60Ah Electric Bike: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for 60ah electric bike

In an increasingly competitive landscape, sourcing a reliable 60Ah electric bike can pose significant challenges for international B2B buyers. Whether it’s addressing the demand for eco-friendly transportation solutions or meeting the diverse needs of consumers in regions like Africa, South America, the Middle East, and Europe, selecting the right electric bike is crucial. This guide is designed to empower businesses by offering a comprehensive overview of the 60Ah electric bike market, detailing various types, applications, and key considerations for supplier vetting.

Buyers will gain insights into the performance metrics of different models, such as range, battery capacity, and motor power, alongside practical applications in urban commuting, recreation, and delivery services. We will also delve into the nuances of pricing, warranty considerations, and potential shipping logistics to ensure that businesses can make informed purchasing decisions.

By understanding the critical factors involved in sourcing 60Ah electric bikes, international buyers can navigate the complexities of this growing market with confidence. This guide serves as a valuable resource, equipping B2B buyers with the knowledge needed to identify reputable suppliers, evaluate product offerings, and ultimately select the best electric bikes to meet their business objectives.

Understanding 60ah electric bike Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Commuter Electric Bikes | Lightweight design, integrated lights, and fenders | Urban commuting, rental services | Pros: Efficient for city travel; Cons: Limited range compared to off-road models. |

| Off-Road Electric Bikes | Fat tires, robust suspension systems, high torque motors | Adventure tourism, outdoor rentals | Pros: Excellent stability and traction; Cons: Heavier and less maneuverable in urban settings. |

| Cargo Electric Bikes | Enhanced cargo capacity, sturdy frames | Delivery services, logistics companies | Pros: High load capacity; Cons: Bulkier design may affect agility. |

| Folding Electric Bikes | Compact, foldable design for easy storage | Urban mobility, shared mobility services | Pros: Space-saving; Cons: Smaller wheels may limit stability on rough terrains. |

| High-Performance Electric Bikes | Powerful motors, long-range batteries | Sports, competitive events | Pros: Fast and efficient; Cons: Higher price point and maintenance costs. |

What Are the Key Characteristics of Commuter Electric Bikes?

Commuter electric bikes are designed primarily for urban environments, featuring lightweight frames, integrated lights, and fenders for all-weather usability. They typically offer a moderate range of 40-60 miles, making them ideal for daily commutes. B2B buyers in urban areas or those managing rental services can find these bikes appealing due to their efficiency and ease of use. However, their limited range compared to off-road models may be a drawback for longer distances.

How Do Off-Road Electric Bikes Stand Out?

Off-road electric bikes are characterized by their fat tires, robust suspension systems, and high torque motors, allowing them to handle rugged terrains with ease. These bikes are particularly suited for adventure tourism and outdoor rental services. B2B buyers in these sectors can leverage their durability and performance to attract customers seeking thrilling experiences. However, their heavier design may present challenges in urban settings where agility is required.

What Are the Advantages of Cargo Electric Bikes?

Cargo electric bikes are equipped with enhanced cargo capacity and sturdy frames, making them an excellent choice for delivery services and logistics companies. They can carry significant loads while maintaining stability, which is crucial for businesses focused on efficiency. While their bulkier design offers high load capacity, it may affect maneuverability in tight urban environments, a consideration for B2B buyers.

Why Choose Folding Electric Bikes for Urban Mobility?

Folding electric bikes provide a compact, space-saving solution ideal for urban mobility and shared services. Their ability to fold makes them convenient for storage and transport, appealing to B2B buyers in metropolitan areas. However, the smaller wheels may limit their stability on rough terrains, which is a consideration for businesses that may require versatility in various riding conditions.

What Makes High-Performance Electric Bikes a Competitive Choice?

High-performance electric bikes feature powerful motors and long-range batteries, designed for sports and competitive events. They offer impressive speeds and efficiency, attracting B2B buyers interested in performance-oriented markets. While their advanced features come with a higher price point and potential maintenance costs, the return on investment can be substantial for businesses targeting serious cyclists and competitive riders.

Key Industrial Applications of 60ah electric bike

| Industry/Sector | Specific Application of 60ah Electric Bike | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Delivery Services | Last-Mile Delivery Solutions | Enhanced efficiency in urban environments, reducing delivery times. | Battery life and reliability for long-distance urban routes. |

| Tourism and Recreation | Guided Eco-Tours and Rentals | Attract eco-conscious tourists, providing a unique riding experience. | Customization options for branding and local regulations. |

| Agriculture | Farm Maintenance and Crop Monitoring | Cost-effective transportation for farm workers and equipment. | Durability and performance on rugged terrain, battery capacity. |

| Urban Transportation | Commuting Solutions for Employees | Reduced operational costs and carbon footprint for businesses. | Compliance with local regulations and charging infrastructure. |

| Emergency Services | Rapid Response Vehicles for Emergency Medical Services | Quick access to remote areas, improving response times. | Reliability in various weather conditions and maintenance support. |

How Can Delivery Services Benefit from 60ah Electric Bikes?

In the delivery services sector, 60ah electric bikes serve as an efficient solution for last-mile delivery. These bikes can easily navigate urban landscapes, reducing delivery times and costs associated with traditional vehicles. The long-range capability (up to 120 miles) ensures that delivery personnel can cover extensive routes without the need for frequent recharging. B2B buyers should consider sourcing bikes with robust battery performance and reliability, as these factors directly impact operational efficiency.

What Advantages Do 60ah Electric Bikes Offer to the Tourism and Recreation Industry?

In tourism and recreation, 60ah electric bikes are increasingly used for guided eco-tours and rentals. These bikes provide a unique way for tourists to explore natural landscapes while minimizing environmental impact. They can be customized for branding purposes, enhancing the customer experience. Buyers in this sector should focus on features like comfort, battery life, and compliance with local regulations to ensure a seamless integration into their services.

How Are 60ah Electric Bikes Transforming Agriculture?

In agriculture, 60ah electric bikes facilitate farm maintenance and crop monitoring, offering a cost-effective transportation solution for workers and equipment. Their ability to traverse rugged terrain makes them ideal for rural settings. B2B buyers should prioritize durability and performance specifications, ensuring that the bikes can handle the demands of agricultural environments while providing extended battery life for longer shifts.

Why Are 60ah Electric Bikes Ideal for Urban Transportation?

For urban transportation, 60ah electric bikes provide a sustainable commuting solution for employees. Businesses can reduce operational costs and their carbon footprint by integrating these bikes into their transport strategies. Key considerations for sourcing include compliance with local regulations, battery charging infrastructure, and the overall reliability of the bikes, which are crucial for daily commutes.

How Can Emergency Services Leverage 60ah Electric Bikes?

Emergency services can utilize 60ah electric bikes as rapid response vehicles, allowing for quick access to remote or congested areas. This capability can significantly improve response times in critical situations. Buyers in this sector should ensure that the bikes are reliable in various weather conditions and that they come with solid maintenance support to keep them operational at all times.

3 Common User Pain Points for ’60ah electric bike’ & Their Solutions

Scenario 1: Difficulty in Ensuring Battery Longevity and Reliability

The Problem: B2B buyers often face challenges in ensuring the longevity and reliability of the 60Ah electric bike batteries, especially in regions with varying climates like Africa and South America. High temperatures can degrade battery performance, while cold weather can reduce range. Buyers worry about the costs associated with battery replacements and the risk of downtime for their fleet if batteries fail prematurely. This concern is heightened when sourcing from suppliers who may not provide adequate warranty or support for battery maintenance.

The Solution: To address these concerns, buyers should prioritize sourcing batteries that adhere to high-quality standards, such as UL certification, which indicates robust safety and performance metrics. Additionally, consider partnerships with suppliers that offer comprehensive warranty policies, including coverage for battery performance over a specified number of charge cycles. It’s also advisable to invest in battery management systems (BMS) that monitor battery health and optimize charging cycles, extending battery life. Buyers can enhance reliability by providing education on proper usage and storage practices for electric bikes, especially in extreme weather conditions. By choosing quality suppliers and implementing proactive battery management strategies, businesses can ensure their electric bike fleets remain operational and cost-effective.

Scenario 2: Challenges with Terrain Adaptability and User Comfort

The Problem: Many B2B buyers are concerned about the adaptability of 60Ah electric bikes to diverse terrains, particularly in regions that have rough and unpaved roads. This issue is compounded by the need for user comfort, as riders may experience fatigue or discomfort on long rides over challenging surfaces. A lack of proper suspension and ergonomically designed components can lead to decreased rider satisfaction, ultimately affecting the fleet’s overall performance and productivity.

The Solution: To mitigate these issues, buyers should focus on sourcing electric bikes equipped with advanced suspension systems, such as dual suspension or adjustable forks, to absorb shocks effectively. Additionally, selecting bikes with wider, all-terrain tires can improve traction and stability on uneven surfaces. Ergonomic features, such as adjustable seats and handlebars, can enhance comfort for a wider range of rider sizes, ensuring a more enjoyable experience. Conducting field tests with different rider profiles can provide valuable feedback on comfort and handling, enabling buyers to make informed decisions about which models best suit their operational needs. By prioritizing adaptability and comfort features, businesses can enhance rider satisfaction and operational efficiency.

Scenario 3: Navigating Supply Chain and Delivery Challenges

The Problem: B2B buyers often encounter significant supply chain challenges, particularly regarding timely delivery of 60Ah electric bikes and their components. Delays can disrupt business operations, especially for companies relying on these bikes for logistics, delivery, or transportation services. In regions with underdeveloped infrastructure, buyers may also struggle with consistent access to spare parts, leading to prolonged downtimes when repairs are necessary.

The Solution: To alleviate supply chain issues, buyers should establish relationships with multiple suppliers to diversify their sourcing options, ensuring that they can obtain products and parts even when one supplier faces delays. It’s also beneficial to evaluate suppliers based on their logistics capabilities, such as their ability to provide real-time tracking and expedited shipping options. Implementing inventory management systems that keep track of parts usage can help anticipate when to reorder components, reducing the risk of running out of essential items. Additionally, consider local partnerships or assembly options that can enhance the availability of bikes and parts. By proactively managing supply chain relationships and inventory, businesses can minimize disruption and maintain consistent operations.

Strategic Material Selection Guide for 60ah electric bike

When selecting materials for a 60Ah electric bike, various factors such as performance, cost, and compliance with international standards must be considered. This guide analyzes four common materials used in the construction of electric bikes, focusing on their properties, advantages, disadvantages, and implications for international buyers, particularly from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Aluminum in Electric Bike Manufacturing?

Aluminum is a widely used material in electric bike frames due to its lightweight nature and resistance to corrosion. It typically boasts a temperature rating of around -40°C to 80°C, making it suitable for various climates. Additionally, aluminum has a high strength-to-weight ratio, which enhances the bike’s performance without adding unnecessary weight.

Pros and Cons:

Aluminum frames are durable and provide excellent performance; however, they can be more expensive than steel and may require specialized manufacturing techniques. The cost of aluminum can vary significantly based on the grade and alloy used, which can influence the overall price of the bike.

Impact on Application:

Aluminum’s corrosion resistance makes it ideal for electric bikes exposed to moisture and varying weather conditions. This property ensures longevity and reliability, crucial for users in regions with harsh climates.

Considerations for International Buyers:

Buyers should ensure that the aluminum used complies with relevant standards such as ASTM B221 for structural aluminum. Different regions may have specific regulations regarding aluminum alloys, which can affect sourcing and manufacturing.

How Does Steel Compare as a Material for Electric Bikes?

Steel is another common material, known for its strength and durability. It has a temperature rating similar to aluminum but offers superior impact resistance. Steel frames can withstand rough handling, making them ideal for off-road applications.

Pros and Cons:

The primary advantage of steel is its lower cost compared to aluminum, making it an attractive option for budget-conscious buyers. However, steel is heavier, which can affect the bike’s overall performance and efficiency. Additionally, steel is prone to rust if not properly treated.

Impact on Application:

Steel’s robustness makes it suitable for rugged terrains, especially in regions where durability is paramount. However, its susceptibility to corrosion necessitates protective coatings, which can add to manufacturing complexity.

Considerations for International Buyers:

Buyers should look for compliance with standards such as ASTM A500 for structural steel. In regions with high humidity or saltwater exposure, additional corrosion-resistant treatments may be necessary.

What Role Does Carbon Fiber Play in Electric Bike Design?

Carbon fiber is increasingly popular in high-end electric bikes due to its exceptional strength-to-weight ratio and stiffness. It can withstand high temperatures and pressures, making it suitable for performance-oriented applications.

Pros and Cons:

Carbon fiber is lightweight and allows for innovative designs, enhancing aerodynamics. However, it is significantly more expensive than both aluminum and steel, and manufacturing processes can be complex and time-consuming.

Impact on Application:

The use of carbon fiber can significantly improve ride quality and efficiency, making it ideal for competitive riders. However, its brittleness can be a concern in extreme conditions, where impacts may cause damage.

Considerations for International Buyers:

Compliance with standards such as ISO 9001 for quality management is crucial when sourcing carbon fiber components. Buyers should ensure that manufacturers follow strict quality control processes to mitigate risks associated with material failure.

How Do Lithium-Ion Batteries Contribute to Electric Bike Performance?

Lithium-ion batteries are essential for powering electric bikes, particularly those with a 60Ah capacity. These batteries typically operate efficiently within a temperature range of -20°C to 60°C and have a long cycle life.

Pros and Cons:

Lithium-ion batteries offer high energy density and lightweight characteristics, which are critical for electric bike performance. However, they can be costly and require careful management to prevent overheating and ensure safety.

Impact on Application:

The energy density of lithium-ion batteries allows for longer ranges, making them ideal for users in regions where charging infrastructure may be limited. Their lightweight nature contributes to overall bike efficiency.

Considerations for International Buyers:

Buyers should ensure compliance with international safety standards such as UN 38.3 for lithium battery transport. Understanding local regulations regarding battery disposal and recycling is also essential.

Summary Table of Material Selection for 60Ah Electric Bikes

| Material | Typical Use Case for 60Ah Electric Bike | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frame construction | Lightweight and corrosion-resistant | Higher cost compared to steel | Medium |

| Steel | Frame construction | Durable and cost-effective | Heavier and prone to rust | Low |

| Carbon Fiber | High-performance models | Exceptional strength-to-weight ratio | Expensive and complex manufacturing | High |

| Lithium-Ion Battery | Power source for electric bikes | High energy density and lightweight | Costly and requires careful management | High |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in 60Ah electric bikes, enabling informed decisions that align with regional requirements and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for 60ah electric bike

What Are the Main Stages in the Manufacturing Process of a 60Ah Electric Bike?

Manufacturing a 60Ah electric bike involves several critical stages, each requiring precision and attention to detail. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Electric Bike Production?

The manufacturing process begins with the selection of high-quality materials. The frame typically uses high-carbon steel or aluminum alloy, chosen for its strength and lightweight properties. Battery components are made from lithium-ion cells, which must meet EV-class safety standards. During material preparation, suppliers conduct inspections to ensure that all raw materials comply with international standards such as ISO 9001. This stage is vital for ensuring that the final product can withstand the rigors of daily use.

What Techniques Are Used in the Forming Stage of Electric Bike Manufacturing?

In the forming stage, the prepared materials undergo various techniques to create bike components. Techniques such as CNC machining, welding, and stamping are commonly employed to produce frame parts, battery housings, and other essential components. Advanced robotics and automated systems are increasingly used to enhance precision and efficiency in this stage. Proper calibration of machinery is crucial to ensure that all parts fit together seamlessly during assembly.

How Is the Assembly Process Conducted for 60Ah Electric Bikes?

The assembly process is where the electric bike comes to life. Components are brought together in a systematic manner, often on an assembly line. Key components such as the motor, battery, and control systems are installed in a specific order to ensure proper functionality. Quality control checkpoints are integrated into the assembly line, where inspectors verify that each component meets the required specifications before moving on to the next stage.

What Finishing Techniques Are Used in Electric Bike Manufacturing?

Once the assembly is complete, the finishing stage involves painting, coating, and final inspections. This step not only enhances the aesthetic appeal of the bike but also protects it from environmental factors. Techniques such as powder coating and anodizing are commonly employed to ensure durability. Final inspections, including functionality tests for the electrical system and mechanical parts, are performed to ensure that the bike operates efficiently and safely.

What Quality Assurance Measures Are Essential for 60Ah Electric Bikes?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that the final product meets both safety and performance standards. International standards such as ISO 9001 provide a framework for quality management systems, while industry-specific certifications like CE and API ensure compliance with safety regulations.

How Are Quality Control Checkpoints Implemented in Electric Bike Manufacturing?

Quality control in electric bike manufacturing is structured around several checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves checking the quality of raw materials and components upon arrival at the manufacturing facility. Suppliers are often required to provide quality assurance documentation, including material test reports.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators conduct regular inspections to identify defects early. This includes checking the accuracy of machining and assembly processes.

-

Final Quality Control (FQC): After assembly, a comprehensive inspection is performed to ensure that the bike meets all specifications. This may include performance tests, safety checks, and aesthetic evaluations.

What Common Testing Methods Are Used to Ensure Quality in Electric Bikes?

Various testing methods are employed to ensure that each electric bike meets quality standards. Common tests include:

-

Electrical Testing: This checks the battery performance, including charge cycles and discharge rates. B2B buyers should look for documentation that confirms these tests were performed according to standards.

-

Mechanical Testing: Stress tests are conducted to ensure that the frame and components can withstand weight and impact without failure. This is crucial for ensuring the bike’s longevity and safety.

-

Safety Testing: Compliance with safety standards, such as UL certification for electrical components, is verified through rigorous testing protocols.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential. Here are some strategies:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control practices. This helps ensure compliance with international standards.

-

Requesting Quality Assurance Documentation: Buyers should request documentation related to quality tests, certifications, and compliance with international standards. This may include test reports, warranty information, and compliance certificates.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control measures. These inspections can be particularly useful for buyers unfamiliar with local manufacturing practices.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers operating in diverse markets must navigate various quality control nuances. For instance, understanding local regulations and standards is critical when importing electric bikes. Buyers should familiarize themselves with the specific certifications required in their target markets, such as CE for Europe or local safety standards in Africa and South America.

Additionally, language barriers and cultural differences can affect communication with suppliers. Establishing clear expectations and maintaining open lines of communication can mitigate these challenges. Building long-term relationships with reliable suppliers can also enhance trust and ensure consistent quality.

In conclusion, the manufacturing processes and quality assurance practices for 60Ah electric bikes are comprehensive and multifaceted. By understanding these processes, B2B buyers can make informed decisions, ensuring they partner with manufacturers that prioritize quality and safety in their products.

Practical Sourcing Guide: A Step-by-Step Checklist for ’60ah electric bike’

When sourcing a 60Ah electric bike, a structured approach is essential to ensure you select the right product and supplier. This guide provides a checklist to help B2B buyers navigate the procurement process efficiently, focusing on key considerations that align with industry standards and regional requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial to meet your operational needs. Consider factors such as motor power, maximum speed, and battery life. For instance, a bike with a 1000W motor may be suitable for urban commuting, while a higher capacity may be needed for rugged terrains.

- Battery Capacity: Ensure the bike has a 60Ah capacity for extended range.

- Weight Capacity: Confirm the maximum load to accommodate your target users.

Step 2: Research Market Trends and Demand

Understanding market demand in your target regions—such as Africa, South America, the Middle East, and Europe—can influence your purchasing decisions. Analyze trends in electric bike usage, preferred models, and customer preferences.

- Regional Preferences: Different regions may favor specific designs, such as step-thru models for urban users.

- Market Growth: Investigate growth rates in e-bike sales and any emerging competitors.

Step 3: Evaluate Potential Suppliers

Before making a commitment, conduct thorough evaluations of potential suppliers. Request company profiles, product catalogs, and references from other buyers in similar markets to gauge reliability.

- Supplier Reputation: Look for suppliers with positive reviews and a history of timely deliveries.

- Quality Assurance: Ensure they have robust quality control measures in place.

Step 4: Verify Compliance with Safety Standards

Safety compliance is paramount in the electric bike industry. Ensure that the bikes adhere to international safety standards, such as UL certification, especially for battery safety.

- Documentation: Request copies of certifications and safety testing results.

- Warranty Terms: Review warranty conditions to understand coverage for defects and service support.

Step 5: Assess After-Sales Support and Service

After-sales support can significantly impact customer satisfaction. Evaluate the support services offered by suppliers, including warranty terms and availability of spare parts.

- Service Network: Ensure the supplier has a service network that can support your region.

- Response Times: Inquire about average response times for service requests.

Step 6: Request Samples or Demonstration Units

Before finalizing your order, it’s advisable to request samples or demonstration units. This allows you to assess the product’s performance and quality firsthand.

- Testing Performance: Evaluate aspects such as battery life, speed, and comfort.

- User Feedback: Gather feedback from potential customers or team members who will use the bikes.

Step 7: Negotiate Terms and Finalize Contracts

Once you’ve selected a supplier, negotiate favorable terms that align with your budget and operational needs. Pay attention to payment terms, delivery schedules, and any bulk purchase discounts.

- Clarity in Contracts: Ensure that all terms are clearly outlined in the contract to avoid future disputes.

- Flexibility: Discuss options for scaling orders as demand increases.

By following this checklist, B2B buyers can make informed decisions when sourcing 60Ah electric bikes, ensuring they meet both business objectives and customer expectations.

Comprehensive Cost and Pricing Analysis for 60ah electric bike Sourcing

What Are the Key Cost Components for Sourcing 60Ah Electric Bikes?

When analyzing the cost structure of sourcing 60Ah electric bikes, several critical components come into play. Materials constitute the largest expense, including the high-capacity battery (typically lithium-ion), frame materials (often high-carbon steel or aluminum), and essential components like motors and brakes. The quality of materials directly impacts performance and safety, which is particularly crucial for international markets.

Labor costs vary significantly based on geographic location. Regions with lower labor costs, such as parts of Asia, may offer more competitive pricing. Conversely, countries with higher labor rates, like Germany, will reflect this in the pricing structure.

Manufacturing overhead includes expenses related to facilities, utilities, and administrative costs. Efficient production processes can help minimize these costs. Tooling expenses for specialized machinery can also be significant, particularly if custom specifications are required.

Quality Control (QC) is non-negotiable in the electric bike industry, especially with varying safety regulations across regions. Investing in rigorous QC processes ensures compliance with international safety standards, which can affect both the cost and the perceived value of the product.

Finally, logistics costs encompass shipping, handling, and customs duties. These can vary widely based on the shipping method and destination, especially for international buyers.

How Do Price Influencers Affect the Cost of 60Ah Electric Bikes?

Several factors influence the pricing of 60Ah electric bikes. Volume or Minimum Order Quantity (MOQ) plays a crucial role; larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their market demand to optimize pricing.

Specifications and customization can also significantly impact price. Custom features—such as unique designs, additional technology (like GPS or advanced displays), or specialized materials—may increase costs. Buyers should weigh the benefits of customization against their budget constraints.

Material quality and certifications are essential considerations. Premium materials with certifications (such as UL for battery safety) can raise costs but may enhance product reliability and marketability. Understanding local regulations and certifications is vital for international buyers.

Supplier factors—including reputation, reliability, and production capacity—can also affect pricing. Established suppliers may charge a premium but can offer greater assurance in terms of quality and delivery timelines.

Incoterms (International Commercial Terms) play a significant role in determining cost structure. They dictate responsibilities for shipping, insurance, and tariffs, affecting the total landed cost for buyers. Familiarity with Incoterms can help buyers make informed purchasing decisions.

What Are Essential Buyer Tips for Negotiating Prices on 60Ah Electric Bikes?

When negotiating prices for 60Ah electric bikes, buyers should focus on total cost of ownership (TCO) rather than just the initial purchase price. This includes considering maintenance costs, warranty terms, and expected lifespan, which can significantly affect long-term profitability.

Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of pricing nuances that may arise from local market conditions, tariffs, and import duties. Conducting thorough market research can provide insights into competitive pricing and help in negotiations.

Establishing a good relationship with suppliers can lead to better pricing and terms. Open communication regarding expectations, challenges, and feedback can foster trust and collaboration, which may result in more favorable pricing arrangements.

Lastly, buyers should be prepared to leverage volume commitments in negotiations. Offering to purchase larger quantities may enable buyers to negotiate better rates, especially with manufacturers looking to optimize their production runs.

Disclaimer on Indicative Prices

Prices for 60Ah electric bikes can vary widely based on the factors mentioned above. The figures referenced in this analysis are indicative and should be used as a guideline rather than a definitive pricing structure. Buyers are encouraged to conduct their own market research and reach out to multiple suppliers for accurate quotes tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing 60ah electric bike With Other Solutions

Exploring Alternatives to the 60Ah Electric Bike

In today’s rapidly evolving market, businesses need to consider various solutions to meet their transportation needs. The 60Ah electric bike is a compelling option, but it is essential to explore alternatives that may better suit specific operational requirements, especially in diverse regions like Africa, South America, the Middle East, and Europe. Below, we compare the 60Ah electric bike with two notable alternatives: the E-scooter and the Electric Moped.

Comparison Table

| Comparison Aspect | 60Ah Electric Bike | E-Scooter | Electric Moped |

|---|---|---|---|

| Performance | Up to 120 miles range, 25-28 mph | 15-30 miles range, 15-20 mph | Up to 80 miles range, 28-34 mph |

| Cost | $1,499.00 | $400 – $1,200 | $1,200 – $2,500 |

| Ease of Implementation | Requires assembly; more user-friendly | Ready to ride; minimal setup | Requires a license in some regions |

| Maintenance | Regular checks on battery and tires | Minimal maintenance required | Moderate maintenance; similar to a motorcycle |

| Best Use Case | Long-distance commutes and rugged terrain | Urban commuting and short distances | Versatile urban and suburban travel |

Detailed Breakdown of Alternatives

E-Scooter

E-scooters have gained popularity in urban environments due to their compact design and ease of use. With a range of approximately 15-30 miles and speeds up to 20 mph, they are ideal for short commutes. Their lower initial cost makes them accessible for businesses looking to provide last-mile solutions. However, e-scooters may not be suitable for rough terrains and have limited range compared to the 60Ah electric bike. Maintenance is generally low, but battery life can diminish with frequent use.

Electric Moped

Electric mopeds offer a balance between speed and range, reaching up to 34 mph and covering distances of around 80 miles on a single charge. They are designed for both urban and suburban environments, making them versatile for various transportation needs. However, the initial investment can be higher, and some regions require a motorcycle license for operation. Maintenance tends to be moderate, similar to traditional motorcycles, which can be a consideration for B2B buyers assessing total cost of ownership.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right transportation solution hinges on understanding your specific operational requirements and constraints. The 60Ah electric bike excels in long-distance travel and rugged conditions, making it ideal for businesses operating in diverse terrains. Conversely, e-scooters and electric mopeds provide cost-effective alternatives for urban commuting and short-distance travel. B2B buyers should evaluate factors such as performance, cost, ease of implementation, and maintenance to make an informed decision that aligns with their business goals and regional challenges. By carefully considering these alternatives, businesses can enhance their operational efficiency and meet their transportation needs effectively.

Essential Technical Properties and Trade Terminology for 60ah electric bike

What Are the Key Technical Properties of a 60Ah Electric Bike?

When evaluating a 60Ah electric bike for B2B procurement, understanding its technical specifications is crucial. Here are several critical specs to consider:

-

Battery Capacity (60Ah)

The 60Ah (amp-hour) rating indicates the battery’s ability to store energy, directly affecting the bike’s range. A higher capacity allows for longer rides without the need for frequent recharging, which is vital for businesses targeting markets with expansive terrains or long-distance commuting needs. For instance, a 60Ah battery typically provides a range of 78 to 120 miles per charge, depending on riding conditions and assist modes. -

Motor Power (Wattage)

The motor power, commonly rated in watts (W), determines the bike’s performance capabilities, including speed and hill-climbing ability. For example, a 1,000W motor can deliver peak power of up to 1,200W, enabling speeds of 25-34 mph. This specification is essential for B2B buyers focusing on performance in diverse environments, from urban commutes to off-road adventures. -

Frame Material and Construction

The choice of frame material (e.g., high-carbon steel or aluminum alloy) impacts durability and weight. A robust frame ensures longevity and can withstand the stresses of varied riding conditions. For buyers, understanding material grades can help assess the bike’s suitability for specific markets, especially in regions with rough terrains. -

Max Load Capacity

This specification defines the maximum weight the bike can safely carry, including the rider and cargo. Typical ratings may range from 330 lbs to 400 lbs. Knowing this capacity is crucial for businesses targeting delivery services or those catering to heavier riders, ensuring compliance with safety standards. -

Brake System Type

The brake system, often hydraulic disc brakes, is a critical safety feature that influences stopping power and reliability. Hydraulic systems provide better modulation and stopping force compared to mechanical brakes, which is a significant consideration for B2B buyers prioritizing rider safety. -

Suspension System

The suspension system (e.g., front and rear dual suspension) enhances ride comfort and stability, especially on uneven terrains. Understanding the suspension type can help buyers assess the bike’s suitability for specific applications, such as recreational riding or rugged commuting.

What Are Common Trade Terms Relevant to the 60Ah Electric Bike Market?

Understanding industry jargon is essential for effective communication and negotiation in B2B environments. Here are several terms frequently used in the electric bike sector:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. For B2B buyers, working with OEMs can ensure quality and compatibility of components in electric bikes, facilitating smoother supply chain management. -

MOQ (Minimum Order Quantity)

The MOQ is the smallest amount of a product a supplier is willing to sell. Understanding MOQs is vital for businesses to manage inventory costs and ensure they meet their sales targets without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other details for specific products. For B2B transactions, issuing RFQs helps buyers compare offers and negotiate better terms, ensuring they get the best value for their investment. -

Incoterms

Short for International Commercial Terms, Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms helps businesses understand their obligations regarding shipping costs, risks, and delivery timelines, which is crucial in global trade. -

Lead Time

This term refers to the time taken from placing an order to its delivery. Knowing the lead time is essential for B2B buyers to plan inventory and meet customer demands effectively, especially in regions with varying logistical challenges. -

Warranty Period

The warranty period indicates the duration a product is guaranteed against defects. For buyers, understanding warranty terms is vital for assessing the long-term reliability of electric bikes and minimizing potential liabilities.

By familiarizing yourself with these technical properties and trade terms, you can make informed decisions that align with your business objectives in the electric bike market.

Navigating Market Dynamics and Sourcing Trends in the 60ah electric bike Sector

What Are the Key Market Drivers and Trends Impacting the 60Ah Electric Bike Sector?

The global electric bike market is witnessing robust growth, driven by a confluence of factors including urbanization, rising fuel prices, and an increasing emphasis on sustainable transportation. The 60Ah electric bike segment is particularly appealing for B2B buyers due to its enhanced range capabilities, making it suitable for both urban commuting and recreational riding. In regions like Africa and South America, where infrastructure for traditional vehicles can be lacking, the 60Ah electric bike provides a practical solution for mobility. Meanwhile, in Europe and the Middle East, the demand is fueled by government initiatives promoting eco-friendly transportation and the push for zero-emission vehicles.

Emerging trends in B2B sourcing highlight the importance of technological advancements such as battery efficiency, smart connectivity, and improved safety features. Buyers are increasingly seeking electric bikes that incorporate IoT capabilities, enabling real-time tracking and data analytics for fleet management. Additionally, partnerships with local distributors and manufacturers are becoming more prevalent as companies look to reduce lead times and enhance local market responsiveness. For international buyers, understanding regional regulations and consumer preferences is crucial for successful market entry.

How Does Sustainability and Ethical Sourcing Impact the 60Ah Electric Bike Supply Chain?

As sustainability becomes a central theme in global commerce, the electric bike industry is not exempt. For B2B buyers, understanding the environmental impact of sourcing materials for 60Ah electric bikes is essential. The production of lithium-ion batteries, for instance, has significant ecological implications, from mining practices to end-of-life disposal. Therefore, buyers should prioritize manufacturers that adhere to ethical sourcing practices, such as using recycled materials and ensuring responsible mining operations.

Furthermore, certifications like ISO 14001 for environmental management and adherence to the Global Battery Alliance’s guidelines can enhance a company’s credibility. These certifications not only demonstrate a commitment to sustainability but also appeal to environmentally conscious consumers. In this evolving market, integrating sustainability into the supply chain can serve as a unique selling proposition, giving businesses a competitive edge while contributing to global efforts to reduce carbon footprints.

What Is the Historical Context of the 60Ah Electric Bike Development?

The evolution of electric bikes dates back to the late 19th century, with early models powered by non-rechargeable batteries. However, it wasn’t until the early 2000s that technological advancements in battery design and electric motors led to the resurgence of interest in electric bicycles. The introduction of lithium-ion batteries revolutionized the sector, allowing for higher energy densities and lighter weights, which paved the way for the modern 60Ah electric bike.

Today, the 60Ah electric bike represents the culmination of decades of innovation, offering extended ranges and enhanced performance. The increasing integration of smart technology and sustainable practices continues to shape the industry’s future, making it a vital area for B2B buyers looking to invest in reliable and innovative transportation solutions. As the market matures, understanding its history provides insights into future trends and potential opportunities for growth.

Frequently Asked Questions (FAQs) for B2B Buyers of 60ah electric bike

-

How do I choose the right 60Ah electric bike for my business needs?

When selecting a 60Ah electric bike, consider factors such as the intended use (urban commuting vs. off-road), battery range, motor power, and load capacity. Evaluate the terrain of your target market and the specific needs of your customers, such as cargo space and rider comfort. Additionally, check the warranty and customer support offered by the manufacturer to ensure long-term reliability and service. Comparing multiple models from different suppliers can also help you identify the best fit for your business. -

What are the key specifications to look for in a 60Ah electric bike?

Key specifications include battery capacity (60Ah), motor power (typically between 1000W to 1500W), maximum range per charge (ideally over 100 miles), and weight capacity (often around 330-400 lbs). Additionally, assess features such as suspension systems for comfort, braking systems for safety, and tire size for versatility on different terrains. A user-friendly display and adjustable riding modes can enhance the rider experience, making the bike more appealing to customers. -

What is the typical minimum order quantity (MOQ) for 60Ah electric bikes?

Minimum order quantities for 60Ah electric bikes can vary significantly depending on the manufacturer and your negotiation skills. Generally, you can expect MOQs to range from 5 to 50 units. Larger orders may provide better pricing and more favorable terms, so consider your inventory needs and market demand before placing an order. Establishing a strong relationship with the supplier may also lead to more flexible MOQ options. -

How can I ensure the quality of the 60Ah electric bikes I purchase?

To ensure quality, conduct thorough due diligence on potential suppliers. Look for manufacturers with relevant certifications (e.g., ISO, CE, UL) and a solid track record in the industry. Request samples for testing and check customer reviews and testimonials. Establish a quality assurance protocol that includes inspections at the manufacturing site and during shipping. A well-defined warranty and return policy are also essential indicators of quality commitment. -

What payment terms are commonly offered by suppliers for electric bikes?

Payment terms can vary, but common practices include a 30% deposit upon order confirmation and the remaining balance before shipping. Some suppliers may offer more flexible terms, such as net 30 or net 60 days, depending on your business relationship and order size. Always negotiate payment terms upfront to secure the best deal and ensure that they align with your cash flow needs. -

What are the shipping options available for importing 60Ah electric bikes?

Shipping options typically include air freight for faster delivery and sea freight for cost-effectiveness on larger orders. Discuss with your supplier about the most suitable option based on your timeline and budget. Ensure that the shipping method chosen complies with international regulations and that the supplier can provide necessary documentation. Additionally, consider the logistics of customs clearance and potential duties that may apply upon arrival. -

How do I handle after-sales support for electric bikes?

After-sales support is crucial for maintaining customer satisfaction. Ensure that the supplier offers comprehensive support, including warranty services and access to spare parts. Establish a clear communication channel for your customers to report issues and seek assistance. Consider providing training for your staff to handle common repairs and maintenance tasks, which can improve response times and enhance your service offering. -

What customization options are available for 60Ah electric bikes?

Customization options can vary by manufacturer but may include color choices, branding (logo placement), and specific features like additional cargo racks or enhanced suspension systems. Discuss your requirements with potential suppliers to understand their flexibility in meeting your needs. Customizing bikes can help differentiate your offerings in the market and cater to the preferences of your target audience, increasing sales potential.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 60Ah Electric Bike Manufacturers & Suppliers List

1. Eahora – Juliet Electric Bike

Domain: eahoraebike.com

Registered: 2019 (6 years)

Introduction: Eahora Juliet Electric Bike – 20″ 60Ah Ultra Battery Ebike Step-thru

– Battery: 48V 60Ah, 2880Wh Pouch-Cell Lithium Battery

– Motor: 1000W (peak 1200W) DC Geared Hub Motor

– Max Torque: 90N·m

– Top Speed: 25 – 28 MPH

– Range: 110 – 120 miles with pedal-assist, 78 – 84 miles without pedal-assist

– Frame: Step-thru design made from high-quality steel

– Weight: Not specified

– Riding Modes: 5 Levels …

2. G-Force – G-FORCE ZM PRO

Domain: g-forcebike.com

Registered: 2020 (5 years)

Introduction: {“model”:”G-FORCE ZM PRO”,”battery_capacity”:”52V 60Ah”,”motor_power”:”1000W (1500W peak)”,”top_speed”:”34 MPH”,”max_range”:”200 miles”,”tire_size”:”20×4 inch”,”max_load”:”400 lbs”,”price”:”$1,899.00 (originally $2,599.00)”,”features”:[“high torque for hill climbing”,”durable and rugged design”,”moto style design with built-in storage”,”IPX6 waterproofing”,”fast charging in 5 hours”,”full-potting …

3. Wallke – H7 Step-Thru E-Bike

Domain: wallkeebike.com

Registered: 2019 (6 years)

Introduction: {“model”:”Wallke H7 Step-Thru”,”motor”:”Dual 1000W (1600W Peak)”,”top_speed”:”34 mph”,”climbing_ability”:”40+°”,”pedal_assist_levels”:”5 Levels”,”battery”:”48V 40Ah / 48V 60Ah”,”tire_size”:”20 x 4 inches”,”brakes”:”4-Piston Hydraulic”,”max_payload”:”400 lbs”,”rider_height”:”5’8.5″ – 6’4″”,”light”:”48V LED Headlight”,”charging_time”:”8-9 hours”,”frame_material”:”20″ Aluminum Alloy”,”display”:”Full-…

4. Wildeway – SummitX Ebike

Domain: wildewayebike.com

Registered: 2022 (3 years)

Introduction: {‘product_name’: ‘SummitX Ebike’, ‘model’: ‘Peak 2000W’, ‘battery_options’: [{‘capacity’: ’32Ah’, ‘price’: {‘US_Warehouse’: ‘$1,099.00’, ‘Canada_Warehouse’: ‘$1,149.00’}}, {‘capacity’: ’60Ah’, ‘price’: {‘US_Warehouse’: ‘$1,499.00’, ‘Canada_Warehouse’: ‘$1,149.00’}}], ‘motor’: ‘2000W Peak Dual Motor’, ‘top_speed’: ’28 mph’, ‘pedal_assist_levels’: 5, ‘walk_mode’: True, ‘usb_charging’: True, ‘front_s…

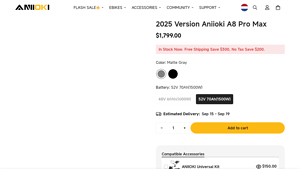

5. Aniioki – 60Ah Battery Power Backup

Domain: aniioki.com

Registered: 2022 (3 years)

Introduction: This company, Aniioki – 60Ah Battery Power Backup, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Juliet II – Enhanced Electric Bike

Domain: forums.electricbikereview.com

Registered: 2010 (15 years)

Introduction: This company, Juliet II – Enhanced Electric Bike, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. E-bike – Long-Range Options Under $3,000

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for a long-range e-bike around $3,000 with a range of approximately 100 miles on a charge. Interested in options like eAhora Juliet/Romero, Freesky Alaska, Himiway dual-battery Rhino, Turbo Vado SL 4.0 EQ, and Wired Freedom. Current bike is a regular mountain bike and a cheap heybike with a 48v/12.5ah battery and 500w hub motor. Preference for a moped-style or regular e-bike that is easy t…

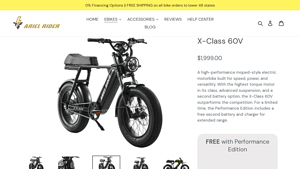

8. Ariel Rider – X-Class 60V Electric Bike

Domain: arielrider.com

Registered: 2013 (12 years)

Introduction: {“name”:”X-Class 60V Electric Bike”,”price”:”$1,999.00″,”description”:”A high-performance moped-style electric motorbike built for speed, power, and versatility. With the highest torque motor in its class, advanced suspension, and a second battery option, the X-Class 60V outperforms the competition.”,”motor”:”132Nm motor (standard in Performance Edition)”,”range”:”Exceeds 100 miles on a single cha…

Strategic Sourcing Conclusion and Outlook for 60ah electric bike

As the demand for electric bikes surges globally, particularly in emerging markets across Africa, South America, the Middle East, and Europe, strategic sourcing becomes essential for B2B buyers aiming to capitalize on this trend. The 60Ah electric bike, with its extended range and robust performance, offers a compelling solution for various applications, from urban commuting to off-road adventures. Buyers should prioritize suppliers that adhere to high safety standards, such as EV-class certifications, to ensure quality and reliability.

Investing in high-capacity electric bikes like the Eahora Juliet and G-FORCE ZM PRO not only enhances customer satisfaction through longer rides but also positions businesses competitively in the growing electric mobility market. With features like dual suspension systems and high torque motors, these bikes are designed for durability and performance, catering to diverse terrains and rider preferences.

Looking ahead, B2B buyers are encouraged to forge strategic partnerships with manufacturers that can offer innovative solutions and reliable support. By embracing the electric bike revolution, businesses can tap into new revenue streams while contributing to sustainable transportation initiatives. Now is the time to explore these opportunities and elevate your offerings in the electric mobility landscape.