Air Conditioner Compressor Scrap Price: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for air conditioner compressor scrap price

In the ever-evolving landscape of global trade, understanding the nuances of air conditioner compressor scrap prices is crucial for international B2B buyers seeking to optimize their procurement strategies. The challenge lies in navigating fluctuating market rates, diverse sourcing options, and the complexities of supplier vetting across different regions, particularly in Africa, South America, the Middle East, and Europe. This guide serves as an essential resource for buyers looking to capitalize on the lucrative opportunities presented by air conditioner compressor scrap, offering insights into types, applications, and market dynamics.

Throughout this comprehensive guide, we will delve into the various grades of compressor scrap, their recycling potential, and how to assess their value effectively. Additionally, we will provide actionable strategies for identifying reliable suppliers, understanding cost fluctuations, and leveraging market intelligence to make informed purchasing decisions. With a focus on enhancing your understanding of the global market, this guide empowers B2B buyers to navigate challenges confidently and seize profitable opportunities in the scrap industry. Whether you are based in Brazil, Vietnam, or elsewhere, the insights provided will equip you with the knowledge needed to thrive in the competitive arena of air conditioner compressor scrap trading.

Understanding air conditioner compressor scrap price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sealed Units | Heavy casing, electric motor inside, typically steel outer shell | Appliance recycling, HVAC equipment repair | Pros: High weight leads to better scrap value. Cons: Requires oil drainage and may need disassembly. |

| Compressors from Units | Varies in size; includes both window and central units | HVAC system dismantling, repair facilities | Pros: Can be sold whole for less labor. Cons: Lower return if not dismantled for copper. |

| Industrial Compressors | Larger units with significant copper content | Industrial machinery recycling | Pros: High copper yield and overall weight. Cons: Requires heavy lifting and transportation logistics. |

| Copper-rich Compressors | High copper content, often from larger commercial units | Scrap metal processing, copper recovery | Pros: Excellent return on copper. Cons: Dismantling can be labor-intensive. |

| Mixed Material Units | Contains a mix of metals including aluminum and steel | General scrap metal recycling | Pros: Easy to collect from various sources. Cons: Lower price due to mixed materials. |

What Are Sealed Units and Their Value in B2B Recycling?

Sealed units are commonly found in appliances like refrigerators and air conditioners. They are characterized by their heavy steel casing and an electric motor that typically contains copper. For B2B buyers, the appeal lies in their weight, which translates into a higher scrap price. However, these units require the oil to be drained before recycling, which adds a step to the processing. Buyers should consider the logistics of transportation and the need for proper handling to maximize value.

How Do Compressors from Air Conditioning Units Differ?

Compressors sourced from window or central air conditioning units vary in size and design. These units can often be sold whole, minimizing labor costs associated with dismantling. While this may simplify the recycling process, buyers should be aware that the return on investment may be lower compared to those that are disassembled for copper extraction. Understanding the type of unit being processed is crucial for determining its resale value in the scrap market.

What Are the Advantages of Industrial Compressors?

Industrial compressors are larger and generally contain a significant amount of copper. They are primarily used in heavy machinery and HVAC systems, making them valuable for B2B buyers focused on industrial applications. The high copper yield and overall weight make these compressors a lucrative option for scrap metal recycling. However, the logistics of handling and transporting these heavy units can pose challenges, and buyers must be prepared for the associated costs.

Why Are Copper-rich Compressors Considered Ideal for Scrap?

Copper-rich compressors, often found in larger commercial units, are highly sought after for their excellent scrap value. The high copper content can lead to a significant return on investment, making these units attractive for B2B buyers in the recycling sector. However, dismantling these compressors can be labor-intensive, and companies must weigh the effort against the potential profit. Understanding the market demand for copper can help buyers make informed decisions.

How Do Mixed Material Units Impact Scrap Value?

Mixed material units contain various metals, including aluminum and steel, which can complicate the recycling process. While these units are easy to collect from diverse sources, their value is generally lower due to the mixture of materials. B2B buyers should consider the processing costs and potential lower returns when dealing with mixed material units. However, their availability can provide a steady supply for recycling operations, making them a practical choice for scrap metal processors.

Key Industrial Applications of air conditioner compressor scrap price

| Industry/Sector | Specific Application of air conditioner compressor scrap price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC Recycling | Recovery of metals (copper, steel) from compressors | Reduces waste and generates revenue from scrap materials | Ensure compliance with local regulations on hazardous materials |

| Automotive Manufacturing | Use of recycled metals in vehicle components | Cost savings on raw materials and reduced environmental impact | Assess quality and purity of recycled metals |

| Electronics Manufacturing | Extraction of copper for circuit boards | Lowers production costs and improves sustainability | Evaluate the reliability of scrap suppliers and logistics |

| Construction | Repurposing metals in structural applications | Contributes to sustainable building practices | Verify the source and quality of scrap materials |

| Renewable Energy | Use of recycled materials in solar and wind energy systems | Enhances sustainability and supports green initiatives | Ensure material meets specific industry standards |

How is ‘air conditioner compressor scrap price’ utilized in HVAC Recycling?

In HVAC recycling, air conditioner compressor scrap is crucial for recovering valuable metals such as copper and steel. Businesses specializing in recycling can extract these materials from compressors, significantly reducing waste while generating revenue. For international buyers, especially in regions like Africa and South America, sourcing reliable suppliers who can ensure compliance with local environmental regulations is essential. Additionally, understanding the fluctuating scrap prices can help in making informed purchasing decisions.

What role does ‘air conditioner compressor scrap price’ play in Automotive Manufacturing?

The automotive industry frequently repurposes recycled metals from air conditioner compressors for manufacturing components. By utilizing these materials, companies can lower their raw material costs and minimize their environmental footprint. For businesses in Europe and the Middle East, it is vital to assess the quality and purity of the recycled metals to meet stringent industry standards. Establishing long-term relationships with trusted suppliers can also enhance supply chain reliability.

How does ‘air conditioner compressor scrap price’ benefit Electronics Manufacturing?

In electronics manufacturing, the extraction of copper from air conditioner compressors is particularly valuable for producing circuit boards. The use of recycled copper helps manufacturers reduce production costs while supporting sustainability initiatives. Buyers from regions like Brazil and Vietnam should focus on sourcing from suppliers that can provide consistent quality and reliable logistics. Additionally, understanding market trends in scrap pricing can aid in strategic procurement.

In what ways can ‘air conditioner compressor scrap price’ be repurposed in Construction?

The construction industry can repurpose metals extracted from air conditioner compressors for various structural applications. This practice not only contributes to sustainable building efforts but also helps contractors save on material costs. For international buyers, ensuring the quality and source of scrap materials is critical to maintaining construction standards. Collaborating with local recycling facilities can also streamline sourcing and reduce transportation costs.

How is ‘air conditioner compressor scrap price’ relevant to Renewable Energy initiatives?

Renewable energy sectors, such as solar and wind energy, increasingly utilize recycled materials from air conditioner compressors. These materials enhance sustainability and support green initiatives, aligning with global efforts to reduce carbon footprints. For businesses in regions like the Middle East and Europe, it is essential to ensure that the recycled materials meet specific industry standards to guarantee performance and safety. Establishing partnerships with reputable scrap suppliers can also facilitate access to high-quality materials.

3 Common User Pain Points for ‘air conditioner compressor scrap price’ & Their Solutions

Scenario 1: Fluctuating Scrap Prices Create Uncertainty

The Problem: B2B buyers often face the challenge of fluctuating scrap prices for air conditioner compressors, which can significantly affect their profit margins. Prices can vary widely based on market demand, global economic conditions, and regional differences. This unpredictability complicates budgeting and financial forecasting for businesses that rely heavily on the sale of scrap metal. Buyers may find themselves in a situation where they purchase compressors at a high price only to sell them at a lower rate due to market changes.

The Solution: To mitigate the impact of fluctuating scrap prices, B2B buyers should establish a robust pricing strategy that incorporates regular market analysis. This involves subscribing to industry newsletters, utilizing scrap price tracking apps, or partnering with scrap yards that provide daily updates on prices. Additionally, buyers can build relationships with multiple scrap metal recyclers to ensure they have options when it comes to selling their compressors. By diversifying their buyer network and utilizing historical price data to forecast trends, businesses can make more informed decisions, minimizing the risk of financial loss.

Scenario 2: Difficulty in Identifying Quality Compressors

The Problem: Another common issue for B2B buyers is the difficulty in identifying quality air conditioner compressors that hold value for scrap. With numerous models and types available, buyers may struggle to distinguish between those that will yield a higher return and those that are not worth the investment. This can lead to wasted resources and missed opportunities, especially for companies that need to manage inventory efficiently.

The Solution: To address this challenge, B2B buyers should invest in training their teams on the characteristics of high-value compressors. This can include understanding the differences between sealed units and other types, as well as recognizing which brands or models are more sought after in the scrap market. Additionally, creating a checklist or guide that outlines key features and specifications to look for can streamline the purchasing process. Collaborating with experienced scrap dealers can also provide valuable insights into market demands, helping buyers make better-informed decisions about which compressors to acquire.

Scenario 3: Environmental Compliance and Safe Disposal

The Problem: B2B buyers are increasingly concerned about environmental regulations and the safe disposal of air conditioner compressors, which often contain hazardous materials like refrigerants and oils. Non-compliance with local and international regulations can result in hefty fines and damage to a company’s reputation. This concern is particularly pronounced in regions with stringent environmental laws, making it essential for businesses to navigate these regulations effectively.

The Solution: To ensure compliance with environmental standards, B2B buyers should familiarize themselves with local regulations concerning the disposal of air conditioner compressors. This includes understanding the proper procedures for draining refrigerants and oils before scrapping. Buyers can work with certified recycling facilities that adhere to environmental guidelines, ensuring that all materials are processed responsibly. Implementing an internal compliance program that includes regular training and audits can further enhance a company’s commitment to environmental stewardship. By taking these proactive steps, businesses not only protect themselves from legal repercussions but also enhance their brand image in an increasingly eco-conscious market.

Strategic Material Selection Guide for air conditioner compressor scrap price

What Are the Key Materials in Air Conditioner Compressors and Their Scrap Value?

When evaluating the scrap value of air conditioner compressors, understanding the materials involved is crucial for B2B buyers. The primary materials found in these compressors include steel, copper, aluminum, and various plastics. Each material has unique properties, advantages, and disadvantages that can influence the overall scrap price and marketability.

How Does Steel Affect the Scrap Price of Air Conditioner Compressors?

Steel is the primary structural material used in air conditioner compressors. It provides strength and durability, making it suitable for high-pressure applications. Steel typically has a high tensile strength and good resistance to deformation under stress, which is essential for compressor performance.

Pros: Steel is relatively inexpensive and widely available, making it a cost-effective choice for manufacturers. Its durability ensures that compressors can withstand harsh operating conditions.

Cons: While steel is strong, it is prone to corrosion if not properly coated or treated. This can impact its longevity and scrap value, especially in humid or corrosive environments.

Impact on Application: Steel’s high melting point allows it to perform well under the heat generated during compressor operation. However, its weight can be a disadvantage in applications where lightweight materials are preferred.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of local recycling regulations and standards for steel scrap, such as ASTM specifications. Compliance with these standards can affect the resale value of the scrap.

What Role Does Copper Play in Compressor Scrap Value?

Copper is a crucial component in the electric motors of air conditioner compressors. It is known for its excellent electrical conductivity and thermal properties, making it ideal for efficient energy transfer.

Pros: Copper’s high scrap value makes it a significant contributor to the overall worth of a compressor. Its recyclability and demand in various industries enhance its marketability.

Cons: The extraction of copper from compressors can be labor-intensive, requiring disassembly. This process may not always yield a high volume of copper compared to the effort involved.

Impact on Application: Copper’s thermal conductivity ensures efficient heat dissipation, which is vital for compressor performance. However, its susceptibility to corrosion can be a concern in certain environments.

Considerations for International Buyers: Buyers in Europe and the Middle East should consider the fluctuating market prices for copper and the importance of adhering to recycling standards, such as those outlined by the European Union’s Waste Electrical and Electronic Equipment (WEEE) Directive.

How Does Aluminum Contribute to the Scrap Value of Air Conditioner Compressors?

Aluminum is often used in the manufacturing of compressor housings and heat exchangers due to its lightweight and corrosion-resistant properties.

Pros: Its low density makes aluminum an attractive option for reducing overall weight, which can lead to lower shipping costs. Additionally, aluminum is highly resistant to corrosion, extending the life of the compressor.

Cons: While aluminum is valuable, its scrap price is generally lower than that of copper. Moreover, the manufacturing process can be more complex, which may increase production costs.

Impact on Application: Aluminum’s thermal conductivity is beneficial for heat exchange applications, but its lower strength compared to steel can be a limiting factor in high-stress scenarios.

Considerations for International Buyers: Buyers from Brazil and Vietnam should be mindful of local market conditions and recycling capabilities for aluminum, as well as international standards like ISO for material quality.

What About the Plastics Used in Air Conditioner Compressors?

Plastics are commonly used for insulation and housing components within compressors. They provide thermal insulation and protect sensitive components from environmental factors.

Pros: Plastics are lightweight and can be molded into complex shapes, making them versatile for various applications. They are also resistant to corrosion and can be cost-effective.

Cons: The scrap value of plastics is generally lower than that of metals, and they can be challenging to recycle due to the need for proper sorting and processing.

Impact on Application: While plastics help in insulation, their lower mechanical strength may not be suitable for all compressor designs, especially in high-pressure applications.

Considerations for International Buyers: Buyers should consider the environmental regulations regarding plastic recycling in their regions, especially in Europe, where stringent guidelines are in place.

Summary Table of Key Materials in Air Conditioner Compressors

| Material | Typical Use Case for air conditioner compressor scrap price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components of compressors | Durable and cost-effective | Prone to corrosion | Low |

| Copper | Electric motors and wiring | High scrap value and excellent conductivity | Labor-intensive extraction process | High |

| Aluminum | Housing and heat exchangers | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Plastics | Insulation and housing components | Lightweight and versatile | Lower scrap value and recycling challenges | Low |

This guide provides valuable insights into the strategic material selection for air conditioner compressor scrap. Understanding these materials can help international B2B buyers optimize their purchasing and recycling strategies.

In-depth Look: Manufacturing Processes and Quality Assurance for air conditioner compressor scrap price

What Are the Main Stages of Manufacturing Processes for Air Conditioner Compressors?

The manufacturing process of air conditioner compressors involves several critical stages, each contributing to the final product’s quality and efficiency. Understanding these stages is essential for B2B buyers looking to evaluate the potential value of compressor scrap.

-

Material Preparation: The process begins with sourcing high-quality raw materials, primarily metals like steel for the casing and copper for the motor windings. Suppliers often conduct material inspections to ensure compliance with industry specifications. For instance, copper quality can significantly impact the scrap value, making it crucial for buyers to verify material grades.

-

Forming: In this stage, the raw materials are shaped into specific components. Techniques such as stamping, machining, and die-casting are commonly employed. Stamping is used for creating the compressor’s casing, while machining is used for precision parts like the rotor and stator. B2B buyers should inquire about the forming techniques used, as these can influence the durability and efficiency of the final product.

-

Assembly: Following the forming stage, components are assembled to create the complete compressor unit. This includes fitting the motor, connecting the electrical components, and sealing the unit to prevent refrigerant leakage. Automated assembly lines are often utilized to enhance precision and reduce production time. Buyers should consider the assembly processes to understand potential weaknesses in the unit that could affect its performance over time.

-

Finishing: The final stage involves surface treatments and quality checks. Components may be coated to prevent corrosion, and the entire unit is tested for leaks and operational efficiency. This stage is crucial, as defects can lead to significant performance issues. Buyers should ensure that suppliers have robust finishing processes that comply with international standards.

How Is Quality Assurance Implemented in Air Conditioner Compressor Manufacturing?

Quality assurance (QA) is vital in ensuring that air conditioner compressors meet both performance and safety standards. It involves systematic processes and checkpoints to maintain product integrity throughout the manufacturing cycle.

-

International Standards and Certifications: Many manufacturers adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards indicates a commitment to quality and customer satisfaction. Additionally, industry-specific certifications like CE for European markets or API for oil and gas applications can further validate product quality.

-

Quality Control Checkpoints: Effective QA processes include several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival to ensure they meet specified requirements. Non-compliance can lead to defective products later in the manufacturing process.

-

In-Process Quality Control (IPQC): During production, regular inspections are conducted to monitor the manufacturing process. This includes checking tolerances, dimensions, and assembly accuracy to catch defects early.

-

Final Quality Control (FQC): Once the units are assembled, they undergo rigorous testing to ensure they meet operational standards. This may involve performance testing under simulated operational conditions.

- Testing Methods for Quality Assurance: Various testing methods are employed to evaluate compressor performance, including:

- Leak Testing: Ensures that the compressor is sealed correctly and does not leak refrigerants.

- Vibration Analysis: Monitors operational stability and identifies potential failures.

- Thermal Testing: Assesses the compressor’s efficiency under different temperature conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensure reliable sourcing of air conditioner compressors.

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, quality control systems, and compliance with international standards. This firsthand observation can help identify potential risks and ensure that the supplier maintains high-quality production practices.

-

Quality Reports and Certifications: Buyers should request detailed quality assurance documentation, including test reports, compliance certificates, and historical data on defect rates. These documents provide insight into the supplier’s quality management practices and reliability.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. These inspections can cover various aspects, including material quality, production processes, and final product evaluations.

-

Quality Control Nuances for International Buyers: Understanding local regulations and industry standards in the supplier’s country is essential. For instance, certain regions may have specific environmental regulations impacting manufacturing processes. Buyers should familiarize themselves with these nuances to ensure compliance and mitigate risks.

Conclusion

Navigating the manufacturing processes and quality assurance protocols for air conditioner compressors is crucial for B2B buyers seeking to maximize the value of compressor scrap. By understanding the stages of manufacturing, quality control checkpoints, and verification methods, international buyers can make informed decisions that align with their business needs. This knowledge not only aids in securing high-quality products but also enhances the overall efficiency of their supply chain operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air conditioner compressor scrap price’

To effectively navigate the procurement of air conditioner compressor scrap, it’s essential to follow a structured approach. This guide provides B2B buyers with a practical checklist to ensure they secure the best prices and quality materials while minimizing risk.

Step 1: Research Current Market Prices

Understanding the current market prices for air conditioner compressor scrap is crucial for negotiation. Prices fluctuate based on factors like location, demand, and global metal prices. Utilize reliable online resources or local scrap yards to gather data on current pricing trends and historical values.

- Tip: Track prices over a period (30 days or more) to identify patterns that may inform your purchasing decisions.

Step 2: Identify Reliable Suppliers

Finding trustworthy suppliers is vital for ensuring consistent quality and pricing. Look for suppliers with a solid reputation in the industry and positive reviews from other buyers.

- Sub-bullets:

- Request references from existing clients, particularly those in your region.

- Verify their business licenses and certifications to ensure they adhere to industry standards.

Step 3: Evaluate Supplier Certifications

Before entering into an agreement, verify that your supplier holds the necessary certifications. This ensures compliance with local and international regulations, particularly regarding environmental standards.

- Tip: Check for certifications like ISO 14001, which indicates effective environmental management, or any regional certifications relevant to scrap metal processing.

Step 4: Assess Material Quality

Quality of the scrap is a key factor in determining its value. Inspect the air conditioner compressors for any visible damage, excessive rust, or oil leaks, which can affect scrap prices.

- Sub-bullets:

- Ensure that the compressors are drained of oil to avoid additional costs or complications during processing.

- Request samples if possible, or arrange for a visit to inspect the materials firsthand.

Step 5: Negotiate Terms Clearly

Once you’ve identified a potential supplier, it’s time to negotiate terms. Be clear about your expectations regarding pricing, delivery schedules, and payment terms.

- Tip: Document all agreements in writing to avoid misunderstandings. Clarify who is responsible for transportation and any associated costs.

Step 6: Implement a Quality Control Process

Establish a quality control process for incoming materials. This ensures that the scrap received meets your specifications and reduces the risk of processing issues later on.

- Sub-bullets:

- Set criteria for acceptable quality based on your production needs.

- Train staff on how to identify acceptable and unacceptable materials.

Step 7: Maintain Open Communication

Once you’ve established a supplier relationship, maintain open lines of communication. Regularly discuss any changes in pricing, availability, or quality issues to ensure a smooth transaction process.

- Tip: Schedule periodic reviews of supplier performance and market conditions to adapt your sourcing strategy as needed.

By following this checklist, B2B buyers can effectively procure air conditioner compressor scrap, ensuring they receive quality materials at competitive prices while establishing strong supplier relationships.

Comprehensive Cost and Pricing Analysis for air conditioner compressor scrap price Sourcing

What Are the Key Cost Components in Air Conditioner Compressor Scrap Pricing?

Understanding the cost structure of air conditioner compressor scrap pricing is essential for B2B buyers aiming to make informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margin.

-

Materials: The base material in air conditioner compressors includes metals like copper, steel, and aluminum. The scrap value of these materials fluctuates based on market demand, making it a significant factor in overall pricing. Buyers should stay updated on current scrap metal prices, as these can vary widely across regions.

-

Labor: Labor costs involve the processing of compressors, including the time taken to dismantle units and separate valuable materials. Skilled labor may command higher wages, impacting the overall cost. Buyers should consider the efficiency of their suppliers’ labor force, as this can influence lead times and pricing.

-

Manufacturing Overhead: This includes expenses related to facilities, equipment, and utilities. Suppliers with higher operational costs may pass these expenses onto buyers. Understanding a supplier’s overhead can provide insights into their pricing strategy.

-

Tooling and Quality Control (QC): Tools and processes required for extracting usable materials from compressors affect pricing. Suppliers that invest in high-quality tools for dismantling and rigorous QC processes may charge a premium, but they often provide better quality materials and reduced contamination risks.

-

Logistics: Transportation costs are crucial, especially for international buyers. Shipping costs can vary based on distance, mode of transport, and local regulations. It’s essential to factor in these costs when evaluating total pricing.

-

Margin: Supplier profit margins will vary based on their market position, demand, and competition. Understanding typical margins in the industry can help buyers negotiate better prices.

What Influences the Price of Air Conditioner Compressor Scrap?

Several factors influence the pricing of air conditioner compressor scrap, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract better pricing due to economies of scale. Suppliers are typically more willing to negotiate on price for bulk purchases.

-

Specifications and Customization: Customized scrap solutions or specific quality requirements may come at a higher price. Buyers should clearly communicate their needs to avoid unexpected costs.

-

Materials and Quality Certifications: The type of materials and the presence of certifications (e.g., ISO standards) can significantly influence price. Higher quality materials or those with specific certifications may command a premium.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a proven track record may charge more, but they often provide more consistent quality and service.

-

Incoterms: The choice of Incoterms affects shipping responsibilities and costs. Buyers should ensure they understand the implications of the chosen terms on overall pricing.

What Tips Can Help Buyers Negotiate Better Prices?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance negotiation outcomes and cost-efficiency.

-

Research Market Prices: Stay informed about current market conditions and scrap metal prices in various regions. This knowledge can provide leverage during negotiations.

-

Assess Total Cost of Ownership (TCO): Look beyond initial purchase prices. Consider transportation, handling, and potential recycling costs to evaluate the overall cost-effectiveness of sourcing decisions.

-

Negotiate Terms: Engage in discussions about payment terms, delivery schedules, and packaging to find mutually beneficial arrangements. Flexibility in these areas can sometimes lead to better pricing.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and service. Regular communication and transparency can foster trust and collaboration.

-

Understand Regional Pricing Nuances: Be aware of local economic conditions and regulations that may affect pricing. Understanding regional variations can help buyers navigate negotiations effectively.

In conclusion, a comprehensive understanding of the cost structure, pricing influencers, and negotiation strategies is essential for B2B buyers looking to source air conditioner compressor scrap effectively. By applying these insights, businesses can optimize their sourcing strategies and improve their bottom line.

Alternatives Analysis: Comparing air conditioner compressor scrap price With Other Solutions

Understanding Alternatives to Air Conditioner Compressor Scrap Price

When considering the value of air conditioner compressor scrap, it’s essential to explore alternative solutions that can provide similar benefits. This analysis compares the pricing of scrap compressors with other viable options in the recycling and waste management sector. Understanding these alternatives can help international B2B buyers make informed decisions based on their specific operational needs and market conditions.

| Comparison Aspect | Air Conditioner Compressor Scrap Price | Alternative 1: Used Equipment Resale | Alternative 2: Recovery of Refrigerants |

|---|---|---|---|

| Performance | Moderate returns based on weight and material composition | High returns if well-maintained and in demand | Value recovery from refrigerants can be high |

| Cost | Low cost of entry; potential for high yields | Initial investment in maintenance and refurbishment | Variable costs; depends on recovery technology |

| Ease of Implementation | Requires minimal tools for scrap collection | Requires expertise in refurbishment | Requires specialized equipment and training |

| Maintenance | Minimal ongoing maintenance; mainly transport | Ongoing maintenance for resale value | Regular maintenance of recovery systems needed |

| Best Use Case | Ideal for businesses focusing on recycling and material recovery | Suitable for businesses looking to upgrade or replace equipment | Best for companies in HVAC or refrigeration sectors needing efficient refrigerant management |

Detailed Breakdown of Alternatives

Alternative 1: Used Equipment Resale

Reselling used air conditioning equipment can yield significant profits, particularly if the items are refurbished and meet current standards. The resale market can be lucrative, especially in regions experiencing rapid industrial growth or equipment scarcity. However, it requires initial investment in refurbishment and an understanding of market demand. Buyers must also consider ongoing maintenance to keep equipment in good condition, which can complicate the operational model.

Alternative 2: Recovery of Refrigerants

Recovering refrigerants from air conditioning systems is another viable option. This method not only provides a financial return but also supports environmental regulations by ensuring that harmful substances are disposed of correctly. The recovery process requires specialized equipment and training, which can pose a barrier to entry for some businesses. However, as regulations tighten globally, investing in refrigerant recovery can become increasingly beneficial, particularly for HVAC companies that need to comply with environmental standards.

Conclusion: Choosing the Right Solution for Your Business Needs

In selecting the best solution, B2B buyers should assess their operational capabilities, market conditions, and environmental responsibilities. The air conditioner compressor scrap price offers a straightforward approach to recycling with low entry costs and minimal maintenance. In contrast, the resale of used equipment can provide higher returns with a greater investment of time and resources, while refrigerant recovery aligns with sustainability goals but requires specialized knowledge. Ultimately, the right choice will depend on the specific business model, regional market dynamics, and commitment to environmental stewardship.

Essential Technical Properties and Trade Terminology for air conditioner compressor scrap price

What are the Key Technical Properties of Air Conditioner Compressors in Scrap Pricing?

Understanding the technical properties of air conditioner compressors is crucial for B2B buyers looking to maximize their scrap value. Here are some essential specifications to consider:

-

Material Composition

Air conditioner compressors are primarily composed of steel, aluminum, and copper. The casing is typically made of steel, while the internal components, including the motor and wiring, often contain copper. The value of scrap compressors is significantly influenced by the current market prices of these metals. B2B buyers should assess the material composition to estimate the potential scrap value accurately. -

Weight

The weight of the compressor is a critical factor that affects scrap pricing. Heavier compressors often yield more scrap metal, leading to higher prices. For example, a large commercial compressor may weigh up to 80 pounds, offering more copper and steel for recycling. Buyers should consider the weight when negotiating prices, as heavier units can provide a better return on investment. -

Condition and Maintenance

The condition of the compressor plays a significant role in its scrap value. Compressors that are intact and have not suffered from significant damage or corrosion tend to fetch higher prices. Buyers should inspect the units for oil leaks or rust, as these factors can decrease the overall value. Proper maintenance prior to scrapping can enhance the marketability of these units. -

Energy Efficiency Rating

Although primarily a concern for operational compressors, energy efficiency ratings can influence the scrap value indirectly. Compressors with higher efficiency ratings may contain more valuable components, making them more desirable for scrap. Understanding these ratings can help buyers identify potentially valuable units for recycling. -

Type of Compressor

There are various types of air conditioning compressors, such as reciprocating, rotary, and scroll compressors. Each type has different internal structures and material compositions, which can affect their scrap value. Buyers should be familiar with the different types to make informed decisions and maximize their returns.

What are Common Trade Terminologies Related to Air Conditioner Compressor Scrap Pricing?

Familiarity with industry-specific jargon can enhance communication and negotiation effectiveness. Here are some key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s product. In the context of scrap, knowing whether a compressor is OEM can affect its perceived value and resale potential. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For scrap compressors, understanding the MOQ can help buyers negotiate better terms, especially when purchasing in bulk. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for specific quantities of products. B2B buyers should prepare RFQs that include detailed specifications of the compressors they wish to purchase to receive accurate quotes. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in shipping transactions. Understanding Incoterms is essential for B2B buyers to clarify shipping costs and responsibilities when importing or exporting scrap compressors. -

Scrap Value

This term refers to the monetary worth of materials that can be recycled. B2B buyers should keep track of market trends to understand how fluctuations in metal prices can affect the scrap value of air conditioner compressors. -

Recycling Rate

The recycling rate indicates the percentage of a product that can be reused or recycled. Knowing the recycling rate of compressors can help buyers assess the sustainability of their scrap operations and the potential profitability of their purchases.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions, negotiate better prices, and ultimately enhance their profitability in the air conditioner compressor scrap market.

Navigating Market Dynamics and Sourcing Trends in the air conditioner compressor scrap price Sector

What Are the Key Drivers Influencing the Air Conditioner Compressor Scrap Price Market?

The air conditioner compressor scrap price market is currently influenced by several global drivers that shape demand and supply dynamics. Increasing urbanization and rising temperatures, particularly in regions like Africa and South America, are driving a surge in air conditioning installations. This, in turn, leads to a higher volume of compressors reaching their end-of-life stage, presenting opportunities for scrap recovery. Additionally, fluctuating metal prices, especially for copper and steel, directly impact the profitability of scrap sales, making it essential for international buyers to stay updated on market trends.

Emerging technologies such as advanced sorting and processing equipment are enhancing the efficiency of scrap metal recycling operations. Innovations in logistics and supply chain management, driven by digital platforms, are also simplifying the sourcing process for international buyers. Blockchain technology is gaining traction, providing transparency in transactions and ensuring traceability in the supply chain, which is crucial for compliance with local and international regulations.

In regions like Europe, stringent regulations on waste management and recycling are further driving the need for responsible sourcing practices. Buyers from the Middle East and South America are increasingly looking for suppliers who can provide reliable pricing and consistent quality, making it essential for sellers to maintain transparency in pricing structures. Understanding these market dynamics is key for B2B buyers aiming to optimize their sourcing strategies and capitalize on the growing air conditioner compressor scrap market.

How Does Sustainability Impact Sourcing Trends for Air Conditioner Compressor Scrap?

Sustainability has become a pivotal concern in the sourcing of air conditioner compressor scrap, influencing buyer preferences and supplier practices. The environmental impact of improper disposal of compressors, which contain hazardous materials, has led to increased regulatory scrutiny across various regions. As a result, B2B buyers are now prioritizing suppliers who adhere to environmentally sound practices and demonstrate compliance with local regulations regarding electronic waste management.

Ethical sourcing is also gaining prominence, with companies seeking to align their procurement strategies with corporate social responsibility (CSR) goals. This trend emphasizes the importance of establishing supply chains that are not only economically viable but also socially responsible. Buyers are encouraged to seek suppliers with certifications such as R2 (Responsible Recycling) or e-Stewards, which validate their commitment to responsible recycling practices.

Moreover, the push for ‘green’ materials is reshaping sourcing strategies. Companies are increasingly interested in recycled metals that contribute to a circular economy, reducing the need for virgin materials and lowering their carbon footprint. By focusing on sustainability and ethical sourcing, international B2B buyers can enhance their brand reputation while meeting the growing consumer demand for environmentally friendly products.

What Is the Historical Context of Air Conditioner Compressor Scrap Pricing?

The pricing of air conditioner compressor scrap has evolved significantly over the past few decades, driven by technological advancements and shifting market demands. Initially, the scrap value of compressors was primarily linked to the weight of the metal components, particularly steel. As recycling technologies improved, the focus shifted towards the extraction of valuable materials like copper and aluminum, which significantly increased the profitability of scrapping compressors.

During the early 2000s, the rise in global demand for copper, driven by its use in electronics and renewable energy technologies, led to a surge in compressor scrap prices. This trend was further amplified by the growing awareness of environmental sustainability, which encouraged more efficient recycling practices. Today, international B2B buyers are not only concerned with the immediate scrap value but also with the long-term sustainability of their sourcing decisions.

As the market continues to evolve, understanding the historical context of air conditioner compressor scrap pricing can provide valuable insights for buyers. By analyzing past trends, companies can better anticipate future market shifts and make informed decisions that align with their business objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of air conditioner compressor scrap price

-

How do I determine the current market price for air conditioner compressor scrap?

To determine the current market price for air conditioner compressor scrap, you should regularly check reliable scrap metal recycling websites or industry reports that provide daily updates on scrap prices. Factors influencing these prices include the type of compressor, market demand, and the current prices of materials like copper and steel. Additionally, engaging with local scrap yards and recyclers can provide insights into regional price variations, enabling you to make informed buying or selling decisions. -

What are the common types of air conditioner compressors, and how do they affect scrap value?

The common types of air conditioner compressors include reciprocating, rotary, and scroll compressors. Each type has different components, affecting its scrap value. For instance, reciprocating compressors often contain more copper and steel, potentially yielding higher scrap prices. Understanding the type of compressor you are dealing with can help you estimate its value and make better purchasing or selling decisions in the international market. -

What should I consider when vetting suppliers for air conditioner compressor scrap?

When vetting suppliers for air conditioner compressor scrap, consider their reputation, reliability, and compliance with environmental regulations. Look for suppliers with certifications in recycling and sustainability practices. Request references from previous clients and check online reviews. Additionally, ensure they provide transparent pricing and quality assurance for the materials supplied. Establishing a good relationship with trustworthy suppliers is crucial for consistent quality and pricing in the long term. -

What are the typical payment terms for purchasing air conditioner compressor scrap?

Payment terms for purchasing air conditioner compressor scrap can vary widely among suppliers. Common practices include payment upon delivery, net 30 days, or partial upfront payments followed by balance upon delivery. Always clarify payment methods accepted, such as bank transfers or letters of credit, particularly in international transactions. Negotiating favorable terms that align with your cash flow needs is important to maintain a healthy business relationship with suppliers. -

How can I ensure quality assurance when sourcing air conditioner compressor scrap?

To ensure quality assurance when sourcing air conditioner compressor scrap, establish clear specifications regarding the type and condition of the scrap you require. Request certifications or documentation that verify the material’s quality and compliance with international standards. Conducting inspections before shipment or utilizing third-party quality assurance services can further mitigate risks. Building a relationship with suppliers who prioritize quality can enhance your overall purchasing experience. -

What logistics considerations should I keep in mind for importing air conditioner compressor scrap?

When importing air conditioner compressor scrap, consider logistics aspects such as shipping methods, customs regulations, and import duties. Choose a reliable freight forwarder familiar with handling scrap materials to navigate the complexities of international shipping. Additionally, ensure that all necessary documentation, including bills of lading and certificates of origin, is prepared to facilitate smooth customs clearance. Factor in transportation costs to assess the overall profitability of your transactions. -

What is the minimum order quantity (MOQ) typically required for air conditioner compressor scrap?

Minimum order quantities (MOQs) for air conditioner compressor scrap can vary based on the supplier and the nature of the transaction. Some suppliers may impose MOQs to ensure efficiency in processing and shipping. It’s important to communicate your needs clearly and negotiate terms that suit your business model. If your volume is lower than the MOQ, consider collaborating with other buyers to consolidate orders or look for suppliers willing to accommodate smaller quantities. -

How do market fluctuations impact the pricing of air conditioner compressor scrap?

Market fluctuations can significantly impact the pricing of air conditioner compressor scrap due to changes in demand for raw materials, economic conditions, and global market trends. For instance, an increase in demand for copper can drive up prices for compressors containing copper. Staying informed about market trends through industry news and reports can help you anticipate price changes and make strategic buying or selling decisions, ensuring you optimize your investments in scrap materials.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Air Conditioner Compressor Scrap Price Manufacturers & Suppliers List

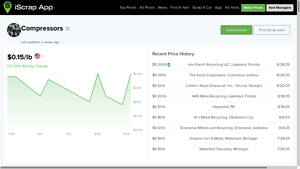

1. iScrap App – Compressor Scrap Prices

Domain: iscrapapp.com

Registered: 2010 (15 years)

Introduction: Compressors Scrap Price: $0.15/lb (33.33% change) as of September 9, 2025. Recent prices from various scrap yards include: $0.20/lb from Iron Ranch Recycling LLC (Lakeland, FL) on 8/26/25, $0.09/lb from The Kroot Corporation (Columbus, IN) on 8/24/25, $0.12/lb from Carter’s Royal Dispos-all, Inc. (Toccoa, GA) on 8/20/25, and $0.20/lb from HAS Metal Recycling (Lakeland, FL) on 8/18/25. Compressors …

2. Makita – Angle Grinder

Domain: scrapmetalforum.com

Registered: 2010 (15 years)

Introduction: Air conditioner compressors can be valuable for scrapping. A middle-sized compressor from a window air conditioner was opened using an angle grinder with a Makita 1/4 inch high duty blade, taking about 15 minutes. The process involved cutting around the middle and draining the oil. The motor was found to weigh about a pound or more, making it worth salvaging, while the copper extracted was less th…

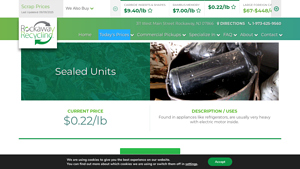

3. Rockaway Recycling – Sealed Units/Compressors

Domain: rockawayrecycling.com

Registered: 2007 (18 years)

Introduction: {“Current Price”:”$0.22/lb”,”Description”:”Sealed Units/Compressors are found in appliances like refrigerators and are usually very heavy with an electric motor inside. They typically have a blackout casing made of steel and contain copper inside the motor. All oil must be drained from the sealed units before they can be accepted for scrap.”,”Usage”:”Sealed Units/Compressors are good to save for s…

4. Reddit – A/C Condenser Compressor

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Compressor from old A/C condenser; worth approximately 20 cents per pound; may contain oil; some scrapyards require a sticker from a heating and cooling contractor indicating proper refrigerant removal.

5. Facebook – AC Unit Recycling

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Recycling a small AC unit, scrap value varies by scrap yard.

6. RecycleInMe – AC Compressor Scrap

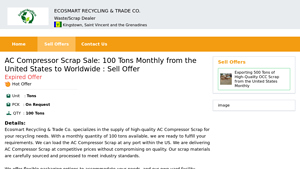

Domain: recycleinme.com

Registered: 2002 (23 years)

Introduction: {“Scrap Type”: “AC Compressor Scrap”, “Quantity”: “100 Tons monthly”, “Packaging”: “On Request”, “Loading Port”: “United States”, “Payment Terms”: “T/T”, “Shipping Terms”: “FOB”, “Preferred Region”: “Worldwide”}

7. Global Recycle – AC Compressor Scrap

Domain: globalrecycle.net

Registered: 2020 (5 years)

Introduction: AC compressor scrap is any unusable air conditioning or refrigeration compressor collected for the purpose of selling for scrap. Compressors are generally stored separately from other scrap metals due to contaminants like oil and residual refrigerant gas. They contain several types of metals including aluminum, steel, cast iron, and copper. AC compressors are sealed units that require a specific r…

8. Scrap Stop – Aluminum-Copper Coils

Domain: myscrapstop.com

Registered: 2011 (14 years)

Introduction: Product: Aluminum-Copper Coils

Location: Scrap Stop, 20749 Prairie St, Chatsworth, CA 91311

Opening Times: Mon – Fri 8:00-4:45pm, Sat 8:00-12:00pm

Contact: 1.818.734.6654, [email protected]

Scrap Pricing:

– Clean Aluminum and Copper Coil: ~$1.60 per pound

– Dirty Aluminum and Copper Coil: ~$1.30 per pound

Average Weight from Disassembling One Air Conditioner:

– Copper Wire: ~2 pounds

– #2 Copper …

Strategic Sourcing Conclusion and Outlook for air conditioner compressor scrap price

In conclusion, understanding the dynamics of air conditioner compressor scrap prices is essential for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. The current market trends indicate a fluctuation influenced by material composition and global demand. Buyers should strategically source compressors with a keen eye on their scrap value, which includes considerations of copper content and the potential for recycling.

Investing in strategic sourcing not only maximizes profitability but also fosters sustainable practices in waste management. By staying informed about daily price updates and historical trends, companies can better navigate the complexities of the scrap metal market.

As we look to the future, the demand for recycled materials is expected to grow, driven by both economic and environmental factors. B2B buyers are encouraged to establish reliable partnerships with scrap processors and recyclers who can provide transparency and competitive pricing. Embrace the opportunities that arise from this evolving landscape, and take proactive steps to secure your position in the market. Your commitment to strategic sourcing will not only enhance your bottom line but also contribute positively to the global recycling efforts.