Unlocking Value: A Strategic Analysis of the R34 Gtr Motor For Sale Market

Introduction: Navigating the Global Market for r34 gtr motor for sale

In the competitive landscape of automotive components, sourcing the right R34 GTR motor for sale poses a significant challenge for international B2B buyers. As demand surges for high-performance engines, particularly in regions like Africa, South America, the Middle East, and Europe, navigating the complexities of this market requires a strategic approach. This comprehensive guide aims to equip businesses with the knowledge necessary to make informed purchasing decisions, covering a range of topics including types of engines available, their applications, and effective supplier vetting processes.

Understanding the nuances of pricing is essential; we will explore cost variations based on engine specifications and sourcing channels, enabling buyers to maximize their investment. Additionally, the guide will highlight critical factors to consider when evaluating suppliers, such as warranty options, engine condition, and import regulations. This resource is tailored for businesses looking to enhance their automotive offerings, ensuring that they not only acquire quality engines but also build lasting relationships with reputable suppliers. By leveraging the insights provided, B2B buyers can confidently navigate the global market for R34 GTR motors, ultimately driving success in their automotive ventures.

Understanding r34 gtr motor for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| HKS Complete Engine RB26DETT | High-performance options (2.8L to 3.0L), advanced V-CAM technology | Racing, high-performance builds | Pros: Exceptional power output; Cons: High cost and complexity. |

| JDM RB26DETT Engine with Transmission | Complete motor package including transmission, wiring, and ECU | Restoration, performance upgrades | Pros: All-in-one solution; Cons: Limited warranty period. |

| HKS Stroker Kits | Enhanced engine displacement (2.8L), optimized for responsiveness | Custom builds, competitive racing | Pros: Improved performance; Cons: Requires precise tuning. |

| OEM Replacement RB26 Engine | Stock internals, ideal for restoration projects | Restoration, classic car markets | Pros: Reliable and cost-effective; Cons: Limited performance enhancements. |

| Turbo Kits (e.g., HKS GTIII-4R) | Turbocharging options for power increases | Performance tuning, racing | Pros: Significant power boost; Cons: Installation complexity. |

What Are the Key Characteristics of HKS Complete Engine RB26DETT?

The HKS Complete Engine RB26DETT is designed for those seeking top-tier performance. Available in various configurations ranging from 2.8L to 3.0L, it features advanced V-CAM technology that enhances power delivery and responsiveness. This engine is primarily suited for competitive racing and high-performance builds, making it an attractive option for B2B buyers in the motorsport industry. However, the high cost and complexity of installation may deter some buyers, necessitating skilled technicians for effective integration.

Why Choose a JDM RB26DETT Engine with Transmission?

The JDM RB26DETT engine package includes not only the engine but also a compatible 6-speed transmission, wiring harness, and ECU, making it a comprehensive solution for businesses looking to restore or upgrade vehicles. This option is particularly valuable for buyers in restoration and performance upgrade markets, as it simplifies the installation process. However, the limited warranty period may be a concern for some, emphasizing the need for thorough testing and quality assurance before purchase.

What Benefits Do HKS Stroker Kits Offer for Custom Builds?

HKS Stroker Kits increase engine displacement to 2.8L, optimizing performance and responsiveness. These kits are ideal for custom builds and competitive racing applications, where maximizing power output is crucial. Buyers should consider the need for precise tuning and adjustments when using these kits, as improper installation can lead to performance issues. The investment in HKS Stroker Kits can yield significant returns in terms of horsepower and torque, appealing to serious performance enthusiasts.

When to Opt for an OEM Replacement RB26 Engine?

The OEM Replacement RB26 Engine is perfect for businesses focused on restoring classic cars to their original specifications. With stock internals and a focus on reliability, this option is cost-effective for those looking to maintain the integrity of their vehicles. While it offers limited performance enhancements, the ease of installation and the assurance of quality make it a go-to choice for restoration projects. Buyers should weigh the benefits of reliability against the performance needs of their clientele.

How Do Turbo Kits Enhance Engine Performance?

Turbo Kits, such as the HKS GTIII-4R, provide significant power increases for RB26DETT engines. These kits are designed for performance tuning and racing applications, offering a cost-effective way to boost horsepower. While they deliver impressive performance enhancements, buyers must consider the complexity of installation and the potential need for additional tuning to ensure optimal performance. Turbo Kits are an excellent investment for businesses focused on competitive racing and high-performance vehicle modifications.

Key Industrial Applications of r34 gtr motor for sale

| Industry/Sector | Specific Application of r34 gtr motor for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Performance | Custom performance builds for racing enthusiasts | Enhanced speed and handling for competitive racing | Ensure compatibility with local regulations and racing standards |

| Motorsports | Engine swaps for racing teams and professional drivers | Proven performance and reliability in high-pressure scenarios | Verify engine condition and performance history |

| Specialty Vehicle Builds | Restoration and modification of classic cars | Unique, high-performance vehicles that attract collectors | Assess availability of OEM parts for maintenance and upgrades |

| Export and Import Trade | Resale of JDM engines to international markets | Access to premium engines in high demand globally | Understand import regulations and shipping logistics |

| Tuning and Modification Shops | Engine tuning and performance enhancement services | Increased customer satisfaction through tailored upgrades | Establish relationships with reliable suppliers for parts |

How is the R34 GTR Motor Applied in Automotive Performance Builds?

The R34 GTR motor is a popular choice for custom performance builds among racing enthusiasts. These engines are known for their high power output and durability, making them ideal for applications where speed and handling are crucial. Buyers in this sector often seek engines that can withstand the rigors of competitive racing while meeting specific performance benchmarks. International buyers, particularly from regions like Africa and South America, should ensure compliance with local racing regulations to avoid issues during competitions.

What Role Does the R34 GTR Motor Play in Motorsports?

In the motorsports industry, the R34 GTR motor is frequently utilized for engine swaps in racing teams and professional drivers looking to enhance their vehicle’s performance. Its proven reliability under extreme conditions makes it a preferred choice for those competing at high levels. Buyers should focus on verifying the engine’s condition and performance history to ensure it meets the rigorous demands of competitive racing, especially in markets where the motorsport culture is growing rapidly.

How is the R34 GTR Motor Used in Specialty Vehicle Builds?

The R34 GTR motor is integral to the restoration and modification of classic cars, allowing builders to create unique, high-performance vehicles that appeal to collectors. The engine’s robust specifications enable it to deliver exceptional power, which is often a selling point for enthusiasts. Buyers should assess the availability of OEM parts for future maintenance and upgrades, ensuring that their investment remains viable over time.

How Does the R34 GTR Motor Impact Export and Import Trade?

In the global market, the R34 GTR motor is a sought-after component for resale in various international markets. Its reputation for performance creates high demand, particularly in regions with a strong automotive culture. Buyers must understand import regulations and shipping logistics to navigate the complexities of international trade effectively, ensuring compliance with both the exporting and importing countries’ laws.

What is the Importance of the R34 GTR Motor in Tuning and Modification Shops?

Tuning and modification shops frequently utilize the R34 GTR motor for engine tuning and performance enhancement services. This engine provides a foundation for significant upgrades, allowing shops to cater to customers seeking tailored performance solutions. Establishing relationships with reliable suppliers for necessary parts is crucial for maintaining a steady workflow and ensuring customer satisfaction in this competitive market.

3 Common User Pain Points for ‘r34 gtr motor for sale’ & Their Solutions

Scenario 1: Navigating Complex Import Regulations for R34 GTR Motors

The Problem: International B2B buyers often encounter significant hurdles when attempting to import R34 GTR motors. These challenges can include a lack of clarity regarding import regulations, duties, and taxes specific to each country. For instance, buyers from Africa or South America might face stringent customs inspections, documentation requirements, and unforeseen tariffs that can inflate costs and lead to delays in receiving their engines.

The Solution: To effectively navigate these complexities, it is crucial to conduct thorough research on the specific import regulations for each target market. Buyers should engage with logistics experts who specialize in automotive imports to ensure all necessary documentation, such as commercial invoices, packing lists, and certificates of origin, are prepared in advance. Furthermore, working with suppliers who have experience in international shipping can streamline the process. It’s advisable to establish a clear line of communication with customs brokers to clarify any potential fees and requirements ahead of time. This proactive approach can minimize delays and unexpected costs, ultimately leading to a smoother transaction.

Scenario 2: Ensuring Quality and Authenticity of R34 GTR Motors

The Problem: Quality assurance is a major concern for B2B buyers, particularly when purchasing high-value items like R34 GTR motors. The market is rife with counterfeit parts and used engines that may not meet the expected performance standards. Buyers might find themselves receiving engines that are not only subpar but also lack essential documentation proving their authenticity, which can lead to costly repairs and reputational damage.

The Solution: To ensure the authenticity and quality of R34 GTR motors, buyers should prioritize sourcing from reputable suppliers with a proven track record in the industry. It’s critical to request detailed information about the engine’s history, including previous maintenance records and any modifications made. Buyers should also demand certifications or warranties that guarantee the engine’s performance and condition. Additionally, utilizing third-party inspection services prior to purchase can provide an unbiased evaluation of the engine’s integrity. By establishing relationships with trusted suppliers and conducting due diligence, buyers can significantly reduce the risk of acquiring substandard products.

Scenario 3: Managing High Costs of R34 GTR Motors

The Problem: The high cost of R34 GTR motors, often exceeding tens of thousands of dollars, can be a significant barrier for B2B buyers. This financial strain can be exacerbated by fluctuating exchange rates and shipping costs, which may not be predictable at the time of purchase. Buyers from regions like Europe or the Middle East, where demand is high, may find themselves outbid or unable to justify the investment without a clear path to profitability.

The Solution: To manage costs effectively, buyers should explore bulk purchasing agreements or partnerships with other businesses to leverage economies of scale. Negotiating long-term contracts with suppliers can also lead to better pricing and stability in costs. Additionally, buyers should conduct a comprehensive market analysis to identify emerging trends and potential resale opportunities that could enhance the return on investment. This might include understanding regional demand for performance upgrades or tuning services that can add value to the engine sale. By strategically planning purchases and aligning with market demands, buyers can mitigate financial risks while maximizing their investment potential.

Strategic Material Selection Guide for r34 gtr motor for sale

What Materials Are Commonly Used in R34 GTR Motors and Their Performance Characteristics?

When considering the purchase of R34 GTR motors, understanding the materials used in their construction is crucial for international B2B buyers. The choice of materials directly influences performance, durability, and overall suitability for specific applications. Here, we analyze four common materials used in R34 GTR motors: aluminum, cast iron, forged steel, and composite materials.

How Does Aluminum Contribute to R34 GTR Motor Performance?

Aluminum is widely used in engine components such as engine blocks, cylinder heads, and intake manifolds. Its key properties include a low density, which contributes to a lighter overall engine weight, and excellent thermal conductivity, allowing for efficient heat dissipation.

Pros: Aluminum offers high strength-to-weight ratios, which enhances vehicle performance and fuel efficiency. It is also corrosion-resistant, making it suitable for various environmental conditions.

Cons: While aluminum is durable, it can be less resistant to high temperatures compared to other metals, leading to potential deformation under extreme conditions. Additionally, the manufacturing process can be complex, increasing production costs.

Impact on Application: Aluminum components are compatible with a variety of media, including oil and fuel, making them versatile for high-performance applications.

Considerations for International Buyers: Compliance with international standards such as ASTM and JIS is essential. Buyers from regions like Africa and South America should consider the availability of aftermarket support for aluminum components.

What Role Does Cast Iron Play in Engine Durability?

Cast iron is commonly used for engine blocks and crankshafts due to its excellent wear resistance and ability to withstand high pressures.

Pros: The durability of cast iron makes it ideal for high-performance engines, as it can handle significant stress without deforming. Its ability to absorb vibrations also contributes to smoother engine operation.

Cons: The primary drawback is its weight, which can negatively impact overall vehicle performance. Additionally, cast iron is prone to corrosion if not properly maintained.

Impact on Application: Cast iron is compatible with various lubricants and fuels, making it a reliable choice for engine components subjected to high stress.

Considerations for International Buyers: Buyers should be aware of the specific grades of cast iron used, as compliance with regional standards (e.g., DIN in Europe) can vary.

How Does Forged Steel Enhance Engine Performance?

Forged steel is often used for crankshafts and connecting rods due to its superior strength and fatigue resistance.

Pros: The forging process aligns the grain structure of the metal, resulting in components that are highly durable and capable of withstanding extreme conditions. This makes forged steel ideal for high-performance applications where reliability is critical.

Cons: The manufacturing process is more expensive and time-consuming than casting, leading to higher costs. Additionally, forged components can be heavier than their aluminum counterparts.

Impact on Application: Forged steel components are particularly effective in high-stress environments, such as racing or heavy-duty applications, ensuring longevity and performance.

Considerations for International Buyers: Buyers should ensure that forged steel components meet international quality standards and certifications, particularly in regions with stringent automotive regulations.

What Advantages Do Composite Materials Offer in Engine Design?

Composite materials, often used in gaskets and seals, provide unique benefits in engine design.

Pros: Composites are lightweight and can be engineered for specific thermal and chemical resistance, which enhances overall engine performance. They also offer excellent sealing capabilities, reducing the risk of leaks.

Cons: The primary limitation is their susceptibility to degradation over time, particularly under high temperatures or exposure to certain chemicals. This can lead to increased maintenance needs.

Impact on Application: Composites are compatible with various engine fluids, making them versatile for use in different engine configurations.

Considerations for International Buyers: Buyers should verify the specifications of composite materials to ensure they meet the operational demands of their specific applications, particularly in regions with varying climate conditions.

Summary Table of Material Selection for R34 GTR Motors

| Material | Typical Use Case for r34 gtr motor for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine blocks, cylinder heads | Lightweight, excellent thermal conductivity | Less resistant to high temperatures | Medium |

| Cast Iron | Engine blocks, crankshafts | High durability, vibration absorption | Heavier, prone to corrosion | Medium |

| Forged Steel | Crankshafts, connecting rods | Superior strength and fatigue resistance | Higher manufacturing costs | High |

| Composite | Gaskets, seals | Lightweight, excellent sealing capabilities | Susceptible to degradation | Medium |

This guide serves as a strategic resource for international B2B buyers, helping them make informed decisions regarding material selection for R34 GTR motors. Understanding these materials and their implications ensures that buyers can optimize performance while meeting regional standards and preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for r34 gtr motor for sale

What Are the Main Stages of Manufacturing the R34 GTR Motor?

The manufacturing process of the R34 GTR motor, specifically the RB26DETT, is a meticulous endeavor that ensures high performance and reliability. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality materials, primarily aluminum for the engine block and forged steel for the crankshaft. Suppliers often conduct rigorous tests on materials to ensure they meet specific mechanical properties.

-

Forming: In this stage, materials are shaped into desired components using advanced manufacturing techniques such as casting and machining. For the RB26DETT engine, precision machining is critical, particularly for components like the cylinder head and crankshaft. CNC (Computer Numerical Control) machines are commonly employed to achieve the tight tolerances required for optimal engine performance.

-

Assembly: Following forming, components are carefully assembled. This stage involves installing critical parts such as pistons, connecting rods, and the oil pump. Skilled technicians ensure that each part is fitted correctly, often using torque wrenches to adhere to specific torque specifications. The assembly process may also involve balancing the rotating assembly to minimize vibrations during operation.

-

Finishing: The final stage focuses on surface treatment and quality checks. Components may undergo processes such as anodizing, coating, or polishing to enhance durability and performance. This stage also includes initial testing to verify that all components function correctly before the engine is shipped.

Which Key Techniques Are Used in R34 GTR Motor Manufacturing?

The manufacturing of the R34 GTR motor employs several advanced techniques to ensure performance and longevity. Key techniques include:

-

Precision Machining: Utilizing CNC technology allows for the production of highly accurate components. This ensures that parts fit together seamlessly and function optimally under high-stress conditions.

-

Heat Treatment: Components such as the crankshaft and connecting rods often undergo heat treatment to enhance their mechanical properties, making them more resistant to wear and fatigue.

-

Assembly Line Automation: Many manufacturers employ automated systems for parts assembly, which increases efficiency and reduces human error. Automation also allows for consistent application of torque and other assembly standards.

How Is Quality Assurance Implemented in R34 GTR Motor Manufacturing?

Quality assurance (QA) is integral to the manufacturing of the R34 GTR motor. It involves several international and industry-specific standards, as well as multiple checkpoints throughout the production process.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001 standards, which emphasize a process-oriented approach to quality management. Compliance with these standards assures B2B buyers of consistent quality and continuous improvement.

-

Industry-Specific Certifications: Depending on the market, additional certifications such as CE (Conformité Européenne) for Europe or API (American Petroleum Institute) standards for lubricants may also be relevant. These certifications indicate that products meet specific safety and performance criteria.

-

Quality Control Checkpoints: Various checkpoints are established throughout the manufacturing process:

– Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, random sampling and inspections occur to monitor the production process and identify any deviations.

– Final Quality Control (FQC): After assembly, the complete engine undergoes rigorous testing, including dyno testing to assess performance metrics.

What Common Testing Methods Are Used for R34 GTR Motors?

Testing methods are essential to ensure that the R34 GTR motor meets performance and reliability standards. Common methods include:

-

Dynamometer Testing: This evaluates the engine’s performance under various load conditions, providing critical data on horsepower and torque output.

-

Leak Testing: Ensures that there are no leaks in the cooling system or oil passages, which is vital for engine longevity and performance.

-

Vibration Analysis: Used to identify any abnormal vibrations that could indicate misalignment or imbalance within the engine.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control practices of suppliers. Here are effective strategies:

-

Conducting Audits: Regular audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards. Buyers should assess their quality management systems and overall production capabilities.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports that outline their quality control processes, testing methods, and results. This documentation can help buyers assess the reliability of the product.

-

Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased evaluation of the manufacturing processes and quality assurance practices of suppliers.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must be aware of specific nuances regarding quality control and certification:

-

Regulatory Compliance: Different regions may have specific regulatory requirements that suppliers must meet. Buyers should ensure that suppliers are aware of and compliant with these regulations to avoid issues during importation.

-

Cultural Differences: Understanding cultural differences in business practices can help buyers navigate communication and expectations related to quality assurance.

-

Logistics and Supply Chain Considerations: Timeliness and reliability of shipping and delivery can impact the overall quality of the engine. Buyers should work closely with suppliers to ensure that logistics are managed effectively.

In conclusion, the manufacturing processes and quality assurance measures for the R34 GTR motor are crucial in ensuring that the product meets the high-performance standards expected by international B2B buyers. By understanding these processes, buyers can make informed decisions and establish strong partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘r34 gtr motor for sale’

Introduction

This practical sourcing guide aims to equip B2B buyers with a systematic checklist for procuring the R34 GTR motor. Given the complexities involved in sourcing high-performance engines, especially for international markets, following these steps will help ensure a successful purchase while minimizing risks.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for the R34 GTR motor is crucial. Determine the engine type, power output, and any modifications needed to meet your performance goals.

– Considerations: Are you looking for a complete engine, a short block, or specific components like turbo kits?

– Compatibility: Ensure that the engine specifications align with the vehicles you intend to use them in.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of R34 GTR motors. Utilize industry forums, automotive trade shows, and online platforms to gather information.

– Supplier Profiles: Look for suppliers with extensive experience in JDM (Japanese Domestic Market) parts and engines.

– Reviews and Feedback: Seek customer reviews and feedback on their reliability and service quality.

Step 3: Evaluate Supplier Certifications

Before making a purchase, verify that your chosen suppliers have the necessary certifications. This ensures that they comply with international standards and regulations.

– Quality Assurance: Check for ISO certifications or any industry-specific quality marks.

– Warranty and Support: Assess the warranty offered on the engine and the after-sales support available.

Step 4: Request Detailed Quotations

Once you’ve narrowed down your options, request detailed quotations from multiple suppliers. This will help you compare pricing and understand what is included in each offer.

– Breakdown of Costs: Ensure the quotation includes all costs such as shipping, taxes, and any additional fees.

– Payment Terms: Review the payment terms and conditions to avoid unexpected charges later.

Step 5: Conduct a Background Check

Perform a background check on the suppliers to confirm their legitimacy and reliability. This step is vital to avoid scams and ensure a secure transaction.

– Business Verification: Look for business registration details and any legal disputes they may have had.

– Contact Previous Clients: If possible, reach out to previous clients for testimonials regarding their experience.

Step 6: Inspect the Engine Before Purchase

If feasible, arrange for a physical inspection of the engine. This is particularly important for used engines to assess their condition.

– Check for Damage: Look for signs of wear, damage, or modifications that could affect performance.

– Documentation: Request maintenance records or previous usage information to gauge the engine’s history.

Step 7: Finalize the Purchase and Arrange Shipping

Once you are satisfied with the engine and supplier, finalize the purchase. Ensure all paperwork is in order and discuss shipping arrangements.

– Shipping Options: Choose a shipping method that balances speed and cost, especially if you are importing from another country.

– Customs and Duties: Be aware of any customs regulations and duties applicable to your region to avoid delays.

By following this structured checklist, B2B buyers can effectively navigate the complexities of sourcing the R34 GTR motor, ensuring a successful and satisfactory procurement process.

Comprehensive Cost and Pricing Analysis for r34 gtr motor for sale Sourcing

What Are the Key Cost Components for Sourcing an R34 GTR Motor?

When sourcing an R34 GTR motor, understanding the cost structure is crucial for effective budgeting and negotiation. The main cost components include:

-

Materials: The RB26DETT engine, known for its high performance, requires high-quality materials. Costs can vary significantly depending on whether parts are OEM or aftermarket, with prices for complete engines ranging from approximately $25,000 to over $74,000, depending on specifications and enhancements.

-

Labor: Labor costs can fluctuate based on the complexity of the engine assembly or modification. Skilled labor is necessary for both manufacturing and installation, impacting the overall cost. Expect additional labor charges if installation services are included.

-

Manufacturing Overhead: This includes expenses related to production facilities, equipment maintenance, and utilities. Efficient manufacturing processes can help keep overheads lower, which is critical for competitive pricing.

-

Tooling: Specialized tooling for custom parts or modifications can add significant costs. If you’re considering bespoke specifications, factor in these expenses early in the sourcing process.

-

Quality Control (QC): Ensuring that parts meet performance and safety standards incurs costs. Engines sourced from reputable suppliers often include a warranty and quality certifications, which may raise upfront costs but reduce risks in the long run.

-

Logistics: Shipping costs can vary widely based on the origin of the engine, destination, and chosen shipping method. For international buyers, understanding Incoterms is vital to accurately estimate total logistics costs, including duties and taxes.

-

Margin: Suppliers typically include a margin in their pricing to cover risks and ensure profitability. This margin can vary based on market conditions, supplier reputation, and the volume of the order.

What Price Influencers Should Buyers Consider When Sourcing?

Several factors can influence the pricing of the R34 GTR motor:

-

Volume/MOQ: Purchasing in larger quantities often leads to discounts. Establishing a Minimum Order Quantity (MOQ) with suppliers can lower the unit price significantly.

-

Specifications and Customization: Customizing the engine for specific performance needs or aesthetic preferences will increase costs. Clearly define your specifications to ensure accurate quotations.

-

Materials and Quality Certifications: The type of materials used can significantly impact the price. High-performance components generally come at a premium. Suppliers offering certifications can provide assurance of quality, which may justify higher costs.

-

Supplier Factors: The reputation and reliability of the supplier can affect price. Established suppliers with a track record of quality may charge more but offer peace of mind.

-

Incoterms: Different shipping agreements can lead to varying costs. Understanding whether costs include shipping, insurance, and duties is essential for calculating total expenses.

What Are Effective Buyer Tips for Negotiating Prices?

B2B buyers should adopt a strategic approach when negotiating prices for the R34 GTR motor:

-

Research and Compare: Collect quotes from multiple suppliers to understand the market price. This will empower you to negotiate better terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but the lifetime costs associated with maintenance, warranties, and potential resale value.

-

Negotiate Based on Commitment: If you can commit to future purchases, leverage this to negotiate better pricing. Suppliers are often willing to offer discounts for long-term relationships.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations and local taxes that could affect the final price. Additionally, consider the impact of geopolitical factors on supply chains.

-

Utilize Local Representation: Engaging a local agent familiar with the region can help navigate cultural nuances and strengthen negotiations.

Disclaimer on Pricing

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier pricing strategies, and specific buyer requirements. Always request up-to-date quotes and consider all cost components when making purchasing decisions.

Alternatives Analysis: Comparing r34 gtr motor for sale With Other Solutions

Exploring Alternatives for the R34 GTR Motor for Sale

In the competitive automotive market, particularly for high-performance vehicles, buyers often seek various options to meet their specific needs. The R34 GTR motor is a sought-after solution for enthusiasts and professionals alike, but several viable alternatives exist. Understanding these alternatives allows B2B buyers to make informed decisions that align with their operational goals and budget constraints.

| Comparison Aspect | R34 GTR Motor For Sale | Alternative 1: JDM RB26DETT Engine | Alternative 2: LS Swap Kit |

|---|---|---|---|

| Performance | High-performance, twin-turbo | Comparable performance with lower RPM range | High torque and horsepower potential |

| Cost | $25,999 – $74,000 | $10,500 – $25,999 | $5,000 – $15,000 |

| Ease of Implementation | Requires specialized skills | Moderate complexity, requires JDM parts knowledge | Generally easier, more widely supported |

| Maintenance | Higher due to performance parts | Moderate, parts availability varies | Lower, more common parts available |

| Best Use Case | Racing and performance builds | Restorations and high-performance projects | Custom builds and daily drivers |

What Are the Benefits and Drawbacks of the JDM RB26DETT Engine?

The JDM RB26DETT engine serves as a direct alternative to the R34 GTR motor. While it offers similar performance characteristics, including a twin-turbo setup, it typically comes at a lower price point. This engine is ideal for those looking to restore or build a high-performance vehicle without the premium price tag of the R34. However, buyers should be aware that sourcing parts may be more challenging, especially outside of Japan, which can impact maintenance and repair costs in the long run.

How Does an LS Swap Kit Compare to the R34 GTR Motor?

The LS swap kit has gained popularity as an alternative due to its affordability and ease of implementation. With a lower price range and a reputation for reliability, the LS engine provides significant torque and horsepower, making it an attractive choice for custom builds. Additionally, the availability of aftermarket parts and community support simplifies maintenance. However, performance enthusiasts may find that the character and performance of an LS engine differ from the iconic RB26DETT, potentially affecting the overall driving experience.

Conclusion: Which Solution Is Right for Your Needs?

When evaluating the right engine solution, B2B buyers should consider their specific use cases, budget, and performance expectations. The R34 GTR motor is a premium choice for those focused on high-performance racing applications. In contrast, the JDM RB26DETT engine offers a more cost-effective option for restorations, while the LS swap kit provides a practical alternative for custom builds. Ultimately, the decision should be guided by the intended application, availability of parts, and maintenance capabilities to ensure the best return on investment.

Essential Technical Properties and Trade Terminology for r34 gtr motor for sale

What Are the Key Technical Properties of the R34 GTR Motor That B2B Buyers Should Know?

When considering the purchase of an R34 GTR motor, understanding its technical properties is crucial. Here are some essential specifications that influence performance, compatibility, and overall value:

-

Engine Configuration: RB26DETT

The RB26DETT is a 2.6L inline-six engine equipped with twin turbochargers. This configuration is known for its high power output and robust performance, making it a popular choice for racing and performance tuning. For B2B buyers, selecting a motor with this configuration ensures compatibility with a range of performance upgrades and aftermarket parts. -

Power Output: 280 HP (Factory Rating)

The factory-rated power output is often capped at 280 horsepower due to Japanese automotive regulations. However, many aftermarket modifications can significantly increase this figure. Understanding the power output is vital for businesses that may need to meet specific performance benchmarks or regulations in their markets. -

Material Composition: Aluminum Alloy and Cast Iron

The engine block is typically made of cast iron for strength, while the cylinder head is crafted from aluminum alloy to reduce weight. This combination optimizes performance and durability. B2B buyers should consider material properties when assessing the longevity and maintenance requirements of the engine. -

Torque Rating: 368 lb-ft

The torque rating is an important specification that impacts acceleration and overall driving dynamics. A higher torque rating allows for better performance in varied driving conditions, which is essential for businesses focused on racing or high-performance applications. -

Compression Ratio: 9.0:1

This ratio indicates the engine’s efficiency and power potential. A higher compression ratio typically results in more power but requires higher-octane fuel. Understanding this property helps businesses choose the appropriate fuel for optimal performance, especially in regions with varying fuel quality. -

Weight: Approximately 600 lbs (272 kg)

The weight of the engine affects vehicle dynamics, including handling and acceleration. For B2B buyers, knowing the weight is essential for ensuring compatibility with vehicle chassis and for logistics during shipping.

What Trade Terminology Should B2B Buyers Understand When Purchasing an R34 GTR Motor?

Familiarity with industry terminology can streamline negotiations and enhance communication with suppliers. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

This term refers to parts made by the original manufacturer of the vehicle. For B2B buyers, OEM components are often seen as reliable choices due to their guaranteed compatibility and quality. It’s essential to clarify whether the motor is OEM or aftermarket to understand warranty and reliability implications. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to ensure they meet supplier requirements without overstocking. It also impacts pricing, as larger orders may qualify for discounts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For B2B transactions, submitting an RFQ can help buyers compare prices and terms across multiple suppliers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers to understand shipping costs, insurance, and delivery responsibilities, reducing the risk of misunderstandings during cross-border transactions. -

Aftermarket

This term refers to parts and components produced by companies other than the original manufacturer. B2B buyers often explore aftermarket options for cost savings or performance enhancements. Understanding this can help buyers identify suitable upgrades or replacements for their motors. -

Warranty Terms

Warranty terms specify the conditions under which a product is covered for repairs or replacement. For B2B buyers, knowing the warranty details is critical for assessing the risk associated with the investment in an R34 GTR motor, particularly in markets where service and parts availability may vary.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing R34 GTR motors, ensuring compatibility, reliability, and value in their investments.

Navigating Market Dynamics and Sourcing Trends in the r34 gtr motor for sale Sector

What Are the Key Market Trends in the R34 GTR Motor for Sale Sector?

The global market for the R34 GTR motor is experiencing a notable resurgence, driven by rising interest in classic Japanese performance vehicles and an expanding collector base. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking high-performance engines to cater to niche automotive markets, such as motorsports and car restoration. The availability of JDM (Japanese Domestic Market) parts has enhanced sourcing capabilities, with various suppliers offering complete engine packages, performance upgrades, and OEM components.

Emerging technologies are reshaping sourcing strategies. For instance, digital platforms are facilitating real-time inventory management, allowing buyers to efficiently track engine availability and pricing fluctuations. Online marketplaces and specialized automotive forums are becoming essential tools for B2B buyers, enabling them to connect with reputable suppliers and negotiate competitive pricing. Additionally, the trend towards customization is prevalent; buyers are looking for specific engine configurations to meet unique performance goals, leading to increased demand for tailored solutions.

How Are Sustainability and Ethical Sourcing Addressed in the R34 GTR Motor Sector?

The automotive industry is progressively adopting sustainability measures, and the R34 GTR motor for sale sector is no exception. B2B buyers are increasingly aware of the environmental impact associated with sourcing engines and parts, which has prompted a shift towards ethical supply chains. Suppliers are now focusing on responsible sourcing practices, ensuring that materials used in engine production comply with environmental regulations and standards.

The importance of certifications such as ISO 14001 for environmental management systems is gaining traction. Buyers are encouraged to seek suppliers that prioritize sustainability, offering products made from recycled or eco-friendly materials. Moreover, the use of energy-efficient manufacturing processes can significantly reduce the carbon footprint associated with engine production. This shift not only aligns with global sustainability goals but also enhances brand reputation among environmentally conscious consumers.

How Has the R34 GTR Motor for Sale Sector Evolved Over Time?

The R34 GTR motor, originally produced between 1999 and 2002, has evolved from being a high-performance engine in a niche market to a highly sought-after collector’s item. Initially designed for racing and performance enthusiasts, the RB26DETT engine has become a symbol of Japanese automotive engineering excellence. Over the years, the aftermarket industry has flourished, providing an array of performance upgrades, including turbo kits, stroker kits, and enhanced engine management systems.

As the market for classic JDM vehicles grows, the R34 GTR’s legacy continues to attract international buyers, leading to increased investment in restoration projects and aftermarket enhancements. This evolution reflects not only the enduring appeal of the R34 GTR motor but also the broader trend of enthusiasts seeking to revive and preserve iconic vehicles from the past.

Frequently Asked Questions (FAQs) for B2B Buyers of r34 gtr motor for sale

-

How do I ensure the quality of an R34 GTR motor before purchase?

To ensure quality, request detailed documentation from the supplier, including engine history, mileage, and previous service records. It’s beneficial to ask for certifications or warranties, which can offer additional assurance. If possible, arrange for an inspection by a trusted mechanic or third-party service to evaluate the engine’s condition. Additionally, consider suppliers who provide a return policy or guarantee, as this can mitigate risks associated with purchasing used motors. -

What is the best way to identify reliable suppliers for R34 GTR motors?

Start by researching suppliers through industry forums, trade shows, and B2B platforms. Look for suppliers with positive reviews and a history of successful transactions. Verify their business credentials and ask for references from previous clients. Engage in direct communication to assess their responsiveness and willingness to provide detailed information about their products. Checking for compliance with international trade regulations can also indicate reliability. -

What customization options are available for R34 GTR motors?

Customization options typically include enhancements like performance tuning, upgraded turbochargers, and changes to internal components such as pistons and camshafts. Suppliers may offer different engine packages tailored for specific applications, such as racing or street use. Discuss your performance goals with the supplier to determine the best options. Always confirm that any modifications comply with local regulations and standards in your country. -

What are the typical minimum order quantities (MOQ) for R34 GTR motors?

Minimum order quantities can vary significantly between suppliers, ranging from single units to larger bulk orders. Many suppliers are willing to accommodate smaller orders, especially if you are a new customer. However, purchasing in bulk can often lead to discounted pricing. It’s advisable to clarify MOQ terms during initial discussions and consider negotiating if you are looking for fewer units. -

What payment terms should I expect when buying R34 GTR motors internationally?

Payment terms can vary, but common practices include advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit upfront, particularly for custom orders. Always ensure you have a clear agreement on payment methods, including currency and any additional fees. It’s also wise to discuss payment security measures to protect against fraud, especially when dealing with international transactions. -

How can I manage logistics when importing an R34 GTR motor?

Managing logistics involves coordinating shipping, customs clearance, and delivery to your location. Work with suppliers who have experience in international shipping to streamline the process. They can provide shipping options and handle documentation required for customs. Ensure you understand your country’s import regulations, including duties and taxes, to avoid unexpected costs. Consider partnering with a freight forwarder for efficient logistics management. -

What warranties or guarantees should I look for with an R34 GTR motor purchase?

Look for suppliers who offer warranties that cover parts and labor for a specified period after purchase. A good warranty should also cover defects in materials and workmanship. Understand the terms of the warranty, including what is excluded and the process for claiming it. Suppliers with a solid reputation often provide robust warranty options, reflecting their confidence in the quality of their products. -

What should I do if the R34 GTR motor I receive does not match the description?

Immediately contact the supplier to report the discrepancy, providing detailed evidence such as photographs and written descriptions. Most reputable suppliers will have a return or exchange policy in place. Familiarize yourself with the terms and conditions regarding returns before making a purchase. If the supplier is unresponsive or unwilling to resolve the issue, consider escalating the matter through trade associations or legal channels, depending on the severity of the situation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 R34 Gtr Motor For Sale Manufacturers & Suppliers List

1. Nissan – GT-R Engines

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: This company, Nissan – GT-R Engines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Original Auto Performance – Engine Packages

Domain: originalautoperformance.com

Registered: 2013 (12 years)

Introduction: Engine Packages:

1. **OEM Replacement Package** – $5,000.00

– All stock internals with fresh bearings

– Tomei metal gaskets

– N1 oil pump

– ARP head studs

– Stock cylinder head with new seals and valve lapping

2. **700R Package** – $10,000.00

– Includes all Cometic gaskets

– Forged internals

– Oil upgrades

– Supertech springs & retainers

– Drop…

3. Lajdm – Turbo Engines for Sale

Domain: lajdm.com

Registered: 2014 (11 years)

Introduction: [{‘stock_number’: ‘161’, ‘model’: ‘RB25DET’, ‘type’: ‘Turbo Engine’, ‘price’: ‘4,299 USD’, ‘mileage’: ‘35,000-55,000 Miles’}, {‘stock_number’: ‘670’, ‘model’: ‘RB25DET Turbo Neo’, ‘type’: ‘2.5L AWD Engine’, ‘year_range’: ‘1998-2002’, ‘price’: ‘3,699 USD’, ‘mileage’: ‘35,000-55,000 Miles’}, {‘stock_number’: ‘521’, ‘model’: ‘RB25DE NEO’, ‘type’: ‘Complete Motor’, ‘price’: ‘1,799 USD’, ‘year_range’: …

4. Nissan – R34 GT-R Engine

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: New R34 GT-R engine available for purchase from Nissan. Price: $50,000. Engine specifications: 450 horsepower. Additional options include a 400 horsepower engine for $39,000 and a 500 horsepower engine for $61,000.

5. HKS – RB26 2.8L Complete Engine

Domain: gt-rr.com

Registered: 2007 (18 years)

Introduction: HKS RB26 2.8L Complete Engine w/ V-CAM for R34 Nissan Skyline GT-R

Price: $61,500.00

SKU: 23011-AN022

Brand: HKS

Engine Specifications:

– Displacement: 2771cc (HKS 2.8L), Stock: 2568cc

– Bore: 87.0mm (HKS 2.8L), Stock: 86.0mm

– Stroke: 77.7mm (HKS 2.8L), Stock: 73.7mm

– Max RPM: 9000 RPM (HKS 2.8L), Stock: 7600 RPM

Key Features:

– Lightweight & high rigidity piston, con rod, and crankshaft

– V-CA…

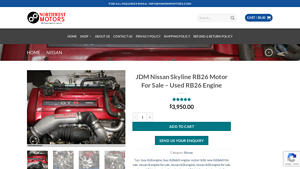

6. Nissan – JDM Skyline RB26 Engine

Domain: nwjdmmotors.com

Registered: 2022 (3 years)

Introduction: {“name”: “JDM Nissan Skyline RB26 Motor”, “type”: “Used RB26 Engine”, “price”: “$3,950.00”, “customer_rating”: “4.95 out of 5 based on 55 customer ratings”, “mileage”: “41,396 Miles”, “engine_specs”: {“manufacturer”: “Yokohama Plant”, “initial_production”: “1989 – 2002”, “cylinder_block_alloy”: “Cast-iron”, “configuration”: “Straight-6”, “valvetrain”: “DOHC 4 valves per cylinder”, “piston_stroke_m…

7. DouraDo Cars – Nissan Skyline GTR R34

Domain: douradocars.com

Registered: 2021 (4 years)

Introduction: Nissan Skyline GTR R34 Motor: A Legend in the Racing World. Known for its iconic design, powerful performance, and technological innovations. Powered by the RB26DETT engine, a 2.6-liter twin-turbocharged inline-six engine, producing 276 horsepower in stock form, capable of exceeding 500 horsepower with modifications. Features include dual overhead camshafts, independent throttle body system for pr…

8. HKS – Step 3 V-CAM RB26DETT Complete Engine

Domain: bulletproofautomotive.com

Registered: 2000 (25 years)

Introduction: {“name”: “HKS Step 3 V-CAM RB26DETT 2.8L Complete Engine for R34 Nissan Skyline GT-R”, “price”: “$69,000.00”, “sku”: “23011-AN019”, “category”: “Engines”, “vehicle”: “Nissan Skyline GT-R”, “brand”: “HKS”, “description”: “The HKS COMPLETE ENGINE POWERED BY HKS is a modern marvel of technology, showcasing HKS’s four-decade-long refinement in creating reliable, high-performance racing engines. This e…

Strategic Sourcing Conclusion and Outlook for r34 gtr motor for sale

As the demand for the R34 GTR motor continues to surge across global markets, strategic sourcing becomes pivotal for B2B buyers aiming to secure high-quality engines and components. Key takeaways include the importance of identifying reputable suppliers who offer verified performance and warranty options, ensuring that your investment is both sound and reliable. With prices for complete engines ranging significantly—from approximately $25,000 to over $74,000—buyers should evaluate their specific needs and budget constraints while considering the long-term benefits of high-performance engines.

Moreover, understanding the nuances of international shipping, import regulations, and local market conditions is essential for seamless transactions. Engaging with suppliers who provide comprehensive support, including installation and maintenance, can enhance value and performance outcomes.

Looking ahead, the market for R34 GTR motors presents immense opportunities for international buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Now is the time to leverage these insights and establish partnerships that will drive your business success. Explore your options, connect with trusted suppliers, and position your company at the forefront of this dynamic automotive segment.