Unlocking Value: A Strategic Analysis of the Sata7 6P Connector Market

Introduction: Navigating the Global Market for sata7 6p connector

In the fast-evolving landscape of technology, sourcing the right components, such as the SATA 7 6P connector, presents a significant challenge for B2B buyers across various sectors. This guide addresses the complexities involved in finding reliable suppliers and understanding the technical specifications of these connectors, which play a crucial role in data storage solutions. With applications ranging from consumer electronics to industrial machinery, the SATA 7 6P connector is vital for ensuring seamless connectivity and data transfer.

This comprehensive guide will delve into the various types of SATA 7 6P connectors available, their specific applications, and how to effectively vet suppliers to ensure quality and compliance with international standards. We will also explore cost considerations and provide insights on negotiating terms that align with your business needs.

By leveraging this guide, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Germany—will be empowered to make informed purchasing decisions. Whether you are looking to streamline your supply chain or enhance the technical capabilities of your products, understanding the nuances of the SATA 7 6P connector will be instrumental in driving your business forward.

Understanding sata7 6p connector Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Slimline SATA Connector | Compact design, 7+6 pin configuration, suitable for space-constrained applications | Laptops, Ultrabooks, External Drives | Pros: Space-efficient, lightweight. Cons: Limited compatibility with standard SATA ports. |

| SATA 7+6P Female Connector | Straight orientation, robust construction with high insulation resistance | Consumer Electronics, Data Storage | Pros: High durability, reliable connections. Cons: Requires specific mating connectors. |

| SATA 7P + Power 4-Pin | Combines data and power in a single connector, 20-inch cable length | Power Supply Units, External Drives | Pros: Simplifies wiring, reduces clutter. Cons: Cable length may limit placement options. |

| Vertical SATA Connector | Vertical mounting, optimized for board-level applications | Motherboards, Custom PC Designs | Pros: Space-saving on PCB, easy to install. Cons: Limited to vertical space. |

| Cable-to-Board SATA Connector | Integrates seamlessly with PCBs, offers flexibility in design | Industrial Applications, Custom Devices | Pros: Versatile, allows for tailored designs. Cons: May require additional assembly time. |

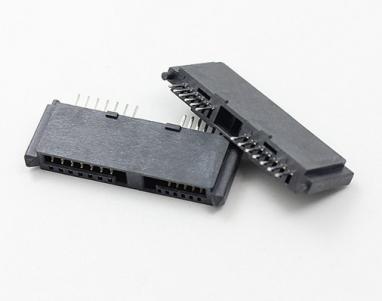

What are the characteristics of Slimline SATA Connectors?

Slimline SATA connectors feature a compact design with a 7+6 pin configuration, making them ideal for applications where space is at a premium, such as in laptops and ultrabooks. Their lightweight nature facilitates integration into portable devices. B2B buyers should consider the compatibility of these connectors with existing systems, as they may not fit standard SATA ports, potentially requiring additional adapters.

How do SATA 7+6P Female Connectors perform in various applications?

The SATA 7+6P Female Connector is characterized by its straight orientation and robust construction, which includes high insulation resistance. This makes it suitable for consumer electronics and data storage applications, where reliability is critical. Buyers should evaluate the mating connectors required for these components, as this can impact overall system integration and performance.

What advantages does a SATA 7P + Power 4-Pin connector provide?

The SATA 7P + Power 4-Pin connector combines data and power transmission into a single unit, often accompanied by a 20-inch cable. This design is particularly beneficial in power supply units and external drives, as it simplifies wiring and minimizes clutter. However, buyers must consider the cable length, as it may limit placement options within specific setups.

Why choose a Vertical SATA Connector for board-level applications?

Vertical SATA connectors are designed for vertical mounting, optimizing the use of space on printed circuit boards (PCBs). This feature is advantageous for motherboards and custom PC designs, where maximizing available space is essential. While these connectors facilitate easy installation, buyers should be aware that they are limited to vertical space, which may affect design flexibility.

What are the benefits of Cable-to-Board SATA Connectors in industrial applications?

Cable-to-board SATA connectors offer seamless integration with PCBs, making them particularly versatile for industrial applications and custom devices. This flexibility allows for tailored designs that meet specific operational requirements. However, B2B buyers should factor in the potential for increased assembly time, which could impact production schedules and costs.

Key Industrial Applications of sata7 6p connector

| Industry/Sector | Specific Application of sata7 6p connector | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Connection in Slimline SATA drives | Enhances data transfer speeds and reduces space usage | Ensure compatibility with existing devices and power requirements. |

| Data Centers | Internal connections for storage solutions | Supports efficient data management and storage capacity | Look for connectors with high reliability and durability. |

| Automotive Technology | Integration in infotainment and navigation systems | Enables seamless data communication and multimedia functions | Verify environmental resistance and compliance with automotive standards. |

| Industrial Automation | Used in various automated machinery for data transfer | Improves operational efficiency and data accuracy | Consider sourcing connectors that can withstand industrial conditions. |

| Telecommunications | Application in network storage devices | Facilitates quick access to large data sets | Prioritize connectors that meet high-speed data transfer standards. |

In the consumer electronics industry, the SATA 7+6P connector is primarily utilized for connecting Slimline SATA drives. These connectors enable high-speed data transfers while occupying minimal space, making them ideal for compact devices like laptops and gaming consoles. For international buyers, especially in regions like Africa and Europe, ensuring compatibility with existing hardware and adherence to power specifications is crucial for successful integration.

In data centers, SATA 7+6P connectors play a vital role in internal connections for storage solutions. They facilitate efficient data management and allow for the expansion of storage capacity without compromising performance. Buyers should prioritize sourcing connectors that exhibit high reliability and durability, as data centers require components that can handle continuous operation under demanding conditions.

The automotive technology sector utilizes SATA 7+6P connectors in infotainment and navigation systems. These connectors support seamless data communication between various components, enhancing multimedia functionality and user experience. Buyers in this sector must verify that connectors meet stringent environmental resistance and automotive compliance standards to ensure longevity and reliability in vehicles.

In industrial automation, SATA 7+6P connectors are essential for data transfer in automated machinery. They contribute to improved operational efficiency and data accuracy, which are critical in manufacturing processes. International buyers should consider sourcing connectors that can withstand harsh industrial conditions, such as high temperatures and vibrations, to maintain performance in demanding environments.

Lastly, in the telecommunications industry, SATA 7+6P connectors are applied in network storage devices. They enable quick access to large data sets, which is essential for efficient network operations. Buyers should prioritize connectors that meet high-speed data transfer standards to support the increasing demand for fast and reliable network connectivity across various regions, including South America and the Middle East.

3 Common User Pain Points for ‘sata7 6p connector’ & Their Solutions

Scenario 1: Difficulty Sourcing High-Quality SATA 7 6P Connectors

The Problem: B2B buyers often face challenges in sourcing high-quality SATA 7 6P connectors that meet their specific performance standards. In regions like Africa and South America, limited access to reliable suppliers can lead to subpar components that result in increased failure rates and production delays. This issue not only affects operational efficiency but also raises concerns about the long-term reliability of the final products.

The Solution: To overcome this sourcing challenge, buyers should prioritize establishing relationships with reputable manufacturers known for their quality control processes. Conducting thorough research and requesting samples before making bulk orders can help verify the quality of the connectors. Additionally, buyers should leverage international trade platforms and industry-specific trade shows to connect with verified suppliers. Setting a minimum order quantity (MOQ) with suppliers, such as the recommended 1,000 pieces, can ensure consistency in quality while allowing for better pricing negotiations. Always inquire about certifications, such as UL flammability ratings, to further ensure the connectors meet safety and quality standards.

Scenario 2: Compatibility Issues with Existing Systems

The Problem: Another common issue arises when B2B buyers encounter compatibility problems between SATA 7 6P connectors and their existing systems. This can happen due to variations in design specifications or differences in pin configurations, leading to costly integration challenges and potential downtime in production.

The Solution: To mitigate compatibility issues, buyers should conduct a thorough assessment of their current systems before purchasing SATA 7 6P connectors. This includes reviewing the technical specifications, such as the number of positions and contact configurations, to ensure alignment with existing hardware. Engaging with product experts from manufacturers can provide valuable insights into which connectors are best suited for specific applications. Additionally, creating a detailed compatibility checklist during the design phase can help prevent future issues. Always consider future-proofing your procurement by opting for connectors that are adaptable to evolving technology standards.

Scenario 3: Misunderstanding Technical Specifications

The Problem: Many B2B buyers struggle with understanding the technical specifications of SATA 7 6P connectors, which can lead to incorrect purchases and wasted resources. Misinterpretations of electrical ratings, contact resistance, and insulation properties can result in selecting the wrong components for a given application, ultimately affecting product performance.

The Solution: To address this knowledge gap, buyers should invest time in educating themselves about the essential specifications of SATA 7 6P connectors. Manufacturers often provide detailed product documentation, including datasheets and application notes, which outline critical parameters such as dielectric withstand voltage and contact resistance. Buyers can also benefit from online webinars or training sessions offered by connector manufacturers to gain a deeper understanding of the technology. Establishing a clear communication channel with suppliers to clarify doubts about specifications can further ensure informed purchasing decisions. When in doubt, consulting with technical support teams before finalizing orders can help prevent costly mistakes and ensure the selected components meet the necessary performance criteria.

Strategic Material Selection Guide for sata7 6p connector

What Are the Key Materials Used in SATA 7 6P Connectors?

When selecting materials for SATA 7 6P connectors, it is essential to consider properties such as electrical conductivity, thermal stability, and resistance to environmental factors. Here are four common materials used in these connectors, along with their advantages and disadvantages from a B2B perspective.

1. LCP (Liquid Crystal Polymer)

Key Properties:

LCP is known for its excellent thermal stability, withstanding temperatures up to 260°C. It also offers high mechanical strength and low moisture absorption, making it ideal for environments with varying humidity levels.

Pros & Cons:

The primary advantage of LCP is its durability and resistance to chemical corrosion, which is crucial for connectors used in diverse applications. However, LCP can be more expensive than other materials and may require specialized manufacturing processes, which can increase lead times.

Impact on Application:

LCP is particularly suitable for high-performance applications, including data centers and consumer electronics, where reliability is paramount. Its compatibility with high-frequency signals makes it ideal for SATA applications.

Considerations for International Buyers:

For buyers in regions like Europe and Germany, compliance with standards such as UL and RoHS is critical. LCP’s properties align well with these regulations, making it a preferred choice for high-end applications.

2. Copper Alloy

Key Properties:

Copper alloys exhibit excellent electrical conductivity and thermal properties. They can handle significant current loads, making them suitable for power transmission in connectors.

Pros & Cons:

The main advantage of copper alloys is their cost-effectiveness and availability. However, they are prone to oxidation and corrosion, which can affect long-term performance if not properly plated or treated.

Impact on Application:

Copper alloys are widely used in consumer electronics and industrial applications where cost is a significant factor. Their conductivity ensures efficient data transfer, but they may require additional protective coatings to enhance durability.

Considerations for International Buyers:

Buyers from regions like Africa and South America should consider the environmental conditions, such as humidity and temperature fluctuations, which could affect copper alloy performance. Compliance with local standards for materials is also essential.

3. Thermoplastic

Key Properties:

Thermoplastics, such as nylon and polycarbonate, offer good insulation properties and are lightweight. They can be molded into complex shapes, providing flexibility in design.

Pros & Cons:

The primary advantage of thermoplastics is their low cost and ease of manufacturing. However, they may not withstand high temperatures as effectively as LCP or metal materials, which can limit their use in high-performance applications.

Impact on Application:

Thermoplastics are often used in consumer-grade SATA connectors where cost is a critical factor. They provide adequate performance for standard applications but may not be suitable for environments with extreme temperatures.

Considerations for International Buyers:

For buyers in the Middle East, where temperatures can be high, it is essential to evaluate the thermal properties of the thermoplastic used. Compliance with international standards for flame retardancy is also a consideration.

4. Nickel-Plated Steel

Key Properties:

Nickel-plated steel combines the strength of steel with the corrosion resistance of nickel plating. This material can handle mechanical stress and is suitable for applications requiring durability.

Pros & Cons:

Nickel-plated steel offers excellent mechanical strength and is relatively low-cost. However, the plating can wear off over time, especially in harsh environments, leading to potential failures.

Impact on Application:

This material is often used in industrial settings where connectors are subject to mechanical stress. While it provides good performance, the longevity may be a concern without proper maintenance.

Considerations for International Buyers:

Buyers in Europe and Germany may need to ensure that the nickel plating meets environmental regulations, such as REACH, which restricts certain substances in manufacturing.

Summary Table of Material Selection for SATA 7 6P Connectors

| Material | Typical Use Case for sata7 6p connector | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| LCP | High-performance electronics | Excellent thermal stability | Higher manufacturing complexity | High |

| Copper Alloy | Consumer electronics | Cost-effective and widely available | Prone to oxidation and corrosion | Medium |

| Thermoplastic | Standard consumer-grade applications | Low cost and easy to manufacture | Limited temperature resistance | Low |

| Nickel-Plated Steel | Industrial applications | High mechanical strength | Plating wear can lead to failures | Medium |

This material selection guide provides a comprehensive overview for B2B buyers, helping them make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for sata7 6p connector

What Are the Main Stages in the Manufacturing Process of SATA 7+6P Connectors?

The manufacturing of SATA 7+6P connectors involves several critical stages, each designed to ensure the final product meets stringent performance and quality standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality materials, such as LCP (Liquid Crystal Polymer) for the housing and copper alloys for the contacts. These materials are selected for their durability and electrical conductivity. Prior to use, materials undergo inspections to confirm they meet specified standards.

-

Forming: During the forming stage, raw materials are processed into specific shapes required for the connectors. This typically involves stamping and molding techniques. For instance, the connector housing is molded under controlled conditions to ensure uniformity and strength, while the contacts are stamped to precise dimensions to facilitate proper mating.

-

Assembly: In the assembly phase, individual components are brought together. Automated machinery is often employed to ensure accuracy and efficiency. Components like the housing, contacts, and hooks are assembled in a clean environment to prevent contamination. This stage may also include soldering, where the contacts are attached to the housing securely.

-

Finishing: The final stage involves applying surface treatments to enhance performance and durability. For SATA connectors, this often includes nickel and tin plating to prevent corrosion and ensure reliable electrical connections. Additionally, quality checks are performed to ensure that the connectors meet dimensional and functional specifications.

How Do International Standards Influence Quality Assurance in SATA 7+6P Connector Manufacturing?

Quality assurance (QA) is critical in the manufacturing of SATA connectors, particularly for international B2B markets. Adhering to recognized international standards such as ISO 9001 ensures that manufacturers implement effective quality management systems. This certification focuses on continuous improvement and customer satisfaction, which are paramount in the competitive connector market.

In addition to ISO standards, industry-specific certifications such as CE and API are relevant. These certifications signify compliance with safety, health, and environmental protection standards, which can be particularly important for buyers in regions like Europe and the Middle East.

What Are the Key Quality Control Checkpoints in SATA 7+6P Connector Production?

The quality control process for SATA 7+6P connectors typically includes several checkpoints:

-

Incoming Quality Control (IQC): At this initial stage, raw materials are inspected upon arrival. This includes verifying the specifications of the materials, ensuring they conform to standards before they proceed to the manufacturing line.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor production parameters. This includes checking dimensions, assembly integrity, and ensuring that the manufacturing processes adhere to established protocols.

-

Final Quality Control (FQC): After assembly and finishing, the final inspection occurs. This stage involves testing the electrical performance, conducting visual inspections, and ensuring that the connectors meet all specified requirements. Common tests include contact resistance, insulation resistance, and dielectric strength.

Which Testing Methods Are Commonly Used to Ensure the Quality of SATA 7+6P Connectors?

To verify the quality and reliability of SATA 7+6P connectors, several testing methods are employed:

- Electrical Testing: This includes measuring contact resistance and insulation resistance to ensure electrical integrity.

- Mechanical Testing: Connectors undergo mechanical stress tests to evaluate their durability under various conditions, including temperature fluctuations and physical stress.

- Environmental Testing: Products may be subjected to environmental conditions such as humidity and temperature extremes to assess their performance in real-world scenarios.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and quality control practices of potential suppliers. This direct engagement allows buyers to assess compliance with international standards.

-

Requesting Documentation: Buyers should request documentation of quality certifications, including ISO, CE, or other relevant certifications. This documentation should outline the supplier’s quality management system and adherence to standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s products and processes. This step is particularly valuable for buyers unfamiliar with the local manufacturing landscape.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is crucial. Different regions may have varying standards and expectations. For instance, buyers in Europe may prioritize CE certifications due to stringent regulatory requirements, while buyers in Africa may focus on local compliance standards.

Additionally, cultural differences in business practices can influence quality expectations. Buyers should establish clear communication with suppliers regarding quality requirements and certifications to ensure mutual understanding and compliance.

Conclusion: Ensuring Quality in SATA 7+6P Connectors for B2B Transactions

In conclusion, the manufacturing processes and quality assurance protocols for SATA 7+6P connectors are intricate and critical for ensuring product reliability and performance. By understanding these processes, international B2B buyers can make informed decisions when selecting suppliers, ultimately leading to successful partnerships and quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sata7 6p connector’

In the competitive landscape of B2B procurement, sourcing the right components is crucial for operational success. This checklist is designed to guide international buyers—particularly those in Africa, South America, the Middle East, and Europe—through the essential steps for procuring SATA 7+6P connectors effectively.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the SATA 7+6P connector you require. This includes the connector type, dimensions, and electrical characteristics. Understanding these parameters will help you communicate your needs effectively to suppliers and ensure compatibility with your existing systems.

Step 2: Research Reliable Suppliers

Identify potential suppliers that specialize in SATA connectors. Look for companies with a strong reputation in the industry, particularly those with experience serving international markets. Use online platforms, trade shows, and industry publications to compile a list of suppliers, focusing on their track record and customer reviews.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that your shortlisted suppliers comply with international standards and possess necessary certifications. This may include ISO certifications or specific industry-related approvals. Compliance ensures that the products meet safety, quality, and performance standards, reducing the risk of faulty components in your operations.

Step 4: Request Product Samples

Before placing a bulk order, request samples of the SATA 7+6P connectors. Testing samples allows you to assess the quality, durability, and compatibility of the connectors with your systems. Ensure that the samples match your defined specifications to avoid issues later in the production process.

Step 5: Negotiate Pricing and Terms

Once you have selected a supplier, engage in negotiations regarding pricing, minimum order quantities, and payment terms. Consider factors such as bulk discounts and shipping costs. Establishing clear terms upfront helps prevent misunderstandings and aligns expectations between both parties.

Step 6: Assess Delivery Times and Logistics

Inquire about the supplier’s delivery times and logistics capabilities. Understanding their shipping options and estimated delivery schedules is vital for planning your production timeline. A reliable supplier should provide transparent information about lead times and any potential delays.

Step 7: Establish a Quality Assurance Process

Finally, implement a quality assurance process to monitor the connectors upon delivery. This includes inspecting the products for defects and ensuring they meet your specifications. Establishing a quality control system helps maintain the integrity of your supply chain and reduces the likelihood of operational disruptions.

By following this practical sourcing checklist, B2B buyers can streamline the procurement process for SATA 7+6P connectors, ensuring they find reliable suppliers and high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for sata7 6p connector Sourcing

What Are the Key Cost Components for Sourcing SATA 7 6P Connectors?

Understanding the cost structure of SATA 7 6P connectors is crucial for international B2B buyers. The overall cost comprises several components:

-

Materials: The primary materials include copper alloys for contacts and LCP (Liquid Crystal Polymer) for housing. Quality certifications, such as UL94-V0 for flammability, can influence material costs significantly. Prices for raw materials fluctuate based on global market trends, affecting the final price of connectors.

-

Labor: Labor costs vary by region, with manufacturing hubs in Asia generally offering lower labor costs compared to Europe. The complexity of assembly and testing processes can also impact labor expenses.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and maintenance. High-volume production often lowers overhead per unit, making it essential to consider the scale of your order.

-

Tooling: Custom tooling for specialized connectors can lead to significant upfront costs. Buyers should factor in these costs, especially if they require unique specifications that necessitate custom molds.

-

Quality Control (QC): Ensuring that connectors meet stringent quality standards may add to costs but is essential for maintaining reliability and performance. Quality assurance processes can include testing for electrical resistance, insulation resistance, and dielectric strength.

-

Logistics: Transportation and handling costs are critical, especially for international shipments. Factors such as distance, shipping methods (air vs. sea), and customs duties can significantly affect the overall price.

-

Margin: Suppliers typically add a margin to cover their costs and generate profit. This margin varies based on market competition and supplier reputation.

How Do Price Influencers Affect the Cost of SATA 7 6P Connectors?

Several factors influence the pricing of SATA 7 6P connectors:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Bulk purchases often lead to lower per-unit costs, so negotiating for higher volumes can provide cost advantages.

-

Specifications and Customization: Custom specifications, such as unique pin configurations or specific plating requirements, can increase costs. Buyers should assess whether standard models meet their needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications often lead to higher prices. However, investing in quality can reduce long-term failure rates and associated costs.

-

Supplier Factors: The reputation and location of suppliers can affect pricing. Established suppliers with a proven track record may charge higher prices due to reliability, while emerging suppliers may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for cost management. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping and insurance costs, impacting the total cost of ownership.

What Buyer Tips Can Help Achieve Cost Efficiency When Sourcing SATA 7 6P Connectors?

-

Negotiate: Building strong relationships with suppliers can lead to better pricing. Don’t hesitate to negotiate on volume discounts, payment terms, and delivery schedules.

-

Evaluate Total Cost of Ownership: Consider not only the purchase price but also the long-term costs associated with quality, reliability, and maintenance. A slightly higher initial investment may yield greater savings over time.

-

Research Supplier Options: Explore multiple suppliers across different regions. This can help identify competitive pricing and ensure that you are getting the best deal without sacrificing quality.

-

Understand Pricing Nuances for International Purchases: Buyers from regions like Africa or South America should be aware of potential tariffs and import duties that could affect final costs. It’s essential to factor in these expenses when budgeting for new connectors.

-

Stay Informed on Market Trends: Keeping abreast of market trends in raw materials and manufacturing costs can provide insights into when to purchase. Timing your orders can lead to significant savings.

Disclaimer

The prices mentioned are indicative and can vary based on market fluctuations, supplier pricing strategies, and specific order requirements. Always request updated quotes and consider all cost factors before making procurement decisions.

Alternatives Analysis: Comparing sata7 6p connector With Other Solutions

Understanding the Need for Alternatives in Connector Solutions

In the dynamic landscape of electronic connectivity, businesses often seek alternatives to established solutions like the SATA 7+6P connector. These alternatives may offer different performance metrics, cost efficiencies, and implementation complexities that can better align with specific project requirements. Evaluating these options allows B2B buyers to make informed decisions that enhance operational efficiency and reduce costs.

Comparative Analysis of Connector Solutions

| Comparison Aspect | SATA 7+6P Connector | Slimline SATA Connector | SATA 15-Pin Connector |

|---|---|---|---|

| Performance | High data transfer rates; supports power and signal | Similar performance; optimized for space | Higher pin count for diverse applications |

| Cost | Moderate cost per unit | Lower cost, varies by length | Higher due to additional functionality |

| Ease of Implementation | Standardized, easy to integrate | Simplified for compact devices | Requires specific board design |

| Maintenance | Low maintenance, durable | Low maintenance, flexible | Moderate, dependent on usage |

| Best Use Case | Desktop and server storage | Slim devices like ultrabooks | High-performance applications requiring multiple signals |

Analyzing the Alternatives

Slimline SATA Connector

The Slimline SATA connector is an attractive alternative, particularly for devices where space is at a premium. It maintains high data transfer rates similar to the SATA 7+6P connector while offering a more compact design. This makes it ideal for ultrabooks and small form-factor PCs. However, while it is cost-effective, its reduced size can limit its application in more robust storage solutions, making it less versatile in larger systems.

SATA 15-Pin Connector

The SATA 15-pin connector expands the functionality of the SATA interface by providing additional pins for power and signal integrity. This option is particularly useful in applications requiring multiple data streams, such as high-performance computing or advanced storage solutions. While it offers a higher performance ceiling, it comes at a greater cost and necessitates specific design considerations on the circuit board, which may complicate implementation for some businesses.

Making the Right Choice for Your Business Needs

When selecting the appropriate connector solution, B2B buyers should consider their specific operational requirements, including performance expectations, cost constraints, and ease of integration. The SATA 7+6P connector is an excellent choice for traditional storage applications, while alternatives like the Slimline SATA connector may better serve space-constrained environments. Conversely, the SATA 15-pin connector is ideal for high-performance applications that demand increased data handling capabilities. Ultimately, assessing the unique needs of your projects will guide you to the most suitable connector solution.

Essential Technical Properties and Trade Terminology for sata7 6p connector

What Are the Key Technical Properties of the SATA 7 6P Connector?

Understanding the essential technical properties of the SATA 7 6P connector is crucial for B2B buyers to ensure compatibility, reliability, and performance in their applications. Here are several critical specifications:

-

Material Composition

The housing of the SATA 7 6P connector is typically made from LCP (Liquid Crystal Polymer), which is rated UL94-V0 for flammability. The contacts are usually crafted from copper alloy with a nickel plating of at least 50µ” and gold plating on the contact area. This material selection is vital for durability, electrical conductivity, and thermal resistance, ensuring long-term reliability in demanding environments. -

Electrical Specifications

Key electrical properties include a maximum contact resistance of 25 mΩ and an insulation resistance of at least 1000 MΩ. These specifications are critical for minimizing signal loss and ensuring the connector can handle the required voltage without breakdown, which is essential for maintaining the integrity of data transmission in high-speed applications. -

Dielectric Withstanding Voltage

A minimum dielectric withstand voltage of 500 VRMS is crucial for ensuring that the connector can operate safely in high-voltage environments. This property protects against electrical breakdown and is particularly important in applications where multiple signals are being transmitted simultaneously. -

Mechanical Durability

The SATA 7 6P connector is designed for a minimum of 500 mating cycles, which is essential for applications requiring frequent connections and disconnections. This durability ensures that the connectors maintain their performance and reliability over time, reducing the need for replacements and minimizing downtime. -

Temperature Range

Operating temperature range is another critical specification, typically between -40°C and 85°C. This wide range ensures that the connector can function effectively in various environments, from industrial settings to consumer electronics, making it versatile for different applications.

Which Trade Terminology Should B2B Buyers Understand for the SATA 7 6P Connector?

Familiarizing oneself with industry-specific terminology can significantly enhance the procurement process. Here are essential terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the role of OEMs is crucial for buyers looking to source components that are compatible with existing systems or equipment. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ can help buyers plan their purchasing strategy, ensuring they meet supplier requirements while managing inventory effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a quote on specific products or services. For B2B buyers, issuing an RFQ is a critical step in the procurement process, allowing them to compare prices and terms across multiple suppliers. -

Incoterms

International Commercial Terms (Incoterms) are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers clarify shipping costs, risks, and responsibilities, facilitating smoother international trade. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. For B2B buyers, knowing the lead time is essential for planning production schedules and inventory management, ensuring that they can meet their operational deadlines. -

Certification Standards

These are industry-specific standards that products must meet to ensure quality and safety. Familiarity with relevant certification standards for the SATA 7 6P connector, such as UL or RoHS, helps buyers make informed decisions about product quality and compliance.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions, enhancing their procurement processes and ensuring they select the right products for their needs.

Navigating Market Dynamics and Sourcing Trends in the sata7 6p connector Sector

What Are the Current Market Dynamics and Key Trends Influencing the SATA 7 6P Connector Sector?

The global market for SATA 7 6P connectors is experiencing notable growth driven by several factors, including the increasing demand for high-speed data transfer in various electronic devices and the expansion of cloud computing infrastructure. In regions such as Africa, South America, the Middle East, and Europe, there is a marked rise in the adoption of advanced technologies, which is contributing to this growth. In particular, industries such as telecommunications, automotive, and consumer electronics are becoming significant consumers of SATA connectors due to their reliability and efficiency.

Emerging trends in sourcing highlight a shift towards more integrated supply chains. International B2B buyers are increasingly favoring suppliers who can offer comprehensive solutions that encompass not just the connectors, but also the necessary cables and assemblies. This trend is particularly prominent in Europe and Germany, where manufacturers prioritize suppliers that can provide just-in-time delivery to enhance production efficiency. Furthermore, the rise of e-commerce platforms is facilitating easier access to a wider range of products, allowing buyers from regions like Nigeria and Brazil to source components more effectively.

Moreover, the push for miniaturization in electronics has led to the development of slimmer, more compact SATA connectors, which are becoming essential in modern designs. As manufacturers innovate to meet these demands, B2B buyers should stay informed about the latest product developments and consider suppliers who invest in research and development.

How Is Sustainability Influencing Sourcing Decisions in the SATA 7 6P Connector Market?

Sustainability is becoming a pivotal aspect of sourcing decisions in the SATA 7 6P connector market. As international buyers become more environmentally conscious, they are increasingly looking for suppliers who adhere to ethical sourcing practices and demonstrate a commitment to reducing their environmental impact. This shift is particularly evident in Europe, where regulatory frameworks are pushing manufacturers to adopt greener practices.

One important consideration for B2B buyers is the certification of materials used in the production of SATA connectors. Certifications such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) are becoming crucial in ensuring that products meet environmental standards. Buyers should prioritize suppliers who can provide documentation and evidence of compliance with these certifications, as this not only reflects responsible sourcing but also enhances brand reputation in increasingly eco-conscious markets.

Moreover, the focus on sustainability is driving innovation in materials, with manufacturers exploring alternatives to traditional plastics and metals that offer reduced environmental footprints. Buyers should engage with suppliers who are investing in ‘green’ technologies and materials, as this can lead to more sustainable product offerings and long-term partnerships built on shared values.

How Have SATA 7 6P Connectors Evolved Over Time?

The evolution of SATA 7 6P connectors can be traced back to the need for faster data transfer rates and improved connectivity in computer systems. Originally introduced as part of the SATA interface standard, these connectors have undergone significant transformations to meet the demands of modern technology. Over the years, advancements in material science and engineering have led to the development of slimmer profiles and enhanced performance characteristics, such as improved electrical resistance and higher durability.

As the demand for high-speed data transfer has surged, particularly with the rise of SSDs (Solid State Drives) and data-intensive applications, SATA 7 6P connectors have adapted to ensure compatibility and performance. This continuous evolution reflects the broader trends within the electronics industry, where the drive for efficiency and miniaturization remains paramount. For B2B buyers, understanding this historical context can provide valuable insights into the future direction of the market and the importance of choosing reliable, innovative suppliers.

Frequently Asked Questions (FAQs) for B2B Buyers of sata7 6p connector

-

How do I ensure the quality of SATA 7 6P connectors when sourcing from international suppliers?

To ensure the quality of SATA 7 6P connectors, conduct thorough supplier vetting. Look for manufacturers with certifications such as ISO 9001, which indicates adherence to quality management standards. Request samples to evaluate the product’s performance and durability. Additionally, consider suppliers who offer detailed product specifications, including material quality and compliance with international standards. Engaging in third-party quality assurance checks can further enhance your confidence in the product’s reliability. -

What are the typical lead times for ordering SATA 7 6P connectors from overseas suppliers?

Lead times for SATA 7 6P connectors can vary significantly based on the supplier’s location, production capacity, and shipping methods. Generally, you can expect lead times ranging from 10 days to several weeks. When placing an order, inquire about the estimated delivery time and any potential delays. It’s wise to factor in additional time for customs clearance, especially when sourcing from regions with stricter import regulations. -

What is the minimum order quantity (MOQ) for SATA 7 6P connectors?

The minimum order quantity (MOQ) for SATA 7 6P connectors typically ranges from 500 to 1,000 pieces, depending on the supplier. Some manufacturers may offer lower MOQs for first-time buyers or trial orders. It’s essential to discuss MOQs upfront, as they can significantly impact your purchasing strategy and inventory management. Consider negotiating for smaller batches if you are testing the market or if storage capacity is a concern. -

What payment terms are common when sourcing SATA 7 6P connectors internationally?

Common payment terms for international orders of SATA 7 6P connectors include options like T/T (telegraphic transfer), L/C (letter of credit), and D/P (documents against payment). Many suppliers require a deposit upfront, often 30% of the total order value, with the balance payable before shipment. Ensure you clarify payment terms during negotiations to avoid misunderstandings and ensure smooth transactions. Always consider the financial stability of the supplier when selecting payment methods. -

Can I customize SATA 7 6P connectors to meet specific project requirements?

Yes, many manufacturers offer customization options for SATA 7 6P connectors, such as variations in length, color, or specific connector configurations. When seeking customization, provide detailed specifications and requirements to the supplier. Be aware that custom orders may come with higher MOQs and longer lead times. Discuss any additional costs associated with customization to ensure your budget aligns with your project needs. -

What are the key specifications I should verify when purchasing SATA 7 6P connectors?

When purchasing SATA 7 6P connectors, verify specifications such as contact resistance, insulation resistance, and dielectric withstand voltage. Additionally, check the materials used for the housing and contacts, as these can affect durability and performance. Pay attention to the connector’s compatibility with existing systems, including dimensions and pin configurations. Request product datasheets from suppliers to ensure you have all the necessary technical information. -

What are the best practices for shipping and logistics when ordering SATA 7 6P connectors?

To optimize shipping and logistics for SATA 7 6P connectors, choose a reliable freight forwarder experienced in handling electronic components. Discuss shipping options, including air freight for urgent needs or sea freight for cost savings. Ensure you understand the customs regulations in your country to avoid delays. Request tracking information and confirm delivery timelines to manage your inventory effectively and plan for any potential disruptions. -

How can I mitigate risks when sourcing SATA 7 6P connectors from international suppliers?

Mitigating risks when sourcing SATA 7 6P connectors involves several strategies. Start by conducting comprehensive research on potential suppliers, including reviews and references. Establish clear contracts outlining quality standards, delivery timelines, and payment terms. Consider using escrow services for large transactions to protect your funds. Finally, maintain open communication with suppliers throughout the process to address any concerns proactively and ensure transparency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Sata7 6P Connector Manufacturers & Suppliers List

1. KLS – KLS1-SATA301 Connector

Domain: klsconnector.com

Registered: 2022 (3 years)

Introduction: {“Model”:”KLS1-SATA301″,”MOQ”:”1000 PCS”,”Payment”:”L/C, D/A, D/P, T/T”,”Place_of_Origin”:”China”,”Delivery_Time”:”10 days”,”Material”:{“Housing”:”LCP, UL94-V0, Black”,”Contact”:”Copper alloy, 50u” min. Nickel plating overall; 100u” min. Tin on solder tail; Gold plating on contact area”,”Hook”:”Copper alloy, Nickel and Tin plating overall”},”Electrical”:{“Contact_Resistance”:”25 mΩ Max.”,”Insulati…

2. TE – SATA Connector Plug

Domain: te.com

Registered: 1992 (33 years)

Introduction: This company, TE – SATA Connector Plug, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Palyoo – SATA 7+6P Female Connector

4. KLS – SATA 7+6P Female Connector

Domain: klsele.com

Introduction: SATA 7+6P Female Connector, Straight

5. BSC – S670-MXA5T-001

Domain: bsc-elec.com

Registered: 2017 (8 years)

Introduction: {“Product Item”:”S670-MXA5T-001″,”Gender”:”Male”,”Pin number”:”13Pin”,”Color”:”Black”,”Insulator”:”LCP”}

Strategic Sourcing Conclusion and Outlook for sata7 6p connector

The strategic sourcing of SATA 7+6P connectors is pivotal for businesses looking to optimize their supply chains and enhance their product offerings. As we have discussed, the reliability and performance of these connectors are paramount in today’s high-speed data environments, making it essential for international buyers to select suppliers who adhere to stringent quality standards. By leveraging insights on manufacturing specifications, such as material properties and electrical performance, B2B buyers can make informed decisions that ensure long-term value.

Moreover, understanding regional market dynamics—especially in emerging economies across Africa, South America, the Middle East, and Europe—can provide a competitive edge. Buyers should prioritize partnerships with manufacturers that offer flexibility in MOQ (Minimum Order Quantity) and favorable payment terms, which can significantly impact cash flow and inventory management.

Looking ahead, the demand for SATA connectors is expected to grow as digital transformation accelerates globally. Now is the time for international buyers to engage with reliable suppliers, negotiate favorable terms, and invest in quality components that will drive their technological advancements. By doing so, businesses can position themselves for success in a rapidly evolving market landscape.