How to Source Pz27 Sheet Pile Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for pz27 sheet pile

In the complex landscape of global construction and infrastructure development, sourcing high-quality PZ27 sheet pile presents a significant challenge for international B2B buyers. The demand for robust, reliable sheet piling solutions is ever-increasing, driven by diverse applications ranging from marine construction to land reclamation projects. This guide serves as an essential resource for understanding the intricacies of the PZ27 sheet pile market, equipping buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Germany—with the insights needed to make informed purchasing decisions.

Throughout this comprehensive guide, we delve into the specifications and applications of PZ27 sheet piles, highlighting their advantages in various construction scenarios. We also address critical aspects of supplier vetting, ensuring that buyers can identify reputable manufacturers and distributors who provide quality materials. Additionally, we explore cost considerations and market trends, empowering buyers to navigate pricing structures effectively. By synthesizing this information, our guide aims to simplify the decision-making process, enabling buyers to select the right products that meet their project requirements while optimizing their procurement strategies. Whether you are looking to enhance your supply chain or ensure project success, this guide is your key to unlocking the potential of PZ27 sheet piles in your construction endeavors.

Understanding pz27 sheet pile Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PZ27 Standard | 18″ width, 12.1″ height, 0.375″ flange and web thickness | Marine construction, retaining walls | Pros: High strength, versatile. Cons: Can be costly compared to alternatives. |

| PZ27 with Coating | Standard PZ27 with additional protective coating | Corrosive environments, coastal areas | Pros: Enhanced durability. Cons: Higher initial investment. |

| PZ27 Used/Surplus | Previously used PZ27 sheets available at lower prices | Cost-sensitive projects | Pros: Economical option. Cons: Potential for wear and reduced lifespan. |

| PZ27 with Splice | Features for easy splicing to extend lengths | Large-scale projects | Pros: Flexible for various applications. Cons: Requires precise installation. |

| PZ27 Composite | Combination of PZ27 with other materials for specific needs | Specialty applications | Pros: Tailored solutions. Cons: May complicate procurement and installation. |

What Are the Key Characteristics of PZ27 Standard Sheet Piles?

The PZ27 Standard sheet pile is characterized by its robust dimensions—18 inches in width and 12.1 inches in height, with a flange and web thickness of 0.375 inches. This standardization makes it a preferred choice for marine construction and retaining walls, where high structural integrity is essential. Buyers should consider the weight and the moment of inertia, which contribute to its effectiveness in resisting lateral pressures. While its high strength makes it suitable for demanding applications, potential buyers should be aware of its cost relative to other sheet pile options.

How Does PZ27 with Coating Enhance Durability?

PZ27 sheet piles can be enhanced with protective coatings, making them particularly suitable for use in corrosive environments, such as coastal areas. The additional coating provides a barrier against environmental factors that can lead to rust and degradation over time. This variation is ideal for projects where longevity is crucial, despite the higher initial investment. When considering this option, buyers must evaluate the cost-benefit balance of longer service life against the upfront costs.

What Are the Advantages of Choosing Used or Surplus PZ27 Sheet Piles?

Used or surplus PZ27 sheet piles present a cost-effective solution for budget-conscious projects. These piles are typically available at significantly lower prices than new options, making them attractive for large-scale applications where budget constraints are critical. However, buyers should be cautious regarding the condition and potential wear of used materials, which may affect their lifespan and performance. Ensuring thorough inspection and certification can mitigate some risks associated with purchasing used sheet piles.

Why Consider PZ27 with Splice Features for Large Projects?

PZ27 sheet piles equipped with splice features allow for easy extension, making them particularly beneficial for large-scale projects that require variable lengths. This flexibility can streamline installation processes and reduce material waste. However, precise installation is crucial to maintain structural integrity and performance. Buyers should ensure that their installation teams are trained in handling these specialized features to maximize their benefits.

What Are the Benefits of PZ27 Composite Solutions?

Composite PZ27 sheet piles combine the standard design with other materials to meet specific engineering requirements. This customization can provide tailored solutions for unique project challenges, such as enhanced load-bearing capacity or resistance to specific environmental conditions. While composite solutions can offer significant advantages, they may complicate procurement and installation processes. Buyers should assess their project needs and consult with manufacturers to understand the implications of using composite materials effectively.

Key Industrial Applications of pz27 sheet pile

| Industry/Sector | Specific Application of pz27 sheet pile | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine Construction | Waterfront structures, including docks and seawalls | Provides durability against water pressure and erosion | Ensure compliance with local marine regulations and standards |

| Civil Engineering | Retaining walls for soil stabilization | Increases safety by preventing soil erosion and collapse | Assess soil conditions and load requirements for optimal design |

| Environmental Projects | Flood control systems | Mitigates flood risks and protects infrastructure | Evaluate environmental impact and sustainability options |

| Transportation Infrastructure | Noise barriers along highways | Enhances community well-being by reducing noise pollution | Consider aesthetic options and local community preferences |

| Industrial Facilities | Temporary site enclosures for construction projects | Secures construction sites and protects materials | Ensure quick delivery and adaptability to various site conditions |

How is pz27 Sheet Pile Used in Marine Construction?

In marine construction, pz27 sheet piles are essential for building robust waterfront structures such as docks, seawalls, and piers. Their unique ball and socket interlock design allows for a strong, flexible connection, making them ideal for resisting the lateral pressures exerted by water. By offering exceptional durability against harsh marine environments, these sheet piles are a preferred choice for projects in regions like Saudi Arabia and South America, where coastal erosion is a significant concern. Buyers should ensure that the selected piles meet local marine engineering standards to guarantee long-lasting performance.

What Role Does pz27 Sheet Pile Play in Civil Engineering?

Civil engineering projects frequently utilize pz27 sheet piles for constructing retaining walls that stabilize soil and prevent erosion. These applications are critical in urban areas where land is at a premium, and safety is paramount. The strength and rigidity of pz27 sheets help maintain soil integrity, especially in regions with challenging geological conditions, such as parts of Europe. Buyers must assess local soil conditions and the anticipated loads on the retaining walls to ensure that the chosen sheet piles meet structural requirements.

How Can pz27 Sheet Pile Aid Environmental Projects?

In environmental projects, pz27 sheet piles are used to create effective flood control systems that protect communities from water damage. Their ability to form a barrier against rising water levels makes them invaluable in regions prone to flooding, particularly in parts of Africa and the Middle East. By investing in these sheet piles, businesses can enhance their resilience against climate impacts while safeguarding infrastructure. It is crucial for buyers to consider the environmental impact assessments and sustainability practices when sourcing these materials.

How Do pz27 Sheet Piles Contribute to Transportation Infrastructure?

Transportation infrastructure projects, such as the construction of noise barriers along highways, leverage pz27 sheet piles to mitigate noise pollution. This application not only improves community well-being but also complies with increasing regulatory requirements for noise reduction in urban planning. In Europe, where environmental regulations are stringent, using pz27 sheet piles can help contractors meet compliance standards effectively. Buyers should consider aesthetic options for the noise barriers to address community preferences while ensuring structural integrity.

What Are the Benefits of Using pz27 Sheet Pile for Industrial Facilities?

In industrial settings, pz27 sheet piles serve as temporary site enclosures during construction projects, providing security and protecting materials from theft and weather. Their ease of installation and adaptability to various site conditions make them a cost-effective solution for contractors. For buyers in developing regions in Africa and South America, timely delivery and the ability to customize sheet piles to specific project needs are critical factors to consider when sourcing these materials.

3 Common User Pain Points for ‘pz27 sheet pile’ & Their Solutions

Scenario 1: Sourcing Quality PZ27 Sheet Pile at Competitive Prices

The Problem: B2B buyers often face challenges when sourcing PZ27 sheet piles, particularly regarding the quality of materials and competitive pricing. In regions like Africa and South America, where the construction market is growing, buyers may encounter suppliers offering subpar products that do not meet industry standards. This can lead to increased project costs due to rework or replacements, not to mention potential delays that can impact project timelines.

The Solution: To ensure that you source high-quality PZ27 sheet piles at competitive prices, it’s vital to establish relationships with reputable suppliers who specialize in structural steel. Look for suppliers with extensive experience in the industry and positive reviews from previous clients. Engage in thorough market research to compare pricing and product specifications, and consider requesting samples before making a bulk purchase. Additionally, leveraging platforms that facilitate the buying and selling of used or surplus materials can provide significant cost savings. For instance, platforms like Eiffel Trading offer surplus PZ27 sheet piles that are still in good condition, allowing you to acquire necessary materials without compromising quality.

Scenario 2: Managing Logistics and Delivery Challenges

The Problem: Logistics can be a significant hurdle for B2B buyers dealing with PZ27 sheet piles, especially in regions with underdeveloped transport infrastructure. Buyers may struggle with timely deliveries, resulting in project delays. The size and weight of PZ27 sheet piles further complicate transportation, as special handling and equipment are often required for safe and efficient delivery.

The Solution: To mitigate logistics challenges, buyers should partner with suppliers who have established logistics networks and expertise in transporting heavy materials. Discuss delivery timelines and logistics options upfront to ensure that your needs align with their capabilities. Additionally, consider local suppliers to reduce transportation distance and costs. If using an international supplier, ensure that they have experience with customs and can navigate any regulatory hurdles to prevent delays. Employing a logistics management platform can also streamline the process, allowing for real-time tracking of shipments and better communication with all parties involved.

Scenario 3: Ensuring Proper Installation and Compliance with Local Regulations

The Problem: Another common pain point is the proper installation of PZ27 sheet piles to ensure structural integrity and compliance with local regulations. Many buyers lack the technical knowledge required for effective installation, which can lead to issues such as misalignment or inadequate support. Additionally, navigating local building codes and regulations can be complex, particularly for international projects.

The Solution: To address installation and compliance challenges, B2B buyers should invest in training or hiring experienced contractors who specialize in sheet pile installation. It is essential to collaborate with engineers who understand the local regulations and can provide guidance on compliance. Before installation, conduct a site assessment to evaluate soil conditions and other factors that may affect the installation process. Additionally, consider utilizing installation services offered by your supplier, as they often have the expertise and equipment necessary to ensure proper installation. Finally, maintaining open communication with local authorities can help clarify regulations and ensure that your project adheres to all required standards, preventing costly fines and project delays.

Strategic Material Selection Guide for pz27 sheet pile

What Are the Key Materials Used for PZ27 Sheet Pile?

In the construction and civil engineering sectors, PZ27 sheet piles are predominantly made from various steel grades and coatings. Understanding the properties, advantages, and limitations of these materials is crucial for international B2B buyers, especially those operating in diverse environments such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Carbon Steel for PZ27 Sheet Pile?

Carbon steel is the most common material for PZ27 sheet piles due to its strength and versatility. Typically, it has a yield strength of around 250 MPa, making it suitable for heavy-duty applications. Carbon steel exhibits excellent mechanical properties, including high tensile strength and good ductility. However, it is susceptible to corrosion, which can be a significant drawback in marine or humid environments.

Pros: The primary advantage of carbon steel is its cost-effectiveness and ease of manufacturing. It can be readily sourced and fabricated into various shapes, including the PZ27 profile.

Cons: The main limitation is its vulnerability to corrosion, necessitating protective coatings or treatments, especially in coastal or chemically aggressive environments.

Impact on Application: Carbon steel PZ27 sheet piles are widely used in retaining walls, cofferdams, and marine structures. Buyers must consider local environmental conditions to determine the need for additional protective measures.

How Do Stainless Steel Variants Enhance PZ27 Sheet Pile Performance?

Stainless steel is another option for PZ27 sheet piles, particularly in environments where corrosion resistance is paramount. Stainless steel provides superior performance with a yield strength that can exceed 500 MPa, making it suitable for high-stress applications. Its inherent corrosion resistance allows for longer service life without the need for additional protective coatings.

Pros: The key advantage of stainless steel is its durability and low maintenance requirements, which can lead to lower lifecycle costs.

Cons: However, stainless steel is significantly more expensive than carbon steel, which can be a barrier for budget-conscious projects.

Impact on Application: Stainless steel PZ27 sheet piles are ideal for marine applications, chemical plants, and other environments where corrosion is a critical concern. Compliance with international standards such as ASTM or DIN for stainless steel grades is essential for buyers.

What Role Do Coatings Play in PZ27 Sheet Pile Applications?

Coated steel sheet piles, including those treated with galvanization or epoxy coatings, are designed to enhance the corrosion resistance of carbon steel. These coatings can significantly extend the lifespan of PZ27 sheet piles in harsh environments.

Pros: The primary advantage of coated PZ27 sheet piles is their enhanced durability and resistance to environmental degradation, making them suitable for a variety of applications.

Cons: The downside is that the coating can be damaged during installation, which may expose the underlying steel to corrosion risks if not properly managed.

Impact on Application: Buyers should consider the local conditions when selecting coated PZ27 sheet piles, ensuring that the coating type aligns with environmental exposure. Compliance with relevant coating standards is also critical.

How Do Composite Materials Impact PZ27 Sheet Pile Choices?

Composite materials, such as fiber-reinforced polymers (FRP), are emerging as alternatives for PZ27 sheet piles. These materials offer high strength-to-weight ratios and excellent corrosion resistance.

Pros: The main advantage of composites is their lightweight nature, which can reduce transportation and installation costs. They also offer superior resistance to chemical and environmental degradation.

Cons: However, composites are generally more expensive and may not provide the same load-bearing capacity as traditional steel options.

Impact on Application: Composite PZ27 sheet piles are suitable for specialized applications, such as in chemical processing or marine environments where traditional materials may fail. Buyers must ensure that the composite materials meet relevant engineering standards.

Summary of Material Selection for PZ27 Sheet Pile

| Material | Typical Use Case for PZ27 Sheet Pile | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Retaining walls, cofferdams, marine structures | Cost-effective and easy to fabricate | Susceptible to corrosion | Low |

| Stainless Steel | Marine applications, chemical plants | Superior corrosion resistance | Higher initial cost | High |

| Coated Steel | Harsh environmental conditions | Enhanced durability and lifespan | Potential for damage during installation | Medium |

| Composite Materials | Chemical processing, specialized environments | Lightweight and excellent corrosion resistance | Higher cost and variable load capacity | High |

This strategic material selection guide aims to equip international B2B buyers with the necessary insights to make informed decisions regarding PZ27 sheet pile materials, ensuring compliance with local standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for pz27 sheet pile

What Are the Key Stages in the Manufacturing Process of PZ27 Sheet Pile?

The manufacturing of PZ27 sheet piles involves several critical stages designed to ensure structural integrity and performance. Understanding these stages can help B2B buyers identify reliable suppliers and assess the quality of the products being offered.

Material Preparation: How Is Raw Material Sourced and Processed?

The process begins with the selection of high-quality steel, typically sourced from reputable mills. This steel is often pre-treated to remove impurities and enhance its properties. The steel is then cut into manageable sizes, which facilitates further processing. Buyers should inquire about the origin of the steel and whether it meets international standards, as the quality of raw materials directly impacts the final product.

Forming: What Techniques Are Used to Shape PZ27 Sheet Piles?

Once the material is prepared, it undergoes hot rolling, a critical process that shapes the steel into the desired PZ27 profile. During hot rolling, the steel is heated to high temperatures and passed through rollers, which form its distinctive Z shape. This stage not only shapes the pile but also refines its mechanical properties, ensuring it can withstand lateral pressures from soil and water.

Advanced techniques such as controlled rolling may be employed to fine-tune the mechanical properties and dimensions, providing additional strength and flexibility. Buyers should verify if the manufacturer uses modern rolling technologies that comply with industry best practices.

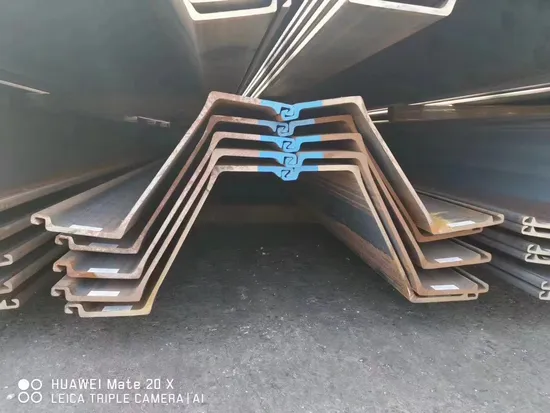

Assembly: How Are PZ27 Sheet Piles Interlocked?

The PZ27 sheet piles feature a mechanical “ball and socket” interlock system. This design allows for easy assembly on-site and provides a robust connection that enhances the overall stability of the structure. During assembly, manufacturers must ensure that the interlocks are precisely formed to avoid gaps that could compromise the structural integrity.

Quality control during this stage is crucial, as even minor defects can lead to significant issues during installation. Buyers should ask about the manufacturer’s assembly processes and any standards they adhere to, ensuring that the interlocks will perform reliably in demanding conditions.

Finishing: What Surface Treatments Are Applied?

After forming and assembly, the PZ27 sheet piles undergo various finishing processes, including surface treatment to enhance corrosion resistance. Common treatments include galvanization or the application of protective coatings. These treatments are essential for extending the lifespan of the piles, particularly in harsh environments such as marine or coastal applications.

B2B buyers should pay close attention to the types of finishing processes used and ask for certification that these treatments meet relevant international standards. This can prevent premature corrosion and ensure the longevity of the investment.

What Are the Quality Control Measures for PZ27 Sheet Pile?

Quality assurance is vital in the manufacturing of PZ27 sheet piles, ensuring that they meet both performance and safety standards. A robust QC system not only ensures product quality but also builds trust with B2B buyers.

Which International Standards Are Relevant for PZ27 Sheet Piles?

Manufacturers of PZ27 sheet piles typically adhere to various international quality standards, including ISO 9001, which outlines requirements for a quality management system. Additionally, CE marking may be required for products sold within the European market, indicating compliance with EU safety and environmental regulations.

For projects in specific regions, such as Saudi Arabia or Germany, local standards and codes may also apply. Buyers should request documentation demonstrating compliance with these standards and consider the regulatory landscape of their respective countries.

What Quality Control Checkpoints Are Commonly Implemented?

Quality control during the manufacturing of PZ27 sheet piles involves several checkpoints:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, various tests are performed to monitor the quality of the products at different stages. This includes checking the dimensional accuracy and mechanical properties.

- Final Quality Control (FQC): Before shipment, finished products undergo final inspection to ensure they meet all specifications and standards. This may involve destructive and non-destructive testing methods.

B2B buyers should inquire about the specific QC procedures implemented by potential suppliers, as these measures can significantly influence the reliability and safety of the PZ27 sheet piles.

How Can Buyers Verify Supplier Quality Control Practices?

To ensure that a supplier adheres to high-quality standards, B2B buyers can take several actions:

- Conduct Supplier Audits: Regular audits of suppliers can help verify their manufacturing processes and quality control measures. This includes assessing their facilities, equipment, and adherence to standards.

- Request Quality Reports: Suppliers should be willing to provide quality assurance documentation, including test reports and certificates of compliance with relevant standards.

- Engage Third-Party Inspection Services: For added assurance, buyers may choose to engage third-party inspection agencies to evaluate the quality of the products before shipment.

What Are the Considerations for International Buyers in Terms of Quality Certification?

For B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality certification is crucial. Each region may have specific requirements and expectations regarding product quality and compliance.

In Europe, for instance, the CE marking indicates compliance with EU regulations, while in the Middle East, local standards may require additional certifications. Buyers should familiarize themselves with the specific requirements of their target market and ensure that suppliers can provide the necessary documentation.

By thoroughly understanding the manufacturing processes and quality control measures associated with PZ27 sheet piles, international B2B buyers can make informed decisions that enhance their project outcomes and ensure the longevity of their investments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pz27 sheet pile’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure PZ27 sheet piles, a critical component for various construction and engineering projects. The PZ27 sheet pile is known for its robust design, making it suitable for applications that require effective soil and water retention. Following this checklist will help you navigate the procurement process efficiently, ensuring you select the right product from reliable suppliers.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the PZ27 sheet piles meet your project’s requirements. Consider factors such as length, thickness, weight, and interlocking capabilities.

– Key details to specify:

– Length options (typically ranging from 12 to 40 feet).

– Required weights (approximately 40.5 lbs/ft).

– Any specific coating requirements for corrosion resistance.

Step 2: Research Market Prices

Understanding the market price for PZ27 sheet piles is essential for making informed purchasing decisions. Prices can vary significantly based on location, supplier, and condition (new vs. used).

– Tips for pricing research:

– Compare prices from multiple suppliers, including both new and surplus options.

– Consider additional costs such as delivery and handling to get a complete picture of total expenditure.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Focus on:

– Supplier’s experience in providing PZ27 sheet piles specifically.

– Customer testimonials and case studies that highlight successful projects.

– Certifications and compliance with international quality standards.

Step 4: Assess Product Quality

Quality assurance is non-negotiable when sourcing PZ27 sheet piles. Verify that the products meet industry standards for strength and durability.

– What to check:

– Certifications such as ISO or ASTM that validate product quality.

– Availability of test reports or inspection certificates for the sheet piles.

Step 5: Negotiate Terms and Conditions

Effective negotiation can lead to better pricing and favorable terms. Discuss payment options, delivery timelines, and warranty provisions.

– Important considerations:

– Payment terms (e.g., upfront, net 30).

– Delivery schedules and potential penalties for delays.

– Warranty duration and coverage details.

Step 6: Confirm Logistics and Delivery

Logistics play a critical role in the timely completion of your projects. Confirm the delivery methods and ensure they align with your project timeline.

– Key logistics factors:

– Shipping options (land, sea, or air) and their associated costs.

– Responsibilities for unloading and site delivery.

– Customs clearance processes if sourcing internationally.

Step 7: Finalize the Purchase Agreement

Once all details are settled, draft a purchase agreement that outlines all terms discussed. This document serves as a legal reference to protect both parties.

– What to include:

– Detailed specifications of the PZ27 sheet piles.

– Payment terms, delivery schedules, and penalties for non-compliance.

– Confidentiality clauses if necessary to protect sensitive information.

By following this checklist, B2B buyers can streamline the procurement of PZ27 sheet piles, ensuring a successful and efficient purchasing experience.

Comprehensive Cost and Pricing Analysis for pz27 sheet pile Sourcing

Analyzing the cost structure and pricing for PZ27 sheet piles is essential for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe, including countries such as Saudi Arabia and Germany. Understanding the various cost components and price influencers can lead to more informed purchasing decisions.

What Are the Key Cost Components of PZ27 Sheet Piles?

-

Materials: The primary component of the cost structure is the raw steel used to manufacture PZ27 sheet piles. Prices for steel can fluctuate based on global market conditions, tariffs, and local availability. As of recent listings, the price for used PZ27 sheet piles ranges from approximately $0.48 to $0.68 per pound, depending on the condition and length of the piles.

-

Labor: Labor costs associated with manufacturing, welding, and assembly can significantly impact the final price. Skilled labor is often required for the precise fabrication of sheet piles, which may vary in cost depending on the region and prevailing wage rates.

-

Manufacturing Overhead: This includes indirect costs such as utilities, facility maintenance, and administrative expenses that contribute to the overall production of PZ27 sheet piles. Efficient manufacturing processes can help keep these costs low.

-

Tooling: The cost of specialized tools and machinery used in the production of sheet piles should also be considered. Investment in modern equipment can improve efficiency and quality, potentially lowering long-term costs.

-

Quality Control (QC): Ensuring the structural integrity and compliance with international standards often involves rigorous quality control measures. This adds to the cost but is essential for preventing future liabilities and ensuring customer satisfaction.

-

Logistics: Shipping and transportation costs play a critical role in the total price, especially for international shipments. Factors such as distance, mode of transport, and local infrastructure can affect logistics costs significantly.

-

Margin: Suppliers typically add a margin to cover their risks and profit expectations, which can vary based on market demand and competition. Understanding this margin can help buyers negotiate better deals.

What Influences the Pricing of PZ27 Sheet Piles?

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to lower prices per unit due to economies of scale. Suppliers may offer discounts for larger orders, making it beneficial for buyers to consolidate their purchases.

-

Specifications and Customization: Custom requirements can increase costs. Buyers should clearly define specifications to avoid unnecessary expenses associated with changes or adjustments during production.

-

Materials and Quality Certifications: The quality of the steel and any certifications (such as ISO or ASTM standards) can influence pricing. Higher quality materials typically come at a premium but can offer better performance and longevity.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may charge more but can provide assurance regarding the material’s performance and compliance.

-

Incoterms: Understanding shipping terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for determining total landed costs. These terms dictate who bears the shipping risks and costs, impacting the overall price paid by the buyer.

What Are the Best Practices for Negotiating PZ27 Sheet Pile Prices?

-

Conduct Market Research: Buyers should familiarize themselves with current market prices and trends for PZ27 sheet piles. This knowledge empowers them during negotiations and helps identify fair pricing.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the long-term costs associated with installation, maintenance, and potential replacements. A higher upfront cost may be justified if it leads to lower long-term expenses.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing and service. Suppliers are often more willing to negotiate and provide favorable terms to repeat customers.

-

Be Clear About Requirements: Clearly outline project specifications and timelines to avoid misunderstandings that could lead to cost overruns or delays.

-

Leverage Volume: When possible, consolidate orders across multiple projects to meet minimum order quantities and secure bulk pricing.

In summary, a comprehensive understanding of the cost structure and pricing dynamics for PZ27 sheet piles can empower international B2B buyers to make informed purchasing decisions. By considering all cost components, price influencers, and negotiation strategies, buyers can enhance their procurement efficiency and value.

Alternatives Analysis: Comparing pz27 sheet pile With Other Solutions

Exploring Alternative Solutions to PZ27 Sheet Pile

When it comes to selecting the right materials for construction and civil engineering projects, PZ27 sheet piles are a popular choice due to their robust performance and versatility. However, various alternative solutions can also meet similar structural and environmental needs. This analysis compares PZ27 sheet piles with two viable alternatives: AZ sheet piles and concrete sheet piles, providing insights that can aid B2B buyers in making informed decisions.

| Comparison Aspect | PZ27 Sheet Pile | AZ Sheet Pile | Concrete Sheet Pile |

|---|---|---|---|

| Performance | High strength, excellent interlock | Good lateral resistance, lighter weight | High compressive strength, durable |

| Cost | Moderate initial cost | Generally lower cost | Higher initial cost |

| Ease of Implementation | Requires specialized equipment for driving | Easier to handle and install | Heavy and requires crane assistance |

| Maintenance | Low maintenance, corrosion-resistant | Moderate maintenance, can corrode | Low maintenance, very durable |

| Best Use Case | Marine and waterfront projects | Temporary structures, light applications | Permanent structures, deep foundations |

What Are the Advantages and Disadvantages of AZ Sheet Piles?

AZ sheet piles are a popular alternative to PZ27 due to their lighter weight and flexibility in various applications. They feature a similar interlocking mechanism but are often used in less demanding environments. Their lower cost makes them attractive for temporary structures or projects with budget constraints. However, while AZ sheet piles can perform well in lighter applications, they may not provide the same level of lateral resistance as PZ27 sheet piles in more demanding conditions, particularly in marine environments where soil and water pressures are significant.

Why Consider Concrete Sheet Piles?

Concrete sheet piles present another alternative that offers high compressive strength and durability. They are particularly effective in permanent structures and can handle heavy loads without significant deformation. Concrete piles are resistant to environmental factors like corrosion, which can be a concern with steel piles. However, the initial cost is typically higher, and the installation process can be more complex due to the weight of the concrete. Additionally, they often require cranes for installation, which can increase labor costs and project timelines.

How Should Buyers Choose the Right Solution?

For B2B buyers evaluating the best solution for their specific projects, several factors should guide their decision-making. The first consideration should be the project requirements, including load-bearing capacity, environmental conditions, and longevity. If the project demands high lateral resistance in challenging conditions, PZ27 sheet piles may be the best choice. On the other hand, if cost is a significant factor and the application is less demanding, AZ sheet piles might suffice. Finally, for projects that require a permanent, durable solution with high compressive strength, concrete sheet piles could be the most suitable option.

In conclusion, understanding the strengths and weaknesses of PZ27 sheet piles compared to alternatives like AZ and concrete sheet piles can empower buyers to make strategic decisions that align with their project needs, budget constraints, and long-term goals.

Essential Technical Properties and Trade Terminology for pz27 sheet pile

What Are the Key Technical Properties of PZ27 Sheet Pile?

PZ27 sheet piles are essential in construction and civil engineering, especially for retaining walls, cofferdams, and marine structures. Understanding their specifications can significantly impact project success.

-

Material Grade: PZ27 sheet piles are typically made from high-strength steel, often conforming to ASTM A572 or equivalent standards. The material grade is crucial as it determines the pile’s resistance to lateral pressures and environmental factors, ensuring durability and longevity in challenging conditions.

-

Dimensions and Weight: The PZ27 sheet pile has a nominal width of 18 inches and a height of 12 inches, with a wall thickness of 0.375 inches. It weighs approximately 40.5 lbs per foot. These specifications are vital for calculating load-bearing capacities and understanding handling requirements during transport and installation.

-

Section Modulus and Moment of Inertia: The section modulus of PZ27 is 30.2 in³/ft, while its moment of inertia is 184.20 in⁴. These measurements indicate the pile’s ability to resist bending and deflection under loads, making them critical for structural integrity in design calculations.

-

Interlocking Mechanism: PZ27 features a mechanical “ball and socket” interlock that allows for easy assembly and flexibility in alignment. This design enhances the efficiency of installation and ensures a tight seal against water and soil pressures, reducing the risk of failure in various applications.

-

Coating Area: The coating area for PZ27 is approximately 4.48 ft²/ft, which is important for corrosion protection strategies. Understanding the surface area helps in determining the quantity of protective coatings required, which can affect maintenance costs over the lifecycle of the structure.

-

Tolerance Levels: Tolerance specifications for PZ27 sheet piles are essential in ensuring that each pile meets quality and performance standards. Variations in thickness, width, and height can lead to complications during installation, affecting the overall stability of the project.

What Are Common Trade Terms Associated with PZ27 Sheet Pile?

Familiarity with industry jargon can enhance communication and streamline the procurement process in B2B transactions involving PZ27 sheet piles.

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products that may be marketed under another brand’s name. In the context of sheet piles, understanding OEM products can help buyers identify reliable sources and ensure consistent quality.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ for PZ27 sheet piles can influence purchasing decisions, especially for smaller projects or companies that may not require large quantities.

-

RFQ (Request for Quotation): An RFQ is a formal process used by buyers to request price quotes from suppliers. For international buyers, submitting an RFQ for PZ27 sheet piles can facilitate competitive pricing and help ensure the best value for their projects.

-

Incoterms (International Commercial Terms): These are a set of predefined commercial terms used in international trade. Understanding Incoterms relevant to the procurement of PZ27 sheet piles can clarify responsibilities regarding shipping, insurance, and delivery, helping buyers manage risks effectively.

-

Lead Time: This term refers to the amount of time it takes from placing an order until the product is delivered. For projects relying on PZ27 sheet piles, understanding lead times can aid in project planning and scheduling.

-

Surplus Inventory: This refers to excess stock that suppliers may sell at discounted rates. Buyers looking for PZ27 sheet piles might benefit from purchasing surplus inventory, potentially reducing costs while still acquiring quality materials.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions and enhance their procurement strategies when engaging with suppliers of PZ27 sheet piles.

Navigating Market Dynamics and Sourcing Trends in the pz27 sheet pile Sector

What Are the Key Market Dynamics Affecting PZ27 Sheet Pile Sourcing?

The global demand for PZ27 sheet piles is being shaped by several factors, including urbanization, infrastructural development, and environmental regulations. As countries in Africa, South America, the Middle East, and Europe invest in coastal defenses, flood management systems, and underground construction, the demand for durable and efficient sheet piling solutions is expected to rise. The PZ27 sheet pile, known for its robust interlocking design and structural integrity, has emerged as a preferred choice for many civil engineering projects.

Emerging technologies in sourcing and supply chain management are also influencing the PZ27 market. Digital platforms are streamlining procurement processes, allowing international buyers to access real-time inventory, pricing, and specifications. Additionally, advancements in logistics and transportation are enhancing the efficiency of delivering heavy materials like sheet piles to remote or challenging locations. Furthermore, the focus on sustainability is prompting suppliers to adopt eco-friendly practices, which can impact sourcing decisions for environmentally-conscious buyers.

How Is Sustainability Influencing PZ27 Sheet Pile Procurement?

Sustainability is becoming increasingly crucial in the procurement of PZ27 sheet piles, driven by both regulatory pressures and market expectations. The environmental impact of steel production and construction practices is under scrutiny, leading buyers to seek suppliers with transparent and ethical sourcing practices. This includes a focus on recycled materials and reducing the carbon footprint associated with manufacturing and transportation.

Buyers are also looking for certifications that demonstrate a commitment to sustainability. Green certifications, such as LEED (Leadership in Energy and Environmental Design), can enhance the credibility of projects utilizing PZ27 sheet piles. Additionally, suppliers that implement sustainable practices—like using energy-efficient production methods or offering recycled steel options—are likely to gain a competitive edge in the market. For B2B buyers, aligning with suppliers who prioritize sustainability not only meets regulatory demands but also appeals to increasingly eco-conscious end-users.

What Is the Historical Context Behind the PZ27 Sheet Pile’s Popularity?

The PZ27 sheet pile has evolved significantly since its introduction, becoming one of the most specified products in the sheet piling market. Initially developed for robust applications in marine and civil engineering, its design features—such as the mechanical ball-and-socket interlock—enable it to withstand extreme lateral pressures while providing flexibility during installation. This adaptability has made it a go-to solution for projects ranging from waterfront developments to flood protection systems.

Over the years, advancements in manufacturing techniques have improved the quality and durability of PZ27 sheet piles, further solidifying their position in the market. As global infrastructure needs have grown, so has the acceptance of the PZ27 as a standard in various regions, particularly in Europe and the Middle East, where stringent engineering standards and environmental considerations drive material selection. Today, the PZ27 sheet pile stands as a testament to the fusion of engineering innovation and market demand, catering to a diverse range of applications across the globe.

Frequently Asked Questions (FAQs) for B2B Buyers of pz27 sheet pile

-

How do I assess the quality of PZ27 sheet pile?

To evaluate the quality of PZ27 sheet piles, consider requesting a mill certificate from the supplier, which details the material properties and compliance with relevant standards. Inspect the piles for any visible defects, such as cracks or rust, and inquire about their history, including previous usage and environmental exposure. Additionally, consider third-party inspections or testing to verify the material’s strength and durability, particularly for critical projects in harsh environments. -

What is the best application for PZ27 sheet piles?

PZ27 sheet piles are ideal for various applications, including retaining walls, flood protection structures, and marine construction projects. Their robust design and ball-and-socket interlock system provide excellent resistance against lateral soil and water pressures, making them suitable for waterfront developments, harbors, and temporary cofferdams. Additionally, their versatility allows for use in both permanent and temporary installations, catering to a wide range of engineering needs. -

What factors should I consider when sourcing PZ27 sheet piles internationally?

When sourcing PZ27 sheet piles from international suppliers, evaluate factors such as compliance with international quality standards, shipping logistics, and customs regulations. Assess the supplier’s reputation and experience in the industry, especially in your target region. It’s also essential to consider lead times, payment terms, and after-sales support to ensure a smooth procurement process and timely delivery of materials to your project site. -

What are the minimum order quantities (MOQs) for PZ27 sheet piles?

Minimum order quantities for PZ27 sheet piles can vary significantly by supplier and region. Typically, MOQs may range from a few tons to several hundred tons. It’s advisable to discuss your specific project needs with potential suppliers to negotiate favorable terms. Additionally, consider consolidating orders with other materials or collaborating with other buyers to meet MOQ requirements without excess inventory. -

How can I verify the supplier’s credentials when purchasing PZ27 sheet piles?

To verify a supplier’s credentials, start by checking their business licenses and certifications, ensuring they comply with local and international standards. Request references from previous clients and review case studies or testimonials to gauge their reliability. Additionally, consider conducting an on-site visit if feasible, or utilize third-party verification services to evaluate the supplier’s manufacturing capabilities and quality control processes. -

What payment terms are typically offered for international transactions involving PZ27 sheet piles?

Payment terms for international transactions can vary widely but often include options such as letters of credit, advance payments, or net payment terms (e.g., net 30 or net 60 days). It’s essential to negotiate terms that align with your cash flow needs while ensuring the supplier’s security. Be aware of any additional fees for currency exchange or international wire transfers, and factor these into your overall project budget. -

What logistics considerations should I keep in mind when importing PZ27 sheet piles?

When importing PZ27 sheet piles, consider logistics aspects such as shipping methods (e.g., container shipping vs. bulk shipping), freight costs, and delivery timelines. Assess the port facilities and infrastructure at both the origin and destination to ensure smooth handling and transport. It’s also crucial to understand the customs clearance process in your country to avoid delays and additional fees, and to plan for potential challenges in transporting heavy materials. -

How can I ensure compliance with local regulations when using PZ27 sheet piles?

To ensure compliance with local regulations, familiarize yourself with construction codes and environmental regulations in your project area. Consult with local authorities or engineering consultants to understand specific requirements for the use of PZ27 sheet piles, including permits and inspections. It’s also beneficial to collaborate with suppliers who have experience working in your region, as they can provide valuable insights into local standards and best practices.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Pz27 Sheet Pile Manufacturers & Suppliers List

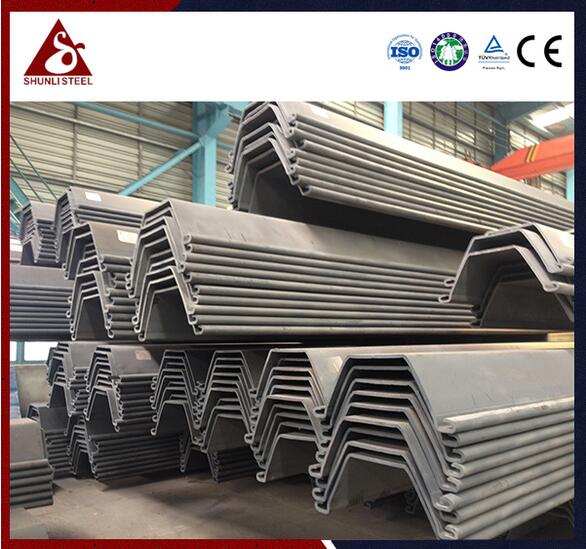

1. Meever USA – PZ27 Hot Rolled Sheet Piles

2. Eiffel Trading – Used PZ and PZC Sheet Pile

Domain: eiffeltrading.com

Registered: 2015 (10 years)

Introduction: Used and surplus PZ and PZC sheet pile for sale. Popular options include PZC-18, PZ-27, PZC-13, PZ-22, and PZ-35. Features a ball and socket interlock and works interchangeably. Listings include:

– 50 Pairs Surplus PZC-13 Sheet Pile at 10′ Lengths, Asking Price: USD $0.68/LB

– 118 Singles of PZC-26 Sheet Pile at 35′ Lengths, Asking Price: USD $0.68/LB

– 26 Pair & 72 Singles of PZ-27 Sheet Pile, As…

3. Hammer Steel – PZ Sheet Piling

Domain: hammersteel.com

Registered: 1999 (26 years)

Introduction: {‘product_name’: ‘PZ Sheet Piling’, ‘models’: [‘PZ 22’, ‘PZ 27’, ‘PZ 35’, ‘PZ 40’], ‘features’: “Mechanical ‘ball and socket’ connections for interlocking, creating a rigid barrier for earth and water, flexible setting, durable under driving conditions.”, ‘specifications’: [{‘model’: ‘PZ 22’, ‘width_in’: 22.0, ‘height_in’: 9.0, ‘flange_thickness_in’: 0.375, ‘web_thickness_in’: 0.375, ‘area_in2_per…

4. Pile Buck – Cast Steel Tip Protection

Domain: pilebuck.com

Registered: 1996 (29 years)

Introduction: Cast steel tip protection for steel sheet piles; available in straight bars for flat and shallow-web sheets; customizable for any ‘Z’ configuration; readily available in one piece for commonly specified Z sections (e.g. PZ-22 and PZ-27); requires only intermittent welds for attachment; welding is not highly recommended for extending steel sheet piles; no satisfactory splicer accessory for sheet pi…

5. China Steel Piling – PZ22 Sheet Pile

Domain: china-steelpiling.com

Registered: 2013 (12 years)

Introduction: PZ22, PZ27, PZ35, PZ40 sheet piles steel sheet pile per foot of wall.

**Specifications:**

– **PZ 22:**

– Width: 9.25 in

– Wall Depth: 22 in

– Web Thickness: 0.375 in

– Flange Thickness: 0.375 in

– Area: 12.2 in²

– Weight Per Foot: 40.3 lbs/ft

– Moment of Inertia: 22.6 in⁴/ft

– Section Modulus: 85.1 in³/ft

– **PZ 27:**

– Width: 12.1 in

– Wall Depth: 18 in

– Web Thickness:…

Strategic Sourcing Conclusion and Outlook for pz27 sheet pile

In navigating the complexities of sourcing PZ27 sheet piles, international buyers from regions such as Africa, South America, the Middle East, and Europe must prioritize strategic partnerships and market intelligence. Understanding the unique specifications and applications of PZ27 sheet piles, including their robust interlocking mechanisms and resistance to lateral pressures, is crucial for optimizing project outcomes.

The ongoing demand for PZ27 sheet piles in various infrastructure projects highlights their value in providing reliable solutions for earth retention and water management. Buyers should leverage the availability of both new and surplus options to enhance cost-effectiveness while ensuring compliance with local regulations and standards.

As the global market continues to evolve, staying informed about emerging trends, price fluctuations, and innovative sourcing strategies will empower businesses to make informed decisions. Engage with reputable suppliers and explore diverse procurement channels to secure the best options for your projects. The future of construction and civil engineering is promising, and by investing in quality materials like PZ27 sheet piles, you are not just meeting current demands but also paving the way for sustainable growth and success in your endeavors.