Rb25 Motor For Sale: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for rb25 motor for sale

In today’s competitive automotive landscape, sourcing an RB25 motor for sale can pose significant challenges for international B2B buyers. The complexities of navigating diverse suppliers, varying engine specifications, and fluctuating prices across regions such as Africa, South America, the Middle East, and Europe can be daunting. This comprehensive guide aims to demystify the global market for RB25 motors by providing insights into different types of engines, their applications, and the essential criteria for vetting suppliers effectively.

By covering critical aspects such as engine performance metrics, condition assessments, and cost variations, this guide empowers buyers to make informed purchasing decisions. The focus on practical strategies ensures that businesses can identify reliable suppliers who not only meet their technical requirements but also align with their budgetary constraints. Furthermore, our guide highlights the importance of understanding local regulations and shipping logistics, ensuring a seamless acquisition process.

Whether you are looking to enhance your inventory or fulfill specific project needs, this guide serves as a valuable resource, equipping you with the knowledge necessary to navigate the complexities of the RB25 motor market with confidence and efficiency.

Understanding rb25 motor for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| RB25DET | Turbocharged, 2.5L inline-six engine, popular in JDM cars | Performance tuning, motorsport applications | Pros: High power potential; Cons: Requires aftermarket support for best performance. |

| RB25 NEO | Enhanced version with improved efficiency and power output | High-performance builds, racing applications | Pros: Better fuel efficiency; Cons: Higher initial cost than older models. |

| RB25DE | Naturally aspirated variant, 2.5L engine without turbo | Daily driving, general automotive repairs | Pros: Simpler installation; Cons: Lower power output compared to turbo variants. |

| RB25DET with 6-Speed Transmission | Comes with a 6-speed manual gearbox for enhanced performance | Racing teams, performance upgrades | Pros: Superior gear ratios; Cons: More complex installation and sourcing parts. |

| RB25 Engine Blocks | Engine blocks available in various conditions, from used to refurbished | Custom builds, engine swaps | Pros: Cost-effective; Cons: Varying quality and warranty issues. |

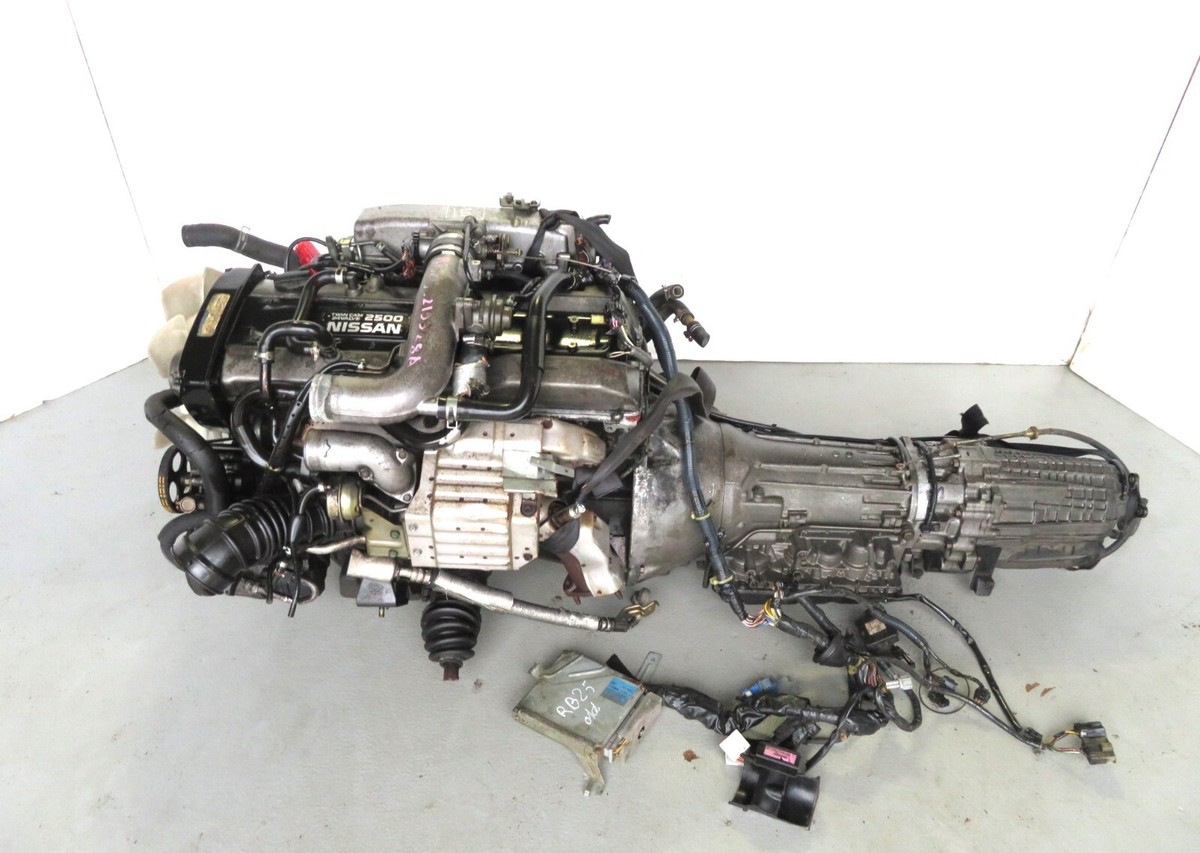

What Are the Characteristics of the RB25DET Motor?

The RB25DET is a turbocharged inline-six engine renowned for its performance capabilities, commonly found in JDM vehicles such as the Nissan Skyline. It typically offers a power output ranging from 250 to 300 horsepower, depending on modifications. This engine is ideal for B2B buyers looking to enhance performance in motorsport applications or custom builds. Key purchasing considerations include sourcing quality parts and ensuring compatibility with other vehicle components, as aftermarket modifications may be necessary for optimal performance.

How Does the RB25 NEO Differ from Other Variants?

The RB25 NEO is an upgraded iteration of the RB25DET, featuring enhancements that improve fuel efficiency and power output. With its advanced engineering, it is particularly suited for high-performance applications, making it a popular choice among racing enthusiasts. B2B buyers should consider the cost-to-benefit ratio when selecting this engine, as its higher price point may be justified by its superior performance and reliability. Additionally, buyers should ensure they have access to compatible parts and support for installation.

What Are the Benefits of the RB25DE Engine?

The RB25DE is a naturally aspirated version of the RB25 family, offering a simpler design and installation process. It is generally more accessible for daily driving and basic automotive repairs, making it an attractive option for businesses focused on reliability rather than high performance. However, its lower power output compared to turbocharged variants may limit its appeal for performance-oriented applications. B2B buyers should assess their specific needs and the engine’s intended use before making a purchase.

Why Consider an RB25DET with 6-Speed Transmission?

This variation of the RB25DET comes equipped with a 6-speed manual transmission, providing superior performance through better gear ratios. It is especially favored by racing teams and performance shops looking to maximize engine output. However, the complexity of installation and the need for additional parts can be a drawback for some buyers. For B2B buyers, it is essential to evaluate the total cost of ownership, including installation and potential maintenance needs.

What Should Buyers Know About RB25 Engine Blocks?

RB25 engine blocks are available in various conditions, from used to refurbished, making them a cost-effective option for custom builds and engine swaps. Buyers should be cautious about the quality and condition of these blocks, as they can vary significantly. It is advisable to verify the warranty and return policies before purchasing, ensuring that the investment aligns with their business needs. Understanding the specific requirements for engine rebuilding or modification will also aid in making informed purchasing decisions.

Key Industrial Applications of rb25 motor for sale

| Industry/Sector | Specific Application of rb25 motor for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Performance | High-performance racing and tuning | Enhanced power and speed for competitive advantage | Ensure compatibility with vehicle models and local regulations. |

| Automotive Repair & Restoration | Engine replacement and upgrades for classic cars | Cost-effective solution for restoring vintage vehicles | Verify engine condition and history; consider warranty options. |

| Motorsports | Drift and track racing vehicles | Increased reliability and performance under extreme conditions | Look for engines with proven performance records and support for modifications. |

| Export and Import Trade | Resale of used JDM engines in international markets | Access to a wider range of customers and markets | Assess shipping logistics, import regulations, and tariffs in target countries. |

| Custom Automotive Builds | Custom builds for specialty vehicles | Tailored solutions for niche markets | Evaluate customization options and sourcing of compatible parts. |

How is the RB25 Motor Used in Automotive Performance Applications?

In the automotive performance sector, the RB25 motor is favored for high-performance racing and tuning. This engine is known for its robust power output and reliability, making it ideal for competitive racing environments. Businesses engaged in motorsports benefit significantly from RB25 motors due to their ability to enhance vehicle performance, providing a competitive edge on the track. International buyers, especially from regions with a growing motorsport culture, should ensure that the engine they source is compatible with their vehicle specifications and adheres to local racing regulations.

What Role Does the RB25 Motor Play in Automotive Repair and Restoration?

For automotive repair and restoration businesses, the RB25 motor serves as an excellent engine replacement option, particularly for classic Nissan models. These engines provide a cost-effective solution for restoring vintage vehicles while maintaining their authenticity. Buyers in this sector should prioritize the condition and history of the engine being purchased, as well as inquire about warranty options to safeguard their investment. This is especially crucial for international buyers who may face additional challenges in sourcing parts for older models.

How is the RB25 Motor Integral to Motorsports?

In the motorsports industry, particularly in drifting and track racing, the RB25 motor is highly sought after for its performance capabilities. It offers increased reliability and power, essential for vehicles subjected to extreme driving conditions. Businesses involved in building or modifying racing vehicles can leverage the RB25 motor to create high-performance machines that meet the demands of competitive racing. Buyers should look for engines with proven performance records and consider sourcing from suppliers that provide support for necessary modifications.

What Opportunities Exist in Export and Import Trade for the RB25 Motor?

The RB25 motor also presents lucrative opportunities in the export and import trade, particularly for businesses that resell used JDM engines in international markets. This sector allows companies to tap into a broader customer base, especially in regions where JDM vehicles are popular. However, businesses must navigate various shipping logistics, import regulations, and tariffs that may affect the profitability of their transactions. Understanding the market dynamics in target countries is crucial for success in this application.

How Can the RB25 Motor Be Used in Custom Automotive Builds?

In the realm of custom automotive builds, the RB25 motor is an excellent choice for specialty vehicles. It allows builders to create tailored solutions that meet specific performance and aesthetic requirements. Companies focusing on custom builds must evaluate customization options and ensure that they can source compatible parts efficiently. This is particularly important for international buyers, who may face challenges in obtaining specific components or ensuring compliance with local automotive standards.

3 Common User Pain Points for ‘rb25 motor for sale’ & Their Solutions

Scenario 1: Navigating Quality Concerns in Used RB25 Motors

The Problem: B2B buyers often face significant anxiety when purchasing used RB25 motors, particularly regarding the quality and condition of the engine. Without a physical inspection, buyers from regions like Africa or South America may worry about receiving a motor that has hidden defects, leading to costly repairs or replacements. This concern is amplified when dealing with international shipping, as the motor may sustain damage during transit or may not match the described specifications.

The Solution: To mitigate these quality concerns, buyers should prioritize suppliers who offer detailed inspection reports and warranties. Engaging with vendors that provide compression tests and thorough diagnostics ensures that the RB25 motor meets performance standards. Additionally, buyers should request high-resolution images and videos of the engine prior to purchase. Establishing clear communication with the supplier regarding the engine’s history, including mileage and previous usage, can also provide reassurance. Finally, opting for suppliers that facilitate third-party inspections or offer return policies can significantly reduce risk and enhance buyer confidence.

Scenario 2: Overcoming Language and Communication Barriers

The Problem: International buyers often encounter language barriers that complicate the negotiation and purchasing process of RB25 motors. Misunderstandings can lead to errors in order fulfillment, incorrect specifications, and ultimately, dissatisfaction with the purchase. For buyers in regions like the Middle East or Europe, clear communication is essential for ensuring that they receive the correct engine with all necessary components.

The Solution: To navigate these communication challenges, buyers should utilize platforms that offer multilingual support and have staff fluent in their preferred language. When approaching suppliers, it is beneficial to use clear and concise language in written communication, supplemented by diagrams or pictures to clarify specifications. Additionally, employing professional translation services for contracts or technical documents can help ensure that both parties have a mutual understanding of terms and conditions. Establishing a local point of contact or a liaison who understands both the language and the product can facilitate smoother transactions and enhance overall satisfaction.

Scenario 3: Managing Logistics and Import Regulations

The Problem: Buyers looking to import RB25 motors often struggle with the complexities of logistics and compliance with import regulations. Each country has unique customs requirements, and mismanagement can lead to delays, additional costs, or even confiscation of goods. For businesses in South America or Africa, navigating these regulatory landscapes can be particularly challenging, especially if they lack experience in international shipping.

The Solution: To streamline the logistics process, buyers should engage with freight forwarders who specialize in automotive parts and have expertise in navigating import regulations for their specific countries. It is advisable to conduct thorough research on the legal requirements for importing used engines, including emission standards and safety regulations. Buyers should work closely with suppliers to ensure that all necessary documentation, such as customs declarations and shipping invoices, is accurate and complete. Additionally, utilizing tracking services can provide real-time updates on the shipment’s status, allowing buyers to prepare for customs clearance in advance. By proactively addressing these logistical concerns, buyers can significantly reduce the risk of delays and unexpected costs.

Strategic Material Selection Guide for rb25 motor for sale

What Are the Key Materials Used in rb25 Motors and Their Properties?

When considering the purchase of an RB25 motor, understanding the materials used in its construction is crucial for ensuring optimal performance, durability, and compatibility with various applications. Below, we analyze four common materials used in the RB25 motor assembly, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Aluminum: A Lightweight Choice for Engine Components

Aluminum is widely used in the construction of engine blocks and cylinder heads due to its excellent strength-to-weight ratio and thermal conductivity. It typically has a temperature rating of around 300°C (572°F) and offers good resistance to corrosion, especially when anodized.

Pros: The lightweight nature of aluminum contributes to better fuel efficiency and performance. It also facilitates easier handling during installation and maintenance.

Cons: While aluminum is durable, it can be prone to warping under extreme heat and pressure, which may lead to engine failure if not properly managed.

Impact on Application: Aluminum is compatible with various engine fluids, but care must be taken to avoid corrosive substances that can degrade its integrity over time.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that their suppliers adhere to international standards for aluminum alloys, such as ASTM B221, to guarantee quality.

Cast Iron: The Traditional Heavyweight

Cast iron is another common material used in RB25 motors, particularly for engine blocks. It is known for its excellent wear resistance and ability to withstand high temperatures and pressures, typically rated up to 500°C (932°F).

Pros: Cast iron offers superior durability and is less susceptible to wear and tear, making it ideal for high-performance applications.

Cons: The weight of cast iron can negatively impact fuel efficiency and performance. Additionally, it is more challenging to machine compared to aluminum.

Impact on Application: Cast iron is compatible with a wide range of engine oils and fuels, but its weight may necessitate additional structural support in vehicle design.

Considerations for International Buyers: Compliance with standards like DIN 1691 is essential for ensuring the quality and performance of cast iron components, especially for buyers in Europe.

Steel: Strength and Versatility

Steel is often used for various engine components such as crankshafts and connecting rods due to its high tensile strength and resistance to deformation. Steel components can handle pressures exceeding 1000 psi and temperatures up to 600°C (1112°F).

Pros: Steel’s strength makes it suitable for high-performance applications, and it is relatively cost-effective compared to other materials.

Cons: While steel is durable, it is heavier than aluminum, which can affect overall vehicle performance. Additionally, it is susceptible to corrosion if not properly treated.

Impact on Application: Steel is compatible with most engine oils and fuels, but its weight may require careful consideration in vehicle design.

Considerations for International Buyers: Buyers should ensure that steel components meet international standards such as JIS G3101 to ensure quality and performance, particularly in the Middle East and Asia.

Composites: The Future of Engine Materials

Composite materials, such as carbon fiber or fiberglass, are increasingly being used in high-performance engines for components like intake manifolds and body panels. These materials can withstand temperatures up to 300°C (572°F) and offer excellent corrosion resistance.

Pros: Composites are lightweight and can be engineered for specific performance characteristics, enhancing overall engine efficiency.

Cons: The manufacturing process for composites can be complex and costly, which may limit their use in budget-sensitive applications.

Impact on Application: Composites are generally compatible with most engine fluids but require careful handling to avoid damage.

Considerations for International Buyers: Compliance with international composite standards, such as ASTM D3039, is crucial for ensuring quality, especially for buyers in Europe and North America.

Summary Table of Material Selection for RB25 Motors

| Material | Typical Use Case for rb25 motor for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine blocks, cylinder heads | Lightweight and good thermal conductivity | Prone to warping under heat | Medium |

| Cast Iron | Engine blocks | Superior durability and wear resistance | Heavy and difficult to machine | Low |

| Steel | Crankshafts, connecting rods | High tensile strength | Heavier than aluminum, corrosion-prone | Medium |

| Composites | Intake manifolds, body panels | Lightweight and performance-tuned | Complex and costly to manufacture | High |

Understanding these materials and their properties will help international B2B buyers make informed decisions when sourcing RB25 motors, ensuring they select components that meet their performance and durability requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for rb25 motor for sale

What Are the Main Stages in the Manufacturing Process of the RB25 Motor?

The manufacturing process of the RB25 motor involves several critical stages that ensure the engine meets the performance and durability expectations of B2B buyers. The main stages include:

-

Material Preparation: This initial stage involves selecting high-quality raw materials, such as aluminum for engine blocks and steel for crankshafts. Suppliers typically source materials that comply with international standards to ensure structural integrity and performance.

-

Forming: During this phase, the prepared materials undergo various forming techniques, including casting and machining. The engine block is often produced through die-casting, which provides the necessary strength while allowing for complex geometries. Precision machining follows to achieve the required tolerances for components like cylinder heads and crankshafts.

-

Assembly: The assembly process involves integrating various components, including the intake and exhaust manifolds, turbochargers, and electrical systems. Automated assembly lines are commonly employed, ensuring consistent quality and reducing assembly time. Skilled technicians perform critical assembly tasks, ensuring that all components fit and function correctly.

-

Finishing: The finishing stage includes surface treatments, such as anodizing and painting, to enhance corrosion resistance and aesthetics. Additionally, engines undergo rigorous cleaning processes to remove any contaminants that could affect performance.

Which Key Techniques Are Used in Manufacturing the RB25 Motor?

Several key manufacturing techniques are employed to ensure the RB25 motor’s reliability and performance:

-

CNC Machining: This technology allows for high precision in machining engine components, ensuring that parts meet exact specifications and tolerances.

-

Heat Treatment: Critical components, such as the crankshaft, undergo heat treatment processes to enhance their hardness and fatigue resistance, ensuring long-term durability.

-

Quality Control During Manufacturing: Implementing in-process quality control (IPQC) measures at various stages minimizes defects. Regular inspections are conducted to verify that components meet predefined specifications before moving to the next stage.

What Are the Quality Assurance Standards for RB25 Motors?

Quality assurance is paramount in the manufacturing of RB25 motors, especially when catering to international B2B buyers. The following standards are typically adhered to:

-

ISO 9001: This international standard outlines the requirements for a quality management system (QMS). Manufacturers seeking ISO 9001 certification demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

-

CE Marking: For suppliers in Europe, obtaining CE marking is essential, indicating that the product complies with EU safety, health, and environmental protection standards.

-

API Standards: In some regions, adherence to API (American Petroleum Institute) standards can be crucial, particularly regarding engine performance and emissions.

What Are the Key Quality Control Checkpoints in RB25 Motor Manufacturing?

Quality control (QC) is a systematic process integrated throughout the manufacturing lifecycle. Key QC checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials and components received from suppliers. Materials that do not meet specified standards are rejected to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves regular inspections and tests to ensure that each stage meets the required standards. This can include dimensional checks and functional tests of components.

-

Final Quality Control (FQC): Once the assembly is complete, FQC is conducted to ensure the entire engine operates as intended. This includes running tests to assess performance metrics such as power output, emissions, and noise levels.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying supplier quality control is essential to ensure they receive reliable products. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality management systems, and adherence to international standards. This firsthand evaluation can uncover potential issues.

-

Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including IQC, IPQC, and FQC reports. These documents can help buyers understand the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. These inspections can be particularly beneficial for buyers from regions with stringent import regulations.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers, especially from Africa, South America, the Middle East, and Europe, face unique challenges regarding quality control. Understanding these nuances can significantly influence procurement decisions:

-

Regulatory Compliance: Different countries have varying regulations regarding automotive components. Buyers must ensure that their suppliers comply with the specific regulations applicable in their target markets.

-

Cultural Differences: Cultural attitudes toward quality and business practices can vary significantly. Establishing clear communication and understanding local practices can help foster better supplier relationships.

-

Logistics and Supply Chain Considerations: The logistics involved in importing engines can introduce risks such as damage during transport. Buyers should discuss packaging and shipping standards with suppliers to minimize these risks.

In summary, the manufacturing and quality assurance processes for the RB25 motor are complex and require careful consideration by international B2B buyers. By understanding these processes, employing effective verification strategies, and being aware of the specific challenges in their regions, buyers can make informed decisions that ensure the reliability and performance of their engine purchases.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rb25 motor for sale’

Introduction

This guide provides a comprehensive checklist for B2B buyers seeking to procure an RB25 motor for sale. Whether you are looking to enhance your automotive offerings or fulfill specific customer demands, following these steps will help streamline your sourcing process, ensuring you acquire high-quality engines from reliable suppliers.

1. Define Your Technical Specifications

Start by clearly outlining the technical requirements for the RB25 motor you need. Consider factors such as engine type (RB25DET or RB25DE), power output, and compatibility with existing vehicle models.

– Why it matters: Precise specifications help you avoid miscommunication with suppliers and ensure the engine meets your performance needs.

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in RB25 motors. Look for companies with a solid reputation in the industry and positive customer reviews.

– What to consider: Focus on suppliers who offer detailed product descriptions, warranties, and customer support to ensure a smooth purchasing experience.

3. Evaluate Supplier Certifications and Compliance

Verify that your chosen suppliers meet industry standards and have the necessary certifications. This may include quality management systems like ISO certification or compliance with local automotive regulations.

– Importance: Certifications can indicate a supplier’s commitment to quality and reliability, reducing the risk of acquiring subpar products.

4. Request Detailed Product Information

Before making a decision, request comprehensive information about the RB25 motors, including mileage, condition, and any modifications. Ask for documentation such as compression test results or service history.

– Key details: A detailed product overview will help you assess the engine’s viability and longevity, ensuring it aligns with your quality standards.

5. Compare Pricing and Payment Terms

Gather pricing information from multiple suppliers to evaluate market rates. Pay attention to payment terms, shipping costs, and potential import duties, especially when sourcing internationally.

– Why this is crucial: Understanding the total cost will help you budget effectively and avoid unexpected expenses that could impact profitability.

6. Assess Shipping and Delivery Options

Inquire about the logistics of shipping the RB25 motor to your location. Look for suppliers who offer reliable shipping methods, tracking options, and clear delivery timelines.

– Considerations: Efficient shipping processes can minimize downtime and ensure that your operations continue smoothly without delays.

7. Establish Communication and Support Channels

Once you have selected a supplier, establish clear lines of communication. Make sure you have access to customer service for any post-purchase support or warranty claims.

– Why it’s important: Effective communication ensures that any issues can be resolved promptly, fostering a long-term relationship with your supplier.

By following this checklist, B2B buyers can navigate the complexities of sourcing RB25 motors with confidence, ensuring they procure high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for rb25 motor for sale Sourcing

What Are the Key Cost Components Involved in Sourcing an RB25 Motor?

Understanding the cost structure associated with sourcing an RB25 motor is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The RB25 motor comprises various components such as engine blocks, turbochargers, and wiring harnesses. The quality and source of these materials significantly impact pricing. For instance, sourcing original parts from Japan can be more expensive than aftermarket alternatives.

-

Labor: Labor costs vary depending on the supplier’s location and the complexity of the engine assembly. Skilled labor in regions like Japan may command higher wages, which can influence the overall cost of the motor.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. Suppliers with advanced manufacturing facilities may incur higher overhead, reflected in their pricing.

-

Tooling: Specialized tools and machinery required for engine assembly can add to the cost. Suppliers who invest in state-of-the-art equipment typically offer higher-quality products, which may justify a premium price.

-

Quality Control: Rigorous QC processes ensure that each motor meets specific performance standards. Suppliers who prioritize QC may charge more, but this investment often leads to greater reliability and longevity of the engine.

-

Logistics: Transportation costs can vary based on shipping methods, distances, and freight terms. International buyers should consider these costs as part of their total acquisition budget.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary widely based on market demand and competition.

How Do Price Influencers Affect the Cost of RB25 Motors?

Several factors influence the pricing of RB25 motors, making it essential for buyers to understand these dynamics to negotiate effectively.

-

Volume/MOQ: Bulk purchases can lead to significant discounts. Suppliers often provide lower prices for larger orders, so buyers should assess their needs and negotiate minimum order quantities (MOQ) accordingly.

-

Specifications and Customization: Custom specifications can lead to increased costs. If a buyer requires specific modifications or features, this could raise the base price of the motor.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO standards) usually come at a premium. Buyers must evaluate whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a proven track record may charge more for their products but often deliver superior quality and service.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can significantly impact total costs. Buyers should ensure clarity on who bears responsibility for shipping, insurance, and customs duties to avoid unexpected expenses.

What Are the Best Buyer Tips for Sourcing RB25 Motors Internationally?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency and overall satisfaction.

-

Negotiation: Always negotiate pricing and payment terms. Suppliers may be willing to offer discounts or flexible payment options, especially for larger orders or long-term partnerships.

-

Total Cost of Ownership: Consider the total cost of ownership beyond the initial purchase price. This includes installation, maintenance, and potential downtime costs. Investing in higher-quality motors may yield lower long-term expenses.

-

Pricing Nuances for Different Regions: Be aware that prices can vary significantly based on geographical factors. For example, motors sourced from Japan may be more expensive than those from local suppliers in Europe or South America due to shipping and import duties.

-

Research and Comparison: Conduct thorough research and compare multiple suppliers. Look for reviews, certifications, and previous buyer experiences to ensure you are making an informed decision.

-

Documentation and Warranty: Ensure that all necessary documentation, including warranties and compliance certificates, is provided. This is crucial for accountability and future support.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on supplier, market conditions, and specific buyer requirements. Always verify current pricing with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing rb25 motor for sale With Other Solutions

Introduction to Alternative Solutions for RB25 Motor Buyers

In the competitive landscape of automotive engines, particularly for performance enthusiasts and businesses, identifying the right engine is crucial. The RB25 motor is a popular choice due to its performance capabilities and aftermarket support. However, various alternatives exist that may suit different operational needs and budget constraints. This analysis provides a comparison between the RB25 motor and two viable alternatives: the RB26 engine and the SR20DET engine, both of which are also Nissan products.

Comparison Table

| Comparison Aspect | Rb25 Motor For Sale | RB26 Engine | SR20DET Engine |

|---|---|---|---|

| Performance | 250-300 hp (upgradable) | 280-320 hp (highly tunable) | 200-250 hp (good for lighter cars) |

| Cost | $4,000 – $7,500 (varies by condition) | $6,000 – $10,000 (premium pricing) | $2,000 – $4,000 (budget-friendly) |

| Ease of Implementation | Moderate; requires specific mounts | High; needs specialized mounts | Low; widely compatible |

| Maintenance | Moderate; parts readily available | High; fewer parts and higher costs | Low; ample parts and support |

| Best Use Case | Performance builds, drifting | High-performance racing | Daily driving, budget builds |

Detailed Breakdown of Alternatives

What are the Advantages and Disadvantages of the RB26 Engine?

The RB26 engine, known for its robust construction and high-performance capabilities, offers a significant power output, making it a favorite among racing enthusiasts. Its tuning potential is vast, allowing for upgrades that can push horsepower well beyond 400 hp. However, the cost is considerably higher than the RB25, which can be a barrier for budget-conscious buyers. Additionally, the complexity of installation may require specialized knowledge, making it less accessible for some businesses.

How Does the SR20DET Engine Compare to the RB25 Motor?

The SR20DET engine serves as a cost-effective alternative, especially for those looking to build lighter, agile vehicles. With a decent power range of 200-250 hp, it is suitable for daily driving and performance applications without the hefty price tag associated with the RB series. Its compatibility with a wider range of chassis also simplifies installation. However, it may not provide the same level of performance or tuning potential as the RB25 or RB26 engines, which could limit its appeal for serious performance builds.

Conclusion: Choosing the Right Engine Solution

When selecting an engine for your automotive needs, it is essential to weigh the performance requirements, budget constraints, and specific use cases. The RB25 motor offers a balanced option for those aiming for moderate performance with solid aftermarket support. In contrast, the RB26 is ideal for high-performance applications, albeit at a premium price. The SR20DET stands out as a budget-friendly alternative for everyday driving or lighter builds. B2B buyers should carefully assess their specific objectives and operational context to make an informed decision that aligns with their business goals.

Essential Technical Properties and Trade Terminology for rb25 motor for sale

What Are the Key Technical Properties of the RB25 Motor?

When evaluating an RB25 motor for sale, understanding its critical technical properties is essential for making informed purchasing decisions. Here are some of the key specifications:

-

Displacement:

The RB25 engine features a displacement of 2.5 liters (2500cc), which is crucial for determining the engine’s power output and efficiency. Displacement directly influences the torque and horsepower, making it a key factor for buyers looking for performance specifications tailored to their needs. -

Turbocharger Type:

Most RB25 engines are equipped with a turbocharger, particularly the RB25DET variant. The type of turbocharger impacts the engine’s performance, responsiveness, and fuel efficiency. Understanding the turbo specifications can help buyers assess the potential for modifications or upgrades, which is critical in competitive markets. -

Power Output:

The RB25 motor typically produces between 250 to 300 horsepower, depending on the specific model and configuration. This metric is vital for buyers who require certain power levels for specific applications, such as racing or heavy-duty usage. -

Material Composition:

The RB25 engine blocks are often made from aluminum alloys, while the internals may include forged steel or cast iron components. Material choice affects durability, weight, and thermal efficiency, which can be significant considerations for buyers looking for long-term reliability. -

Fuel System:

The RB25 utilizes a multi-port fuel injection system, which is essential for optimizing fuel delivery and engine performance. An understanding of the fuel system is important for buyers who may need to source compatible fuel injectors or consider modifications for performance enhancements. -

Engine Configuration:

The RB25 is an inline-six engine, known for its smooth operation and balance. This configuration is often favored for high-performance applications, and understanding its layout can help buyers assess compatibility with existing vehicles or performance builds.

What Are Common Trade Terms Used in the RB25 Motor Market?

Familiarity with industry jargon and trade terminology can enhance communication and negotiation between buyers and sellers. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer):

This term refers to parts made by the original manufacturer of the vehicle. OEM parts are often preferred for their guaranteed compatibility and quality. Understanding whether an RB25 motor is OEM can significantly impact the purchasing decision for buyers focused on quality and reliability. -

MOQ (Minimum Order Quantity):

MOQ is the smallest number of units that a supplier is willing to sell. For international buyers, knowing the MOQ can assist in planning inventory and budgeting, especially when considering bulk purchases for resale or use in multiple projects. -

RFQ (Request for Quotation):

An RFQ is a document that buyers send to suppliers requesting pricing and other details for specific products. For businesses looking to acquire RB25 motors, submitting an RFQ can streamline the procurement process and ensure competitive pricing. -

Incoterms:

These are international commercial terms that define the responsibilities of buyers and sellers in shipping and delivery. Familiarity with Incoterms is crucial for buyers to understand shipping costs, risks, and responsibilities, especially when importing RB25 motors from international markets. -

Aftermarket:

This term refers to parts that are made by companies other than the OEM, often providing performance enhancements or modifications. Buyers interested in upgrading their RB25 motors should consider the aftermarket landscape for parts and modifications. -

Warranty:

A warranty is a guarantee provided by the seller regarding the condition of the engine and its components. Understanding warranty terms is vital for buyers to assess the potential risks associated with their purchase and ensure that they are covered for any defects or issues.

Understanding these technical properties and trade terms can empower international B2B buyers in making well-informed decisions regarding the RB25 motor for sale, ultimately leading to successful transactions and satisfied customers.

Navigating Market Dynamics and Sourcing Trends in the rb25 motor for sale Sector

What Are the Key Market Drivers for RB25 Motors in Global Trade?

The RB25 motor market has seen a significant uptick in demand driven by the growing interest in performance vehicles and motorsport culture globally. Key markets in Africa, South America, the Middle East, and Europe are particularly active, as buyers seek reliable, high-performance engines for both commercial applications and personal projects. The increasing availability of second-hand RB25 motors, often at competitive prices ranging from $50 to $500 depending on condition, has further stimulated market activity. This sector is also benefiting from the rise of online marketplaces that facilitate international trade, allowing buyers from diverse regions to access high-quality products from Japan and other manufacturing hubs.

Emerging trends in B2B sourcing include the use of technology to streamline the purchasing process. Many suppliers now offer comprehensive online catalogs with detailed specifications, customer reviews, and competitive pricing, enabling buyers to make informed decisions quickly. Additionally, the integration of logistics solutions is enhancing the efficiency of cross-border transactions, reducing lead times, and improving inventory management. As buyers in regions like Germany and Vietnam become more sophisticated, they are also looking for suppliers who can provide not just engines but complete solutions, including installation services and warranties.

How Does Sustainability Impact the Sourcing of RB25 Motors?

Sustainability is becoming a crucial factor in the B2B sourcing of RB25 motors. The environmental impact of sourcing and manufacturing processes is under increasing scrutiny, prompting buyers to consider the sustainability practices of their suppliers. Ethical sourcing, which includes ensuring that parts are obtained from suppliers with responsible labor practices and environmentally friendly production methods, is gaining traction.

Buyers are encouraged to look for suppliers that offer “green” certifications or materials, which can not only enhance their brand reputation but also meet regulatory requirements in their home markets. In the context of used engines, the concept of circular economy is particularly relevant; sourcing second-hand RB25 motors contributes to waste reduction and resource conservation. As such, B2B buyers are advised to prioritize suppliers who demonstrate a commitment to sustainability through transparent supply chains and environmental stewardship.

What Is the Historical Context of the RB25 Motor’s Popularity in Global Markets?

The RB25 motor, originally developed by Nissan for the Skyline series, has a storied history that has contributed to its current status as a sought-after engine in the performance car segment. Launched in the early 1990s, the RB25 engine was known for its robust performance and tuning potential, making it a favorite among car enthusiasts and tuners alike. Its reputation was solidified through its association with motorsport, particularly in Japan, where it became a staple in competitive racing.

Over the years, the RB25 has evolved, with various iterations and improvements, including the introduction of turbocharged versions. This adaptability has kept the engine relevant in modern markets, appealing to both vintage car restorers and contemporary performance seekers. Today, the RB25’s legacy continues to thrive, supported by a vibrant aftermarket and a dedicated community of enthusiasts, ensuring its enduring demand in international B2B markets.

Frequently Asked Questions (FAQs) for B2B Buyers of rb25 motor for sale

-

How do I ensure the quality of an RB25 motor before purchasing?

To ensure the quality of an RB25 motor, request detailed information from the supplier regarding the engine’s history, including mileage, previous usage, and any modifications made. Consider asking for a compression test report or other diagnostic assessments to verify the engine’s condition. If possible, request video footage or photographs of the engine running. Engaging a third-party inspection service can also provide an unbiased assessment of the motor’s quality before you finalize your purchase. -

What factors should I consider when selecting a supplier for RB25 motors?

When selecting a supplier for RB25 motors, evaluate their reputation and experience in the industry. Look for reviews and testimonials from previous clients to gauge reliability. Verify their compliance with international trade regulations and inquire about their warranty policies. It’s also beneficial to assess their ability to provide after-sales support and technical assistance. Establish a clear line of communication to discuss any specific requirements or concerns you may have. -

What customization options are available for the RB25 motor?

Customization options for the RB25 motor can include performance upgrades, such as enhanced turbochargers, intercoolers, or engine tuning to meet specific horsepower goals. Additionally, you can request alterations to the engine’s wiring harness or ECU for compatibility with your vehicle’s systems. Discuss your needs with the supplier to explore available packages or bespoke modifications that align with your project requirements. -

What is the minimum order quantity (MOQ) for RB25 motors?

The minimum order quantity (MOQ) for RB25 motors varies by supplier and can depend on factors such as inventory availability and production capabilities. Generally, suppliers may offer single units for small-scale buyers, but bulk purchasing can lead to better pricing and shipping terms. Always clarify MOQ expectations with your supplier upfront, especially if you are considering a larger-scale operation or distribution. -

What payment terms are typically offered when purchasing RB25 motors?

Payment terms for purchasing RB25 motors can vary significantly among suppliers. Common arrangements include upfront payments, partial deposits with the balance due upon shipment, or payment upon delivery. Some suppliers may also offer financing options or credit terms for established businesses. It is crucial to discuss and negotiate payment terms that are favorable and secure for both parties before finalizing the transaction. -

How can I navigate international shipping for RB25 motors?

Navigating international shipping for RB25 motors involves understanding the logistics of customs clearance, tariffs, and shipping methods. Choose a reliable freight forwarder who is experienced in automotive parts shipping and can handle documentation. Ensure that the supplier provides all necessary paperwork, including bills of lading and customs declarations. Discuss shipping insurance options to protect your investment during transit, especially if the motor is being shipped internationally. -

What are the warranty options available for RB25 motors?

Warranty options for RB25 motors can vary widely based on the supplier and the condition of the engine. Most reputable suppliers will offer some form of warranty, typically covering defects in materials or workmanship for a specific period or mileage. Be sure to review the warranty details, including what is covered and any conditions that apply. It’s advisable to select a supplier that provides a comprehensive warranty to safeguard your investment. -

What should I do if the RB25 motor arrives damaged or not as described?

If the RB25 motor arrives damaged or does not match the description, immediately document the issue with photographs and detailed notes. Contact the supplier as soon as possible to report the problem, providing them with your evidence. Familiarize yourself with the supplier’s return policy and warranty conditions to determine the next steps, which may include returning the motor for a replacement or obtaining a refund. Prompt communication is essential to resolve the issue efficiently.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Rb25 Motor For Sale Manufacturers & Suppliers List

1. Platinum Racing Products – Second Hand Nissan Engine Blocks

Domain: platinumracingproducts.com

Registered: 2010 (15 years)

Introduction: Second Hand Nissan RB25 RB26 RB30 Engine Blocks

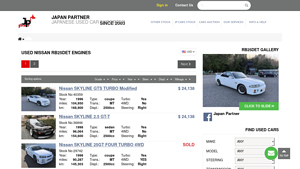

2. Nissan – RB25DET Engine Details

Domain: japan-partner.com

Registered: 2001 (24 years)

Introduction: Nissan RB25DET engine details:

– Type: RB25DET

– Manufacturer: Nissan

– Engine Displacement: 2500cc

– Turbocharged: Yes

– Available Models:

1. Nissan SKYLINE GTS TURBO

– Year: 1996

– Mileage: 104,950 km

– Transmission: MT

– Price: $24,138

2. Nissan SKYLINE 2.5 GT-T

– Year: 1998

– Mileage: 96,064 km

– Transmission: MT

– Price: $24,138

3….

3. RB25 – Engine Swap Costs

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: RB25 motors are priced at $4000+, but additional costs for rebuilding and completing the swap can exceed $10,000. Many RB25 motors available online do not include a transmission, which can add another $3-4k to the total cost. The market for these engines has inflated due to nostalgia and limited supply, making them less cost-effective compared to other options like KA24 motors or K series setups. …

4. Nissan – RB25DET Neo Turbo Engine

Domain: redlinejdm.com

Registered: 2020 (5 years)

Introduction: Nissan Skyline R34 RB25DET Neo Turbo Engine 2.5L AWD JDM Motor for Sale

Price: $3,599

Engine Type: RB25DET

Year: 1996+

Mileage: 35,000-55,000 miles

Applications: Nissan Skyline 1996+

Modifications: Use as a long block, keep intake wiring and accessories from old engine

Warranty: 30 days from receiving

Shipping: Shipped the following business day, free local pickup available

Stock: 1 left in stock

…

Strategic Sourcing Conclusion and Outlook for rb25 motor for sale

In today’s competitive automotive market, strategic sourcing of RB25 motors presents a vital opportunity for international B2B buyers. The diverse range of options available, from second-hand engine blocks to complete JDM engines, allows businesses to tailor their purchases according to specific performance needs and budget constraints. Notably, prices can vary significantly based on condition and specifications, making it crucial for buyers to thoroughly assess their options before making a decision.

Furthermore, leveraging relationships with reliable suppliers can enhance supply chain efficiency, ensuring timely delivery and quality assurance. As demand for high-performance engines continues to rise in regions like Africa, South America, the Middle East, and Europe, the importance of strategic sourcing cannot be overstated.

Looking ahead, businesses should remain proactive in exploring emerging markets and trends, as well as fostering partnerships with trusted suppliers. This approach not only mitigates risks but also positions companies to capitalize on future growth opportunities. Engage with reputable suppliers today to secure the best deals on RB25 motors and ensure your business remains competitive in this dynamic market.