A B2B Buyer’s Guide to U Shaped Nail: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for u shaped nail

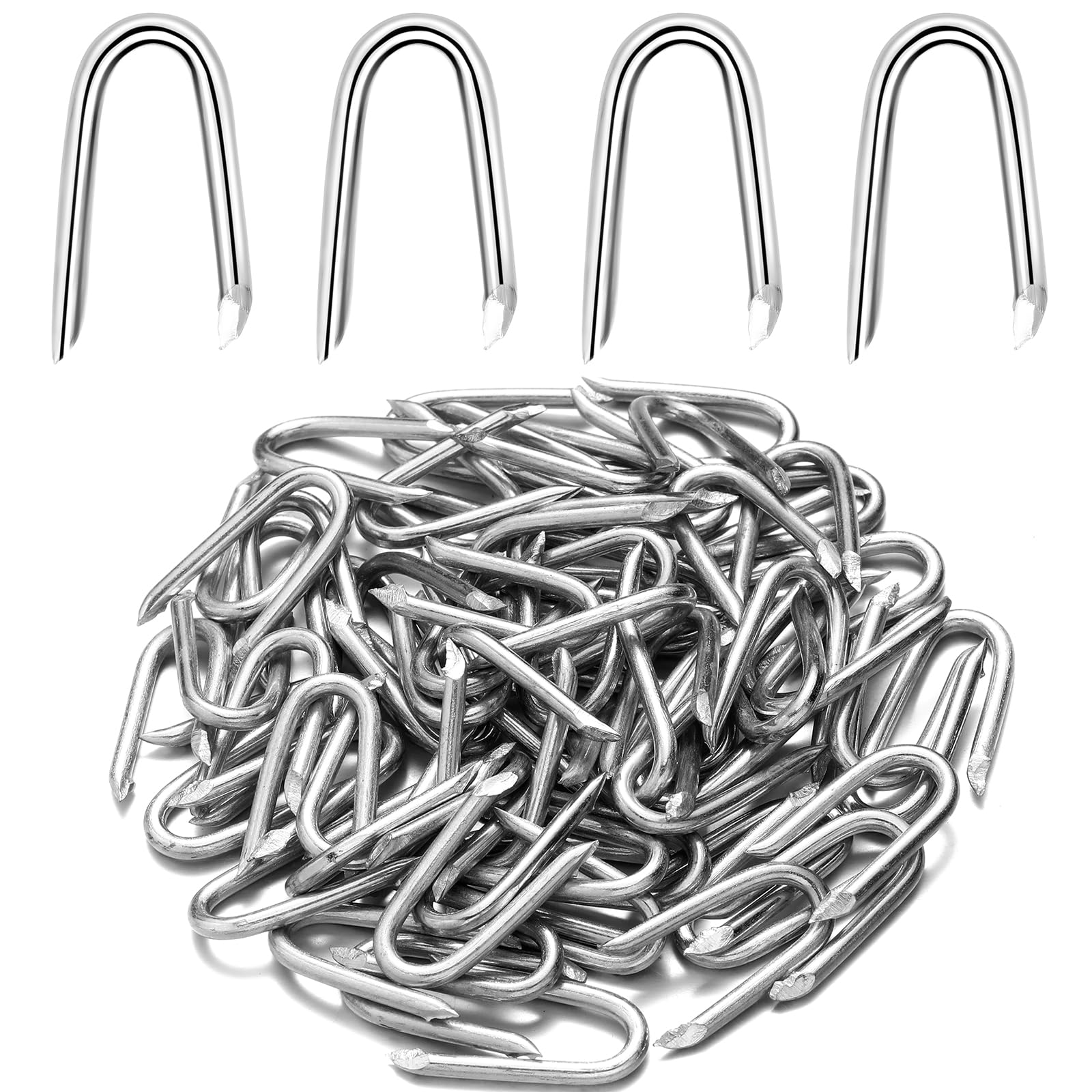

In the ever-evolving global market, sourcing reliable and high-quality U-shaped nails can pose significant challenges for international B2B buyers. Whether you are in construction, agriculture, or garden landscaping, understanding the nuances of U-shaped nails—from their various types and applications to the intricacies of supplier vetting—is crucial for making informed purchasing decisions. This guide serves as a comprehensive resource that delves into the diverse categories of U-shaped nails, including smooth and barbed shank options, and highlights their applications across multiple sectors such as fencing, netting, and horticulture.

Our aim is to equip buyers, particularly those from Africa, South America, the Middle East, and Europe (including Germany and Vietnam), with the insights needed to navigate this competitive landscape. By offering detailed information on pricing structures, quality assessments, and sourcing strategies, this guide empowers businesses to minimize risks and maximize value. Whether you’re looking to enhance the durability of your projects or streamline your supply chain, our expert analysis will help you identify the best suppliers and products to meet your specific needs. Together, let’s unlock the potential of U-shaped nails for your business success.

Understanding u shaped nail Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Galvanized U Nails | Coated for rust resistance; smooth or barbed shank options | Fencing, gardening, netting applications | Pros: Durable, weather-resistant. Cons: May be more expensive than non-galvanized options. |

| Heavy-Duty U Nails | Thicker gauge for increased strength; often barbed | Heavy-duty fencing, agricultural structures | Pros: Superior holding power. Cons: Can be harder to install due to thickness. |

| Plastic Cap U Nails | Integrated plastic cap for added surface area and stability | Securing tarps, fabric, and mesh fencing | Pros: Reduces risk of tearing; easier to install. Cons: Less suitable for heavy-duty applications. |

| Smooth Shank U Nails | Straight shank for easy insertion; available in various lengths | General-purpose fastening in construction | Pros: Versatile and easy to use. Cons: Less grip than barbed options. |

| Barbed U Nails | Features barbs for enhanced holding capacity | Animal coops, trellises, and fencing | Pros: Excellent staying power. Cons: More challenging to remove if needed. |

What Are Galvanized U Nails and Their Applications?

Galvanized U nails are coated to prevent rust, making them ideal for outdoor applications. They come in smooth or barbed shank variants, allowing for flexibility based on project requirements. Businesses engaged in fencing, gardening, or netting applications will find these nails particularly useful due to their durability and resistance to the elements. When purchasing, consider the environmental conditions of the application area to ensure longevity.

How Do Heavy-Duty U Nails Differ from Standard Options?

Heavy-duty U nails are designed with a thicker gauge, providing increased strength and durability. They are often barbed, enhancing their holding capacity, making them suitable for demanding environments such as agricultural structures and heavy fencing. Buyers should assess the specific weight and tension requirements of their projects, as these nails can be more challenging to install but offer superior performance in high-stress applications.

What Are the Advantages of Using Plastic Cap U Nails?

Plastic cap U nails feature an integrated cap that increases surface area, providing extra stability when securing materials like tarps or mesh fencing. These nails are especially beneficial in applications where fabric tearing is a concern. While they are easier to install and reduce the risk of damage, they may not be suitable for heavy-duty tasks. B2B buyers should evaluate their specific project needs when considering this type.

When Should Smooth Shank U Nails Be Used?

Smooth shank U nails are characterized by their straight shank, which allows for easy insertion into various materials. They are versatile and suitable for general-purpose fastening in construction projects. While they lack the grip of barbed options, their ease of use makes them a popular choice for many businesses. Buyers should consider the material being fastened and the required holding power before selecting this type.

Why Choose Barbed U Nails for Your Projects?

Barbed U nails are designed with barbs along the shank, providing excellent holding power, particularly in applications such as animal coops and trellises. Their enhanced grip makes them less likely to pull out under tension, which is crucial for securing fencing and netting. However, they can be more difficult to remove if adjustments are needed. B2B buyers should weigh the benefits of their strong hold against the potential challenges of removal when making a purchasing decision.

Key Industrial Applications of u shaped nail

| Industry/Sector | Specific Application of U Shaped Nail | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Securing Fencing and Netting for Livestock | Enhances livestock security and minimizes animal escapes | Durability against weather conditions; galvanized options preferred for rust resistance. |

| Construction | Attaching Wire Mesh to Wooden Structures | Provides robust support for structures, ensuring stability | Varied sizes and types (smooth or barbed) to suit different materials and applications. |

| Gardening and Horticulture | Fixing Plant Trellises and Garden Fencing | Promotes plant growth and organization in garden layouts | Sourcing for eco-friendly materials; compatibility with various garden types. |

| Animal Husbandry | Building Chicken Coops and Rabbit Hutches | Ensures a safe environment for animals, reducing loss and injury | Need for specific gauge and length based on animal type and structure design. |

| Landscape Design | Securing Ground Covers and Landscape Fabrics | Improves soil retention and plant health in landscaped areas | Consideration of soil type and climate; options for easy removal and reuse. |

How is U Shaped Nail Used in Agriculture for Securing Fencing and Netting?

In the agriculture sector, U shaped nails are essential for securing fencing and netting around livestock areas. They prevent animals from escaping and protect crops from wildlife. The nails are driven into wooden posts, providing a strong hold for barbed or smooth wire fencing. Buyers in regions like Africa and South America should prioritize galvanized options to ensure durability against harsh weather conditions, which can lead to rust and failure of the fencing.

What Role Does U Shaped Nail Play in Construction for Attaching Wire Mesh?

In construction, U shaped nails are widely used for attaching wire mesh to wooden structures. This application is vital for reinforcing walls, roofs, and other frameworks. The nails offer a reliable fastening solution that withstands environmental stresses. Buyers in Europe, particularly in Germany, should consider the specific gauge and length of U shaped nails to match the construction requirements, ensuring structural integrity and compliance with local building codes.

How Can U Shaped Nail Benefit Gardening and Horticulture?

U shaped nails are invaluable in gardening and horticulture for fixing plant trellises and securing fencing around gardens. This application helps organize plant growth and protects crops from pests. International buyers, especially in the Middle East, should focus on sourcing eco-friendly materials that are compatible with organic farming practices. Additionally, the nails must be easy to install and remove, allowing for flexible garden designs.

Why is U Shaped Nail Important for Animal Husbandry?

In animal husbandry, U shaped nails are crucial for constructing safe environments, such as chicken coops and rabbit hutches. They secure the structure, preventing predators from accessing the animals. Buyers from regions like South America should ensure they select nails of appropriate gauge and length based on the specific design and animal type. This ensures the safety and well-being of livestock, ultimately reducing losses.

How Does U Shaped Nail Enhance Landscape Design?

U shaped nails are also used in landscape design for securing ground covers and landscape fabrics, which help with soil retention and promote healthy plant growth. This application is particularly beneficial in regions with challenging soil conditions. Buyers in Europe should consider the climate and soil type when sourcing U shaped nails, as these factors will influence the effectiveness and longevity of the fastening solution.

3 Common User Pain Points for ‘u shaped nail’ & Their Solutions

Scenario 1: Difficulty in Securing Netting for Animal Enclosures

The Problem: B2B buyers in the agriculture and pet care industries often encounter challenges when securing netting around animal enclosures. This can lead to safety issues, as unsecured netting can allow animals to escape or predators to enter. Buyers may find that standard fasteners fail to hold up against wear and tear, especially in outdoor environments where exposure to the elements can degrade materials quickly. The frustration stems from a lack of reliable solutions that ensure both durability and ease of installation.

The Solution: To effectively secure netting, sourcing high-quality galvanized U-shaped nails is crucial. These nails are specifically designed to resist rust and corrosion, making them ideal for outdoor use. When selecting U-shaped nails, buyers should opt for barbed shank designs, which provide superior holding power compared to smooth shanks. It’s advisable to space the nails approximately 4 inches apart to ensure even distribution of tension and strength across the netting. Additionally, consider pre-installing a rope edging around the netting to reinforce the seams. This not only enhances the structural integrity but also simplifies the installation process. By taking these steps, buyers can create a secure and effective enclosure that stands up to the rigors of outdoor conditions.

Scenario 2: Inconsistent Sizing and Quality of U-Shaped Nails

The Problem: Another common pain point for B2B buyers is the inconsistency in the sizing and quality of U-shaped nails from different suppliers. This inconsistency can lead to project delays and increased costs, as mismatched nails may require additional time and resources to rectify. Buyers may also experience frustration when nails bend or break during installation, further complicating the task and potentially leading to unsafe conditions if the netting is not properly secured.

The Solution: To mitigate this issue, B2B buyers should establish relationships with reputable suppliers who offer standardized sizes and consistent quality. When placing orders, it’s essential to specify the exact gauge, length, and type of U-shaped nail required for the project. Buyers should also inquire about the supplier’s quality assurance processes to ensure that the nails meet industry standards. Furthermore, conducting a small trial order can help verify the quality and compatibility of the nails before committing to larger purchases. By prioritizing supplier reliability and maintaining clear specifications, businesses can avoid the headaches associated with inconsistent product quality.

Scenario 3: Challenges in Installation Efficiency

The Problem: Installation efficiency is often a significant concern for contractors and B2B buyers working with U-shaped nails, particularly in large-scale projects. Time-consuming installation processes can lead to increased labor costs and project overruns. Users frequently struggle with manually hammering in nails, especially in dense materials where positioning can be tricky. This not only slows down progress but also raises the risk of damaging the netting or the surrounding structure.

The Solution: To enhance installation efficiency, buyers should consider investing in specialized tools designed for U-shaped nail application. Nail guns that accommodate U-shaped nails can dramatically speed up the process, allowing for quick and consistent placements without the physical strain of manual hammering. When using a nail gun, ensure that the nails are compatible with the tool to avoid jams and misfires. Additionally, training staff on best practices for using these tools can further improve installation speed and quality. By integrating the right tools and techniques, businesses can significantly reduce installation time, leading to cost savings and more successful project outcomes.

Strategic Material Selection Guide for u shaped nail

When selecting materials for U-shaped nails, it is essential to consider their properties, applications, and suitability for different environments. Here, we analyze four common materials used in the manufacturing of U-shaped nails: carbon steel, stainless steel, galvanized steel, and plastic. Each material has unique characteristics that can significantly impact performance and application.

What Are the Key Properties of Carbon Steel U-Shaped Nails?

Carbon steel is a widely used material for U-shaped nails due to its strength and versatility. It typically offers high tensile strength and durability, making it suitable for various applications, including fencing and agricultural use. However, carbon steel is prone to corrosion if not treated, which can limit its lifespan in outdoor environments.

Pros:

– High strength and durability.

– Cost-effective compared to other materials.

Cons:

– Susceptible to rust and corrosion without protective coatings.

– Limited temperature resistance.

For international buyers, especially in humid or coastal regions of Africa and South America, the risk of corrosion is a significant consideration. Compliance with local standards, such as ASTM for the U.S. or DIN for Germany, is crucial to ensure quality.

How Does Stainless Steel Compare for U-Shaped Nails?

Stainless steel offers excellent corrosion resistance, making it ideal for applications exposed to moisture or chemicals. Its durability and aesthetic appeal make it suitable for high-end projects, such as architectural applications or marine environments.

Pros:

– Superior corrosion resistance.

– Long lifespan and minimal maintenance.

Cons:

– Higher cost compared to carbon steel and galvanized options.

– More challenging to manufacture due to its hardness.

For B2B buyers in the Middle East and Europe, where environmental conditions can be harsh, stainless steel U-shaped nails may be the preferred choice despite the higher initial investment. Compliance with international standards like ISO can also enhance marketability.

What Are the Benefits of Galvanized Steel U-Shaped Nails?

Galvanized steel nails are coated with a layer of zinc, providing a barrier against corrosion. This makes them suitable for outdoor applications, such as securing fencing and netting in gardens and agricultural settings.

Pros:

– Good corrosion resistance.

– Cost-effective and widely available.

Cons:

– The zinc coating can wear off over time, especially in harsh conditions.

– Less durable than stainless steel.

For buyers in regions like Africa and South America, where exposure to moisture is common, galvanized steel presents a balanced option. It meets various compliance standards, ensuring that it is suitable for local markets.

Are Plastic U-Shaped Nails a Viable Alternative?

Plastic U-shaped nails are increasingly popular for specific applications, particularly in gardening and landscaping. They are lightweight, resistant to corrosion, and easy to handle, making them user-friendly.

Pros:

– Corrosion-resistant and lightweight.

– Safe for use in sensitive environments, such as organic farming.

Cons:

– Lower tensile strength compared to metal options.

– Limited temperature resistance.

International buyers in Europe and South America may find plastic nails appealing for eco-friendly projects. However, they should ensure compliance with local environmental regulations.

Summary Table of Material Selection for U-Shaped Nails

| Material | Typical Use Case for U Shaped Nail | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Fencing, general construction | High strength and durability | Prone to rust without treatment | Low |

| Stainless Steel | Marine applications, high-end projects | Superior corrosion resistance | Higher cost and manufacturing complexity | High |

| Galvanized Steel | Outdoor fencing, agricultural use | Good corrosion resistance | Zinc coating can wear off | Medium |

| Plastic | Gardening, landscaping | Lightweight and corrosion-resistant | Lower tensile strength | Low |

This guide provides a comprehensive overview of material options for U-shaped nails, helping international B2B buyers make informed decisions tailored to their specific needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for u shaped nail

What Are the Key Stages in the Manufacturing Process of U-Shaped Nails?

The manufacturing of U-shaped nails involves several critical stages that ensure the final product meets the quality and performance expectations of B2B buyers. Understanding these stages can help buyers make informed decisions when selecting suppliers.

1. Material Preparation: What Materials Are Used in U-Shaped Nails?

The primary material for U-shaped nails is carbon steel, chosen for its strength and durability. The steel typically comes in various grades, such as Q195 or Q235, which influence the tensile strength and corrosion resistance of the final product. The raw materials are sourced from reliable suppliers who adhere to international standards to ensure quality.

Once the steel is procured, it undergoes a preparation phase where it is cleaned and cut into specified lengths based on product requirements. The diameter of the wire can vary, typically ranging from 9 to 16 gauge, depending on the intended application.

2. Forming: How Are U-Shaped Nails Shaped and Crafted?

The forming process involves several techniques to create the U shape. Most manufacturers utilize a wire forming machine that bends the steel wire into the desired U shape. This process can include:

- Cold Forming: This technique uses pressure to shape the wire at room temperature, maintaining the material’s strength and integrity.

- Heat Treatment: Depending on the specifications, some manufacturers may apply heat treatment to enhance hardness and durability.

The nails may also be produced with smooth or barbed shanks, depending on the application. Barbed U-nails provide enhanced holding power, making them suitable for applications requiring greater resistance to pull-out forces.

3. Assembly: How Are U-Shaped Nails Finished for Optimal Performance?

After forming, the nails undergo a finishing process, which may include:

- Surface Treatment: U-shaped nails are often galvanized or coated to improve corrosion resistance. Galvanization involves applying a zinc coating to prevent rusting, which is crucial for outdoor applications.

- Quality Control Checks: Each batch of nails is subjected to quality control measures to ensure they meet specifications, including dimensions and surface quality.

In some cases, additional features such as a polished finish or copper plating may be applied to enhance aesthetics and performance.

What Quality Assurance Standards Should B2B Buyers Expect?

Quality assurance is paramount in the manufacturing of U-shaped nails, particularly for international B2B transactions. Buyers should look for suppliers who comply with recognized international standards and industry-specific certifications.

1. What Are the Relevant International Standards?

-

ISO 9001: This is a widely recognized standard for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. Suppliers with ISO 9001 certification demonstrate their commitment to quality control and continuous improvement.

-

CE Marking: For suppliers in Europe, CE marking indicates compliance with EU safety and environmental requirements. This is particularly important for buyers in the European market.

-

API Certification: For applications in oil and gas, suppliers may also need to meet American Petroleum Institute (API) standards, which ensure that products are suitable for high-stress environments.

How Are Quality Control Processes Implemented in U-Shaped Nail Production?

Quality control is integrated throughout the manufacturing process, involving several checkpoints to ensure the final product meets specifications.

1. Incoming Quality Control (IQC)

IQC is the first line of defense, where raw materials are inspected upon arrival at the manufacturing facility. This includes verifying the material type, dimensions, and surface quality. Any materials that do not meet the required standards are rejected.

2. In-Process Quality Control (IPQC)

During the manufacturing process, IPQC measures are taken at various stages, including:

- Monitoring Machine Settings: Ensuring that the forming machines are calibrated correctly to produce nails of the specified dimensions.

- Random Sampling: Conducting random checks on batches of nails to assess their shape, size, and finish.

3. Final Quality Control (FQC)

FQC involves a thorough inspection of the finished product before packaging and shipping. This includes:

- Dimensional Checks: Verifying that the nails meet specified lengths and diameters.

- Strength Testing: Conducting tensile tests to ensure that the nails can withstand the forces they will encounter in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control practices of potential suppliers.

1. Conducting Supplier Audits

Buyers can request audits of the manufacturing facilities to assess compliance with quality standards. This can include reviewing production processes, quality control measures, and certifications.

2. Reviewing Quality Control Reports

Suppliers should provide detailed quality control reports that outline testing methods, results, and compliance with international standards. This transparency helps build trust and confidence in the supplier’s capabilities.

3. Utilizing Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These services can conduct on-site inspections and testing to ensure compliance with agreed specifications.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control is essential for international B2B transactions. Different regions may have varying standards and expectations, which can impact product quality.

1. Regional Standards Compliance

Buyers should be aware of specific regulations in their region. For instance, European buyers may require CE marking, while buyers in North America may focus on ASTM standards. Being informed about these requirements can prevent compliance issues and ensure product acceptance in the target market.

2. Language and Communication Barriers

Effective communication is crucial in international transactions. Buyers should ensure that suppliers can provide documentation and support in a language they understand, reducing the risk of misunderstandings regarding quality expectations.

In summary, the manufacturing processes and quality assurance practices for U-shaped nails are multifaceted and essential for meeting the needs of B2B buyers. By understanding these processes and verification methods, buyers can make informed decisions and establish successful partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘u shaped nail’

This guide provides B2B buyers with a comprehensive checklist for sourcing U-shaped nails, ensuring you make informed purchasing decisions that meet your operational needs. U-shaped nails, or U-nails, are essential fasteners widely used in various applications, from securing fencing to attaching netting in agricultural and construction settings.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. Consider the dimensions, material (such as galvanized steel for rust resistance), and specific applications (e.g., fencing, netting) for which you need the nails. This clarity will streamline your search and help you communicate effectively with potential suppliers.

Step 2: Research and Identify Suppliers

Conduct thorough research to identify potential suppliers specializing in U-shaped nails. Look for manufacturers with a strong reputation in your region or industry. Utilize online platforms, trade shows, and industry directories to compile a list of suppliers who meet your specifications.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, product catalogs, and references from buyers in a similar industry or region. Assess their experience, production capacity, and delivery timelines to ensure they align with your operational needs.

- Check Reviews: Look for customer feedback on quality and service.

- Request Samples: Obtain samples to evaluate the quality and suitability of the nails for your intended use.

Step 4: Verify Compliance and Certifications

Ensure that the suppliers comply with relevant industry standards and possess necessary certifications. This might include ISO certifications or compliance with local regulations. Verification of these credentials helps mitigate risks associated with product quality and safety.

Step 5: Compare Pricing and Payment Terms

Once you have a shortlist of suppliers, compare pricing structures and payment terms. Be cautious of pricing that seems too good to be true; it could indicate inferior quality. Negotiate terms that suit your cash flow and ensure you understand any hidden costs.

- Bulk Discounts: Inquire about bulk purchasing options for cost savings.

- Payment Flexibility: Look for suppliers offering flexible payment terms or credit facilities.

Step 6: Assess Logistics and Shipping Options

Evaluate the logistics capabilities of your chosen suppliers. Consider shipping times, costs, and the reliability of their delivery systems. Efficient logistics are critical to maintaining your production schedules and minimizing downtime.

Step 7: Establish a Communication Channel

Once you select a supplier, establish a clear communication channel. Regular updates on production, shipping status, and any potential issues will foster a strong business relationship and ensure timely resolution of any concerns.

By following this checklist, B2B buyers can confidently navigate the sourcing process for U-shaped nails, ensuring they secure high-quality products that meet their specific needs while building reliable supplier relationships.

Comprehensive Cost and Pricing Analysis for u shaped nail Sourcing

What Are the Key Cost Components in U Shaped Nail Production?

When sourcing U shaped nails, it’s crucial to understand the various cost components involved in their production. The primary cost factors include:

-

Materials: The raw materials, typically carbon steel or galvanized steel, significantly influence the cost. Prices can fluctuate based on market demand and availability. Premium materials might incur higher costs but offer better durability and resistance to corrosion.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. In countries with higher labor costs, such as Germany, total production costs may rise, impacting the final price of the nails.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including factory utilities, equipment depreciation, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Initial setup costs for specialized equipment can be substantial. High-quality tooling can improve production efficiency and product consistency, but these costs need to be amortized over production volume.

-

Quality Control (QC): Implementing stringent QC measures is vital to ensure product reliability. While this may add to costs, it can prevent more significant expenses related to product failures or recalls.

-

Logistics: Transportation and shipping costs, particularly for international buyers, can significantly impact the overall price. Factors such as distance, shipping methods, and customs duties should be considered.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin varies by supplier and can be negotiated based on order volume.

How Do Price Influencers Affect U Shaped Nail Sourcing?

Several factors can influence the pricing of U shaped nails, which B2B buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Suppliers are more willing to negotiate prices for bulk purchases, making it beneficial for companies with substantial needs.

-

Specifications and Customization: Custom specifications, such as specific sizes or finishes (e.g., barbed vs. smooth shank), can lead to increased costs. Buyers should evaluate whether customization is necessary for their application.

-

Material Quality and Certifications: Nails made from higher-quality materials or those that meet specific industry standards (like ASTM certifications) may come at a premium. This investment can enhance product performance, particularly in demanding applications.

-

Supplier Factors: Reliability, reputation, and geographical location of the supplier can affect pricing. Established suppliers might charge higher prices due to their proven track record, but they may also offer better service and product quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international transactions. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost and should be clearly defined in contracts.

What Are Effective Buyer Tips for Sourcing U Shaped Nails Internationally?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, adopting strategic sourcing practices can lead to cost savings:

-

Negotiate Wisely: Build relationships with suppliers and negotiate terms that benefit both parties. Understanding their cost structure can provide leverage in negotiations.

-

Consider Total Cost of Ownership (TCO): Look beyond the purchase price. Evaluate the long-term costs associated with quality, durability, and potential failures. A cheaper product may lead to higher replacement costs.

-

Stay Informed on Pricing Nuances: Be aware of regional market trends and economic factors that can affect pricing. For instance, fluctuations in steel prices can impact costs significantly.

-

Evaluate Logistics Options: Assess shipping methods and timelines. While faster shipping might be more expensive, it can also prevent production delays and associated costs.

-

Engage with Multiple Suppliers: Request quotes from various suppliers to ensure competitive pricing. This practice not only helps in price comparison but also provides insights into the market.

In conclusion, a comprehensive understanding of cost components, price influencers, and effective sourcing strategies is essential for B2B buyers looking to procure U shaped nails efficiently and cost-effectively. As market dynamics evolve, staying informed will empower businesses to make strategic decisions that enhance their supply chain resilience.

Alternatives Analysis: Comparing u shaped nail With Other Solutions

When evaluating options for securing materials such as netting, fencing, or other installations, it’s essential for B2B buyers to consider various alternatives to U-shaped nails. Each solution has its own unique benefits and drawbacks depending on the specific application, material compatibility, and environmental conditions. This analysis will compare U-shaped nails with two viable alternatives: galvanized staples and fencing clips.

| Comparison Aspect | U Shaped Nail | Galvanized Staples | Fencing Clips |

|---|---|---|---|

| Performance | Strong grip; suitable for heavy-duty use | Good for lightweight applications; decent grip | Excellent for quick installations; adjustable |

| Cost | Low cost per unit; bulk options available | Moderate cost; bulk packs offer savings | Higher initial cost; reusable design |

| Ease of Implementation | Requires hammering; may need pre-drilling | Easy to use; can be hammered in without pre-drilling | Simple to install; often requires minimal tools |

| Maintenance | Generally low; occasional replacements needed | Low; if properly installed, minimal upkeep | Moderate; may need replacement if damaged |

| Best Use Case | Heavy-duty fencing, agricultural uses | Garden netting, temporary installations | Quick fence repairs, temporary barriers |

What are the Advantages and Disadvantages of Galvanized Staples Compared to U Shaped Nails?

Galvanized staples are a popular alternative, particularly for lighter installations such as garden netting. They are easy to install and do not require pre-drilling, making them suitable for quick applications. However, their grip strength may not match that of U-shaped nails, particularly under heavy loads. While they can be more cost-effective in smaller quantities, bulk purchases may not yield the same savings as U-shaped nails.

How Do Fencing Clips Compare in Terms of Versatility and Convenience?

Fencing clips provide a highly convenient alternative, especially for temporary installations. They are designed for easy adjustment, allowing users to reposition fencing or netting without needing to remove and replace fasteners. This feature is particularly advantageous in applications requiring flexibility. However, the initial cost of fencing clips is typically higher, and they may not be as robust as U-shaped nails for permanent solutions. Maintenance can also be more involved, as clips can be damaged more easily than nails.

Conclusion: How Can B2B Buyers Select the Right Fastening Solution for Their Needs?

Choosing the right fastening solution ultimately depends on the specific requirements of the project. For heavy-duty applications that demand strong, long-lasting support, U-shaped nails are an excellent choice. If the project involves lighter materials or requires quick installation, galvanized staples might be more appropriate. On the other hand, for temporary solutions or projects needing flexibility, fencing clips could be the best option. B2B buyers should evaluate their specific needs, including load requirements, installation environment, and budget constraints, to make an informed decision.

Essential Technical Properties and Trade Terminology for u shaped nail

What Are the Key Technical Properties of U Shaped Nails?

When considering u shaped nails for B2B applications, understanding their technical properties is crucial for ensuring performance and compatibility with various projects. Here are some essential specifications:

-

Material Grade

U shaped nails are typically made from carbon steel, which provides excellent strength and durability. The specific material grades, such as Q195 and Q235, indicate the tensile strength and flexibility of the nails. For outdoor applications, galvanization is common to prevent rust and corrosion, extending the lifespan of the product. Selecting the right material is vital for applications exposed to moisture or varying environmental conditions. -

Shank Type

U shaped nails come with different shank designs: smooth, single barbed, and double barbed. The barbed versions offer enhanced grip, preventing the nails from pulling out once driven into the material. This feature is particularly important in high-stress applications, such as securing fencing or netting, where stability is essential. Understanding the shank type helps buyers select the appropriate nail for their specific needs. -

Diameter and Length

These nails are available in various diameters (ranging from 1.0 to 6.5 mm) and lengths (from 3/4″ to 2″). The diameter affects the holding power, while the length determines how deeply the nail penetrates the substrate. For instance, larger diameters are more suitable for heavy-duty applications, while shorter lengths may suffice for lighter tasks. Choosing the right size ensures optimal performance and minimizes the risk of damage to the materials being fastened. -

Point Type

U shaped nails typically feature either diamond or cut points. Diamond points are designed for easier penetration into hard materials, while cut points are effective in softer substrates. The type of point affects installation efficiency and overall project timelines, making it an important consideration for B2B buyers looking to maximize productivity. -

Surface Treatment

The surface treatment of u shaped nails, which can include electro-galvanization, copper plating, or polishing, directly impacts their resistance to rust and corrosion. For projects in humid or outdoor environments, selecting nails with appropriate surface treatments can prevent premature failure and ensure long-term reliability.

What Are Common Trade Terms Associated with U Shaped Nails?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms associated with u shaped nails:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products to be sold under another brand’s name. For buyers, understanding OEM relationships can help in sourcing high-quality u shaped nails that meet specific standards without compromising on brand integrity. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers to manage inventory levels and ensure cost-effectiveness. Suppliers may set MOQs based on production capabilities or material sourcing requirements. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For buyers, issuing an RFQ for u shaped nails can facilitate competitive pricing and allow for better budget planning. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international contracts to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand shipping costs and risk management when sourcing u shaped nails from overseas suppliers. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. For B2B buyers, knowing the lead time for u shaped nails is crucial for project planning and ensuring materials arrive when needed to avoid delays. -

Specifications Sheet

This document outlines detailed information about a product’s characteristics, including dimensions, materials, and performance standards. Reviewing a specifications sheet is essential for buyers to ensure that the u shaped nails meet their project requirements and industry standards.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing u shaped nails, ensuring they select the right products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the u shaped nail Sector

What Are the Key Market Trends Affecting U-Shaped Nails Globally?

The U-shaped nail market is experiencing dynamic shifts driven by various global factors. An increasing demand for sustainable construction practices is prompting manufacturers to develop eco-friendly alternatives, such as nails made from recycled materials. This trend is particularly evident in regions like Europe, where stringent regulations encourage the use of sustainable products. Additionally, the rise of e-commerce is facilitating easier access to these products for international B2B buyers, especially in emerging markets in Africa and South America. Digital platforms are streamlining the sourcing process, enabling buyers to compare prices and quality more efficiently.

Emerging technologies such as automation and robotics in manufacturing processes are enhancing production efficiency and lowering costs, making U-shaped nails more accessible to a broader audience. Moreover, the growing popularity of DIY projects is contributing to increased sales, as both consumers and businesses seek reliable fasteners for various applications, from fencing to gardening. Buyers from regions like the Middle East and Vietnam are particularly interested in bulk purchasing options, reflecting their expanding construction and agricultural sectors.

How Important Is Sustainability and Ethical Sourcing in the U-Shaped Nail Sector?

Sustainability and ethical sourcing are becoming critical components of the U-shaped nail sector. As environmental concerns continue to rise, buyers are increasingly prioritizing products that minimize ecological impact. This includes sourcing nails that are galvanized or made from recycled steel, reducing the carbon footprint associated with production. For B2B buyers, understanding the environmental impact of their sourcing choices can enhance brand reputation and meet growing consumer demand for responsible products.

Ethical supply chains are also gaining traction, with companies focusing on transparency and fair labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a manufacturer’s commitment to sustainable practices. Buyers are encouraged to evaluate potential suppliers based on their adherence to these standards, ensuring that their procurement processes align with global sustainability goals.

How Has the U-Shaped Nail Market Evolved Over Time?

The evolution of the U-shaped nail market can be traced back to its initial use in agriculture and construction. Originally made from wrought iron, the material transitioned to more durable options such as steel, which offered enhanced strength and longevity. The introduction of galvanization techniques in the mid-20th century further improved corrosion resistance, making U-shaped nails suitable for outdoor applications.

In recent years, the focus has shifted toward innovation and sustainability. Manufacturers are now producing nails that not only meet functional requirements but also adhere to environmental standards. This transformation reflects broader trends in construction and agriculture, where the demand for reliable, eco-friendly materials is shaping product development. As the market continues to adapt, international B2B buyers must stay informed about advancements and shifts in sourcing strategies to remain competitive.

Frequently Asked Questions (FAQs) for B2B Buyers of u shaped nail

-

How do I choose the right U-shaped nail for my project?

Selecting the right U-shaped nail depends on your specific application. Consider the material you will be fastening—wood, wire mesh, or fencing—and the environmental conditions. For outdoor use, galvanized or copper-plated nails are ideal due to their rust resistance. Determine the required length and gauge, as thicker nails provide better holding power, especially in softer woods or heavy-duty applications. Additionally, barbed shank nails offer increased grip for demanding conditions, while smooth shank nails are suitable for lighter tasks. -

What is the best U-shaped nail for securing wire fencing?

The best U-shaped nail for securing wire fencing typically features a barbed shank design, which provides superior holding power against pull-out forces. A length of 1.25 to 2 inches is generally recommended, allowing for deep penetration into wooden posts or frames. Galvanized options are advisable for outdoor applications to prevent rust. Additionally, ensure the diameter is compatible with your fencing material to maintain a secure fit. -

What are the minimum order quantities (MOQ) for U-shaped nails?

Minimum order quantities for U-shaped nails can vary widely among suppliers, often ranging from 1,000 to 10,000 pieces depending on the manufacturer and customization options. For bulk orders, many suppliers offer discounts. It’s advisable to negotiate terms if you anticipate regular purchases. Always confirm the MOQ with the supplier to ensure it aligns with your project needs and budget. -

What payment terms should I expect when sourcing U-shaped nails internationally?

Payment terms can differ based on the supplier’s policies and your relationship with them. Common options include upfront payment, partial payment (e.g., 30% upfront and 70% upon delivery), or payment upon receipt of goods. For new suppliers, using secure payment methods like PayPal or letters of credit can mitigate risks. Always clarify terms before placing an order to avoid unexpected costs. -

How can I vet suppliers for U-shaped nails?

To vet suppliers effectively, research their reputation through online reviews and industry references. Request samples to assess product quality firsthand. Check for certifications that indicate compliance with international standards, such as ISO or ASTM. Establish communication to gauge responsiveness and reliability. Additionally, visiting the supplier’s facility, if feasible, can provide valuable insights into their production capabilities and ethical practices. -

What customization options are available for U-shaped nails?

Customization options for U-shaped nails can include varying lengths, diameters, and surface treatments (such as galvanized or copper-plated finishes). Some manufacturers also offer barbed or smooth shank designs tailored to specific applications. When discussing customization, provide detailed specifications and intended use to ensure the supplier meets your requirements accurately. -

What quality assurance processes should be in place for U-shaped nails?

Quality assurance processes should include rigorous testing of materials and finished products to ensure they meet specified standards. Look for suppliers who employ third-party inspections and have established protocols for quality checks at various production stages. Request documentation of these processes, including certificates of compliance, to ensure that the nails will perform reliably in your applications. -

How are logistics and shipping managed for international orders of U-shaped nails?

Logistics for international orders typically involve coordination between the supplier and a freight forwarder. Consider factors such as shipping methods (air or sea), estimated delivery times, and customs clearance processes. Ensure that the supplier provides all necessary documentation, including invoices and certificates of origin, to facilitate smooth customs procedures. Discuss shipping costs upfront to avoid surprises and consider insurance for valuable shipments.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 U Shaped Nail Manufacturers & Suppliers List

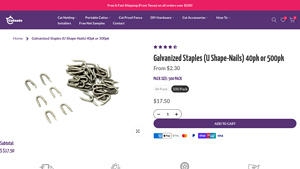

1. Catnetting – Galvanized U Shape-Nails

Domain: catnetting.com

Registered: 2017 (8 years)

Introduction: Galvanized Staples (U Shape-Nails) available in 40 pack or 500 pack. Prices start from $2.30 for the 40 pack and $17.50 for the 500 pack. Designed for installing netting onto timber surfaces, these U-Nails can be attached directly to the netting. Recommended to use edging rope for a neat seam, with U-Nails spaced 4 inches apart when used with edging rope. Fast shipping from Texas. Premium quality,…

2. Iron Wire Nails – U Shaped Nails

Domain: ironwirenails.com

Registered: 2010 (15 years)

Introduction: U Shaped Nails – Used for securing mesh fencing to wooden posts. Available in smooth or barbed shank types for different needs. Designed for gardening and agriculture, featuring a U shaped head for binding wires. Slice cut sharp point for easy operation. Great staying power and resistant to bending. Made from carbon steel (Q195, Q235). Diameter: 9–16 gauge. Length: 3/4″ – 2″. Head type: U shape. S…

3. Pinterest – Nail Art & Designs

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: U shaped nails, Fake Nails, Nail Art Shapes, Types of Long Nails, Nail Tips, Different Nail Shapes, Black French Birthday Nails, Classic Nails, Oval Nails, Flare Shape Nails, Tapered Round Nails, Short Coffin Shape Nails, V Cut Nails, French Tip Nails, Acrylic Nails Shapes.

4. Nail Care – Essential Tips and Products

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Nail shape recommendation: Glass file for even shaping. Nail polish flaking issue: Use alcohol to dehydrate nails before applying base coat. Recommended oils for nail growth: Jojoba oil, almond oil, olive oil. Importance of using base and top coat for nail protection.

5. eBay – Premium Iron Garden Fencing Fixings

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: This company, eBay – Premium Iron Garden Fencing Fixings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. RainyRoses – U-Shaped Press-On Nails

Domain: rainyroses.com

Registered: 2022 (3 years)

Introduction: U-shaped nails are characterized by their curved edges resembling the letter ‘U’. They come in three sizes: Small (for petite fingers), Medium (the most common size), and Large (ideal for bold styles). RainyRoses offers press-on nails starting at $4.99, with free shipping on all orders. Promotions include Buy 3 Get 1 Free with code: 4YOU and Buy 5 Get 5 Free with code: 5FREE.

Strategic Sourcing Conclusion and Outlook for u shaped nail

In the competitive landscape of construction and agricultural supplies, U-shaped nails represent a practical and cost-effective solution for securing various materials, from netting to fencing. Their versatility is underscored by options such as smooth or barbed shanks, catering to a range of applications across different sectors, including horticulture, animal husbandry, and general construction. Strategic sourcing of these fasteners is crucial; it not only ensures the procurement of high-quality products but also fosters relationships with reliable suppliers who can meet your specific needs.

As international buyers from Africa, South America, the Middle East, and Europe explore procurement options, it is imperative to consider factors such as product durability, shipping efficiency, and supplier credibility. Engaging with manufacturers that offer transparent sourcing practices and robust customer support can significantly enhance your supply chain resilience.

Looking ahead, the demand for U-shaped nails is expected to grow alongside the expansion of construction and agricultural projects globally. By prioritizing strategic sourcing now, B2B buyers can position themselves to capitalize on emerging opportunities, ensuring their projects are both successful and sustainable. Embrace this moment to secure reliable partnerships and elevate your procurement strategy for the future.