Tgm Air Conditioner: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for tgm air conditioner

In today’s competitive landscape, sourcing reliable TGM air conditioners presents a significant challenge for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With varied climatic conditions and energy efficiency standards, making informed choices on HVAC equipment is crucial for ensuring customer satisfaction and operational efficiency. This comprehensive guide aims to illuminate the complexities of the TGM air conditioning market, equipping buyers with the knowledge they need to navigate product offerings, applications, and supplier vetting processes.

Throughout this guide, we will explore the diverse range of TGM air conditioning solutions available, from mini-split systems to high-efficiency units tailored for specific environments. We will also delve into the critical aspects of cost considerations, warranty coverage, and post-purchase support, helping you understand the total cost of ownership. By providing actionable insights and expert advice, this guide empowers B2B buyers to make informed purchasing decisions that align with their organizational needs and budget constraints.

Whether you’re a contractor in Brazil seeking dependable units for a new project or a distributor in Nigeria looking to expand your product line, this guide serves as your roadmap to successfully navigating the global market for TGM air conditioners. Equip yourself with the knowledge to enhance your procurement strategy and ensure your HVAC solutions meet the highest standards of quality and performance.

Understanding tgm air conditioner Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Speed Mini-Split Series | On/Off operation, R-410A refrigerant, available in 60 Hz & 50 Hz | Residential and small commercial spaces | Pros: Best value, easy installation. Cons: Limited energy efficiency compared to inverter systems. |

| DOE-Approved Window Unit | Meets 2015 DOE standards, R-410A refrigerant, healthy filters | Small offices and residential units | Pros: Affordable, good for small spaces. Cons: Less efficient for larger areas. |

| Inverter Technology Four Way Cassette | Up to 14 SEER efficiency, 360° air outlet design, built-in water pump | Medium to large commercial spaces | Pros: Energy-efficient, excellent air distribution. Cons: Higher upfront cost. |

| Quantum Inverter Series | Wi-Fi compatible, gold-fin coating, improved maintenance design | Commercial and high-end residential | Pros: High efficiency, corrosion resistance. Cons: Requires professional installation. |

| Luxury Inverter System | 16+ SEER efficiency, R-410A refrigerant, rotary compressor option | Luxury residential and commercial | Pros: High performance, modern design. Cons: Premium price point. |

What are the Key Characteristics of the Fixed Speed Mini-Split Series?

The Fixed Speed Mini-Split Series is designed for efficient cooling in residential and small commercial environments. Utilizing R-410A refrigerant, these units operate on a straightforward on/off system, making them easy to install and maintain. They are available in both 60 Hz and 50 Hz options, catering to various international electrical standards. While they provide excellent value, buyers should consider their lower energy efficiency compared to inverter models, which may lead to higher operational costs over time.

How Does the DOE-Approved Window Unit Serve Small Applications?

The DOE-Approved Window Unit is tailored for small offices and residential spaces, meeting stringent 2015 Department of Energy standards. It features R-410A refrigerant and a combination of healthy filters to ensure clean air circulation. This unit is cost-effective and simple to install, making it a popular choice among budget-conscious buyers. However, its cooling capacity may be inadequate for larger areas, which could necessitate multiple units or alternative solutions.

What Makes the Inverter Technology Four Way Cassette Ideal for Commercial Use?

The Inverter Technology Four Way Cassette is engineered for medium to large commercial spaces, offering up to 14 SEER efficiency. Its unique 360° air outlet design ensures even air distribution throughout the area, enhancing comfort for occupants. Additionally, the built-in water pump simplifies drainage, making it suitable for various installation scenarios. While it presents a higher upfront cost, the energy savings and improved comfort level can justify the investment for businesses seeking long-term efficiency.

Why Choose the Quantum Inverter Series for High-End Applications?

The Quantum Inverter Series stands out with its Wi-Fi compatibility and gold-fin coating, which enhances corrosion resistance and heat transfer. This series is ideal for commercial and high-end residential applications, where efficiency and aesthetics are paramount. The improved design facilitates easier maintenance, making it a practical choice for busy environments. However, potential buyers should be prepared for professional installation, which may add to the overall project cost.

What are the Benefits of the Luxury Inverter System for Premium Installations?

The Luxury Inverter System is designed for high-performance applications in luxury residential and commercial settings. With a SEER rating of 16+, it delivers superior energy efficiency while utilizing R-410A refrigerant. The option for rotary or twin-rotary compressors allows for flexibility in installation. While the system offers modern aesthetics and advanced performance, its premium pricing may require justification through energy savings and enhanced comfort for high-end buyers.

Key Industrial Applications of tgm air conditioner

| Industry/Sector | Specific Application of tgm air conditioner | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Climate control in hotels and resorts | Enhanced guest comfort leading to improved satisfaction | Energy efficiency ratings and service support availability |

| Food & Beverage | Temperature regulation in storage and processing facilities | Preservation of perishable goods, reducing waste | Compliance with local health regulations and efficiency |

| Healthcare | Air conditioning in hospitals and clinics | Maintaining sterile environments and patient comfort | Reliability and low maintenance requirements |

| Retail | In-store climate control for customer comfort | Increased foot traffic and sales due to a pleasant environment | Flexibility in installation and energy consumption |

| Manufacturing | Cooling in production areas and warehouses | Improved worker productivity and equipment longevity | Durability and capacity to handle operational heat loads |

How Are TGM Air Conditioners Used in the Hospitality Sector?

In the hospitality industry, TGM air conditioners are essential for maintaining comfortable environments in hotels and resorts. These units provide efficient climate control, ensuring that guests enjoy a pleasant stay, which is crucial for positive reviews and repeat business. International buyers, particularly in regions like Africa and South America, should consider energy efficiency ratings and the availability of local service support to mitigate downtime during peak seasons.

What Role Do TGM Air Conditioners Play in the Food & Beverage Industry?

In food and beverage applications, TGM air conditioners are used for temperature regulation in storage and processing facilities. These systems help preserve perishable goods, significantly reducing waste and ensuring compliance with health regulations. Buyers must prioritize units that meet local standards and consider the energy efficiency of the systems to optimize operational costs, especially in regions with high energy prices.

Why Are TGM Air Conditioners Critical in Healthcare Facilities?

TGM air conditioners are vital in healthcare settings, such as hospitals and clinics, where maintaining a sterile environment is paramount. These units not only provide cooling but also help filter and purify the air, contributing to patient comfort and safety. For international buyers, it is crucial to ensure the reliability of these systems and their ability to operate efficiently under varying loads, which can be influenced by local climate conditions.

How Do TGM Air Conditioners Enhance Retail Environments?

In retail, TGM air conditioners improve in-store climate control, creating a comfortable shopping experience that can drive foot traffic and increase sales. The ability to customize settings for different areas of a store is a significant advantage. Retailers should focus on sourcing units that offer flexibility in installation and low energy consumption to maximize profitability, particularly in competitive markets across Europe and the Middle East.

What Benefits Do TGM Air Conditioners Provide in Manufacturing?

In manufacturing, TGM air conditioners are utilized to cool production areas and warehouses, thus improving worker productivity and extending the lifespan of equipment. These systems are designed to handle high operational heat loads effectively. Buyers in this sector should look for durable models that can withstand industrial environments and ensure consistent performance, particularly in regions with high ambient temperatures, such as Nigeria and Brazil.

3 Common User Pain Points for ‘tgm air conditioner’ & Their Solutions

Scenario 1: High Operational Costs Due to Inefficient Cooling Systems

The Problem: Many businesses in regions with extreme climates face the challenge of high operational costs associated with inefficient air conditioning systems. B2B buyers may struggle with outdated units that consume excessive energy, resulting in soaring electricity bills. This is particularly relevant in areas like Africa and South America, where cooling demands are significant, and energy costs can heavily impact the bottom line. The lack of energy-efficient solutions can also hinder competitive pricing for businesses relying on climate control.

The Solution: TGM Air Conditioning offers a range of energy-efficient models, such as their Inverter Technology series, which provides superior cooling while consuming less energy. B2B buyers should prioritize selecting systems with high SEER (Seasonal Energy Efficiency Ratio) ratings. For instance, units like the Dream Inverter 19 Series boast impressive efficiency ratings of up to 19 SEER, which translates to substantial energy savings over time. It is advisable to conduct a thorough energy audit to identify specific cooling requirements and select an appropriately sized unit. Additionally, consider integrating smart controls and maintenance schedules to ensure optimal performance and longevity of the air conditioning systems.

Scenario 2: Unreliable Supply Chain and Parts Availability

The Problem: International buyers often face difficulties with supply chain reliability, particularly when it comes to sourcing spare parts and maintenance supplies for air conditioning units. Delays in receiving components can lead to prolonged downtimes, impacting business operations. This is especially critical in markets like the Middle East, where maintaining a comfortable environment is essential for customer satisfaction and operational efficiency.

The Solution: TGM Air Conditioning has established distribution hubs in key locations, including South Florida, the Dominican Republic, and Puerto Rico, ensuring quicker access to parts and service support. B2B buyers should leverage TGM’s vast network to establish reliable procurement channels for spare parts and maintenance services. It is also beneficial to create partnerships with local distributors who can facilitate quick deliveries and provide on-the-ground support. Regular communication with TGM’s customer service and technical support can also preemptively address potential supply chain issues, allowing for timely resolutions and minimizing operational disruptions.

Scenario 3: Complex Installation and Maintenance Requirements

The Problem: Many B2B buyers encounter challenges related to the installation and maintenance of air conditioning systems, particularly when dealing with complex setups like multi-split or cassette systems. Inadequate installation can lead to performance issues, increased wear and tear, and potential safety hazards. Buyers in Europe and emerging markets may find that their local contractors lack the expertise needed to install modern HVAC systems effectively.

The Solution: TGM provides comprehensive installation guides and technical support to ensure proper setup and maintenance of their units. B2B buyers should invest time in training local technicians or collaborating with TGM-certified professionals for installation. Prior to installation, conduct a site assessment to determine the best configuration for the space, which can help prevent common issues such as inadequate airflow or refrigerant leaks. Furthermore, establishing a routine maintenance schedule is crucial; TGM’s trained technicians can assist with preventative measures that extend the lifespan of the units and maintain optimal performance. Regularly scheduled maintenance can identify issues before they escalate, thus safeguarding the investment and ensuring that the systems operate at peak efficiency.

Strategic Material Selection Guide for tgm air conditioner

What Are the Common Materials Used in TGM Air Conditioners?

In the manufacturing of TGM air conditioners, the selection of materials is crucial for ensuring product performance, durability, and compliance with international standards. Here, we analyze four common materials used in TGM air conditioners, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Copper Contribute to TGM Air Conditioners’ Efficiency?

Copper is widely used in TGM air conditioners, particularly for refrigerant lines and heat exchangers. It boasts excellent thermal conductivity, allowing for efficient heat transfer, which is essential for optimal cooling performance. Copper also exhibits good corrosion resistance, particularly when coated, making it suitable for various environments.

Pros:

– High thermal conductivity enhances energy efficiency.

– Corrosion resistance extends the lifespan of components.

Cons:

– Higher cost compared to alternatives like aluminum.

– Requires skilled labor for installation due to its malleability.

Impact on Application: Copper is compatible with a wide range of refrigerants, making it versatile for different air conditioning systems.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local regulations regarding copper usage, as well as consider the availability of skilled labor for installation.

Why is Aluminum a Preferred Material for TGM Air Conditioners?

Aluminum is another common material in TGM air conditioners, especially for the outer casing and some internal components. Its lightweight nature and resistance to corrosion make it an attractive option for manufacturers.

Pros:

– Lightweight, which reduces shipping costs and installation complexity.

– Excellent corrosion resistance, particularly in humid environments.

Cons:

– Lower thermal conductivity compared to copper, which may affect efficiency.

– Can be more susceptible to physical damage.

Impact on Application: Aluminum is suitable for outdoor units exposed to various weather conditions, ensuring durability.

Considerations for International Buyers: Compliance with local standards for aluminum quality, such as ASTM or DIN, is essential, particularly in regions with high humidity or saline environments.

How Does Steel Enhance the Structural Integrity of TGM Air Conditioners?

Steel is often used in the structural components of TGM air conditioners, such as frames and supports. Its high tensile strength provides durability and stability, essential for heavy-duty applications.

Pros:

– Exceptional strength and durability, enhancing structural integrity.

– Cost-effective compared to other metals.

Cons:

– Heavier, which can increase shipping costs.

– Prone to corrosion unless properly coated.

Impact on Application: Steel is ideal for supporting heavy components and can withstand significant operational stresses.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings to prevent rust, especially in coastal areas or regions with high moisture levels.

What Role Does Plastic Play in TGM Air Conditioners?

Plastics, particularly high-density polyethylene (HDPE) and polypropylene, are used in various non-structural components, such as fan blades and housing. Their lightweight and moldable nature allows for innovative designs.

Pros:

– Lightweight and easy to mold into complex shapes.

– Resistant to corrosion and chemicals.

Cons:

– Lower thermal conductivity compared to metals.

– Can degrade under UV exposure if not treated.

Impact on Application: Plastics are suitable for components that do not require high thermal conductivity but need to withstand environmental exposure.

Considerations for International Buyers: Buyers should check for UV resistance ratings and compliance with local environmental regulations regarding plastic materials.

Summary Table of Material Selection for TGM Air Conditioners

| Material | Typical Use Case for TGM Air Conditioner | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Refrigerant lines, heat exchangers | High thermal conductivity | Higher cost, requires skilled labor | High |

| Aluminum | Outer casing, internal components | Lightweight, excellent corrosion resistance | Lower thermal conductivity, susceptible to damage | Medium |

| Steel | Structural components | Exceptional strength and durability | Heavier, prone to corrosion | Medium |

| Plastic | Fan blades, housing | Lightweight, resistant to corrosion | Lower thermal conductivity, UV degradation | Low |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in TGM air conditioners, enabling informed decision-making based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for tgm air conditioner

What Are the Key Stages in the Manufacturing Process of TGM Air Conditioners?

The manufacturing process of TGM air conditioners is designed to ensure high quality and efficiency while incorporating the latest technological advancements. The process can be broken down into several key stages:

Material Preparation

The first stage involves sourcing high-quality raw materials that meet international standards. TGM prioritizes the procurement of components such as R-410A refrigerant, high-density filters, and advanced electrical components. These materials are rigorously tested for compliance with specifications and environmental standards before they enter the manufacturing line.

Forming

During the forming stage, raw materials are shaped into the necessary components of the air conditioning units. Techniques such as stamping, molding, and cutting are employed to create parts like the casing, evaporator coils, and fan components. Automation plays a significant role in this phase, enhancing precision and reducing manufacturing time.

Assembly

The assembly stage is where the individual components come together to form a complete air conditioning unit. Skilled technicians, guided by automated systems, ensure that every part fits correctly and operates efficiently. This stage often includes the integration of advanced technologies, such as inverter systems for enhanced energy efficiency and smart control features, which align with TGM’s commitment to modern product offerings.

Finishing

In the finishing stage, the assembled units undergo a series of treatments to ensure durability and aesthetic appeal. This includes painting, coating (such as gold-fin for corrosion resistance), and final inspections. Quality checks are integrated at various points during this stage to ensure that the finished product meets TGM’s high standards.

How Does TGM Ensure Quality Assurance in Its Manufacturing Processes?

Quality assurance is a critical aspect of TGM’s manufacturing philosophy. The company adheres to several international standards and implements a robust quality control system to maintain its reputation for reliability.

What International Standards Does TGM Comply With?

TGM Air Conditioning is committed to adhering to international quality standards, including:

- ISO 9001: This standard focuses on quality management systems and ensures that TGM consistently meets customer and regulatory requirements.

- CE Marking: Indicates that the products meet European health, safety, and environmental protection standards.

- AHRI Certification: Validates the performance of HVAC systems, ensuring they meet specified efficiency ratings.

These certifications not only enhance TGM’s credibility but also facilitate easier market entry for B2B buyers in diverse regions.

What Are the Key Quality Control Checkpoints?

Quality control at TGM is structured around several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet quality specifications before being used in production.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process, with technicians checking for defects or deviations from standards at various stages.

- Final Quality Control (FQC): Finished products undergo thorough testing for functionality, safety, and compliance with performance standards before they are packaged for distribution.

What Testing Methods Are Utilized to Ensure Product Quality?

TGM employs a range of testing methods to ensure that its air conditioning units operate efficiently and reliably:

- Performance Testing: Units are tested under various operational conditions to verify cooling capacity, energy efficiency, and noise levels.

- Durability Testing: Products are subjected to stress tests to evaluate their longevity and performance under extreme conditions.

- Safety Testing: Electrical components undergo rigorous testing to ensure they meet safety standards and reduce the risk of hazards.

How Can B2B Buyers Verify TGM’s Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are some ways to do this:

- Audits: Buyers can request to conduct audits of TGM’s manufacturing facilities to assess compliance with quality standards and practices.

- Quality Reports: TGM can provide documentation detailing quality control measures, testing results, and certifications, allowing buyers to evaluate the effectiveness of these processes.

- Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of the manufacturing and quality assurance processes.

What Are the Specific Quality Control Considerations for International Buyers?

International buyers, especially those from Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances:

- Compliance with Local Regulations: Ensure that the products meet local regulations and standards in the buyer’s country, which may differ from TGM’s country of origin.

- Adaptability to Environmental Conditions: TGM products should be assessed for their suitability in the specific climatic conditions of the buyer’s region, such as high humidity or extreme temperatures.

- Warranty and Support Services: Buyers should inquire about warranty coverage and the availability of technical support, especially in the event of product issues post-purchase.

Conclusion: Why Quality Assurance Matters in B2B Air Conditioning Purchases

In conclusion, TGM Air Conditioning’s commitment to high-quality manufacturing and rigorous quality assurance processes is designed to meet the demands of B2B buyers across various international markets. By understanding the manufacturing stages, quality control measures, and verification processes, buyers can make informed decisions and ensure they are investing in reliable, high-performance air conditioning solutions that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tgm air conditioner’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring TGM air conditioners, ensuring a streamlined and efficient purchasing process. By following this step-by-step checklist, you can make informed decisions that align with your operational needs and budgetary constraints, ultimately leading to greater satisfaction with your investment.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it is essential to clearly outline your technical requirements. Identify the type of air conditioning system needed (e.g., mini-split, window unit, or central system) and the specific capacity (BTUs) based on your space requirements.

– Consider factors such as energy efficiency ratings (SEER), refrigerant type (e.g., R-410A), and any unique features like smart technology or noise levels.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers that specialize in TGM air conditioning products. Utilize industry directories, trade shows, and online platforms to compile a list of reputable distributors.

– Look for suppliers with established distribution hubs in regions relevant to your business, such as South Florida, the Dominican Republic, and Puerto Rico, which are key areas for TGM.

Step 3: Evaluate Supplier Certifications and Reputation

Before finalizing a supplier, verify their certifications and industry reputation. Ensure they comply with local and international standards for HVAC equipment, which can impact product quality and reliability.

– Request documentation of certifications (e.g., AHRI, ETL) and seek reviews or testimonials from other B2B clients to gauge their experience.

Step 4: Request Detailed Product Information

Once potential suppliers are shortlisted, request comprehensive product specifications for the TGM air conditioners. This should include technical datasheets, warranty information, and installation guidelines.

– Pay attention to the availability of replacement parts and the supplier’s support for troubleshooting, as this will be critical for long-term maintenance.

Step 5: Analyze Pricing and Terms of Sale

Carefully compare pricing structures among suppliers, taking into account not just the initial cost but also shipping, installation, and warranty coverage. TGM is known for aggressive pricing, so leverage this during negotiations.

– Inquire about bulk purchase discounts or financing options, especially if you are sourcing for a large project or multiple units.

Step 6: Assess After-Sales Support and Service

Evaluate the after-sales support offered by your potential suppliers. Reliable support is crucial for addressing any issues that may arise post-purchase, such as installation challenges or product malfunctions.

– Confirm that the supplier provides access to trained technicians and adequate warranty coverage, ensuring that you have a plan in place should any problems occur.

Step 7: Finalize the Purchase Agreement

After conducting due diligence on suppliers and products, proceed to finalize the purchase agreement. Ensure all terms are clearly outlined, including delivery timelines, payment terms, and conditions for warranty service.

– It is advisable to have legal counsel review the agreement to protect your interests and ensure compliance with local regulations.

By following these steps, you can confidently navigate the procurement of TGM air conditioners, ensuring that your investment meets your operational needs while providing long-term value.

Comprehensive Cost and Pricing Analysis for tgm air conditioner Sourcing

What are the Key Cost Components in Sourcing TGM Air Conditioners?

When sourcing TGM air conditioners, understanding the cost structure is essential for B2B buyers. The key components include:

-

Materials: The primary materials, such as R-410A refrigerant, copper tubing, and high-density filters, contribute significantly to the overall cost. Sourcing quality materials can influence both the performance and longevity of the units.

-

Labor: Labor costs encompass the wages of skilled workers involved in manufacturing, assembly, and quality control. As TGM maintains a commitment to high-quality service, labor expenses may be higher due to the skilled workforce required for rigorous testing and assembly.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, maintenance, and administrative expenses. A well-optimized manufacturing process can lead to lower overhead costs, which can be reflected in competitive pricing.

-

Tooling: The initial investment in tooling for production can be substantial, especially for custom or specialized units. This cost is often amortized over the production volume, influencing pricing strategies.

-

Quality Control (QC): TGM’s emphasis on low defect rates necessitates a robust QC process, which adds to overall costs. However, this investment ensures reliability and minimizes long-term maintenance issues.

-

Logistics: Shipping costs from distribution hubs in South Florida, the Dominican Republic, and Puerto Rico play a crucial role. These costs can vary based on the destination and volume, impacting the final pricing structure.

-

Margin: The profit margin applied by TGM is essential to consider. Competitive pricing strategies aim to balance affordability while ensuring profitability.

How Do Price Influencers Affect TGM Air Conditioner Costs?

Several factors influence the pricing of TGM air conditioners, particularly for international buyers:

-

Volume/MOQ: Higher order volumes often lead to reduced per-unit costs. Buyers should consider negotiating minimum order quantities (MOQs) to secure better pricing.

-

Specifications/Customization: Custom features or specifications can increase costs. Understanding the necessary features for your market can help balance cost and functionality.

-

Materials and Quality Certifications: Premium materials and certifications (like AHRI and ETL) may raise initial costs but can enhance the product’s appeal and longevity, ultimately offering better value.

-

Supplier Factors: The reputation and reliability of TGM as a supplier can influence pricing. Established suppliers with a track record of quality and service may justify higher costs.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers in shipping and logistics. Understanding these terms can help buyers avoid unexpected costs.

What Buyer Tips Can Help Ensure Cost-Efficiency?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips:

-

Negotiation: Always negotiate pricing, especially for bulk orders. Highlighting long-term partnership potential can lead to favorable terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes initial costs, maintenance, and operational expenses. Investing in higher-quality units may result in lower long-term costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and potential tariffs that can affect overall costs. It’s advisable to factor these into your budgeting.

-

Research Local Market Conditions: Understanding local competition and pricing strategies can provide leverage during negotiations.

-

Supplier Relationships: Building a strong relationship with TGM can lead to better pricing and service options, as well as insights into future product offerings.

Disclaimer on Indicative Prices

Prices for TGM air conditioners can vary significantly based on the factors discussed above. Buyers should conduct thorough market research and engage directly with TGM or authorized distributors to obtain accurate and current pricing tailored to their specific needs.

Alternatives Analysis: Comparing tgm air conditioner With Other Solutions

Understanding Alternatives in Air Conditioning Solutions

In the competitive landscape of air conditioning solutions, businesses often seek alternatives to ensure they make informed purchasing decisions that align with their operational needs. TGM Air Conditioning stands out with its robust features and competitive pricing, but several alternatives also warrant consideration. This analysis compares TGM Air Conditioner with two viable alternatives: Split-System Air Conditioners and Portable Air Conditioners. Each option has unique advantages and disadvantages that can influence a buyer’s decision.

| Comparison Aspect | TGM Air Conditioner | Split-System Air Conditioner | Portable Air Conditioner |

|---|---|---|---|

| Performance | High efficiency (up to 20 SEER), quiet operation | Variable efficiency (typically 14-24 SEER), quiet | Lower efficiency (typically 8-12 SEER) |

| Cost | Competitive pricing, long-term savings | Higher upfront costs, but energy-efficient | Lower upfront costs, higher operational costs |

| Ease of Implementation | Requires professional installation | Professional installation needed | Easy to set up, no installation required |

| Maintenance | Low defect rate, extensive warranty | Regular maintenance needed | Minimal maintenance, easy to clean |

| Best Use Case | Residential/commercial spaces needing permanent solutions | Large rooms or multiple rooms | Temporary cooling for small spaces or events |

What Are the Benefits and Drawbacks of Split-System Air Conditioners?

Split-system air conditioners are a common alternative to TGM units. They offer high efficiency, often rated between 14 to 24 SEER, making them suitable for larger residential or commercial spaces. Their quiet operation and ability to cool multiple rooms through a single outdoor unit enhance their appeal. However, the initial investment can be significant, and they require professional installation. Regular maintenance is also necessary to ensure optimal performance. For businesses with substantial cooling needs and a budget that can accommodate higher upfront costs, split systems may provide long-term energy savings.

How Do Portable Air Conditioners Compare?

Portable air conditioners present a flexible solution for businesses that require temporary cooling. They are easy to set up and do not require professional installation, making them ideal for short-term applications, such as events or temporary workspaces. However, their cooling capacity is generally lower, with SEER ratings ranging from 8 to 12, which can lead to higher operational costs over time. Additionally, while they are easy to maintain, they may not provide the same level of comfort as fixed installations like TGM units or split systems. For companies looking for immediate, short-term solutions without significant investment, portable air conditioners can be a practical choice.

How Can B2B Buyers Select the Right Air Conditioning Solution?

Choosing the right air conditioning solution involves assessing specific operational needs, budget constraints, and long-term goals. TGM Air Conditioning offers a balance of efficiency, reliability, and competitive pricing, making it an excellent choice for businesses seeking a permanent installation. However, for those with fluctuating needs or limited budgets, split-system and portable air conditioners may also provide viable alternatives. By carefully evaluating performance, cost, and maintenance requirements, B2B buyers can identify the solution that best aligns with their unique operational demands and ensure a comfortable environment for their workforce.

Essential Technical Properties and Trade Terminology for tgm air conditioner

What Are the Key Technical Properties of TGM Air Conditioners?

When evaluating TGM air conditioners, several technical properties are crucial for ensuring optimal performance and reliability. Understanding these specifications can aid B2B buyers in making informed purchasing decisions.

-

SEER Rating (Seasonal Energy Efficiency Ratio)

The SEER rating measures the cooling output divided by the total electric energy input during a typical cooling season. A higher SEER rating indicates better energy efficiency, which translates to lower operational costs. For instance, TGM models boast SEER ratings ranging from 14 to over 20, appealing to businesses looking to reduce energy expenses while meeting sustainability goals. -

BTU (British Thermal Unit) Capacity

BTU capacity indicates the cooling power of an air conditioning unit. TGM offers a range of capacities, from 9,000 to 60,000 BTUs, accommodating various commercial and residential applications. Selecting the appropriate BTU capacity ensures efficient cooling without overworking the system, thus extending its lifespan. -

Refrigerant Type

TGM air conditioners primarily use R-410A refrigerant, known for its efficiency and environmental friendliness compared to older refrigerants like R-22. Understanding refrigerant types is essential for compliance with environmental regulations and for maintaining system performance. -

Noise Level (dB)

Noise level is measured in decibels (dB) and is an important consideration for environments where quiet operation is desired, such as offices or hospitals. TGM air conditioners are designed for low noise operation, enhancing user comfort and satisfaction. -

Material Grade and Construction

The materials used in air conditioner manufacturing, such as high-density filters and corrosion-resistant coatings, affect durability and maintenance requirements. TGM emphasizes high-quality materials, which contribute to low defect rates and long-term reliability. -

Warranty and Support Services

TGM products come with extensive warranty coverage, reflecting the manufacturer’s confidence in their quality. Understanding warranty terms is vital for B2B buyers, as it impacts the total cost of ownership and provides peace of mind regarding potential repairs.

What Trade Terminology Should B2B Buyers Know for TGM Air Conditioners?

Familiarity with industry-specific jargon is essential for effective communication and negotiation in B2B transactions. Here are some key terms relevant to TGM air conditioners:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. When sourcing air conditioning units, understanding whether a product is OEM can impact pricing and reliability. -

MOQ (Minimum Order Quantity)

The MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ for TGM air conditioners helps buyers plan their inventory and ensure they meet order requirements for cost-effectiveness. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing information and terms for specific products. Buyers looking to procure TGM air conditioners should prepare detailed RFQs to ensure they receive accurate and competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping and delivery obligations. Familiarity with these terms helps buyers understand their liability and the costs involved in transporting TGM air conditioners across borders. -

HVAC (Heating, Ventilation, and Air Conditioning)

HVAC encompasses the technology of indoor environmental comfort, which includes air conditioning systems. Understanding HVAC systems is crucial for B2B buyers as it relates to installation, maintenance, and energy efficiency. -

Installation and Commissioning

This term refers to the process of setting up an air conditioning system and ensuring it operates correctly. Buyers should consider installation services and support when purchasing TGM units, as proper installation is vital for maximizing performance and longevity.

Understanding these technical properties and trade terminology equips B2B buyers with the knowledge necessary to make informed purchasing decisions regarding TGM air conditioners, ensuring they meet their operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the tgm air conditioner Sector

What Are the Key Market Drivers and Trends in the TGM Air Conditioner Sector?

The TGM air conditioner sector is witnessing significant shifts driven by global climate change, urbanization, and technological advancements. As temperatures rise, there is a heightened demand for efficient cooling solutions, particularly in regions like Africa, South America, and the Middle East, where extreme heat is prevalent. International B2B buyers are increasingly seeking air conditioning systems that not only provide comfort but also incorporate energy-efficient technologies, such as inverter technology and R-410A refrigerant, which are crucial for reducing operational costs and environmental impact.

Emerging trends also include the growing importance of smart technology integration. B2B buyers are looking for systems that offer Wi-Fi compatibility and smart diagnostics, enabling remote monitoring and control. This trend is particularly relevant in Europe and urban areas in South America, where tech-savvy consumers expect seamless integration with their smart home systems. Additionally, the shift toward modular and scalable solutions is becoming prominent, allowing businesses to adapt to fluctuating demands without incurring excessive costs.

Furthermore, as supply chains become increasingly global, international buyers must navigate complexities related to sourcing and logistics. TGM’s strategic distribution hubs in South Florida, the Dominican Republic, and Puerto Rico facilitate efficient shipping and support for clients across the Americas. This geographic advantage enables TGM to provide timely delivery and competitive pricing, making it an appealing choice for B2B buyers.

How Is Sustainability and Ethical Sourcing Influencing the TGM Air Conditioner Market?

Sustainability has become a cornerstone of modern B2B purchasing decisions, especially in the HVAC sector. TGM Air Conditioning is committed to minimizing its environmental footprint through responsible manufacturing processes and the use of eco-friendly refrigerants. The incorporation of R-410A refrigerant not only meets stringent environmental standards but also contributes to enhanced energy efficiency, aligning with global sustainability goals.

In addition, ethical sourcing is increasingly important for B2B buyers who want to ensure that their supply chains reflect their corporate social responsibility commitments. TGM emphasizes transparency in its supply chain, which is crucial for building trust with international partners. Buyers are encouraged to consider suppliers that demonstrate adherence to ethical labor practices and environmental stewardship.

Certification plays a vital role in this context. Products that carry green certifications not only signify compliance with environmental regulations but also appeal to consumers who prioritize sustainability. TGM’s focus on high-quality materials and innovative designs supports the creation of durable products that reduce waste and promote longevity, further enhancing its appeal in a competitive market.

How Has the TGM Air Conditioner Sector Evolved Over Time?

The evolution of the TGM air conditioner sector can be traced back to its commitment to innovation and quality. Initially focused on basic cooling solutions, TGM has transformed its product offerings to include advanced technologies such as inverter systems and smart controls. This evolution has been driven by a combination of market demand and technological advancements, allowing TGM to remain competitive in a rapidly changing landscape.

Moreover, the company has adapted to regional market needs, customizing its products to meet the specific requirements of diverse climates and consumer preferences. By maintaining rigorous testing standards and incorporating feedback from contractors and end-users, TGM has established itself as a leader in the HVAC industry, offering solutions that meet the highest quality benchmarks while ensuring customer satisfaction.

This historical perspective not only highlights TGM’s adaptability but also underscores the importance of continuous improvement in the B2B space, as companies strive to meet the evolving needs of their clients.

Frequently Asked Questions (FAQs) for B2B Buyers of tgm air conditioner

-

How do I solve issues with TGM air conditioners not cooling effectively?

To address cooling issues with TGM air conditioners, first check the thermostat settings to ensure it’s set lower than the room temperature. Inspect the air filters; dirty filters can restrict airflow and reduce cooling efficiency. Additionally, ensure that the outdoor unit is clear of debris and that the refrigerant levels are adequate. If problems persist, consult TGM’s customer support or a qualified technician for troubleshooting and potential repairs. Regular maintenance is key to avoiding these issues. -

What is the best TGM air conditioner model for commercial applications?

For commercial applications, the TGM Quantum Inverter Series is highly recommended due to its energy efficiency and robust performance. With SEER ratings of up to 23, it provides significant energy savings, which is crucial for large-scale operations. This series also features Wi-Fi compatibility for remote monitoring and control, ensuring optimal performance and convenience. Evaluate your specific cooling capacity needs to select the model that fits your space requirements. -

How can I customize TGM air conditioners for my specific needs?

TGM offers a range of customizable options for their air conditioning units, including different cooling capacities, installation types, and energy efficiency ratings. Buyers can discuss specific requirements with TGM’s sales team to explore options such as additional features like Wi-Fi connectivity or unique installation configurations. Customization may also involve selecting specific refrigerants or modifying certain operational settings to meet local regulations or business needs. -

What are the minimum order quantities (MOQ) for purchasing TGM air conditioners?

The minimum order quantities (MOQ) for TGM air conditioners vary depending on the model and the buyer’s location. Typically, larger orders may qualify for better pricing and terms. For precise MOQ details, it is best to contact TGM’s sales department or local distributors directly. They can provide tailored information based on your purchasing needs and regional distribution capabilities. -

What payment terms are available for B2B buyers purchasing TGM air conditioners?

TGM offers flexible payment terms for B2B buyers, which may include options such as net 30, net 60, or even advance payments based on the order size and buyer relationship. It is advisable to discuss your payment preferences during the negotiation process to reach an agreement that suits both parties. Credit checks may be required for larger orders to ensure financial reliability. -

How does TGM ensure quality assurance for their air conditioning products?

TGM implements rigorous quality assurance processes throughout the manufacturing and distribution stages. Each unit undergoes extensive testing to meet industry standards, ensuring low defect rates and high reliability. Additionally, TGM offers comprehensive warranty coverage, giving buyers peace of mind. In case of any field issues, trained technicians are available to assist with troubleshooting and product replacement, ensuring a seamless experience. -

What logistics support does TGM provide for international buyers?

TGM has established distribution hubs in strategic locations, including South Florida, the Dominican Republic, and Puerto Rico, facilitating efficient logistics for international buyers. They collaborate with reliable shipping partners to ensure timely delivery while handling customs documentation and other logistical challenges. Buyers can discuss their shipping needs with TGM to arrange optimal shipping solutions based on their location and order size. -

How can I vet TGM as a reliable supplier for air conditioning units?

To vet TGM as a reliable supplier, consider their industry reputation, years of experience, and customer reviews. Evaluate their product offerings and certifications, ensuring they comply with local regulations and standards. Additionally, engage with their customer service to gauge responsiveness and support. Seeking references from other B2B buyers who have worked with TGM can also provide valuable insights into their reliability and service quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 1 Tgm Air Conditioner Manufacturers & Suppliers List

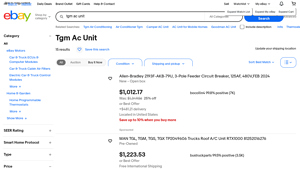

1. Leviton – TGM10-1LI Touch Dimmer Switch

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: TGM AC Unit products available on eBay include:

1. Leviton TGM10-1LI Ivory 3-Way Magnetic Low Volt Touch Dimmer Switches (1000W) – Brand New, priced at $75.99 with $15.39 delivery.

2. A/C Climate Control Unit Module for MAN TGS TGX TGL TGM Truck (Part Number: 81619906078 F8) – Brand New, priced at $292.62 with $100.00 delivery.

3. Remote Control for TGM RG51B/E MWPOT12SA MWPOT12S MWPOT18S MWPOT24S…

Strategic Sourcing Conclusion and Outlook for tgm air conditioner

In the competitive landscape of HVAC solutions, TGM Air Conditioning stands out as a leader in quality, innovation, and customer satisfaction. With a commitment to rigorous testing and modern design, TGM ensures that its products not only meet but exceed industry standards. The strategic sourcing of TGM air conditioners offers international buyers the advantage of aggressive pricing, extensive warranty coverage, and top-tier support from trained technicians, making it a reliable choice for businesses across diverse markets.

For B2B buyers in Africa, South America, the Middle East, and Europe, the value of strategic sourcing extends beyond mere cost savings; it encompasses long-term partnerships with a company dedicated to quality and innovation. TGM’s extensive distribution network ensures prompt delivery and service, further enhancing the purchasing experience.

As you consider your air conditioning needs, look towards TGM Air Conditioning for a future where cutting-edge technology and exceptional service converge. Embrace the opportunity to elevate your business operations and customer satisfaction by integrating TGM’s advanced solutions into your projects. Connect with TGM today to explore how their offerings can meet your specific requirements and contribute to your success in the global marketplace.