The Definitive Guide to Rangement Cles Usine: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for rangement cles usine

In today’s global marketplace, sourcing effective solutions for rangement clés usine—or key storage systems for factories—poses significant challenges for international B2B buyers. With an increasing demand for organized and secure key management solutions across diverse industries, businesses must navigate a complex landscape of products that vary in design, functionality, and compliance with safety standards. This guide aims to empower buyers from regions like Africa, South America, the Middle East, and Europe—specifically targeting countries such as Brazil and Nigeria—by providing a comprehensive overview of the key storage systems available.

This guide delves into the various types of rangement clés—from simple wall-mounted cabinets to sophisticated electronic locking systems—highlighting their applications across different sectors. Furthermore, it covers crucial considerations for supplier vetting, ensuring that quality, reliability, and sustainability are prioritized in your purchasing decisions. We will also discuss cost factors, helping you understand the pricing structures associated with these essential tools.

By equipping you with the knowledge to make informed decisions, this guide aims to simplify the procurement process and enhance operational efficiency in your organization. With insights into market trends and practical recommendations, you’ll be positioned to choose the most suitable key storage solutions that meet your unique business needs, ensuring both security and accessibility in your operations.

Understanding rangement cles usine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wall-Mounted Key Cabinets | Space-saving design, multiple key hooks, lockable options | Offices, schools, industrial facilities | Pros: Efficient use of space; Cons: Limited capacity compared to larger cabinets. |

| Electronic Key Safes | Digital locking mechanism, programmable access, high security | Financial institutions, government buildings | Pros: Enhanced security; Cons: Requires power supply and may need technical support. |

| Mobile Key Storage Units | Portable, often on wheels, designed for multiple keys | Event management, rental companies | Pros: Flexibility and mobility; Cons: Less secure than fixed installations. |

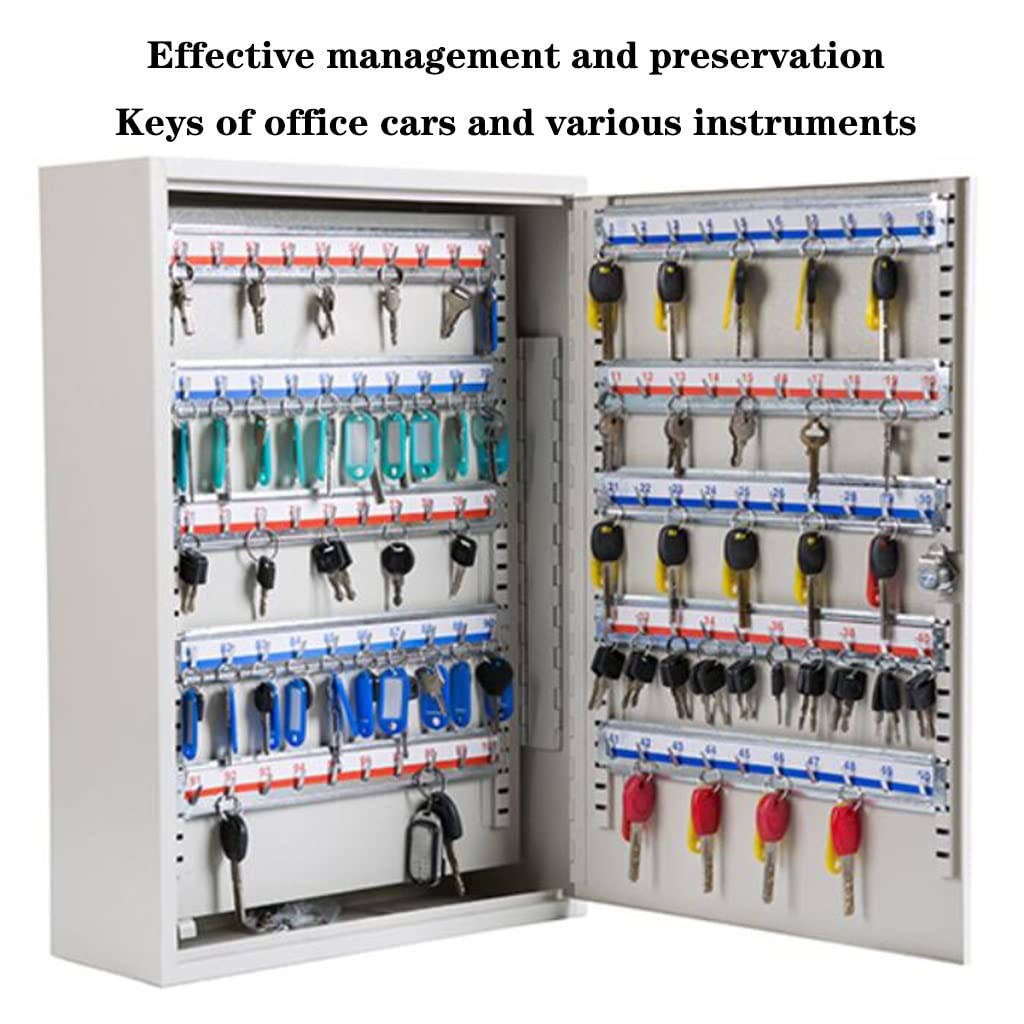

| High-Capacity Key Cabinets | Large storage capacity, reinforced construction, various lock types | Large enterprises, property management | Pros: Can store hundreds of keys; Cons: Higher upfront cost and requires more space. |

| Key Management Software Systems | Digital tracking, inventory management, integration with access control | Corporate offices, logistics companies | Pros: Streamlined management and reporting; Cons: Initial setup can be complex and costly. |

What Are the Key Characteristics of Wall-Mounted Key Cabinets?

Wall-mounted key cabinets are designed for efficient space utilization, making them ideal for environments where floor space is limited. These cabinets typically feature multiple hooks for hanging keys and often come with a lockable door to enhance security. They are commonly used in offices, schools, and industrial facilities where quick access to keys is essential but space is at a premium. When purchasing, consider the number of hooks, the material of the cabinet, and the locking mechanism to ensure it meets your specific needs.

Why Choose Electronic Key Safes for Enhanced Security?

Electronic key safes are equipped with advanced locking mechanisms that allow for programmable access, making them suitable for high-security environments such as financial institutions and government buildings. These units offer the advantage of customizable access codes, ensuring that only authorized personnel can retrieve keys. However, it’s important to consider the power supply requirements and potential technical support needs when selecting these safes, as they may require maintenance over time.

What Benefits Do Mobile Key Storage Units Offer?

Mobile key storage units provide the flexibility of portability, making them an excellent choice for event management and rental companies. These units often come equipped with wheels and can accommodate multiple keys, allowing for easy transport between locations. While they offer great convenience, buyers should be aware that they may not provide the same level of security as fixed installations, making them less suitable for high-risk environments.

How Do High-Capacity Key Cabinets Meet Business Demands?

High-capacity key cabinets are designed to store a large number of keys, making them ideal for large enterprises and property management companies. These cabinets are constructed with reinforced materials and come with various locking options to ensure the security of stored keys. When considering a high-capacity cabinet, evaluate the dimensions, weight, and locking mechanism to ensure it fits your organizational needs and available space.

What Are the Advantages of Key Management Software Systems?

Key management software systems facilitate the digital tracking and management of keys, integrating seamlessly with existing access control systems. These solutions are particularly beneficial for corporate offices and logistics companies that require detailed reporting and inventory management. While they streamline key management processes, potential buyers should consider the complexity of initial setup and associated costs, as these systems may require significant investment and training.

Key Industrial Applications of rangement cles usine

| Industry/Sector | Specific Application of rangement cles usine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Key management systems for hotels | Enhanced security and organization of guest and staff keys | Durability, capacity, and electronic locking features |

| Automotive | Storage solutions for dealership keys | Improved access control and reduced key loss | Size, material, and ability to withstand environmental factors |

| Real Estate | Centralized key storage for property management | Efficient management of multiple properties and keys | Scalability, security features, and ease of installation |

| Manufacturing | Key storage for machinery and equipment access | Streamlined operations and reduced downtime | Robustness, lock types, and integration with existing systems |

| Healthcare | Secure key cabinets for medical facilities | Protection of sensitive areas and equipment access | Compliance with safety regulations and secure locking systems |

How is ‘rangement cles usine’ utilized in the hospitality industry?

In the hospitality sector, effective key management is crucial for ensuring the security of guest rooms and staff areas. Hotels utilize ‘rangement cles usine’ to store and organize keys, reducing the risk of loss or unauthorized access. With features such as electronic locks and tracking systems, these cabinets enhance security while providing easy access for staff. International buyers should consider durability and capacity to accommodate varying hotel sizes, especially in regions like Africa and South America, where hospitality is rapidly growing.

What role does ‘rangement cles usine’ play in the automotive industry?

Automotive dealerships require efficient key management systems to handle numerous vehicle keys securely. ‘Rangement cles usine’ solutions provide organized storage, enabling quick access while minimizing the risk of key loss or theft. These systems often include features like RFID tracking or electronic locks for enhanced security. Buyers in regions like Europe and the Middle East should prioritize solutions that offer robust materials and weather resistance, given the diverse environmental conditions affecting their operations.

How is ‘rangement cles usine’ essential for real estate management?

In real estate, managing keys for multiple properties can be a logistical challenge. ‘Rangement cles usine’ offers centralized key storage solutions that streamline access for property managers and maintenance personnel. This organization not only improves efficiency but also enhances security by controlling access to properties. Buyers in emerging markets such as Nigeria and Brazil should consider scalability and ease of installation to accommodate growing property portfolios.

Why is ‘rangement cles usine’ important in manufacturing environments?

Manufacturing facilities often require secure access to machinery and equipment through controlled key management. ‘Rangement cles usine’ solutions help streamline operations by ensuring that only authorized personnel can access critical areas. By reducing downtime caused by misplaced keys, these systems significantly enhance productivity. Buyers should focus on robustness and compatibility with existing security measures, particularly in regions where manufacturing is a key economic driver.

How does ‘rangement cles usine’ improve security in healthcare facilities?

In healthcare settings, securing sensitive areas and equipment is paramount. ‘Rangement cles usine’ provides secure storage for keys that control access to restricted zones, ensuring patient safety and compliance with regulations. These solutions often feature advanced locking mechanisms and tracking capabilities to monitor key access. Buyers, especially in Europe where regulatory compliance is strict, should ensure that their chosen systems meet all necessary safety and security standards.

3 Common User Pain Points for ‘rangement cles usine’ & Their Solutions

Scenario 1: Managing Large Volumes of Keys Efficiently

The Problem: For businesses that manage a significant number of keys, such as hotels, car rental services, or large facilities, the challenge lies in efficiently organizing and securing these keys. Mismanagement can lead to lost keys, security breaches, or operational delays, which ultimately affect customer satisfaction and the bottom line. Many B2B buyers find themselves overwhelmed by the sheer volume of keys, often struggling to locate specific keys quickly when needed.

The Solution: To address this issue, B2B buyers should invest in key cabinets designed for high-capacity storage. Opt for models that feature organized compartments and labeling systems. For instance, a cabinet with a digital lock and customizable key tags can enhance security and streamline access. Suppliers should be selected based on their ability to provide durable and customizable options that cater to the specific needs of the business. Implementing a digital inventory management system that tracks key usage can further reduce the chances of keys being misplaced. Regular audits and staff training on proper key management practices will also help in maintaining an organized system.

Scenario 2: Balancing Security and Accessibility

The Problem: Many businesses face a critical challenge in balancing the need for security with the requirement for quick access to keys. Organizations such as schools or government buildings must ensure that keys are not easily accessible to unauthorized personnel while still allowing authorized users to retrieve them without delay. This dichotomy can lead to frustration and security vulnerabilities if not addressed properly.

The Solution: Investing in electronic key management systems can provide a practical solution. These systems allow for controlled access through biometric readers or keypad entry, ensuring that only authorized personnel can access sensitive keys. B2B buyers should seek suppliers who offer integrated systems that can be monitored remotely and provide audit trails of key usage. Furthermore, selecting cabinets with a combination of physical locks and electronic features can enhance both security and accessibility. It’s also beneficial to establish clear protocols for key access and train employees on the importance of maintaining security, thereby fostering a culture of responsibility.

Scenario 3: Adapting to Changing Security Needs

The Problem: As businesses evolve, so do their security needs. Companies may expand, relocate, or undergo restructuring, which can lead to outdated key management systems that no longer serve their requirements. This can result in increased risks of unauthorized access or inefficiencies in key retrieval processes, leaving B2B buyers in a predicament as they attempt to adapt to these changes.

The Solution: To proactively address this issue, B2B buyers should prioritize flexible and scalable key management solutions. Look for key cabinets that allow for easy reconfiguration or expansion, accommodating future growth without requiring a complete overhaul of the existing system. Suppliers who provide modular key systems that can be upgraded with additional features, such as advanced locking mechanisms or integration with existing security systems, can be particularly valuable. Additionally, conducting regular assessments of security needs will help identify gaps and inform necessary adjustments. Training staff to adapt to new systems and protocols as the business evolves is also crucial for maintaining security and efficiency.

By understanding these common pain points and implementing the suggested solutions, B2B buyers can enhance their key management practices, ensuring both security and operational efficiency.

Strategic Material Selection Guide for rangement cles usine

What Materials Are Commonly Used in Rangement Clés Usine?

When selecting materials for ‘rangement clés usine’ (key storage solutions), it is crucial to consider their properties, advantages, and limitations. The following analysis focuses on four common materials: steel, aluminum, plastic, and wood. Each material offers distinct characteristics that can significantly impact product performance and suitability for various applications.

How Does Steel Perform in Key Storage Solutions?

Steel is one of the most widely used materials in the manufacturing of key cabinets and storage solutions. Known for its high strength and durability, steel offers excellent resistance to wear and tear, making it suitable for environments where heavy usage is expected. Key properties include high corrosion resistance when treated or coated, as well as the ability to withstand high temperatures.

Pros: Steel cabinets are robust, providing superior security for keys. They are also available in various finishes, enhancing aesthetic appeal.

Cons: The primary downside is the weight of steel, which can complicate installation and transportation. Additionally, untreated steel may rust in humid environments, necessitating protective coatings.

For international buyers, especially in regions like Africa and South America, compliance with local standards for safety and environmental impact is essential. Steel products should ideally meet ASTM or ISO standards to ensure quality and reliability.

What Advantages Does Aluminum Offer for Key Cabinets?

Aluminum is another popular choice for key storage solutions due to its lightweight nature and resistance to corrosion. It is often used in environments where weight is a concern, such as in mobile key storage units.

Pros: Aluminum is highly resistant to rust and corrosion, making it ideal for humid or coastal environments. It is also easier to manipulate during manufacturing, which can lead to lower production costs.

Cons: While strong, aluminum is not as durable as steel and may not provide the same level of security. It is also more prone to dents and scratches.

International buyers should be aware of the varying quality standards for aluminum products. Ensuring compliance with standards such as DIN or JIS can help maintain product integrity across different markets.

How Do Plastic Materials Compare in Key Storage Applications?

Plastic is often utilized in the production of lightweight key storage solutions, particularly for less demanding applications. Its versatility allows for a wide range of designs and colors.

Pros: Plastic is lightweight, resistant to corrosion, and often less expensive than metal options. It can also be molded into complex shapes, providing unique design opportunities.

Cons: The primary limitation is its lower durability compared to metal, which may not withstand heavy use or extreme conditions. Additionally, plastic can degrade under UV light exposure.

For international buyers, it is crucial to ensure that plastic products meet safety and environmental regulations, especially in regions with strict compliance requirements.

What Role Does Wood Play in Key Storage Solutions?

Wood is less common but still relevant in certain applications, particularly in high-end or decorative key storage solutions. It offers a warm aesthetic that can complement various interior designs.

Pros: Wood provides a unique look and feel, which can enhance the overall design of a space. It is also relatively easy to work with and can be finished in numerous ways.

Cons: Wood is susceptible to moisture and can warp or decay over time, making it less suitable for outdoor or high-humidity environments. Additionally, it may require more maintenance than metal or plastic options.

For international buyers, ensuring that wood products comply with sustainability standards is vital, especially in regions where environmental impact is a significant concern.

Summary of Material Selection for Rangement Clés Usine

| Material | Typical Use Case for rangement clés usine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty key cabinets for high-security environments | High durability and security | Heavy and may rust without treatment | Medium |

| Aluminum | Lightweight mobile key storage solutions | Corrosion-resistant and lightweight | Less durable than steel | Medium |

| Plastic | Budget-friendly key storage for low-demand applications | Lightweight and versatile | Lower durability and UV sensitivity | Low |

| Wood | Decorative key storage solutions in upscale settings | Aesthetic appeal and warmth | Susceptible to moisture and requires maintenance | Medium |

This material selection guide provides valuable insights for B2B buyers looking to make informed decisions regarding key storage solutions. By understanding the properties, advantages, and limitations of each material, buyers can select the most suitable options for their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for rangement cles usine

What Are the Main Stages of the Manufacturing Process for Rangement Clés Usine?

The manufacturing process for rangement clés usine (key storage solutions) typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is designed to ensure that the final product meets the required specifications and quality standards.

-

Material Preparation: This initial stage involves selecting high-quality materials, which can include metals such as steel or aluminum, plastics, and sometimes recycled materials. Suppliers often conduct inspections to ensure that the raw materials meet specific criteria such as tensile strength and corrosion resistance.

-

Forming: During the forming stage, raw materials are shaped into components using techniques such as stamping, bending, or injection molding. Advanced technologies like CNC machining may also be employed to achieve precise dimensions. The choice of forming technique can impact the durability and functionality of the final product.

-

Assembly: In this stage, various components are assembled to create the final product. This may involve manual labor or automated assembly lines, depending on the scale of production. Key features such as locks, hooks, and electronic components are integrated during this phase.

-

Finishing: The finishing stage enhances both the aesthetic and functional qualities of the product. This can include powder coating for corrosion resistance, painting, or applying a protective film. Quality control checks are often performed at this stage to ensure that the finish meets specified standards.

What Key Techniques Are Employed in Manufacturing Rangement Clés Usine?

Manufacturers utilize various techniques tailored to the specific needs of key storage solutions. Some of the most common techniques include:

-

Laser Cutting: This technique is employed for precise cutting of metal sheets, ensuring high accuracy and minimal waste. It is particularly useful for creating intricate designs and shapes.

-

Welding: Used to join metal parts together, welding is essential for ensuring the structural integrity of key cabinets. Different welding methods, such as MIG or TIG welding, may be used based on the materials and desired strength.

-

Injection Molding: For plastic components, injection molding allows for the mass production of consistent parts with complex geometries. This method is often used for creating key hooks and other plastic elements of the storage solution.

-

Surface Treatment: Techniques such as galvanization or powder coating are applied to enhance corrosion resistance and durability. These treatments are critical for products intended for outdoor or industrial use.

How Is Quality Assurance Implemented in Rangement Clés Usine Manufacturing?

Quality assurance is vital in the manufacturing of rangement clés usine to ensure that products meet international standards and customer expectations. Here are key aspects of the quality assurance process:

-

Adherence to International Standards: Many manufacturers comply with ISO 9001 standards, which focus on quality management systems. This certification indicates that a company has established a quality management framework that enhances customer satisfaction and ensures continuous improvement.

-

Industry-Specific Certifications: Depending on the application, additional certifications such as CE marking for European markets or API specifications for specific industrial uses may be required. These certifications demonstrate compliance with safety and performance standards.

-

Quality Control Checkpoints: Quality control typically involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet quality specifications.

– In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process identify defects early, allowing for immediate corrective actions.

– Final Quality Control (FQC): The finished products undergo comprehensive testing to ensure they meet all design and functional specifications before shipment.

What Common Testing Methods Are Used for Rangement Clés Usine Products?

To ensure that the final products meet safety and performance standards, manufacturers employ various testing methods. Common tests include:

- Drop Tests: Assess the durability of key cabinets by simulating falls and impacts.

- Load Tests: Evaluate the strength of hooks and shelves by testing their ability to hold specified weights without deformation.

- Corrosion Resistance Tests: Subjecting products to salt spray or humidity tests to evaluate their resistance to corrosion over time.

- Functionality Tests: Ensuring that locks and electronic components operate smoothly and securely.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers. Here are some effective strategies:

-

Supplier Audits: Conduct on-site audits to evaluate manufacturing processes, quality control systems, and compliance with international standards. This hands-on approach provides insight into the supplier’s operational capabilities.

-

Request Quality Assurance Reports: Suppliers should provide documentation outlining their quality control measures, including test results and certification compliance. Reviewing these reports can help buyers assess the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased evaluation of the manufacturing and quality control processes. This is particularly important for international transactions where direct oversight may not be feasible.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, B2B buyers should be aware of several nuances in quality control:

-

Regulatory Compliance: Different regions may have varying regulations regarding product safety and environmental impact. Understanding these regulations is essential for compliance and market access.

-

Cultural Differences: Communication styles and business practices can differ significantly across cultures. Establishing clear expectations and fostering strong relationships can help mitigate misunderstandings related to quality assurance.

-

Shipping and Logistics Considerations: Quality control does not end with production; it also extends to shipping. Ensuring that products are packed and transported safely can prevent damage and maintain quality upon arrival.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for rangement clés usine is crucial for B2B buyers. By focusing on these aspects, buyers can make informed decisions and establish partnerships with reliable suppliers that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rangement cles usine’

Introduction

When sourcing ‘rangement cles usine’, it is essential to follow a structured approach to ensure that you select the right products and suppliers. This guide provides a step-by-step checklist designed specifically for B2B buyers, focusing on key considerations and actionable insights that will facilitate a smooth procurement process. By following these steps, you can ensure that your sourcing aligns with your business needs and compliance requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications for your key storage solutions. Consider factors such as capacity, security features (e.g., electronic locks vs. traditional locks), and dimensions.

- Capacity Needs: Determine the number of keys you need to store and whether you require expandable options.

- Security Level: Assess whether basic locks suffice or if advanced security features are necessary, especially for sensitive environments.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in ‘rangement cles usine’. Look for companies with a proven track record in your industry and geographical area.

- Supplier Reputation: Check online reviews, testimonials, and industry forums to gauge supplier reliability.

- Experience: Prioritize suppliers who have experience serving similar markets, particularly in regions like Africa, South America, or Europe.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess the necessary certifications to ensure quality and compliance with industry standards.

- Quality Assurance: Look for ISO certifications or similar quality management certifications.

- Sustainability Certifications: If environmental impact is a concern, seek suppliers with certifications like the Global Recycled Standard, which indicate sustainable practices.

Step 4: Request Product Samples

Before making a bulk purchase, always request samples of the products you are considering. This step is crucial to assess the quality and functionality of the items firsthand.

- Quality Check: Inspect the materials, finishes, and overall craftsmanship to ensure they meet your standards.

- Fit for Purpose: Confirm that the samples align with your defined specifications and operational needs.

Step 5: Compare Pricing and Terms

Once you have narrowed down your options, compare pricing and terms from different suppliers. Look beyond just the unit price to evaluate the total cost of ownership.

- Additional Costs: Consider shipping, customs duties, and installation fees that may affect the overall budget.

- Payment Terms: Negotiate payment terms that align with your cash flow requirements, such as deposit percentages and payment timelines.

Step 6: Negotiate Contracts Carefully

After selecting a supplier, engage in contract negotiations to ensure clarity and protection for both parties. Pay attention to key contract elements that can impact your sourcing experience.

- Warranties and Returns: Ensure the contract includes clear terms for warranties and return policies in case the products do not meet expectations.

- Delivery Timelines: Specify delivery dates and conditions to avoid potential supply chain disruptions.

Step 7: Establish a Follow-Up Process

After procurement, set up a follow-up process to evaluate the supplier’s performance and product quality over time. This step is critical for maintaining supplier relationships and ensuring ongoing satisfaction.

- Performance Reviews: Schedule regular evaluations to assess product performance and supplier reliability.

- Feedback Mechanism: Create a system for providing feedback to the supplier, which can help improve future transactions.

By adhering to this checklist, B2B buyers can enhance their sourcing strategies for ‘rangement cles usine’, ensuring that they make informed decisions that support their business goals.

Comprehensive Cost and Pricing Analysis for rangement cles usine Sourcing

What Are the Key Cost Components in Sourcing Rangement Clés Usine?

When sourcing rangement clés usine, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials for key storage solutions include steel, plastic, and recycled materials. Premium materials like stainless steel or those with sustainability certifications can elevate costs but may attract eco-conscious buyers.

-

Labor: Labor costs vary by region and can be influenced by local wage standards and skill levels. In markets like Africa and South America, labor might be less expensive, potentially reducing overall production costs.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help in controlling these overheads.

-

Tooling: The initial setup costs for molds and machinery tailored for specific products can be substantial, particularly for customized solutions. Buyers should consider whether a supplier can absorb these costs through volume orders.

-

Quality Control (QC): Ensuring that products meet quality standards is essential, especially for international shipments. QC processes add to the overall cost but are vital for maintaining brand reputation and customer satisfaction.

-

Logistics: Transportation and warehousing costs vary based on the shipping method (air, sea, or land) and the distance from the supplier to the buyer. Understanding Incoterms is critical, as they define responsibilities for shipping and handling costs.

-

Margin: Suppliers typically add a profit margin to their costs. This margin can fluctuate based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect the Cost of Rangement Clés Usine?

Several factors can influence pricing for rangement clés usine:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs due to economies of scale. Negotiating favorable terms based on projected volume can enhance cost-efficiency.

-

Specifications and Customization: Custom features or unique designs may increase costs. Buyers should assess whether such customizations are necessary or if standard products suffice.

-

Materials and Quality Certifications: Products that meet specific quality standards or certifications, such as ISO or environmental certifications, may come at a premium. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to attract business.

-

Incoterms: Understanding Incoterms is essential for budgeting. Different terms (like FOB, CIF) dictate who bears the cost and risk at various stages of shipping, impacting the total landed cost.

What Tips Can Help Buyers Negotiate Better Prices for Rangement Clés Usine?

For international B2B buyers, especially those from regions like Africa, South America, and the Middle East, effective negotiation strategies can lead to significant savings:

-

Negotiate Volume Discounts: Leverage bulk purchasing to negotiate lower prices. Presenting a long-term purchasing plan can enhance bargaining power.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial price but also long-term costs associated with maintenance, durability, and potential for resale. This approach can justify a higher upfront investment.

-

Research Market Prices: Understanding the competitive landscape and average market prices can provide leverage in negotiations. Access to reliable market data can help in making informed decisions.

-

Be Mindful of Payment Terms: Flexible payment options can aid cash flow management and may provide room for negotiation on price.

-

Cultural Sensitivity: When dealing with suppliers from different regions, understanding cultural nuances in business practices can facilitate smoother negotiations.

Conclusion

Sourcing rangement clés usine involves a multifaceted analysis of costs and pricing influencers. By comprehensively understanding these elements and employing strategic negotiation techniques, international B2B buyers can optimize their sourcing strategies while ensuring quality and cost-effectiveness. Keep in mind that prices can fluctuate based on market conditions, so always request indicative pricing from suppliers for the most accurate estimates.

Alternatives Analysis: Comparing rangement cles usine With Other Solutions

Exploring Alternatives to Rangement Clés Usine for Key Management

In the realm of key management and storage, businesses often seek efficient and secure solutions to handle their keys. While “rangement clés usine” serves as a robust option, several alternatives exist that can also fulfill the needs of organizations. This analysis will compare the effectiveness of “rangement clés usine” with other viable solutions, including electronic key management systems and traditional key cabinets.

Comparison Table

| Comparison Aspect | Rangement Clés Usine | Electronic Key Management System | Traditional Key Cabinet |

|---|---|---|---|

| Performance | High capacity for organized storage | Real-time tracking and access | Simple storage solution |

| Cost | Moderate initial investment | Higher upfront and maintenance costs | Lower cost, minimal investment |

| Ease of Implementation | Generally easy to set up | Requires training and integration | Easy to install and use |

| Maintenance | Low maintenance required | Regular software updates needed | Minimal upkeep needed |

| Best Use Case | Factories and warehouses needing bulk storage | Facilities requiring high security and tracking | Small businesses or offices needing basic storage |

Detailed Breakdown of Alternatives

1. Electronic Key Management System

Electronic key management systems (EKMS) provide an advanced solution for key storage and tracking. These systems often utilize RFID technology or biometric access controls to ensure that only authorized personnel can access specific keys. The primary advantage of EKMS is its ability to offer real-time tracking of key usage, reducing the risk of loss or theft. However, the initial investment and ongoing maintenance can be significant, making it less suitable for smaller enterprises or those with limited budgets.

2. Traditional Key Cabinet

Traditional key cabinets are a straightforward and cost-effective solution for managing keys. These cabinets can vary in size and capacity and typically feature hooks for hanging keys. The main benefits of using a traditional key cabinet include its simplicity and low cost, making it ideal for small businesses or offices. However, these cabinets may lack advanced security features and tracking capabilities, which can be a disadvantage for organizations that require stringent security measures.

Conclusion: How to Choose the Right Key Management Solution

Selecting the appropriate key management solution depends largely on your organization’s specific needs and budget. If your business operates in a high-security environment and requires real-time tracking, investing in an electronic key management system may be justified despite the higher costs. Conversely, if you are managing a smaller operation with basic key storage needs, a traditional key cabinet or “rangement clés usine” may be sufficient. Assessing factors such as performance requirements, cost constraints, and ease of implementation will aid B2B buyers in making an informed decision that best aligns with their operational demands.

Essential Technical Properties and Trade Terminology for rangement cles usine

What Are the Key Technical Properties of Rangement Clés Usine?

When considering the procurement of rangement clés usine (key storage solutions), understanding the essential technical properties is crucial for making informed decisions. Here are some critical specifications:

-

Material Grade: The most common materials used in key cabinets include steel, aluminum, and high-density plastic. Steel cabinets typically offer superior durability and security, making them ideal for high-traffic environments. Aluminum is lightweight and corrosion-resistant, suitable for various settings, while high-density plastics can be cost-effective for less demanding applications.

-

Capacity: This refers to the number of keys a cabinet can hold, often ranging from a few dozen to several hundred. Understanding capacity is vital for businesses with varying storage needs, ensuring they select a product that aligns with their operational requirements.

-

Locking Mechanism: The type of lock is a significant security feature. Options include traditional key locks, combination locks, and electronic locks. Electronic locks offer enhanced security with features like audit trails and remote access, which can be particularly beneficial for larger organizations managing sensitive keys.

-

Dimensions: Knowing the external and internal dimensions of a key cabinet is essential for space planning. Cabinets should fit the designated area while providing sufficient internal space for organized key storage.

-

Mounting Options: Key cabinets can be wall-mounted, freestanding, or designed for drawer installation. Depending on the workspace layout, the right mounting option can optimize accessibility and security.

-

Weight: The weight of the cabinet often correlates with its durability and security features. Heavier models may be more secure but less portable, while lighter models may be easier to install and relocate.

What Are Common Trade Terms Related to Rangement Clés Usine?

Familiarizing yourself with industry jargon can streamline communication and negotiation processes. Here are several essential terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM can help buyers identify reliable suppliers and assess product quality.

-

MOQ (Minimum Order Quantity): MOQ is the smallest number of units a supplier is willing to sell. This is crucial for businesses to understand as it can affect inventory management and initial investment costs.

-

RFQ (Request for Quotation): An RFQ is a document that a buyer sends to suppliers to request pricing and other information for specific products. Utilizing RFQs can help businesses compare different suppliers and negotiate better terms.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms can prevent misunderstandings regarding shipping costs, insurance, and risk transfer.

-

Lead Time: This term refers to the amount of time it takes from placing an order until it is delivered. Understanding lead times is essential for inventory planning and ensuring that businesses have the necessary key storage solutions available when needed.

-

Certification Standards: Various certifications, such as ISO or Global Recycled Standard (GRS), indicate compliance with specific quality and environmental standards. Knowing these certifications can help buyers assess the reliability and sustainability of products.

By grasping these technical properties and trade terms, B2B buyers can navigate the market for rangement clés usine more effectively, ensuring they select the right products to meet their operational needs while maximizing security and efficiency.

Navigating Market Dynamics and Sourcing Trends in the rangement cles usine Sector

What Are the Key Trends Shaping the Rangement Clés Usine Market?

The global landscape for the rangement clés usine sector is influenced by several key drivers, particularly the increasing need for efficient key management solutions across various industries. The rise of digitalization in inventory and asset management systems has led to the adoption of smart key cabinets and electronic locking mechanisms. Furthermore, the growing emphasis on security in commercial environments—spurred by rising theft rates—has intensified demand for robust key storage solutions.

Emerging technologies such as IoT-enabled key cabinets are gaining traction, allowing businesses to monitor access in real-time and streamline key distribution. In regions like Africa and South America, the market is evolving rapidly, driven by urbanization and the expansion of businesses that require secure key management systems. Buyers from these regions are particularly focused on cost-effective solutions that do not compromise on quality, given the budget constraints many face.

Additionally, European markets are seeing a shift toward customizable and scalable solutions, with businesses favoring products that can adapt to changing needs. This trend points to a broader demand for flexibility and innovation within the sector, necessitating that suppliers keep abreast of technological advancements and customer preferences to remain competitive.

How Is Sustainability Impacting B2B Sourcing for Rangement Clés Usine?

Sustainability has become a pivotal aspect of sourcing strategies within the rangement clés usine sector. International B2B buyers are increasingly prioritizing products that minimize environmental impact. This shift is partly driven by regulatory pressures and a growing consumer demand for transparency in supply chains.

Buyers are encouraged to seek out suppliers who utilize sustainable materials, such as those certified by the Global Recycled Standard (GRS), which verifies that products contain a significant amount of recycled content. The integration of eco-friendly practices not only enhances corporate responsibility but also appeals to a broader customer base that values sustainability.

Ethical sourcing is also gaining importance, with companies expected to demonstrate commitment to fair labor practices and the welfare of workers involved in the production process. By ensuring that their supply chains adhere to ethical standards, businesses can bolster their brand reputation and foster long-term partnerships with conscientious consumers and organizations.

How Has the Rangement Clés Usine Sector Evolved Over Time?

The evolution of the rangement clés usine sector can be traced back to the traditional key management practices that relied heavily on physical locks and manual inventory systems. Historically, businesses faced challenges in efficiently managing large volumes of keys, leading to security breaches and operational inefficiencies.

With the advent of technology, the sector has transformed significantly. The introduction of electronic locks and automated key management systems has streamlined processes, allowing for improved security and accountability. Today’s market is characterized by innovation, with advanced features such as remote access, real-time tracking, and integration with existing security systems becoming commonplace.

As businesses continue to prioritize security, efficiency, and sustainability, the future of the rangement clés usine sector appears to be one of continuous adaptation, fueled by technological advancements and evolving consumer expectations. This historical context underscores the importance of understanding market dynamics for international B2B buyers, enabling them to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of rangement cles usine

-

1. How do I ensure the quality of key storage cabinets when sourcing from international suppliers?

To ensure quality, conduct thorough research on potential suppliers. Request samples before placing large orders to evaluate material quality and craftsmanship. Verify suppliers’ certifications and compliance with international standards. Utilize third-party quality assurance services to perform inspections during production and before shipping. Establish clear quality control metrics and ensure they are documented in your contract. Regular communication and updates during the manufacturing process can also help address any concerns early. -

2. What is the best type of key storage solution for large organizations?

For large organizations, consider using key cabinets with electronic locks or high-capacity models that can store 100+ keys. Electronic locks offer enhanced security and easier access management, while larger cabinets can accommodate extensive key sets, reducing clutter and improving organization. Look for models with customizable features, such as key tags and tracking systems, which can help streamline operations. Evaluate your specific needs, such as space and accessibility, to choose the most effective solution. -

3. What are the common payment terms when dealing with international suppliers?

Payment terms can vary widely depending on the supplier and the country of origin. Common terms include a percentage upfront (usually 30-50%) with the balance paid upon delivery or a letter of credit. Ensure you discuss and agree upon payment methods such as bank transfers, PayPal, or escrow services to protect your interests. Be mindful of foreign transaction fees and currency fluctuations that may affect total costs. Establishing clear payment terms in your contract can help avoid disputes later. -

4. How do I vet suppliers for key storage solutions effectively?

Vetting suppliers involves checking their credentials, customer reviews, and industry reputation. Request references from previous clients and follow up to gauge their experiences. Consider visiting the supplier’s facility if feasible or use virtual tours to assess their operations. Look for suppliers who exhibit transparency in their processes and are willing to share information about their sourcing and manufacturing practices. Utilizing platforms that provide supplier ratings can also help in making informed decisions. -

5. What is the minimum order quantity (MOQ) for key storage cabinets?

Minimum order quantities (MOQs) can vary significantly based on the supplier and product type. Typically, MOQs for key cabinets can range from 10 to 100 units. Always discuss MOQs upfront to avoid misunderstandings. Some suppliers may offer flexibility with MOQs for first-time buyers or bulk orders, while others may have strict policies. If the MOQ is higher than your needs, consider negotiating or exploring suppliers that cater to smaller orders. -

6. How can I customize key storage solutions to fit my organization’s needs?

Customization options often include size, color, locking mechanisms, and internal organization features like hooks or compartments. Many manufacturers offer tailored solutions based on your specifications. When discussing customization, provide detailed requirements and ask for design prototypes if possible. Ensure that any custom features do not compromise the product’s integrity or security. Document all customization requests in your contract to ensure clarity and accountability. -

7. What logistics considerations should I keep in mind when sourcing key cabinets internationally?

When sourcing internationally, consider shipping costs, delivery timelines, and customs regulations. Research potential tariffs and taxes that may apply to your order, as these can affect overall pricing. Choose reliable logistics partners who can handle customs clearance and provide tracking information. It’s also wise to consider the mode of transport—air freight is faster but more expensive, while sea freight is cost-effective for larger orders. Ensure that the supplier is well-versed in international shipping protocols. -

8. What certifications should I look for in key storage solutions?

When sourcing key storage cabinets, look for certifications that demonstrate compliance with international safety and quality standards. Common certifications include ISO 9001 for quality management and ISO 14001 for environmental management. Additionally, certifications such as CE mark indicate compliance with EU safety regulations. If sustainability is a priority, seek products with eco-friendly certifications, such as Global Recycled Standard (GRS), which verifies the recycled content of materials.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Rangement Cles Usine Manufacturers & Suppliers List

1. ARREGUI – PLL20 Key Cabinet

Domain: amazon.fr

Registered: 2008 (17 years)

Introduction: Best Seller in Key Cabinets ARREGUI PLL20 Key Cabinet with 20 Hooks | Lockable Steel Wall Key Box | Wall Cabinet for Storage of 20 Keys | Easy Installation Wall Mounted | 20 x 16 x 6 cm | Light Grey, Price: €12.25, Rating: 4.6 out of 5 stars, 498 sold; Relaxdays Key Cabinet, Bamboo, 8 Hooks, Size: 27 x 19 x 7.5 cm, Price: €23.32, Rating: 4.6 out of 5 stars, 59 sold; BGS 1177 – Storage rack for com…

2. Rottner Tresor – Armoire à Clés S100

Domain: 1001coffres.com

Registered: 2018 (7 years)

Introduction: {“price_ttc”:”170,70 €”,”price_ht”:”142,25 €”,”product_name”:”Armoire à Clés Rottner S100 Serrure À Clé”,”brand”:”Rottner Tresor”,”model”:”MCT01508″,”capacity”:”100 Clés”,”dimensions”:{“height”:”550 mm”,”width”:”380 mm”,”depth”:”80 mm”},”lock_type”:”Serrure à clé”,”weight”:”6.5 Kg”,”recommended_use”:”Argent, Clés, Document A4, Fixation mur”,”warranty”:”1 an”,”free_delivery”:”sous 10 jours ouvrés”}

3. ABSJDFD – Boîte de gestion de clés

Domain: amazon.ca

Registered: 2000 (25 years)

Introduction: {“product_name”: “Boîte de gestion de clés”, “capacity”: “24 ~ 120 clés”, “usage”: “Entrepôt d’usine, entreprise de sécurité d’hôtel”, “type”: “Armoire à clés murales”, “color”: “gris”, “sizes_available”: [24, 32, 48, 72, 96, 120, 150, 180], “brand”: “ABSJDFD”, “price”: “479,99 $”, “mounting_type”: “Montage mural”, “features”: [“Rangement de plusieurs clés”, “Gestion facile des clés avec étiquette…

4. Tianshun – Boîte à Clés en Acier

Domain: fr.tianshuncashbox.com

Registered: 2021 (4 years)

Introduction: Boîte à clés en acier pour 36 clés, taille : 250 x 180 x 60 mm, construction en acier massif avec finition enduite de crème, serrure à cylindre avec 2 clés. Boîte à clés en acier pour 20 clés, armoire de sécurité en acier massif laminé à froid de 0,08 cm, peint en noir. Boîte à clés en acier pour 48 clés, construction solide et durable, entièrement en acier. Grande boîte à clés en acier avec charn…

5. La Maison du Porte Cle – Industrial Wall Key Holders

Domain: la-maison-du-porte-cle.com

Registered: 2020 (5 years)

Introduction: Industrial Wall Key Holder collection featuring various designs and materials, including wrought iron, stainless steel, and solid oak. Prices range from 19.90€ to 77.00€. Products include Wall Key Holder Classic Metal, The Storage Workshop, The Decorative Octopus, The Industrial Animal, and more. Key holders are designed for practicality and aesthetic appeal, suitable for different interior styles…

Strategic Sourcing Conclusion and Outlook for rangement cles usine

How Can Strategic Sourcing Enhance Your Key Storage Solutions?

In the rapidly evolving market for rangement cles usine, strategic sourcing emerges as a critical driver for operational efficiency and cost-effectiveness. By leveraging a global network of suppliers, businesses can identify high-quality key storage solutions that align with their unique operational needs. This includes not only traditional cabinets and secure storage options but also innovative solutions that integrate sustainability into their design and functionality.

International buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize suppliers that offer robust features like electronic locks, space-efficient designs, and environmentally friendly materials. These attributes not only enhance security but also demonstrate a commitment to sustainability—a growing concern for many businesses today.

Looking ahead, the key storage industry will continue to innovate, with advancements in technology and design. By embracing these changes and adopting a strategic sourcing approach, businesses can ensure they remain competitive and responsive to market demands. Now is the time to explore partnerships that will enhance your key management solutions and drive your business forward. Engage with suppliers who understand your needs and can provide tailored solutions that meet the challenges of tomorrow.