Unlocking Value: A Strategic Analysis of the Carport Frame Tubing Market

Introduction: Navigating the Global Market for carport frame tubing

Navigating the complexities of sourcing carport frame tubing can be a daunting challenge for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The varying standards, material qualities, and supplier capabilities across different markets can lead to confusion and costly mistakes. This guide aims to demystify the global market for carport frame tubing by providing a comprehensive overview of the types available, their applications, and crucial factors to consider when selecting suppliers.

From galvanized square tubing to innovative slip-fit frame systems, this guide will explore the diverse materials and structural designs that meet specific needs, whether for residential use or commercial projects. We will also address supplier vetting processes to ensure quality and reliability, as well as cost considerations that can impact overall budget planning.

By empowering B2B buyers with actionable insights and strategic guidance, this resource is designed to facilitate informed purchasing decisions that align with local requirements and global standards. Whether you’re based in Nigeria, Germany, or elsewhere, understanding these key aspects will not only streamline your sourcing process but also enhance the durability and effectiveness of your carport solutions.

Understanding carport frame tubing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Galvanized Square Tubing | Corrosion-resistant, available in various wall thicknesses | Carports, industrial frameworks, agricultural structures | Pros: Durable and weather-resistant; Cons: Heavier than alternatives, potentially higher shipping costs. |

| Aluminum Tubing | Lightweight, rust-resistant, easy to handle | Portable carports, temporary structures | Pros: Lightweight and easy to assemble; Cons: Less strength than steel options. |

| Rectangular Tubing | Versatile shape, good load-bearing capacity | Custom carports, commercial buildings | Pros: Excellent structural integrity; Cons: May require additional supports for larger spans. |

| Slip-Fit Frame Systems | Quick assembly, pre-engineered for ease of installation | DIY carports, residential applications | Pros: Fast setup and flexibility; Cons: May have limitations in customization. |

| Hot-Dipped Galvanized | Superior corrosion resistance through zinc coating | Long-term outdoor applications | Pros: Enhanced durability against harsh environments; Cons: Higher initial cost compared to standard options. |

What Are the Characteristics of Galvanized Square Tubing?

Galvanized square tubing is a popular choice for carport frameworks due to its exceptional corrosion resistance. Available in various lengths and wall thicknesses, this type of tubing is suitable for a range of applications, from residential carports to heavy-duty industrial frameworks. Buyers should consider the weight and potential shipping costs, as galvanized square tubing is typically heavier than alternatives. Its durability makes it ideal for long-term outdoor use, particularly in environments prone to moisture.

How Does Aluminum Tubing Compare for Carport Structures?

Aluminum tubing is favored for its lightweight and rust-resistant properties, making it easy to handle and transport. This type of tubing is particularly suitable for portable carports and temporary structures, appealing to businesses that require flexibility in their operations. While aluminum offers ease of assembly and mobility, it does have limitations in strength compared to steel options. Buyers should weigh the benefits of ease of installation against the potential need for additional supports in larger structures.

What Advantages Does Rectangular Tubing Offer for Custom Applications?

Rectangular tubing is known for its versatility and excellent load-bearing capacity, making it a strong candidate for custom carports and commercial buildings. The shape allows for efficient use of materials while providing structural integrity. When considering rectangular tubing, B2B buyers should evaluate the specific load requirements of their projects, as larger spans may necessitate additional supports. Its adaptability makes it a popular choice for various industrial applications.

Why Choose Slip-Fit Frame Systems for DIY Projects?

Slip-fit frame systems are designed for quick assembly, making them an ideal choice for DIY carport projects. Pre-engineered components ensure that installation is straightforward, allowing businesses to set up structures rapidly with common tools. While these systems provide flexibility and ease of use, buyers should note that they may have limitations in customization options. This type of tubing is particularly appealing to B2B buyers looking for efficient solutions in residential applications.

What Are the Benefits of Hot-Dipped Galvanized Tubing?

Hot-dipped galvanized tubing is distinguished by its superior corrosion resistance due to a protective zinc coating. This makes it an excellent choice for long-term outdoor applications, especially in harsh environments. While the initial cost may be higher than standard options, the long-term durability often justifies the investment. B2B buyers should consider the specific environmental conditions their structures will face when selecting hot-dipped galvanized tubing, as its enhanced protection can lead to lower maintenance costs over time.

Key Industrial Applications of carport frame tubing

| Industry/Sector | Specific Application of carport frame tubing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Vehicle storage and protection canopies | Safeguards vehicles from harsh weather conditions, extending their lifespan. | Durability against corrosion, compliance with local building codes, and ease of assembly. |

| Agriculture | Equipment and livestock shelters | Protects machinery and animals from environmental elements, enhancing productivity. | Material strength, resistance to rust, and adaptability to different climates. |

| Construction & Real Estate | Temporary storage solutions for construction materials | Provides secure and weather-resistant space for materials, reducing loss and damage. | Customizable sizes, structural integrity, and quick installation capabilities. |

| Retail | Outdoor display and storage units | Increases product visibility and protects inventory from weather, improving sales. | Aesthetic appeal, structural stability, and compliance with safety regulations. |

| Renewable Energy | Solar panel mounting structures | Optimizes space for solar energy generation, promoting sustainability. | Load capacity, compatibility with solar equipment, and resistance to environmental stressors. |

How is Carport Frame Tubing Used in the Automotive Industry?

In the automotive sector, carport frame tubing is utilized to create protective canopies for vehicles. These structures shield cars from adverse weather conditions such as rain, snow, and UV rays, which can lead to rust and paint deterioration. For international buyers, particularly in regions like Africa and South America where weather extremes are prevalent, sourcing high-quality, galvanized tubing is crucial. Buyers should consider the tubing’s resistance to corrosion and ensure compliance with local construction regulations to guarantee longevity and safety.

What Role Does Carport Frame Tubing Play in Agriculture?

In agricultural settings, carport frame tubing serves as the backbone for equipment and livestock shelters. These structures provide essential protection from harsh weather, which can affect both machinery and animal health. For businesses in the Middle East, where high temperatures and sandstorms are common, selecting durable, rust-resistant materials is vital. Buyers should also consider the tubing’s strength to withstand heavy loads and its adaptability to various environmental conditions, ensuring a reliable solution for their agricultural needs.

How is Carport Frame Tubing Beneficial in Construction and Real Estate?

In construction and real estate, carport frame tubing is often employed for temporary storage solutions for construction materials. These frameworks can be quickly assembled on-site, providing secure protection against the elements, which helps in minimizing material loss and damage. Buyers, especially from Europe and Africa, should prioritize sourcing customizable tubing that meets local building codes and can endure the specific environmental challenges of their region, ensuring a robust and compliant storage solution.

How Can Carport Frame Tubing Enhance Retail Operations?

Retail businesses leverage carport frame tubing to create outdoor display and storage units. These structures not only enhance product visibility but also protect inventory from weather-related damage, thereby improving sales potential. For international retailers, especially in regions with fluctuating climates, sourcing aesthetically pleasing yet durable tubing is essential. Additionally, compliance with safety regulations and structural stability should be key considerations when selecting materials for retail applications.

What Benefits Does Carport Frame Tubing Provide for Renewable Energy Solutions?

In the renewable energy sector, carport frame tubing is often used to construct mounting structures for solar panels. These frameworks optimize space for energy generation while ensuring durability and stability under varying weather conditions. Buyers in Europe, where sustainability initiatives are prevalent, should focus on sourcing tubing that can support the weight of solar equipment and withstand environmental stressors. Compatibility with existing solar technologies and local regulations are also critical factors to consider when sourcing materials for renewable energy applications.

3 Common User Pain Points for ‘carport frame tubing’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Tubing for Diverse Projects

The Problem: B2B buyers often encounter challenges when trying to source high-quality carport frame tubing that meets specific project requirements. In regions like Africa and South America, the availability of reliable suppliers can be limited, leading to difficulties in obtaining the right dimensions, materials, and grades. Buyers may face issues such as inconsistent product quality, delays in delivery, and the risk of receiving defective materials, which can disrupt timelines and increase project costs.

The Solution: To overcome sourcing challenges, buyers should establish relationships with multiple reputable suppliers who specialize in carport frame tubing. Conducting due diligence by reviewing supplier certifications, customer testimonials, and product samples can help ensure quality. For international transactions, consider suppliers with a proven track record of shipping to your region. Additionally, leveraging online platforms that aggregate multiple suppliers can streamline the search process. Ensure to specify your requirements clearly, including dimensions, wall thickness, and corrosion resistance standards, to minimize the risk of miscommunication and defects.

Scenario 2: Challenges with Installation and Assembly of Carport Structures

The Problem: Many B2B buyers, especially those in construction and infrastructure sectors, face difficulties with the installation and assembly of carport frames. Buyers may find that their teams lack the technical skills or experience necessary to efficiently assemble the frame tubing, leading to prolonged project timelines and increased labor costs. Furthermore, inadequate installation can result in structural weaknesses, compromising the safety and durability of the carport.

The Solution: To facilitate a smoother installation process, buyers should opt for carport frame tubing that comes with comprehensive assembly instructions and pre-engineered components. Consider sourcing from manufacturers that offer DIY kits with all necessary hardware included. Providing training sessions for the installation team or hiring experienced contractors to oversee the assembly can also enhance efficiency and safety. Additionally, leveraging modern technologies like 3D modeling can help visualize the assembly process and identify potential issues before physical work begins.

Scenario 3: Ensuring Compliance with Local Building Codes and Regulations

The Problem: Navigating the myriad of local building codes and regulations can be a daunting task for B2B buyers dealing with carport frame tubing. This is particularly true in regions like the Middle East and Europe, where regulations may vary significantly between municipalities. Buyers may struggle to ensure that their carport structures comply with local safety standards, load requirements, and zoning laws, which can lead to costly fines, legal issues, or even project cancellations.

The Solution: To ensure compliance, B2B buyers should engage local engineering consultants or building code experts who understand regional requirements. Before finalizing any purchase, it is crucial to research and obtain the latest building codes applicable to the project location. When sourcing carport frame tubing, prioritize suppliers who provide documentation or certifications that validate compliance with local standards. Furthermore, incorporating flexibility in design by allowing for future modifications can help meet evolving regulations without incurring additional costs. Regularly consulting local authorities during the planning phase can also provide clarity and prevent compliance-related setbacks.

Strategic Material Selection Guide for carport frame tubing

What Are the Key Properties of Common Materials for Carport Frame Tubing?

When selecting materials for carport frame tubing, several common options stand out due to their unique properties and suitability for various applications. Understanding these materials is crucial for B2B buyers looking to make informed purchasing decisions.

Steel: A Durable Choice for Carport Frame Tubing

Steel is one of the most prevalent materials used for carport frame tubing due to its strength and durability. Key properties include high tensile strength, making it suitable for heavy loads and adverse weather conditions. Steel also has good temperature tolerance, allowing it to withstand extreme climates.

Pros: Steel is highly durable, cost-effective, and readily available in various forms, including galvanized options that enhance corrosion resistance. It is also easy to fabricate, enabling manufacturers to create custom designs.

Cons: The primary disadvantage is its susceptibility to rust if not properly treated. This can be a concern in humid or coastal environments. Additionally, the weight of steel can complicate transportation and installation.

Impact on Application: Steel is compatible with various media, including automotive and industrial applications, making it versatile. However, buyers should consider local climate conditions to determine the need for additional protective coatings.

Aluminum: Lightweight and Corrosion-Resistant

Aluminum is another popular choice for carport frame tubing, especially in regions with high humidity or coastal areas. Its key properties include excellent corrosion resistance and a low weight, which simplifies installation.

Pros: Aluminum’s lightweight nature reduces shipping costs and allows for easier handling during installation. It also does not rust, making it ideal for outdoor applications.

Cons: The main limitation is its lower strength compared to steel, which may not be suitable for heavy-duty applications. Additionally, aluminum can be more expensive than steel, impacting overall project costs.

Impact on Application: Aluminum is particularly advantageous for applications requiring frequent relocation or temporary structures. Buyers should ensure that the structural integrity meets local building codes.

Galvanized Steel: The Best of Both Worlds

Galvanized steel combines the strength of steel with a protective zinc coating that enhances corrosion resistance. This makes it an ideal choice for carport frame tubing in various environments.

Pros: The galvanization process significantly extends the lifespan of the steel, making it suitable for outdoor applications where moisture is a concern. It also maintains the structural integrity of the frame over time.

Cons: While galvanized steel is durable, it can still be prone to scratches that expose the underlying steel, leading to rust if not addressed. The initial cost may also be higher than standard steel.

Impact on Application: Galvanized steel is suitable for diverse applications, including residential and commercial carports. Buyers should verify compliance with international standards, such as ASTM or EN, depending on their region.

Stainless Steel: Premium Performance for Specialized Applications

Stainless steel offers exceptional corrosion resistance and aesthetic appeal, making it suitable for high-end carport designs. Its key properties include high strength and resistance to staining and rust.

Pros: The durability and low maintenance requirements of stainless steel make it an excellent long-term investment. Its aesthetic qualities also appeal to buyers looking for visually appealing structures.

Cons: The primary drawback is the cost, as stainless steel is significantly more expensive than other materials. Additionally, its weight can pose challenges during installation.

Impact on Application: Stainless steel is ideal for high-end applications where aesthetics and longevity are paramount. Buyers should consider local availability and compliance with international standards.

Summary Table of Material Selection for Carport Frame Tubing

| Material | Typical Use Case for carport frame tubing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty carports | High strength and durability | Susceptible to rust | Medium |

| Aluminum | Lightweight, temporary structures | Excellent corrosion resistance | Lower strength compared to steel | High |

| Galvanized Steel | Outdoor carports in humid areas | Extended lifespan due to corrosion resistance | Prone to scratches exposing steel | Medium |

| Stainless Steel | High-end, aesthetic carports | Exceptional durability and aesthetics | High cost and installation challenges | High |

This guide aims to assist international B2B buyers in selecting the most suitable material for their specific needs, considering various factors such as cost, performance, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for carport frame tubing

What Are the Main Stages of Manufacturing Carport Frame Tubing?

The manufacturing process for carport frame tubing involves several critical stages that ensure the final product meets both structural integrity and aesthetic standards.

Material Preparation

The first stage involves sourcing high-quality steel, typically galvanized to enhance corrosion resistance. Galvanization can be achieved through hot-dipping or electro-galvanizing methods. The choice of material affects not only the durability of the carport but also its ability to withstand various environmental conditions, which is particularly important for international buyers in diverse climates.

Before fabrication begins, the steel is cut into specified lengths using advanced cutting technology, ensuring precision that minimizes waste. Additionally, suppliers may conduct preliminary tests on the raw materials to check for defects, ensuring only the highest quality materials proceed to the next stage.

Forming Processes

Once the materials are prepared, they undergo forming processes, which can include bending, rolling, and welding.

-

Bending: This process shapes the tubing to create the necessary angles and curves for the carport frame. Advanced CNC bending machines are often employed to achieve precise angles and consistent dimensions.

-

Rolling: For certain designs, rolling processes are utilized to create round or curved sections of tubing. This is especially relevant for carports that require rounded edges or specific architectural features.

-

Welding: The individual pieces of tubing are then welded together to form the structural frame. This step is critical, as it determines the strength and stability of the finished product. Automated welding machines are increasingly used to ensure uniformity and reduce human error.

Assembly Techniques

The assembled frame is then prepared for finishing. This stage may involve additional components such as brackets, supports, or joints that enhance the structural integrity of the carport. Modular designs are common, allowing for easy assembly and disassembly, which is appealing to DIY customers.

The assembly process is often optimized for efficiency, allowing for quicker turnaround times without compromising quality.

Finishing Processes

Finally, the carport frame undergoes finishing processes, which may include additional galvanization or powder coating. Powder coating not only provides an extra layer of protection against the elements but also enhances the aesthetic appeal of the product.

Quality control checks are typically conducted throughout the finishing process to ensure the final product meets the required specifications.

How Is Quality Assurance Implemented in Carport Frame Tubing Production?

Quality assurance is paramount in the production of carport frame tubing, and it is typically governed by international standards and industry-specific certifications.

What Are the Relevant International Standards?

International standards such as ISO 9001 are widely recognized and provide a framework for quality management systems. Adherence to these standards ensures that manufacturers have processes in place for continuous improvement and customer satisfaction.

Additionally, industry-specific certifications may be relevant, such as CE marking in Europe, which indicates compliance with health, safety, and environmental protection standards. For buyers from Africa and the Middle East, understanding local regulations and compliance requirements is crucial, as these may differ significantly from those in Europe or South America.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage checks the raw materials for compliance with specifications. Any defects are identified and addressed before production begins.

-

In-Process Quality Control (IPQC): This ongoing assessment occurs during manufacturing. It involves monitoring the various stages of production, such as welding and assembly, to ensure adherence to quality standards.

-

Final Quality Control (FQC): After the frame is completed, a thorough inspection is conducted to ensure that the final product meets all specifications and standards. This may include visual inspections, dimensional checks, and testing for structural integrity.

What Common Testing Methods Are Used?

Common testing methods for carport frame tubing may include:

-

Tensile Testing: Measures the strength of the steel to ensure it can withstand specified loads.

-

Bending Tests: Assess the material’s flexibility and resistance to deformation under stress.

-

Corrosion Resistance Testing: Evaluates the effectiveness of galvanization and other protective coatings.

These tests provide critical data that help ensure the product’s longevity and performance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential to ensure product reliability.

What Steps Should Buyers Take?

-

Supplier Audits: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. This is especially important for buyers who may not be able to physically inspect products before purchase.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality assurance reports, including results from any testing conducted during manufacturing. These documents should demonstrate compliance with international standards.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of the manufacturing processes and product quality. This is particularly valuable for buyers operating in regions with varying regulatory standards.

What Are the QC/CERT Nuances for International Buyers?

International buyers should be aware that quality certifications may vary by region. Understanding local regulations and compliance standards is crucial for ensuring that imported products meet the necessary legal and quality requirements.

Additionally, buyers should consider the logistical aspects of sourcing products internationally, including shipping times, customs regulations, and potential tariffs. These factors can influence not only the overall cost but also the timeliness of project completion.

By understanding the intricacies of manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing carport frame tubing, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘carport frame tubing’

Introduction

Sourcing carport frame tubing requires careful consideration to ensure that you obtain quality materials that meet your specific needs. This step-by-step checklist is designed to guide B2B buyers through the procurement process, helping you make informed decisions that can impact the durability and cost-effectiveness of your carport structures.

Step 1: Define Your Technical Specifications

Before you begin sourcing, outline the technical specifications of the carport frame tubing you require. This includes dimensions, wall thickness, material type (e.g., galvanized steel for corrosion resistance), and any specific structural requirements based on local climate conditions.

– Consider regional factors: Evaluate wind and snow load ratings relevant to your area, as these will influence the tubing’s strength requirements.

Step 2: Research Material Options

Understanding the different types of materials available for carport frame tubing is essential. Common options include galvanized steel, aluminum, and stainless steel, each offering unique benefits.

– Corrosion resistance: Galvanized tubing is highly recommended for its ability to withstand harsh weather conditions, particularly in humid or coastal regions.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure they meet your quality and service standards. Request detailed company profiles, including case studies and references from similar projects.

– Assess certifications: Verify that the suppliers hold relevant industry certifications, which can indicate adherence to quality standards and regulatory compliance.

Step 4: Request Sample Materials

Once you’ve narrowed down your suppliers, request samples of the carport frame tubing. This step allows you to assess the quality and suitability of the materials for your intended application.

– Inspect samples: Look for consistency in finish, wall thickness, and any signs of defects that could affect the structural integrity.

Step 5: Compare Pricing and Terms

After gathering samples and evaluating quality, compare pricing structures across different suppliers. Be mindful of the total cost, including shipping, taxes, and any potential duties for international transactions.

– Negotiate terms: Establish clear terms regarding minimum order quantities, lead times, and payment conditions to avoid surprises later.

Step 6: Confirm Delivery and Logistics

Before finalizing your order, confirm the logistics of delivery. Understand the shipping methods, estimated delivery times, and any potential customs requirements if you are importing materials.

– Plan for contingencies: Discuss what measures the supplier has in place for delays or issues during transit, ensuring you have a backup plan.

Step 7: Establish a Quality Assurance Process

Once your order is placed, develop a quality assurance process to monitor the materials upon delivery. This step is critical for ensuring that the received products meet your initial specifications.

– Conduct inspections: Set up a system for inspecting the frame tubing upon arrival to catch any discrepancies before they impact your project timeline.

By following this checklist, B2B buyers can navigate the complexities of sourcing carport frame tubing more effectively, ensuring that they secure the right materials for their projects while minimizing risks.

Comprehensive Cost and Pricing Analysis for carport frame tubing Sourcing

What Are the Key Cost Components in Carport Frame Tubing Sourcing?

Understanding the cost structure for sourcing carport frame tubing is vital for international B2B buyers. The primary cost components include:

-

Materials: The choice of steel, typically galvanized for corrosion resistance, significantly impacts costs. Prices can vary based on market conditions and quality (e.g., hot-dipped vs. electrogalvanized).

-

Labor: Labor costs can vary widely based on geographic location and skill levels. In regions like Africa or South America, labor may be less expensive, but quality and availability should be scrutinized.

-

Manufacturing Overhead: This includes costs associated with running manufacturing facilities, such as utilities, maintenance, and administrative expenses. Suppliers in different regions may have varying overheads that can influence pricing.

-

Tooling: Custom tooling for specific designs or specifications can add to the initial costs. Standardized products usually have lower tooling costs, whereas customized solutions may require significant investment.

-

Quality Control (QC): Ensuring the final product meets quality standards is essential. Enhanced QC processes can add to the cost but are necessary for compliance with international standards, especially in markets like Europe.

-

Logistics: Shipping costs can vary dramatically based on the supplier’s location and the destination. Incoterms play a critical role in determining who bears these costs and risks.

-

Margin: Suppliers will typically add a margin to cover their costs and profit, which can vary based on competition, demand, and market conditions.

How Do Price Influencers Affect Carport Frame Tubing Costs?

Several factors can influence the pricing of carport frame tubing:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract bulk pricing discounts. Buyers should negotiate to maximize cost savings, especially for high-volume projects.

-

Specifications and Customization: Custom specifications may lead to higher costs due to unique tooling and manufacturing processes. Buyers should balance the need for customization against the potential for increased costs.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (such as ISO or ASTM) may cost more upfront but can lead to savings in maintenance and longevity.

-

Supplier Factors: Supplier reliability, reputation, and financial stability can impact pricing. Established suppliers may charge a premium but provide better service and quality assurance.

-

Incoterms: Understanding Incoterms is crucial for international buyers. They define the responsibilities of buyers and sellers in terms of shipping costs, insurance, and risk, which can affect the total landed cost.

What Tips Can Help Buyers Negotiate Better Prices for Carport Frame Tubing?

For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, here are actionable tips:

-

Negotiate Effectively: Always negotiate prices based on volume, payment terms, and delivery schedules. Leverage competitive quotes from multiple suppliers to strengthen your position.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also logistics, installation, maintenance, and potential resale value. A lower upfront cost may lead to higher TCO if the product is of inferior quality.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, tariffs, and trade agreements can significantly impact costs. Buyers should factor these elements into their pricing discussions.

-

Build Long-term Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms over time. Suppliers are often willing to offer discounts to loyal customers.

-

Conduct Market Research: Stay informed about market trends and material costs. Being aware of fluctuations can provide leverage in negotiations and help anticipate cost changes.

Disclaimer for Indicative Prices

Prices for carport frame tubing can vary widely based on market conditions, supplier negotiations, and geographical factors. The figures provided in this analysis are indicative and should be verified with suppliers for accurate quotes tailored to specific requirements.

Alternatives Analysis: Comparing carport frame tubing With Other Solutions

Exploring Alternatives to Carport Frame Tubing

In the quest for effective shelter solutions, carport frame tubing serves as a robust option, but it is essential to consider other alternatives that may better suit specific needs or preferences. This analysis compares carport frame tubing with two viable alternatives: pre-engineered metal carport kits and wooden carport structures. Each option presents unique advantages and limitations, making it important for B2B buyers to evaluate these alternatives based on various criteria.

| Comparison Aspect | Carport Frame Tubing | Pre-Engineered Metal Carport Kits | Wooden Carport Structures |

|---|---|---|---|

| Performance | High durability; resistant to rust and corrosion; customizable designs | Strong and durable; quick installation; limited customization | Aesthetic appeal; moderate durability; requires treatment for longevity |

| Cost | Moderate initial investment; long-term value due to durability | Higher upfront costs; often includes delivery and assembly | Generally lower initial costs; may incur higher maintenance costs |

| Ease of Implementation | Requires welding and fabrication skills; DIY-friendly with proper tools | Pre-fabricated; easy assembly with minimal tools | Requires carpentry skills; time-consuming construction |

| Maintenance | Low maintenance; resistant to weathering | Low maintenance; materials often treated for longevity | Higher maintenance; susceptible to rot and insect damage |

| Best Use Case | Industrial and commercial applications; highly customizable | Residential and light commercial use; ideal for quick setups | Residential settings; preferred for aesthetic and natural look |

In-Depth Look at Alternatives

Pre-Engineered Metal Carport Kits

Pre-engineered metal carport kits offer a strong and durable solution that can be assembled quickly with minimal tools. These kits typically come with all necessary components, including panels and frames, which simplifies the construction process. While the initial investment is usually higher than carport frame tubing, the time savings and ease of installation can justify the cost for many buyers. However, customization options may be limited compared to carport frame tubing, which can be tailored to specific dimensions and design preferences.

Wooden Carport Structures

Wooden carports provide an aesthetic appeal that many buyers prefer for residential settings. They can be less expensive upfront, but they require regular maintenance to protect against rot, weathering, and insect damage. The construction of wooden carports often demands significant carpentry skills, making them less accessible for DIY projects. While they may not match the durability of metal options, they can be a charming addition to homes, particularly in areas where natural materials are favored.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the ideal carport solution, B2B buyers should consider their specific requirements, including budget, intended use, and desired aesthetics. Carport frame tubing offers durability and customization, making it suitable for industrial applications. Alternatively, pre-engineered metal carport kits provide ease of installation, while wooden structures offer a natural look but require ongoing maintenance. By weighing these factors against the unique needs of their projects, buyers can make informed decisions that best align with their operational goals.

Essential Technical Properties and Trade Terminology for carport frame tubing

What Are the Key Technical Properties of Carport Frame Tubing?

Understanding the technical specifications of carport frame tubing is crucial for B2B buyers to ensure they select the right materials for their projects. Here are some critical properties to consider:

1. Material Grade

The material grade refers to the type and quality of the steel used in manufacturing the tubing. Common grades include ASTM A500 for structural tubing and A53 for pipe. Higher grades typically offer better strength and durability, which is essential for carports that need to withstand various weather conditions. Selecting the appropriate grade can affect the longevity and safety of the structure.

2. Wall Thickness

Wall thickness is a vital specification that directly impacts the strength and load-bearing capacity of the frame. Common wall thicknesses range from 0.065 inches to 0.120 inches. Thicker walls provide enhanced resistance to bending and deformation, making them suitable for areas prone to heavy snowfall or strong winds. This property is crucial for ensuring the structural integrity of carports over time.

3. Length and Size

Carport frame tubing is available in various lengths and sizes, typically measured in feet. Standard lengths include 20 and 24 feet, while sizes can vary from 1 inch to 6 inches in width. Understanding the available dimensions allows buyers to optimize their designs and reduce waste during construction. It is important to ensure that the dimensions align with the specific requirements of the carport being constructed.

4. Corrosion Resistance

Corrosion resistance is a critical property, especially in regions with high humidity or salt exposure. Galvanized tubing, which is coated with a layer of zinc, offers superior protection against rust and corrosion. This property is essential for maintaining the longevity of carports, reducing maintenance costs, and ensuring safety over time.

5. Load Ratings

Load ratings indicate the maximum weight the carport frame can support, including snow loads and wind resistance. Manufacturers often provide these ratings based on standardized testing. Buyers should ensure that the selected frame tubing meets or exceeds local building codes and environmental conditions to avoid structural failures.

6. Tolerance

Tolerance refers to the permissible limit of variation in the dimensions of the tubing. This specification is critical for ensuring that components fit together correctly during assembly. A tighter tolerance can lead to improved structural performance and ease of installation, which is particularly important for DIY projects.

What Are Common Trade Terms Used in Carport Frame Tubing?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B sector. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of carport frame tubing, it can indicate suppliers that provide components designed specifically for carports, ensuring compatibility and reliability.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it can affect inventory management and pricing. A higher MOQ may lead to cost savings, but it also requires careful planning to avoid excess stock.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing an RFQ can help compare prices and services from multiple suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping, insurance, and tariffs. Understanding Incoterms is vital for international buyers to avoid unexpected costs and ensure smooth logistics.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. It is an important consideration for project planning, as longer lead times can delay construction schedules. Buyers should inquire about lead times when sourcing carport frame tubing to ensure timely project execution.

6. Certification

Certification indicates that the products meet specific industry standards or regulations. Common certifications for steel products include ISO and ASTM. Buyers should seek certified materials to ensure quality and compliance with safety standards, especially in international markets.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing carport frame tubing, ultimately leading to successful projects and satisfied customers.

Navigating Market Dynamics and Sourcing Trends in the carport frame tubing Sector

What Are the Current Market Dynamics and Key Trends in the Carport Frame Tubing Sector?

The carport frame tubing market is witnessing significant growth driven by the increasing demand for outdoor structures, particularly in regions with challenging weather conditions. Countries in Africa, South America, the Middle East, and Europe are seeing a surge in carport installations as consumers and businesses alike recognize the value of protecting vehicles and other assets from environmental elements. Notably, the global shift towards DIY solutions and customizable structures has led to a rise in the popularity of modular carport kits, which are easier to assemble and transport.

Technological advancements are also shaping the market, with the integration of design software that allows buyers to visualize their projects before purchase. Suppliers are increasingly leveraging e-commerce platforms to reach international buyers, enabling streamlined ordering processes and better inventory management. Additionally, the emphasis on sustainability is prompting manufacturers to explore innovative materials and manufacturing processes that reduce environmental impact.

Emerging trends include the use of galvanized steel, which offers enhanced corrosion resistance, making it a preferred choice for regions with high humidity or extreme weather conditions. Furthermore, buyers are increasingly seeking products that comply with local building codes and standards, reflecting a growing awareness of safety and structural integrity.

How Is Sustainability and Ethical Sourcing Influencing B2B Buying Decisions?

The importance of sustainability and ethical sourcing is becoming paramount for B2B buyers in the carport frame tubing sector. Environmental impact considerations are driving businesses to select suppliers who prioritize eco-friendly practices. Many companies are now opting for materials that are recyclable or sourced from sustainable processes, such as those that use recycled steel. This shift not only reduces the carbon footprint but also appeals to environmentally conscious consumers.

Moreover, ethical supply chains are gaining traction, with buyers increasingly scrutinizing the sourcing practices of their suppliers. This includes a focus on fair labor practices and transparency in the supply chain. Certifications for ‘green’ materials and processes, such as ISO 14001 for environmental management, are becoming essential credentials for suppliers looking to attract international buyers.

As more companies commit to corporate social responsibility (CSR) initiatives, B2B buyers are encouraged to partner with manufacturers who demonstrate a commitment to ethical practices. This trend not only enhances brand reputation but also aligns with the values of consumers who prefer to support businesses that contribute positively to society and the environment.

What Is the Historical Context Behind the Carport Frame Tubing Sector?

The carport frame tubing sector has evolved significantly over the past few decades. Initially, carports were often constructed from wood or other less durable materials, which limited their lifespan and resistance to weather. The introduction of steel as a primary material for carports marked a pivotal shift, providing enhanced durability, strength, and resistance to environmental factors.

As manufacturing techniques advanced, particularly with the advent of galvanized and coated steel, the industry began to embrace more sustainable practices. The move towards modular designs and DIY kits has further revolutionized the market, making carports more accessible to a broader range of consumers. Today’s carport solutions reflect a blend of innovation, sustainability, and customer-centric design, catering to the diverse needs of international B2B buyers across various regions.

Frequently Asked Questions (FAQs) for B2B Buyers of carport frame tubing

-

How do I choose the right carport frame tubing for my project?

Selecting the appropriate carport frame tubing involves assessing several factors, including the dimensions of your carport, the local climate (wind and snow loads), and the materials required for durability. Consider galvanized steel for corrosion resistance, especially in humid or coastal areas. It’s also essential to evaluate the tubing’s wall thickness and size; thicker walls provide greater strength. Consult with manufacturers to ensure compliance with local building codes and standards. -

What are the advantages of galvanized steel tubing for carports?

Galvanized steel tubing is highly favored for carport frames due to its excellent resistance to rust and corrosion, which is critical in various climates. The galvanization process extends the material’s lifespan, reducing maintenance costs over time. Additionally, it offers structural strength and durability, making it suitable for supporting roofs in windy or snowy conditions. This type of tubing also requires minimal upkeep, making it a cost-effective option for long-term use. -

What customization options are available for carport frame tubing?

Most suppliers offer customization options for carport frame tubing, including varying lengths, sizes, and wall thicknesses. You can also specify the type of finish, such as powder coating or galvanized, to suit your aesthetic and functional needs. Discussing your project requirements with the supplier can lead to tailored solutions, ensuring that the tubing fits perfectly with your design specifications. Be prepared to provide detailed dimensions and any specific structural requirements. -

What is the minimum order quantity (MOQ) for carport frame tubing?

Minimum order quantities for carport frame tubing can vary by supplier and region. Generally, manufacturers may have an MOQ of several tons or specific footage, particularly for custom orders. It’s advisable to reach out directly to suppliers to inquire about their MOQ and any potential discounts for bulk purchases. Additionally, consider your project needs and budget to determine the most cost-effective order size. -

What payment terms should I expect when sourcing carport frame tubing internationally?

Payment terms for international purchases of carport frame tubing can vary significantly. Common options include upfront payments, partial deposits, or letters of credit. Some suppliers may also offer payment through platforms like PayPal or escrow services to protect both parties. Always clarify payment terms before finalizing any agreements to ensure transparency and security in your transactions. -

How do I vet suppliers for carport frame tubing?

Vetting suppliers is crucial for ensuring quality and reliability. Begin by researching potential suppliers through industry directories and trade shows. Check for certifications, such as ISO or ASTM, which indicate compliance with quality standards. Request samples to assess material quality, and seek references or customer reviews. It’s also beneficial to verify their manufacturing processes and supply chain practices to ensure they meet your requirements. -

What logistics considerations should I keep in mind when importing carport frame tubing?

When importing carport frame tubing, consider shipping methods, customs regulations, and potential tariffs. It’s essential to understand the lead times for production and shipping, as these can impact project timelines. Collaborating with a freight forwarder can simplify the logistics process, helping you navigate documentation and compliance issues. Additionally, ensure that your supplier can provide necessary shipping documentation, such as bills of lading and certificates of origin. -

What quality assurance measures should be in place for carport frame tubing?

Quality assurance is vital to ensure that the carport frame tubing meets specified standards. Suppliers should conduct regular inspections during production and provide certifications for material properties. Request test reports for tensile strength and corrosion resistance, and consider third-party inspections for additional assurance. Establishing clear quality expectations and protocols with your supplier can help mitigate risks associated with material defects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Carport Frame Tubing Manufacturers & Suppliers List

1. Steel Supply LP – Galvanized Square Tubing

Domain: steelsupplylp.com

Registered: 2005 (20 years)

Introduction: Galvanized Square Tubing available in 20 and 24 foot lengths. Types include Electrogalvanized and Hot Dipped Galvanized. Sizes include: .500-X-.500, .750-X-.750, 1.00-X-1.00, 1.25-X-1.25, 1.50-X-1.50, 2.00-X-2.00, 2.50-X-2.50, 3.00-X-3.00, 4.00-X-4.00. Wall thicknesses available: 0.250, 11 GAUGE, 14 GAUGE, 16 GAUGE. Example products: GST.500 X 16GA X 24 (SKU: 149126, Weight: 9.24, Price: $15.06), …

2. Versatube – Frame Only Classic Carport

Domain: versatube.com

Registered: 1997 (28 years)

Introduction: Frame Only Classic Carport (2×2) – Dimensions: 10’W x 31.5’L x 7’H – Availability: In stock – Regular Price: $1,630 – Special Price: $1,600 – Price Drop: $30 – Frame ships in 5 business days – Made in the USA – Steel Tubing Size: 2″ x 3″ – Steel Gauge: 14 Gauge – Warranty: 20 Year Product Pledge – Connections: Patented Slip Fit Connections – Snow Rating: Up to 41.3 PSF – Wind Rating: Up to 165 MPH…

3. Gregory Tube – Galvanized Square Tubing

Domain: gregorycorp.com

Registered: 1999 (26 years)

Introduction: Gregory Tube offers a wide variety of galvanized square tubing designed for carport applications. The steel tubing is corrosion resistant and weatherproof, providing protection for property and increasing property value. The company has over 120 years of manufacturing expertise, ensuring dependable, sturdy, and high-quality products. Their continuous galvanizing process enhances durability and qua…

4. Americas Elite Garages – Galvanized Steel Carports

Domain: americaselitegaragesandcarports.com

Registered: 2019 (6 years)

Introduction: This company, Americas Elite Garages – Galvanized Steel Carports, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

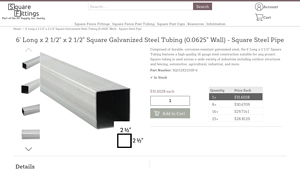

5. Square Fittings – Galvanized Steel Square Fitting 6′

Domain: squarefittings.com

Registered: 2013 (12 years)

Introduction: {‘length’: “6′”, ‘size’: ‘2 1/2″ x 2 1/2″‘, ‘gauge’: ’16 Gauge’, ‘wall_thickness’: ‘0.0625″‘, ‘material’: ‘Galvanized Steel’, ‘part_number’: ‘SQ212X212GP-6’, ‘price_per_unit’: ‘$31.6028’, ‘applications’: ‘Outdoor structures, fencing, automotive, agricultural, industrial’, ‘features’: ‘Can be cut to any size, heavy-duty, corrosion-resistant’}

6. Your Custom Carport – Metal Tubing Features

Domain: yourcustomcarport.com

Registered: 2022 (3 years)

Introduction: Metal tubing is a versatile building material made from steel, aluminum, or other metals, available in round, square, and rectangular shapes. Key features include: 1. Strength and Durability: Exceptional strength to withstand heavy loads and harsh conditions. 2. Corrosion and Rust Resistance: Galvanized steel offers low-maintenance properties, ideal for outdoor applications. 3. Customization and F…

7. All American Metal Sales – Carports and Covers

Domain: allamericanmetalsales.com

Registered: 2018 (7 years)

Introduction: Carports and covers available in various sizes and styles, designed for durability and protection against weather elements. Options include single and double carports, RV covers, and custom designs. Made from high-quality materials, offering a range of colors and finishes. Installation services provided, with options for DIY kits. Suitable for residential and commercial use.

8. Midwest Steel – Steel Frame Gauge Options

Domain: midweststeelcarports.com

Registered: 2016 (9 years)

Introduction: Midwest Steel offers two steel frame gauge options: 14 gauge and 12 gauge.

14 Gauge:

– Standard option for steel buildings

– Economical choice

– 7-year warranty on rust through of frame

– Dimensions: 2 1/2″ x 2 1/2″ in diameter, .0747 inch thick

– Industry standard for carports

12 Gauge:

– Heavy duty option with high tensile strength

– Best for heavy snow loads and high winds

– 20-year warranty…

9. GenSteel – Tube Carport Sizes

Domain: gensteel.com

Registered: 1998 (27 years)

Introduction: Tube Carport Sizes: 12×12, 12×20, 12×24, 12×30, 20×30, 20×40. 12×12 is suitable for a single vehicle. 12×20 can protect a single car, ATVs, or lawn tractors. 12×24 is designed for two cars. 12×30 shelters two vehicles or provides extra storage. 20×30 is for multiple vehicles, ATVs, or lawn tractors. 20×40 is for multiple cars or a motorhome.

10. Reddit – Tubing Safety Concerns and Alternatives

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 30 posts of tubing, potentially galvanized steel, not designed for load-bearing, concerns about welding safety and structural integrity, suggestions for alternative tubing available on the market.

Strategic Sourcing Conclusion and Outlook for carport frame tubing

In the realm of strategic sourcing for carport frame tubing, international B2B buyers must prioritize quality, durability, and adaptability. The increasing demand for versatile structures, particularly in regions like Africa, South America, the Middle East, and Europe, highlights the importance of selecting suppliers that offer a range of galvanized options. High-quality materials, such as hot-dipped galvanized steel, provide essential corrosion resistance, ensuring longevity and reducing maintenance costs.

Moreover, embracing innovative framing systems, such as those that allow for easy assembly and customization, can significantly enhance project efficiency and reduce lead times. As buyers seek to maximize their investments, understanding local building codes and climatic conditions will be crucial in making informed purchasing decisions.

Looking ahead, the global market for carport frame tubing is poised for growth, driven by the rising interest in cost-effective shelter solutions. As you navigate this evolving landscape, consider forging strategic partnerships with reliable suppliers who can meet your specific needs. Now is the time to leverage these insights and secure your supply chain, ensuring your projects are built on a foundation of quality and resilience.