A Deep Dive into Sunroom Roof Panels Solution

Introduction: Navigating the Global Market for sunroom roof panels

In the competitive landscape of global construction and outdoor living solutions, sourcing high-quality sunroom roof panels presents a significant challenge for B2B buyers. The need for durable, energy-efficient, and aesthetically pleasing panels that can withstand diverse climatic conditions is paramount, particularly for businesses operating in regions such as Africa, South America, the Middle East, and Europe. This guide is designed to empower international buyers with comprehensive insights into the various types of sunroom roof panels available, their applications, and the critical factors to consider when vetting suppliers.

As you navigate this complex market, you will explore the distinct advantages of insulated roof systems, their structural integrity, and energy efficiency, ensuring that your investment aligns with both customer expectations and local building codes. Additionally, this guide will delve into cost considerations, installation processes, and maintenance requirements, providing you with the tools necessary to make informed purchasing decisions.

By leveraging the knowledge contained in this guide, B2B buyers can confidently select sunroom roof panels that not only enhance the value of their offerings but also meet the specific needs of their diverse clientele. From maximizing outdoor spaces to creating inviting environments for leisure and relaxation, understanding the nuances of sunroom roof panels will ultimately facilitate successful projects and foster long-term partnerships in the global market.

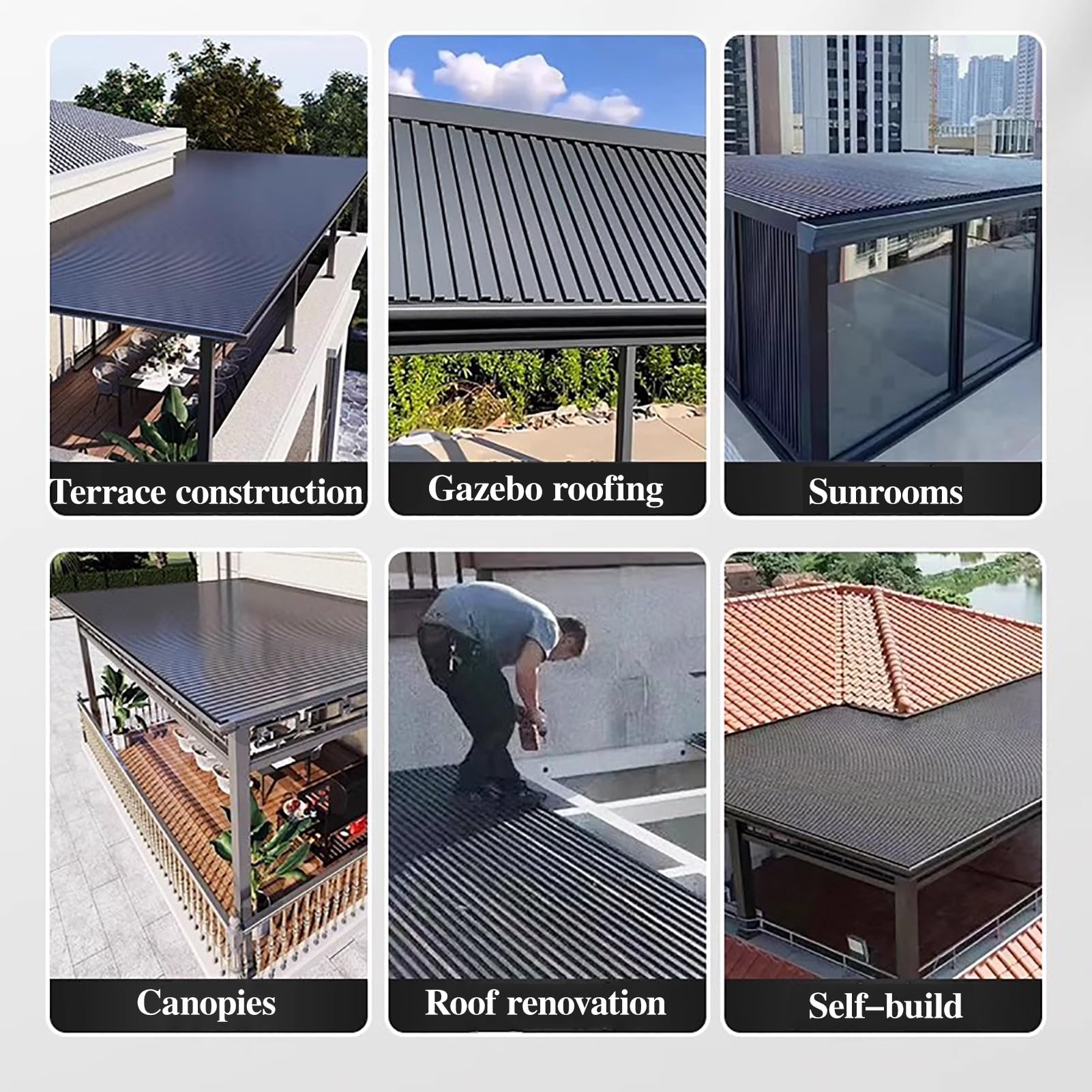

Understanding sunroom roof panels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Insulated Aluminum Panels | Dual aluminum skins with a foam core, high strength, energy-efficient | Residential sunrooms, commercial patios | Pros: Excellent insulation, low maintenance. Cons: Higher initial cost. |

| Polycarbonate Panels | Lightweight, UV resistant, available in clear or tinted options | Greenhouses, pool enclosures, commercial use | Pros: Cost-effective, good light transmission. Cons: Less insulation than aluminum. |

| Structural Insulated Panels (SIPs) | Prefabricated panels with high insulation values, customizable | Multi-family housing, large sunroom projects | Pros: Quick installation, energy-efficient. Cons: Requires precise measurements for customization. |

| Glass Roof Panels | Provides maximum natural light, can be treated for UV protection | High-end residential sunrooms, conservatories | Pros: Aesthetically pleasing, enhances ambiance. Cons: Higher maintenance, potential for heat loss. |

| Fabric Canopies | Flexible materials, available in various colors and patterns | Temporary structures, outdoor events | Pros: Lightweight, easy to install. Cons: Limited durability and insulation. |

What are the Characteristics of Insulated Aluminum Panels for Sunrooms?

Insulated aluminum panels are characterized by their dual aluminum skins enclosing a high-density foam core. This design offers exceptional strength and thermal insulation, making them ideal for various climates. They are particularly suitable for residential sunrooms and commercial patios where energy efficiency and durability are paramount. B2B buyers should consider the initial investment against long-term energy savings and minimal maintenance requirements, as these panels are designed to withstand harsh weather conditions.

How Do Polycarbonate Panels Compare for Sunroom Applications?

Polycarbonate panels are lightweight and UV resistant, making them a popular choice for greenhouses and pool enclosures. They come in clear or tinted options, allowing for versatile design applications. While they are cost-effective and provide good light transmission, their insulation properties are not as robust as those of insulated aluminum panels. B2B buyers should evaluate the balance between cost and insulation needs when considering polycarbonate panels for their projects.

Why Choose Structural Insulated Panels (SIPs) for Larger Projects?

Structural insulated panels (SIPs) are prefabricated, offering high insulation values and customizable sizes. They are particularly advantageous for multi-family housing and larger sunroom projects due to their quick installation and energy efficiency. Buyers should focus on precise measurements during the purchasing process, as customization is essential to ensure optimal performance. The initial cost can be offset by long-term energy savings and reduced construction time.

What are the Benefits of Glass Roof Panels in Sunroom Design?

Glass roof panels are favored for high-end residential sunrooms and conservatories because they maximize natural light and create an inviting atmosphere. These panels can be treated for UV protection, enhancing their functionality. However, they may require more maintenance than other options and can lead to heat loss if not properly insulated. B2B buyers should weigh the aesthetic benefits against the potential for increased upkeep and energy costs.

When Should Fabric Canopies Be Considered for Sunroom Structures?

Fabric canopies offer flexibility in design and are available in various colors and patterns, making them suitable for temporary structures and outdoor events. They are lightweight and easy to install, appealing to buyers seeking quick solutions. However, their limited durability and insulation capabilities may not make them suitable for permanent sunroom applications. B2B buyers should assess the intended use and longevity required when considering fabric canopies for their projects.

Key Industrial Applications of sunroom roof panels

| Industry/Sector | Specific Application of Sunroom Roof Panels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Outdoor Cafe and Restaurant Patio Covers | Enhances guest experience while providing weather protection | Durability, UV resistance, aesthetic appeal, and local climate suitability |

| Real Estate | Residential Sunrooms and Conservatories | Adds value to properties, offering additional living space | Energy efficiency, insulation properties, and compliance with local building codes |

| Agriculture | Greenhouses and Agricultural Enclosures | Extends growing seasons and protects crops from extreme weather | Thermal insulation, light transmission, and structural integrity |

| Retail | Store Entrance and Outdoor Display Areas | Increases foot traffic while providing shelter for customers | Customization options, branding opportunities, and ease of installation |

| Construction and Renovation | Modular Sunroom Kits and Patio Covers for Residential Projects | Quick installation and versatile design for various climates | Quality of materials, ease of assembly, and compliance with international standards |

How Are Sunroom Roof Panels Used in the Hospitality Sector?

In the hospitality industry, sunroom roof panels are extensively utilized for outdoor cafe and restaurant patio covers. These panels provide guests with a comfortable outdoor dining experience while protecting them from sun, rain, and snow. This application not only enhances the aesthetic appeal of the venue but also extends the usable space year-round. For international buyers, sourcing panels that are durable and UV resistant is critical, especially in regions with extreme weather conditions.

What Role Do Sunroom Roof Panels Play in Real Estate?

In real estate, sunroom roof panels are a valuable addition to residential properties, particularly for creating sunrooms and conservatories. These structures add significant value by providing additional living space and enhancing the home’s appeal. Buyers in this sector need to consider energy-efficient panels that offer superior insulation to maintain comfortable indoor temperatures across different climates, which is essential for markets in Europe, Africa, and South America.

How Are Sunroom Roof Panels Beneficial in Agriculture?

Agricultural applications of sunroom roof panels are primarily found in greenhouses and agricultural enclosures. These panels help extend growing seasons by providing a controlled environment that protects crops from harsh weather. The thermal insulation properties of these panels are crucial for maintaining optimal temperatures, which is particularly relevant for buyers in regions with extreme climates, such as parts of the Middle East and Africa. Sourcing panels with excellent light transmission and structural integrity is essential for maximizing agricultural productivity.

How Do Retail Businesses Utilize Sunroom Roof Panels?

In the retail sector, sunroom roof panels are often used in store entrances and outdoor display areas. These installations help increase foot traffic by providing a welcoming and protected environment for customers. Businesses must consider customization options for branding and aesthetic coherence with their store designs. Additionally, sourcing panels that are easy to install and maintain is important, especially for international buyers who may face varying local regulations and installation practices.

What Are the Advantages of Sunroom Roof Panels in Construction and Renovation?

In construction and renovation, modular sunroom kits and patio covers featuring sunroom roof panels offer a quick and versatile solution for residential projects. These kits simplify installation, making them appealing for DIY enthusiasts and contractors alike. Buyers should prioritize high-quality materials that comply with international building codes, particularly in regions like Africa and South America where construction standards may vary widely. The ability to adapt designs to local climates and aesthetic preferences is also a key consideration.

3 Common User Pain Points for ‘sunroom roof panels’ & Their Solutions

Scenario 1: Insufficient Insulation Leading to Temperature Fluctuations

The Problem: B2B buyers often face the challenge of selecting sunroom roof panels that provide adequate insulation. In regions with extreme weather, such as the Middle East or Northern Europe, fluctuating temperatures can lead to discomfort for occupants and increased energy costs. When panels lack sufficient insulation, they fail to keep the sunroom warm in winter and cool during the summer months, ultimately affecting customer satisfaction and operational efficiency.

The Solution: To address insulation issues, B2B buyers should prioritize sourcing roof panels that feature advanced insulation technologies, such as high-density expanded polystyrene (EPS) cores, which are known for their superior thermal performance. When specifying panels, consider options with varying thicknesses (e.g., 3″, 4″, or 6″) based on local climate demands. Collaborating with manufacturers who offer panels engineered for specific weather conditions ensures that the product will meet or exceed local building codes. Additionally, integrating an energy-efficient design, such as a built-in gutter system for rainwater management, can enhance the panel’s performance and longevity. Conduct thorough thermal performance assessments and request test data from suppliers to ensure the selected panels meet your insulation requirements.

Scenario 2: Installation Complexity and Cost Overruns

The Problem: Many buyers encounter challenges with the installation process of sunroom roof panels, which can lead to unexpected costs and extended timelines. Inadequate installation instructions or the need for specialized labor can complicate the process, particularly for DIY projects or small construction firms that may not have the expertise or resources. This complexity can deter potential customers or delay project completion, ultimately affecting profitability.

The Solution: To mitigate installation challenges, B2B buyers should seek manufacturers that provide comprehensive installation guides and support. Look for modular systems that simplify the assembly process, such as those with snap-lock designs that eliminate the need for exposed screws and reduce installation time. Additionally, consider sourcing panels that come with pre-fabricated kits tailored for different building applications, ensuring that all necessary components are included. If possible, arrange for training sessions or workshops conducted by the manufacturer for installation teams to enhance their skills and confidence. This proactive approach can minimize errors, reduce labor costs, and ensure that projects stay on schedule and within budget.

Scenario 3: Durability Concerns in Harsh Environments

The Problem: Buyers often grapple with the challenge of selecting sunroom roof panels that can withstand harsh environmental conditions, such as heavy snowfall, intense UV rays, or high winds. Panels that lack durability may lead to structural failures or require frequent repairs, causing significant long-term costs and diminishing the overall value of the investment. In regions like Canada or parts of South America, the risk of panel degradation can be a major concern.

The Solution: To ensure durability, B2B buyers should focus on sourcing panels made from high-quality materials, such as aluminum skins bonded to robust insulation cores. Look for products with proven performance ratings in extreme weather conditions, including wind and snow load tests. Additionally, consider options with protective finishes, such as Krystal Kote, that enhance resistance to UV radiation and corrosion. When evaluating suppliers, ask for warranties that cover structural integrity over an extended period, indicating the manufacturer’s confidence in their product’s longevity. Regular maintenance schedules and inspections should also be established to identify potential issues early, ensuring that the sunroom remains safe and functional for years to come.

Strategic Material Selection Guide for sunroom roof panels

What Are the Key Materials for Sunroom Roof Panels?

When selecting materials for sunroom roof panels, several options stand out based on their performance, durability, and suitability for various climates. Below, we analyze four common materials: aluminum, polycarbonate, fiberglass, and structural insulated panels (SIPs).

How Does Aluminum Perform as a Material for Sunroom Roof Panels?

Aluminum is a popular choice for sunroom roof panels due to its lightweight nature and excellent corrosion resistance. It typically has a high strength-to-weight ratio, allowing for expansive spans without the need for additional support. Aluminum can withstand extreme temperatures, making it suitable for various climates.

Pros: Aluminum is durable and requires minimal maintenance, which is appealing for long-term investments. Its recyclability also aligns with sustainability goals.

Cons: The initial cost can be higher compared to other materials, and it may conduct heat, leading to temperature regulation issues without proper insulation.

Impact on Application: Aluminum panels are compatible with various roofing systems, but they may require specific coatings to enhance thermal performance.

Considerations for International Buyers: Compliance with standards like ASTM and DIN is crucial. Buyers in Africa and the Middle East may also need to consider local corrosion factors, given the high humidity and saline environments.

What Benefits Does Polycarbonate Offer for Sunroom Roof Panels?

Polycarbonate is a thermoplastic material known for its high impact resistance and excellent light transmission. It is available in various thicknesses and can be either clear or tinted, allowing for customization based on aesthetic preferences.

Pros: Polycarbonate panels are lightweight and can be easily installed, making them suitable for DIY projects. They also provide good thermal insulation.

Cons: While durable, polycarbonate can be prone to scratching and may yellow over time if not treated with UV protection.

Impact on Application: Polycarbonate is ideal for applications requiring transparency and light diffusion, such as in greenhouses or sunrooms.

Considerations for International Buyers: Buyers should ensure that the polycarbonate panels meet international standards for UV resistance and structural integrity, particularly in regions with intense sunlight.

Why Choose Fiberglass for Sunroom Roof Panels?

Fiberglass is another viable option for sunroom roof panels, known for its strength and thermal insulation properties. It is often used in applications where high durability and resistance to environmental stressors are required.

Pros: Fiberglass panels are lightweight, resistant to corrosion, and can be molded into various shapes, allowing for design flexibility.

Cons: The manufacturing process can be complex, leading to higher costs. Fiberglass also requires protective coatings to prevent degradation from UV exposure.

Impact on Application: Fiberglass is suitable for both residential and commercial applications, particularly in areas with high humidity or salt exposure.

Considerations for International Buyers: Compliance with local building codes and standards is essential. Buyers should be aware of the potential for fiberglass to require additional treatments in humid climates.

What Are Structural Insulated Panels (SIPs) and Their Advantages?

Structural Insulated Panels (SIPs) consist of an insulating foam core sandwiched between two structural facings, typically made of oriented strand board (OSB) or metal. They provide excellent insulation and are engineered for high strength.

Pros: SIPs offer superior energy efficiency and are quick to install, reducing labor costs. They also provide excellent structural integrity, making them suitable for harsh weather conditions.

Cons: The initial investment can be significant, and they may require specialized knowledge for installation.

Impact on Application: SIPs are ideal for energy-efficient sunrooms and can be used in various climates, providing good thermal performance.

Considerations for International Buyers: Buyers should ensure SIPs meet local building codes and standards, especially in regions prone to extreme weather conditions.

Summary Table of Material Selection for Sunroom Roof Panels

| Material | Typical Use Case for sunroom roof panels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Residential and commercial sunrooms | Lightweight and corrosion-resistant | Higher initial cost | Medium |

| Polycarbonate | Greenhouses and sunrooms | High impact resistance and light transmission | Prone to scratching and yellowing | Medium |

| Fiberglass | High-humidity and coastal areas | Excellent thermal insulation | Complex manufacturing process | High |

| Structural Insulated Panels (SIPs) | Energy-efficient sunrooms | Superior energy efficiency | Significant initial investment | High |

This guide provides insights into the materials available for sunroom roof panels, helping international B2B buyers make informed decisions based on performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for sunroom roof panels

What Are the Key Stages in the Manufacturing Process of Sunroom Roof Panels?

The manufacturing of sunroom roof panels involves several critical stages that ensure the panels meet high standards of performance and durability.

Material Preparation

The initial stage involves selecting high-quality raw materials, typically aluminum skins and insulated cores made from expanded polystyrene (EPS) or other materials. Aluminum is chosen for its strength, lightweight properties, and resistance to corrosion, making it ideal for outdoor applications. The core material is essential for providing thermal insulation. Each material undergoes rigorous testing to verify its suitability for production, including assessments of mechanical properties and thermal conductivity.

Forming Techniques: How Are Sunroom Roof Panels Shaped?

Once the materials are prepared, they undergo forming processes. The aluminum sheets are cut to the required dimensions and then bonded to the core material. This is often achieved through advanced techniques such as lamination or extrusion, which ensure a strong bond and structural integrity. The panels may also be designed with specific profiles to enhance their aesthetic appeal and functionality.

Assembly: How Are Different Components Joined Together?

After forming, the panels are assembled into complete roof systems. This stage may include the integration of additional components such as gutters, insulation barriers, and support beams. The assembly process is crucial as it affects the overall performance of the roof system, especially concerning load-bearing capacity and water drainage.

Finishing Touches: What Treatments Enhance Performance?

The final stage is finishing, where the panels receive protective coatings, often including a baked-on enamel finish for enhanced durability and aesthetic appeal. This finish helps protect against UV rays, weathering, and corrosion. Quality control measures at this stage ensure that the coatings are applied uniformly and meet the required specifications.

How Is Quality Assurance Implemented in Sunroom Roof Panel Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final product meets international standards and customer expectations.

What Are the Relevant International Standards for Sunroom Roof Panels?

Manufacturers often adhere to international standards such as ISO 9001, which outlines a framework for quality management systems. Compliance with these standards signifies that a manufacturer has established effective processes for maintaining quality throughout production. Additionally, region-specific certifications, such as CE marking for the European market and API standards for certain applications, are crucial for ensuring that products are safe and reliable.

What Quality Control Checkpoints Are Essential During Manufacturing?

Quality control checkpoints are established at various stages of production:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon delivery to ensure they meet specified quality criteria.

- In-Process Quality Control (IPQC): During the manufacturing process, random samples are tested for dimensional accuracy, structural integrity, and bonding strength.

- Final Quality Control (FQC): After assembly, the completed panels undergo a final inspection, which may include performance testing such as thermal resistance and load-bearing capacity assessments.

Which Testing Methods Are Commonly Used?

Manufacturers employ a range of testing methods to validate the quality of sunroom roof panels. Common methods include:

- Load Testing: Evaluating the panels’ ability to withstand specified weights, simulating real-world conditions.

- Thermal Performance Testing: Measuring the insulation effectiveness to ensure energy efficiency.

- Weather Resistance Tests: Assessing how well panels can endure environmental factors such as rain, snow, and UV exposure.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is vital for ensuring product reliability.

What Are the Best Practices for Conducting Supplier Audits?

Conducting thorough supplier audits can provide valuable insights into a manufacturer’s quality assurance processes. Buyers should look for:

- Documentation: Review quality management system documentation, including procedures and policies related to manufacturing and testing.

- Certifications: Confirm that the manufacturer possesses relevant quality certifications and standards that apply to the intended market.

- Facility Visits: If feasible, visiting the manufacturing facility allows buyers to observe the production processes and quality control measures firsthand.

How Can Buyers Utilize Reports and Third-Party Inspections?

Buyers can request quality control reports that detail the findings of internal inspections and testing. Engaging third-party inspection services can also provide unbiased verification of product quality. These inspections can cover aspects like material integrity, manufacturing processes, and compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control is essential for international buyers. Different regions may have specific regulations and standards that affect the importation and use of sunroom roof panels.

How Do Regional Regulations Impact Quality Assurance?

For instance, regulations in Europe often require CE marking for construction materials, ensuring they meet safety and performance standards. In contrast, buyers from Africa or South America might face different regulatory challenges, including local building codes that must be adhered to.

What Should Buyers Consider Regarding Warranty and After-Sales Support?

In addition to quality assurance, buyers should consider the warranty offered by manufacturers. A robust warranty indicates confidence in product durability and performance. Furthermore, after-sales support is crucial for addressing any issues that may arise post-installation.

Conclusion

The manufacturing processes and quality assurance protocols for sunroom roof panels are designed to meet high performance and durability standards. By understanding these processes and implementing thorough verification methods, international B2B buyers can ensure they procure reliable, high-quality products suited to their specific needs. This knowledge empowers buyers to make informed decisions, ultimately enhancing their investment in sunroom roof systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sunroom roof panels’

Introduction

Sourcing sunroom roof panels requires careful consideration to ensure that the materials meet your specific needs and standards. This guide outlines a practical checklist to help B2B buyers navigate the procurement process effectively, focusing on critical aspects like specifications, supplier evaluation, and compliance.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications required for your sunroom roof panels. Consider factors such as thickness, insulation properties, and material composition. For instance, panels with a thicker EPS core may provide better insulation and structural support, essential for regions with extreme weather conditions.

Step 2: Research Market Trends and Innovations

Stay updated on the latest trends and technological advancements in sunroom roofing solutions. Innovations like insulated aluminum panels or patented snap-lock systems can offer enhanced durability and energy efficiency. Understanding market trends helps you choose products that not only meet current standards but also anticipate future needs.

Step 3: Evaluate Potential Suppliers

Before finalizing your supplier, conduct thorough evaluations. Request detailed company profiles, product samples, and references from past clients in similar industries. Look for suppliers with a proven track record in your region, as local climate considerations can significantly impact the performance of roofing materials.

Step 4: Verify Certifications and Compliance

Ensure that the sunroom roof panels comply with local building codes and international standards. Verify if suppliers have certifications for quality and safety, such as ISO or ASTM ratings. Compliance not only ensures durability but also protects you from potential legal liabilities during installation.

Step 5: Assess Customization Options

Consider whether the supplier offers customization for your roofing needs. Options like color choices, panel thickness, and additional features such as built-in gutters or skylights can enhance the functionality and aesthetics of your sunroom. Custom solutions can also help you stand out in a competitive market.

Step 6: Request Detailed Quotations

When you’ve shortlisted potential suppliers, request detailed quotations that break down costs, including materials, shipping, and installation if applicable. Compare not just the prices but also the value offered in terms of warranties, support, and after-sales services. A lower price may not always equate to better value if it comes with limited support or inferior quality.

Step 7: Plan for Logistics and Delivery

Finally, consider the logistics involved in the procurement process. Verify the supplier’s delivery capabilities, timelines, and shipping costs. Efficient logistics are crucial to ensure that your roofing materials arrive on time and in good condition, minimizing disruptions in your project timeline.

By following this checklist, B2B buyers can make informed decisions when sourcing sunroom roof panels, ultimately leading to successful projects and satisfied clients.

Comprehensive Cost and Pricing Analysis for sunroom roof panels Sourcing

What Are the Key Cost Components for Sunroom Roof Panels?

When sourcing sunroom roof panels, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. High-quality aluminum skins, insulation cores (like EPS or polyisocyanurate), and protective coatings can increase costs. For example, insulated panels with a thicker core generally command a higher price due to improved energy efficiency and structural integrity.

-

Labor: Installation labor costs vary by region and complexity of the project. DIY kits may reduce labor costs, but professional installation ensures compliance with local building codes and enhances safety.

-

Manufacturing Overhead: This includes factory expenses, equipment maintenance, and utilities. Suppliers with advanced manufacturing processes may offer more consistent quality but at a premium.

-

Tooling: Customization often requires specialized tooling, which can add to initial costs. However, investing in the right tooling can lead to better long-term pricing for repeat orders.

-

Quality Control (QC): Rigorous QC processes ensure product reliability, but they also increase costs. Certifications (e.g., ISO, CE) that guarantee quality and safety standards can further influence pricing.

-

Logistics: Shipping costs depend on the distance, mode of transport, and weight of the panels. International buyers must account for potential tariffs and customs fees that can significantly affect overall costs.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the market rates can help buyers gauge whether the offered prices are competitive.

How Do Price Influencers Affect Sunroom Roof Panel Costs?

Several factors can influence the pricing of sunroom roof panels:

-

Volume/MOQ: Higher order volumes often lead to discounts. Establishing a Minimum Order Quantity (MOQ) with suppliers can yield significant savings.

-

Specifications and Customization: Custom specifications (e.g., panel thickness, colors, or additional features like skylights) can increase costs. Standardized products are usually more cost-effective.

-

Material Quality and Certifications: Panels that meet higher quality standards or possess certifications for energy efficiency or weather resistance can come at a premium.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding Incoterms (e.g., FOB, CIF) is essential for assessing total costs. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

For international B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, strategic sourcing is key:

-

Negotiation: Engage suppliers in discussions about bulk pricing, discounts for early payment, or longer-term contracts. Building a rapport can lead to better terms.

-

Total Cost of Ownership (TCO): Assess the long-term costs associated with a product, including installation, maintenance, and energy efficiency. A higher upfront cost may be justified by lower operational costs.

-

Pricing Nuances: Be aware of local market conditions and currency fluctuations. Understanding regional demand can provide leverage in negotiations.

-

Supplier Diversity: Consider multiple suppliers to compare offers and ensure competitive pricing. This can also mitigate risks associated with supply chain disruptions.

What Are the Limitations of Indicative Pricing for Sunroom Roof Panels?

It is essential to approach indicative pricing with caution. Costs can vary widely based on the factors discussed, including market trends, regional economic conditions, and specific project requirements. Always request detailed quotes that break down costs to better understand what you are paying for and ensure alignment with your budget and project goals.

Alternatives Analysis: Comparing sunroom roof panels With Other Solutions

Understanding Alternatives to Sunroom Roof Panels

In the realm of outdoor living solutions, sunroom roof panels are a popular choice for enhancing spaces while providing protection from the elements. However, various alternatives exist that may better suit specific applications or budgets. This analysis will compare sunroom roof panels with two viable alternatives: traditional roofing systems and retractable awnings. Each option has unique benefits and considerations that can influence a B2B buyer’s decision.

| Comparison Aspect | Sunroom Roof Panels | Traditional Roofing Systems | Retractable Awnings |

|---|---|---|---|

| Performance | Excellent insulation and durability; designed for various weather conditions | Variable performance depending on materials; often less insulated | Provides shade but minimal insulation; suitable for sunny conditions |

| Cost | Moderate to high initial investment, but low long-term maintenance costs | Wide range; can be economical to luxurious based on materials | Generally lower initial costs, but may require replacement or maintenance |

| Ease of Implementation | Moderate complexity; professional installation recommended | Varies widely; some systems can be DIY, while others require contractors | Easy to install; often available as DIY kits |

| Maintenance | Low maintenance; resistant to weather damage | Can require regular maintenance and repairs | Moderate; fabric may need cleaning or replacement over time |

| Best Use Case | Ideal for permanent sunrooms, patios, and outdoor living spaces | Suitable for traditional homes and various applications | Best for temporary shade and protection in residential or commercial outdoor areas |

What Are the Pros and Cons of Traditional Roofing Systems?

Traditional roofing systems, such as shingles or metal roofs, provide a conventional approach to covering sunrooms or outdoor spaces. They can be cost-effective, especially for new constructions or renovations where the roof is being replaced. However, traditional roofs may lack the insulation and weather resistance found in specialized sunroom roof panels, potentially leading to higher energy costs or discomfort in extreme weather conditions. Additionally, traditional roofs may require more maintenance over time, especially in climates with significant weather fluctuations.

How Do Retractable Awnings Compare to Sunroom Roof Panels?

Retractable awnings offer a flexible solution for shade and protection from the sun. They are typically less expensive than sunroom roof panels and can be easily installed by the end-user. However, their performance is limited to providing shade rather than full protection from elements like rain or snow. While they can enhance outdoor comfort during sunny days, retractable awnings may not be ideal for permanent structures, as they do not offer the same level of insulation or durability against harsh weather conditions.

Choosing the Right Solution for Your Needs

When selecting the best roofing solution for sunrooms or outdoor spaces, B2B buyers should carefully consider their specific needs, including climate, budget, and intended use. Sunroom roof panels are an excellent investment for those seeking durability, insulation, and minimal maintenance, especially in areas prone to extreme weather. In contrast, traditional roofing systems may appeal to those looking for flexibility and lower upfront costs, while retractable awnings are best suited for temporary shade solutions. By weighing the pros and cons of each option, businesses can make informed decisions that align with their operational requirements and customer expectations.

Essential Technical Properties and Trade Terminology for sunroom roof panels

What Are the Key Technical Properties of Sunroom Roof Panels?

Understanding the technical specifications of sunroom roof panels is crucial for B2B buyers to make informed purchasing decisions. Below are some essential properties that impact performance, durability, and suitability for various applications.

1. Material Composition and Grade

Sunroom roof panels are typically constructed from materials like aluminum and high-density foam cores, often polystyrene or polyurethane. The grade of these materials affects their strength, insulation properties, and longevity. For instance, aluminum skins provide weather resistance, while the foam core ensures thermal insulation, making them ideal for energy-efficient designs. Buyers should evaluate material grades based on regional climate requirements, particularly for those in extreme weather areas.

2. Insulation Thickness

Insulation thickness is a critical specification, with common options ranging from 3 inches to 6 inches. Thicker panels offer better thermal resistance, reducing heating and cooling costs. This is especially important in regions with significant temperature fluctuations. B2B buyers must consider local building codes and energy efficiency standards when selecting the appropriate thickness to ensure compliance and optimal performance.

3. Load-Bearing Capacity

The load-bearing capacity of sunroom roof panels is vital, particularly in areas prone to heavy snow or high winds. Manufacturers often provide specifications indicating the maximum load the panels can support, which is essential for structural integrity. Buyers should seek panels that meet or exceed local building codes to guarantee safety and durability in their specific environments.

4. Weather Resistance Ratings

Weather resistance ratings encompass a panel’s ability to withstand environmental factors such as UV exposure, moisture, and wind. Panels with high weather resistance ratings reduce the risk of degradation over time, making them a wise investment for long-term use. B2B buyers should inquire about these ratings to ensure that the products meet the expected performance standards in their respective climates.

5. Color and Finish Options

Aesthetic appeal can influence buyer decisions, especially in the residential market. Sunroom roof panels come in various colors and finishes, such as baked-on enamel or protective coatings. These options not only enhance the visual aspect but also contribute to the panel’s durability and maintenance needs. Buyers should consider their design preferences and the potential need for future maintenance when selecting colors and finishes.

What Are Common Trade Terms Related to Sunroom Roof Panels?

Familiarity with industry jargon can enhance communication and negotiation processes in the B2B marketplace. Here are several common terms that buyers should understand.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of sunroom roof panels, buyers may deal with OEMs for customized solutions tailored to specific project needs. Understanding OEM relationships can provide insights into product quality and sourcing.

2. MOQ (Minimum Order Quantity)

MOQ denotes the minimum quantity that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cost structures. Buyers should assess their project requirements against the MOQ to ensure they are making financially sound decisions.

3. RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers. It typically includes detailed specifications of the required products, including sizes, materials, and quantities. Crafting a comprehensive RFQ can help buyers compare offers and negotiate better terms.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of sellers and buyers in international transactions. They outline aspects such as shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers engaging in cross-border purchases of sunroom roof panels, ensuring clarity in logistics and delivery responsibilities.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. This term is significant for project timelines, as longer lead times can delay construction schedules. Buyers should inquire about lead times during the procurement process to align their project schedules accordingly.

By grasping these technical properties and trade terminologies, B2B buyers can make well-informed decisions that align with their project requirements and business goals.

Navigating Market Dynamics and Sourcing Trends in the sunroom roof panels Sector

What Are the Key Trends Shaping the Sunroom Roof Panels Market?

The global sunroom roof panels market is experiencing notable growth, driven by increasing consumer demand for outdoor living spaces and energy-efficient solutions. Factors such as rising disposable incomes in emerging markets, particularly in Africa, South America, and the Middle East, are propelling investments in residential construction and renovation. B2B buyers should note that the sunroom roof panels sector is increasingly influenced by technological advancements in materials, such as insulated aluminum and structural insulated panels (SIPs), which offer improved thermal performance and durability.

Emerging trends include the rise of modular and prefabricated solutions, which streamline installation processes and reduce labor costs. These innovations are particularly appealing to international buyers seeking efficiency in project execution. Additionally, the shift towards DIY installations is gaining traction, allowing businesses to cater to a growing segment of cost-conscious consumers who prefer hands-on approaches to home improvement.

Furthermore, sustainability is becoming a central theme in sourcing decisions. Buyers are increasingly prioritizing products that demonstrate a commitment to eco-friendly practices, such as the use of recycled materials and energy-efficient designs. As regulatory frameworks in various regions tighten around building standards, B2B buyers must stay abreast of compliance requirements to avoid penalties and ensure smooth project execution.

How Is Sustainability Influencing the Sourcing of Sunroom Roof Panels?

Sustainability is a critical factor in the sourcing of sunroom roof panels, with buyers increasingly focusing on the environmental impact of their materials. The construction industry is under pressure to reduce carbon footprints, leading to a growing emphasis on using sustainable and ethically sourced materials. B2B buyers should actively seek suppliers who provide transparency in their supply chains and can demonstrate compliance with environmental standards.

The use of green certifications, such as LEED (Leadership in Energy and Environmental Design) and FSC (Forest Stewardship Council), is becoming more prevalent. These certifications not only assure buyers of the environmental integrity of the products but also enhance their marketability. Buyers looking for sunroom roof panels should inquire about the sustainability credentials of their suppliers and the materials used in their products.

Moreover, the demand for energy-efficient roofing solutions is on the rise, with many buyers looking for panels that minimize heat transfer, thereby reducing heating and cooling costs. Innovations like insulated roof systems that incorporate high-performance foam cores are gaining popularity, as they meet both energy efficiency and structural integrity requirements. Sourcing from manufacturers committed to sustainable practices not only aligns with global sustainability goals but also positions businesses favorably in an increasingly eco-conscious market.

How Has the Sunroom Roof Panels Industry Evolved Over Time?

The sunroom roof panels industry has evolved significantly over the past few decades, transitioning from traditional materials like wood and glass to advanced composite solutions that offer superior performance and longevity. Initially, the market was dominated by basic aluminum and single-pane glass structures, which often fell short in terms of insulation and durability.

With the advent of modern technologies, manufacturers began introducing insulated panels, such as structural insulated panels (SIPs) and modular designs, which have revolutionized the sector. These innovations provide enhanced thermal performance, allowing for year-round use of sunrooms in various climates. The introduction of prefabricated solutions has also simplified the installation process, making it accessible to a broader range of consumers, including those interested in DIY projects.

As environmental concerns have gained prominence, the industry has shifted towards more sustainable practices, incorporating recycled materials and energy-efficient designs into their offerings. This evolution reflects a broader trend within the construction industry, where sustainability and efficiency are increasingly prioritized by both consumers and businesses alike.

Frequently Asked Questions (FAQs) for B2B Buyers of sunroom roof panels

-

How do I select the right sunroom roof panel for my climate?

Choosing the right sunroom roof panel depends largely on your local climate conditions. For regions with heavy snowfall, opt for thicker panels (4” or 6”) that can withstand substantial weight and provide excellent insulation. In hotter climates, prioritize panels with UV protection and energy-efficient designs to minimize heat transfer. Always consult local building codes and consider suppliers with products specifically engineered for your area’s weather patterns to ensure durability and performance. -

What are the key features to look for in insulated roof panels?

When sourcing insulated roof panels, consider features such as thickness, core material, and structural integrity. Panels should have a high-density foam core for superior insulation and energy efficiency. Additionally, look for products that offer a maintenance-free finish and weather-resistant properties. A built-in gutter system can also enhance drainage and prevent water accumulation. Lastly, ensure that panels meet international building codes for safety and compliance. -

What customization options are available for sunroom roof panels?

Many manufacturers offer customization options for sunroom roof panels, including thickness, color, and additional features like skylights or fan beams. You can often choose from various core materials to enhance insulation based on your specific climate needs. Additionally, some suppliers allow for bespoke sizes to fit unique architectural designs. Discuss your requirements with potential suppliers to explore their customization capabilities and ensure your panels meet your project specifications. -

What is the typical minimum order quantity (MOQ) for sunroom roof panels?

The minimum order quantity (MOQ) for sunroom roof panels varies by supplier, typically ranging from a few panels to full container loads. For smaller projects, some manufacturers may offer lower MOQs or allow for mixed orders. However, to negotiate better pricing and terms, consider bulk purchases. Always clarify MOQ details upfront and explore options with multiple suppliers to find the best fit for your business needs. -

How can I ensure the quality of the sunroom roof panels I purchase?

To ensure the quality of sunroom roof panels, start by vetting suppliers through reviews and testimonials from other B2B buyers. Request certifications that demonstrate compliance with international standards and local building codes. Additionally, inquire about the manufacturing process, materials used, and warranty policies. If possible, request product samples to assess quality firsthand before placing a bulk order, ensuring the panels meet your durability and performance expectations. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary significantly among international suppliers. Common options include upfront payment, partial payment upon order confirmation, and the balance upon delivery. Some suppliers may also offer credit terms, especially for established business relationships. Always clarify payment terms in your purchase agreement and consider using secure payment methods, such as letters of credit or escrow services, to mitigate risks in international transactions. -

What logistics considerations should I keep in mind when importing sunroom roof panels?

When importing sunroom roof panels, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with your destination country to handle shipping and customs clearance efficiently. Be aware of tariffs and import duties that may apply, as these can significantly impact overall costs. Additionally, ensure that your supplier provides proper documentation for a smooth import process. -

How can I find reliable suppliers for sunroom roof panels?

To find reliable suppliers for sunroom roof panels, start by researching industry directories, trade shows, and online marketplaces. Attend construction and building expos to network with manufacturers and distributors. Utilize platforms like LinkedIn to connect with industry professionals and request recommendations. Additionally, consider joining trade associations that focus on building materials, as they often have member directories and resources to assist in finding reputable suppliers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Sunroom Roof Panels Manufacturers & Suppliers List

1. Craft-Bilt – PanelCraft™ Insulated Roof Panels

Domain: craft-bilt.com

Registered: 2010 (15 years)

Introduction: PanelCraft™ Insulated Roof Panels are designed for patio covers and sunrooms, featuring two aluminum skins bonded to a stabilizing core material for strength. They provide protection from sun, rain, and snow, making them ideal for outdoor gatherings. The panels are maintenance-free and come in three thicknesses: 3″, 4½”, and 6″, with spans of up to 18 feet. They are made with ASTM 3105 alloy alumi…

2. OMEGA – Modular Sunrooms & Insulated Roof Panels

Domain: homeporchandpatiokits.com

Registered: 2016 (9 years)

Introduction: OMEGA Modular Sunrooms | Modular Insulated Roof Panels | DIY Project | Aluminum Patio Covers | Screening Systems | Modular Walls | Modular Sunrooms | Screened Enclosures | Retractable Screens | Window Awnings | Four Season DIY Sunrooms | Insulated Pre-Fab Patio Enclosures | Made in U.S.A. | High quality 4″ insulated aluminum wall system | Patented roof-lock WeatherGuard insulated roof system | Roo…

3. Titansunrooms – Gable Roofing Essentials

Domain: titansunrooms.com

Registered: 2010 (15 years)

Introduction: The text discusses various types of roofing materials for sunrooms, highlighting the following key details: 1. **Gable Roofing**: – Dual sloping panels and central ridge. – Provides excellent ventilation and efficient water runoff. – Aesthetic harmony with various home architectures. – Facilitates optimal air circulation and snow/water shedding. – Internal cathedral ceiling enhances spaciousness. …

4. Dulando – Structall Snap-N-Lock Insulated Panels

Domain: dulandoscreen.com

Registered: 1997 (28 years)

Introduction: Insulated aluminum roof panels recommended for sunrooms, specifically Structall Snap-N-Lock Insulated Panels. Features include:

– Durability: Resists high winds, condensation, and pests.

– Affordability: Lightweight, lower material costs, quick installation, reduced labor costs.

– Flexibility: Available in various sizes to fit different floor plans.

– Aesthetics: Range of colors and textures, …

5. Aluminum Porch – Insulated Roof Panels

Domain: aluminumporch.net

Registered: 2014 (11 years)

Introduction: Insulated Roof Panels (4ft Width) available in white color. Customization and pricing based on linear feet measurement. SKU: Insulated Roof Panels. Availability: 99994 in stock.

6. Sunroom California – WeatherGuard™ Roof System

Domain: sunroomcalifornia.com

Registered: 2015 (10 years)

Introduction: Roof Materials for Patio Rooms & Sunrooms:

– WeatherGuard™ Roof System: Solid roof system for patio rooms, gabled rooms, and patio covers.

– Construction: Solid foam and aluminum for insulation, durability, and aesthetics.

– Widths: Available in 3″, 4″, and 6″ to meet local building codes.

– Insulation: Superior insulation against heat and cold.

– Surface: Durable aluminum finish (white) that…

7. Gaco – Roofing Silicone

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Gaco roofing silicone, Tremco products, Sherwin Williams similar product, MFM peel and seal roll roofing, fiberglass/resin roofing kits.

8. Lifetime Enclosures – Durable Roof Solutions for Sunrooms

Domain: lifetimeenclosures.com

Registered: 1997 (28 years)

Introduction: The guide discusses the importance of a durable roof for sunrooms, highlighting features such as weather protection, energy efficiency, and structural support. It outlines three popular roof types: Gable Roofs (classic look, excellent ventilation), Hip Roofs (modern design, superior wind resistance), and Single-Slope Roofs (cost-effective, minimalist). It emphasizes the need to choose the right an…

Strategic Sourcing Conclusion and Outlook for sunroom roof panels

What Are the Key Takeaways for Sourcing Sunroom Roof Panels?

In the competitive landscape of sunroom roof panels, strategic sourcing emerges as a crucial factor for international B2B buyers. Understanding the diverse applications and robust features of products like insulated aluminum panels can enhance decision-making processes. Buyers should focus on the durability, energy efficiency, and low maintenance requirements that modern panels offer, ensuring that they meet local building codes and withstand varying climates.

How Can Strategic Sourcing Enhance Your Business Operations?

Investing in high-quality sunroom roof panels not only improves customer satisfaction but also reduces long-term costs associated with repairs and replacements. By partnering with reputable manufacturers, businesses can secure reliable supply chains that facilitate timely deliveries and competitive pricing. This strategic approach allows for better inventory management and can significantly influence project timelines.

What’s Next for International B2B Buyers in the Sunroom Market?

As the demand for outdoor living spaces grows, so does the opportunity for international buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Now is the time to explore innovative sunroom solutions that align with market trends. Engage with trusted suppliers, leverage technological advancements, and expand your offerings to capture the evolving needs of your clientele. Make your move today to ensure your business thrives in this dynamic market.