The Definitive Guide to Parini Cast Iron Pan: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for parini cast iron pan

As the demand for high-quality cookware continues to rise globally, sourcing the right Parini cast iron pan can be a pivotal challenge for B2B buyers. With its durability, heat retention, and versatility, the Parini cast iron pan stands out as a preferred choice for restaurants, catering services, and culinary institutions. This guide delves into the intricacies of the global market for Parini cast iron pans, covering essential aspects such as product types, diverse applications, supplier vetting processes, and cost considerations.

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe—including key markets like Germany and Saudi Arabia—will find this guide invaluable. It aims to empower informed purchasing decisions by providing insights into the quality craftsmanship and material integrity that define Parini cookware. By understanding these elements, buyers can confidently navigate their procurement strategies, ensuring they select products that not only meet their operational needs but also align with budgetary constraints.

Additionally, this comprehensive resource addresses potential challenges in sourcing, offering actionable solutions that can enhance the buying experience. Equip your business with the knowledge necessary to capitalize on the benefits of Parini cast iron pans, ensuring your culinary offerings are both exceptional and cost-effective.

Understanding parini cast iron pan Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Parini Cast Iron Skillet | Thick construction, seasoned for natural nonstick, versatile | Restaurants, catering services, home kitchens | Pros: Excellent heat retention, versatile cooking methods. Cons: Requires maintenance to retain seasoning. |

| Parini Dutch Oven | Enameled surface, even heat distribution, moisture retention | Bakeries, gourmet restaurants, home cooks | Pros: Ideal for slow cooking and baking; easy to clean. Cons: Heavier and may require careful handling. |

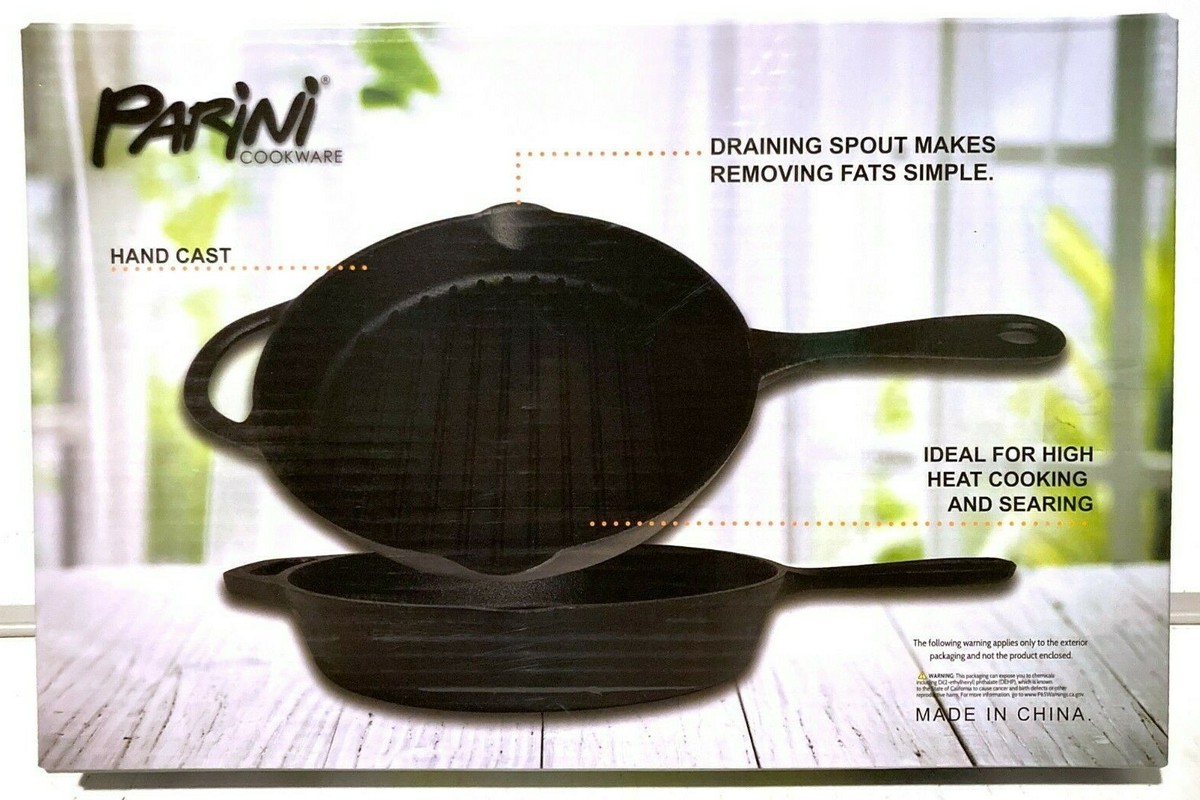

| Parini Grill Pan | Ribbed surface for grilling, durable cast iron | Food trucks, restaurants, outdoor cooking | Pros: Provides authentic grill marks; robust construction. Cons: Limited cooking capacity due to size. |

| Parini Casserole Dish | Deep sides, lid for moisture retention, enameled finish | Catering, meal prep services, family dining | Pros: Versatile for baking and stovetop; retains heat well. Cons: Bulky for storage; requires careful cleaning. |

| Parini Pizza Pan | Shallow, perforated design for crisp crusts, cast iron | Pizzerias, food trucks, home kitchens | Pros: Excellent for achieving a crispy pizza base. Cons: Limited to specific cooking tasks. |

What are the Key Characteristics of Parini Cast Iron Skillets?

The Parini Cast Iron Skillet is designed for versatility, allowing for frying, sautéing, baking, or broiling. Its thick construction ensures excellent heat retention and even cooking, making it a staple in both commercial and residential kitchens. B2B buyers should consider its ability to withstand high temperatures, which is essential for professional cooking environments. However, it requires regular seasoning to maintain its nonstick properties, a factor that may necessitate additional training for staff in commercial settings.

How Does the Parini Dutch Oven Stand Out?

The Parini Dutch Oven is characterized by its enameled surface and thick cast iron build, which provides superior heat distribution and moisture retention. This cookware is ideal for restaurants and bakeries that require slow-cooked dishes or artisan bread. Its ease of cleaning and maintenance makes it a practical choice for busy kitchens. However, its weight and size may pose storage challenges, so buyers should evaluate their kitchen space and staff capabilities before purchase.

What are the Advantages of Using a Parini Grill Pan?

The Parini Grill Pan features a ribbed surface that allows users to achieve authentic grill marks while cooking. It is particularly suited for food trucks and restaurants focusing on grilled dishes. This type of pan is durable and can handle high heat, making it an excellent investment for commercial applications. However, its cooking capacity may be limited, so businesses should consider their volume of service when selecting this type of cookware.

Why Choose a Parini Casserole Dish for Your Business?

Parini Casserole Dishes are designed with deep sides and a lid, making them perfect for slow-cooking and baking. Their enameled finish allows for easy cleaning, which is beneficial for meal prep services and catering businesses. The heat retention properties ensure that food stays warm for longer periods, a crucial aspect in dining establishments. However, their bulkiness may be a drawback in terms of storage space, which should be taken into account by potential buyers.

How Does the Parini Pizza Pan Enhance Cooking?

The Parini Pizza Pan is designed with a shallow, perforated surface that promotes even cooking and a crispy crust. It is particularly beneficial for pizzerias and food trucks, allowing for quick service of high-quality pizzas. Its cast iron material provides excellent heat retention. However, its specific use case may limit its versatility in a varied kitchen environment, making it essential for buyers to assess their product offerings before investing in this type of cookware.

Key Industrial Applications of parini cast iron pan

| Industry/Sector | Specific Application of parini cast iron pan | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Cooking and serving signature dishes in restaurants | Enhances flavor and presentation of meals, leading to higher customer satisfaction | Consistency in quality, durability, and ease of maintenance |

| Food Service | Catering for large events with high-volume cooking | Efficient heat retention allows for even cooking and reduced cooking times | Bulk purchasing options and reliable delivery schedules |

| Culinary Schools | Teaching students various cooking techniques | Provides hands-on experience with versatile cookware, essential for skill development | Availability of educational discounts and product durability |

| Retail | Selling cookware to consumers and restaurants | High-quality product can enhance brand reputation and customer loyalty | Competitive pricing and attractive packaging for display |

| Export/Import | Distributing cookware to international markets | Expands market reach and meets diverse culinary needs | Compliance with international standards and shipping logistics |

How is the parini cast iron pan utilized in the hospitality industry?

In the hospitality sector, the parini cast iron pan is essential for chefs in restaurants to create and serve signature dishes. Its ability to retain heat and evenly distribute it ensures that meals are cooked to perfection, enhancing flavor profiles. This quality not only improves customer satisfaction but also encourages repeat business. For international buyers, sourcing considerations include ensuring consistent quality and durability, as well as ease of maintenance, which are crucial for high-volume kitchen environments.

What role does the parini cast iron pan play in food service?

In food service, particularly for catering large events, the parini cast iron pan is invaluable due to its efficiency in handling high-volume cooking. Its heat retention capabilities allow for even cooking, reducing preparation times, which is critical during busy service periods. When sourcing for this application, businesses should consider bulk purchasing options and reliable delivery schedules to ensure that they have adequate supplies on hand for large-scale events.

Why is the parini cast iron pan significant in culinary schools?

Culinary schools utilize the parini cast iron pan to teach students various cooking techniques, from frying to baking. This hands-on experience with versatile cookware is essential for skill development, as students learn the importance of heat retention and distribution. For schools, key sourcing considerations include the availability of educational discounts and the durability of the cookware, ensuring that it withstands frequent use over time.

How does the parini cast iron pan benefit retail operations?

In retail, the parini cast iron pan serves as a high-quality product that can enhance a store’s brand reputation and customer loyalty. Retailers can market the pan as a must-have for home cooks seeking reliable and functional cookware. When sourcing for retail, businesses should focus on competitive pricing and attractive packaging to draw in consumers and optimize shelf appeal.

What are the export/import opportunities for the parini cast iron pan?

The parini cast iron pan presents significant opportunities in export and import markets, allowing businesses to distribute high-quality cookware to international customers. This expands market reach and caters to diverse culinary needs across various cultures. Key sourcing considerations for international trade include compliance with international standards and efficient shipping logistics to ensure timely delivery and customer satisfaction.

3 Common User Pain Points for ‘parini cast iron pan’ & Their Solutions

Scenario 1: Ensuring Consistent Quality in Bulk Orders of Parini Cast Iron Pans

The Problem: B2B buyers often face challenges when sourcing cookware in bulk, particularly with products like the Parini cast iron pan. Variability in quality between batches can lead to significant issues, such as inconsistent cooking performance and customer dissatisfaction. This is especially critical for distributors or retailers who promise high-quality kitchenware to their clientele. A single defective batch can tarnish a brand’s reputation and lead to costly returns.

The Solution: To mitigate this risk, B2B buyers should establish a robust quality assurance protocol with their suppliers. This involves requesting samples from different production batches before committing to large orders. Additionally, implementing a quality checklist that includes factors such as weight, finish, and heat retention can help ensure that every pan meets the expected standards. Collaborating closely with Parini to understand their production processes and scheduling regular quality audits can also provide peace of mind and reinforce trust in the product’s reliability.

Scenario 2: Addressing Maintenance and Longevity Concerns for Cast Iron Cookware

The Problem: Many B2B buyers are concerned about the maintenance requirements of cast iron pans, particularly regarding seasoning and rust prevention. Buyers in regions with high humidity, such as parts of South America and the Middle East, may find that their cast iron pans require more frequent care to avoid rusting. This can be a deterrent for businesses looking to stock these products, as they want to provide items that require minimal upkeep.

The Solution: Educating end-users about proper maintenance techniques can alleviate these concerns. B2B buyers should create and distribute clear instructional materials on how to season and care for Parini cast iron pans. This could include detailed guides or video tutorials that emphasize the importance of drying pans immediately after washing and applying a thin layer of oil to prevent rust. Offering a maintenance kit that includes oil, scrub brushes, and care instructions as part of the purchase could also enhance customer satisfaction and encourage repeat business.

Scenario 3: Maximizing Versatility in Commercial Kitchen Applications

The Problem: B2B buyers often need to cater to a variety of cooking methods in commercial kitchens, which can make it difficult to choose the right cookware. Parini cast iron pans are versatile, but some buyers may be unsure how to best utilize them in diverse cooking environments, such as restaurants or catering services, where efficiency is key.

The Solution: To enhance the versatility of Parini cast iron pans in commercial settings, buyers should emphasize their multipurpose capabilities through targeted marketing strategies. Providing training sessions or workshops for chefs and kitchen staff on how to effectively use cast iron pans for frying, baking, and slow-cooking can demonstrate their value. Additionally, suggesting recipes or meal prep ideas that showcase the pans’ adaptability can inspire creativity in menu planning. This not only positions the pans as a valuable investment but also helps buyers tap into various culinary applications, driving sales and customer satisfaction.

Strategic Material Selection Guide for parini cast iron pan

What Are the Key Properties of Cast Iron for Parini Cookware?

Cast iron is renowned for its exceptional heat retention and even heat distribution, making it ideal for various cooking methods, including frying, baking, and braising. The material can withstand high temperatures, typically rated up to 500°F (260°C), which is essential for applications requiring searing or slow-cooking. Additionally, cast iron’s natural non-stick properties improve with seasoning, enhancing its usability over time.

What Are the Advantages and Disadvantages of Using Cast Iron?

From a durability perspective, cast iron is incredibly robust, often outlasting other cookware materials. It is resistant to warping and can endure the rigors of everyday cooking. However, its weight can be a drawback, making it less user-friendly, particularly for consumers who may struggle with heavy cookware. Cast iron pans also require careful maintenance to prevent rusting, which can deter some buyers.

How Does Cast Iron Impact Cooking Applications?

Cast iron pans are particularly suited for high-heat applications and can be used on various cooking surfaces, including induction, gas, and electric stoves. They are also compatible with oven use, making them versatile for baking and roasting. However, they can react with acidic foods, such as tomatoes, if not properly seasoned, which may limit their application in certain recipes.

What Should International B2B Buyers Consider When Sourcing Cast Iron Cookware?

For international buyers, especially those in Africa, South America, the Middle East, and Europe, compliance with local standards is critical. Many regions have specific regulations regarding cookware materials, including safety and environmental considerations. For instance, in Europe, adherence to the EN 13851 standard for cookware safety is essential. Additionally, buyers should consider the cost implications of sourcing cast iron cookware, as shipping and import duties can significantly affect pricing. Understanding local market preferences, such as the demand for heavy-duty versus lightweight cookware, can also guide purchasing decisions.

Summary Table of Material Properties for Parini Cast Iron Pan

| Material | Typical Use Case for parini cast iron pan | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Searing, frying, baking, braising | Excellent heat retention | Heavy and requires maintenance | Medium |

| Enameled Cast Iron | Slow cooking, baking, serving | Non-reactive surface, easy to clean | More expensive, can chip easily | High |

| Carbon Steel | Searing, stir-frying, sautéing | Lighter than cast iron, versatile | Requires seasoning, less durable | Medium |

| Stainless Steel | General cooking, sautéing, boiling | Durable, non-reactive, easy to clean | Poor heat retention compared to cast iron | Medium |

This analysis provides valuable insights for B2B buyers looking to make informed decisions about sourcing Parini cast iron pans, considering both performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for parini cast iron pan

What Are the Main Stages in the Manufacturing Process of Parini Cast Iron Pans?

The manufacturing process of Parini cast iron pans involves several critical stages that ensure the final product meets high standards of durability and performance.

Material Preparation

The process begins with the careful selection of raw materials, primarily high-quality iron ore, which is melted in a furnace at high temperatures. This molten iron is then alloyed with various elements to enhance its properties, such as strength and corrosion resistance. The chosen materials must comply with international standards to ensure that the final product can withstand rigorous cooking conditions.

Forming Techniques

Once the materials are prepared, the molten iron undergoes forming processes. This typically involves casting the iron into molds that define the shape of the pans. Parini employs sand casting techniques, where sand molds are used to create precise shapes. This method is favored for its ability to produce intricate designs and maintain the integrity of the material during cooling.

Assembly Processes

After forming, the cast iron pans are assembled, which may include attaching handles or lids, depending on the product line. These components are often made from materials that complement the cast iron, such as stainless steel or heat-resistant plastic. The assembly is performed with precision to ensure durability and ease of use.

Finishing Techniques

The final stage of manufacturing includes finishing processes such as polishing, seasoning, and applying protective coatings. For Parini cast iron pans, seasoning is critical as it creates a natural non-stick surface. The pans are typically heated and coated with vegetable oil, allowing the oil to bond with the iron. This process not only enhances cooking performance but also helps prevent rusting.

What Quality Assurance Measures Are Implemented During Production?

Quality assurance (QA) is paramount in the manufacturing of Parini cast iron pans to guarantee product reliability and customer satisfaction.

What International Standards Guide Quality Assurance?

Parini adheres to international quality management standards, such as ISO 9001, which outlines a framework for consistent quality in manufacturing processes. Compliance with such standards ensures that the products are produced consistently and that the processes are continually improved.

Additionally, industry-specific certifications such as CE marking for compliance with European health, safety, and environmental protection standards are crucial for accessing certain markets, particularly in Europe.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are tested for compliance with specifications before they are used in production. This includes checking for impurities and ensuring that the materials meet the required standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, inspections are conducted to ensure that the casting, assembly, and finishing processes are executed correctly. This may involve measuring dimensions and visual inspections for defects.

-

Final Quality Control (FQC): Once the pans are finished, they undergo a comprehensive inspection to assess their performance, appearance, and safety. This may include functionality tests such as heat retention and non-stick performance.

What Testing Methods Are Commonly Used for Cast Iron Pans?

Testing methods are essential for verifying that Parini cast iron pans meet the required performance and safety standards.

-

Thermal Conductivity Tests: These tests measure how evenly the pans distribute heat, which is crucial for effective cooking.

-

Durability Testing: Pans are subjected to stress tests to evaluate their resistance to cracking and warping under extreme temperatures.

-

Non-Stick Performance Tests: The effectiveness of the seasoning and non-stick properties is evaluated through cooking tests, ensuring that the pans meet customer expectations.

-

Safety Tests: These tests ensure that no harmful substances leach into food during cooking, particularly important for international markets with stringent safety regulations.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those operating in international markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is critical.

What Steps Can Buyers Take to Ensure Supplier Compliance?

-

Supplier Audits: Conducting regular audits of the manufacturing facility can provide insights into the production processes, quality control measures, and adherence to safety standards.

-

Requesting Quality Reports: Buyers should ask for detailed quality control reports that outline the testing methods used and the results obtained. This documentation can serve as a basis for evaluating the supplier’s reliability.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. These services can conduct inspections at various stages of production and provide certification of compliance with international standards.

What Are the Quality Control Nuances for International Buyers?

International buyers should be aware of specific nuances in quality control that may affect their procurement processes.

-

Regulatory Compliance: Different regions have varying standards for cookware safety and performance. Buyers must ensure that the products they import comply with local regulations, such as those set by the FDA in the USA or EFSA in Europe.

-

Cultural Preferences: Buyers from different regions may have unique preferences regarding cookware design and functionality. Understanding these preferences can help in selecting products that meet market demands.

-

Cost vs. Quality Trade-offs: While affordability is crucial, it is essential to balance cost with quality to avoid issues that may arise from subpar products. Establishing long-term relationships with reliable suppliers can mitigate risks associated with quality inconsistencies.

By understanding the manufacturing processes and quality assurance measures associated with Parini cast iron pans, B2B buyers can make informed purchasing decisions that align with their quality expectations and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parini cast iron pan’

To aid international B2B buyers in procuring the Parini cast iron pan effectively, this guide provides a structured checklist to ensure a smooth sourcing process. By following these steps, buyers can make informed decisions and establish fruitful partnerships.

Step 1: Define Your Technical Specifications

Clearly outline the specifications required for the Parini cast iron pan, including size, weight, and any additional features such as enameled surfaces or ergonomic handles. This step is essential because it ensures that suppliers understand your precise needs and can provide suitable products that meet your quality standards.

- Size Options: Consider whether you need standard sizes (e.g., 10-inch or 12-inch pans) or specialty sizes for specific cooking tasks.

- Material Quality: Ensure that the cast iron used is of high quality, promoting durability and even heat distribution.

Step 2: Research Potential Suppliers

Take the time to investigate various suppliers of Parini cookware, focusing on those with a proven track record in the market. Researching potential suppliers is crucial to identify reputable companies that can deliver quality products consistently.

- Supplier Reviews: Look for customer feedback and ratings to gauge the reliability and performance of their products.

- Experience and Reputation: Consider suppliers with extensive experience in the cookware industry, particularly those specializing in cast iron products.

Step 3: Evaluate Product Certifications

Verify that the Parini cast iron pan complies with international safety and quality standards. This step helps mitigate risks associated with product safety and ensures that the cookware is suitable for commercial use.

- Quality Standards: Check for certifications such as ISO, FDA, or CE marking that demonstrate adherence to manufacturing quality.

- Environmental Compliance: Ensure that the supplier follows eco-friendly practices in their production processes, which is increasingly important for global buyers.

Step 4: Request Samples for Testing

Before placing a large order, request samples of the Parini cast iron pan to evaluate their quality firsthand. Testing samples allows you to assess durability, performance, and usability, ensuring they meet your expectations.

- Cooking Performance: Conduct tests to see how well the pan retains heat and distributes it evenly during cooking.

- Ease of Maintenance: Evaluate the non-stick properties and ease of cleaning after use.

Step 5: Negotiate Pricing and Terms

Once you have identified a reliable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Effective negotiation is vital to ensure you receive the best possible value for your investment.

- Bulk Purchase Discounts: Inquire about discounts for larger orders or repeat business to maximize cost savings.

- Payment Flexibility: Discuss payment terms that suit your cash flow, such as net 30 or net 60 options.

Step 6: Confirm Shipping and Delivery Options

Finalize arrangements for shipping and delivery to ensure the timely arrival of your Parini cast iron pans. Understanding logistics is crucial to avoid delays that could impact your operations.

- Shipping Methods: Evaluate various shipping options (air freight, sea freight) based on urgency and cost-effectiveness.

- Customs and Duties: Be aware of any import duties or customs regulations that may apply to your order, particularly for international shipments.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the performance of the Parini cast iron pans upon delivery. This step is important to maintain product quality and ensure customer satisfaction.

- Inspection Protocols: Develop a checklist for inspecting each batch of pans for defects or inconsistencies.

- Feedback Loop: Create a system for gathering feedback from end-users to continually assess the product’s performance and address any issues promptly.

By following this comprehensive checklist, B2B buyers can effectively source Parini cast iron pans that meet their operational needs while ensuring quality and reliability.

Comprehensive Cost and Pricing Analysis for parini cast iron pan Sourcing

What Are the Key Cost Components in Sourcing Parini Cast Iron Pans?

When sourcing Parini cast iron pans, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The raw materials for cast iron pans consist primarily of high-quality iron, which is often sourced from regions with robust mining industries. Additionally, any enamel coating or seasoning treatment contributes to the material costs.

-

Labor: Labor costs can vary significantly depending on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but this should be balanced against potential quality concerns. Skilled labor is essential for processes like molding and finishing.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead, which can be passed on as savings to buyers.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs or specialized molds. However, these costs are typically amortized over larger production runs, making it more economical for buyers who can meet minimum order quantities (MOQs).

-

Quality Control (QC): Investing in QC is vital to ensure that the pans meet both safety standards and performance expectations. Rigorous testing processes may increase upfront costs but can reduce the likelihood of returns and enhance brand reputation.

-

Logistics: Shipping and handling costs, including freight charges, customs duties, and insurance, can significantly impact the final price. This is particularly relevant for international buyers who must navigate various import regulations.

-

Margin: Suppliers will typically include a margin to cover their costs and ensure profitability. Understanding the standard margin in the cookware industry can help buyers negotiate better deals.

What Influences the Pricing of Parini Cast Iron Pans?

Several factors can influence the pricing of Parini cast iron pans for B2B buyers:

-

Volume and Minimum Order Quantities (MOQ): Larger orders generally lead to lower per-unit costs. Suppliers may offer tiered pricing, encouraging bulk purchases.

-

Specifications and Customization: Custom designs or specific features (like unique colors or sizes) can increase costs due to additional tooling and labor requirements.

-

Material Quality and Certifications: Pans made from higher-grade materials or those with specific certifications (e.g., food safety standards) may command higher prices. Buyers should assess the long-term value of these investments.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with proven track records may charge premium prices but offer superior quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial as they define the responsibilities of buyers and sellers regarding shipping, risk, and costs. Different terms can significantly affect the total landed cost.

What Are Effective Buyer Tips for Negotiating Prices?

International B2B buyers should consider the following strategies to enhance cost efficiency when sourcing Parini cast iron pans:

-

Negotiate Bulk Discounts: Don’t hesitate to discuss volume discounts or loyalty programs with suppliers. Building a long-term relationship can lead to better pricing and terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider factors like durability, maintenance, and potential replacement costs. A higher initial investment might yield lower TCO over time.

-

Understand Pricing Nuances: Be aware of market trends and seasonal fluctuations in pricing. Engage in market research to benchmark prices against competitors.

-

Leverage Local Knowledge: For buyers from Africa, South America, the Middle East, and Europe, understanding regional market dynamics can provide leverage in negotiations. Local suppliers may offer advantages in terms of logistics and reduced tariffs.

-

Request Samples: Before committing to large orders, request samples to evaluate quality. This can prevent costly mistakes and ensure the product meets your specifications.

Disclaimer on Indicative Prices

Pricing for Parini cast iron pans can vary widely based on the factors outlined above. It is advisable to conduct thorough market research and engage directly with suppliers to obtain accurate quotes tailored to your specific needs.

Alternatives Analysis: Comparing parini cast iron pan With Other Solutions

Understanding Alternatives to the Parini Cast Iron Pan

In the competitive landscape of cookware, the Parini cast iron pan stands out for its quality and affordability. However, buyers may seek alternatives that offer different benefits or align better with specific culinary needs. This analysis compares the Parini cast iron pan against other viable options, including a stainless steel skillet and a non-stick frying pan, to help B2B buyers make informed decisions.

| Comparison Aspect | Parini Cast Iron Pan | Stainless Steel Skillet | Non-Stick Frying Pan |

|---|---|---|---|

| Performance | Excellent heat retention, ideal for high-temperature cooking | Quick heating and precise temperature control | Superior ease of cooking and cleaning for low-fat meals |

| Cost | Mid-range pricing, good value for durability | Generally higher due to material quality | Affordable options available, but longevity can vary |

| Ease of Implementation | Requires seasoning for optimal use | Ready to use, no special preparation needed | Simple to use, minimal learning curve |

| Maintenance | Requires regular seasoning and careful cleaning | Dishwasher safe, but may require occasional polishing | Easy to clean, but surface can wear over time |

| Best Use Case | Ideal for slow cooking, baking, and frying | Best for sautéing, searing, and deglazing | Perfect for quick meals and low-fat cooking |

Detailed Breakdown of Alternatives

Stainless Steel Skillet

Stainless steel skillets are prized for their durability and ability to withstand high temperatures without warping. They heat quickly and offer excellent temperature control, making them suitable for tasks such as sautéing and deglazing. However, they can be more expensive than cast iron pans and require a bit of practice to prevent food from sticking. While maintenance is straightforward, occasional polishing is necessary to maintain their aesthetic and performance.

Non-Stick Frying Pan

Non-stick frying pans are a popular choice for their ease of use and cleaning. They excel in cooking low-fat meals due to their non-stick surface, which requires less oil. This makes them ideal for quick meals or for those who prioritize convenience. However, their longevity can be a concern, as the non-stick coating may wear off over time, leading to the need for replacement. Additionally, they may not perform well at high temperatures compared to cast iron or stainless steel options.

Conclusion: How to Choose the Right Cookware for Your Needs

When selecting cookware for your business or kitchen, consider factors such as performance, cost, ease of use, and maintenance. The Parini cast iron pan offers excellent heat retention and durability, making it a solid choice for slow cooking and high-heat applications. However, if quick cooking and easy cleanup are priorities, a non-stick frying pan may be more suitable. For those who need precise temperature control and versatile cooking options, a stainless steel skillet could be the best fit. Ultimately, the right choice will depend on your specific culinary requirements and budget considerations.

Essential Technical Properties and Trade Terminology for parini cast iron pan

What Are the Key Technical Properties of the Parini Cast Iron Pan?

When considering the Parini cast iron pan for your business needs, understanding its technical properties is crucial. Here are several key specifications that define its quality and performance in a commercial kitchen setting:

-

Material Grade

The Parini cast iron pan is constructed from high-grade cast iron, known for its exceptional heat retention and even heat distribution. This material allows for versatile cooking methods, including frying, baking, and sautéing. For B2B buyers, selecting cookware made from superior materials ensures longevity and reliability in high-demand environments. -

Enameled Coating

Many Parini cast iron pans feature an enameled finish, which not only enhances aesthetic appeal but also provides a non-reactive surface ideal for cooking acidic foods. This coating simplifies maintenance and cleaning, vital for busy kitchens. Understanding the benefits of enameled versus non-enameled cast iron can help businesses choose the right product for their culinary applications. -

Thickness

The thickness of the pan is a critical factor influencing heat retention and cooking performance. Parini cast iron pans typically have a thickness of around 4-5mm, which helps to evenly distribute heat and reduce hot spots. For buyers, this property is essential to ensure consistent cooking results, especially in professional settings where precision is key. -

Weight

A typical Parini cast iron pan weighs between 2.5 to 3.5 kg, depending on its size. The weight of the pan contributes to its stability on the stovetop and helps maintain temperature during cooking. Understanding the weight specifications allows businesses to consider ergonomic factors for their staff, ensuring ease of handling during food preparation. -

Heat Resistance

Parini cast iron pans can withstand high temperatures, making them suitable for various cooking techniques, including broiling and baking. Their heat resistance is essential for commercial kitchens that require versatile cookware capable of performing under different cooking conditions. Buyers should ensure that the heat tolerance aligns with their cooking processes.

What Are Common Trade Terminology and Concepts Related to Parini Cast Iron Pans?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms associated with purchasing cookware like the Parini cast iron pan:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of cookware, understanding OEM relationships can help buyers identify reliable suppliers and manufacturers who adhere to quality standards. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. For businesses looking to purchase Parini cast iron pans, knowing the MOQ can help in planning inventory and managing budgets effectively. -

RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers. For B2B buyers, issuing an RFQ for Parini cookware allows for competitive pricing and ensures that procurement aligns with budget expectations. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of sellers and buyers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping responsibilities, insurance, and risk management when importing Parini products. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. For businesses, understanding lead times for Parini cast iron pans can impact inventory management and planning, ensuring that kitchen supplies are available when needed. -

Warranty Period

This term indicates the timeframe during which a product is guaranteed against defects. For B2B buyers, knowing the warranty period for Parini cast iron pans is important for assessing long-term value and potential replacement costs.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing Parini cast iron pans for their operations, ensuring they select the right products that meet their culinary and financial needs.

Navigating Market Dynamics and Sourcing Trends in the parini cast iron pan Sector

What Are the Key Market Dynamics and Trends Influencing the Parini Cast Iron Pan Sector?

The global cookware market, particularly in the cast iron segment, is experiencing significant growth driven by increasing consumer interest in home cooking and culinary experiences. Factors such as a rise in disposable income, urbanization, and a shift towards healthier cooking methods are propelling demand for durable and versatile cookware like the Parini cast iron pan. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for products that combine quality with affordability, making Parini an attractive option.

Emerging B2B tech trends include the use of e-commerce platforms and digital marketplaces to facilitate sourcing. Buyers are leveraging technology to analyze product specifications, compare pricing, and read customer reviews, thus making informed purchasing decisions. Additionally, innovations in manufacturing processes, such as improved casting techniques and enameled finishes, enhance product performance and longevity, further appealing to B2B buyers seeking reliable kitchen solutions.

Moreover, the market dynamics are influenced by shifts towards sustainable practices. Retailers and distributors are increasingly prioritizing products that reflect environmental consciousness, prompting brands like Parini to focus on sustainability in their sourcing and manufacturing processes. This trend highlights the importance of understanding regional market nuances and consumer preferences, which can vary significantly across different markets.

How Is Sustainability and Ethical Sourcing Impacting the Parini Cast Iron Pan Market?

Sustainability and ethical sourcing are paramount concerns for modern B2B buyers, particularly in the cookware sector. The environmental impact of cookware production, including resource extraction and manufacturing processes, is under scrutiny. Parini, committed to quality craftsmanship, is also focusing on sustainable practices by sourcing raw materials responsibly and ensuring that production methods minimize environmental harm.

Buyers are increasingly seeking products that carry ‘green’ certifications or are made from eco-friendly materials. In the case of Parini cast iron pans, the use of recycled materials and adherence to strict environmental regulations can bolster their market appeal. Ethical supply chains are also becoming a selling point, as consumers demand transparency regarding labor practices and sourcing.

As B2B buyers prioritize sustainability, suppliers who can demonstrate their commitment to ethical sourcing and environmental stewardship are likely to gain a competitive advantage. This trend not only aligns with consumer values but also meets the growing regulatory pressures regarding sustainability and corporate responsibility.

What Is the Evolution of the Parini Cast Iron Pan in the Cookware Market?

The Parini cast iron pan has evolved significantly since its inception, transitioning from traditional cookware to a contemporary kitchen staple. Initially favored for its heat retention and durability, cast iron cookware has gained renewed popularity due to the rising trend of home cooking and culinary experimentation. Parini has capitalized on this trend by modernizing its product offerings, incorporating enameled finishes for easier maintenance and improved aesthetics.

The brand’s commitment to affordability while ensuring high-quality standards has positioned it effectively in the competitive cookware market. As consumers increasingly seek versatile and functional kitchen tools, Parini has adapted to meet these demands, making the cast iron pan an essential item for both amateur and professional chefs alike. This evolution reflects broader market trends towards practical, sustainable, and stylish cooking solutions that resonate well with international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of parini cast iron pan

-

How do I ensure the quality of Parini cast iron pans when sourcing?

To ensure the quality of Parini cast iron pans, request product samples before placing a bulk order. Evaluate the pans for weight, finish, and craftsmanship. Additionally, check for certifications or quality assurance processes the manufacturer follows. Engaging in a factory visit, if feasible, can further help assess production standards and quality control measures. Verify the manufacturer’s reputation by reviewing their customer feedback and industry standing to confirm reliability. -

What are the best practices for negotiating pricing with Parini cookware suppliers?

When negotiating pricing, start by understanding the supplier’s cost structure and market pricing trends. Express interest in long-term partnerships, which can provide leverage for better pricing. Be transparent about your expected order volumes and inquire about discounts for bulk purchases. Also, consider discussing payment terms to align cash flow needs with pricing agreements. Building rapport with the supplier can lead to more favorable terms. -

What is the minimum order quantity (MOQ) for Parini cast iron pans?

The minimum order quantity (MOQ) for Parini cast iron pans can vary by supplier, typically ranging from 100 to 500 units depending on the product line. When approaching suppliers, inquire about their MOQ policies upfront. If your initial order volume is below the MOQ, discuss potential flexibility or consider consolidating orders with other products to meet the requirement. Understanding MOQ is crucial for budgeting and inventory management. -

What customization options are available for Parini cast iron pans?

Customization options for Parini cast iron pans may include branding with your company logo, selecting specific colors, or even altering sizes or features. Discuss your requirements with the supplier during initial communications, as many manufacturers are open to bespoke requests for larger orders. Ensure you understand any additional costs or extended lead times associated with customization to plan accordingly. -

What payment terms should I expect when sourcing Parini cookware internationally?

Payment terms for international orders of Parini cookware may include options such as advance payment, letters of credit, or payment upon delivery. It’s common for suppliers to request a deposit, typically 30-50% of the total order value, with the balance due before shipment. Always clarify payment methods accepted and ensure that terms are documented in the purchase agreement to prevent misunderstandings. -

How can I efficiently manage logistics and shipping for my Parini cookware orders?

To manage logistics efficiently, collaborate closely with your supplier to understand their shipping capabilities and timelines. Choose a reliable freight forwarder familiar with international shipping regulations and customs processes in your region. Ensure that you factor in shipping costs, potential tariffs, and delivery timelines in your overall budget. Tracking your shipment and maintaining communication with your supplier can help mitigate delays. -

What quality assurance measures should be in place for Parini cast iron pans?

Quality assurance measures should include regular inspections during production, adherence to international quality standards, and comprehensive testing of the final product. Request documentation of quality checks performed, such as tests for durability, heat retention, and non-stick properties. Establishing a clear return policy for defective items is also crucial, ensuring that you can address any quality issues post-delivery efficiently. -

What factors should I consider when selecting a supplier for Parini cast iron pans?

When selecting a supplier, consider their production capacity, reputation, and experience in the cookware industry. Evaluate their compliance with international safety and quality standards, as well as their ability to meet your specific requirements. Request references from other clients, and if possible, visit their manufacturing facility. Assess their communication responsiveness and willingness to provide support throughout the ordering process, as these factors can significantly impact your business relationship.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Parini Cast Iron Pan Manufacturers & Suppliers List

1. Parini – Cookware Essentials

Domain: theparini.com

Registered: 2024 (1 years)

Introduction: Parini Cookware Products include:

1. Parini Dutch Oven: Thick cast iron construction with enameled surface for even heat distribution and moisture retention, ideal for stews, braises, and bread.

2. Parini Pizza Cooker: Mimics professional pizza oven with double-walled stainless steel interior and nonstick surface for charred pizza crusts.

3. Parini Cast Iron Skillet: Seasoned for natural nonstick…

2. Parini – Kitchen Cookware

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Parini cookware includes a variety of kitchen items such as dutch ovens, a small slow cooker, a salad spinner, bowls, plates, and a revolving spice rack. The cookware is associated with promotions from casinos, and there are concerns about the quality, as one user reported a salad spinner that broke after light use. The brand is part of a larger company in China, and some items are available on eB…

3. Parini – 9 Cast Iron Round Pan

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: This company, Parini – 9 Cast Iron Round Pan, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. PARINI – NWT Organic Cast Iron Hot Pot

Domain: poshmark.com

Registered: 2011 (14 years)

Introduction: This company, PARINI – NWT Organic Cast Iron Hot Pot, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Parini – Cast Iron Dutch Oven Set

Domain: macys.com

Registered: 1994 (31 years)

Introduction: This company, Parini – Cast Iron Dutch Oven Set, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Parini – Cast Iron Skillets Set

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Cast Iron Skillets Parini Golden Oil Collection 8″ & 10″ BOTH NEW IN SEALED BOX

7. Parini Cookware – Premium Dutch Oven & Colorful Mini Casseroles

Domain: parini-cookware.com

Registered: 2025 (0 years)

Introduction: Parini Cookware offers a variety of high-quality cookware products including:

1. **Round 4.0 Qt Dutch Oven** – Made from premium stainless steel, designed for even heat distribution, includes a snug-fitting lid to lock in moisture and flavor.

2. **Colorful Stoneware Mini Casserole Pots** – Vibrant, lidded mini pots inspired by classic French designs, ideal for serving individual portions and kee…

Strategic Sourcing Conclusion and Outlook for parini cast iron pan

In evaluating the strategic sourcing of Parini cast iron pans, it’s clear that these products exemplify a balance of quality, affordability, and functionality that appeals to diverse markets. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, investing in Parini cast iron cookware offers an opportunity to meet consumer demands for durable and versatile kitchen essentials. The emphasis on quality craftsmanship and material integrity ensures that these pans not only perform well but also provide long-term value, making them an attractive choice for retailers seeking reliable products.

Furthermore, strategic sourcing allows businesses to capitalize on the growing trend of home cooking and culinary exploration, especially in regions where kitchenware quality directly impacts cooking experiences. By partnering with a reputable brand like Parini, buyers can enhance their product offerings while appealing to budget-conscious consumers who prioritize value without compromising on quality.

As the global market continues to evolve, now is the time for B2B buyers to consider integrating Parini cast iron pans into their inventory. This strategic move not only positions businesses to meet emerging demands but also fosters customer loyalty through exceptional cooking experiences. Embrace this opportunity to elevate your kitchenware lineup and drive sales growth in your market.