and isolation tests. Suppliers should also offer warranties or guarantees, reflecting their confidence in product durability. Regular audits and compliance with international safety standards should be standard practices for trustworthy suppliers. -

How can logistics impact the sourcing of AC input isolators internationally?

Logistics plays a crucial role in the international sourcing of AC input isolators, affecting delivery times, costs, and product integrity during transit. Consider factors such as shipping methods, customs regulations, and potential tariffs that may apply. Engage with suppliers who have established logistics partnerships to ensure smoother transportation and handling of products. Understanding the logistics landscape in your region, including port efficiency and local regulations, can help mitigate delays and enhance the overall procurement process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Ac Input Isolator 1440 Manufacturers & Suppliers List

1. SurgeX – UPS-1440-LI-ISO

Domain: markertek.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “SurgeX UPS-1440-LI-ISO”, “Load Rating”: {“Input”: “12A”, “Output”: “12.0A/10.8A”}, “Voltage Rating”: “120V”, “Power Requirement”: “0”, “Input/Mains Plug Type”: “5-20P”, “Input/Mains Cord Length”: “6′”, “Number of Receptacles”: “8”, “Receptacle Type”: “(8) 5-20R”, “Under-Voltage Auto Shutdown”: “Yes”, “Over-Voltage Auto Shutdown”: “Yes”, “Over-Current Auto Shutdown”: “Yes”, “Featu…

2. Touchboards – Surgex UPS 1440 LI ISO

3. Analog Devices – ADUM1440ARQZ-RL7 Isolator

Domain: digikey.in

Registered: 2006 (19 years)

Introduction: ADUM1440ARQZ-RL7, Analog Devices Inc., Isolators

4. SurgeX – 1440VA Line Interactive UPS with Isolation Transformer

Domain: avlgear.com

Registered: 2008 (17 years)

Introduction: {“Product Name”: “SurgeX 1440VA Line Interactive UPS with Isolation Transformer, 2U”, “SKU”: “SUR-5814479R”, “Price”: “$3,929.00”, “Configurations”: [{“Type”: “UPS with Isolation Transformer”, “Model”: “UPS-1440-Li-ISO”, “Load Capacity”: “1440 VA / 1440 W”}, {“Type”: “UPS with Extended Battery Pack”, “Model”: “UPS-1440-LI-ISO-“, “Price”: “$4,350.50”}], “Technology”: “Line-Interactive with Low Impe…

5. AVLIS-CO – General Purpose Digital Isolator

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“MPN”:”ADUM1440ARSZ”,”Brand”:”AVLIS-CO”,”Condition”:”New”,”Description”:”General Purpose Digital Isolator 3.75KV 4CH GP 20SSOP, RoHs: C”,”Price”:”US $7.99″,”Shipping”:”US $7.49 USPS First Class”,”Returns”:”30 days returns, Seller pays for return shipping”,”Quantity Available”:”More than 10 available”,”Seller Rating”:”100% positive feedback”,”Location”:”Watsonville, California, United States”,”Est…

6. Eaton – SMART1500LCDTXL

Domain: tripplite.eaton.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “SMART1500LCDTXL”, “Type”: “Line Interactive UPS”, “Power Capacity”: “1440 VA / 1200 W”, “Outlets”: “8 NEMA 5-15R outlets”, “Features”: [“Automatic Voltage Regulation (AVR)”, “USB and Serial connectivity”, “LCD display”, “Extended run tower design”]}

7. Rockwell Automation – 1440-SPD02-01RB Speed Measurement Module

Domain: rockwellautomation.com

Registered: 1997 (28 years)

Introduction: {“Product Name”: “1440-SPD02-01RB Speed Measurement Module”, “Lifecycle Status”: “Active”, “Repair Options”: “Available”, “Technical Specifications”: {“Rated Control Supply Voltage”: “24 V DC”, “Rated Operating Frequency”: “0.0167 kHz”, “Power Dissipation”: {“Max”: “7 W”, “Typical”: “4 W”}, “Isolation Voltage”: “250 V (continuous)”, “Operating Temperature”: “-20 °C to 65 °C”, “Storage Temperature”…

Strategic Sourcing Conclusion and Outlook for ac input isolator 1440

In conclusion, the strategic sourcing of the AC Input Isolator 1440 presents a significant opportunity for international B2B buyers, particularly in markets across Africa, South America, the Middle East, and Europe. By prioritizing high-quality isolators like the SurgeX and Analog Devices options, businesses can ensure enhanced electrical safety, reduced noise, and improved performance of sensitive equipment. The integration of advanced features such as low impedance isolation and true sine wave output is vital for industries relying on uninterrupted power supply.

Moreover, establishing strong relationships with reliable suppliers can lead to better pricing, timely deliveries, and access to cutting-edge technology. As the demand for robust electrical solutions continues to grow, investing in strategic sourcing will yield long-term benefits, enabling companies to maintain a competitive edge in their respective markets.

Looking ahead, B2B buyers should act proactively to assess their sourcing strategies, align them with the latest technological advancements, and build partnerships that foster innovation and sustainability. Embrace the future of electrical solutions by sourcing effectively and ensuring your operations are backed by the best isolators available.