10 Car Window Tint Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for 10 car window tint

In the ever-evolving automotive industry, sourcing high-quality car window tint solutions can pose significant challenges for international B2B buyers. With the increasing demand for both aesthetics and functionality, businesses must navigate a complex landscape to identify the best options that cater to diverse market needs. This guide focuses on ten essential car window tint products, providing detailed insights into their types, applications, and the nuances of supplier vetting.

As businesses in regions like Africa, South America, the Middle East, and Europe, including Saudi Arabia and Brazil, seek to enhance their vehicle offerings, understanding the intricacies of window tint solutions becomes crucial. From ceramic films that offer superior heat rejection to dyed and carbon options that balance cost and performance, this comprehensive resource will empower buyers to make informed purchasing decisions.

Additionally, we will delve into considerations such as local tint regulations, warranty options, and the long-term cost implications of various tint types. By equipping international buyers with actionable insights and practical tips, this guide aims to facilitate strategic sourcing and foster successful partnerships in the global car window tint market. Whether enhancing vehicle aesthetics or improving energy efficiency, your journey toward finding the right window tint begins here.

Understanding 10 car window tint Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ceramic Tint | High heat and UV rejection, non-metallic, color-stable | Automotive, commercial buildings | Pros: Excellent performance, longevity; Cons: Higher initial cost |

| Carbon Tint | Enhanced heat rejection, matte finish, UV protection | Automotive, residential properties | Pros: Cost-effective, aesthetic appeal; Cons: May fade over time |

| Dyed Tint | Basic heat and UV protection, dyed layers for color | Budget vehicles, fleet services | Pros: Affordable, easy installation; Cons: Limited durability and performance |

| Metalized Tint | Reflective surface, blocks heat and UV rays | Automotive, commercial vehicles | Pros: Durable, enhances privacy; Cons: Can interfere with electronics |

| Hybrid Tint | Combination of dyed and metalized layers | Automotive, luxury vehicles | Pros: Balanced performance, aesthetic options; Cons: Compromise on some features |

What Are the Key Characteristics of Ceramic Tint?

Ceramic tint is known for its superior heat and UV rejection capabilities, making it an ideal choice for both automotive and commercial applications. Its non-metallic nature prevents interference with electronic devices, which is crucial for modern vehicles equipped with advanced technology. Buyers should consider the initial investment, as ceramic films tend to be more expensive but offer long-term savings through energy efficiency and durability.

How Does Carbon Tint Stand Out in the Market?

Carbon tint features a matte finish and is effective at blocking infrared rays, which helps maintain a cooler interior temperature. This type of tint is particularly popular among automotive and residential property owners looking for a cost-effective solution that provides aesthetic value. While carbon tint is generally more affordable than ceramic options, potential buyers should be aware that it may not perform as well over extended periods, especially in terms of fading.

Why Choose Dyed Tint for Budget-Friendly Solutions?

Dyed tint is often the go-to choice for budget-conscious buyers, offering basic UV protection and a range of color options. This type is commonly used in fleet services and budget vehicles, where cost efficiency is paramount. However, businesses should weigh the pros and cons, as dyed films can fade over time and may not provide the same level of durability or performance as higher-end options.

What Are the Advantages of Metalized Tint?

Metalized tint is recognized for its reflective properties, which effectively block heat and UV rays. It is commonly utilized in automotive and commercial settings, enhancing privacy and vehicle aesthetics. While metalized films are durable and long-lasting, businesses should consider the potential downsides, such as possible interference with GPS and cellular signals, which can be a critical factor for many buyers.

How Does Hybrid Tint Provide a Compromise Solution?

Hybrid tint combines the benefits of dyed and metalized films, offering a balanced approach to performance and aesthetics. It is often favored in luxury vehicles where visual appeal is as important as functionality. While hybrid films can deliver a good mix of heat rejection and UV protection, buyers should assess their specific needs, as they may not excel in any one area compared to dedicated film types.

Key Industrial Applications of 10 car window tint

| Industry/Sector | Specific Application of 10 car window tint | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Vehicle Window Tinting for Passenger and Fleet Vehicles | Enhances comfort, reduces glare, and protects interiors | Compliance with local regulations and tint laws |

| Construction | Tinting for Commercial Buildings | Energy savings, improved aesthetics, and UV protection | Certification of tint quality and sustainability |

| Hospitality | Tinting for Hotels and Resorts | Increases guest comfort, enhances privacy, reduces energy costs | Customization options for branding and design |

| Transportation & Logistics | Tinting for Freight and Delivery Vehicles | Protects cargo from UV damage and maintains temperature | Durability and performance under various weather conditions |

| Security Services | Tinting for Armored Vehicles | Enhances privacy and protects against break-ins | High-performance films with security certifications |

How is ’10 car window tint’ utilized in the Automotive Industry?

In the automotive sector, ’10 car window tint’ serves as a crucial enhancement for passenger and fleet vehicles. By reducing glare and blocking up to 99% of harmful UV rays, it significantly improves passenger comfort, especially in regions with intense sunlight, such as the Middle East and Africa. This tint also protects vehicle interiors from fading and cracking, extending the life of upholstery and dashboard materials. International B2B buyers should ensure compliance with local tint regulations, as varying laws exist across regions like Europe and South America.

What role does ’10 car window tint’ play in Construction?

In the construction industry, ’10 car window tint’ is applied to commercial buildings to provide energy efficiency and aesthetic appeal. By rejecting heat and UV radiation, the tint contributes to lower energy costs for cooling systems, making it an attractive option for businesses looking to reduce operational expenses. Additionally, it enhances the building’s exterior appearance and provides occupants with increased comfort. Buyers must consider certifications and sustainability claims when sourcing tint, ensuring compliance with local building codes and environmental standards.

How is ’10 car window tint’ beneficial for the Hospitality Sector?

Hotels and resorts utilize ’10 car window tint’ to improve guest experiences by enhancing comfort and privacy. By reducing heat and glare, the tint creates a more enjoyable environment, which can lead to higher guest satisfaction and repeat business. Furthermore, it can be customized to align with branding efforts, integrating seamlessly with the overall design of the property. International buyers should focus on customization options and the durability of the tint, ensuring it meets the specific aesthetic and functional needs of their establishments.

Why is ’10 car window tint’ essential for Transportation & Logistics?

In the transportation and logistics sector, ’10 car window tint’ is vital for freight and delivery vehicles. It protects cargo from UV damage, which is particularly important for perishable goods or sensitive materials. Moreover, it helps maintain a consistent interior temperature, reducing energy costs associated with climate control systems. Buyers in this sector should prioritize the durability and performance of the tint, especially in varying weather conditions, to ensure it withstands the rigors of transportation.

How does ’10 car window tint’ enhance security services?

Security services benefit from ’10 car window tint’ applied to armored vehicles, as it enhances privacy and deters potential break-ins. The tint can obscure the view into the vehicle, making it harder for criminals to assess the valuables inside. Additionally, high-performance films can offer added protection against shattering glass during a break-in attempt. Buyers should seek out tints with security certifications to ensure they meet the necessary standards for protective films.

3 Common User Pain Points for ’10 car window tint’ & Their Solutions

Scenario 1: Complications with Compliance and Regulations

The Problem: Many B2B buyers, especially those in regions like the Middle East and South America, often face challenges with local regulations surrounding window tinting. These regulations can vary significantly from country to country or even city to city, creating uncertainty about the types of tints that can be legally applied. For instance, a buyer might invest heavily in a high-quality ceramic tint only to find that it exceeds the allowable darkness or reflection levels. This can lead to costly removals, potential fines, and damaged reputations.

The Solution: To navigate these regulatory hurdles, B2B buyers should prioritize thorough research before making a purchase. This includes consulting local laws regarding window tinting and seeking advice from local authorities or legal experts. Buyers should also work closely with suppliers who are familiar with compliance in their specific markets. For added assurance, sourcing tints that come with documentation proving their compliance with local regulations can help mitigate risks. Additionally, maintaining open communication with installation partners ensures that the tinting is done according to legal specifications, thereby avoiding future complications.

Scenario 2: Quality Assurance and Performance Issues

The Problem: A common concern among B2B buyers is the inconsistency in quality and performance of window tints. Buyers may have previously experienced products that fade, bubble, or peel shortly after installation, leading to customer dissatisfaction and increased warranty claims. This issue is particularly prevalent when sourcing from multiple suppliers without established quality controls, especially for those new to the market or looking to cut costs.

The Solution: To ensure high-quality purchases, B2B buyers should establish a reliable supply chain with reputable manufacturers known for their quality assurance processes. It’s advisable to request samples and conduct thorough testing under various conditions (such as heat and UV exposure) before placing larger orders. Buyers should also ask for warranties that cover product longevity and performance, ensuring they have recourse in case of defects. Collaborating with suppliers who provide comprehensive installation training can further improve outcomes, as proper application is crucial for the performance and longevity of window tints.

Scenario 3: Installation Challenges and Customer Satisfaction

The Problem: Installation issues can severely impact customer satisfaction and lead to increased operational costs. Many buyers find that their teams lack the necessary skills or tools to install window tint correctly, resulting in unsightly bubbles, misalignment, or damage to the vehicle’s glass. This not only frustrates customers but also leads to costly rework and damage claims.

The Solution: B2B buyers should invest in training programs for their installation teams, ensuring they are well-equipped with the necessary skills and knowledge to perform high-quality installations. Partnering with suppliers that offer installation kits, tools, and ongoing support can facilitate smoother operations. Additionally, providing comprehensive product guides and video tutorials can help teams avoid common pitfalls during installation. Creating a feedback loop with customers post-installation can also help identify issues quickly, allowing for timely resolutions that enhance customer loyalty and trust.

Strategic Material Selection Guide for 10 car window tint

What Are the Key Materials Used in Car Window Tinting?

When selecting materials for car window tint, it is essential to consider the properties, advantages, and limitations of various options. The most common materials used in car window tinting include dyed films, metalized films, carbon films, and ceramic films. Each material presents unique characteristics that can significantly influence performance, durability, and cost-effectiveness, particularly for international B2B buyers.

How Do Dyed Films Perform in Car Window Tinting?

Dyed films are made by infusing color into a polyester base layer. They are primarily used for aesthetic purposes and provide a moderate level of heat and UV rejection.

Key Properties: Dyed films typically offer a light transmission range of 5% to 50%, depending on the shade chosen. They have a lower temperature resistance compared to other materials and can fade over time due to UV exposure.

Pros & Cons: The main advantage of dyed films is their affordability, making them a popular choice for budget-conscious buyers. However, they are less durable and can suffer from fading, bubbling, and peeling, especially in harsh climates, which can be a significant drawback for buyers in regions like Saudi Arabia or Brazil.

Impact on Application: Dyed films are suitable for applications where aesthetic appeal is prioritized over performance. However, their limited UV protection may not meet regulatory standards in some countries.

What Are the Benefits of Metalized Films?

Metalized films incorporate thin layers of metal, enhancing their reflective properties. This material is effective in blocking heat and UV rays while providing a sleek appearance.

Key Properties: Metalized films can reject up to 99% of UV rays and significantly reduce heat. However, they can interfere with electronic signals, which may be a concern for vehicles equipped with GPS or satellite radio.

Pros & Cons: The reflective nature of metalized films provides excellent solar control, making them suitable for hot climates. However, their metallic composition can lead to corrosion over time, particularly in humid environments, which can be a disadvantage for buyers in coastal regions.

Impact on Application: Metalized films are often favored for their performance but may not be compatible with all vehicle types due to potential interference with electronic systems.

Why Choose Carbon Films for Car Window Tinting?

Carbon films are known for their durability and performance. They are made from carbon particles, which provide a non-reflective finish and excellent heat rejection.

Key Properties: Carbon films can block up to 99% of UV rays and provide significant heat rejection without the reflective properties of metalized films. They are also color-stable, meaning they won’t fade over time.

Pros & Cons: The primary advantage of carbon films is their longevity and performance, making them suitable for various climates. However, they tend to be more expensive than dyed films, which could be a consideration for budget-sensitive buyers.

Impact on Application: Carbon films are ideal for high-performance applications, particularly in regions with extreme temperatures, as they maintain their effectiveness over time.

What Advantages Do Ceramic Films Offer?

Ceramic films are the premium option in the window tint market, made from advanced ceramic materials that provide superior performance.

Key Properties: They offer excellent UV and infrared rejection (up to 99%) without interfering with electronic signals. Ceramic films are also highly durable and resistant to fading.

Pros & Cons: The main advantage of ceramic films is their unmatched performance and longevity, making them a worthwhile investment. However, they come at a higher cost compared to other options, which may deter some buyers.

Impact on Application: Ceramic films are particularly suitable for high-end vehicles and applications where maximum performance is required, making them a preferred choice in markets with stringent regulations regarding UV protection.

Summary Table of Material Selection for Car Window Tint

| Material | Typical Use Case for 10 Car Window Tint | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Dyed Films | Budget-friendly tinting solutions | Cost-effective and aesthetically pleasing | Prone to fading and bubbling | Low |

| Metalized Films | Performance-focused applications | Excellent heat and UV rejection | Can interfere with electronic signals | Medium |

| Carbon Films | High-performance tinting | Durable and color-stable | Higher cost compared to dyed films | Medium |

| Ceramic Films | Premium applications | Superior performance and longevity | High initial investment | High |

This analysis provides B2B buyers with a comprehensive understanding of the materials available for car window tinting, enabling informed decisions based on performance, cost, and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 10 car window tint

What Are the Key Stages in the Manufacturing Process of Car Window Tint?

The manufacturing process of car window tint involves several crucial stages, ensuring that the final product meets the high standards expected by B2B buyers globally. The main stages include material preparation, forming, assembly, and finishing.

1. Material Preparation:

The process begins with selecting high-quality raw materials. For ceramic tints, nano-ceramic particles are often used, which are non-metallic and non-conductive. These materials are sourced from reputable suppliers and must undergo rigorous testing to ensure they meet specified standards. During this stage, manufacturers often evaluate the material’s optical clarity, UV resistance, and thermal properties.

2. Forming:

In the forming stage, the raw materials are processed into thin films. This is typically achieved through techniques such as casting or extrusion. The film’s thickness can vary, but it generally ranges from 1 to 2 mils. Advanced technologies like nano-coating may also be employed to enhance the film’s properties, such as scratch resistance and durability.

3. Assembly:

Once the films are formed, they are cut to size based on customer specifications. This stage may include the application of adhesive layers that facilitate easy installation on vehicle windows. Quality control measures are implemented at this point to ensure that the dimensions and adhesive properties are consistent and meet the required standards.

4. Finishing:

The finishing stage involves applying protective layers to the tint film to enhance its durability and performance. This may include treatments to improve scratch resistance or to give the film specific aesthetic qualities, such as a glossy or matte finish. The final product is then rolled or packaged for distribution.

How is Quality Assurance Implemented in Car Window Tint Manufacturing?

Quality assurance (QA) is integral to the manufacturing of car window tint, ensuring that products meet or exceed international and industry standards. Key aspects of QA include adherence to internationally recognized standards, strategic checkpoints throughout the production process, and robust testing methods.

International Standards:

Manufacturers often adhere to ISO 9001 standards, which focus on quality management systems. Compliance with these standards ensures that manufacturers maintain consistent quality in their processes. In addition to ISO, regional certifications such as CE in Europe or API standards may apply, particularly for products intended for specific markets.

Quality Control Checkpoints:

Several checkpoints are established throughout the manufacturing process to ensure quality is maintained:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet predefined criteria before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to monitor the quality of the product as it is being produced. This can include checking film thickness, clarity, and adherence to specifications.

-

Final Quality Control (FQC): Before the product is shipped, a final inspection is conducted to ensure that it meets all quality standards and specifications. This may include visual inspections as well as functional tests, such as checking for proper adhesion and UV blocking capabilities.

What Common Testing Methods Are Used in Quality Assurance for Window Tint?

To ensure that car window tints perform as expected, manufacturers implement various testing methods. These tests assess critical attributes such as UV resistance, heat rejection, and glare reduction.

-

UV Resistance Testing: This test measures how well the tint blocks harmful UV rays. It is crucial for protecting vehicle interiors and occupants.

-

Heat Rejection Testing: This evaluates the film’s ability to reject solar heat, which can significantly impact the comfort of vehicle occupants and the performance of air conditioning systems.

-

Adhesion Testing: This method assesses how well the tint adheres to glass surfaces, which is vital for longevity and durability.

-

Color Stability Testing: This ensures that the tint does not fade or change color over time, which can be a significant concern for end-users.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must conduct due diligence to verify the quality control practices of their suppliers. Here are some actionable steps:

1. Supplier Audits:

Conducting on-site audits allows buyers to assess the manufacturing processes and quality assurance measures firsthand. This can include reviewing production facilities, quality control checkpoints, and employee training programs.

2. Quality Assurance Reports:

Requesting detailed quality assurance reports from suppliers can provide insights into their testing methods, results, and any corrective actions taken in response to quality issues.

3. Third-Party Inspections:

Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control processes. These inspections can verify compliance with international standards and provide additional assurance of product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing car window tint from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances related to quality control and certification.

-

Regulatory Compliance: Different regions may have varying regulations regarding the use of window tint. It is crucial for buyers to ensure that products comply with local laws, including tint darkness and reflective properties.

-

Certification Recognition: Not all certifications are recognized universally. Buyers should verify that the certifications held by suppliers are relevant and accepted in their target markets. This ensures that products meet local quality and safety standards.

-

Cultural Considerations: Understanding local market preferences and cultural perceptions regarding window tint can influence purchasing decisions. Buyers should be aware of the aesthetic and functional preferences specific to their regions.

In summary, a comprehensive understanding of the manufacturing processes and quality assurance practices for car window tint can significantly benefit B2B buyers. By focusing on supplier verification, compliance with international standards, and robust testing methods, buyers can ensure they procure high-quality products that meet their needs and the expectations of their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ’10 car window tint’

To successfully procure high-quality car window tint, particularly for B2B buyers in diverse markets such as Africa, South America, the Middle East, and Europe, it is essential to follow a structured approach. This guide will help you navigate the sourcing process effectively, ensuring that you select the best products for your business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clarify your technical requirements. This includes the type of tint (e.g., ceramic, carbon, dyed), thickness, UV rejection rates, and any specific regulations applicable in your region. Clear specifications will help you communicate effectively with suppliers and ensure that the products meet your needs.

Step 2: Research Market Trends and Regulations

Understanding current market trends and local regulations is crucial. Investigate the demand for different tint types in your target market and familiarize yourself with local laws regarding tinting, as these can vary significantly. Compliance with these regulations will prevent potential legal issues and enhance customer satisfaction.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers to ensure reliability and quality. Look for suppliers with a strong market presence and positive reviews from other B2B clients. Key aspects to consider include:

– Certifications: Check for industry certifications that validate the quality of their products.

– Samples: Request product samples to assess quality firsthand before making bulk orders.

Step 4: Compare Pricing and Terms

Once you have a list of potential suppliers, compare their pricing structures and terms of sale. Ensure you understand what is included in the price (e.g., shipping, warranties, and support). Look for suppliers that offer competitive pricing without compromising on quality, as this can significantly impact your profit margins.

Step 5: Verify Warranty and Support Options

A robust warranty and reliable support can be critical in the tinting business. Confirm the warranty period offered on the tint products and what it covers. Additionally, evaluate the supplier’s customer service capabilities to ensure you have support when needed, especially regarding installation guidance or product issues.

Step 6: Request References and Case Studies

To gauge a supplier’s reliability and performance, ask for references and case studies from other businesses in your industry. This step will provide insights into their track record and help you make an informed decision. Look for suppliers who have successfully worked with companies similar to yours, particularly in your geographical region.

Step 7: Negotiate Terms and Place Your Order

Once you’ve selected a supplier, engage in negotiations to secure favorable terms. This may include price, payment terms, and delivery schedules. Clear communication during this phase will help establish a solid foundation for your business relationship. After finalizing terms, place your order and ensure you have a system in place to track delivery and inventory.

By following this step-by-step checklist, you will enhance your sourcing strategy for car window tint, ensuring that you select high-quality products that meet both your specifications and market demands.

Comprehensive Cost and Pricing Analysis for 10 car window tint Sourcing

What are the Key Cost Components in Sourcing Car Window Tint?

In the B2B market for car window tint, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the desired profit margin.

-

Materials: The type of tint film—be it dyed, carbon, or ceramic—significantly impacts the cost. High-quality ceramic films, for example, provide superior heat rejection and durability but are generally more expensive than their dyed counterparts.

-

Labor: Labor costs encompass both production and installation. Skilled labor may command higher wages, particularly in regions where expertise is scarce. This is crucial for ensuring proper installation, as poor installation can lead to customer dissatisfaction and increased returns.

-

Manufacturing Overhead: This includes costs associated with the production facility, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce these costs, allowing suppliers to offer more competitive pricing.

-

Tooling and Quality Control: Investment in quality assurance processes and tools is necessary to ensure that the tint meets regulatory standards and customer expectations. This may involve additional costs but can result in fewer defects and returns.

-

Logistics: Shipping and handling costs are particularly relevant for international buyers. These costs can vary significantly based on the destination, shipment size, and chosen Incoterms.

-

Margin: Suppliers typically add a profit margin to cover their business expenses and generate profit. This margin can vary based on market conditions, competition, and the perceived value of the product.

How Do Price Influencers Affect Car Window Tint Sourcing?

Several factors can influence the pricing of car window tint, which is essential for buyers to understand when negotiating and making purchasing decisions.

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for discounts, making it crucial for businesses to evaluate their needs carefully. Establishing a good relationship with suppliers can also lead to more favorable pricing.

-

Specifications and Customization: Custom tint specifications, such as specific shades or sizes, can lead to increased costs. Buyers should weigh the benefits of customization against the potential for higher prices.

-

Materials and Quality Certifications: Products that come with certifications for UV protection or energy efficiency may carry a premium price. However, these certifications can also enhance customer satisfaction and reduce long-term costs.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can all impact pricing. Working with established suppliers may come at a higher price but can offer reliability and quality assurance.

-

Incoterms: Understanding the terms of shipping and delivery can significantly affect total costs. Buyers should clarify responsibilities for shipping, insurance, and customs duties to avoid unexpected expenses.

What Tips Can Help Buyers Negotiate Better Prices for Car Window Tint?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost-efficiency when sourcing car window tint.

-

Negotiate Terms: Don’t hesitate to negotiate pricing, payment terms, and shipping costs. Suppliers may be willing to offer better terms for larger orders or long-term contracts.

-

Focus on Total Cost of Ownership (TCO): When assessing different products, consider not just the initial purchase price but also the long-term benefits, such as durability, maintenance, and energy savings. Higher-quality films may have a higher upfront cost but can save money in the long run.

-

Understand Pricing Nuances for International Trade: Be aware of the additional costs associated with international shipping, such as tariffs, customs fees, and currency fluctuations. These can significantly affect the final price.

-

Leverage Local Market Knowledge: Buyers should engage with local distributors who understand regional regulations and market conditions. This can lead to better sourcing options and pricing strategies.

-

Stay Informed on Industry Trends: Keeping abreast of developments in materials and technology can provide leverage in negotiations, as buyers can push for innovative products that offer better performance at competitive prices.

In conclusion, understanding the comprehensive cost structure and pricing factors involved in sourcing car window tint is vital for international B2B buyers. By leveraging these insights, buyers can negotiate better deals, ensuring they receive quality products that meet their specific needs.

Alternatives Analysis: Comparing 10 car window tint With Other Solutions

In the competitive landscape of automotive enhancements, choosing the right car window tint or alternative solution is crucial for businesses. This section explores ’10 car window tint’ alongside other viable technologies that offer similar benefits, such as heat rejection, UV protection, and aesthetic enhancement. B2B buyers must weigh these alternatives based on performance, cost, implementation ease, maintenance requirements, and specific use cases to make informed purchasing decisions.

| Comparison Aspect | 10 Car Window Tint | Ceramic Coatings | Smart Glass |

|---|---|---|---|

| Performance | High UV and IR rejection | Excellent UV protection, moderate IR | Adjustable tinting, good UV protection |

| Cost | Moderate ($100-$300 per vehicle) | High ($500-$1,500 per vehicle) | Very High ($1,000-$5,000 per window) |

| Ease of Implementation | Requires professional installation | Requires professional application | Complex installation, requires electrical setup |

| Maintenance | Low maintenance | Requires occasional reapplication | Low, but dependent on electrical systems |

| Best Use Case | Everyday vehicles and fleet usage | Luxury vehicles and high-end markets | Smart buildings, luxury vehicles |

What Are the Pros and Cons of Ceramic Coatings Compared to ’10 Car Window Tint’?

Ceramic coatings are a premium alternative that provide high levels of UV protection and durability. Their advanced formulation protects against scratches and environmental pollutants, making them an appealing choice for high-end vehicles. However, the initial cost can be a barrier for many businesses, as prices can range from $500 to $1,500 per vehicle. Additionally, while ceramic coatings require less frequent maintenance, they still need professional application, which can add to overall project costs.

How Does Smart Glass Compare to ’10 Car Window Tint’ in Terms of Performance?

Smart glass offers a cutting-edge solution that allows users to adjust the tint of the glass based on their preferences or environmental conditions. This technology provides excellent UV protection and can enhance privacy, making it particularly attractive for luxury vehicles and high-end buildings. However, the complexity of installation and significantly higher costs (ranging from $1,000 to $5,000 per window) can deter many businesses from choosing this option. Furthermore, smart glass requires a reliable electrical system for operation, which may not be feasible for all applications.

Conclusion: How Should B2B Buyers Choose the Right Solution for Their Needs?

When selecting between ’10 car window tint’ and its alternatives, B2B buyers should consider their specific use cases, budget constraints, and the desired balance between performance and cost. For businesses focused on everyday vehicle use, ’10 car window tint’ offers an effective and cost-efficient solution. In contrast, luxury markets might find greater value in ceramic coatings or smart glass despite their higher costs and implementation complexities. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to make the best choice for their operational needs.

Essential Technical Properties and Trade Terminology for 10 car window tint

What Are the Key Technical Properties of Car Window Tint?

Understanding the technical properties of car window tint is crucial for B2B buyers looking to invest in high-quality products. Here are some critical specifications that should be evaluated:

1. Material Composition

The material used in window tint films significantly affects performance and durability. Common materials include dyed, metalized, and ceramic films. Ceramic films, for instance, are known for their superior heat rejection and UV protection without the risk of signal interference, making them ideal for modern vehicles equipped with advanced technology.

2. Total Solar Energy Rejected (TSER)

TSER measures the percentage of solar energy that the tint film can block. A higher TSER indicates better protection from heat, which is particularly important in regions with extreme climates, such as the Middle East and parts of Africa. This property can directly influence energy costs for air conditioning in vehicles and buildings.

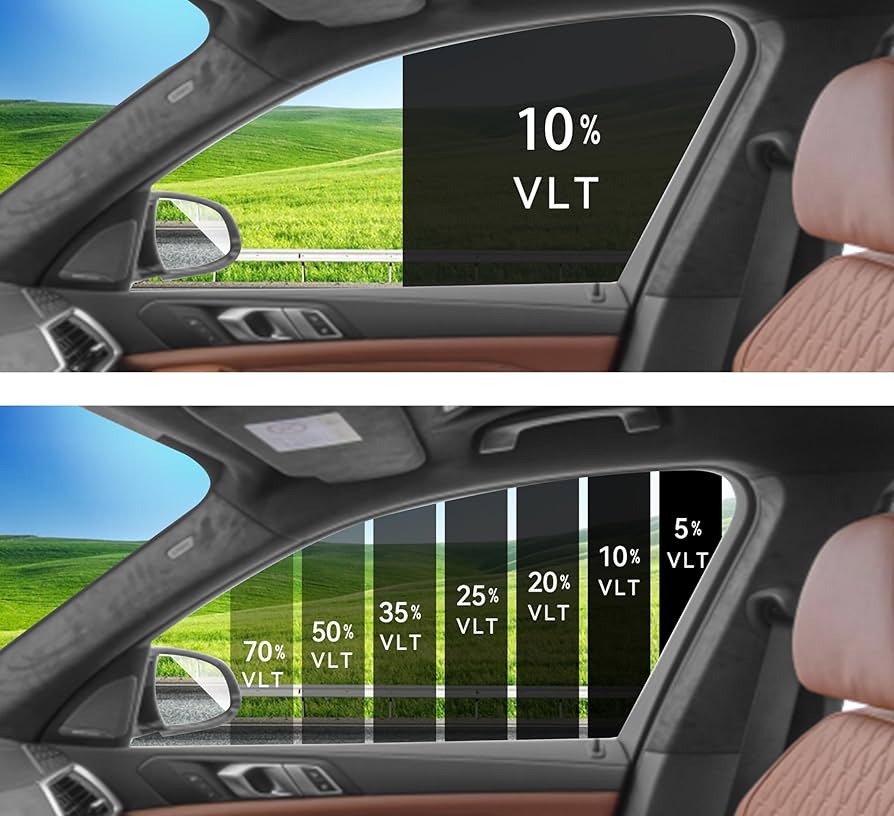

3. Light Transmission (VLT)

Visible Light Transmission (VLT) refers to the amount of light that passes through the tint. This is typically expressed as a percentage. A lower VLT percentage means darker tint, which can provide better glare reduction but may also impact visibility. Understanding VLT is essential for compliance with local regulations, which can vary significantly across regions.

4. Thickness

The thickness of window tint films is often measured in mils (thousandths of an inch). Thicker films (usually 1.5 to 2.5 mils) are generally more durable and resistant to scratching and peeling. This property is crucial for ensuring a longer lifespan of the tint, reducing the need for replacements and associated costs.

5. Warranty Period

The warranty period indicates the manufacturer’s confidence in their product’s durability and performance. A longer warranty (often ranging from 5 to 10 years) suggests that the film is less likely to fade or degrade over time. This is an important consideration for B2B buyers, as it reflects potential long-term savings.

What Are Common Trade Terms in the Window Tint Industry?

Familiarity with industry terminology is essential for effective communication and negotiation. Here are some key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that are used in another company’s end product. In the context of window tint, an OEM may provide films specifically designed for vehicle manufacturers, ensuring compatibility and quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is vital for buyers to plan their inventory and ensure they meet supplier requirements without overcommitting capital.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers use to solicit price quotes from suppliers. It often includes specifications for the products needed, allowing suppliers to provide tailored pricing. This process helps buyers compare options effectively.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for buyers to manage shipping costs and risks.

5. Tensile Strength

This property measures how much force a material can withstand while being stretched or pulled before breaking. For window films, high tensile strength is crucial for ensuring that the film adheres properly and remains intact under various environmental conditions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, negotiate better deals, and ultimately improve their product offerings in the automotive window tint market.

Navigating Market Dynamics and Sourcing Trends in the 10 car window tint Sector

What Are the Current Market Dynamics and Key Trends in the 10 Car Window Tint Sector?

The global market for car window tinting is experiencing robust growth, driven by factors such as increased awareness of UV protection, energy efficiency, and enhanced aesthetic appeal. In regions like Africa, South America, the Middle East, and Europe, the demand for high-quality window films is surging, particularly in countries such as Saudi Arabia and Brazil, where extreme weather conditions necessitate effective heat and glare reduction solutions. Technological advancements in window tinting, especially with nano-ceramic films, are making these products more appealing due to their superior performance in rejecting heat and UV rays while maintaining clarity and durability.

Emerging trends in B2B sourcing include a shift towards online wholesale platforms, enabling buyers to access a wider range of products and competitive pricing. Distributors are increasingly leveraging data analytics to understand consumer preferences and optimize inventory management. Additionally, the growth of installation services bundled with product sales is becoming a common practice, providing a comprehensive solution for end-users. As a result, international buyers should focus on suppliers that offer not just quality films but also reliable installation training and tools to enhance their service offerings.

How Is Sustainability and Ethical Sourcing Shaping the 10 Car Window Tint Industry?

The environmental impact of manufacturing processes is increasingly under scrutiny in the car window tint sector. Buyers are now prioritizing suppliers that demonstrate a commitment to sustainability through eco-friendly practices. This includes the use of non-toxic materials and adherence to strict environmental regulations during production. Ethical sourcing has become a critical factor, as companies are expected to ensure their supply chains are transparent and responsible.

Certifications such as Green Seal or ISO 14001 can be strong indicators of a supplier’s commitment to sustainability. Moreover, the demand for ‘green’ products is influencing manufacturers to develop window films that not only perform effectively but also minimize environmental harm. This trend is particularly pertinent for international buyers from regions where consumers are increasingly eco-conscious, making it essential for businesses to align their sourcing strategies with sustainable practices to maintain competitiveness.

How Has the 10 Car Window Tint Sector Evolved Over Time?

The evolution of the car window tint sector can be traced back to the introduction of basic dyed films, which offered limited UV protection and aesthetic benefits. As technology progressed, advancements led to the development of more sophisticated films, including metalized and carbon-based options, enhancing performance characteristics such as heat rejection and glare reduction. The latest innovation, nano-ceramic technology, represents a significant leap forward, offering superior durability and environmental benefits without compromising visibility.

This historical progression reflects the industry’s response to consumer demands for higher quality and more effective solutions. For B2B buyers, understanding this evolution is crucial, as it highlights the importance of selecting suppliers that stay at the forefront of technology and innovation, ultimately contributing to better customer satisfaction and long-term business success.

Frequently Asked Questions (FAQs) for B2B Buyers of 10 car window tint

-

1. How do I choose the right car window tint for my business needs?

Choosing the right car window tint involves assessing several factors including the material type (dyed, carbon, or ceramic), desired heat and UV rejection levels, and local regulations. Ceramic films, for instance, offer superior protection and durability but may come at a higher cost. Consider the specific needs of your clientele—whether they prioritize aesthetics, heat rejection, or privacy—and ensure the tint complies with local laws in your target markets, such as those in Europe or the Middle East. -

2. What are the most important factors to consider when vetting a window tint supplier?

When vetting window tint suppliers, prioritize their reputation, product quality, and compliance with international standards. Look for suppliers who offer warranties and certifications, which can assure you of the film’s performance and durability. Additionally, assess their customer service, ability to provide samples, and responsiveness to inquiries. Check reviews and testimonials from other B2B clients to gauge reliability, especially in regions like Africa or South America, where supplier reliability may vary. -

3. What minimum order quantities (MOQ) should I expect when sourcing car window tint?

MOQs can vary significantly between suppliers, typically ranging from 50 to 500 rolls depending on the tint type and brand. Some manufacturers may offer lower MOQs for specific products or promotional items. Discuss your business needs upfront with potential suppliers to negotiate favorable terms, especially if you are a startup or looking to test the market in regions like Brazil or Saudi Arabia. -

4. What payment terms are commonly offered by window tint suppliers?

Payment terms can differ widely, but many suppliers offer options such as 30-day net terms or payment upon delivery. It’s essential to clarify these terms before placing an order to avoid cash flow issues. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment, especially when dealing with suppliers from different continents. -

5. How can I ensure quality assurance (QA) for car window tints before shipment?

To ensure quality assurance, request samples before finalizing your order and establish a clear QA process with the supplier. This can include third-party inspections or certifications that verify the film’s performance against industry standards. Clearly outline your quality expectations in the contract, and consider including penalties for non-compliance to protect your business interests. -

6. What logistics considerations should I be aware of when importing car window tint?

Logistics considerations include shipping methods, customs regulations, and import tariffs specific to your target market. Choose reliable freight forwarders experienced in handling window films to avoid damage during transport. Additionally, familiarize yourself with local regulations regarding tint imports, which can vary across regions such as the Middle East or Europe, to ensure compliance and prevent delays. -

7. Are there customization options available for car window tint products?

Many suppliers offer customization options such as specific shades, widths, or branding on the film. Discuss your requirements directly with suppliers to see if they can accommodate your needs. Customization may come with additional costs and longer lead times, so factor this into your planning, especially if you’re targeting niche markets in regions like Africa or South America. -

8. How do I stay updated on the latest trends and regulations in car window tinting?

Staying updated requires regular engagement with industry publications, trade shows, and networking with other professionals in the automotive sector. Consider joining industry associations or online forums where you can share insights and receive updates on regulatory changes affecting window tinting. Following manufacturers’ newsletters and social media channels can also provide timely information on product innovations and market trends, especially relevant to your target regions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 10 Car Window Tint Manufacturers & Suppliers List

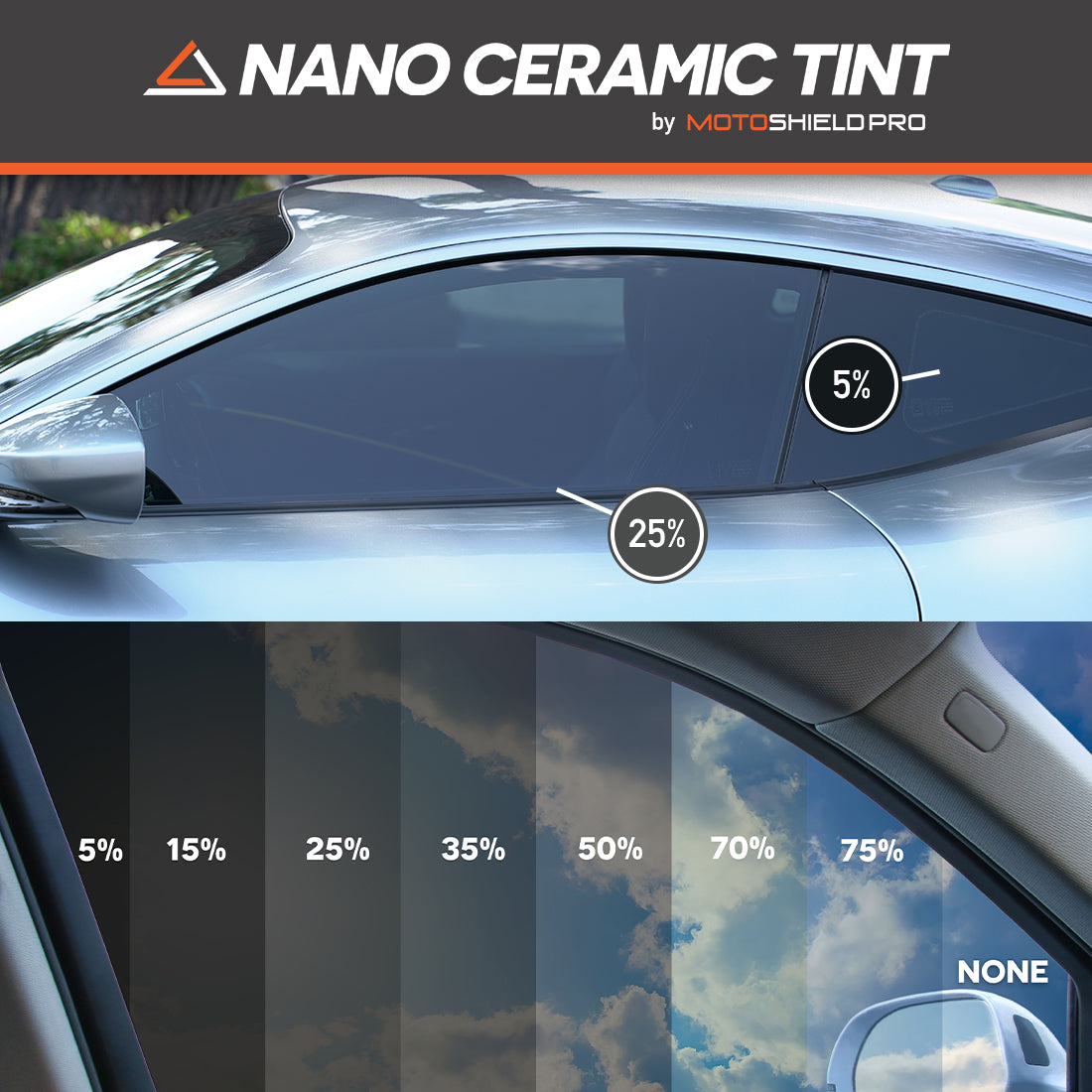

1. MotoShield Pro – 36×10 Ceramic Tint Window Film

Domain: motoshieldpro.com

Registered: 2015 (10 years)

Introduction: 36″x10″ Ceramic Tint Window Film Roll – MotoShield Pro

2. Vinyl Frog – 10% Window Tint

3. Global Window Films – Color Stable Window Films

Domain: globalwindowfilms.com

Registered: 2001 (24 years)

Introduction: This company, Global Window Films – Color Stable Window Films, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for 10 car window tint

In navigating the dynamic landscape of car window tint products, strategic sourcing emerges as a critical component for B2B buyers looking to maximize value and quality. By focusing on high-performance films such as nano-ceramic options, buyers can offer superior solar protection, UV rejection, and durability to their customers. The competitive pricing available from manufacturers provides an opportunity to enhance profit margins while meeting diverse market demands across regions like Africa, South America, the Middle East, and Europe.

Key takeaways include the importance of understanding local regulations regarding tint application, as compliance can significantly influence product selection and customer satisfaction. Additionally, leveraging relationships with reputable suppliers ensures access to innovative technologies and cost-effective solutions, thereby fostering long-term partnerships that can drive business growth.

As the demand for vehicle customization and energy efficiency continues to rise, international buyers are encouraged to explore new sourcing channels and product offerings. Investing in quality window tint not only elevates your brand but also positions your business to thrive in an evolving market. Engage with trusted distributors today to secure the best options for your clientele and stay ahead of industry trends.