A Deep Dive into Odm Shackles Solution

Introduction: Navigating the Global Market for odm shackles

In today’s competitive landscape, sourcing high-quality ODM shackles poses significant challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With a myriad of suppliers and varying quality standards, ensuring safety, durability, and compliance with industry regulations can be daunting. This guide aims to simplify your purchasing journey by offering comprehensive insights into the diverse types of ODM shackles available, their applications across various industries, and essential factors for supplier vetting.

Navigating through the complexities of the global market for ODM shackles requires an understanding of product specifications, material grades, and the significance of certifications. Buyers will benefit from detailed discussions on cost considerations, helping to align budgetary constraints with quality expectations. Additionally, the guide will highlight best practices for evaluating suppliers, empowering you to make informed decisions that prioritize both safety and reliability.

As international B2B buyers from countries such as Nigeria and Vietnam engage with this guide, they will uncover actionable strategies to optimize their sourcing processes. By leveraging the knowledge shared within, you can confidently select ODM shackles that meet your operational needs while ensuring compliance with local and international standards. This resource is designed to equip you with the tools necessary to navigate the complexities of the global market effectively.

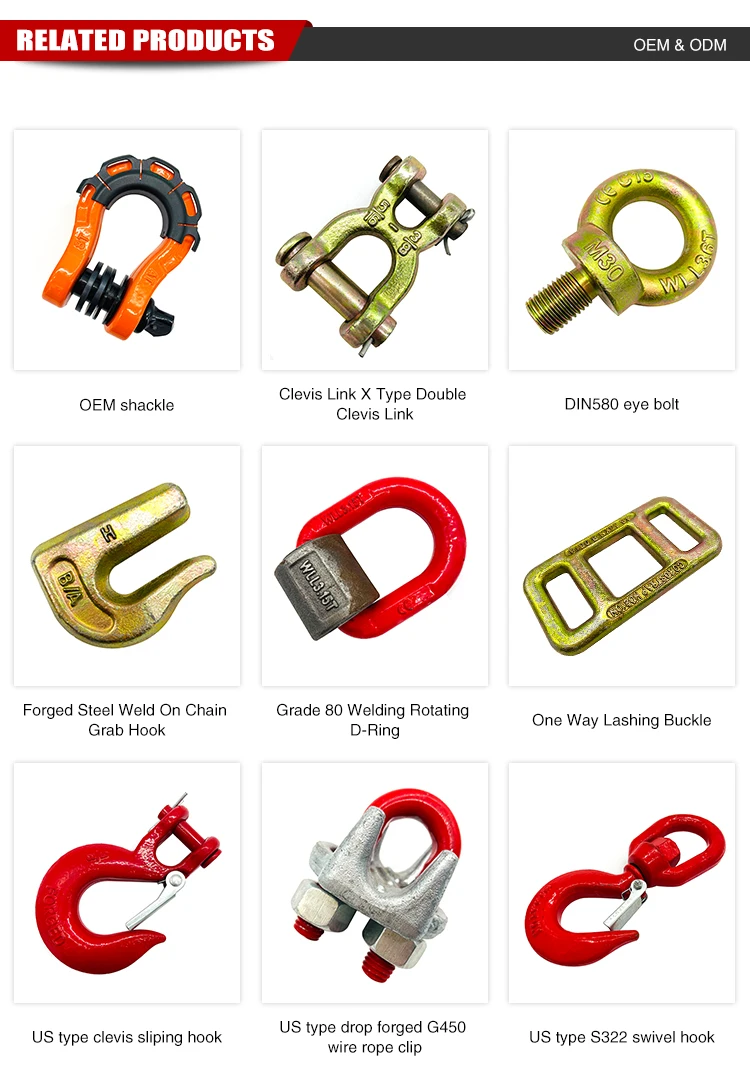

Understanding odm shackles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bow Shackle | Larger bow for easier connections; certified design | Marine mooring, rigging, and lifting | Pros: High load capacity, versatile; Cons: May require specific sizing for applications. |

| Dee Shackle | Straight design with a narrow profile | Construction, transportation, and lifting | Pros: Compact, easy to handle; Cons: Limited load capacity compared to bow shackles. |

| Dogbone Shackle | Unique shape designed for heavy-duty applications | Rigging, lifting, and industrial uses | Pros: High strength, resistant to wear; Cons: Heavier, may not suit all applications. |

| Greasable Shackle | Allows lubrication for maintenance | Automotive, heavy machinery, and off-road | Pros: Extends lifespan, easy maintenance; Cons: Slightly more expensive due to additional features. |

| Chain Shackle | Designed to connect chain links securely | Marine, construction, and rigging | Pros: Strong connection, durable; Cons: Requires precise matching with chain specifications. |

What are the characteristics of Bow Shackles and their B2B suitability?

Bow shackles, often referred to as omega shackles, feature a larger bow that allows for easier connections and load distribution. They are primarily used in marine applications, such as mooring and lifting, due to their high load capacity and versatility. When considering bow shackles for purchase, buyers should evaluate the required load ratings, material certifications, and compatibility with existing equipment to ensure safety and efficiency in operations.

How do Dee Shackles differ in design and application?

Dee shackles are characterized by their straight design and narrow profile, making them compact and easy to handle. They are commonly employed in construction and transportation, where space constraints are a consideration. While they are lightweight and convenient, buyers must be cautious about their load capacity, which is generally lower than that of bow shackles. It’s essential to match the shackle size and strength with the specific application requirements.

What makes Dogbone Shackles ideal for heavy-duty applications?

Dogbone shackles are designed with a unique shape that provides exceptional strength and durability, making them suitable for heavy-duty applications in rigging and lifting. They are often made from high-strength materials that resist wear and tear, ensuring long-term reliability. When purchasing dogbone shackles, B2B buyers should consider the specific load requirements, material properties, and the potential need for corrosion-resistant options, particularly in maritime environments.

Why should businesses consider Greasable Shackles?

Greasable shackles are designed for easy maintenance, allowing for lubrication without removal, which can significantly extend the lifespan of the component. This feature is particularly beneficial in automotive and heavy machinery applications, where performance and longevity are critical. Buyers should weigh the initial cost against the long-term savings from reduced maintenance and replacement needs when considering greasable shackles for their operations.

In what scenarios are Chain Shackles most effectively utilized?

Chain shackles are specifically designed to connect chain links securely, making them indispensable in marine, construction, and rigging applications. Their strength and durability are essential for ensuring secure connections under heavy loads. Buyers must ensure that the selected shackles match the specifications of the chain being used, including size and material, to maintain safety and performance standards in their operations.

Key Industrial Applications of odm shackles

| Industry/Sector | Specific Application of odm shackles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine and Shipping | Mooring operations for vessels | Ensures safe and secure mooring, preventing accidents | Certification standards, material durability, corrosion resistance |

| Construction | Rigging and lifting heavy materials | Enhances safety and efficiency in lifting operations | Load capacity, compliance with safety regulations, material quality |

| Oil and Gas | Connecting pipelines and heavy equipment | Facilitates safe transport and installation of equipment | Compatibility with harsh environments, material strength, certification |

| Renewable Energy | Wind turbine installation and maintenance | Supports heavy lifting and assembly, ensuring operational efficiency | Adaptability to varying loads, resistance to environmental factors |

| Automotive | Suspension systems in off-road vehicles | Improves durability and ride quality in rugged conditions | Quality of materials, ease of maintenance, compatibility with existing systems |

How are odm shackles utilized in the marine and shipping industry?

In the marine and shipping sector, odm shackles are essential for mooring operations where vessels are secured to docks or buoys. They are used to connect mooring lines and chains, providing a reliable means of securing large ships against wind and wave forces. The primary concern for international buyers, especially in regions like Africa and South America, is ensuring the shackles meet stringent certification standards to guarantee safety and compliance. Buyers must prioritize materials that resist corrosion and wear, given the harsh marine environments.

What role do odm shackles play in construction projects?

In construction, odm shackles are pivotal in rigging and lifting operations. They connect various lifting devices like chains and slings to heavy loads, ensuring safe transportation of materials. The value lies in their ability to enhance operational safety and efficiency, reducing the risk of accidents on-site. Buyers should focus on shackles that comply with local safety regulations and possess the necessary load capacities. Additionally, the quality of the materials used is crucial to withstand the rigors of construction environments.

How are odm shackles applied in the oil and gas industry?

In the oil and gas industry, odm shackles facilitate the connection of pipelines and heavy equipment during installation and maintenance. They ensure safe transport and secure connections in challenging environments, where reliability is paramount. International buyers must consider the shackles’ compatibility with harsh conditions, such as extreme temperatures and corrosive substances. Sourcing shackles made from high-strength materials that meet industry certifications is essential for ensuring operational safety and efficiency.

Why are odm shackles important in renewable energy projects?

Odm shackles are vital in renewable energy projects, particularly during the installation and maintenance of wind turbines. They are used to lift and secure heavy components, promoting operational efficiency and safety. Buyers in this sector should focus on shackles that can adapt to varying loads and environmental conditions, as wind energy installations often face unique challenges. Ensuring that the shackles are made from durable materials that withstand exposure to wind and moisture is critical for long-term performance.

How do odm shackles enhance automotive applications?

In the automotive sector, particularly for off-road vehicles, odm shackles are used in suspension systems to connect leaf springs. They facilitate smooth operation and enhance durability under heavy loads, improving ride quality in rugged terrains. Buyers should look for shackles that are easy to maintain and made from high-quality materials that can withstand the stresses of off-road conditions. The ability to provide greaseable options can also extend the life of the shackles, making them a smart investment for automotive manufacturers and suppliers.

3 Common User Pain Points for ‘odm shackles’ & Their Solutions

Scenario 1: Ensuring Load Safety and Compliance

The Problem: B2B buyers often face the challenge of ensuring that the shackles they purchase meet industry standards and safety regulations. This is especially critical in sectors such as construction, shipping, and oil and gas, where the failure of a shackle can lead to catastrophic accidents. Buyers may struggle with understanding the varying quality standards across different manufacturers, which can result in the procurement of subpar products that do not meet the necessary load-bearing requirements.

The Solution: To mitigate this issue, buyers should prioritize sourcing ODM shackles from manufacturers who provide certification and compliance documentation. Look for suppliers that adhere to recognized international standards, such as ISO 9001 for quality management systems. When evaluating potential vendors, request samples and ask for detailed specifications, including the material grade, load ratings, and testing certifications. Additionally, consider establishing long-term partnerships with suppliers who are transparent about their quality assurance processes. This proactive approach not only ensures safety but also fosters trust and reliability in the supply chain.

Scenario 2: Navigating Material Selection for Diverse Applications

The Problem: Another common pain point for B2B buyers is selecting the appropriate material for ODM shackles that will be used in specific applications. Different environments—such as marine, industrial, or construction settings—present unique challenges such as corrosion, heavy loads, and temperature extremes. Buyers may find it overwhelming to determine the right type of steel or finish required, leading to potential failures and operational delays.

The Solution: Buyers should conduct a thorough assessment of the environmental conditions where the shackles will be used. For instance, marine applications require stainless steel or galvanized shackles to resist corrosion, while heavy-duty industrial applications might necessitate high-strength alloy steels. Collaborate with engineering teams to define the load requirements and environmental factors. Furthermore, engage with suppliers who offer customization options, allowing for tailored solutions that meet specific material and design needs. Utilizing a checklist of application requirements can streamline this selection process, ensuring that buyers choose shackles that are not only fit for purpose but also enhance operational efficiency.

Scenario 3: Managing Inventory and Supply Chain Challenges

The Problem: B2B buyers frequently encounter issues related to inventory management and supply chain disruptions, particularly when dealing with ODM shackles. Fluctuations in demand, delays in shipping, and unexpected production issues can lead to shortages or excess inventory, impacting project timelines and budget constraints. This unpredictability can create stress for procurement teams trying to maintain a balance between availability and cost-effectiveness.

The Solution: Implementing a robust inventory management system is essential for addressing these challenges. Buyers should consider adopting just-in-time (JIT) inventory practices to minimize excess stock while ensuring that necessary supplies are readily available when needed. Establishing a close relationship with reliable suppliers can facilitate better communication about lead times and stock levels, allowing for more accurate forecasting. Additionally, diversifying the supplier base can provide backup options in case of disruptions, enabling buyers to maintain continuity in their operations. Regularly reviewing inventory turnover and adjusting procurement strategies based on project schedules will further enhance supply chain resilience and efficiency.

Strategic Material Selection Guide for odm shackles

What Are the Key Properties of Common Materials Used in ODM Shackles?

When selecting materials for ODM shackles, it is essential to consider properties that directly influence product performance, such as strength, durability, and resistance to environmental factors. Below, we analyze four common materials used in the manufacturing of ODM shackles.

1. Carbon Steel

Key Properties: Carbon steel is known for its high tensile strength and toughness, making it suitable for heavy-duty applications. It typically has a temperature rating up to 300°C and can withstand moderate pressure.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and ease of manufacturing. However, it is susceptible to corrosion if not properly coated or treated, which can limit its lifespan in harsh environments.

Impact on Application: Carbon steel shackles are often used in construction and marine applications where strength is paramount. However, exposure to moisture or corrosive agents can lead to premature failure.

Considerations for International Buyers: Compliance with standards such as ASTM A36 is crucial. Buyers from regions like Africa and South America should ensure that carbon steel shackles are coated or galvanized to enhance corrosion resistance.

2. Stainless Steel

Key Properties: Stainless steel offers excellent corrosion resistance, making it ideal for marine and chemical applications. It can withstand temperatures up to 600°C and is less affected by environmental factors.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to rust. However, it is more expensive than carbon steel and can be more complex to manufacture due to its hardness.

Impact on Application: Stainless steel shackles are commonly used in offshore and chemical industries where exposure to corrosive materials is a concern. They maintain structural integrity over time, even in challenging environments.

Considerations for International Buyers: Buyers should look for certifications such as ASTM A240 for stainless steel. In regions like the Middle East, where humidity levels are high, stainless steel is often preferred for its longevity.

3. Alloy Steel

Key Properties: Alloy steel combines carbon steel with other elements like chromium, molybdenum, or nickel to enhance its properties. It offers improved strength and toughness, with temperature ratings often exceeding 400°C.

Pros & Cons: The main advantage of alloy steel is its superior strength-to-weight ratio, making it suitable for high-load applications. However, it is generally more expensive and requires specialized manufacturing processes.

Impact on Application: Alloy steel shackles are ideal for heavy lifting and rigging applications, particularly in industries such as mining and construction. Their enhanced properties make them suitable for extreme conditions.

Considerations for International Buyers: Compliance with international standards such as ASTM A514 is essential. Buyers in Europe and South America may prioritize alloy steel for its performance in demanding environments.

4. Aluminum

Key Properties: Aluminum is lightweight and resistant to corrosion, with a temperature rating up to 200°C. It is not as strong as steel but offers a favorable strength-to-weight ratio.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, making it easy to handle and transport. However, it is less durable under heavy loads compared to steel options.

Impact on Application: Aluminum shackles are often used in applications where weight savings are critical, such as in the aerospace and automotive industries. They are also suitable for marine applications due to their corrosion resistance.

Considerations for International Buyers: Buyers should ensure that aluminum shackles meet standards like ASTM B221. In regions such as Africa and Vietnam, where weight considerations are crucial, aluminum may be favored despite its lower load capacity.

Summary Table of Material Selection for ODM Shackles

| Material | Typical Use Case for odm shackles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Construction, marine applications | Cost-effective and strong | Susceptible to corrosion | Low |

| Stainless Steel | Offshore, chemical industries | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Alloy Steel | Heavy lifting, mining | Superior strength-to-weight ratio | More expensive and complex to manufacture | Med |

| Aluminum | Aerospace, automotive, marine | Lightweight and corrosion-resistant | Lower load capacity compared to steel | Med |

This analysis provides valuable insights for international B2B buyers, helping them make informed decisions about material selection for ODM shackles based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for odm shackles

What are the Key Manufacturing Processes for ODM Shackles?

The manufacturing of ODM (Original Design Manufacturer) shackles involves a series of meticulously controlled processes designed to ensure high-quality performance and safety. Understanding these processes is crucial for international B2B buyers, particularly those sourcing from diverse markets like Africa, South America, the Middle East, and Europe.

What are the Main Stages in the Manufacturing Process of ODM Shackles?

-

Material Preparation

The foundation of a durable shackle begins with selecting the right materials. Common materials include high-strength steel grades such as 45# steel, 35CrMo, and 40Cr. These materials are chosen for their superior strength, toughness, and resistance to wear. The preparation phase involves cutting the raw materials to precise dimensions and conducting initial inspections to verify their quality. -

Forming

This stage involves shaping the prepared materials into the desired shackle form. Techniques such as forging and casting are prevalent, where the metal is heated and shaped under high pressure. Forging is particularly favored for its ability to enhance the material’s grain structure, thereby improving strength and durability. For ODM shackles, forming must meet stringent tolerances to ensure compatibility with other rigging components. -

Assembly

After forming, various components of the shackle are assembled. This may include integrating pins, locks, and other hardware. In some cases, additional features such as greasable pins may be included to enhance maintenance and longevity. This stage is critical, as proper assembly directly impacts the operational safety of the shackle. -

Finishing

The finishing stage involves surface treatments that protect the shackle from corrosion and wear. Techniques such as galvanizing, powder coating, or applying zinc plating are commonly used. These coatings not only enhance the aesthetic appeal but also significantly extend the life of the shackles, making them suitable for harsh marine and industrial environments.

How is Quality Assurance Implemented in ODM Shackle Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that ODM shackles meet international standards and customer specifications. For B2B buyers, understanding the QA processes can aid in selecting reliable suppliers.

What International Standards Should B2B Buyers Consider?

-

ISO 9001 Certification

This globally recognized standard focuses on quality management systems. Manufacturers with ISO 9001 certification demonstrate a commitment to consistent quality, customer satisfaction, and continuous improvement. Buyers should seek suppliers who are certified to ensure adherence to these quality principles. -

Industry-Specific Certifications

Depending on the application, additional certifications such as CE marking for European markets or API standards for the oil and gas industry may be relevant. These certifications indicate that the products meet specific safety and quality requirements pertinent to their respective industries.

What are the Key Quality Control Checkpoints?

-

Incoming Quality Control (IQC)

This initial inspection stage assesses the quality of raw materials before they enter the production process. It includes verifying material certifications and conducting tests to ensure compliance with specified standards. -

In-Process Quality Control (IPQC)

Throughout the manufacturing stages, IPQC involves regular inspections and tests to monitor the production process. This includes checking dimensions, tolerances, and assembly integrity. It helps identify defects early, preventing costly rework. -

Final Quality Control (FQC)

After manufacturing, FQC ensures that the finished shackles meet all specifications and standards. This stage may involve comprehensive testing, including load testing, to verify strength and durability. Documentation of these tests is crucial for traceability.

How Can B2B Buyers Verify Supplier Quality Control?

Ensuring quality control in the supply chain is vital for B2B buyers. Here are practical steps to verify supplier capabilities:

-

Conduct Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Audits should cover facility conditions, compliance with quality standards, and the effectiveness of their QA systems. -

Request Quality Reports

Suppliers should be able to provide detailed quality reports, including results from IQC, IPQC, and FQC. Reviewing these documents can help buyers assess the reliability of the supplier’s quality management practices. -

Engage Third-Party Inspectors

Utilizing independent third-party inspectors can provide an objective assessment of the supplier’s quality control processes. These inspectors can perform checks at various stages of production, providing additional assurance of quality.

What Nuances Should International B2B Buyers Be Aware of?

When sourcing ODM shackles from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should consider several nuances:

-

Cultural and Regulatory Differences

Different regions may have varying regulatory requirements and cultural approaches to quality assurance. Buyers should familiarize themselves with local standards and practices to ensure compliance. -

Logistics and Supply Chain Management

International shipping can introduce risks related to product integrity and delivery timelines. Establishing clear communication channels with suppliers and understanding the logistics involved can mitigate these risks. -

Building Long-Term Relationships

Developing strong relationships with suppliers can enhance collaboration on quality assurance. Regular communication and partnership can lead to continuous improvement in product quality and service.

By comprehensively understanding the manufacturing processes and quality assurance measures for ODM shackles, B2B buyers can make informed decisions, ensuring they procure reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘odm shackles’

To assist international B2B buyers in successfully sourcing ODM shackles, this practical guide outlines essential steps to ensure a smooth procurement process. By following this checklist, you can make informed decisions that align with your operational needs and compliance standards.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the ODM shackles you need. This includes load capacity, material specifications (such as stainless steel or alloy), and any specific design features necessary for your applications. A well-defined specification helps to communicate your needs effectively to potential suppliers and ensures that the products meet safety and performance standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in ODM shackles. Look for manufacturers with a proven track record in your industry and region. Utilize online directories, trade shows, and industry forums to gather a list of candidates. Prioritize suppliers who have positive reviews and strong references from other B2B clients.

Step 3: Evaluate Supplier Certifications

✅ Verify Supplier Certifications

Before finalizing any agreements, ensure that the suppliers have relevant certifications, such as ISO 9001 for quality management and CE marking for compliance with European safety standards. Certifications indicate that the supplier adheres to industry best practices and regulatory requirements, which is crucial for maintaining product safety and reliability.

Step 4: Request Samples for Testing

Ask shortlisted suppliers to provide samples of their ODM shackles for testing. This step is critical as it allows you to assess the quality, durability, and performance of the shackles in real-world conditions. Evaluate the samples against your defined specifications and perform load tests if necessary to confirm their suitability for your applications.

Step 5: Understand Pricing Structures

Discuss pricing structures with potential suppliers to understand the cost breakdown of the ODM shackles. Consider factors such as bulk order discounts, shipping costs, and payment terms. A comprehensive understanding of pricing will help you negotiate better deals and ensure that you stay within budget while obtaining high-quality products.

Step 6: Clarify Lead Times and Delivery Terms

✅ Clarify Lead Times and Delivery Terms

Establish clear timelines for production and delivery to ensure that your operations are not disrupted. Inquire about the supplier’s capacity to meet your deadlines and understand their logistics capabilities. This information is vital for planning and managing your inventory effectively.

Step 7: Review Contract Terms Carefully

Before signing a contract, review all terms and conditions thoroughly. Pay attention to warranty provisions, return policies, and liability clauses. A well-drafted contract protects your interests and ensures that you have recourse in case of product defects or non-compliance with agreed specifications.

By following these steps, you can enhance your sourcing strategy for ODM shackles, ensuring that you partner with reliable suppliers who can meet your operational needs efficiently.

Comprehensive Cost and Pricing Analysis for odm shackles Sourcing

What Are the Key Cost Components Involved in Sourcing ODM Shackles?

When sourcing ODM shackles, understanding the cost structure is crucial for effective budgeting and negotiation. The main cost components include:

-

Materials: The choice of material significantly influences costs. Common materials such as 45# steel, anchor chain steel, and stainless steel vary in price due to their strength, durability, and corrosion resistance. High-quality materials often lead to higher upfront costs but can reduce long-term maintenance expenses.

-

Labor: Labor costs are associated with the manufacturing process. Skilled labor is essential for producing high-quality shackles, especially when intricate designs or custom specifications are involved. Regions with lower labor costs may offer more competitive pricing, but this could impact quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help keep these costs down.

-

Tooling: Custom tooling for specific designs or large production runs can add to initial costs but is often amortized over large quantities. Buyers should consider the tooling costs when evaluating unit prices for smaller orders.

-

Quality Control (QC): Rigorous QC processes ensure that shackles meet safety and performance standards. Implementing robust QC protocols can increase costs but is essential for minimizing risks associated with product failures.

-

Logistics: Transportation and warehousing costs can vary significantly based on the origin of the shipment and destination. Incoterms, which dictate the responsibilities of buyers and sellers in shipping, can also influence total logistics costs.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market competition, brand reputation, and product quality.

How Do Price Influencers Affect ODM Shackle Costs?

Several factors influence the pricing of ODM shackles:

-

Volume/MOQ: Larger order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their demand forecasts to achieve cost efficiencies.

-

Specifications/Customization: Custom designs and specifications can increase costs. Buyers should clearly define their requirements to avoid unnecessary modifications that can inflate prices.

-

Materials: The choice of material not only affects durability but also the cost. Stainless steel shackles, for instance, will generally be more expensive than carbon steel options but offer better corrosion resistance.

-

Quality/Certifications: Shackles that meet international safety standards and certifications may carry a premium price tag. However, investing in certified products can reduce liability and enhance safety.

-

Supplier Factors: Supplier reputation, reliability, and service quality can influence pricing. Established suppliers may charge more due to their proven track record, while new entrants may offer competitive pricing to gain market share.

-

Incoterms: The chosen Incoterms can greatly impact the total landed cost of products. Buyers should understand their responsibilities regarding shipping costs, insurance, and duties to avoid unexpected expenses.

What Are Effective Buyer Tips for Sourcing ODM Shackles?

-

Negotiate Smartly: Leverage volume purchases to negotiate better pricing and payment terms. Establishing long-term relationships with suppliers can also lead to more favorable terms.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the purchase price. Assess potential long-term savings from higher quality or more durable shackles.

-

Be Aware of Pricing Nuances: International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be mindful of currency fluctuations, tariffs, and trade agreements that may affect pricing.

-

Request Detailed Quotations: Ensure suppliers provide comprehensive quotes that break down costs. This transparency will help identify areas for negotiation or cost reduction.

-

Conduct Market Research: Understanding market trends and competitor pricing can provide leverage in negotiations. Stay informed about industry standards and innovations that may impact pricing.

Disclaimer

Prices for ODM shackles can vary widely based on numerous factors, including market conditions, supplier capabilities, and specific buyer requirements. It is recommended to conduct thorough market research and obtain multiple quotations to gain a realistic understanding of the pricing landscape.

Alternatives Analysis: Comparing odm shackles With Other Solutions

Understanding the Importance of Alternative Solutions in the Marine Industry

In the marine and industrial sectors, selecting the right fastening solutions is critical for operational safety and efficiency. While ODM shackles are renowned for their strength and reliability, it is essential to consider alternative solutions that may offer distinct advantages based on specific requirements. This analysis compares ODM shackles against other viable options to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Odm Shackles | Alternative 1: Dogbone Shackles | Alternative 2: Greasable Shackles |

|---|---|---|---|

| Performance | High strength, versatile usage | Strong, ideal for rigging | Enhanced durability with lubrication |

| Cost | Moderate pricing | Generally lower cost | Higher initial investment |

| Ease of Implementation | Simple to install | User-friendly, no special tools | Requires maintenance for lubrication |

| Maintenance | Low maintenance | Low maintenance | Requires periodic lubrication |

| Best Use Case | Marine applications, heavy lifting | Industrial rigging and lifting | Off-road vehicles, suspension systems |

In-Depth Analysis of Alternatives

1. Dogbone Shackles

Dogbone shackles are essential components in various industrial applications, particularly in rigging and lifting operations. They are made from high-strength materials like 45# steel and offer excellent resistance to wear and tear. Their design facilitates easy connection between equipment, making them user-friendly. However, while they tend to be more cost-effective than ODM shackles, they may lack the versatility and strength required for extreme marine conditions. Therefore, they are best suited for general industrial uses rather than specialized marine applications.

2. Greasable Shackles

Greasable shackles, such as those offered by Old Man Emu, provide a unique advantage through their lubrication feature. This design enhances the longevity of the shackles by ensuring minimal friction and wear between the pins and bushings. While these shackles are typically more expensive upfront, the reduced maintenance frequency can lead to lower total costs over time. They are particularly beneficial in off-road vehicle applications where load-bearing and durability are critical. The requirement for periodic lubrication can be seen as a downside, but the improved performance under heavy loads often justifies this maintenance.

Making the Right Choice for Your Needs

When choosing between ODM shackles and alternative solutions, B2B buyers should carefully evaluate their specific operational requirements. Factors such as the type of application, environmental conditions, and budget constraints play a crucial role in the decision-making process. For marine applications demanding high strength and reliability, ODM shackles may be the best fit. In contrast, for general industrial rigging tasks, dogbone shackles offer a cost-effective solution. Lastly, for applications that involve significant wear and tear, greasable shackles might provide the best long-term investment despite their higher initial cost. By analyzing these factors, businesses can select the optimal fastening solution to enhance safety and efficiency in their operations.

Essential Technical Properties and Trade Terminology for odm shackles

What Are the Critical Technical Properties of ODM Shackles?

When sourcing ODM shackles, understanding their technical properties is essential for ensuring that they meet the specific demands of your application. Here are some of the most important specifications to consider:

-

Material Grade

The material used in the production of shackles significantly influences their strength and durability. Common materials include carbon steel, stainless steel, and alloy steel. For example, carbon steel is often used for heavy-duty applications due to its high tensile strength, while stainless steel is preferred for environments that require corrosion resistance. Selecting the right material grade ensures that the shackle can withstand the operational stresses and environmental conditions it will face. -

Working Load Limit (WLL)

The WLL indicates the maximum load that a shackle can safely handle during operation. This specification is crucial for preventing accidents and equipment failures. Buyers should ensure that the WLL of the shackles they choose exceeds the maximum anticipated loads in their applications, providing a safety margin that accounts for dynamic loads and potential shock loading. -

Safety Factor

The safety factor is a ratio that compares the shackle’s WLL to the maximum load it can sustain before failure. A higher safety factor indicates a more robust product, which is particularly important in critical lifting and rigging applications. Understanding the required safety factor for your specific use case can help in selecting the right shackle to prevent catastrophic failures. -

Tolerance

Tolerance refers to the permissible limit of variation in the dimensions of the shackles. Precise tolerances are vital in ensuring compatibility with other rigging equipment, such as hooks and chains. When shackles have tighter tolerances, they fit better and function more reliably, which is essential for maintaining safety and efficiency in operations. -

Finish and Coating

The finish or coating of a shackle can impact its resistance to corrosion and wear. Common finishes include hot-dip galvanizing, powder coating, and zinc plating. Selecting the appropriate finish based on the environmental conditions—such as exposure to saltwater or chemicals—can significantly extend the lifespan of the shackles. -

Size and Dimensions

The size of a shackle affects its application and compatibility with other rigging equipment. It is essential to choose shackles that fit the specific dimensions required for your operations. This includes understanding the inner width, height, and pin diameter, which can vary between different types of shackles.

Which Trade Terms Should Buyers Understand When Sourcing ODM Shackles?

Familiarizing yourself with industry jargon is key to navigating the procurement process effectively. Here are some common trade terms relevant to ODM shackles:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of shackles, an OEM may provide custom designs or modifications based on the buyer’s specifications, ensuring that the products meet unique operational requirements. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. Understanding the MOQ is crucial for budgeting and inventory management. Buyers must assess their needs against the MOQ to avoid excess inventory or insufficient supplies. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For buyers sourcing ODM shackles, issuing an RFQ can help compare offers from multiple suppliers, ensuring that they obtain competitive pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for determining who is responsible for shipping, insurance, and tariffs, thereby avoiding misunderstandings during the procurement process. -

Lead Time

Lead time refers to the time it takes from placing an order until it is delivered. Knowing the lead time helps buyers plan their projects and manage timelines effectively, ensuring that they have the necessary equipment when needed. -

Certification Standards

Certification standards, such as ISO or ASTM, signify that a product meets specific safety and quality benchmarks. Buyers should verify that the shackles they are considering are certified, as this can be crucial for compliance with safety regulations in their industry.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring that they select the most suitable ODM shackles for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the odm shackles Sector

What Are the Current Market Dynamics and Key Trends Affecting the ODM Shackles Sector?

The global ODM shackles market is experiencing notable growth driven by increased demand across various sectors, including marine, construction, and logistics. Key factors propelling this growth include the expansion of the shipping industry, rising infrastructure development, and the growing need for reliable lifting and rigging solutions. In regions like Africa and South America, infrastructure projects are significantly boosting demand, while in the Middle East and Europe, stringent safety regulations are compelling businesses to invest in high-quality shackles that meet compliance standards.

Emerging technologies are also reshaping sourcing trends in the ODM shackles sector. The integration of digital tools such as e-procurement platforms and supply chain management software is enhancing transparency and efficiency in sourcing processes. Additionally, manufacturers are leveraging automation and advanced materials to produce shackles that are not only stronger but also lighter, improving usability across various applications. International buyers, particularly from markets like Nigeria and Vietnam, are encouraged to adopt these technologies for streamlined operations and better supplier engagement.

How Is Sustainability and Ethical Sourcing Impacting the ODM Shackles Market?

Sustainability is becoming an essential consideration in the ODM shackles sector, with increasing pressure on manufacturers to minimize environmental impacts. This shift is largely driven by international buyers prioritizing ethical supply chains and sustainable practices. Organizations are now looking for suppliers that demonstrate a commitment to reducing carbon footprints and utilizing recyclable materials in their products.

Ethical sourcing is also gaining traction as companies face growing scrutiny from consumers and regulatory bodies. Buyers are advised to seek manufacturers that possess certifications such as ISO 14001 (Environmental Management) or those that use green materials, like recycled steel or eco-friendly coatings, in their products. By aligning sourcing strategies with sustainability goals, B2B buyers not only enhance their brand reputation but also contribute to a more sustainable future.

How Has the ODM Shackles Sector Evolved Over Time?

The ODM shackles sector has evolved significantly over the decades, transitioning from traditional manufacturing methods to advanced production techniques. Initially, shackles were primarily made from wrought iron and steel, focusing on basic functionality. However, with the advent of new materials and technologies, manufacturers have been able to produce shackles that offer superior strength, durability, and resistance to corrosion.

The rise of global trade and increased safety regulations has further influenced the evolution of this sector. Manufacturers now prioritize quality assurance and compliance with international standards, ensuring that their products can withstand the rigors of various industrial applications. As a result, today’s ODM shackles are not only robust and reliable but also designed to meet the specific needs of diverse markets, reflecting a more sophisticated approach to manufacturing and sourcing.

By understanding these market dynamics and trends, international buyers can make informed decisions when sourcing ODM shackles, ensuring they select products that meet their operational needs while aligning with sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of odm shackles

-

1. How do I choose the right ODM shackle for my application?

Selecting the appropriate ODM shackle involves assessing the specific requirements of your application, including load capacity, material, and environmental conditions. Consider whether you need a bow shackle for lifting or a dogbone shackle for rigging. Evaluate the materials available, such as steel or stainless steel, based on their strength, corrosion resistance, and durability. Additionally, ensure that the shackle meets international standards and certifications, as this will guarantee safety and reliability in operation. -

2. What is the minimum order quantity (MOQ) for ODM shackles?

The minimum order quantity for ODM shackles can vary significantly depending on the manufacturer and the type of shackle required. Generally, MOQs can range from a few dozen to several hundred units. It is advisable to discuss your specific needs with suppliers to negotiate suitable terms. Some manufacturers may offer flexible MOQs for first-time buyers or bulk orders, so it’s beneficial to inquire about discounts or lower limits when placing larger orders. -

3. What payment terms should I expect when sourcing ODM shackles?

Payment terms for ODM shackles typically depend on the supplier and the size of your order. Common options include a 30% deposit upfront with the remaining balance due before shipment, or payment in full prior to production. Some suppliers may also accept letters of credit or offer financing options for larger orders. Always clarify payment terms upfront to avoid misunderstandings and ensure a smooth transaction process. -

4. How can I ensure the quality of ODM shackles before purchasing?

To ensure the quality of ODM shackles, request certifications and test reports from suppliers that demonstrate compliance with international standards, such as ISO or ASTM. Consider visiting the manufacturing facility if possible or requesting samples for testing. Additionally, seek reviews and references from other buyers to gauge the supplier’s reputation. A robust quality assurance process should be in place, including inspections during and after production. -

5. What are the common materials used for ODM shackles, and how do they impact performance?

Common materials for ODM shackles include carbon steel, stainless steel, and alloy steel. Carbon steel offers high strength and is suitable for heavy-duty applications but may be prone to rust if not coated. Stainless steel is ideal for marine and corrosive environments due to its resistance to rust and corrosion. Alloy steel provides enhanced strength and toughness, making it suitable for high-load applications. Choosing the right material is crucial for ensuring safety and durability in your specific application. -

6. What logistics considerations should I keep in mind when importing ODM shackles?

When importing ODM shackles, consider shipping methods, lead times, and customs regulations in your country. Determine whether you will use air freight for faster delivery or sea freight for cost efficiency. Ensure that you understand the import duties and taxes applicable to your order and plan for potential delays in customs clearance. Collaborating with a reliable freight forwarder can help streamline the logistics process and provide guidance on documentation requirements. -

7. How do I vet suppliers for ODM shackles effectively?

To vet suppliers for ODM shackles, start by checking their certifications and industry experience. Look for suppliers with a strong track record of quality and reliability, ideally with experience in your specific industry. Request references and conduct online research to find reviews or testimonials from previous clients. Additionally, consider visiting the supplier’s facility or engaging in video calls to assess their operations and capabilities directly. -

8. What customization options are typically available for ODM shackles?

Customization options for ODM shackles may include specific sizes, load ratings, materials, and finishes tailored to your requirements. Some manufacturers also offer engraving or labeling for branding purposes. Discuss your needs with potential suppliers, as many are willing to accommodate unique specifications. Keep in mind that customization may affect lead times and costs, so it’s essential to clarify these factors during the negotiation process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 2 Odm Shackles Manufacturers & Suppliers List

1. Mantus Marine – Anchor Shackles

Domain: mantusmarine.com

Registered: 2016 (9 years)

Introduction: Product Name: Mantus Anchor Shackles

Material: 2205 Duplex Stainless Steel

Design: Forged, with a flush hex head for smooth passage through bow roller

Features:

– Hole in hex head for safety wiring the pin

– Compatible with Hi Test G4 Chain and other chain types

– Working Load Limit (WLL) and Ultimate Breaking Strength (UBS) provided for various sizes

Price Range: $8.00 – $64.00

Sizes Available: …

2. Yojiu – UL Type Shackle

Domain: yojiu.com

Registered: 2000 (25 years)

Introduction: UL Type Shackle is used for connecting insulator string of transformer substation to overhead transmission line or fixing stranded wire to pole. It is made of malleable iron or casting steel and hot-dip galvanized. Cotter pins are stainless steel, and the other parts are hot-dip galvanized steel.

Item No. | Dimension (mm) | Ultimate Strength (kn) | Weight (kg)

UL-7 | 20 x 16 x 16 | 120 | 0.65

…

Strategic Sourcing Conclusion and Outlook for odm shackles

In navigating the complex landscape of ODM shackles, international B2B buyers must prioritize strategic sourcing to ensure they secure high-quality products that meet their operational needs. Key takeaways from this guide highlight the importance of selecting manufacturers who adhere to strict quality standards and offer a range of materials suited for various applications. This not only enhances safety and reliability but also promotes long-term durability, especially in challenging environments like those found in Africa, South America, the Middle East, and Europe.

As the demand for robust marine hardware continues to grow, so too does the opportunity for businesses to leverage partnerships with reputable suppliers. By investing time in evaluating potential manufacturers and understanding the unique specifications of their products, buyers can significantly reduce risks associated with procurement.

Looking ahead, the focus should be on fostering strong relationships with suppliers who can provide not only custom solutions but also innovative products that adapt to evolving market needs. Engage actively with manufacturers, share your requirements, and explore how ODM shackles can enhance your operational efficiency. The future is promising for those who approach sourcing with strategic intent and collaboration.