A B2B Buyer’s Guide to M12 1.50 Wheel Nut: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for m12 1.50 wheel nut

In today’s global market, sourcing reliable M12 1.50 wheel nuts can present a significant challenge for international B2B buyers. As the automotive industry continues to expand across Africa, South America, the Middle East, and Europe, the demand for quality wheel nuts has surged. This comprehensive guide is designed to empower buyers by providing crucial insights into the various types of M12 1.50 wheel nuts available, their specific applications, and essential considerations for supplier vetting.

From understanding the different seat styles—such as conical and bulge—to evaluating materials like steel and zinc, this guide covers all necessary aspects to facilitate informed purchasing decisions. Additionally, it delves into cost factors, enabling businesses to balance quality and budget effectively.

Whether you’re a distributor in Nigeria seeking competitive pricing or an automotive manufacturer in Saudi Arabia aiming for high-performance components, this guide serves as a valuable resource. By leveraging the insights provided, B2B buyers can confidently navigate the complexities of the global wheel nut market, ensuring they secure products that meet their operational standards and customer expectations.

Understanding m12 1.50 wheel nut Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conical Seat Lug Nuts | 60-degree taper, designed for standard fit | General automotive applications | Pros: Widely compatible, easy installation. Cons: Limited to specific wheel designs. |

| Ball Seat Lug Nuts | Rounded seat for better grip on wheels | Specialty vehicles and performance cars | Pros: Enhanced grip, ideal for racing. Cons: May not fit standard vehicles. |

| Bulge Acorn Lug Nuts | Rounded top, larger diameter for added grip | Aftermarket wheels and custom applications | Pros: Robust design, improved aesthetics. Cons: Heavier, may require specific tools. |

| Spline Drive Lug Nuts | Unique spline design for security | High-performance and theft-resistant needs | Pros: Enhanced security, unique fit. Cons: Requires special key for installation. |

| Open End Lug Nuts | Hollow design for extended reach | Custom wheel designs and aftermarket setups | Pros: Versatile, fits various applications. Cons: Less secure than closed variants. |

What Are Conical Seat Lug Nuts and Their Applications?

Conical seat lug nuts feature a 60-degree taper that allows for a secure fit against the wheel’s conical seat. They are commonly used in general automotive applications, making them a staple for many vehicle types. When purchasing, buyers should consider compatibility with existing wheel designs and the ease of installation, as these nuts are typically straightforward to fit.

How Do Ball Seat Lug Nuts Enhance Performance?

Ball seat lug nuts are characterized by their rounded seating surface, providing a better grip on the wheel. This design is particularly advantageous for specialty vehicles and performance cars, where enhanced grip is crucial for high-speed stability. Buyers should evaluate whether their vehicle’s wheel design accommodates this type and consider the potential need for specialized installation tools.

What Are the Benefits of Bulge Acorn Lug Nuts?

Bulge acorn lug nuts have a rounded top and a larger diameter, which not only provides a secure fit but also adds to the aesthetic appeal of the wheel. They are ideal for aftermarket wheels and custom applications, where both style and functionality are desired. Buyers should weigh the benefits of their robust design against the potential need for specific tools due to their size.

Why Choose Spline Drive Lug Nuts for Security?

Spline drive lug nuts feature a unique spline design that enhances security, making them a popular choice for high-performance vehicles and those requiring theft resistance. These nuts require a special key for installation, which adds an extra layer of security but may also pose a challenge if the key is lost. Buyers should consider the security benefits and the implications of needing specialized tools.

When to Use Open End Lug Nuts?

Open end lug nuts are designed with a hollow interior, allowing for an extended reach when fitting wheels. They are versatile and can be used across various applications, especially with custom wheel designs. However, buyers should be aware that while they offer flexibility, they may not provide the same level of security as closed variants. Evaluating the specific needs of their vehicle setup will help in making the right choice.

Key Industrial Applications of m12 1.50 wheel nut

| Industry/Sector | Specific Application of m12 1.50 wheel nut | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Used in assembly of passenger vehicles and trucks | Ensures safety and reliability in vehicle performance | Quality standards, material specifications, and bulk pricing |

| Heavy Equipment | Securing wheels on construction and mining vehicles | Enhances operational efficiency and safety in rugged environments | Durability against harsh conditions and compatibility with OEM specifications |

| Transportation & Logistics | Maintenance of fleet vehicles | Reduces downtime and maintenance costs | Availability of various finishes and sizes for different vehicle models |

| Agriculture | Wheel attachment on tractors and farm machinery | Increases productivity and reliability in farming operations | Resistance to corrosion and compatibility with agricultural equipment |

| Automotive Aftermarket | Replacement for worn-out lug nuts in vehicles | Provides cost-effective solutions for vehicle maintenance | Sourcing from reputable suppliers with warranty options |

How is the m12 1.50 Wheel Nut Used in Automotive Manufacturing?

In the automotive manufacturing sector, the m12 1.50 wheel nut is integral to the assembly of passenger vehicles and trucks. These nuts secure the wheels to the vehicle’s hub, ensuring safety and reliability. By using high-quality materials and precise manufacturing processes, automotive companies can enhance vehicle performance and safety. International buyers, particularly from regions such as Africa and South America, must consider local regulations, quality standards, and the availability of compatible products to ensure compliance and performance.

What Role Does the m12 1.50 Wheel Nut Play in Heavy Equipment?

Heavy equipment, such as construction and mining vehicles, rely on the m12 1.50 wheel nut for securing wheels in extreme conditions. These nuts must withstand significant stress and harsh environments, making durability essential. The right wheel nut can enhance operational efficiency and safety, preventing wheel detachments that could lead to accidents. Buyers in the Middle East and Europe should focus on sourcing nuts that meet OEM specifications to guarantee performance and safety in their machinery.

Why is the m12 1.50 Wheel Nut Essential for Transportation & Logistics?

In the transportation and logistics sector, the m12 1.50 wheel nut is vital for the maintenance of fleet vehicles. Properly secured wheels reduce the risk of accidents and ensure the reliability of deliveries. Regular maintenance using quality lug nuts minimizes downtime and cuts maintenance costs, leading to increased profitability. B2B buyers should prioritize sourcing from suppliers that offer bulk purchasing options and a variety of finishes to accommodate different fleet vehicles.

How Does the m12 1.50 Wheel Nut Benefit Agriculture?

In agriculture, the m12 1.50 wheel nut secures wheels on tractors and other farm machinery, playing a crucial role in operational reliability. These nuts must resist corrosion and wear due to exposure to harsh farming conditions. By ensuring that machinery remains functional and safe, businesses can boost productivity and efficiency in their operations. Buyers from agricultural sectors in regions like Africa need to ensure that the sourced products are robust enough to withstand local environmental challenges.

What is the Importance of the m12 1.50 Wheel Nut in the Automotive Aftermarket?

The m12 1.50 wheel nut serves as a replacement for worn-out lug nuts in the automotive aftermarket. Offering cost-effective solutions for vehicle maintenance, these nuts ensure that vehicles remain safe and operational. B2B buyers should look for suppliers who provide warranties and guarantee product quality, as this can significantly impact the overall reliability of the vehicles they service. Understanding the local market and vehicle specifications is key for buyers in Europe and the Middle East to effectively meet customer needs.

3 Common User Pain Points for ‘m12 1.50 wheel nut’ & Their Solutions

Scenario 1: Sourcing Quality M12 1.50 Wheel Nuts in Diverse Markets

The Problem: B2B buyers often face difficulties in sourcing high-quality M12 1.50 wheel nuts due to varying standards and specifications across different regions. For instance, a buyer in Nigeria may struggle to find a supplier that offers lug nuts compatible with local vehicle models, while also ensuring that the materials meet durability requirements. This inconsistency can lead to purchasing substandard products that compromise vehicle safety and increase maintenance costs.

The Solution: To effectively source quality M12 1.50 wheel nuts, buyers should prioritize suppliers who provide detailed product specifications and certifications. Engaging with suppliers that have a strong reputation in international markets can ensure compliance with local standards. Additionally, buyers should consider forming partnerships with regional distributors who understand local needs and can offer tailored solutions. It’s beneficial to request samples and conduct rigorous quality checks before placing bulk orders, ensuring that the product meets both performance and safety standards specific to the vehicles in their market.

Scenario 2: Managing Inventory for M12 1.50 Wheel Nuts

The Problem: Inventory management can pose a significant challenge for B2B buyers dealing with M12 1.50 wheel nuts, especially for businesses that experience fluctuating demand. Holding excessive stock can lead to increased carrying costs, while insufficient inventory can result in lost sales and customer dissatisfaction. This balancing act is particularly tricky when dealing with various vehicle models that require different specifications of wheel nuts.

The Solution: Implementing a just-in-time (JIT) inventory system can streamline the management of M12 1.50 wheel nuts. This approach minimizes excess stock by aligning inventory levels closely with current demand. Buyers should invest in inventory management software that integrates sales forecasts and real-time data analytics to track usage patterns. Additionally, establishing strong relationships with reliable suppliers can facilitate quicker restocking and allow for flexible order quantities. Regularly reviewing inventory turnover rates will also help in adjusting stock levels based on market trends, ensuring that the right products are available when needed.

Scenario 3: Ensuring Compatibility of M12 1.50 Wheel Nuts with Various Vehicles

The Problem: A frequent concern for B2B buyers is ensuring that the M12 1.50 wheel nuts they purchase are compatible with a wide range of vehicles. This challenge is compounded when dealing with different seat types (e.g., conical, spherical) and hex sizes, which can vary significantly across manufacturers. Misalignment can lead to improper fit, which poses safety risks and may require costly replacements.

The Solution: To mitigate compatibility issues, buyers should invest time in creating a comprehensive database of the vehicle models they service, including specific lug nut requirements for each model. When sourcing M12 1.50 wheel nuts, buyers should look for suppliers that offer detailed product descriptions, including dimensions, seat types, and hex specifications. Additionally, using a standardized compatibility chart can help quickly identify which lug nuts fit which vehicles. Training staff to understand these specifications will also enhance the accuracy of orders and reduce the likelihood of returns due to compatibility issues. Regularly updating the database as new vehicle models are introduced will keep the inventory relevant and effective.

Strategic Material Selection Guide for m12 1.50 wheel nut

When selecting materials for M12 1.50 wheel nuts, it’s crucial to consider the properties of various materials that can impact performance, durability, and compliance with international standards. Here, we analyze four common materials used in manufacturing these wheel nuts: steel, aluminum, stainless steel, and titanium.

What are the Key Properties of Steel for M12 1.50 Wheel Nuts?

Steel is the most widely used material for M12 1.50 wheel nuts due to its strength and durability. Typically, carbon steel is used, which can withstand high temperatures and pressures. Steel wheel nuts can also be treated with coatings such as zinc or chrome to enhance corrosion resistance.

Pros: Steel offers excellent tensile strength and is relatively inexpensive, making it a cost-effective choice for mass production. Its availability and ease of machining further simplify manufacturing processes.

Cons: However, steel is prone to rusting if not properly coated, which can lead to premature failure in corrosive environments. Additionally, its weight can be a drawback in applications where reducing weight is essential.

Impact on Application: Steel wheel nuts are suitable for a wide range of vehicles, especially in regions with moderate climates. However, in humid or coastal areas, additional corrosion protection is necessary.

How Does Aluminum Compare for M12 1.50 Wheel Nuts?

Aluminum is another popular choice, particularly for performance vehicles where weight reduction is critical. Aluminum wheel nuts are lightweight and can be anodized for enhanced corrosion resistance.

Pros: The primary advantage of aluminum is its low density, which contributes to overall vehicle weight reduction. Anodizing also provides a protective layer that prevents corrosion.

Cons: However, aluminum is less strong than steel and may not be suitable for heavy-duty applications. It can also be more expensive than steel, impacting overall production costs.

Impact on Application: Aluminum wheel nuts are ideal for racing and high-performance vehicles, especially in regions like Europe and South America, where performance is often prioritized.

What Advantages Does Stainless Steel Offer for M12 1.50 Wheel Nuts?

Stainless steel combines the strength of steel with enhanced corrosion resistance due to its chromium content. This makes it an excellent choice for environments prone to rust and corrosion.

Pros: Stainless steel provides high tensile strength and is resistant to oxidation and corrosion. This durability makes it suitable for a wide range of applications, including those in harsh environments.

Cons: The primary disadvantage is its higher cost compared to regular steel and aluminum. Additionally, stainless steel can be more challenging to machine, which may complicate manufacturing processes.

Impact on Application: Stainless steel wheel nuts are particularly advantageous in regions like the Middle East and coastal areas where exposure to salt and moisture is prevalent.

Why Consider Titanium for M12 1.50 Wheel Nuts?

Titanium is a premium material known for its exceptional strength-to-weight ratio and corrosion resistance. Although it is less common for standard applications, it is increasingly used in high-performance and specialty vehicles.

Pros: Titanium is incredibly strong yet lightweight, making it ideal for applications where performance and weight savings are critical. Its resistance to corrosion is also superior to that of stainless steel.

Cons: The main drawback is the high cost of titanium, which can significantly increase the overall price of the wheel nuts. Additionally, titanium can be difficult to machine, requiring specialized equipment.

Impact on Application: Titanium wheel nuts are best suited for high-end automotive applications, particularly in Europe and North America, where performance and weight are prioritized.

Summary Table of Material Selection for M12 1.50 Wheel Nuts

| Material | Typical Use Case for M12 1.50 Wheel Nut | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General automotive applications | High strength, cost-effective | Prone to corrosion without coating | Low |

| Aluminum | Performance and racing vehicles | Lightweight, good corrosion resistance | Less strength, higher cost | Med |

| Stainless Steel | Harsh environments, marine applications | Excellent corrosion resistance | Higher cost, more complex manufacturing | High |

| Titanium | High-performance and specialty vehicles | Exceptional strength-to-weight ratio | Very high cost, difficult to machine | High |

This strategic material selection guide provides B2B buyers with valuable insights to make informed decisions when sourcing M12 1.50 wheel nuts, considering factors such as performance, cost, and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for m12 1.50 wheel nut

What Are the Key Stages in the Manufacturing Process of M12 1.50 Wheel Nuts?

Manufacturing M12 1.50 wheel nuts involves several critical stages, each designed to ensure the final product meets high-quality standards.

-

Material Preparation: The process begins with the selection of raw materials, typically high-strength steel or alloy steel. These materials are chosen for their durability and resistance to corrosion. After procurement, the materials undergo cleaning and inspection to remove any impurities or defects.

-

Forming: The cleaned steel is subjected to forming techniques such as forging or machining. Forging is preferred for its ability to enhance the mechanical properties of the metal, producing a denser and stronger wheel nut. This is followed by processes like threading, where the M12 x 1.50 threads are cut or rolled onto the nut to ensure precise fitment.

-

Assembly: While M12 wheel nuts are generally a single component, additional features such as washers or lock nuts may require assembly. This stage involves ensuring all components fit together seamlessly, which is critical for maintaining the structural integrity of the wheel assembly.

-

Finishing: The final stage involves applying surface treatments such as galvanization or chrome plating to enhance corrosion resistance and aesthetic appeal. This not only protects the wheel nut from environmental factors but also contributes to its longevity.

How Is Quality Assurance Implemented During Manufacturing?

Quality assurance (QA) is integral to the manufacturing of M12 1.50 wheel nuts. A robust QA process ensures that products meet international standards and are safe for use in various automotive applications.

-

International Standards Compliance: Many manufacturers adhere to international quality standards like ISO 9001, which outlines the requirements for a quality management system. Compliance with such standards helps ensure consistency and quality across production batches.

-

Industry-Specific Certifications: Depending on the market, wheel nuts may also need to comply with industry-specific certifications such as CE (Conformité Européenne) or API (American Petroleum Institute) standards. These certifications often involve rigorous testing and documentation to ensure safety and reliability.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified requirements.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps identify and rectify issues before they affect the final product.

– Final Quality Control (FQC): The completed wheel nuts undergo thorough testing, including dimensional inspections and strength testing, to confirm they meet all specifications.

What Common Testing Methods Are Used in Quality Assurance?

Quality assurance for M12 1.50 wheel nuts employs various testing methods to verify performance and safety.

- Mechanical Testing: This includes tensile strength tests, hardness tests, and fatigue tests to ensure the wheel nuts can withstand the stresses experienced during operation.

- Dimensional Inspection: Precision measuring tools are used to verify that the dimensions, such as thread pitch and hex size, meet the required specifications.

- Corrosion Testing: Salt spray tests are often conducted to evaluate the effectiveness of protective coatings and to assess how well the wheel nuts resist corrosion over time.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability.

-

Supplier Audits: Conducting on-site audits of the manufacturing facility allows buyers to assess the quality management systems in place and ensure compliance with international standards.

-

Quality Assurance Reports: Requesting detailed QA reports, including results from testing and inspection processes, provides insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an impartial evaluation of the manufacturing processes and the quality of the products being supplied.

What Are the Quality Control and Certification Nuances for International Buyers?

When sourcing M12 1.50 wheel nuts, international buyers must be aware of specific quality control nuances that can impact procurement.

-

Regulatory Compliance: Different regions may have distinct regulations regarding automotive components. Buyers must ensure that the products meet local standards, which may involve additional testing and certification.

-

Documentation: Maintaining thorough documentation of compliance certificates, quality reports, and test results is essential for international trade. This documentation may be required for customs clearance and can facilitate smoother transactions.

-

Cultural Considerations: Understanding the cultural and business practices in different regions can enhance communication with suppliers. This is particularly important in markets such as Africa and the Middle East, where relationship-building is key.

Conclusion

In conclusion, the manufacturing processes and quality assurance practices for M12 1.50 wheel nuts are multifaceted and critical to ensuring product safety and performance. For B2B buyers, understanding these processes not only aids in selecting reliable suppliers but also enhances the overall procurement strategy, particularly in diverse and global markets. By focusing on quality assurance, compliance with international standards, and rigorous testing, buyers can secure durable and dependable wheel nuts that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘m12 1.50 wheel nut’

When sourcing M12 1.50 wheel nuts, it is essential to follow a structured approach that ensures quality, compatibility, and cost-effectiveness. This guide serves as a comprehensive checklist for B2B buyers, particularly in international markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring compatibility with your vehicles or machinery. Consider the thread size (M12-1.50), hex size (typically 19mm), and seat style (usually conical). These specifications will help narrow down options and facilitate discussions with suppliers.

Step 2: Research and Identify Reliable Suppliers

Conduct thorough research to identify potential suppliers specializing in automotive hardware. Look for suppliers with a proven track record in your target markets, such as those who have experience exporting to regions like Nigeria or Saudi Arabia. Utilize online directories, trade shows, and industry associations to compile a list of reputable vendors.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with international standards. This includes checking for ISO certifications, quality assurance processes, and adherence to local regulations. Suppliers with proper certifications are more likely to provide reliable products and services.

Step 4: Request Samples for Quality Assessment

Always request samples of the M12 1.50 wheel nuts before placing a bulk order. This step allows you to assess the quality, finish, and durability of the nuts. Conduct tests for strength and compatibility with your vehicle to ensure they meet your operational requirements.

Step 5: Compare Pricing and Payment Terms

Once you have identified suitable suppliers, compare their pricing structures and payment terms. Take note of any additional costs such as shipping, customs duties, or minimum order quantities. Negotiating favorable payment terms can enhance your cash flow management and overall procurement strategy.

Step 6: Review Lead Times and Delivery Options

Understanding lead times and delivery options is critical for maintaining your supply chain efficiency. Ask suppliers about their production capacities and typical shipping times to your region. This information will help you plan your inventory and avoid potential delays.

Step 7: Establish a Communication Plan

Effective communication is vital for successful sourcing. Establish a clear communication plan with your chosen supplier, including regular updates on order status, potential issues, and feedback mechanisms. This proactive approach can help mitigate misunderstandings and foster a strong business relationship.

By following this checklist, B2B buyers can streamline the procurement process for M12 1.50 wheel nuts, ensuring they select the right products from reliable suppliers while maintaining cost-effectiveness and quality standards.

Comprehensive Cost and Pricing Analysis for m12 1.50 wheel nut Sourcing

When sourcing M12 1.50 wheel nuts, understanding the comprehensive cost structure is crucial for B2B buyers, particularly in diverse international markets such as Africa, South America, the Middle East, and Europe. This analysis delves into the various cost components, price influencers, and actionable tips for buyers to optimize their purchasing decisions.

What Are the Key Cost Components for M12 1.50 Wheel Nuts?

The cost structure for M12 1.50 wheel nuts can be broken down into several key components:

-

Materials: The primary material used is steel, often treated with zinc plating for corrosion resistance. The quality of the steel and any additional treatments can significantly impact costs. For example, premium grades or specialized coatings may lead to higher prices.

-

Labor: Labor costs can vary based on the region of manufacturing. Countries with lower labor costs may offer competitive pricing, but this can sometimes come at the expense of quality. Understanding the labor dynamics in the supplier’s region is vital.

-

Manufacturing Overhead: This includes costs associated with factory operations, maintenance, and utilities. Efficient manufacturing processes can help keep these costs down, potentially leading to more favorable pricing for buyers.

-

Tooling: Initial setup costs for machinery and molds can be substantial, especially for custom or specialized products. However, these costs are typically amortized over larger production runs, so ordering in bulk can mitigate this factor.

-

Quality Control (QC): Ensuring that the wheel nuts meet specific standards requires rigorous QC processes. Suppliers may pass these costs onto buyers, so it’s essential to consider the implications of quality assurance on overall pricing.

-

Logistics: Transportation costs, including shipping and handling, can vary widely based on the supplier’s location and the destination market. Incoterms will also influence who bears these costs, impacting the final price.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure sustainability. This margin can vary based on market demand, competition, and the supplier’s positioning.

How Do Price Influencers Affect M12 1.50 Wheel Nut Pricing?

Several factors influence the pricing of M12 1.50 wheel nuts:

-

Volume/MOQ: Many suppliers offer tiered pricing based on order volume. Higher quantities often lead to lower per-unit costs, making it advantageous for buyers to negotiate for bulk orders.

-

Specifications and Customization: Custom specifications can significantly increase costs. Buyers should weigh the need for unique features against the potential for higher pricing.

-

Quality and Certifications: Compliance with international standards or certifications (e.g., ISO) may enhance quality but can also raise costs. Buyers should assess the importance of these certifications based on their market requirements.

-

Supplier Factors: The reputation and reliability of a supplier can affect pricing. Established suppliers may command higher prices due to their track record, while newer or less reputable ones might offer lower costs to attract business.

-

Incoterms: These terms define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs. Understanding the implications of Incoterms can help buyers avoid unexpected costs.

What Are the Best Tips for B2B Buyers When Sourcing Wheel Nuts?

-

Negotiate Wisely: Always negotiate pricing, especially for larger orders. Suppliers may be willing to offer discounts or more favorable terms to secure a deal.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors such as durability, maintenance, and replacement costs. A lower-priced nut may result in higher long-term expenses if it requires frequent replacement.

-

Understand Pricing Nuances for International Markets: Different regions may have unique pricing structures based on local demand and supply dynamics. For instance, buyers in Nigeria may face different logistical challenges compared to those in Saudi Arabia, affecting overall costs.

-

Request Samples: Before placing large orders, request samples to evaluate quality. This step can prevent costly mistakes and ensure that the product meets your specifications.

In summary, a thorough understanding of the cost components and price influencers, coupled with strategic buying practices, can significantly enhance the sourcing process for M12 1.50 wheel nuts in the international B2B market. Always keep in mind that prices can fluctuate, and it’s advisable to approach sourcing with a flexible and informed mindset.

Alternatives Analysis: Comparing m12 1.50 wheel nut With Other Solutions

Introduction: Understanding Alternatives to the M12 1.50 Wheel Nut

When considering the right fastener for automotive applications, such as wheel nuts, it’s essential to explore various options available in the market. The M12 1.50 wheel nut is a popular choice among B2B buyers, but there are alternative solutions that may better suit specific needs based on factors like performance, cost, and application. This analysis will compare the M12 1.50 wheel nut with two viable alternatives: the M12-1.25 wheel nut and the use of lug nut locks.

Comparison Table

| Comparison Aspect | M12 1.50 Wheel Nut | M12-1.25 Wheel Nut | Lug Nut Locks |

|---|---|---|---|

| Performance | High strength, reliable for heavy loads | Suitable for lighter applications | Enhances security against theft |

| Cost | Moderate, typically ranges from $15-$30 | Generally lower, around $10-$25 | Higher initial cost, $30-$60 |

| Ease of Implementation | Standard installation procedures | Similar installation ease | Requires additional key or tool |

| Maintenance | Low maintenance; durable materials | Low maintenance; less durable than M12 1.50 | Periodic checks needed for security |

| Best Use Case | Heavy-duty vehicles and trucks | Compact cars and lighter vehicles | Vehicles in high-theft areas |

Detailed Breakdown of Alternatives

M12-1.25 Wheel Nut: A Lighter Alternative

The M12-1.25 wheel nut offers a viable alternative for applications where weight and load are less critical. Its finer thread pitch makes it suitable for lighter vehicles, allowing for efficient fastening without the added bulk. While it may be less robust than the M12 1.50 variant, its lower cost and ease of installation make it appealing for smaller fleets or passenger vehicles. However, B2B buyers should be cautious, as using this type of wheel nut on heavier vehicles could lead to compromised safety and performance.

Lug Nut Locks: Enhanced Security Option

Lug nut locks serve as an alternative for those prioritizing vehicle security. These specialized nuts require a unique key for removal, deterring theft and unauthorized access. While their initial cost is higher compared to standard wheel nuts, the investment can pay off for businesses operating in areas with high theft rates. However, they can complicate routine maintenance and tire changes, as the special key must always be on hand. This trade-off between security and convenience should be carefully considered by B2B buyers.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate wheel nut or fastening solution hinges on understanding the specific requirements of your application. The M12 1.50 wheel nut excels in heavy-duty scenarios, while the M12-1.25 provides a cost-effective solution for lighter vehicles. For those concerned about theft, lug nut locks offer additional security, albeit with some potential drawbacks in maintenance. B2B buyers should evaluate their operational needs, budget constraints, and security concerns to make an informed choice that aligns with their vehicle and fleet requirements.

Essential Technical Properties and Trade Terminology for m12 1.50 wheel nut

What Are the Key Technical Properties of an M12 1.50 Wheel Nut?

When purchasing M12 1.50 wheel nuts, understanding their technical properties is essential for ensuring compatibility and performance. Here are some critical specifications that buyers should consider:

-

Thread Size and Pitch: The M12 designation indicates a metric thread size of 12 mm, while the ‘1.50’ specifies the pitch, which is the distance between threads. This specification is crucial because it ensures that the wheel nut will fit the corresponding wheel stud. Incompatibility can lead to safety issues, including wheel detachment.

-

Hex Size: The hex size, typically 19 mm for M12 1.50 nuts, determines the type of wrench required for installation and removal. A correct fit is vital for avoiding damage to the nut or wheel stud during installation, ensuring ease of service and maintenance.

-

Material Composition: Most M12 1.50 wheel nuts are made from high-strength steel, often with a zinc coating for corrosion resistance. The material grade is important for durability and load-bearing capacity, which impacts the wheel nut’s lifespan and performance under stress.

-

Seat Style: The seat style, often conical (60 degrees), refers to the shape of the contact surface that interfaces with the wheel. This design helps distribute the load evenly and provides a secure fit. The wrong seat style can lead to improper seating and potential wheel failure.

-

Height and Diameter: The height (typically around 14 mm) and outer diameter are additional dimensions that affect the overall compatibility with the wheel and vehicle specifications. These measurements ensure that the nut fits snugly without interfering with brake components or wheel designs.

-

Finish: The finish of the wheel nut, such as chrome or zinc plating, not only enhances aesthetics but also provides protection against rust and wear. This is particularly important in regions with harsh weather conditions, helping to extend the lifespan of the wheel nut.

What Are Common Trade Terms Related to M12 1.50 Wheel Nuts?

Familiarity with industry jargon can streamline the procurement process. Here are some important terms to know:

-

OEM (Original Equipment Manufacturer): Refers to the original manufacturer of the vehicle or its components. OEM parts, including wheel nuts, are designed to meet specific standards, ensuring compatibility and quality. Buyers often prefer OEM parts for reliability.

-

MOQ (Minimum Order Quantity): This term defines the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for budgeting and ensuring that your order meets the supplier’s requirements, especially for bulk purchases.

-

RFQ (Request for Quotation): An RFQ is a formal document sent to suppliers requesting pricing and terms for specified products. When sourcing M12 1.50 wheel nuts, an RFQ helps buyers compare offers and negotiate better pricing.

-

Incoterms (International Commercial Terms): These terms define the responsibilities of buyers and sellers in international shipping. Knowing which Incoterm applies to your order can clarify who bears the costs and risks during transportation, impacting overall pricing.

-

Lead Time: This term refers to the time taken from placing an order to delivery. Understanding lead times helps in inventory management and planning, ensuring that you have the necessary components when required.

-

Aftermarket: Refers to parts not made by the original manufacturer. Aftermarket wheel nuts can be more affordable, but it’s essential to verify that they meet the required specifications and quality standards.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing M12 1.50 wheel nuts, ensuring both performance and compatibility in their applications.

Navigating Market Dynamics and Sourcing Trends in the m12 1.50 wheel nut Sector

What Are the Key Trends Driving the M12 1.50 Wheel Nut Market?

The global market for M12 1.50 wheel nuts is experiencing significant transformation, influenced by various drivers such as rising vehicle production, the expanding automotive aftermarket, and increased safety regulations. In regions like Africa, South America, and the Middle East, the growing middle class and urbanization are contributing to higher vehicle ownership rates, driving demand for reliable and high-quality automotive components. Moreover, the surge in e-commerce has made it easier for international B2B buyers to source these products directly from manufacturers across the globe, promoting competitive pricing and diverse options.

Emerging technologies are reshaping sourcing trends as well. The adoption of digital platforms for procurement and inventory management is streamlining the buying process, allowing buyers to access real-time data and analytics for better decision-making. Manufacturers are increasingly leveraging automation and advanced materials to improve product durability and performance, catering to the evolving needs of the market. Additionally, the emphasis on customization and aesthetic appeal in wheel nut designs, including various finishes and styles, is becoming a crucial factor for buyers looking to differentiate their offerings.

How Important is Sustainability and Ethical Sourcing in the M12 1.50 Wheel Nut Sector?

As global awareness of environmental issues rises, sustainability and ethical sourcing have become vital considerations for B2B buyers in the M12 1.50 wheel nut sector. The production of these components often involves significant resource consumption and environmental impact, prompting a shift toward greener practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through responsible sourcing of raw materials, reduced carbon footprints, and waste management strategies.

Ethical supply chains are essential in ensuring that materials used in manufacturing are sourced responsibly, without contributing to social or environmental harm. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) are becoming important indicators for buyers assessing supplier credibility. Furthermore, using recycled materials or eco-friendly coatings can enhance product appeal, as consumers are more inclined to support brands that align with their values. For international buyers, especially in regions like Europe where regulatory frameworks are stricter, partnering with certified suppliers can also mitigate risk and enhance brand reputation.

What is the Historical Context of the M12 1.50 Wheel Nut Market?

The M12 1.50 wheel nut has evolved significantly since its inception, reflecting changes in automotive technology and consumer preferences. Initially designed for basic functionality, these nuts have progressed to include various styles and finishes, catering to both performance and aesthetic demands. The automotive industry’s shift towards safety and quality has led to stricter manufacturing standards, ensuring that products like the M12 1.50 wheel nut not only meet but exceed industry requirements.

In recent years, the rise of aftermarket modifications has further propelled the growth of specialized wheel nuts, as consumers seek personalized options for their vehicles. This evolution underscores the importance of adaptability within the sector, as manufacturers and suppliers strive to meet the changing needs of a diverse global market. As the automotive landscape continues to evolve, understanding this historical context will enable B2B buyers to make informed sourcing decisions that align with current trends and future developments.

Frequently Asked Questions (FAQs) for B2B Buyers of m12 1.50 wheel nut

-

How do I ensure the quality of M12 1.50 wheel nuts when sourcing internationally?

To ensure quality, it’s essential to vet suppliers thoroughly. Request product samples to assess material quality and manufacturing standards. Look for certifications such as ISO 9001, which indicates adherence to quality management systems. Additionally, consider suppliers with a proven track record and positive reviews in your region. Engaging in third-party quality assurance checks can further mitigate risks, especially when importing from regions with varying manufacturing standards. -

What is the best type of M12 1.50 wheel nut for my vehicle?

The best type of M12 1.50 wheel nut depends on your vehicle’s specifications, particularly the wheel type and seat style. Conical seat (60-degree) nuts are commonly used for standard applications, while bulge acorn nuts may be better for aftermarket wheels. Consult your vehicle manual or a mechanic to ensure compatibility. Choosing the right nut not only enhances safety but also ensures optimal wheel performance. -

What are the typical minimum order quantities (MOQ) for M12 1.50 wheel nuts?

MOQs can vary significantly among suppliers. Generally, MOQs for M12 1.50 wheel nuts range from 100 to 1,000 units, depending on the manufacturer and the type of nut. Some suppliers may offer lower MOQs for customized products, while others might require larger quantities for bulk pricing discounts. It’s advisable to discuss your needs with suppliers to negotiate terms that suit your purchasing strategy. -

What payment terms should I expect when sourcing M12 1.50 wheel nuts?

Payment terms can vary widely among suppliers and regions. Common terms include a 30% deposit upfront with the balance due upon delivery or before shipping. Some suppliers may offer letter of credit (LC) options, especially for larger orders. It’s crucial to establish clear payment conditions before finalizing agreements to avoid misunderstandings. Always consider using secure payment methods to protect your transaction. -

How can I customize M12 1.50 wheel nuts for my business?

Customization options may include changes to color, finish, or branding (such as adding your logo). Many manufacturers offer these services, but it’s important to discuss your specific requirements during initial negotiations. Keep in mind that customized products may have higher MOQs and longer lead times. Ensure that you clearly communicate your needs to the supplier to avoid delays in production. -

What are the logistics considerations when importing M12 1.50 wheel nuts?

Logistics involve understanding shipping options, customs regulations, and lead times. Choose a reliable freight forwarder familiar with international shipping to facilitate smooth delivery. Ensure that you are aware of any tariffs or import duties applicable to your region. Additionally, plan for potential delays and communicate with your supplier regarding shipping timelines to manage inventory effectively. -

How do I verify the credibility of a supplier for M12 1.50 wheel nuts?

To verify a supplier’s credibility, research their business history, customer reviews, and industry reputation. Utilize platforms like Alibaba or Global Sources to check ratings and feedback. Request references from previous clients and inquire about their experience with the supplier. Conducting a factory visit or utilizing third-party inspection services can also provide valuable insights into the supplier’s capabilities and reliability. -

What are the common applications for M12 1.50 wheel nuts in various industries?

M12 1.50 wheel nuts are widely used in the automotive industry for passenger vehicles, trucks, and motorcycles. They are essential for securing wheels in transportation and logistics sectors. Additionally, they find applications in manufacturing and assembly lines where vehicle maintenance is critical. Understanding the specific needs of your target market can guide purchasing decisions and ensure you stock the appropriate types of wheel nuts for various applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 M12 1.50 Wheel Nut Manufacturers & Suppliers List

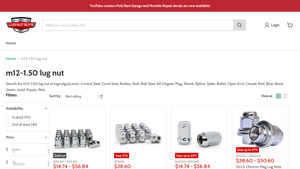

1. Lug Nut Guys – Key Product

Domain: lugnutguys.com

Registered: 2010 (15 years)

Introduction: Key Product Details:

– Product Type: m12-1.50 Lug Nut

– Seat Types: Conical Seat, Cone Seat, Radius Seat, Ball Seat, 60 Degree, Mag, Shank, Spline, Spike, Bullet, Open End, Closed

– Available Colors: Red, Blue, Black, Green, Gold, Purple, Pink

– Availability: In stock (93), Out of stock (45)

– Price Range: $14.74 – $56.84

– Original Prices: $30.00 – $114.00

– Specific Fitment:

– Fits mos…

2. Lawson Products – M12-1.50 Wheel Nut

3. Dorman – Wheel Nut M12-1.50 Capped

Domain: dormanproducts.com

Registered: 2001 (24 years)

Introduction: This company, Dorman – Wheel Nut M12-1.50 Capped, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Dorman – Wheel Nut M12-1.50

Domain: dormanhdsolutions.com

Registered: 2011 (14 years)

Introduction: This company, Dorman – Wheel Nut M12-1.50, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Advance Auto Parts – Lug Nut 711-315A

Domain: shop.advanceautoparts.com

Registered: 1997 (28 years)

Introduction: {“Part No.”: “711-315A”, “Warranty”: “LIMITED LIFETIME REPLACEMENT”, “Thread”: “M12-1.50”, “Seat Style”: “Conical 60 deg”, “Lug Length”: “1.35 in”, “Color”: “Black Chrome”, “Bolt Grade”: “Grade 5”, “Flanged”: “No”, “Grade Type”: “Standard Replacement”, “Head Style”: “Spline Drive”, “Lock Design Pattern”: “External”, “Lug Outside Diameter”: “0.789 in”, “Material”: “Chrome”, “Package Contents”: “4 S…

6. NAPA – 10 Pack Wheel Nut M12-1.50

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “10 Pack Wheel Nut M12-1.50 641-3372”, “Condition”: “New”, “Brand”: “NAPA”, “Manufacturer Part Number”: “641-3372”, “Price”: “$42.99 or Best Offer”, “Shipping”: “Free shipping”, “Estimated Delivery”: “Fri, Sep 12 – Tue, Sep 16”, “Quantity Available”: “1”}

Strategic Sourcing Conclusion and Outlook for m12 1.50 wheel nut

In summary, the strategic sourcing of M12-1.50 wheel nuts presents significant opportunities for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The demand for high-quality, durable wheel nuts is driven by the automotive industry’s need for reliable components that ensure safety and performance. Buyers should focus on suppliers that offer a range of options, including various finishes and designs, to meet specific vehicle requirements and preferences.

Establishing strong relationships with reputable manufacturers can lead to competitive pricing, timely deliveries, and access to the latest innovations in wheel nut technology. Moreover, understanding local market dynamics and consumer trends will empower buyers to make informed purchasing decisions that align with regional demands.

As we look to the future, it is essential for B2B buyers to proactively explore partnerships that foster sustainability and efficiency in sourcing. By prioritizing strategic sourcing practices, companies can not only enhance their supply chain resilience but also drive growth in their respective markets. Now is the time to engage with suppliers who can meet your needs and elevate your business in the competitive automotive landscape.