Choosing Your 115 Johnson Outboard Motor: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for 115 johnson outboard motor

Navigating the complexities of sourcing a 115 Johnson outboard motor can be a daunting challenge for international B2B buyers, especially when considering varying regulations, performance specifications, and supplier reliability across different regions. This guide provides a comprehensive overview of the Johnson 115 outboard motor, covering essential topics such as model variations, applications in diverse marine environments, and critical factors for evaluating and vetting suppliers.

From the bustling fishing markets of Africa to the expansive recreational boating industry in Europe, the demand for reliable and efficient outboard motors like the Johnson 115 is on the rise. This guide empowers decision-makers by delivering actionable insights into cost considerations, maintenance requirements, and performance metrics, ensuring that buyers can make informed choices that align with their operational needs.

Whether you’re an established distributor looking to expand your product line or a new entrant seeking reliable motors for a specific market, this resource equips you with the knowledge to navigate the global marketplace effectively. By understanding the nuances of the Johnson 115 outboard motor and its applications, you can mitigate risks and enhance your purchasing strategies, ensuring a successful investment in this essential marine technology.

Understanding 115 johnson outboard motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 115ESL Series | Standard two-stroke engine, various model years | Commercial fishing, recreational boating | Pros: Reliable performance; Cons: Older models may have limited parts availability. |

| 115EL Series | Electric start feature, often more advanced technology | Marine transport, leisure activities | Pros: Ease of use; Cons: Higher maintenance costs due to electric components. |

| 115TX Series | Extended shaft for larger boats, versatile horsepower | Professional marine services | Pros: Better handling in rough waters; Cons: Heavier, may require stronger transom. |

| 115HP Four-Stroke Models | Fuel-efficient, quieter operation, lower emissions | Eco-friendly marine applications | Pros: Environmentally friendly; Cons: Initial higher investment cost. |

| 115G Series | Gear-driven design, enhanced torque for heavy-duty use | Commercial fishing, heavy-duty tasks | Pros: Superior power; Cons: Heavier and more complex maintenance. |

What are the characteristics of the 115ESL Series Johnson Outboard Motor?

The 115ESL series is known for its standard two-stroke engine, which has been a staple in the Johnson lineup since its inception. With models spanning from 1969 to the late 1990s, these motors are often favored by commercial fishermen and recreational boaters due to their reliability and performance. Buyers should consider the availability of parts, as older models may face challenges in sourcing components, impacting long-term maintenance.

How does the 115EL Series enhance operational efficiency?

The 115EL series features an electric start, making it user-friendly for those who prioritize convenience in marine operations. This series is suitable for both marine transport and leisure boating, appealing to a wide range of users. However, potential buyers should be aware of the increased maintenance costs associated with electric components, which can affect overall operational expenses.

What advantages does the 115TX Series offer for larger vessels?

The 115TX series is designed with an extended shaft, making it ideal for larger boats that require enhanced stability and handling in rough waters. This motor is commonly used in professional marine services, where durability and performance are critical. While it offers significant advantages, buyers must consider the added weight and ensure their vessel’s transom can support the motor’s demands.

Why are 115HP Four-Stroke Models becoming popular in eco-friendly applications?

The 115HP four-stroke models are gaining traction due to their fuel efficiency and quieter operation, making them suitable for eco-friendly marine applications. These motors produce lower emissions, aligning with global trends towards sustainability. However, the initial investment may be higher compared to two-stroke models, which could be a consideration for budget-conscious buyers.

What makes the 115G Series suitable for heavy-duty tasks?

The 115G series features a gear-driven design that enhances torque, making it an excellent choice for heavy-duty marine tasks, including commercial fishing. Its robust construction allows it to handle demanding conditions, appealing to businesses that require reliability. However, buyers should be prepared for the weight and complexity of maintenance associated with this powerful motor.

Key Industrial Applications of 115 johnson outboard motor

| Industry/Sector | Specific Application of 115 Johnson Outboard Motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Commercial Fishing | Used on fishing boats for deep-sea and coastal fishing | High horsepower allows for quick travel to fishing spots, maximizing catch time. | Reliability, fuel efficiency, and ease of maintenance. |

| Tourism and Recreation | Powering recreational boats for tours and leisure activities | Enhances customer experience with reliable performance and speed, attracting more tourists. | Availability of parts and service support in the region. |

| Aquaculture | Supporting transport vessels for fish farming operations | Efficiently moves feed and harvest, reducing operational delays. | Compatibility with aquaculture systems and environmental regulations. |

| Marine Research | Employed in research vessels for data collection and exploration | Provides researchers with reliable mobility to access remote marine areas. | Durability in various marine conditions and ease of operation. |

| Government Services | Utilized in patrol boats for coastal security and rescue operations | Ensures swift response times in emergencies, enhancing safety and security. | Compliance with safety standards and availability of training for operators. |

How is the 115 Johnson Outboard Motor Beneficial in Commercial Fishing?

The 115 Johnson outboard motor is an essential asset for commercial fishing operations, powering vessels that navigate both deep-sea and coastal waters. Its high horsepower translates to faster travel to productive fishing grounds, thus maximizing the time spent fishing. For international buyers, particularly in regions like Africa and South America, sourcing reliable outboard motors is critical to maintaining operational efficiency. Buyers should prioritize fuel efficiency and ease of maintenance, as these factors significantly impact profitability.

What Role Does the 115 Johnson Outboard Motor Play in Tourism and Recreation?

In the tourism sector, the 115 Johnson outboard motor is commonly used in recreational boats that offer tours and leisure activities. Its dependable performance ensures a smooth and enjoyable experience for tourists, which is vital for business reputation and repeat customers. B2B buyers in this industry should consider the availability of spare parts and service support in their regions, ensuring minimal downtime during peak tourist seasons.

How Does the 115 Johnson Outboard Motor Support Aquaculture Operations?

In aquaculture, the 115 Johnson outboard motor is utilized in transport vessels that facilitate feed distribution and fish harvesting. The motor’s efficiency helps reduce operational delays, which can be detrimental in the fast-paced aquaculture environment. Buyers in this sector must ensure that the motor is compatible with existing aquaculture systems and adheres to environmental regulations, particularly in regions with strict sustainability practices.

Why is the 115 Johnson Outboard Motor Ideal for Marine Research?

Marine research vessels benefit significantly from the reliability and mobility provided by the 115 Johnson outboard motor. This motor allows researchers to access remote marine areas for data collection and exploration, which is crucial for various scientific studies. For international buyers, especially those in Europe and the Middle East, the durability of the motor in diverse marine conditions is a key consideration, alongside the ease of operation for research personnel.

How is the 115 Johnson Outboard Motor Used in Government Services?

Government agencies often employ the 115 Johnson outboard motor in patrol boats tasked with coastal security and rescue operations. Its swift response capabilities are essential for ensuring safety in maritime environments. Buyers from governmental sectors need to focus on compliance with safety standards and the availability of training programs for operators, which are critical for effective and safe operations.

3 Common User Pain Points for ‘115 johnson outboard motor’ & Their Solutions

Scenario 1: Difficulty in Sourcing Replacement Parts for Older Models

The Problem: B2B buyers often face significant challenges when it comes to sourcing replacement parts for older models of the 115 Johnson outboard motor. As these engines age, manufacturers may discontinue certain parts, leading to difficulties in finding compatible replacements. This not only causes delays in repairs but can also increase operational costs for businesses that rely on these motors for commercial fishing, tourism, or other marine activities. The frustration of dealing with outdated inventory systems and limited supplier options can hinder operational efficiency.

The Solution: To effectively address this problem, buyers should establish relationships with specialized marine parts suppliers who focus on older outboard motors. A proactive approach includes creating a comprehensive inventory list of the specific model and serial numbers, which helps suppliers locate the exact parts needed. Additionally, leveraging online platforms that specialize in marine parts can streamline the search process. Joining forums or industry groups where fellow buyers share resources and experiences can also provide valuable insights into where to find rare components. Finally, buyers should consider investing in aftermarket parts that meet industry standards, as these can often be more readily available and cost-effective.

Scenario 2: Troubleshooting Performance Issues with 115 Johnson Outboard Motors

The Problem: Performance issues such as rough idling, stalling, or loss of power are common pain points for users of the 115 Johnson outboard motors. These problems can arise from various factors, including fuel quality, maintenance neglect, or worn-out components. For B2B buyers, particularly those operating fleets of vessels, these performance issues can lead to costly downtime, impacting overall productivity and customer satisfaction.

The Solution: To mitigate these issues, buyers should implement a rigorous maintenance schedule that includes regular inspections and servicing of the outboard motors. It is crucial to use high-quality fuel and ensure that the fuel system is clean to prevent clogging of filters and injectors. Additionally, investing in training for maintenance staff can help them identify and resolve common performance issues proactively. Utilizing diagnostic tools to monitor engine performance can provide real-time data, allowing for timely interventions before problems escalate. Furthermore, maintaining a close relationship with certified technicians can facilitate quick resolutions to more complex issues.

Scenario 3: Navigating Regulatory Compliance for Marine Engines

The Problem: B2B buyers in regions like Europe, South America, and the Middle East face increasing regulatory scrutiny regarding emissions and environmental standards for marine engines, including the 115 Johnson outboard motors. Non-compliance can lead to hefty fines, operational restrictions, and damage to a company’s reputation. Understanding the specific regulations applicable in different jurisdictions can be daunting and time-consuming.

The Solution: To navigate these regulatory challenges, buyers should stay informed about local and international marine engine regulations that affect their operations. Regularly consulting with legal experts or industry associations can provide clarity on compliance requirements. Additionally, buyers should consider upgrading to more environmentally friendly models or retrofitting existing motors with emission-reducing technologies. Engaging with suppliers who offer compliant parts and engines is essential for ensuring adherence to regulations. Implementing comprehensive training programs for staff on compliance issues will further enhance understanding and accountability within the organization. Finally, documenting compliance efforts can be beneficial for audits and inspections, providing evidence of a commitment to sustainable practices.

Strategic Material Selection Guide for 115 johnson outboard motor

What Materials Are Commonly Used in 115 Johnson Outboard Motors?

When selecting materials for the 115 Johnson outboard motor, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. The following analysis covers four common materials used in these motors: aluminum, stainless steel, composite materials, and cast iron.

Aluminum: A Lightweight and Corrosion-Resistant Option

Aluminum is widely used in outboard motors due to its excellent strength-to-weight ratio and corrosion resistance. It can withstand harsh marine environments, making it ideal for components such as the motor housing and propellers. The material typically has a temperature rating up to 200°C and good pressure resistance.

Pros: Aluminum is lightweight, which enhances fuel efficiency and overall performance. It is also relatively inexpensive and easy to manufacture, allowing for cost-effective production.

Cons: While aluminum is durable, it can be prone to wear and tear over time, especially in high-stress applications. It may require protective coatings to enhance its longevity.

Impact on Application: Aluminum is compatible with various marine environments, but it may not be suitable for applications involving highly abrasive materials.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers should also consider local corrosion resistance requirements, especially in regions with high salinity, like coastal areas in Africa and South America.

Stainless Steel: Strength and Durability in Marine Applications

Stainless steel is another popular material for components like shafts and fasteners in the 115 Johnson outboard motor. Known for its exceptional corrosion resistance and strength, stainless steel can withstand higher temperatures and pressures than aluminum, typically rated up to 300°C.

Pros: The durability of stainless steel makes it ideal for high-stress applications, ensuring a longer lifespan for critical components.

Cons: The primary drawback is its higher cost compared to aluminum. Additionally, stainless steel can be heavier, which may affect the overall weight of the motor.

Impact on Application: Stainless steel is suitable for various marine applications, particularly where strength and corrosion resistance are paramount.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM A240 for stainless steel grades. In markets like Europe and the Middle East, buyers may prioritize materials with high resistance to pitting corrosion.

Composite Materials: Lightweight and Versatile

Composite materials, such as fiberglass and carbon fiber, are increasingly used in outboard motors for components like cowlings and fuel tanks. These materials offer excellent weight savings and can be molded into complex shapes.

Pros: Composites provide high strength-to-weight ratios and excellent resistance to corrosion and UV damage.

Cons: The manufacturing process for composites can be more complex and costly. Additionally, they may not be as repairable as metals.

Impact on Application: Composites are ideal for applications requiring lightweight components but may not be suitable for high-load-bearing parts.

Considerations for International Buyers: International buyers should consider the environmental regulations surrounding composite materials, as some regions have strict guidelines on their use and disposal.

Cast Iron: Strength for Heavy-Duty Applications

Cast iron is often used in the engine block and other heavy-duty components of the 115 Johnson outboard motor due to its excellent durability and wear resistance. It can handle high temperatures and pressures, typically rated up to 400°C.

Pros: Cast iron provides exceptional strength and is relatively inexpensive compared to other materials.

Cons: The primary disadvantage is its weight, which can negatively impact fuel efficiency. Additionally, cast iron is prone to corrosion if not properly maintained.

Impact on Application: Cast iron is suitable for high-stress applications but may require additional coatings or treatments to enhance corrosion resistance.

Considerations for International Buyers: Buyers should be aware of the specific grades of cast iron that comply with local standards, particularly in markets with stringent quality requirements like Germany.

Summary of Material Selection for 115 Johnson Outboard Motor

| Material | Typical Use Case for 115 Johnson Outboard Motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Motor housing, propellers | Lightweight and corrosion-resistant | Prone to wear over time | Low |

| Stainless Steel | Shafts, fasteners | Exceptional strength and durability | Higher cost and weight | High |

| Composite Materials | Cowlings, fuel tanks | High strength-to-weight ratio | Complex manufacturing process | Medium |

| Cast Iron | Engine block, heavy-duty components | Exceptional strength | Heavy and prone to corrosion | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on material properties, application suitability, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 115 johnson outboard motor

What Are the Key Stages in the Manufacturing Process of the 115 Johnson Outboard Motor?

The manufacturing of the 115 Johnson outboard motor involves several critical stages that ensure the final product meets rigorous performance and durability standards. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for the 115 Johnson Outboard Motor?

Material preparation begins with sourcing high-quality raw materials, including aluminum, steel, and composite plastics, which are essential for the motor’s components. Suppliers are often vetted for compliance with international standards, ensuring that materials meet specifications for strength and corrosion resistance. This stage may also involve machining processes, where raw materials are cut, shaped, and prepared for subsequent steps.

What Forming Techniques Are Employed in Manufacturing?

Once the materials are prepared, forming techniques such as casting, forging, and machining are employed. For the 115 Johnson outboard motor, aluminum components are typically cast using die-casting techniques, which offer precision and consistency. Steel components may undergo forging processes to enhance their structural integrity. Machining processes, including CNC (Computer Numerical Control) milling, are utilized to achieve tight tolerances on critical components such as the crankshaft and cylinder head.

How Is the Assembly Process Conducted for the 115 Johnson Outboard Motor?

The assembly stage is where individual components come together to form the complete motor. This process involves several sub-stages, including:

- Sub-Assembly: Key components like the powerhead, lower unit, and electrical systems are assembled separately. This ensures that each section is thoroughly tested before final integration.

- Main Assembly: The sub-assemblies are then combined, often utilizing automated assembly lines that enhance efficiency and reduce human error.

- Final Assembly: This stage includes the installation of additional components such as the fuel system, cooling system, and external casing. Each assembly line is equipped with specialized tools to ensure precision and reliability.

What Quality Assurance Standards Are Relevant for the 115 Johnson Outboard Motor?

Quality assurance (QA) is a critical aspect of the manufacturing process, particularly for products that operate in demanding marine environments. The 115 Johnson outboard motor is manufactured under strict adherence to international standards, including ISO 9001, which focuses on effective quality management systems.

How Are QC Checkpoints Established During Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing stages help identify defects or deviations early in the process. Techniques such as statistical process control (SPC) are often employed.

- Final Quality Control (FQC): Once the motor is assembled, it undergoes comprehensive testing, including performance, durability, and safety checks to ensure it meets all operational standards.

What Testing Methods Are Commonly Used in Quality Assurance?

The 115 Johnson outboard motor undergoes various testing methods to validate its performance and reliability. Common methods include:

- Hydraulic Testing: To ensure the cooling system is functioning properly and can withstand pressure.

- Load Testing: Simulates operational conditions to assess power output and efficiency.

- Vibration Testing: Evaluates the motor’s performance under various operational vibrations, ensuring longevity and reliability.

- Corrosion Testing: Especially important for marine applications, this testing assesses the motor’s resistance to saltwater and other corrosive environments.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

B2B buyers looking to procure the 115 Johnson outboard motor can take several steps to verify the quality assurance processes of suppliers:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, equipment, and adherence to quality standards.

- Quality Reports: Requesting detailed quality assurance reports can provide insights into the testing processes and outcomes.

- Third-Party Inspections: Engaging independent inspectors can further validate a supplier’s quality processes and product reliability.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, there are specific nuances to consider in quality control:

- Regulatory Compliance: Different regions may have varying compliance requirements. Buyers should ensure that the products meet local regulations, such as CE marking in Europe or other relevant certifications.

- Supply Chain Transparency: Understanding the entire supply chain is crucial. Buyers should inquire about the sourcing of materials and the manufacturing processes to mitigate risks related to quality.

- Cultural and Communication Factors: Establishing clear communication channels with suppliers can help address quality concerns and facilitate timely resolutions.

Conclusion

The manufacturing processes and quality assurance protocols for the 115 Johnson outboard motor are designed to ensure that each unit performs reliably in challenging marine environments. By understanding these processes, B2B buyers can make informed decisions when sourcing outboard motors, ensuring they partner with suppliers who prioritize quality and compliance with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘115 johnson outboard motor’

Introduction

This practical sourcing guide aims to assist B2B buyers in effectively procuring the 115 Johnson Outboard Motor. Given the motor’s diverse applications across different industries, understanding the procurement process is essential for ensuring reliability, efficiency, and compliance with regional standards. The following checklist outlines critical steps to streamline your sourcing process.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical requirements for the 115 Johnson Outboard Motor. This includes specifying horsepower, model year, and any additional features necessary for your operations.

– Consider compatibility: Ensure that the motor aligns with your vessel’s specifications and intended use.

– Consult technical documentation: Review product manuals or manufacturer specifications to avoid any discrepancies.

Step 2: Identify Reputable Suppliers

Conduct thorough research to identify suppliers that specialize in Johnson outboard motors. Look for established companies with a proven track record in your region, particularly those with experience in marine equipment.

– Check reviews and ratings: Utilize platforms like Google Reviews or industry-specific forums to gauge supplier reliability.

– Network within your industry: Connect with other businesses or industry associations for recommendations on trusted suppliers.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with international standards. This step is crucial to ensure that the motors meet quality and safety regulations.

– Request documentation: Ask for certificates that demonstrate compliance with ISO standards or local maritime regulations.

– Investigate warranty policies: A reliable supplier should offer warranties that protect your investment.

Step 4: Request Quotes and Compare Pricing

Contact multiple suppliers to obtain quotes for the 115 Johnson Outboard Motor. Comparing prices not only helps you find the best deal but also provides insights into market rates.

– Be clear about your needs: Provide the same specifications to each supplier to ensure accurate comparisons.

– Consider total cost of ownership: Factor in shipping, taxes, and potential maintenance costs when evaluating pricing.

Step 5: Assess After-Sales Support

Evaluate the after-sales support offered by potential suppliers. Strong customer service can significantly impact your experience with the product and supplier.

– Inquire about technical support: Ensure that the supplier provides assistance for installation and troubleshooting.

– Check for parts availability: Confirm that replacement parts for the 115 Johnson Outboard Motor are readily available to minimize downtime.

Step 6: Negotiate Terms and Finalize the Agreement

Once you have selected a supplier, engage in negotiations to finalize the terms of purchase. This step can help you secure better pricing or additional services.

– Discuss payment terms: Establish clear payment schedules and methods that suit both parties.

– Clarify delivery timelines: Ensure that you have a mutual understanding of delivery dates to align with your operational needs.

Step 7: Conduct a Final Review Before Purchase

Before completing your order, conduct a final review of all agreements and specifications. This ensures that all details align with your original requirements and expectations.

– Double-check documentation: Review all contracts and agreements for accuracy.

– Communicate any last-minute changes: Confirm any adjustments to specifications or terms with the supplier to avoid misunderstandings.

By following this checklist, B2B buyers can navigate the procurement process for the 115 Johnson Outboard Motor with confidence and ensure a successful purchase that meets their operational needs.

Comprehensive Cost and Pricing Analysis for 115 johnson outboard motor Sourcing

Analyzing the cost and pricing structure for sourcing the 115 Johnson outboard motor involves understanding various components that contribute to the overall expense. International B2B buyers need to consider a comprehensive breakdown of these costs to ensure they make informed purchasing decisions.

What Are the Key Cost Components for Sourcing 115 Johnson Outboard Motors?

-

Materials: The primary materials include aluminum, steel, and various composites used in the manufacturing of the outboard motor. The cost of raw materials can fluctuate based on market demand, geopolitical factors, and supply chain disruptions. Buyers should consider sourcing from multiple suppliers to mitigate risks associated with material shortages.

-

Labor: Labor costs vary significantly by region. In developing countries, labor may be less expensive, which can lead to lower overall production costs. However, this can also impact the quality of the final product. Buyers should assess the skill level of the workforce in the manufacturing region to ensure that quality standards are met.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and factory operations. Efficient manufacturing processes can help reduce overhead costs, making it essential for buyers to evaluate the supplier’s production capabilities and operational efficiencies.

-

Tooling: Specialized tools and molds are often necessary for producing specific models of outboard motors. The initial investment in tooling can be significant, especially for customized orders. Buyers should inquire about tooling costs and whether they can amortize these expenses over larger order volumes.

-

Quality Control (QC): Implementing robust QC processes is crucial to ensure the reliability and performance of the outboard motors. Costs associated with testing and certification can vary widely depending on the supplier’s standards and the certifications required for specific markets, such as ISO or CE standards.

-

Logistics: Shipping costs can significantly impact the total cost of ownership. Factors such as distance, shipping method, and customs duties should be considered. Buyers should explore different logistics providers to identify the most cost-effective solutions, especially when importing motors from overseas.

-

Margin: Supplier profit margins can vary. Understanding the markup applied by manufacturers and distributors is essential for negotiating fair prices. Buyers should aim to establish long-term relationships with suppliers to gain better pricing terms.

How Do Price Influencers Affect the Sourcing of 115 Johnson Outboard Motors?

Several factors can influence the pricing of the 115 Johnson outboard motors:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should assess their needs and consider pooling orders with other buyers to achieve better pricing.

-

Specifications and Customization: Customized motors or those with specific features may come at a premium. Buyers should clearly define their requirements to avoid unnecessary costs.

-

Materials and Quality Certifications: Higher-quality materials and certifications typically lead to higher prices. Buyers need to balance the quality they require with their budget constraints.

-

Supplier Factors: The reputation, reliability, and production capabilities of the supplier can impact pricing. Conducting thorough research on potential suppliers is crucial.

-

Incoterms: Understanding the shipping terms agreed upon can significantly affect costs. Buyers should clarify whether they are responsible for shipping and handling or if these costs are included in the quoted price.

What Are the Best Tips for Negotiating Prices and Ensuring Cost-Efficiency?

B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should adopt several strategies:

-

Negotiate Terms: Always negotiate payment terms, delivery schedules, and pricing. Leveraging multiple quotes can provide leverage in negotiations.

-

Consider Total Cost of Ownership: Evaluate not just the purchase price but also long-term costs associated with maintenance, repairs, and operational efficiency.

-

Understand Pricing Nuances: Familiarize yourself with market trends and seasonal fluctuations in prices. This knowledge can help in timing purchases effectively.

-

Build Long-term Relationships: Establishing rapport with suppliers can lead to better pricing, priority service, and potential discounts on future orders.

Disclaimer on Pricing

Prices for the 115 Johnson outboard motors can vary significantly based on the above factors, and the information provided here is indicative. Buyers should conduct thorough market research and obtain multiple quotes to ensure they secure the best possible pricing for their specific needs.

Alternatives Analysis: Comparing 115 johnson outboard motor With Other Solutions

Understanding Alternatives for the 115 Johnson Outboard Motor

When evaluating marine propulsion solutions, it’s essential for B2B buyers to consider various alternatives to the 115 Johnson Outboard Motor. Different technologies and models can offer distinct advantages depending on the specific needs of the user, such as performance, cost, and maintenance requirements. This analysis will compare the 115 Johnson Outboard Motor with two viable alternatives: the Mercury 115 FourStroke Outboard and the Yamaha F115 Outboard.

Comparison Table

| Comparison Aspect | 115 Johnson Outboard Motor | Mercury 115 FourStroke Outboard | Yamaha F115 Outboard |

|---|---|---|---|

| Performance | 115 HP, reliable for various marine applications | 115 HP, fuel-efficient, quieter operation | 115 HP, high torque, excellent acceleration |

| Cost | Generally lower initial cost | Moderate initial cost, high resale value | Higher initial cost but long-term savings |

| Ease of Implementation | Simple installation, well-documented | Easy installation, widespread service network | Requires some technical knowledge for installation |

| Maintenance | Needs regular maintenance, parts may be harder to find | Low maintenance, readily available parts | Moderate maintenance, good parts availability |

| Best Use Case | Recreational boating, fishing | Commercial applications, recreational use | Fishing, recreational, and light commercial |

Detailed Breakdown of Alternatives

Mercury 115 FourStroke Outboard

The Mercury 115 FourStroke Outboard is a modern alternative known for its fuel efficiency and quiet operation. With similar horsepower, it offers enhanced performance features that appeal to both recreational and commercial users. One of its notable strengths is the extensive service network and parts availability, making maintenance straightforward. However, the initial purchase cost can be higher than that of the Johnson motor, which may deter budget-conscious buyers. Overall, it presents a solid option for businesses focused on long-term operational efficiency.

Yamaha F115 Outboard

The Yamaha F115 Outboard is another strong contender in the 115 HP category. It is recognized for its high torque and excellent acceleration, making it particularly suitable for fishing and recreational activities. While the upfront cost is generally higher than both the Johnson and Mercury options, the Yamaha’s reputation for reliability and durability can lead to lower overall costs in the long run. Maintenance is manageable, but some technical knowledge may be required for installation. This motor is ideal for businesses that prioritize performance and are willing to invest in quality.

Conclusion: How to Choose the Right Outboard Motor

When selecting the right outboard motor, B2B buyers should consider their specific operational needs, budget constraints, and maintenance capabilities. The 115 Johnson Outboard Motor offers a cost-effective solution for those seeking reliability in recreational boating. However, if long-term efficiency and performance are priorities, the Mercury 115 FourStroke and Yamaha F115 may provide better value despite their higher initial costs. Ultimately, assessing the intended use case, the availability of service networks, and the total cost of ownership will guide buyers toward the most suitable choice for their marine operations.

Essential Technical Properties and Trade Terminology for 115 johnson outboard motor

What Are the Essential Technical Properties of the 115 Johnson Outboard Motor?

Understanding the technical specifications of the 115 Johnson outboard motor is crucial for B2B buyers, particularly when assessing compatibility, performance, and reliability for various marine applications. Here are key properties that should be considered:

-

Horsepower (HP)

The 115 Johnson outboard motor is rated at 115 horsepower, which is a critical measurement indicating the engine’s power output. This specification is vital for buyers as it determines the motor’s suitability for various boat sizes and types, affecting speed and towing capacity. -

Weight

The typical weight of the 115 Johnson outboard motor ranges between 350 to 400 pounds. Weight affects the boat’s balance and performance. Buyers must consider this when selecting a motor to ensure it aligns with the boat’s specifications and intended use. -

Fuel Type

Most models of the 115 Johnson outboard motor utilize unleaded gasoline. Understanding fuel requirements is essential for buyers to ensure they can source the appropriate fuel type, which can impact operational costs and engine performance. -

Material Composition

The motor components are often made from aluminum alloys and stainless steel to enhance durability and resistance to corrosion, especially in saltwater environments. Knowledge of material properties is important for buyers focused on longevity and maintenance costs. -

Cooling System

The 115 Johnson outboard motor typically features a water-cooling system that prevents overheating during operation. This specification is vital, as overheating can lead to engine failure, and understanding it helps buyers assess the motor’s reliability. -

Propeller Shaft Rotation

The standard rotation is counterclockwise when viewed from the rear. This specification is important for compatibility with propellers and can affect the performance of the boat. Buyers must ensure that the motor’s rotation aligns with their existing propeller systems.

What Are Common Trade Terms Relevant to the 115 Johnson Outboard Motor?

Familiarity with industry terminology enhances communication and ensures clarity in transactions. Here are essential trade terms associated with the 115 Johnson outboard motor:

-

OEM (Original Equipment Manufacturer)

This term refers to parts or products made by the company that originally manufactured the motor. Understanding OEM parts is crucial for buyers seeking genuine components that meet quality standards, ensuring optimal performance and longevity. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier will sell. For B2B buyers, knowing the MOQ is vital for budgeting and inventory management, especially when scaling operations or entering new markets. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price bids for specific products or services. B2B buyers should understand how to effectively create and submit RFQs to ensure they receive competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

These are a set of predefined international rules published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers manage shipping costs, risks, and delivery timelines effectively. -

Warranty Period

This refers to the duration during which the manufacturer guarantees the motor against defects. Understanding warranty terms is essential for buyers to evaluate the risk associated with their purchase and plan for potential future costs. -

Aftermarket Parts

These are replacement parts made by third-party manufacturers, not the original manufacturer. Knowing about aftermarket options is beneficial for buyers looking for cost-effective solutions for maintenance and repairs without compromising quality.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and market demands, ensuring successful procurement of the 115 Johnson outboard motor.

Navigating Market Dynamics and Sourcing Trends in the 115 johnson outboard motor Sector

What Are the Current Market Dynamics and Key Trends Influencing the 115 Johnson Outboard Motor Sector?

The global market for outboard motors, particularly the 115 Johnson models, is driven by several key factors. First, the increasing demand for recreational boating and fishing activities across regions, especially in Africa, South America, the Middle East, and Europe, is propelling growth. The rise of eco-tourism and fishing tourism has led to an uptick in the purchase of reliable and efficient outboard motors, with the 115 HP Johnson model being a popular choice due to its balance of power and fuel efficiency.

Emerging technologies are also reshaping the sourcing landscape. Digital platforms for procurement are gaining traction, allowing B2B buyers to streamline the sourcing process. These platforms enhance transparency, enabling buyers to assess suppliers’ performance and product quality efficiently. Furthermore, the trend towards customization is becoming prominent, with buyers looking for specific features tailored to their operational needs. As a result, manufacturers are increasingly offering modular options for outboard motors, which can be adapted for various applications.

The competitive landscape is also evolving, with a shift towards sustainable practices. Manufacturers are focusing on reducing emissions and improving fuel efficiency, aligning with global environmental regulations. This trend is particularly relevant for international buyers who are increasingly scrutinizing the environmental impact of their purchases.

How Important Is Sustainability and Ethical Sourcing in the B2B Outboard Motor Market?

Sustainability has emerged as a cornerstone of modern B2B sourcing strategies, especially in the outboard motor sector. The environmental impact of manufacturing and operating outboard motors is significant, with emissions and waste being key concerns. As a result, ethical sourcing practices have become essential for businesses aiming to enhance their brand reputation and meet regulatory standards.

For the 115 Johnson outboard motor, buyers should prioritize suppliers who adhere to stringent environmental regulations and showcase commitment to sustainability. This includes sourcing materials that are certified as ‘green’ or environmentally friendly. Certifications such as ISO 14001 for environmental management and the use of recycled materials are becoming critical indicators of a supplier’s commitment to sustainability.

Moreover, ethical supply chains not only mitigate environmental risks but also enhance operational resilience. As international buyers navigate complex sourcing environments, ensuring that suppliers maintain ethical labor practices and minimize their carbon footprint can provide a competitive advantage in the market. This focus on sustainability is increasingly influencing purchasing decisions, making it imperative for suppliers to align with these values to remain relevant.

What Is the Historical Context Behind the Johnson Outboard Motor Brand?

The Johnson brand, a part of the legacy of outboard motors, has a rich history dating back to the early 20th century. Initially established as a manufacturer of marine engines, Johnson quickly gained a reputation for reliability and innovation. The 115 HP model has been particularly significant, reflecting advancements in technology and consumer preferences over the decades.

From its inception in the 1960s, the Johnson 115 outboard motor has undergone numerous enhancements, including improvements in fuel efficiency and reduction in emissions. This evolution has allowed it to remain competitive in a rapidly changing market. As international B2B buyers, understanding this historical context provides valuable insights into the brand’s reliability and commitment to quality, which are critical factors in making informed purchasing decisions.

In conclusion, the 115 Johnson outboard motor sector is characterized by dynamic market trends and a growing emphasis on sustainability, making it essential for international buyers to stay informed and adapt their sourcing strategies accordingly.

Frequently Asked Questions (FAQs) for B2B Buyers of 115 johnson outboard motor

-

How do I troubleshoot common issues with the Johnson 115 outboard motor?

To troubleshoot common issues with the Johnson 115 outboard motor, first check for fuel supply and ensure the fuel is fresh. Inspect the electrical connections for corrosion and ensure the battery is charged. Verify that the propeller is clear of debris and that the engine is not overheating. If issues persist, consult the owner’s manual for specific troubleshooting steps or contact a certified technician for diagnostics. -

What are the key specifications of the Johnson 115 outboard motor?

The Johnson 115 outboard motor typically features a 115 horsepower rating with a 2-stroke engine design, allowing for efficient performance. It has a displacement of approximately 2.6 liters and offers various gear ratios, making it suitable for a range of boating applications. The motor’s weight varies by model year, so it’s crucial to check specific model details when considering compatibility with your boat. -

What factors should I consider when sourcing Johnson 115 outboard motors internationally?

When sourcing Johnson 115 outboard motors internationally, consider factors such as supplier reliability, product quality, and compliance with local regulations. It’s essential to verify certifications and warranties offered by the manufacturer. Additionally, assess the supplier’s experience in exporting to your region, as this can affect shipping logistics and delivery times. -

What are the minimum order quantities (MOQ) for Johnson 115 outboard motors?

Minimum order quantities (MOQ) for Johnson 115 outboard motors can vary significantly between suppliers. Typically, MOQs might range from one unit for direct purchases to larger quantities for wholesale orders. Always clarify the MOQ during negotiations and evaluate whether bulk purchasing provides cost advantages or logistical efficiencies. -

How can I ensure the quality of the Johnson 115 outboard motor before purchase?

To ensure quality, request product samples or detailed specifications from the supplier. Conduct inspections and ask for certifications that verify quality standards, such as ISO or CE marks. Additionally, seek references or reviews from other buyers to gauge the supplier’s reputation and the reliability of their products. -

What payment terms are commonly used for international transactions involving outboard motors?

Common payment terms for international transactions include letters of credit, wire transfers, or escrow services. Many suppliers may require a deposit upfront, typically 30% to 50% of the total order value, with the balance due upon shipment. Always negotiate terms that protect your interests, especially regarding currency fluctuations and transaction fees. -

What logistics considerations should I be aware of when importing Johnson 115 outboard motors?

When importing Johnson 115 outboard motors, consider shipping methods (air vs. sea freight), customs duties, and local regulations for importing marine equipment. Ensure you have a reliable freight forwarder who can manage documentation and handle customs clearance. Familiarize yourself with import tariffs and compliance requirements in your country to avoid unexpected costs. -

Can I customize the Johnson 115 outboard motor for specific applications?

Yes, customization options for the Johnson 115 outboard motor may be available depending on the supplier. Customizations can include modifications to the engine for specific fuel types, adjustments to the propeller size for enhanced performance, or additional features such as electronic controls. Discuss your specific requirements with the supplier to explore available options and ensure compatibility with your intended use.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 115 Johnson Outboard Motor Manufacturers & Suppliers List

1. Outboard Motors – Complete Engines

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 115 HP Outboard Motor Complete Outboard Engines for sale on eBay. Related brands include Yamaha, Mercury, Evinrude, and Johnson. Categories include complete outboard engines, lower units, powerheads, and various components such as cooling systems, electrical systems, and rigging. Popular related searches include 110 hp, 125 hp, 135 hp, and 4 stroke outboard motors.

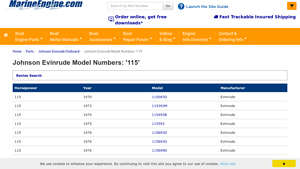

2. Evinrude – 115 HP Outboard Motor

Domain: marineengine.com

Registered: 1999 (26 years)

Introduction: Model Number: 115, Horsepower: 115 HP, Manufacturer: Evinrude, Years Available: 1969, 1970, 1973, 1974, 1975, 1976, 1977, 1978, 1979, 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003, 2004, 2005, 2006, 2007, 2008, 2009, 2010, 2011, with various model numbers including 115083D, 115393M, 115493B, 115593, 115693D, 115790S, 115890C, 115990R, BE115ELEDR, E115DBXIIB, E115DPLISF, E115FPLEEC, E115FSLE…

3. Crowley Marine – Johnson 115 HP Outboard Parts

Domain: crowleymarine.com

Registered: 2001 (24 years)

Introduction: Parts for Johnson 115 HP Outboard Models, Summer Sale: 10-50% discount on all OEM parts, flat $4.95 shipping, over 1 million OEM parts available, easy-to-use parts diagrams, best price guarantee, expert live support, 50+ years serving boaters, huge selection of OEM parts from 1950 to 2025, most parts in stock with same day fulfillment. Models by year include: 1969 (115ESL69E, 115ESL69S), 1970 (115…

4. Scream And Fly – Reliable Outboards

Domain: screamandfly.com

Registered: 1999 (26 years)

Introduction: This company, Scream And Fly – Reliable Outboards, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Johnson – 100-200HP Boat Engines

Domain: il.ebay.com

Registered: 1995 (30 years)

Introduction: Johnson 100-200HP Boat Engines available on eBay. Related products include Johnson Outboard Engines, components, and accessories. Various models listed include 100 HP, 115 HP, 140 HP, 175 HP, and 200 HP engines. Options for new and pre-owned parts, including lower unit gearcases, decals, and powerheads. Prices range from ILS 95.45 for decals to ILS 16,410.46 for a pre-owned 150 HP outboard motor. …

6. Wellcraft – 180 Fisherman Outboard Options

Domain: bdoutdoors.com

Registered: 2008 (17 years)

Introduction: 1987 Wellcraft 180 Fisherman; Original 115 HP Johnson 2-stroke outboard; Replacement considerations include Evinrude e-tec and Yamaha; Weight sensitivity for older hulls; Potential need to replace tach, gauges, and cables; New motors are quieter and have less exhaust; Suggested price for new Mercury 115-4 with installation is approximately $18-19k; Bolt pattern compatibility noted; Steering may be…

7. Johnson – 115hp V4 Outboard Motor

Domain: justanswer.com

Registered: 2004 (21 years)

Introduction: Johnson 115hp V4 Outboard Motor; common issues include power loss while maintaining full RPM; potential causes include propeller hub spinning, fuel delivery issues, ignition timing problems, and cylinder drop; recommended checks include inspecting fuel filter, carburetor, spark plugs, and conducting a compression test.

Strategic Sourcing Conclusion and Outlook for 115 johnson outboard motor

In conclusion, the strategic sourcing of the 115 Johnson outboard motor presents a robust opportunity for international B2B buyers. With a diverse range of models spanning decades, the 115 horsepower outboard motors are known for their reliability and performance, making them a valuable asset for various marine applications. Buyers should prioritize sourcing from reputable suppliers who can provide genuine parts and service support to ensure optimal functionality and longevity of their engines.

Emphasizing strategic sourcing not only enhances procurement efficiency but also mitigates risks associated with counterfeit products and inadequate after-sales support. As markets in Africa, South America, the Middle East, and Europe continue to grow, the demand for dependable marine engines like the Johnson 115 is expected to rise.

To capitalize on this trend, international buyers are encouraged to establish strong partnerships with trusted distributors and manufacturers. By doing so, they can secure competitive pricing and ensure access to essential parts and service, ultimately driving success in their marine ventures. Embrace the future of marine power by making informed sourcing decisions today.