Jumbo Yarn In Bulk: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for jumbo yarn in bulk

Navigating the intricacies of sourcing jumbo yarn in bulk can pose significant challenges for international B2B buyers. With the growing demand for high-quality, versatile yarn across various applications, from textiles to crafts, understanding the nuances of bulk purchasing becomes essential. This guide offers a comprehensive exploration of the jumbo yarn market, covering diverse types, including chunky chenille and super bulky options, alongside their specific applications and benefits.

Additionally, we delve into the critical aspects of supplier vetting, ensuring that you partner with reliable manufacturers who meet quality standards. Cost considerations are also a key focus, providing insights on pricing structures, bulk order discounts, and potential shipping costs tailored for buyers from regions such as Africa, South America, the Middle East, and Europe, including notable markets like Nigeria and Brazil.

By equipping you with actionable insights and expert recommendations, this guide empowers you to make informed purchasing decisions that enhance your business offerings. Whether you are a retailer looking to expand your inventory or a manufacturer seeking quality materials, understanding the global market dynamics of jumbo yarn in bulk will position your business for success in a competitive landscape.

Understanding jumbo yarn in bulk Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Chenille Yarn | Soft, velvety texture; thick and fluffy; available in bulk | Blankets, scarves, home décor items | Pros: Highly tactile; appealing for comfort items. Cons: Higher cost; requires specific care. |

| Super Bulky Yarn | Very thick; quick to knit or crochet; often made from acrylic or wool | Winter apparel, blankets, large projects | Pros: Fast project completion; warm fabric. Cons: Limited design flexibility; may require larger needles. |

| Merino Wool Yarn | Soft, breathable, and durable; available in various weights | High-end apparel, luxury blankets | Pros: Excellent warmth-to-weight ratio; premium feel. Cons: Higher price point; may not be vegan-friendly. |

| Velvet Yarn | Shiny finish; smooth texture; often made from synthetic fibers | Fashion accessories, plush toys | Pros: Luxurious appearance; easy to work with. Cons: Can be slippery; may require special handling. |

| Tube Yarn | Hollow structure; lightweight; often used for chunky projects | Cushions, bags, large garments | Pros: Lightweight yet warm; unique texture. Cons: May not be suitable for all projects; niche market appeal. |

What Are the Characteristics of Chenille Yarn in Bulk?

Chenille yarn is known for its soft, velvety texture, which makes it particularly appealing for products designed for comfort, such as blankets and scarves. When purchased in bulk, it often comes in large skeins, which can be advantageous for businesses looking to produce items in bulk. B2B buyers should consider the yarn’s care requirements, as it is typically machine washable but not suitable for tumble drying, which could affect product longevity.

How Does Super Bulky Yarn Benefit B2B Buyers?

Super bulky yarn stands out due to its thickness, allowing for rapid project completion. This makes it ideal for winter apparel and large blankets, appealing to retailers focused on seasonal items. Buyers should note that while the quick production time is a significant advantage, the yarn’s size may limit design options, as it often requires larger needles and hooks. Additionally, super bulky yarns are typically made from synthetic or blended fibers, which can affect the overall product appeal depending on the target market.

Why Choose Merino Wool Yarn for High-End Products?

Merino wool yarn is celebrated for its softness, breathability, and durability, making it a top choice for high-end apparel and luxury blankets. Bulk purchasing allows businesses to capitalize on the premium nature of this yarn, enhancing their product offerings. However, B2B buyers should be aware of the higher price point associated with merino wool, which may impact pricing strategies. Additionally, the non-vegan nature of wool could limit market appeal among environmentally conscious consumers.

What Are the Key Features of Velvet Yarn for B2B Projects?

Velvet yarn, characterized by its shiny finish and smooth texture, is often used in fashion accessories and plush toys. When sourcing velvet yarn in bulk, businesses can benefit from its luxurious appearance, which can elevate product lines. However, buyers should consider that velvet yarn can be slippery and may require special handling during production. This can increase labor costs, so understanding the production process is crucial for effective budgeting.

How Is Tube Yarn Different and What Should Buyers Know?

Tube yarn is unique due to its hollow structure, making it lightweight yet warm, ideal for cushions, bags, and large garments. Bulk purchases can be advantageous for businesses looking to create unique, chunky products. However, tube yarn may not be suitable for all projects, and its niche appeal means that businesses should conduct market research to ensure sufficient demand. Understanding the specific applications and customer preferences is vital for successful product development in this category.

Key Industrial Applications of jumbo yarn in bulk

| Industry/Sector | Specific Application of jumbo yarn in bulk | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Textile Manufacturing | Production of blankets and throws | High demand for cozy products in retail, boosting sales | Consistent quality, delivery timelines, and bulk pricing |

| Home Décor | Upholstery and cushion covers | Enhances product offerings with unique textures and colors | Variety in colors, yarn durability, and eco-friendly options |

| Fashion & Apparel | Creation of oversized knitwear | Taps into fashion trends for chunky knit garments | Yarn softness, color fastness, and compliance with fashion standards |

| Crafting & DIY | Supplies for artisans and hobbyists | Fosters creativity and customization for end consumers | Availability of different yarn types and bulk discounts |

| Pet Products | Manufacturing pet beds and toys | Growing market for pet comfort products | Safety standards, hypoallergenic materials, and bulk order flexibility |

How is Jumbo Yarn in Bulk Utilized in Textile Manufacturing?

Jumbo yarn in bulk is primarily used in textile manufacturing for creating blankets and throws. The softness and thickness of this yarn cater to consumer demand for cozy, luxurious products, which are particularly popular in colder climates. Buyers from regions like Europe and South America should prioritize consistent quality and timely deliveries to meet retail demands. Additionally, bulk pricing can significantly reduce production costs, allowing manufacturers to maintain competitive pricing.

What Role Does Jumbo Yarn Play in Home Décor?

In the home décor sector, jumbo yarn is favored for upholstery and cushion covers. Its unique texture and variety of colors enhance the aesthetic appeal of furniture, making it a valuable material for designers. For international buyers, sourcing yarn that meets durability standards and offers eco-friendly options can help differentiate their products in the market. Ensuring reliable supply chains is also crucial for maintaining inventory levels.

How is Jumbo Yarn Beneficial for Fashion and Apparel?

The fashion industry leverages jumbo yarn to create oversized knitwear, aligning with current trends that favor chunky, statement pieces. This application allows brands to tap into niche markets that appreciate unique textures and styles. Buyers should look for yarn that is not only soft but also colorfast to withstand washing and wear. Compliance with fashion standards can also be a determining factor when selecting suppliers.

Why is Jumbo Yarn Important for Crafting and DIY?

In the crafting sector, jumbo yarn serves as a primary supply for artisans and hobbyists, encouraging creativity and customization. Its bulk availability allows crafters to produce items like scarves, hats, and home accessories at scale. Buyers, especially from regions with vibrant crafting communities, should consider the variety of yarn types available and potential bulk discounts that can enhance their profitability.

How is Jumbo Yarn Applied in Pet Products?

The pet products industry increasingly utilizes jumbo yarn for manufacturing comfortable pet beds and toys. With pet owners prioritizing comfort for their animals, the demand for high-quality, soft materials is on the rise. Buyers should ensure that the yarn complies with safety standards and is made from hypoallergenic materials to cater to health-conscious consumers. Flexibility in bulk orders can also facilitate better inventory management for businesses in this sector.

3 Common User Pain Points for ‘jumbo yarn in bulk’ & Their Solutions

Scenario 1: Navigating Bulk Order Discounts Effectively

The Problem: B2B buyers often struggle to maximize the benefits of bulk order discounts when purchasing jumbo yarn. Many suppliers offer tiered pricing structures, but without a clear understanding of how much yarn is needed for specific projects, buyers may end up over-ordering or under-ordering. This not only affects cost efficiency but can also lead to excess inventory that may not be used, tying up valuable capital and storage space.

The Solution: To tackle this issue, B2B buyers should conduct a detailed analysis of their project requirements before placing an order. Start by calculating the total quantity of yarn needed based on planned projects—considering factors like project size and the number of items to be produced. For example, if creating oversized blankets, use the estimated yarn quantity per blanket to inform the total order. Additionally, buyers should communicate with suppliers to clarify discount thresholds, ensuring they understand how to optimize their order quantity to benefit from the best available pricing. This proactive approach allows buyers to align their needs with supplier offerings, ensuring a financially sound purchase.

Scenario 2: Ensuring Quality and Consistency in Bulk Purchases

The Problem: One of the most significant pain points for B2B buyers is ensuring the quality and consistency of jumbo yarn purchased in bulk. Variations in dye lots and fiber quality can lead to discrepancies in finished products, causing dissatisfaction among clients or consumers. This inconsistency can damage a company’s reputation and lead to costly returns or rework.

The Solution: To mitigate quality concerns, buyers should establish clear specifications and quality assurance processes with their suppliers. Before finalizing a bulk order, request sample skeins from different dye lots to evaluate color consistency and texture. It’s also beneficial to inquire about the supplier’s quality control measures and production practices. Implementing a small-scale trial order can help assess the quality of the yarn before committing to a larger purchase. Additionally, maintaining open lines of communication with suppliers regarding production batches can help buyers stay informed about potential variations, allowing for adjustments in future orders.

Scenario 3: Managing International Shipping and Customs Challenges

The Problem: For international B2B buyers, navigating the complexities of shipping and customs can be a daunting task. Delays in shipping or unexpected customs fees can disrupt production schedules and inflate costs, making it difficult for businesses to maintain profitability and meet delivery deadlines.

The Solution: To streamline the shipping process, buyers should work closely with suppliers who have experience with international logistics. It’s crucial to clarify shipping terms (such as Incoterms) to understand who is responsible for shipping costs and customs duties. Buyers should also research the customs regulations of their destination country to prepare for any potential hurdles. Creating a detailed shipping timeline that includes estimated delivery dates and customs clearance can help manage expectations and reduce the risk of delays. Moreover, establishing relationships with local customs brokers can facilitate smoother transactions and provide guidance on navigating any regulatory challenges. By proactively managing logistics, buyers can minimize disruptions and ensure timely delivery of their jumbo yarn orders.

Strategic Material Selection Guide for jumbo yarn in bulk

What Are the Key Materials Used in Jumbo Yarn for Bulk Orders?

When selecting jumbo yarn in bulk, understanding the properties and applications of various materials is crucial for making informed purchasing decisions. Below, we analyze four common materials used in jumbo yarn, focusing on their performance characteristics, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Polyester

Key Properties:

Polyester yarn is known for its excellent durability and resistance to shrinking, stretching, and mildew. It offers good color retention and is typically machine washable, making it suitable for a variety of applications.

Pros & Cons:

The main advantage of polyester is its affordability and widespread availability. However, it may not provide the same level of warmth and breathability as natural fibers. Additionally, while it is durable, it can be less comfortable against the skin compared to other materials.

Impact on Application:

Polyester is ideal for projects requiring easy maintenance, such as blankets and home décor items. However, it may not be the best choice for garments that require breathability and softness.

Considerations for International Buyers:

Buyers in regions like Africa and South America should ensure compliance with local textile standards, such as ASTM or DIN, especially regarding chemical treatments and dyeing processes.

2. Chenille

Key Properties:

Chenille yarn is characterized by its velvety texture and softness, making it a popular choice for cozy products. It is typically made from polyester or a blend of fibers, providing a plush feel.

Pros & Cons:

The primary advantage of chenille is its luxurious texture, which appeals to consumers looking for comfort. However, it can be more expensive than standard yarns and may require special care during washing to maintain its appearance.

Impact on Application:

Chenille is particularly suited for blankets, stuffed toys, and other soft items. Its unique texture can elevate the perceived quality of the end product, making it a favorite among crafters and consumers alike.

Considerations for International Buyers:

B2B buyers should consider the sourcing of chenille yarn, ensuring it meets ethical standards, especially if it is produced in developing countries. Certifications related to sustainability can enhance marketability.

3. Merino Wool

Key Properties:

Merino wool is renowned for its softness, breathability, and natural temperature regulation. It is effective at wicking moisture away from the body, making it suitable for both warm and cool climates.

Pros & Cons:

The key advantage of merino wool is its comfort and performance in various weather conditions. However, it is generally more expensive than synthetic options and may require careful washing to avoid shrinkage.

Impact on Application:

Merino wool is ideal for high-quality garments, such as sweaters and scarves, where softness and warmth are paramount. Its natural properties make it a preferred choice for outdoor and active wear.

Considerations for International Buyers:

Buyers from Europe and the Middle East should be aware of the EU regulations regarding wool sourcing and animal welfare. Certifications like Oeko-Tex can add value to the product.

4. Acrylic

Key Properties:

Acrylic yarn mimics the texture of wool but is lighter and more affordable. It is resistant to moths and mildew, making it a practical choice for various projects.

Pros & Cons:

The main advantage of acrylic is its cost-effectiveness and ease of care. However, it may not provide the same warmth or breathability as natural fibers and can pill over time.

Impact on Application:

Acrylic is commonly used for budget-friendly projects, such as children’s clothing and home décor. Its versatility allows for a wide range of colors and patterns, appealing to diverse consumer preferences.

Considerations for International Buyers:

When sourcing acrylic yarn, it’s essential to check for compliance with international safety standards, especially regarding flame retardancy for children’s products.

Summary Table of Jumbo Yarn Materials

| Material | Typical Use Case for jumbo yarn in bulk | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Blankets, home décor | Durable and affordable | Less breathable and comfortable | Low |

| Chenille | Soft toys, blankets | Luxurious texture | More expensive, requires special care | Medium |

| Merino Wool | High-quality garments | Soft, breathable, temperature regulating | Higher cost, requires careful washing | High |

| Acrylic | Children’s clothing, home décor | Cost-effective and easy to care for | Less warmth, can pill | Low |

This guide provides essential insights into material selection for jumbo yarn in bulk, helping international B2B buyers make informed decisions that align with their product requirements and market expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for jumbo yarn in bulk

The manufacturing of jumbo yarn in bulk involves several critical stages that ensure the production of high-quality products suitable for various applications, from cozy blankets to fashion items. For B2B buyers, understanding these processes is essential for making informed purchasing decisions and ensuring that suppliers meet international standards.

What Are the Main Stages in the Manufacturing Process of Jumbo Yarn?

The manufacturing process of jumbo yarn typically encompasses four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The journey begins with the selection of raw materials, which can include natural fibers like wool and cotton, or synthetic fibers such as polyester and acrylic. Suppliers often prioritize sourcing high-quality fibers, as the quality of the raw material directly impacts the final product’s durability and texture. In this phase, fibers are cleaned, sorted, and blended to achieve the desired characteristics. For example, a blend of cotton and acrylic may be used to enhance softness while maintaining durability.

-

Forming: After preparation, the fibers undergo a spinning process, where they are twisted together to form yarn. In the case of jumbo yarn, this process requires specialized spinning techniques to create thicker strands. The spinning can be done using various methods, including ring spinning or open-end spinning, which affect the yarn’s texture and strength. Advanced machinery may also be employed to ensure consistency in thickness and quality throughout the production run.

-

Assembly: Once spun, the yarn is wound into skeins or balls, making it ready for sale. This stage may involve additional treatments such as dyeing, where colors are added to meet market demands. The dyeing process can also affect the yarn’s properties, such as its washability and colorfastness. For instance, a dyeing technique that utilizes natural dyes may appeal to eco-conscious consumers, while synthetic dyes can offer a wider color range.

-

Finishing: The final stage involves a series of processes that enhance the yarn’s performance and appearance. This may include treatments to soften the yarn, improve its resistance to wear, or add water-repellent properties. Finishing processes are critical, as they can elevate the yarn’s quality and marketability. For B2B buyers, understanding the specific finishing techniques used by suppliers can provide insight into the end product’s suitability for various applications.

How Is Quality Assurance Maintained Throughout the Manufacturing Process?

Quality assurance (QA) is paramount in the production of jumbo yarn, ensuring that the final product meets both international standards and customer expectations. Key components of QA include adherence to international standards, systematic quality control checkpoints, and the implementation of rigorous testing methods.

-

Relevant International Standards: Compliance with recognized international standards such as ISO 9001 is crucial. This standard focuses on quality management systems and helps manufacturers ensure consistent quality in their products. Additionally, industry-specific certifications such as CE marking for yarns used in apparel may also be relevant. B2B buyers should inquire about these certifications to ensure that suppliers adhere to recognized quality benchmarks.

-

Quality Control Checkpoints: Quality control (QC) processes typically involve several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. Suppliers may conduct fiber tests, moisture content analysis, and visual inspections.

– In-Process Quality Control (IPQC): During production, regular checks are performed to monitor the consistency of the yarn’s thickness, strength, and color. This step helps identify any deviations from quality standards early in the process.

– Final Quality Control (FQC): After production, the finished yarn undergoes comprehensive testing to verify that it meets all quality specifications. This may include tensile strength tests, colorfastness tests, and a review of the packaging integrity. -

Common Testing Methods: Various testing methods are employed to assess the quality of jumbo yarn. Tensile tests measure the strength of the yarn, while abrasion tests evaluate its durability. Additionally, colorfastness tests ensure that the yarn maintains its color after washing. For B2B buyers, understanding these testing methods can provide assurance of the yarn’s quality and longevity.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital for ensuring product reliability. Here are actionable steps buyers can take:

-

Conduct Supplier Audits: Regular audits of suppliers can help buyers assess their manufacturing processes and quality assurance practices. An audit should include a review of the production facilities, quality control measures, and adherence to international standards.

-

Request Quality Reports: Suppliers should be able to provide documentation detailing their quality control processes and results from recent testing. Buyers should ask for these reports to verify that the yarn meets the required specifications.

-

Utilize Third-Party Inspection Services: Engaging third-party inspection services can provide an objective assessment of the supplier’s quality control. These services can conduct random inspections of the production process and provide detailed reports on compliance with quality standards.

-

Understand Quality Certifications: Familiarizing oneself with the various quality certifications relevant to yarn production is crucial. Buyers should seek suppliers who hold certifications that align with their quality requirements and market needs.

What Are the QC and Certification Nuances for International Buyers?

International buyers should be aware of specific nuances in quality control and certification that may vary by region. For example, regulations regarding product safety and environmental impact can differ significantly between countries. Buyers from Africa and South America might encounter challenges related to varying standards for textile imports, while European buyers may face stricter regulations regarding sustainability and labor practices.

When sourcing jumbo yarn, buyers should consider the following:

- Local Regulations: Understanding the local regulations in the supplier’s country can help buyers anticipate potential challenges regarding customs and compliance.

- Cultural Considerations: Building strong relationships with suppliers can facilitate better communication regarding quality standards and expectations.

- Sustainability Practices: Increasingly, buyers are prioritizing suppliers who implement sustainable practices. Inquire about the supplier’s approach to sustainability, including material sourcing, manufacturing processes, and waste management.

By understanding the manufacturing processes and quality assurance measures for jumbo yarn in bulk, B2B buyers can make informed decisions that align with their business goals and customer expectations. This knowledge not only enhances procurement strategies but also fosters strong partnerships with suppliers committed to delivering high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘jumbo yarn in bulk’

To assist B2B buyers in sourcing jumbo yarn in bulk effectively, this guide outlines crucial steps to ensure quality, cost-effectiveness, and smooth procurement. By following this checklist, businesses can make informed decisions that align with their operational needs and market demands.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the jumbo yarn you need. This includes yarn type (e.g., chenille, merino wool), weight, fiber content, and color. Defining these parameters helps streamline supplier searches and ensures that the yarn meets your production requirements and customer expectations.

- Consider the End Product: Different projects may require specific yarn characteristics, such as softness or durability.

- Establish Quantity Needs: Determine the bulk quantity based on your production schedule and anticipated demand.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers who specialize in jumbo yarn. Utilize trade directories, industry forums, and online marketplaces to identify reputable sources.

- Evaluate Supplier Reputation: Look for reviews and testimonials from previous customers to gauge reliability and product quality.

- Check Industry Certifications: Ensure suppliers comply with industry standards for quality and sustainability.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step not only confirms their credibility but also provides insight into their experience and customer service.

- Ask About Production Capacity: Ensure that the supplier can meet your bulk order requirements within your timeline.

- Inquire About Quality Assurance Processes: Understand how they maintain product quality through their manufacturing and inspection procedures.

Step 4: Request Samples for Quality Assessment

Always request samples of the jumbo yarn before placing a bulk order. This allows you to evaluate the texture, color accuracy, and overall quality of the product.

- Conduct Tests: Assess the yarn’s durability, color fastness, and softness to ensure it aligns with your specifications.

- Compare Multiple Samples: If possible, compare samples from different suppliers to make an informed decision.

Step 5: Negotiate Pricing and Terms

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Bulk orders often qualify for discounts, so don’t hesitate to discuss potential savings.

- Understand Minimum Order Quantities: Clarify the minimum order requirements to avoid unexpected costs.

- Discuss Shipping Arrangements: Ensure you are aware of shipping costs, delivery times, and any potential customs fees.

Step 6: Verify Compliance with Import Regulations

Before finalizing your order, ensure that the yarn complies with the import regulations of your country. This step is particularly important for international buyers.

- Check for Tariffs and Duties: Be aware of any additional costs associated with importing yarn to avoid budget overruns.

- Confirm Documentation: Ensure that the supplier provides all necessary shipping and compliance documentation.

Step 7: Establish a Communication Plan

Once the order is placed, maintain open communication with the supplier throughout the process. This helps address any issues that may arise during production or shipping.

- Set Regular Check-Ins: Schedule updates to stay informed about order status and any potential delays.

- Prepare for After-Sales Support: Discuss return policies and after-sales service to ensure a smooth transaction.

By following these steps, B2B buyers can effectively source jumbo yarn in bulk, ensuring they receive high-quality materials that meet their production needs while optimizing costs and supplier relationships.

Comprehensive Cost and Pricing Analysis for jumbo yarn in bulk Sourcing

What are the Key Cost Components in Jumbo Yarn Bulk Sourcing?

When sourcing jumbo yarn in bulk, understanding the cost structure is essential for B2B buyers. Key cost components include:

-

Materials: The primary cost driver is the raw materials used, which can vary significantly based on the type of yarn (e.g., polyester, wool, or specialty fibers). Prices fluctuate based on market demand and availability, making it crucial to establish relationships with reliable suppliers who can provide quality materials at competitive rates.

-

Labor: Labor costs encompass the wages paid to workers involved in the production process. This includes both direct labor for manufacturing and indirect labor for roles such as quality control and logistics management. In regions with lower labor costs, such as parts of South America and Africa, sourcing from local manufacturers can yield significant savings.

-

Manufacturing Overhead: This includes costs associated with the production facility, utilities, equipment depreciation, and maintenance. Efficient manufacturing processes can help reduce these overhead costs, which can be a critical factor in pricing.

-

Tooling: Depending on the yarn’s specifications, certain tooling costs may be incurred, especially if custom machinery or molds are needed. Buyers should discuss tooling costs upfront to avoid unexpected expenses.

-

Quality Control (QC): Ensuring that the yarn meets quality standards is vital. QC processes can add to the cost but are essential for maintaining product integrity. Investing in robust QC systems can help mitigate returns and enhance customer satisfaction.

-

Logistics: Shipping and handling costs are significant, particularly for international transactions. Factors such as shipping method, distance, and freight terms (Incoterms) affect overall logistics costs. Buyers should consider these factors carefully to optimize expenses.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the market average for margins can help buyers negotiate better deals.

What Influences Pricing for Jumbo Yarn in Bulk Orders?

Several factors can influence the pricing of jumbo yarn, including:

-

Volume/MOQ: Bulk orders often come with discounts. For instance, suppliers may offer tiered pricing models where larger quantities lead to reduced per-unit costs. Buyers should inquire about minimum order quantities (MOQs) to maximize savings.

-

Specifications and Customization: Customization requests, such as unique colors or blends, can lead to increased costs. Buyers should assess whether customization is necessary or if standard options would suffice.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (e.g., organic, fair trade) typically carry a premium price. Buyers should evaluate the value of these certifications against their target market’s expectations.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality and timely delivery may charge more but can reduce risk.

-

Incoterms: Understanding Incoterms is essential for managing costs effectively. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears responsibility for shipping and insurance, significantly impacting the total cost.

What Tips Can Help Buyers Negotiate Better Prices?

-

Negotiation: Engage suppliers in discussions about pricing, highlighting your potential for repeat business. Building a strong relationship can lead to better terms and conditions.

-

Cost-Efficiency: Consider the total cost of ownership, which includes not only the purchase price but also shipping, handling, and potential wastage. Analyzing these factors can lead to more informed purchasing decisions.

-

Pricing Nuances for International Buyers: For buyers in regions like Africa and South America, it’s essential to account for currency fluctuations and import duties, which can significantly affect the final price. Researching local regulations and engaging local experts can help navigate these complexities.

In conclusion, a comprehensive understanding of the cost structure and pricing influencers is essential for B2B buyers sourcing jumbo yarn in bulk. By leveraging this knowledge, buyers can negotiate more effectively and ensure they are making cost-efficient purchasing decisions. Always keep in mind that the prices mentioned in sourcing discussions are indicative and may vary based on market conditions.

Alternatives Analysis: Comparing jumbo yarn in bulk With Other Solutions

When considering the procurement of materials for textile and crafting projects, it’s essential to analyze various options available in the market. Jumbo yarn in bulk is a popular choice due to its versatility and ease of use, but other alternatives may also serve similar purposes. This section explores how jumbo yarn stacks up against two viable alternatives: super bulky yarn and chenille yarn.

| Comparison Aspect | Jumbo Yarn In Bulk | Super Bulky Yarn | Chenille Yarn |

|---|---|---|---|

| Performance | Excellent for quick, large projects | Similar performance, slightly less bulk | Soft texture ideal for cozy items |

| Cost | Competitive pricing for bulk orders | Generally lower cost per unit | Higher price point for quality |

| Ease of Implementation | Simple to work with, minimal prep | Easy to handle, but may require more skill | Requires careful handling due to texture |

| Maintenance | Low maintenance, machine washable | Varies; some are hand wash only | Low maintenance, machine washable |

| Best Use Case | Blankets, oversized garments | Quick projects like hats, scarves | Home decor items, plush toys |

What Are the Advantages and Disadvantages of Super Bulky Yarn Compared to Jumbo Yarn?

Super bulky yarn is an excellent alternative, particularly for projects that require rapid completion. Its primary advantage is the cost-effectiveness, often being cheaper per unit compared to jumbo yarn. However, while it may offer similar performance in terms of creating warm and thick fabrics, super bulky yarn can sometimes be less forgiving in terms of texture and may require more advanced knitting or crocheting skills. This makes it ideal for experienced crafters looking to create quick, stylish pieces but may pose challenges for beginners.

How Does Chenille Yarn Compete with Jumbo Yarn?

Chenille yarn stands out for its soft, velvety texture, making it a favored choice for items such as baby blankets and plush toys. Its unique feel provides a cozy touch that jumbo yarn may lack. However, chenille yarn tends to be more expensive, which could be a drawback for bulk buyers. Additionally, while it is easy to care for, the handling of chenille requires more caution due to its delicate fibers, which can be prone to fraying if not managed properly. It’s best used in applications where softness is paramount, such as home decor and children’s products.

How Can B2B Buyers Make the Right Choice Between These Yarn Options?

When selecting the right yarn for your business needs, consider the specific applications you have in mind. If your focus is on creating large, quick-to-finish projects, jumbo yarn in bulk may be the most suitable choice. For budget-sensitive buyers, super bulky yarn can provide an economical solution without sacrificing too much on quality. On the other hand, if your products require a soft touch and luxurious feel, chenille yarn may justify its higher price point. Evaluating these factors against your target market’s preferences will help ensure that you choose the most effective material for your needs.

Essential Technical Properties and Trade Terminology for jumbo yarn in bulk

What Are the Key Technical Properties of Jumbo Yarn in Bulk?

When sourcing jumbo yarn in bulk, it’s crucial to understand several key technical specifications that can impact both product quality and operational efficiency.

1. Material Composition

The material composition of jumbo yarn varies widely, with common options including polyester, acrylic, wool, and blends. Each material offers distinct properties, such as softness, durability, and washability. For instance, 100% polyester yarn is known for its vibrant colors and resistance to fading, making it ideal for vibrant, long-lasting projects. Understanding the material helps B2B buyers select the right yarn for their specific applications, whether for apparel, home goods, or crafts.

2. Yarn Weight

Yarn weight is a critical specification that indicates the thickness of the yarn. Jumbo yarn typically falls under the super bulky category, which can range from 6 to 7 on the Craft Yarn Council’s weight scale. This weight is suitable for projects that require quick results, such as blankets and oversized accessories. Buyers should be aware of the weight category to ensure compatibility with their intended use, especially when calculating yarn requirements for large-scale projects.

3. Tolerance and Gauge

Tolerance refers to the acceptable variation in the thickness of the yarn. A tighter tolerance means more consistency in the yarn’s thickness, leading to uniformity in finished products. The gauge, measured in stitches per inch, is essential for determining how many stitches are needed for a project. Buyers should pay attention to these specifications to ensure that the finished products meet their quality standards.

4. Yardage and Package Size

Yardage indicates the length of yarn provided in each skein or package. Jumbo yarn is often sold in bulk packages, which can range from 2.2 lbs (1 kg) to larger quantities like 13 lbs (6 kg). Understanding the yardage allows B2B buyers to calculate how much yarn is needed for specific projects, reducing waste and ensuring adequate supply for production runs.

5. Care Instructions

Care instructions provide essential guidance on how to maintain the yarn after production. Common instructions include machine washability, drying methods, and ironing guidelines. Knowing these details helps B2B buyers inform their customers about the product’s longevity and ease of care, which can influence purchasing decisions.

What Are Common Trade Terms Related to Jumbo Yarn in Bulk?

Familiarity with industry jargon is essential for smooth communication and effective transactions in the jumbo yarn market.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products for other brands, which can include yarn suppliers who produce yarn under private labels. Understanding OEM relationships can help buyers identify potential partners that offer custom solutions tailored to specific needs.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of yarn that a supplier is willing to sell in a single order. This term is crucial for B2B buyers as it can affect inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases and avoid overcommitting to large quantities they may not need.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for a specific quantity of yarn. This process allows buyers to compare offers and negotiate terms effectively, ensuring they secure the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international shipping. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Understanding these terms helps buyers clarify shipping costs and liabilities, ensuring smoother transactions.

5. Lead Time

Lead time refers to the duration from placing an order to receiving the goods. For jumbo yarn, lead times can vary based on the supplier’s location and production capabilities. Knowing the expected lead time helps buyers manage their project timelines effectively.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions when sourcing jumbo yarn in bulk, ultimately leading to successful project outcomes and business growth.

Navigating Market Dynamics and Sourcing Trends in the jumbo yarn in bulk Sector

What Are the Key Market Dynamics and Trends Influencing Jumbo Yarn in Bulk?

The jumbo yarn market is experiencing significant growth driven by various global factors. One of the most notable trends is the increasing demand for chunky and oversized knitted and crocheted products, particularly in home decor and fashion. This trend is fueled by a consumer shift towards cozy, handcrafted items that offer both aesthetic appeal and comfort. Additionally, the rise of social media platforms has amplified the visibility of DIY crafting, encouraging more individuals and businesses to invest in quality jumbo yarn.

Another emerging trend is the integration of technology in sourcing and purchasing processes. B2B buyers are increasingly leveraging e-commerce platforms and digital marketplaces to streamline procurement, ensuring they access a wider range of suppliers and competitive pricing. This shift is particularly relevant for buyers in regions such as Africa, South America, and the Middle East, where traditional supply chains may present challenges. Furthermore, the implementation of data analytics allows businesses to forecast demand more accurately, leading to optimized inventory management.

In terms of market dynamics, the competitive landscape is evolving as manufacturers diversify their product offerings. Buyers are now able to source not just traditional materials like wool and acrylic, but also innovative blends that cater to specific consumer preferences, such as vegan or eco-friendly options. This diversification is essential for international buyers, particularly in emerging markets like Nigeria and Brazil, where consumer preferences are rapidly changing.

How Is Sustainability and Ethical Sourcing Shaping the Jumbo Yarn Market?

Sustainability has become a pivotal concern within the jumbo yarn sector, with B2B buyers increasingly prioritizing eco-friendly sourcing practices. The environmental impact of traditional yarn production—ranging from water usage to chemical runoff—has prompted many manufacturers to adopt greener practices. Buyers are encouraged to seek suppliers that utilize sustainable materials, such as organic cotton or recycled fibers, which can significantly reduce their carbon footprint.

Moreover, ethical sourcing is gaining traction as consumers become more conscious of the origins of the products they purchase. This has led to an emphasis on transparency within the supply chain, where suppliers are expected to demonstrate fair labor practices and responsible sourcing. Certifications such as OEKO-TEX, GOTS (Global Organic Textile Standard), and Fair Trade are becoming crucial for B2B buyers looking to align their purchasing decisions with their corporate social responsibility goals.

International buyers should also consider the impact of their sourcing decisions on local communities. By partnering with suppliers that prioritize fair wages and ethical labor practices, companies can not only enhance their brand reputation but also contribute positively to the socio-economic conditions of the regions they source from. This dual focus on sustainability and ethics can provide a competitive edge in today’s market.

What Is the Historical Context Behind Jumbo Yarn Sourcing?

The jumbo yarn market has evolved significantly over the past few decades. Initially, the focus was primarily on standard yarn weights, but as crafting trends shifted towards larger, more tactile products, the demand for jumbo yarn surged. This shift can be traced back to the rise of home crafting movements in the early 2000s, which were further propelled by the advent of social media platforms showcasing DIY projects.

As consumers sought to create oversized knitted items, manufacturers responded by developing yarn that catered specifically to this niche. The introduction of modern, synthetic fibers, alongside traditional materials, broadened the options available to both hobbyists and commercial buyers. This evolution reflects a growing recognition of the value of jumbo yarn not just for personal crafting but also as a viable product in retail environments.

Today, the jumbo yarn sector is characterized by a diverse array of materials and colors, allowing B2B buyers to meet the varied demands of their customers. As the market continues to grow, the focus on sustainability and ethical sourcing will likely shape the future of jumbo yarn procurement, ensuring that it remains relevant in a rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of jumbo yarn in bulk

-

How do I choose the right jumbo yarn for my projects?

When selecting jumbo yarn for your projects, consider the type of project you’re undertaking, the material composition, and the yarn weight. Jumbo yarn typically ranges from 6 to 7 on the yarn weight scale and is ideal for projects requiring bulk, such as blankets, scarves, and home décor items. Evaluate the fiber content—options like polyester, acrylic, or wool offer different textures and warmth. If you plan to sell finished products, think about the market preferences in your region, as well as color availability and trends. -

What are the typical minimum order quantities (MOQs) for jumbo yarn?

Minimum order quantities (MOQs) for jumbo yarn can vary significantly by supplier. Generally, MOQs range from 20 lbs to 60 skeins, depending on the manufacturer and the specific yarn type. It’s essential to confirm the supplier’s MOQ before placing an order to ensure it aligns with your production needs. Some suppliers may offer bulk discounts or tiered pricing based on order volume, which can be beneficial for larger projects or reselling. -

What are the payment terms I should expect when sourcing jumbo yarn?

Payment terms for jumbo yarn orders can differ by supplier but often include options like net 30, net 60, or advance payment. Many suppliers may require a deposit upfront, especially for large bulk orders. It’s prudent to clarify payment methods accepted, such as wire transfers or credit cards, and inquire about any additional fees related to currency conversion or international transactions. Building a good relationship with your supplier can also facilitate more favorable payment arrangements. -

How can I ensure the quality of jumbo yarn before purchasing?

To ensure yarn quality, request samples from suppliers before committing to a bulk order. Inspect the texture, color consistency, and fiber quality. Additionally, check for certifications or compliance with international quality standards, especially if sourcing from overseas. Reading customer reviews and testimonials can provide insights into the supplier’s reliability and product quality. Establishing a quality assurance process, including on-site inspections, can further mitigate risks. -

What should I know about shipping and logistics for jumbo yarn orders?

Shipping logistics for jumbo yarn can be complex, especially for international orders. Check the supplier’s shipping policies, including costs, delivery times, and available carriers. Ensure that shipping includes tracking capabilities to monitor your order’s status. Be aware of customs duties and import taxes applicable in your region, as these can significantly impact overall costs. Establish clear communication with your supplier regarding shipping terms to avoid unexpected delays. -

Can I customize my jumbo yarn order in terms of color and packaging?

Many suppliers offer customization options for jumbo yarn, including specific color choices and packaging formats. Customization may require a larger MOQ and longer lead times, so it’s crucial to discuss your needs upfront. Some manufacturers can provide color matching services or allow you to create your own color blends. Ensure you clarify any additional costs associated with customization to maintain budgetary control. -

What are the advantages of sourcing jumbo yarn from international suppliers?

Sourcing jumbo yarn from international suppliers can provide cost advantages, access to unique materials, and a wider range of colors and textures. Suppliers from regions like Asia may offer competitive pricing due to lower manufacturing costs. Additionally, international suppliers may provide access to innovative yarn blends that aren’t available locally. However, it’s vital to weigh these benefits against potential challenges, such as longer shipping times and import regulations. -

How do I vet potential suppliers for jumbo yarn?

To vet suppliers for jumbo yarn, start by researching their reputation and experience in the industry. Look for certifications, reviews, and case studies that demonstrate their reliability and product quality. Engage in direct communication to assess their responsiveness and willingness to address your queries. Request references from other B2B clients to gain insights into their experiences. Finally, consider conducting a factory visit if feasible, or utilize third-party inspection services to ensure compliance with your quality standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Jumbo Yarn In Bulk Manufacturers & Suppliers List

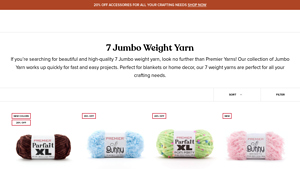

1. Premier Yarns – Parfait® XL Jumbo

Domain: premieryarns.com

Registered: 2005 (20 years)

Introduction: 7 Jumbo Weight Yarn collection from Premier Yarns includes high-quality yarns that work up quickly for fast and easy projects. Ideal for blankets and home decor. Key products include: 1. Premier Yarns Parfait® XL Jumbo – 100% Polyester, rated 4.7 out of 5, priced at $6.39 (originally $7.99). 2. Premier Yarns Bunny 200g Jumbo – 100% Polyester, rated 4.8 out of 5, priced at $5.84 (originally $8.99)….

2. The Wool Art – Chunky Chenille Yarn Bulk 13 lb

Domain: thewoolart.com

Registered: 2016 (9 years)

Introduction: Product Name: Chunky Chenille Yarn Bulk 13 lb (6 kg)

Price: $291.00 (originally $388.00)

Expected Delivery Date: 17-Sep-2025

Material: 100% soft polyester

Yarn Weight: 2.2 lb (1 kg) per ball

Yarn Length: 98 yards (1 kg = 90 m)

Thread Thickness: 0.8 inches (2 cm)

Approximate Yarn Quantities Needed:

– Oversized Scarf (8″ x 70″): 0.9 lb (20 x 180 cm – 0.4 kg)

– Lap Blanket (24″ x 47″): 1.8 lb (60 x 1…

3. Faire – Wholesale Chunky Yarn

Domain: faire.com

Registered: 1998 (27 years)

Introduction: Wholesale chunky yarn for your store. Shop wholesale online from over 100,000 brands.

4. Darn Good Yarn – High-Quality Yarn & Apparel

Domain: darngoodyarn.com

Registered: 2008 (17 years)

Introduction: Darn Good Yarn offers wholesale access to high-quality yarn, apparel, and home goods. Their products include cotton yarn, undyed yarn, handspun yarn, vegan yarn, lace weight yarn, recycled yarn & ribbon, wool yarn, banana fiber yarn, and silk. They also sell best-selling sari wrap skirts, scarves, and home goods. The company emphasizes a strict no child labor policy, ensuring that all products are…

5. WEBS – Malabrigo Rasta

Domain: yarn.com

Registered: 1995 (30 years)

Introduction: Super Bulky Weight Yarn at WEBS includes various options suitable for quick knitting or crochet projects, creating warm and cozy fabrics. Recommended gauge: 2.75 stitches per inch (knitting) and 1.75-2.25 single crochets per inch (crochet). Key products include: 1. Malabrigo Rasta – 100% Merino Wool, 90yds (82m)/150g (5.29oz), Price: $24.00 2. Paintbox Yarns Simply Super Chunky – 100% Acrylic, 66y…

6. Bernat – Jumbo Yarn 7

Domain: supplyleader.com

Registered: 2010 (15 years)

Introduction: Bernat Jumbo Yarn 7, Wholesale, Chunky, Soft, Versatile, Ideal for DIY Knitting Projects, Available at SupplyLeader.com

Strategic Sourcing Conclusion and Outlook for jumbo yarn in bulk

In conclusion, strategic sourcing of jumbo yarn in bulk presents significant advantages for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By capitalizing on bulk order discounts, such as those offered by suppliers like BeCozi and Premier Yarns, businesses can optimize their purchasing costs while ensuring a steady supply of high-quality materials. Understanding the diverse types of jumbo yarn available—ranging from chunky chenille to super bulky blends—enables buyers to cater to various market demands, from crafting cozy blankets to producing fashionable apparel.

Furthermore, establishing relationships with reputable suppliers like Darn Good Yarn can enhance product quality assurance, as these companies often emphasize ethical sourcing and sustainability. As the global market continues to evolve, staying informed about trends in yarn material preferences and consumer behaviors will be crucial for maintaining a competitive edge.

Looking ahead, now is the time for B2B buyers to engage with suppliers, negotiate favorable terms, and explore innovative yarn solutions to meet the growing demand. By doing so, you can position your business for success in the dynamic world of textile production. Embrace the opportunity to source strategically and enhance your product offerings today.