A Deep Dive into Fob Vs Exw Solution

Introduction: Navigating the Global Market for fob vs exw

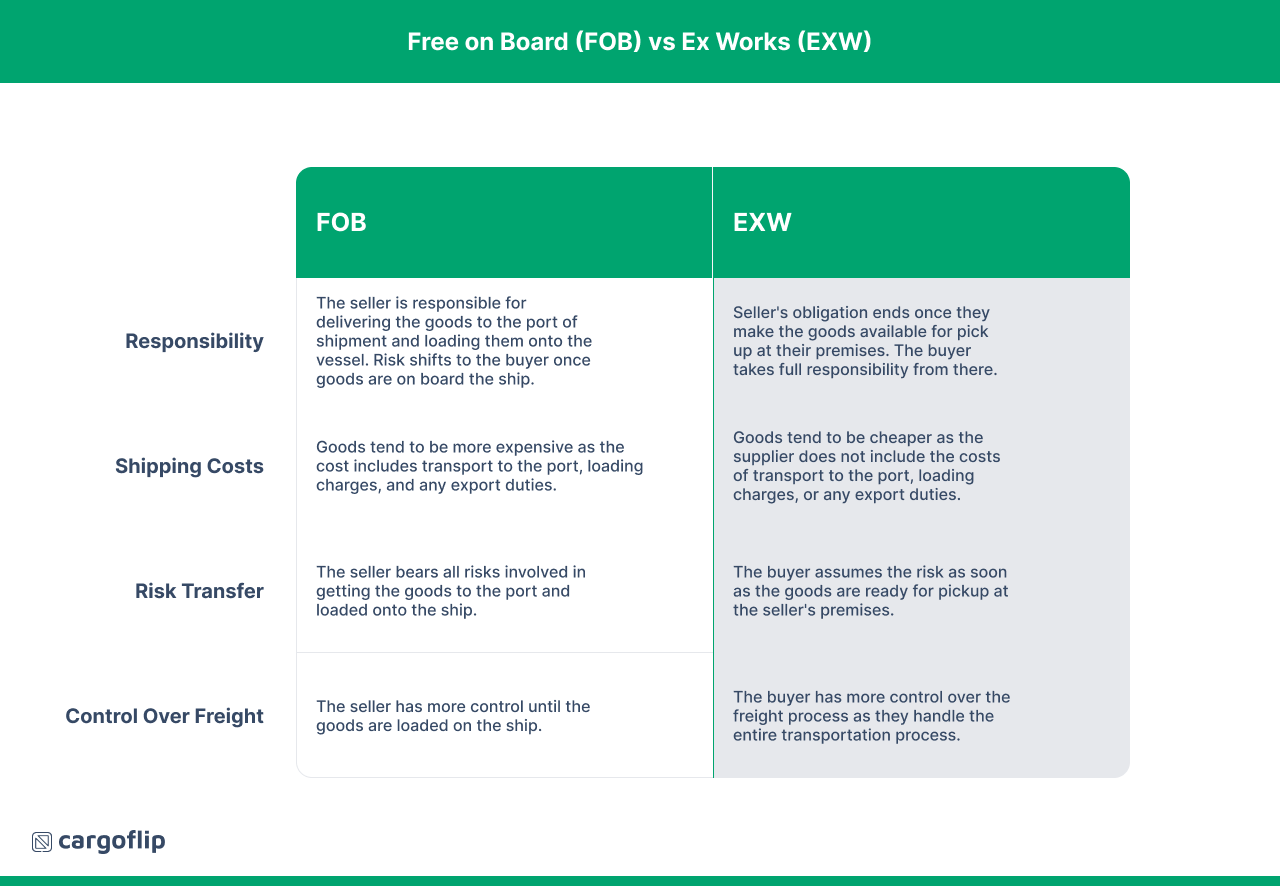

In the complex world of international trade, navigating the intricacies of shipping terms such as FOB (Free On Board) and EXW (Ex Works) can be a daunting task for B2B buyers. Understanding the nuances of these Incoterms is essential, especially when sourcing goods from diverse regions like Africa, South America, the Middle East, and Europe. Choosing the right shipping term can significantly impact costs, responsibilities, and overall supply chain efficiency. This guide delves into the key differences between FOB and EXW, helping you assess which term aligns best with your business objectives and operational capabilities.

Throughout this comprehensive resource, we will explore the types and applications of FOB and EXW, provide actionable insights for supplier vetting, and analyze the cost implications associated with each shipping method. By examining real-world scenarios and expert recommendations, this guide empowers international buyers to make informed purchasing decisions that can enhance profitability and streamline logistics. Whether you’re a seasoned buyer or new to global trade, understanding these essential shipping terms will equip you with the knowledge to navigate the complexities of international logistics confidently. With the right information at your fingertips, you can optimize your supply chain and establish successful partnerships across borders.

Understanding fob vs exw Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| FOB (Free On Board) | Seller covers costs and risks until goods are loaded on the vessel. | Suitable for bulk shipments and established trade routes. | Pros: Reduced risk during transit; clear responsibility transfer. Cons: Potentially higher costs if seller’s logistics are inefficient. |

| EXW (Ex Works) | Seller only makes goods available at their location; buyer handles all transport. | Ideal for buyers with strong logistics networks or experience. | Pros: Lower initial costs; buyer has control over shipping arrangements. Cons: Higher risk for buyer; seller’s limited responsibility. |

| FOB Destination | Seller assumes responsibility until goods reach the buyer’s location. | Useful for buyers seeking maximum seller accountability. | Pros: Reduced risk during transport; predictable delivery. Cons: Potentially higher shipping costs; less control over logistics. |

| EXW with Freight Forwarder | Buyer arranges transport but may use a freight forwarder for efficiency. | Beneficial for buyers unfamiliar with local shipping. | Pros: Cost-effective; access to expert logistics support. Cons: Coordination complexities; buyer still assumes risk. |

| FOB vs. CIF (Cost, Insurance, and Freight) | FOB only covers transport; CIF includes insurance and freight costs. | Appropriate for buyers wanting comprehensive coverage. | Pros: Greater security with insurance; simplified logistics. Cons: Higher overall cost; less flexibility in choosing shipping methods. |

What Are the Key Characteristics of FOB (Free On Board)?

FOB (Free On Board) is characterized by the seller’s responsibility for all costs and risks until the goods are loaded onto the vessel. This term is particularly beneficial for bulk shipments or when trading on established routes, as it provides a clear delineation of responsibilities. Buyers can expect reduced risk during transit, as the seller is liable until the loading point. However, it may result in higher costs if the seller’s logistics are not efficient. B2B buyers should assess their relationship with the supplier and the efficiency of their logistics operations when considering this option.

How Does EXW (Ex Works) Suit Buyers?

EXW (Ex Works) places minimal responsibility on the seller, as they are only required to make the goods available at their premises. This arrangement is ideal for buyers with strong logistics capabilities or experience in international shipping. While it allows for lower initial costs and greater control over shipping arrangements, it also increases risk for the buyer, who must manage the entire logistics process. Businesses considering EXW should evaluate their familiarity with local transport regulations and their ability to handle potential challenges during shipping.

What Are the Benefits of Using FOB Destination?

FOB Destination is a variation where the seller retains responsibility for the goods until they reach the buyer’s location. This term is advantageous for buyers looking for maximum accountability from the seller, as it minimizes their risk during transport. Predictable delivery timelines are another benefit, making it easier for businesses to plan their inventory management. However, buyers may encounter higher shipping costs and less control over logistics, which can be a concern for those managing tight budgets or complex supply chains.

How Can Buyers Leverage EXW with a Freight Forwarder?

When using EXW with a freight forwarder, the buyer arranges transport while leveraging the expertise of a logistics professional. This hybrid approach is beneficial for buyers who are not familiar with local shipping practices but want to maintain control over costs. It offers a cost-effective solution by tapping into the freight forwarder’s established networks and expertise. However, coordination complexities can arise, and the buyer still assumes the risk once the goods leave the seller’s premises. This option is best suited for businesses looking to balance cost savings with logistical support.

Why Consider FOB vs. CIF for Comprehensive Coverage?

FOB (Free On Board) only covers the transport of goods, while CIF (Cost, Insurance, and Freight) includes insurance and freight costs. Buyers seeking comprehensive coverage may prefer CIF, as it provides greater security against loss or damage during transport. While CIF simplifies logistics by bundling costs, it typically results in higher overall expenses. Buyers should weigh their need for security against budget constraints when deciding between these terms, ensuring they choose an option that aligns with their risk tolerance and logistical capabilities.

Key Industrial Applications of fob vs exw

| Industry/Sector | Specific Application of fob vs exw | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Sourcing raw materials from overseas | Reduces logistical complexities and costs for manufacturers | Understanding local regulations and transport options |

| Electronics | Importing components for assembly | Ensures timely delivery while managing risks effectively | Supplier reliability and shipping infrastructure |

| Agriculture | Exporting produce to international markets | Optimizes export processes and reduces risk of spoilage | Knowledge of export regulations and perishability issues |

| Automotive | Acquiring parts from global suppliers | Streamlines supply chain management and cost control | Evaluating supplier capabilities and shipping terms |

| Textiles | Importing fabrics and materials | Enhances control over shipping costs and timelines | Assessing local transportation networks and customs |

How Do Different Industries Utilize FOB and EXW in Their Operations?

In the manufacturing sector, businesses often leverage FOB when sourcing raw materials from overseas suppliers. This arrangement allows manufacturers to transfer the risk of loss or damage to the buyer once the goods are loaded on the vessel. For companies based in regions like Africa or South America, understanding the logistics in the supplier’s country is crucial. FOB provides security and predictability, making it easier to manage production schedules.

In the electronics industry, where timely delivery of components is vital, companies often prefer FOB agreements. This ensures that suppliers are responsible for the goods until they are loaded onto the shipping vessel, minimizing risks associated with delays. Buyers from Europe or the Middle East need to evaluate the reliability of suppliers and shipping routes to avoid disruptions in their supply chains.

For the agriculture sector, exporting produce often involves EXW agreements. This term allows sellers to minimize their responsibilities, making products available at their facility. Buyers must manage the logistics of transportation, which can be challenging due to perishability. International buyers, particularly from regions like Nigeria or Brazil, must be well-versed in export regulations and the best practices for transporting perishable goods to ensure freshness upon arrival.

In the automotive industry, acquiring parts from global suppliers typically involves FOB terms. This allows automotive manufacturers to streamline their supply chain and maintain control over shipping costs. Buyers must carefully assess supplier capabilities and shipping terms to ensure that parts arrive on time and meet quality standards, especially in competitive markets.

Lastly, the textiles industry frequently utilizes EXW when importing fabrics and materials. This arrangement gives buyers more control over shipping costs and timelines, which is crucial for meeting fashion trends and production deadlines. However, buyers need to evaluate local transportation networks and customs regulations to avoid potential delays in the import process. Understanding these factors can significantly impact the efficiency and cost-effectiveness of sourcing in the textile sector.

3 Common User Pain Points for ‘fob vs exw’ & Their Solutions

Scenario 1: Difficulty in Understanding Responsibilities

The Problem: Many B2B buyers, particularly those new to international trade, often grapple with the nuances of FOB and EXW terms. This confusion can lead to misunderstandings about who is responsible for shipping costs, insurance, and potential risks during transit. For instance, a buyer from Brazil might assume that choosing EXW means the seller will handle all logistics, only to find out they are responsible for arranging transport and managing customs clearance themselves. This can result in unexpected delays, additional costs, and frustration.

The Solution: To navigate these complexities, buyers should invest time in understanding the specific responsibilities tied to each Incoterm. A practical approach is to create a checklist that outlines the obligations of both parties under FOB and EXW. Buyers should also engage in open communication with suppliers, asking clarifying questions about logistics and responsibilities. For instance, if opting for EXW, they should confirm details such as where to pick up the goods, local customs procedures, and recommended freight forwarders. Additionally, leveraging resources such as Incoterms training or consulting with freight forwarders can help demystify the terms and ensure informed decision-making.

Scenario 2: Unexpected Costs and Budget Overruns

The Problem: B2B buyers often face budget overruns when selecting between FOB and EXW. For example, a Nigerian buyer might choose EXW to save on upfront costs, only to encounter hidden expenses related to transportation, customs duties, and insurance that exceed their initial budget. Such financial surprises can strain cash flow and affect overall project viability.

The Solution: To mitigate the risk of unexpected costs, buyers should conduct a comprehensive cost analysis before finalizing their choice of Incoterm. This involves obtaining quotes from multiple freight forwarders to understand the total landed cost of goods when using EXW versus FOB. Buyers should also factor in potential additional costs like customs duties, taxes, and insurance premiums. Implementing a detailed budgeting framework that includes these variables will provide a clearer financial picture. Furthermore, buyers can negotiate with suppliers for clearer pricing structures or explore options for shared logistics to minimize costs.

Scenario 3: Navigating Shipping Delays and Risks

The Problem: Shipping delays and risks are common challenges in international trade, and they can vary significantly between FOB and EXW arrangements. A South American buyer, for instance, may choose FOB for a shipment but still face delays due to factors like port congestion or unforeseen customs inspections. Conversely, a buyer using EXW may struggle with logistics delays if they are unfamiliar with local transport conditions, leading to a frustrating experience and potential losses.

The Solution: To effectively manage shipping risks and delays, buyers should implement a robust logistics strategy that includes contingency planning. This involves setting realistic timelines for shipments and maintaining regular communication with suppliers and freight forwarders. Buyers should also consider purchasing insurance that covers potential delays or losses, regardless of the Incoterm chosen. Utilizing technology, such as shipment tracking systems, can provide real-time updates and facilitate proactive responses to any issues that arise. Finally, establishing strong relationships with reliable freight forwarders can help in navigating local logistics and mitigating risks effectively.

By addressing these common pain points with actionable solutions, B2B buyers can better navigate the complexities of international shipping and make more informed decisions between FOB and EXW terms.

Strategic Material Selection Guide for fob vs exw

What Are the Key Properties of Common Materials in FOB vs EXW Shipping?

When selecting materials for international shipping under FOB (Free On Board) and EXW (Ex Works) terms, it’s crucial to consider the properties of the materials involved. Different materials present unique challenges and advantages that can impact shipping costs, logistics, and end-product performance.

How Do Steel and Aluminum Compare in FOB vs EXW Shipping?

Steel is renowned for its strength and durability, making it a popular choice for a variety of applications. It typically has high temperature and pressure ratings, along with excellent corrosion resistance when treated. However, its weight can lead to higher shipping costs, especially under EXW terms where the buyer assumes full responsibility for transport.

Pros of steel include its robustness and long lifespan, which make it suitable for heavy-duty applications. Conversely, cons include higher costs associated with weight and potential corrosion if not properly treated. For international buyers, compliance with standards such as ASTM for steel grades is essential, particularly in regions like Europe and North America.

Aluminum, on the other hand, is lightweight and resistant to corrosion, which can significantly reduce shipping costs under both FOB and EXW terms. Its lower density allows for easier handling and transport. However, aluminum may not be suitable for high-pressure applications compared to steel.

Pros of aluminum include its lightweight nature and excellent corrosion resistance, making it ideal for shipping goods that require less weight. The cons are its higher material costs and lower strength compared to steel. Buyers from Africa and South America should consider local availability and standards compliance, such as JIS in Japan or DIN in Europe.

What Are the Advantages and Disadvantages of Using Plastics in Shipping?

Plastics are versatile materials used in various applications due to their lightweight and corrosion resistance. They can be molded into complex shapes, which is beneficial for packaging and product design. Under FOB terms, the seller is responsible for shipping until the goods are loaded, which can be advantageous for plastic products that are often lightweight.

Pros of plastics include their cost-effectiveness and adaptability for different applications. However, cons include lower durability and potential environmental concerns regarding disposal. For international buyers, ensuring compliance with regulations related to plastic materials is crucial, particularly in regions with strict environmental laws.

How Do Composites Perform in FOB vs EXW Shipping Scenarios?

Composites, which combine materials like fiberglass and resin, offer excellent strength-to-weight ratios and corrosion resistance. They are increasingly used in industries such as aerospace and automotive. Under EXW terms, the complexity of handling composites can be a challenge, as they often require specialized logistics.

Pros of composites include their lightweight nature and superior performance in specific applications. However, cons involve higher manufacturing costs and complexity in production. Buyers in the Middle East and Europe should ensure that suppliers meet relevant standards, such as ASTM or ISO certifications.

Summary Table of Material Selection for FOB vs EXW

| Material | Typical Use Case for fob vs exw | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Construction, heavy machinery | High strength and durability | Heavy weight increases shipping costs | High |

| Aluminum | Aerospace, automotive components | Lightweight and corrosion-resistant | Higher material costs, lower strength | Medium |

| Plastics | Packaging, consumer goods | Cost-effective and versatile | Lower durability, environmental concerns | Low |

| Composites | Aerospace, automotive, marine | Excellent strength-to-weight ratio | Higher manufacturing complexity | High |

Understanding the properties and implications of various materials in the context of FOB and EXW shipping can empower international B2B buyers to make informed decisions that align with their operational needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for fob vs exw

What Are the Main Stages of Manufacturing Processes for FOB and EXW?

When it comes to international trade, understanding the manufacturing processes involved in FOB (Free On Board) and EXW (Ex Works) shipments is essential for B2B buyers. The manufacturing process typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring that the final product meets quality standards and buyer expectations.

How Is Material Prepared in Manufacturing for FOB and EXW?

Material preparation is the foundational step in manufacturing. This stage involves sourcing and selecting raw materials that meet specific quality criteria. For both FOB and EXW shipments, suppliers must ensure that the materials are compliant with international standards such as ISO 9001, which sets the criteria for a quality management system.

B2B buyers should inquire about the supplier’s sourcing practices, including whether they utilize sustainable materials or certified suppliers. This can affect the overall quality of the product and its compliance with regulations in the buyer’s country.

What Techniques Are Used in the Forming Stage for FOB and EXW?

Forming is the process where raw materials are shaped into the desired form. Techniques vary depending on the type of product being manufactured. Common forming techniques include casting, forging, and machining.

For FOB shipments, the responsibility for ensuring that the products are formed correctly lies primarily with the seller until the goods are loaded onto the transport vessel. Conversely, in EXW agreements, the seller’s responsibility is limited to making the goods available for pickup, which places more emphasis on the buyer to ensure that proper forming techniques are used.

How Does Assembly Contribute to Quality in FOB and EXW Manufacturing?

Assembly involves putting together the various components of a product. This stage is critical for ensuring that all parts fit and function correctly. Quality assurance measures, such as standardized assembly procedures, should be in place to minimize errors and defects.

For both FOB and EXW shipments, it’s vital for B2B buyers to understand the assembly process. Buyers should ask suppliers about their assembly protocols and any certifications they hold, as this can impact the reliability and performance of the final product.

What Finishing Techniques Are Essential for Quality Assurance?

Finishing refers to the final processes applied to a product to enhance its appearance and functionality. Common finishing techniques include painting, plating, and polishing.

Quality control during the finishing stage is crucial, as any defects can affect the product’s marketability. B2B buyers should ensure that suppliers adhere to industry-specific standards, such as CE marking for products sold in Europe, which indicates compliance with safety, health, and environmental protection standards.

What Are the Key Quality Control Standards for FOB and EXW?

Quality control (QC) is a vital aspect of manufacturing, especially for international shipments. Understanding the relevant international standards and industry-specific certifications can help B2B buyers ensure that they are receiving high-quality products.

Which International Standards Should B2B Buyers Consider?

ISO 9001 is one of the most widely recognized quality management standards globally. It sets the criteria for a quality management system, emphasizing consistent quality in products and services. Suppliers adhering to ISO 9001 demonstrate their commitment to quality, which is crucial for both FOB and EXW agreements.

In addition to ISO standards, B2B buyers should consider industry-specific certifications. For example, products in the medical field may require FDA approval in the U.S. or CE marking in Europe, while oil and gas equipment might need API certification.

What Are the QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are essential to maintain product quality throughout the manufacturing process. The three main checkpoints are:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before production begins. It ensures that the materials meet specified quality standards.

-

In-Process Quality Control (IPQC): This ongoing inspection takes place during the manufacturing process. IPQC helps identify defects early, minimizing rework and waste.

-

Final Quality Control (FQC): Conducted at the end of the manufacturing process, FQC ensures that the final product meets all specifications before shipping.

B2B buyers should inquire about the QC procedures their suppliers implement at each of these checkpoints to ensure product quality.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is crucial for mitigating risks associated with international trade. There are several effective methods for B2B buyers to ensure their suppliers maintain high-quality standards.

What Role Do Audits Play in Supplier Quality Verification?

Conducting supplier audits is a proactive approach to verifying quality control. These audits can be either internal or third-party assessments. Internal audits allow buyers to evaluate their suppliers’ processes, while third-party audits provide an unbiased review of the supplier’s compliance with industry standards.

Buyers should establish a regular audit schedule to monitor supplier performance and ensure ongoing compliance with quality standards. This practice is particularly important for B2B buyers from regions like Africa and South America, where varying standards may apply.

How Can Quality Reports Enhance Transparency in the Supply Chain?

Requesting quality reports from suppliers is another effective way to verify their quality control processes. These reports should detail the outcomes of inspections, testing methods used, and any corrective actions taken in response to defects.

B2B buyers should look for transparency in these reports, as they reflect the supplier’s commitment to quality. Consistent documentation can also help in resolving disputes that may arise during the shipping process.

What Are the QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, especially from diverse regions such as Africa, South America, the Middle East, and Europe, understanding QC and certification nuances is vital. Different countries may have varying regulations and standards, making it essential for buyers to navigate these complexities effectively.

How Do Different Regions Influence Quality Standards?

Quality standards can differ significantly from one region to another. For example, European Union regulations are generally more stringent than those in some developing countries. B2B buyers should familiarize themselves with the specific quality requirements applicable in their home countries and ensure that their suppliers comply with these standards.

What Should Buyers Consider About Certification Validity?

Lastly, B2B buyers should confirm that any certifications held by suppliers are current and valid. Certifications may have expiration dates and require periodic renewal. Verifying this information helps buyers ensure that they are working with suppliers who are committed to maintaining high-quality standards.

In summary, understanding the manufacturing processes and quality assurance practices associated with FOB and EXW shipments is essential for B2B buyers. By focusing on key manufacturing stages, quality control standards, and verification methods, buyers can mitigate risks and ensure they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fob vs exw’

When navigating international trade, understanding the nuances of shipping terms such as FOB (Free On Board) and EXW (Ex Works) is essential. This guide provides a practical checklist for B2B buyers to help them make informed decisions when procuring goods under these Incoterms.

Step 1: Understand Your Responsibilities Under Each Incoterm

Before making a choice, clarify what responsibilities you are willing to accept. Under FOB, the seller is responsible for costs and risks until goods are loaded onto the ship. In contrast, EXW places the onus on you, the buyer, to arrange for transport and assume risks from the seller’s location.

Step 2: Evaluate Your Experience with International Shipping

Assess your knowledge and experience in international logistics. If you are comfortable managing shipping logistics and customs clearance, EXW may be suitable. However, if you are less experienced, opting for FOB can mitigate risk as the seller handles the initial shipping process.

Step 3: Identify Your Cost Management Preferences

Consider how you want to manage shipping costs. With FOB, the seller manages costs until goods are loaded, which can streamline budgeting. In contrast, EXW allows you to negotiate your own shipping terms, potentially leading to cost savings if you have strong logistics partnerships.

Step 4: Assess Supplier Relationships and Trust Levels

Evaluate the relationship you have with your supplier. If you have a strong, established rapport and trust their handling of goods, EXW could be a viable choice. However, if you are uncertain about the supplier’s capabilities, FOB can provide peace of mind as it limits your exposure to risks during transport.

Step 5: Determine Shipping Destination and Mode

Identify where the goods will ultimately be shipped and the mode of transportation. FOB is only applicable when shipping by sea, while EXW can be used for any transport method. Ensure your choice aligns with your logistical capabilities and the supplier’s shipping options.

Step 6: Review Legal and Compliance Obligations

Understand the legal implications of each Incoterm in your specific trade context. Different countries may have varying regulations affecting shipping and liability. Consult with legal experts to ensure compliance and to understand how the choice between FOB and EXW could impact your contracts and responsibilities.

Step 7: Document Everything Clearly in the Contract

Ensure that your chosen Incoterm is explicitly stated in the purchase agreement. Clear documentation helps avoid misunderstandings regarding responsibilities and liabilities. Include details on shipping arrangements, payment terms, and timelines to protect both parties involved.

By following this checklist, B2B buyers can navigate the complexities of FOB and EXW, ensuring a smoother procurement process and minimizing risks associated with international shipping.

Comprehensive Cost and Pricing Analysis for fob vs exw Sourcing

What Are the Key Cost Components in FOB vs EXW Sourcing?

When evaluating the cost structure of FOB (Free On Board) and EXW (Ex Works) sourcing, it’s essential to break down the various cost components involved. These components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of raw materials will be constant regardless of the Incoterm used. However, sourcing from different regions might yield price variations due to local market conditions, exchange rates, and tariffs.

-

Labor: Labor costs can differ significantly based on the region and the complexity of the manufacturing process. Countries in Africa and South America may have lower labor costs compared to Europe, but factors like skill level and productivity also play a vital role in overall pricing.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and administrative expenses. These costs are generally fixed, but they can vary based on the efficiency of the production process and the scale of operations.

-

Tooling: For customized products, tooling costs can be substantial. When using FOB, these costs may be absorbed by the seller until the goods are loaded. In contrast, EXW may require the buyer to manage these costs upfront.

-

Quality Control (QC): Quality assurance processes can add to the overall cost, particularly for international shipments where compliance with specific standards is crucial. FOB may offer more assurance of quality as the seller is responsible until loading, while with EXW, buyers must rely on their own QC processes.

-

Logistics: This is where the distinction between FOB and EXW becomes significant. Under FOB, the seller handles logistics up to the port of shipment, potentially simplifying the process for the buyer. Conversely, with EXW, buyers must arrange for transportation, which can be more complex and costly if they are unfamiliar with local logistics systems.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can be influenced by the complexities involved in logistics and risk management, making it crucial for buyers to understand how the chosen Incoterm affects the overall pricing structure.

How Do Price Influencers Affect FOB and EXW Costs?

Several factors influence the pricing in both FOB and EXW transactions. These include:

-

Volume/MOQ: Higher order volumes often lead to better pricing due to economies of scale. Suppliers may offer discounts for larger quantities, which can significantly affect total costs.

-

Specifications/Customization: Customized products usually incur higher costs due to additional tooling and production time. Buyers should clearly communicate their specifications to avoid unexpected costs.

-

Materials and Quality Certifications: The quality of materials and any required certifications can impact pricing. Buyers should ensure they understand the quality standards applicable in their region, as this can lead to price variations.

-

Supplier Factors: The reliability and experience of the supplier can also influence pricing. Established suppliers with a track record may charge higher prices but offer lower risks and better quality assurance.

-

Incoterms: The chosen Incoterm has a profound impact on cost allocation between buyer and seller, affecting everything from logistics costs to responsibility for insurance and duties.

What Are the Best Negotiation Strategies for B2B Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings:

-

Understand Total Cost of Ownership (TCO): Look beyond the initial price and consider logistics, duties, and potential risks. TCO analysis provides a comprehensive view of long-term costs.

-

Leverage Volume Discounts: If your business has the capacity, consolidating orders can enhance negotiation power and lead to lower prices.

-

Foster Supplier Relationships: Building a strong relationship with suppliers can lead to better pricing and favorable terms. Trust can reduce perceived risk, allowing for more flexibility in negotiations.

-

Clarify Terms and Conditions: Ensure that all aspects of the agreement, including payment terms, delivery schedules, and responsibilities, are clearly defined to avoid misunderstandings that could lead to additional costs.

-

Stay Informed on Market Trends: Understanding fluctuations in material costs, currency exchange rates, and geopolitical factors can provide leverage in negotiations.

Conclusion

Choosing between FOB and EXW involves a detailed understanding of various cost components and pricing influencers. By strategically negotiating and considering the Total Cost of Ownership, B2B buyers can make informed decisions that optimize their sourcing strategies while minimizing costs. Always remember that pricing may vary significantly based on market conditions, so it’s advisable to approach negotiations with flexibility and awareness of the broader economic landscape.

Alternatives Analysis: Comparing fob vs exw With Other Solutions

Introduction: Exploring Alternatives to FOB and EXW

When navigating international trade, understanding shipping terms is crucial for B2B buyers. While Free on Board (FOB) and Ex Works (EXW) are popular Incoterms that define responsibilities between sellers and buyers, there are alternative solutions that may better suit specific business needs. This section delves into viable alternatives to FOB and EXW, allowing buyers to make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Fob Vs Exw | Alternative 1 Name: DAP (Delivered at Place) | Alternative 2 Name: CIF (Cost, Insurance, Freight) |

|---|---|---|---|

| Performance | Moderate; seller handles loading | High; seller manages delivery to a location | High; seller covers shipping, insurance, and freight |

| Cost | Variable; depends on logistics | Higher than EXW, lower than CIF | Typically higher due to included costs |

| Ease of Implementation | Moderate; requires coordination | High; clear responsibilities for seller | Moderate; seller manages several logistics aspects |

| Maintenance | Low; minimal ongoing management | Low; maintenance of shipping arrangements | Low; seller manages shipping risks |

| Best Use Case | When buyer has shipping experience | Ideal for buyers who want hassle-free delivery | Best for high-value goods requiring insurance |

Detailed Breakdown of Alternatives

What is DAP (Delivered at Place) and Why Choose It?

DAP (Delivered at Place) shifts the responsibility of delivery from the buyer to the seller, who must ensure that goods arrive at a specified destination. This option is particularly beneficial for buyers who want a streamlined shipping process without the burden of coordinating logistics. The primary advantage of DAP is that it simplifies the supply chain, as the seller handles all costs and risks associated with transportation. However, this may come at a premium compared to EXW, as the seller includes these costs in the pricing.

Understanding CIF (Cost, Insurance, Freight) and Its Advantages

CIF (Cost, Insurance, Freight) is another alternative that includes not only the cost of goods but also the insurance and freight charges up to the destination port. This method is advantageous for B2B buyers dealing with high-value items or international shipping where the risk of loss is significant. CIF provides a safety net through insurance coverage during transit, which can be a decisive factor for many buyers. On the downside, CIF can lead to higher overall costs, and buyers might have less flexibility in negotiating shipping arrangements.

Conclusion: Choosing the Right Solution for Your B2B Needs

Selecting the appropriate shipping method is vital for B2B buyers aiming to optimize their logistics strategy. While FOB and EXW offer distinct advantages, alternatives like DAP and CIF can provide more tailored solutions based on specific business requirements. DAP is ideal for those who prefer a hands-off approach to logistics, whereas CIF is best suited for high-value shipments needing comprehensive insurance coverage. Ultimately, understanding the nuances of each option enables buyers to align their shipping strategies with their operational goals, ensuring a smoother international trade experience.

Essential Technical Properties and Trade Terminology for fob vs exw

What Are the Key Technical Properties of FOB and EXW in International Trade?

Understanding the essential technical properties of FOB (Free On Board) and EXW (Ex Works) is crucial for international B2B buyers. These specifications determine the allocation of costs, risks, and responsibilities in the shipping process, which can significantly impact a buyer’s bottom line and logistics management.

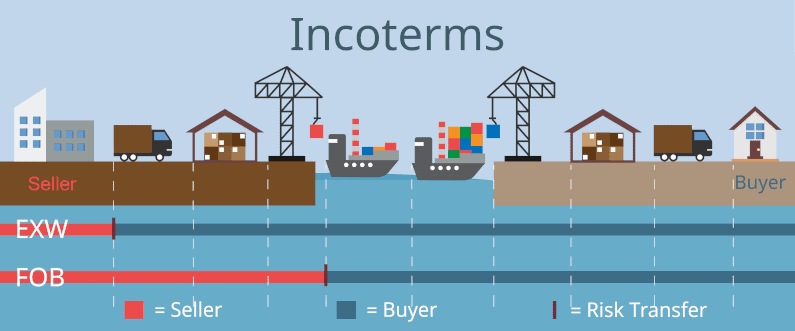

1. Risk Transfer Point

The risk transfer point is a pivotal aspect of both FOB and EXW. Under FOB terms, the seller is responsible for the goods until they are loaded onto the vessel at the designated port. This means that the seller bears the risk of loss or damage during transit to the loading dock. Conversely, EXW places the risk on the buyer as soon as the goods are made available for pickup at the seller’s premises. Understanding this transfer point helps buyers assess their risk exposure and plan accordingly.

2. Cost Allocation

Cost allocation defines who is responsible for various shipping expenses. In a FOB arrangement, the seller covers costs related to transportation, insurance, and customs duties up until the loading point. Once the goods are on board, the buyer assumes all subsequent costs. EXW, however, places the burden of all transportation and associated costs on the buyer from the moment the goods are ready for pickup. This distinction is essential for budget planning and financial forecasting.

3. Loading Responsibilities

The loading responsibilities differ significantly between these two Incoterms. FOB requires the seller to load the goods onto the buyer’s chosen vessel, ensuring that they are ready for export. In contrast, under EXW, the seller merely makes the goods available for the buyer to collect, with no obligation to load them. This impacts logistics strategies, especially for buyers unfamiliar with the local shipping environment.

4. Documentation and Compliance

Both FOB and EXW involve various documentation requirements, including bills of lading, invoices, and export permits. FOB typically necessitates more documentation from the seller, as they are responsible for ensuring compliance with export regulations until the goods are loaded. EXW shifts this responsibility entirely to the buyer, who must ensure all necessary documents are in order for the subsequent transport. Understanding these requirements is vital for compliance and avoiding delays.

5. Transport Mode Flexibility

The choice of transport mode can also influence the decision between FOB and EXW. FOB is specifically designated for maritime transport, while EXW can apply to any mode of transport, including air, road, or rail. This flexibility can be advantageous for buyers who need to adapt their logistics to different shipping scenarios, especially in regions with varying infrastructure.

What Are Common Trade Terms Related to FOB and EXW?

Familiarity with industry jargon is essential for effective communication and negotiation in international trade. Here are some key terms that frequently arise in discussions about FOB and EXW:

1. Incoterms

Incoterms, short for International Commercial Terms, are standardized trade terms published by the International Chamber of Commerce (ICC). They define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is critical for making informed decisions about shipping terms, risk management, and cost allocation.

2. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of FOB and EXW, OEM buyers often negotiate terms that protect their interests while ensuring that components are delivered on time and in compliance with specifications.

3. MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell. This term is significant when negotiating FOB or EXW terms, as it can impact shipping costs and logistics planning. Buyers must be aware of MOQs to ensure they meet supplier requirements while optimizing their inventory levels.

4. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. It is essential for determining shipping terms like FOB or EXW, as it allows buyers to compare costs and responsibilities across different suppliers.

5. Freight Forwarder

A freight forwarder is an intermediary that arranges the shipment of goods on behalf of the buyer. They play a crucial role in both FOB and EXW scenarios, assisting with logistics, documentation, and compliance. Understanding the role of freight forwarders can help buyers streamline their shipping processes and mitigate risks.

By comprehending these technical properties and industry terms, international B2B buyers can make informed decisions that optimize their shipping strategies and enhance their overall trade experience.

Navigating Market Dynamics and Sourcing Trends in the fob vs exw Sector

What Are the Current Market Dynamics Influencing FOB and EXW Sourcing?

The international trade landscape is continually evolving, shaped by various global drivers that impact the FOB and EXW sourcing options. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe (e.g., Brazil, Nigeria) navigate these waters, they must stay attuned to emerging trends. One significant driver is the shift towards digitalization in supply chain management, with technologies like blockchain and AI enhancing transparency and efficiency. This tech evolution supports buyers in making informed decisions about shipping terms, allowing them to assess risks and costs more effectively.

Additionally, geopolitical factors, such as trade agreements and tariffs, can influence the choice between FOB and EXW. For instance, countries in Africa and South America may experience varying levels of regulatory compliance, affecting logistics planning. As buyers gain more experience in international trade, there is a growing preference for FOB agreements, which provide a clearer risk transfer and cost structure, especially for less experienced importers. Conversely, seasoned buyers with strong local networks might lean towards EXW for cost control and flexibility.

Another emerging trend is the focus on end-to-end visibility in the supply chain, prompting companies to reevaluate their sourcing strategies. The ability to track shipments in real-time and manage logistics proactively is becoming essential for maintaining competitiveness, making the choice between FOB and EXW pivotal in meeting customer expectations.

How Do Sustainability and Ethical Sourcing Impact FOB and EXW Decisions?

The growing emphasis on sustainability and ethical sourcing in international trade has significant implications for the FOB and EXW frameworks. Buyers are increasingly aware of the environmental impact of their supply chains, prompting them to seek suppliers who prioritize eco-friendly practices. This shift is particularly pronounced in markets like Europe, where regulations regarding carbon footprints and sustainability certifications are stringent.

Choosing between FOB and EXW can affect a company’s sustainability strategy. Under FOB agreements, suppliers are responsible for logistics until the goods are loaded, allowing buyers to select carriers who align with their sustainability goals. In contrast, EXW places the onus on buyers to manage transportation, which can lead to challenges in ensuring that shipping methods adhere to environmental standards.

Moreover, ethical sourcing is becoming a priority, with buyers seeking suppliers who demonstrate social responsibility. Certifications such as Fair Trade and ISO standards for sustainability can guide purchasing decisions. By opting for suppliers that comply with these certifications, businesses can enhance their reputation and meet the increasing consumer demand for ethically sourced products. Thus, integrating sustainability into sourcing strategies not only fulfills corporate responsibility but also positions businesses competitively in the global market.

What Is the Historical Context of FOB and EXW in International Trade?

The terms FOB (Free On Board) and EXW (Ex Works) have their roots in the evolution of international trade practices and the need for standardized shipping terms. Established by the International Chamber of Commerce (ICC) in 1936, Incoterms provide a framework that clarifies the responsibilities of buyers and sellers in shipping agreements. These terms have evolved through various revisions, with the latest update in 2020 reflecting contemporary trade practices and emerging complexities.

Historically, FOB has been favored in maritime trade, where risk transfer occurs at the shipping point. This term became essential as global trade expanded, providing a clear demarcation of liability and responsibilities between parties. Conversely, EXW emerged as a flexible option for sellers, allowing them to minimize their obligations while empowering buyers to manage logistics directly.

As international trade has grown, the adoption of these terms has been influenced by factors such as globalization, technological advancements, and the rise of e-commerce. Understanding their historical context helps B2B buyers appreciate the significance of selecting the appropriate Incoterm, as it can impact cost structures, risk management, and overall supply chain efficiency in today’s dynamic market environment.

Frequently Asked Questions (FAQs) for B2B Buyers of fob vs exw

-

1. How do I choose between FOB and EXW for my international shipments?

Choosing between FOB and EXW depends on your specific needs and experience with international shipping. If you prefer the seller to handle logistics until the goods are loaded on the ship, FOB is a safer option, especially for less experienced buyers. Conversely, if you have a good grasp of shipping logistics and want more control over costs, EXW could be advantageous. Assess your familiarity with the supplier’s country, the nature of the goods, and your risk tolerance to make an informed decision. -

2. What are the risks associated with using EXW for international trade?

Using EXW places the maximum responsibility on the buyer. You must handle all logistics, including loading, transport, and customs clearance. This means any issues during transit, such as delays or damages, fall on you. If you’re unfamiliar with the local shipping regulations or logistics in the seller’s country, it may lead to complications. Therefore, it’s essential to have a reliable shipping partner or logistics provider if you opt for EXW. -

3. What advantages does FOB provide over EXW for international buyers?

FOB offers several advantages, particularly for buyers new to international trade. The seller is responsible for logistics until the goods are loaded onto the ship, providing more predictability and reduced risk for buyers. It simplifies the shipping process, as the seller typically has better knowledge of local regulations and shipping practices. This can lead to smoother transactions and fewer unexpected costs, making FOB a preferred choice for many businesses. -

4. How do I verify the credibility of a supplier when considering FOB or EXW?

To verify a supplier’s credibility, conduct thorough research, including checking their business licenses, certifications, and trade references. Request testimonials from previous clients and assess their responsiveness and professionalism during initial communications. Platforms like Alibaba or trade-specific directories can provide insights into supplier ratings. Additionally, consider visiting their facility if feasible, or use third-party inspection services to ensure they meet your quality and operational standards. -

5. What should I consider regarding payment terms when using FOB or EXW?

Payment terms can significantly affect your cash flow and risk management. With FOB, you might negotiate terms that allow partial payment upfront and the balance upon shipment. In contrast, EXW often requires full payment before the goods are picked up, increasing your exposure to risk if the goods are damaged or lost post-payment. Always clarify payment structures in your contract and consider using letters of credit or escrow services to mitigate risks. -

6. How can I ensure quality assurance (QA) during shipping when using FOB or EXW?

Quality assurance is vital regardless of the shipping term used. For FOB, include specific quality standards in your contract and consider hiring an independent inspector to assess the goods before loading. For EXW, you should inspect the goods at the seller’s facility before transport. Establish clear communication with your supplier about QA processes and consider implementing a quality management system to ensure your standards are consistently met. -

7. What are the implications of minimum order quantities (MOQ) when selecting FOB or EXW?

Minimum order quantities (MOQ) can impact your overall costs and inventory management. With FOB, suppliers may be more flexible with MOQs since they are responsible for logistics until loading. However, with EXW, you may face stricter MOQs as the supplier may prioritize larger orders to offset their costs. Discuss MOQs with your supplier upfront, considering your business needs and how they align with their production capabilities. -

8. How do logistics costs differ between FOB and EXW?

Logistics costs vary significantly between FOB and EXW. With FOB, the seller covers the costs of transportation to the shipping port, including export clearance, which can simplify budgeting for buyers. In contrast, with EXW, the buyer bears all logistics costs from the seller’s location, including loading, transport, and customs duties, which can lead to higher overall expenses. Analyze potential logistics costs thoroughly and factor them into your pricing strategy when deciding on the Incoterm.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Fob Vs Exw Manufacturers & Suppliers List

1. Unicargo – FOB and EXW Shipping Terms

Domain: unicargo.com

Registered: 1997 (28 years)

Introduction: FOB (Free On Board) and EXW (Ex Works) are two Incoterms used in international shipping. FOB requires the seller to load goods onto the buyer’s chosen ship, covering costs and risks until that point. The buyer assumes responsibility once the goods are loaded. Key characteristics include: seller’s responsibility for costs until loading, buyer’s responsibility for transportation from the port, and F…

2. Investopedia – International Shipping Terms Explained

Domain: investopedia.com

Registered: 1999 (26 years)

Introduction: Ex Works (EXW) and Free on Board (FOB) are international shipping terms (Incoterms) that define the responsibilities of buyers and sellers in shipping goods. EXW requires the seller to make products available at a designated location, with the buyer responsible for transportation costs and risks. FOB mandates the seller to load goods onto the buyer’s transport at the shipping point, retaining resp…

3. CargoFlip – Essential Incoterms Explained

Domain: cargoflip.com

Registered: 2019 (6 years)

Introduction: Ex Works (EXW) and Free on Board (FOB) are two essential Incoterms used in international trade. EXW signifies the seller’s minimum obligation, where the seller’s responsibility ends once the goods are made available at their premises. The buyer assumes all responsibilities from that point, including transportation, loading, and insurance. FOB indicates the point at which the buyer assumes responsi…

4. China Division – International Shipping Terms Explained

Domain: chinadivision.com

Registered: 2015 (10 years)

Introduction: The text discusses the differences between three international shipping terms: FCA (Free Carrier), FOB (Free On Board), and EXW (Ex Works).

1. **FCA (Free Carrier)**:

– Seller delivers goods to a carrier designated by the buyer at a specified location.

– Applicable to all transport modes (land, sea, air, rail).

– Seller is responsible for export customs clearance; buyer assumes respo…

5. Ship4wd – Incoterm Selection for SMB Shipping

Domain: ship4wd.com

Registered: 2020 (5 years)

Introduction: EXW vs. FOB: Choosing the Right Incoterm for Your SMB Services Shipping Full-Container Load (FCL) Ocean Freight Less-Than-Container Load (LCL) Ocean Freight Air Freight Additional Services Customs Clearance Cargo Insurance Pre-Shipment Inspection Online Payments Pay After Cargo Arrival Dangerous Goods Walmart Marketplace

6. PROSENSO™ – Nitrile & Latex Gloves

Domain: ewmedico.com

Registered: 2020 (5 years)

Introduction: PROSENSO™ BLUE NITRILE GLOVES, PROSENSO™ BLUE FEATHER NITRILE GLOVES, PROSENSO™ BLACK NITRILE GLOVES, PROSENSO™ WHITE NITRILE GLOVES, PROSENSO™ PEARL LATEX GLOVES, PROSENSO™ BIODEGRADABLE, PROSENSO™ SURGICAL PPE

7. Eurosender – Key Differences Between EXW and FOB Incoterms

Domain: eurosender.com

Registered: 2014 (11 years)

Introduction: EXW (Ex Works) and FOB (Free On Board) are Incoterms that define the responsibilities and risks of sellers and buyers in international freight transport. Key differences include:

1. Responsibility Shift: Under FOB, the seller is responsible for loading goods onto the vessel, while under EXW, the seller only makes goods available at a designated location.

2. Transport Costs: FOB sellers pay for t…

8. LinkedIn – Key International Trade Terms

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: The article discusses six international trade terms: EXW (Ex Works), FOB (Free On Board), CFR (Cost and Freight), CIF (Cost, Insurance, and Freight), DDU (Delivered Duty Unpaid), and DDP (Delivered Duty Paid). Each term defines the responsibilities and risks of buyers and sellers in cross-border transactions. EXW places minimal obligation on the seller, while DDP offers maximum convenience for the…

Strategic Sourcing Conclusion and Outlook for fob vs exw

How Can Understanding FOB and EXW Enhance Your Strategic Sourcing?

In the intricate world of international trade, the choice between Free on Board (FOB) and Ex Works (EXW) is pivotal for optimizing your sourcing strategy. FOB empowers buyers by transferring risk only after goods are loaded onto the vessel, providing a sense of security, especially for less experienced importers. Conversely, EXW places the onus on the buyer to manage logistics from the seller’s premises, which can lead to cost savings for savvy businesses familiar with local regulations and transport dynamics.

Understanding these Incoterms enables international buyers—particularly from Africa, South America, the Middle East, and Europe—to make informed decisions that align with their operational capabilities and risk tolerance. The strategic sourcing process not only enhances negotiation leverage with suppliers but also streamlines logistics management, ultimately improving the bottom line.

As you navigate the complexities of global trade, consider your unique business context and relationships with suppliers when selecting the appropriate Incoterm. Embrace the power of strategic sourcing to enhance your procurement practices and position your business for sustainable growth. Take the next step today—evaluate your sourcing strategies and leverage the insights gained from FOB and EXW to drive success in your international operations.