The Definitive Guide to 5 Gal Peanut Oil: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for 5 gal peanut oil

In the competitive landscape of global food supply, sourcing 5-gallon peanut oil presents unique challenges for international B2B buyers. Whether you’re operating a bustling restaurant in Brazil or a food processing plant in Nigeria, understanding the complexities of this market is crucial. This guide serves as a comprehensive resource, addressing key aspects such as types of peanut oil, diverse culinary applications, supplier vetting processes, and cost considerations. By navigating these elements, you can make informed purchasing decisions that align with your business needs.

The demand for peanut oil continues to rise due to its versatility and high smoke point, making it ideal for frying, sautéing, and even salad dressings. However, with numerous suppliers and varying quality standards, discerning the right product can be daunting. This guide empowers B2B buyers from Africa, South America, the Middle East, and Europe to confidently identify reliable suppliers, assess product quality, and negotiate favorable terms.

With insights into market trends, regulatory considerations, and logistical challenges, you will be equipped to streamline your procurement strategy. By leveraging this guide, you can not only enhance your operational efficiency but also elevate the quality of your offerings, ultimately driving greater customer satisfaction and loyalty.

Understanding 5 gal peanut oil Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Refined Peanut Oil | High smoke point (450°F), light flavor, minimal odor | Commercial kitchens, food processing | Pros: Versatile, stable for frying; Cons: Less flavor than unrefined. |

| Organic Peanut Oil | Non-GMO, produced without synthetic pesticides or fertilizers | Health-focused businesses, organic food brands | Pros: Appeals to health-conscious consumers; Cons: Higher cost. |

| Blended Peanut Oil | Combination of peanut and other oils (e.g., vegetable oil) | Large-scale food service, deep frying | Pros: Cost-effective; Cons: May compromise flavor profile. |

| Cold-Pressed Peanut Oil | Extracted without heat, retains more nutrients | Gourmet restaurants, specialty food markets | Pros: Rich flavor, retains nutrients; Cons: Lower smoke point. |

| Specialty Peanut Oil | Flavored or infused varieties (e.g., garlic-infused) | Niche markets, gourmet food producers | Pros: Unique flavor profiles; Cons: Limited applications and higher price. |

What Are the Characteristics of Refined Peanut Oil for B2B Buyers?

Refined peanut oil is a highly versatile cooking oil with a high smoke point of around 450°F, making it ideal for frying and sautéing. Its light flavor and minimal odor allow it to complement a variety of dishes without overpowering them. This oil is particularly suited for commercial kitchens and food processing operations where consistency and reliability are essential. Buyers should consider its stability under high temperatures, but note that the refining process may strip some of the oil’s natural flavor.

Why Choose Organic Peanut Oil for Health-Conscious Markets?

Organic peanut oil is produced without synthetic pesticides or fertilizers, making it a preferred choice for health-focused businesses and organic food brands. This oil retains a more robust flavor compared to its refined counterpart, appealing to consumers seeking healthier options. While it can command a higher price point, the demand for organic products in the market can justify the investment. B2B buyers should consider their target audience’s preferences when deciding on this option.

How Do Blended Peanut Oils Serve Large-Scale Operations?

Blended peanut oils, which combine peanut oil with other vegetable oils, are designed for cost-effective frying in large-scale food service operations. These oils can lower overall costs while still providing satisfactory frying performance. However, buyers should be aware that blending may dilute the distinct flavor of pure peanut oil. This option is particularly beneficial for businesses looking to optimize their operational expenses without significantly compromising on quality.

What Are the Benefits of Cold-Pressed Peanut Oil?

Cold-pressed peanut oil is extracted without the application of heat, which helps retain its nutritional properties and rich flavor. This type of oil is ideal for gourmet restaurants and specialty food markets that prioritize quality and taste. While it offers a unique flavor profile and higher nutritional value, its lower smoke point means it may not be suitable for high-temperature cooking methods. B2B buyers should assess their cooking methods and target market to determine if this oil fits their needs.

What Niche Markets Can Specialty Peanut Oils Target?

Specialty peanut oils include flavored or infused varieties, such as garlic-infused peanut oil. These oils cater to niche markets and gourmet food producers seeking unique flavor profiles to enhance their offerings. While they can command higher prices, their limited applications may restrict their appeal. Buyers should consider how these specialty oils can differentiate their products in a competitive market, making them an attractive option for businesses focused on innovation and quality.

Key Industrial Applications of 5 gal peanut oil

| Industry/Sector | Specific Application of 5 gal peanut oil | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Deep frying and cooking in restaurants | High smoke point allows for versatile cooking, enhancing flavor and texture of dishes. | Ensure oil is non-GMO and free from trans fats; consider local regulations on food safety. |

| Snack Production | Frying snacks like chips and nuts | Provides a desirable flavor profile and crispiness, improving product quality and customer satisfaction. | Verify supply chain reliability and consistency in oil quality; consider bulk purchasing for cost savings. |

| Catering Services | Cooking for large events and gatherings | Efficient for high-volume frying, saving time and labor costs in food preparation. | Look for bulk options and suppliers with a strong reputation for quality and service. |

| Food Manufacturing | Ingredient in packaged food products | Enhances flavor and preserves freshness; essential for products requiring stable frying oils. | Assess supplier certifications and quality control processes to ensure product safety and compliance. |

| Confectionery | Producing fried confections and pastries | Adds unique flavors and textures, appealing to diverse consumer tastes. | Evaluate the oil’s shelf life and storage requirements to maintain product integrity. |

How is 5 Gal Peanut Oil Used in the Food Service Industry?

In the food service industry, 5-gallon peanut oil is primarily utilized for deep frying and cooking various dishes, from fried chicken to stir-fries. Its high smoke point (around 450°F) makes it ideal for high-heat cooking methods, ensuring that food retains its flavor and texture. For international buyers, especially in regions like Africa and South America, sourcing non-GMO and trans-fat-free options is crucial to meet health standards and consumer preferences.

What Role Does Peanut Oil Play in Snack Production?

Snack production facilities use 5-gallon peanut oil for frying products such as chips and nuts. The oil not only enhances the flavor but also contributes to the desirable crunch and texture that consumers expect. For B2B buyers, understanding the importance of a reliable supply chain and the benefits of bulk purchasing can lead to significant cost savings and consistent product quality, especially in markets like Nigeria and Brazil where snack consumption is high.

How Does Peanut Oil Benefit Catering Services?

Catering services leverage 5-gallon peanut oil for cooking large quantities of food efficiently, particularly for events and gatherings. The oil’s versatility in deep frying means that caterers can prepare a wide range of dishes quickly, reducing preparation time and labor costs. Buyers in this sector should prioritize suppliers who offer bulk options and have a strong reputation for quality service to ensure smooth operations during high-demand periods.

Why is Peanut Oil Important for Food Manufacturing?

In food manufacturing, 5-gallon peanut oil serves as a key ingredient in various packaged products, helping to enhance flavor and preserve freshness. It is especially vital for products that require stable frying oils. International buyers must assess supplier certifications and quality control processes to ensure compliance with safety regulations, which can vary significantly across regions such as the Middle East and Europe.

How is Peanut Oil Used in Confectionery Production?

Peanut oil is also integral to the confectionery industry, where it is used in producing fried confections and pastries. Its unique flavor profile adds depth to sweet treats, appealing to a diverse range of consumer tastes. For B2B buyers, evaluating the oil’s shelf life and storage requirements is essential to maintain product integrity, particularly in markets with varying climate conditions.

3 Common User Pain Points for ‘5 gal peanut oil’ & Their Solutions

Scenario 1: Sourcing High-Quality Peanut Oil for Food Processing

The Problem: B2B buyers in the food processing industry often struggle with sourcing high-quality peanut oil that meets both their operational needs and regulatory standards. Given the diverse suppliers available, it can be challenging to determine which products are truly non-GMO, free from harmful additives, and suitable for high-heat cooking. Additionally, buyers may face inconsistencies in oil quality and flavor, impacting the final product’s taste and safety.

The Solution: To ensure the procurement of high-quality peanut oil, buyers should prioritize suppliers that provide transparent sourcing information and certifications. Look for brands that explicitly state their oil is non-GMO and free from trans fats. Engaging with suppliers who can offer third-party lab testing results will also help verify the oil’s purity and quality. Establishing long-term relationships with reputable manufacturers can also guarantee consistent supply and quality. When specifying requirements, include details on the desired smoke point, flavor profile, and any certifications required for compliance in your region. This proactive approach will help mitigate risks associated with sourcing.

Scenario 2: Managing Inventory and Reducing Waste

The Problem: Another common pain point for B2B buyers of peanut oil is managing inventory effectively to avoid overstocking or running out of stock, especially in industries like restaurants or food production where oil is a staple ingredient. Overstocking can lead to waste, especially if the oil has a limited shelf life. Conversely, running out of oil can halt production, leading to lost revenue and dissatisfied customers.

The Solution: Implementing an inventory management system tailored for food products can significantly alleviate this issue. Utilize inventory tracking software that monitors stock levels in real-time and sends alerts when supplies are running low. This system should be integrated with your purchasing process, allowing for automatic reorder triggers based on preset stock levels. Additionally, consider negotiating bulk purchasing agreements with suppliers to secure better pricing while ensuring a steady supply. Regularly reviewing usage patterns and adjusting your reorder levels based on seasonal demands can also help maintain optimal inventory levels, reducing both waste and downtime.

Scenario 3: Ensuring Compliance with Health and Safety Standards

The Problem: Compliance with health and safety regulations is a critical concern for B2B buyers, particularly in regions with strict food safety laws. Buyers may face challenges in understanding the specific requirements for using peanut oil, including labeling, storage, and handling procedures. Non-compliance can lead to severe penalties, product recalls, and damage to reputation.

The Solution: To navigate compliance challenges effectively, B2B buyers should familiarize themselves with local and international food safety regulations related to cooking oils. Regular training sessions for staff on proper handling and storage practices can ensure everyone is on the same page regarding safety protocols. Additionally, buyers should request detailed product information sheets from suppliers, outlining ingredient specifications, potential allergens, and recommended usage guidelines. Conducting routine audits of storage facilities can also help maintain compliance and ensure that oil is stored under optimal conditions to prevent spoilage. Engaging a compliance consultant or legal expert specializing in food safety can provide tailored advice and keep your operations aligned with evolving regulations.

Strategic Material Selection Guide for 5 gal peanut oil

What Are the Key Materials for Packaging 5 Gallons of Peanut Oil?

When selecting materials for packaging 5-gallon containers of peanut oil, it’s essential to consider various factors such as compatibility with the oil, cost, and regional compliance standards. Below are analyses of four common materials used in the packaging of peanut oil, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

High-Density Polyethylene (HDPE)

Key Properties: HDPE is known for its excellent chemical resistance, making it suitable for containing oils. It can withstand temperatures up to 120°C (248°F) and has a density of 0.93-0.97 g/cm³.

Pros & Cons: HDPE is lightweight and cost-effective, which reduces shipping costs. However, it has a lower resistance to UV light, which can lead to degradation if exposed to sunlight. Additionally, while it is durable, it may not be as robust under extreme pressure compared to other materials.

Impact on Application: HDPE containers are compatible with peanut oil and can maintain the oil’s quality over time. However, the material’s susceptibility to UV light may necessitate additional protective measures in regions with high sunlight exposure.

Considerations for International Buyers: HDPE is widely accepted and complies with many international standards, including ASTM and ISO. Buyers from Africa and South America should ensure that suppliers adhere to local regulations regarding food-grade materials.

Glass

Key Properties: Glass is non-reactive and can withstand high temperatures, making it an excellent choice for food products. It has a high resistance to corrosion and does not leach chemicals into the oil.

Pros & Cons: Glass provides superior protection against external contaminants and maintains the oil’s flavor and quality. However, it is heavier and more fragile than plastic alternatives, which can increase shipping costs and the risk of breakage during transport.

Impact on Application: Glass packaging is ideal for premium peanut oil products, as it enhances shelf appeal and consumer trust. However, its weight may be a disadvantage in regions where transportation costs are a significant concern.

Considerations for International Buyers: Glass packaging must comply with stringent safety and quality standards, especially in Europe, where regulations regarding food safety are strict. Buyers should ensure that glass containers are sourced from reputable manufacturers.

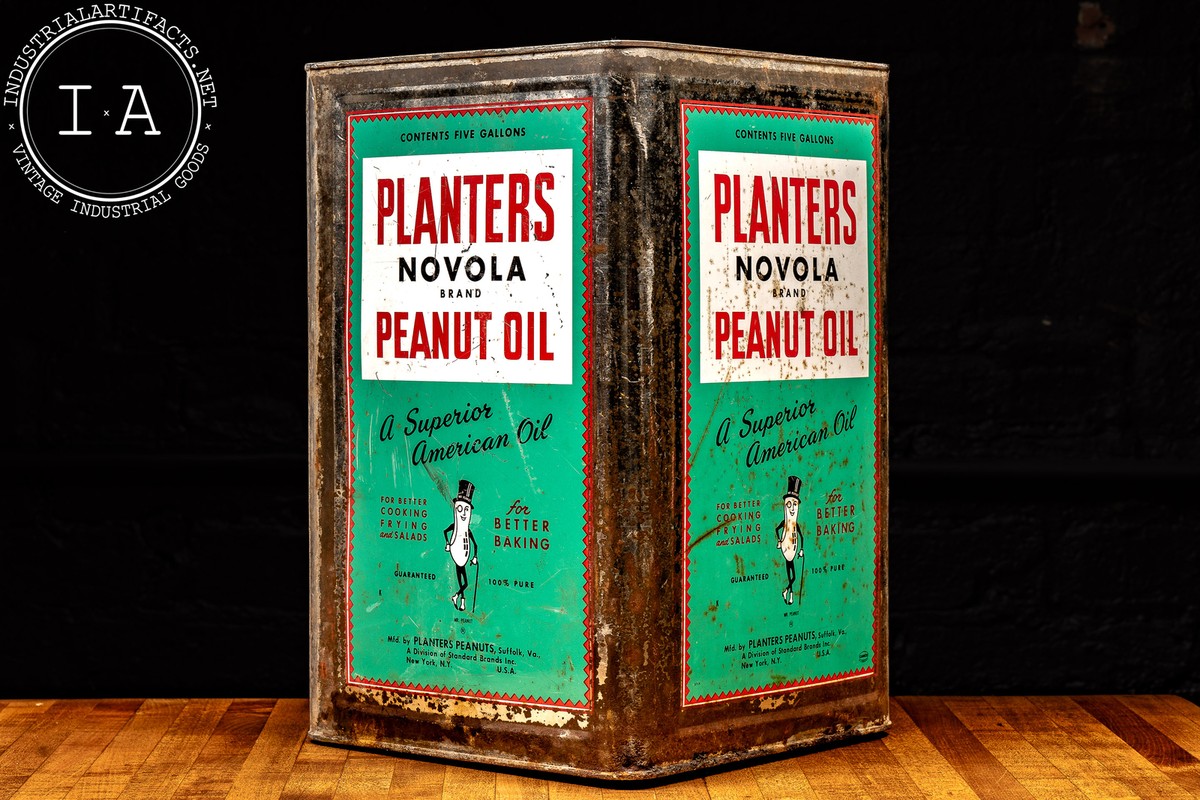

Metal (Tinplate)

Key Properties: Tinplate is a steel sheet coated with tin, providing excellent corrosion resistance and strength. It can withstand high temperatures and is recyclable, making it an environmentally friendly option.

Pros & Cons: Metal containers are durable and provide excellent protection against light and air, which can degrade oil quality. However, they can be more expensive than plastic options and may require additional coatings to ensure food safety.

Impact on Application: Tinplate is suitable for long-term storage of peanut oil, as it prevents oxidation. However, the initial higher cost may deter some buyers, particularly in price-sensitive markets.

Considerations for International Buyers: Compliance with international food safety standards is crucial when using metal packaging. Buyers should verify that the tinplate used is food-grade and free from harmful coatings.

Flexible Pouches

Key Properties: Flexible pouches made from multi-layer films can provide excellent barrier properties against moisture and oxygen. They are lightweight and can be designed to withstand various temperatures.

Pros & Cons: These pouches are cost-effective and reduce shipping costs due to their lightweight nature. However, they may not provide the same level of protection as rigid containers and can be prone to punctures.

Impact on Application: Flexible pouches are suitable for smaller quantities of peanut oil or for brands looking to offer a more eco-friendly packaging solution. However, they may not be as appealing for bulk buyers.

Considerations for International Buyers: Buyers should ensure that flexible pouches meet local regulations regarding food safety and are made from materials that are safe for oil storage.

Summary Table

| Material | Typical Use Case for 5 gal peanut oil | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Density Polyethylene (HDPE) | Bulk packaging for food service | Lightweight and cost-effective | Lower UV resistance | Low |

| Glass | Premium peanut oil products | Non-reactive and flavor-preserving | Heavy and fragile | High |

| Metal (Tinplate) | Long-term storage | Excellent barrier against light/air | Higher initial cost | Medium |

| Flexible Pouches | Smaller quantities or eco-friendly options | Cost-effective and lightweight | Prone to punctures | Low |

By understanding the properties and implications of each material, international B2B buyers can make informed decisions that align with their operational needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 5 gal peanut oil

What Are the Key Stages in the Manufacturing Process of 5 Gallon Peanut Oil?

The manufacturing process for 5-gallon peanut oil involves several critical stages that ensure the quality and safety of the final product. These stages include material preparation, extraction, refining, and packaging.

-

Material Preparation: The process begins with sourcing high-quality peanuts. Suppliers often employ stringent criteria for selecting peanuts, which may include inspecting for size, moisture content, and presence of impurities. The peanuts are then cleaned to remove any foreign matter, such as dirt or stones, and are often subjected to drying processes to achieve optimal moisture levels.

-

Extraction: The next step involves extracting the oil from the peanuts. This is typically done using mechanical pressing or solvent extraction methods. Mechanical pressing involves crushing the peanuts to release the oil, while solvent extraction uses chemicals like hexane to dissolve the oil. The choice of extraction method can affect the flavor and nutritional profile of the peanut oil.

-

Refining: After extraction, the crude peanut oil undergoes refining to remove impurities, free fatty acids, and unwanted flavors. This process often includes degumming, neutralization, bleaching, and deodorization. Each step is crucial for enhancing the oil’s stability and shelf life, making it suitable for cooking and frying applications.

-

Packaging: The final stage involves packaging the refined peanut oil into 5-gallon containers. This step must be performed in a controlled environment to prevent contamination. The containers are labeled with important information, including nutritional facts, expiration dates, and storage instructions, to ensure compliance with international regulations.

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance (QA) is an integral component of the peanut oil manufacturing process, ensuring that the final product meets both safety and quality standards. Various international and industry-specific standards guide these QA practices.

-

International Standards: Many manufacturers adhere to ISO 9001 standards, which outline requirements for a quality management system (QMS). This certification demonstrates a commitment to consistent quality and customer satisfaction. Additionally, compliance with food safety standards such as HACCP (Hazard Analysis Critical Control Points) is essential, especially for international markets.

-

Quality Control Checkpoints: Throughout the manufacturing process, several quality control (QC) checkpoints are established:

– Incoming Quality Control (IQC): This phase involves inspecting raw materials (peanuts) upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During extraction and refining, samples may be taken at various stages to assess quality parameters such as acidity, color, and odor.

– Final Quality Control (FQC): Once the peanut oil is packaged, a final inspection is conducted to verify that the product meets all regulatory and quality standards before distribution. -

Common Testing Methods: Various testing methods are employed to assess the quality of peanut oil, including:

– Chemical Analysis: Tests for free fatty acid content, peroxide value, and moisture content help determine the oil’s quality.

– Sensory Evaluation: Flavor, aroma, and appearance are evaluated by trained panels to ensure product consistency.

– Microbial Testing: Testing for pathogens and spoilage organisms ensures that the oil is safe for consumption.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must conduct due diligence when selecting suppliers to ensure that their peanut oil products meet necessary quality standards. Several strategies can be employed to verify supplier QC practices.

-

Supplier Audits: One of the most effective methods for assessing a supplier’s quality control is through on-site audits. Buyers can evaluate the supplier’s manufacturing processes, QC checkpoints, and adherence to international standards. Audits can reveal potential areas of non-compliance and provide insights into the supplier’s overall operations.

-

Quality Assurance Reports: Requesting detailed QA reports from suppliers can provide valuable information about their quality management systems. These reports should include data from IQC, IPQC, and FQC phases, along with any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. These inspectors can verify compliance with international standards and conduct random sampling of products for testing.

What Are the QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial for ensuring compliance with local regulations.

-

Regional Regulations: Different countries may have varying regulations regarding food safety and oil production. Buyers must familiarize themselves with local laws and standards to ensure that the products they import comply with these requirements.

-

Certification Requirements: Some regions may require specific certifications, such as Non-GMO or Organic certifications, for peanut oil products. Buyers should verify that suppliers possess the necessary certifications and that they are up-to-date.

-

Documentation: Proper documentation is essential for international trade. Buyers should ensure that suppliers provide all relevant documentation, including certificates of analysis, compliance reports, and shipping documents. This documentation helps facilitate smooth customs clearance and ensures compliance with international standards.

In conclusion, understanding the manufacturing processes and quality assurance protocols for 5-gallon peanut oil is vital for B2B buyers. By focusing on key stages of production, quality control checkpoints, and verification methods, buyers can make informed decisions that ensure they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘5 gal peanut oil’

Introduction

Sourcing high-quality peanut oil in bulk, such as 5-gallon containers, requires careful consideration and strategic planning. This guide provides a step-by-step checklist designed for B2B buyers looking to procure peanut oil efficiently and effectively, ensuring that quality, compliance, and cost-effectiveness are prioritized.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the peanut oil meets your operational needs. Consider factors such as oil purity, refining methods, and intended culinary applications. For instance, if you plan to use the oil for frying, look for a high smoke point and low levels of impurities.

- Smoke Point: Aim for a smoke point of at least 450°F for frying applications.

- Refining Process: Determine if you need refined, unrefined, or organic oil based on your product requirements.

Step 2: Identify Your Target Market and Compliance Requirements

Understanding your target market is essential for compliance with local regulations and standards. Different regions may have specific labeling, health, and safety regulations for food products.

- Labeling Requirements: Research the necessary nutritional and ingredient disclosures for your target region.

- Quality Certifications: Check for certifications such as ISO, HACCP, or local food safety standards that may be required.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, a thorough evaluation is crucial. Look for suppliers who can provide solid references, product samples, and transparency about their production processes.

- Request Documentation: Ask for company profiles, case studies, and references from similar businesses in your industry.

- Site Visits: If possible, conduct site visits to assess manufacturing practices and quality control measures firsthand.

Step 4: Verify Supplier Certifications and Quality Control Measures

Supplier certifications are indicative of product quality and safety standards. Ensure that your potential suppliers hold relevant certifications that align with international food safety regulations.

- Non-GMO and Allergen Information: Verify claims about non-GMO status and allergen management, especially since peanut oil is derived from peanuts.

- Quality Control Protocols: Inquire about the supplier’s quality control processes, including testing for contaminants and product consistency.

Step 5: Negotiate Terms and Pricing

Once you have shortlisted potential suppliers, it’s time to negotiate terms and pricing. This step is critical for ensuring that you receive the best value without compromising quality.

- Bulk Pricing Options: Discuss bulk pricing and any discounts for long-term contracts or larger orders.

- Payment Terms: Clarify payment terms, including deposits, credit options, and payment schedules.

Step 6: Establish a Logistics and Delivery Plan

Logistics play a significant role in the timely procurement of peanut oil. Work with your supplier to establish a clear delivery plan that meets your operational timeline.

- Shipping Methods: Discuss shipping options that align with your budget and timeline, including freight forwarding and customs considerations if importing.

- Tracking and Communication: Ensure there are systems in place for tracking shipments and maintaining open communication throughout the delivery process.

Step 7: Implement a Quality Assurance Process

After procurement, establishing a quality assurance process is essential for maintaining product integrity. Regularly assess the quality of the peanut oil received to ensure it meets your specifications.

- Sample Testing: Conduct regular testing of samples for purity and quality.

- Feedback Loop: Create a feedback loop with your supplier to address any quality issues promptly and enhance future orders.

By following this checklist, B2B buyers can streamline their sourcing process for 5-gallon peanut oil, ensuring a successful procurement strategy that aligns with their operational needs and market demands.

Comprehensive Cost and Pricing Analysis for 5 gal peanut oil Sourcing

What Are the Key Cost Components in Sourcing 5 Gallons of Peanut Oil?

When sourcing 5-gallon containers of peanut oil, several cost components must be considered to arrive at an accurate pricing structure. The primary components include:

- Materials: The primary ingredient is peanut oil, which can vary in cost based on quality and source. Non-GMO and organic certifications typically command higher prices.

- Labor: Labor costs encompass the workforce involved in extraction, refining, and bottling processes. These costs can fluctuate based on local wage rates and labor laws in the manufacturing country.

- Manufacturing Overhead: This includes utilities, equipment depreciation, and facility maintenance. Efficient operations can reduce these costs, impacting the final pricing.

- Tooling: Specialized equipment for processing and packaging peanut oil can incur significant upfront costs, which are amortized over production volumes.

- Quality Control (QC): Ensuring product quality is essential, especially for export. QC processes add to labor and material costs but are necessary for maintaining standards.

- Logistics: Transportation costs, including shipping, customs duties, and warehousing, can significantly influence overall pricing, particularly for international buyers.

- Margin: Supplier profit margins will vary based on market conditions, competition, and the value-added services provided, such as certification and customization.

How Do Price Influencers Affect the Cost of Peanut Oil?

Several factors can influence the price of peanut oil, especially for B2B buyers:

- Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced per-unit costs. Suppliers may offer tiered pricing based on order size, making it beneficial for buyers to consolidate purchases.

- Specifications/Customization: Custom formulations or packaging can increase costs. Buyers should clarify their requirements upfront to avoid unexpected charges.

- Materials Quality/Certifications: Premium pricing applies to oils with certifications such as organic or non-GMO. Buyers should weigh the importance of these certifications against their budget.

- Supplier Factors: The supplier’s reputation, reliability, and experience can affect pricing. Established suppliers may offer more competitive rates due to economies of scale.

- Incoterms: Understanding shipping terms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is critical for determining total landed costs. These terms dictate who bears the transportation risks and costs.

What Are the Best Practices for Negotiating Peanut Oil Prices?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings:

- Leverage Total Cost of Ownership (TCO): Consider all costs associated with sourcing peanut oil, including logistics, storage, and potential quality issues. A lower upfront price might not be the most cost-effective in the long run.

- Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms. Consistent orders can enhance negotiation power.

- Research Market Prices: Understanding the market price range helps in negotiating effectively. Keep abreast of commodity price fluctuations and global supply chain trends.

- Flexible Payment Terms: Offering to pay in advance or negotiating for extended payment terms can sometimes yield better pricing.

- Explore Alternative Suppliers: Diversifying your supplier base can foster competition and lead to more favorable pricing.

Are There Pricing Nuances for International B2B Buyers?

International buyers must navigate additional complexities when sourcing peanut oil. Currency fluctuations can impact costs, making it essential to agree on pricing in stable currencies or consider hedging options. Additionally, import tariffs and local taxes can add to the total cost, so understanding local regulations is crucial.

Always request and review quotes that include all potential costs, including shipping, tariffs, and insurance, to avoid surprises.

Disclaimer on Indicative Prices

Pricing for 5-gallon peanut oil can vary widely based on market conditions, supplier negotiations, and other external factors. This analysis provides a framework for understanding potential costs but should not be construed as definitive pricing. Always conduct thorough due diligence and request updated quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing 5 gal peanut oil With Other Solutions

Exploring Alternatives to 5 Gallon Peanut Oil for Cooking and Food Preparation

When considering cooking oils for industrial and commercial use, it’s essential to evaluate various alternatives that can meet specific needs. In this analysis, we will compare 5-gallon peanut oil with two viable alternatives: canola oil and avocado oil. Each option has unique properties that can impact cooking performance, cost-effectiveness, and overall suitability for different culinary applications.

| Comparison Aspect | 5 Gal Peanut Oil | Canola Oil | Avocado Oil |

|---|---|---|---|

| Performance | High smoke point (450°F), ideal for frying and sautéing; enhances flavor | Moderate smoke point (400°F), versatile for various cooking methods | High smoke point (520°F), rich in monounsaturated fats, great for frying |

| Cost | Generally higher cost due to specialty | More affordable, often mass-produced | Premium pricing, less available in bulk |

| Ease of Implementation | Requires careful storage and handling; can be used directly | Widely available, easy to use in various applications | Requires specific storage conditions to maintain quality |

| Maintenance | Needs regular filtering and replacement for optimal use | Low maintenance, stable shelf life | Moderate, can oxidize if not stored properly |

| Best Use Case | Ideal for frying, especially in deep-frying turkey or Asian cuisine | Suitable for baking, frying, and salad dressings | Best for high-heat cooking and dressings, adds unique flavor |

Canola Oil: A Cost-Effective and Versatile Alternative

Canola oil is a popular choice for many commercial kitchens due to its affordability and versatility. With a moderate smoke point of 400°F, it can be used for frying, baking, and salad dressings. Its neutral flavor allows it to blend well with various dishes without altering the taste. However, it is often refined and may contain GMOs, which could be a concern for some buyers. Additionally, while it is easy to implement in a cooking routine, the lower smoke point compared to peanut oil may limit its effectiveness for certain high-heat applications.

Avocado Oil: A Premium Choice for Health-Conscious Buyers

Avocado oil is gaining popularity due to its health benefits, including high levels of monounsaturated fats and antioxidants. With an impressive smoke point of 520°F, it is excellent for high-heat cooking methods like frying and grilling. Its rich, buttery flavor can enhance dishes significantly. However, avocado oil typically comes at a premium price and may not be as readily available in larger quantities as peanut oil. For businesses focused on health and premium quality, avocado oil is a compelling option, but budget constraints may limit its use in some settings.

Conclusion: How to Choose the Right Cooking Oil for Your Business Needs

Selecting the right cooking oil for your business involves assessing various factors, including performance, cost, and the specific culinary applications you require. While 5-gallon peanut oil excels in frying applications and adds a unique flavor, alternatives like canola oil and avocado oil offer distinct advantages based on budget and health considerations. B2B buyers should evaluate their operational needs, target market preferences, and overall cost-effectiveness to make an informed decision that aligns with their culinary goals.

Essential Technical Properties and Trade Terminology for 5 gal peanut oil

What Are the Essential Technical Properties of 5 Gallon Peanut Oil?

When evaluating 5-gallon peanut oil for commercial use, several technical properties are critical for B2B buyers to consider. Understanding these properties helps in making informed purchasing decisions that align with business needs.

-

Smoke Point: The smoke point of peanut oil is typically around 450°F (232°C). This high smoke point makes it ideal for high-heat cooking methods such as frying and sautéing, ensuring that the oil maintains its integrity and flavor. For businesses in the food service industry, selecting oils with appropriate smoke points is essential to avoid off-flavors and to ensure food quality.

-

Fatty Acid Composition: Peanut oil is predominantly composed of monounsaturated fats (approximately 50%), followed by polyunsaturated fats (around 30%) and saturated fats (about 20%). This composition not only influences health perceptions but also impacts the oil’s stability during cooking. B2B buyers should consider these ratios when selecting oils that meet dietary preferences and regulatory standards in their regions.

-

Non-GMO Certification: Many suppliers offer non-GMO peanut oil, which is increasingly important in global markets, particularly in Europe and North America. This certification can be a selling point for businesses that prioritize sustainability and consumer health. Buyers should verify this status to ensure compliance with market demands.

-

Preservatives and Additives: Some peanut oils may contain additives such as TBHQ (tert-butylhydroquinone) and citric acid, which help preserve freshness and prevent foaming. Understanding the presence of these chemicals is crucial for companies that prioritize clean labeling and natural ingredients. Buyers should assess whether these additives align with their product offerings.

-

Packaging and Shelf Life: The packaging of peanut oil can affect its shelf life and usability. Typically, 5-gallon containers are designed for ease of use in commercial settings. Understanding shelf life and storage conditions will help businesses manage inventory efficiently and minimize waste.

What Are Common Trade Terms Used in the Peanut Oil Industry?

Navigating the trade landscape of peanut oil involves familiarizing oneself with specific terminology that can impact procurement and logistics.

-

MOQ (Minimum Order Quantity): This term refers to the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for buyers to manage inventory costs effectively and ensure that they are not overcommitting resources.

-

RFQ (Request for Quotation): An RFQ is a document issued by a buyer to solicit price bids from suppliers for specific quantities and specifications of products. This process is crucial for comparing prices and terms across suppliers, allowing buyers to make cost-effective decisions.

-

OEM (Original Equipment Manufacturer): In the context of peanut oil, an OEM refers to a company that produces oil under its brand, often using another company’s formulation. Understanding OEM relationships can help buyers identify quality and consistency in product offerings.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms such as FOB (Free On Board) and CIF (Cost Insurance and Freight) is vital for buyers to understand shipping costs and risk transfers.

-

B2B (Business-to-Business): This term describes transactions between businesses, as opposed to direct sales to consumers. Recognizing the B2B nature of peanut oil procurement helps buyers understand market dynamics and the importance of building relationships with suppliers.

By grasping these technical properties and trade terminologies, B2B buyers can enhance their decision-making processes, ensuring that they select the right peanut oil to meet their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the 5 gal peanut oil Sector

What Are the Current Market Dynamics and Key Trends Influencing the 5 Gallon Peanut Oil Sector?

The global peanut oil market has been experiencing significant growth, driven by increasing consumer preferences for healthier cooking oils and the rise of the foodservice industry. Particularly in regions such as Africa, South America, the Middle East, and Europe, the demand for peanut oil is propelled by its high smoke point and versatility in cooking. For international B2B buyers, understanding local consumer trends is crucial; for instance, in Brazil and Nigeria, peanut oil is favored for traditional frying methods, while in European markets, its health benefits are emphasized.

Emerging technologies are shaping sourcing trends in this sector. The adoption of digital platforms for procurement is gaining traction, allowing buyers to streamline their supply chain operations. Additionally, data analytics tools are being utilized to forecast demand and optimize inventory levels, helping businesses avoid stockouts or overstock situations. As competition intensifies, buyers are increasingly looking for suppliers that can provide transparent sourcing information and timely deliveries.

Furthermore, the market is witnessing a shift toward organic and non-GMO peanut oil, reflecting a broader consumer trend toward health-conscious products. Suppliers that can certify the quality and origin of their products are likely to gain a competitive edge. With global supply chains becoming more intricate, buyers must also navigate geopolitical factors and logistics challenges that could impact pricing and availability.

How Is Sustainability and Ethical Sourcing Impacting the 5 Gallon Peanut Oil Market?

Sustainability is becoming a crucial factor in the procurement process for peanut oil. B2B buyers are increasingly aware of the environmental impact associated with traditional agricultural practices, such as deforestation and pesticide use. As a result, there is a growing demand for sustainably sourced peanut oil that meets eco-friendly standards. Suppliers who can demonstrate a commitment to sustainable farming practices are more likely to attract environmentally conscious buyers.

Ethical sourcing is also gaining prominence, as businesses recognize the importance of maintaining fair labor practices within their supply chains. Certifications such as Fair Trade and organic can enhance a supplier’s reputation and appeal to buyers looking for ethical products. These certifications not only signify quality but also assure buyers that their procurement choices support local farmers and communities.

Moreover, integrating ‘green’ certifications into product offerings can open new market opportunities. For instance, companies that promote their peanut oil as non-GMO or organic can tap into a premium segment of the market, which is particularly lucrative in Europe and North America. By prioritizing sustainability and ethical sourcing, B2B buyers can align their purchasing decisions with their corporate social responsibility goals, enhancing brand loyalty and trust.

What Is the Historical Context of Peanut Oil in B2B Markets?

The history of peanut oil as a cooking oil dates back centuries, with its origins rooted in Africa and Asia. Traditionally used in local cuisines, it gained international recognition in the early 20th century as a healthier alternative to animal fats and other oils. The industrialization of peanut farming and advancements in oil extraction technologies contributed to its increased availability and affordability.

In the B2B context, peanut oil has evolved from a niche product to a staple in commercial kitchens, particularly in the foodservice sector. The rise of fast food chains and the popularity of deep-fried foods have solidified its position in the market. Today, peanut oil is not just valued for its culinary properties but also for its nutritional profile, rich in monounsaturated fats and vitamins.

As the market continues to expand, understanding this historical context can help B2B buyers appreciate the significance of peanut oil in global culinary traditions, as well as its potential for future growth in diverse markets.

Frequently Asked Questions (FAQs) for B2B Buyers of 5 gal peanut oil

-

1. How do I ensure the quality of 5-gallon peanut oil before purchasing?

To guarantee the quality of peanut oil, request samples from potential suppliers for testing. Look for certifications such as ISO or HACCP that demonstrate adherence to food safety standards. Additionally, inquire about the oil’s extraction process and whether it is refined, unrefined, or cold-pressed. Conducting a thorough supplier audit and reviewing customer testimonials can further assure you of their reliability and product quality. -

2. What is the best peanut oil for deep frying?

The best peanut oil for deep frying is refined peanut oil due to its high smoke point of around 450°F (232°C), making it ideal for high-heat cooking. Refined oils also have a neutral flavor that enhances the taste of fried foods without overpowering them. When sourcing, consider options that are Non-GMO and free from trans fats, ensuring a healthier choice for your culinary needs. -

3. What are the minimum order quantities (MOQ) for 5-gallon peanut oil?

Minimum order quantities for 5-gallon peanut oil can vary significantly among suppliers, typically ranging from 100 to 500 gallons or more, depending on the supplier’s capacity and your location. It’s essential to communicate your needs clearly and negotiate MOQs that align with your business requirements. Bulk purchasing often leads to better pricing and favorable terms, so consider establishing a long-term relationship with a reliable supplier. -

4. How can I vet international suppliers for peanut oil?

Vetting international suppliers involves several steps: researching their company history, checking for relevant certifications, and requesting references from previous clients. Utilize platforms like Alibaba or Global Sources to find verified suppliers, and consider conducting on-site visits if feasible. Additionally, assess their production capabilities, quality control processes, and compliance with international food safety standards to ensure they meet your expectations. -

5. What payment terms should I negotiate when sourcing peanut oil?

Payment terms can vary widely, but common practices include 30% upfront and 70% upon delivery, or net 30 days after receipt of goods. It’s advisable to negotiate terms that minimize financial risk while ensuring supplier trust. Consider using letters of credit or escrow services for larger orders, which can provide additional security for both parties involved in the transaction. -

6. What logistics considerations should I keep in mind for importing peanut oil?

When importing peanut oil, consider shipping methods, customs regulations, and storage requirements. Ensure that the oil is packaged appropriately to prevent spoilage during transit. Familiarize yourself with the import duties and taxes applicable in your country, and collaborate with a freight forwarder who can guide you through the complexities of international shipping and customs clearance. -

7. Can I customize my order of peanut oil for specific dietary needs?

Many suppliers offer customization options, such as organic or non-GMO peanut oil, to cater to specific dietary preferences. When discussing your order, clearly communicate your requirements, including any certifications needed for health and dietary claims. This will help ensure that the supplier can meet your specifications and enhance your product offerings to your customers. -

8. What are the common uses for 5-gallon peanut oil in B2B settings?

In B2B settings, 5-gallon peanut oil is widely used in restaurants, catering services, and food processing industries for frying, sautéing, and baking. Its high smoke point and nutty flavor make it suitable for a variety of dishes, including fried chicken, stir-fries, and snacks. Additionally, it is often utilized in the production of sauces and marinades, making it a versatile ingredient in commercial kitchens.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 5 Gal Peanut Oil Manufacturers & Suppliers List

1. Kirkland Signature – Peanut Oil 35 lbs

Domain: costcobusinessdelivery.com

Registered: 1998 (27 years)

Introduction: Kirkland Signature Peanut Oil, 35 lbs

2. MPBio – Peanut Oil 5 Gallon

3. Smart & Final – First Street Peanut Oil

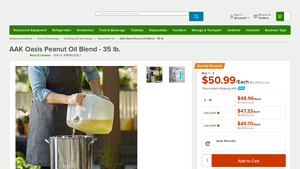

4. AAK – Oasis Peanut Oil Blend

Domain: webstaurantstore.com

Registered: 2003 (22 years)

Introduction: {“Product Name”: “AAK Oasis Peanut Oil Blend”, “Weight”: “35 lbs”, “Volume”: “Approx 4.5 Gallons”, “Smoke Point”: “450 degrees Fahrenheit”, “Usage”: [“Deep Frying”, “Light Frying”, “Sautéing”], “Popular Uses”: [“Turkey”, “French fries”, “Stir fry”, “Battered fish”], “UPC Code”: “079836141355”, “Customer Rating”: “4.9 out of 5 stars”, “Number of Reviews”: “9”, “Price”: {“1-2 units”: “$50.99/Each”, …

Strategic Sourcing Conclusion and Outlook for 5 gal peanut oil

In the competitive landscape of edible oils, particularly for 5-gallon peanut oil, strategic sourcing is essential for maximizing value and ensuring supply chain resilience. International buyers should focus on establishing relationships with reliable suppliers who can provide high-quality, non-GMO peanut oil, which is increasingly favored due to its versatility and high smoke point. Understanding regional market dynamics, such as demand fluctuations and import regulations, is crucial for effective sourcing strategies.

Additionally, leveraging bulk purchasing can significantly reduce costs, making it an attractive option for businesses in food service and retail sectors. As health-conscious consumers continue to seek healthier cooking oils, the demand for peanut oil is expected to rise, especially in regions like Africa, South America, and Europe.

Looking ahead, it is imperative for B2B buyers to stay informed about market trends and innovations in peanut oil production and packaging. Engaging in collaborative partnerships with suppliers can facilitate better pricing and consistent quality. By prioritizing strategic sourcing, businesses can not only enhance their product offerings but also ensure long-term sustainability in an evolving market landscape. Now is the time to evaluate your sourcing strategies and align them with the emerging trends in the global peanut oil market.