Unlocking Value: A Strategic Analysis of the Ollies Wood Flooring Market

Introduction: Navigating the Global Market for ollies wood flooring

In the competitive landscape of flooring solutions, international B2B buyers face the pressing challenge of sourcing high-quality ollies wood flooring that balances durability, aesthetics, and cost-effectiveness. With the demand for sustainable and stylish flooring on the rise, understanding the nuances of the global market is essential for making informed purchasing decisions. This comprehensive guide delves into the various types of ollies wood flooring available, their diverse applications across different sectors, and the critical factors to consider when vetting suppliers.

Buyers will gain insights into the cost structures associated with ollies wood flooring, enabling them to evaluate pricing effectively against market standards. Furthermore, the guide offers actionable strategies for identifying reputable suppliers, ensuring that buyers can confidently navigate their sourcing journey. With a focus on key regions, including Africa, South America, the Middle East, and Europe—specifically markets like Saudi Arabia and Vietnam—this guide empowers businesses to optimize their procurement processes and enhance their flooring offerings.

By equipping B2B buyers with essential knowledge and resources, this guide aims to streamline the decision-making process, ultimately leading to successful partnerships and profitable investments in ollies wood flooring. Whether you are a distributor, retailer, or project manager, understanding these dynamics will be crucial to your success in the global marketplace.

Understanding ollies wood flooring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Waterproof Vinyl Plank | 7″ x 48″ size, click or tap-in locking system, premium underlayment, 40-year residential warranty | Residential and commercial spaces | Pros: Durable, water-resistant; Cons: Limited aesthetic compared to natural wood. |

| Laminate Flooring | 7.6″ x 50.79″, glue-free click-in locking system, 10-year warranty | Retail stores, offices | Pros: Cost-effective, easy installation; Cons: Less authentic feel than hardwood. |

| Engineered Hardwood | Multi-layered construction, real wood veneer, various finishes | High-end residential, hotels | Pros: Aesthetic appeal, stability in fluctuating climates; Cons: Higher price point. |

| Solid Hardwood | Made from a single piece of wood, various species available | Luxury residential, custom builds | Pros: Long-lasting, can be refinished; Cons: Sensitive to moisture, requires maintenance. |

| Linoleum Flooring | Eco-friendly, resilient, available in various colors and patterns | Schools, healthcare facilities | Pros: Easy to clean, sustainable; Cons: Can be less durable in high-traffic areas. |

What Are the Key Features of Waterproof Vinyl Plank Flooring?

Waterproof vinyl plank flooring is designed for durability and moisture resistance, making it ideal for environments prone to spills or humidity. With a standard size of 7″ x 48″, this flooring features a click or tap-in locking system for straightforward installation. The premium underlayment enhances comfort and sound absorption. B2B buyers should consider this option for both residential and commercial applications, particularly in areas like kitchens and bathrooms. Its long warranty period, up to 40 years for residential use, provides confidence in investment longevity.

How Does Laminate Flooring Compare in the Market?

Laminate flooring, often priced competitively, offers a glue-free click-in locking system, simplifying installation. With dimensions of 7.6″ x 50.79″ and a 10-year warranty, it appeals to businesses seeking cost-effective solutions. This flooring type is particularly suitable for retail stores and office spaces where aesthetics and budget are crucial. Buyers should weigh its affordability against the less authentic feel compared to solid hardwood, making it a practical choice for mid-range projects.

Why Choose Engineered Hardwood for B2B Applications?

Engineered hardwood flooring combines the beauty of real wood with the strength of layered construction, making it a versatile choice for high-end residential projects and hotels. With a real wood veneer, it offers a premium aesthetic while remaining stable in various climates. B2B buyers should consider its suitability for upscale renovations and custom builds, although the higher price point may be a barrier for budget-conscious projects. Its ability to withstand humidity makes it a smart investment in diverse environments.

What Are the Advantages of Solid Hardwood Flooring?

Solid hardwood flooring is crafted from a single piece of wood, providing unmatched durability and a classic aesthetic. This type is often used in luxury residential and custom builds, appealing to buyers looking for longevity and the option to refinish. However, potential buyers must be aware of its sensitivity to moisture, which can lead to warping. Regular maintenance is required to preserve its appearance, making it essential for businesses to evaluate the long-term investment versus initial costs.

How Does Linoleum Flooring Serve Commercial Needs?

Linoleum flooring is an eco-friendly option that offers resilience and a variety of colors and patterns, making it suitable for spaces like schools and healthcare facilities. Its ease of cleaning and sustainability are significant advantages for B2B buyers focused on environmental responsibility. However, while it can withstand moderate traffic, it may not be as durable in high-traffic areas compared to other flooring types. Businesses should consider its lifecycle costs and maintenance requirements when selecting linoleum for their projects.

Key Industrial Applications of ollies wood flooring

| Industry/Sector | Specific Application of ollies wood flooring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel lobbies and guest rooms | Enhances aesthetic appeal, durability, and comfort | Ensure moisture resistance and ease of maintenance |

| Retail | Showrooms and retail spaces | Creates inviting atmospheres, increases customer dwell time | Consider foot traffic levels and aesthetic alignment with brand |

| Residential Construction | Family homes and apartments | Provides warmth and style while being cost-effective | Focus on warranty, ease of installation, and design options |

| Educational Institutions | Classrooms and common areas | Promotes a welcoming learning environment | Look for durability, safety features, and ease of cleaning |

| Commercial Offices | Office spaces and conference rooms | Improves workplace aesthetics and employee morale | Evaluate acoustic properties and compatibility with office furniture |

How is Ollies Wood Flooring Used in the Hospitality Sector?

In the hospitality industry, ollies wood flooring is often utilized in hotel lobbies and guest rooms to create a warm and inviting environment. Its aesthetic appeal enhances the overall guest experience, while its durability ensures that it can withstand high foot traffic. For international buyers, particularly those in the Middle East and Europe, sourcing options should prioritize moisture resistance due to varying climate conditions, alongside easy maintenance features to minimize upkeep costs.

What Role Does Ollies Wood Flooring Play in Retail Spaces?

In retail environments, ollies wood flooring is employed in showrooms and retail spaces to foster an inviting atmosphere that encourages customer engagement. The flooring’s natural look and feel can significantly enhance product displays, leading to increased customer dwell time and potentially higher sales. B2B buyers from Africa and South America should consider the flooring’s ability to endure heavy foot traffic and its alignment with brand aesthetics when sourcing for retail applications.

Why Choose Ollies Wood Flooring for Residential Construction?

Residential construction projects frequently incorporate ollies wood flooring in family homes and apartments due to its combination of style and cost-effectiveness. The flooring offers a warm ambiance, making spaces feel more welcoming, while its competitive pricing helps keep overall project costs manageable. Buyers should focus on the warranty and ease of installation when sourcing, ensuring that the chosen product aligns with the specific design preferences of the region.

How Can Educational Institutions Benefit from Ollies Wood Flooring?

Educational institutions often utilize ollies wood flooring in classrooms and common areas to create a welcoming learning environment. The flooring not only enhances the aesthetic appeal of the space but also contributes to a more comfortable atmosphere conducive to learning. For B2B buyers in Europe and Africa, it is essential to consider the durability and safety features of the flooring, as well as its ease of cleaning, to ensure long-term usability in high-traffic educational settings.

What Advantages Does Ollies Wood Flooring Offer Commercial Offices?

In commercial office settings, ollies wood flooring is used in office spaces and conference rooms to improve aesthetics and employee morale. The natural wood look can create a more inviting workplace, positively impacting productivity and employee satisfaction. When sourcing for this application, buyers should evaluate the acoustic properties of the flooring and its compatibility with office furniture to ensure a cohesive and functional office environment.

3 Common User Pain Points for ‘ollies wood flooring’ & Their Solutions

Scenario 1: Sourcing Quality Wood Flooring at Competitive Prices

The Problem: B2B buyers, especially those in the construction and interior design sectors, often struggle to find high-quality wood flooring that fits within tight budget constraints. This is particularly challenging in regions like Africa and South America, where import costs can inflate prices significantly. Furthermore, buyers may encounter issues with inconsistent quality and supply shortages, leading to project delays and increased costs.

The Solution: To effectively source ‘ollies wood flooring’, buyers should establish relationships with local distributors who regularly stock Ollie’s products. These partnerships can provide insights into inventory levels and upcoming deals, allowing for bulk purchasing at discounted rates. Additionally, leveraging online platforms for real-time inventory checks can help identify available stock and seasonal discounts. When selecting wood flooring, buyers should focus on specifications such as thickness, warranty terms, and installation methods to ensure they are investing in durable products that meet project needs. Engaging with Ollie’s customer service can also provide clarity on product availability, ensuring that purchases align with project timelines.

Scenario 2: Navigating Installation Challenges for Wood Flooring

The Problem: Many buyers face difficulties during the installation of wood flooring, particularly when dealing with unfamiliar products or installation systems. In regions with varying climate conditions, such as the Middle East and parts of Europe, improper installation can lead to issues like warping or buckling, which can be costly to rectify.

The Solution: Buyers should prioritize understanding the installation requirements specific to ‘ollies wood flooring’. This includes familiarizing themselves with the click-lock installation system commonly used in Ollie’s products, as well as the importance of acclimating the flooring to the local environment prior to installation. It is advisable to invest in training sessions for installation teams, which can be arranged through local distributors or Ollie’s workshops. Furthermore, incorporating a reliable underlayment can significantly enhance the flooring’s performance, providing moisture resistance and sound insulation. A detailed installation guide should be followed meticulously, and buyers should consider hiring professional installers with experience in handling similar products to ensure a flawless finish.

Scenario 3: Ensuring Long-Term Durability and Maintenance of Wood Flooring

The Problem: Once installed, maintaining the quality and appearance of wood flooring can be a major concern for B2B buyers. Many are unsure of the best maintenance practices to prolong the life of their investment, especially in regions with high foot traffic or varying humidity levels, leading to premature wear and tear.

The Solution: To guarantee the longevity of ‘ollies wood flooring’, buyers should implement a comprehensive maintenance plan tailored to their specific environment. This plan should include regular cleaning with appropriate products designed for wood flooring, as harsh chemicals can damage the finish. Additionally, establishing a schedule for periodic inspections can help identify and address minor issues before they escalate. For high-traffic areas, it may be beneficial to apply a protective sealant every few years to maintain the floor’s appearance and resilience. Buyers should also educate their staff on the proper care techniques, such as using furniture pads to prevent scratches and placing mats at entryways to minimize dirt accumulation. By investing in quality maintenance practices, buyers can maximize the return on their flooring investment and enhance the overall aesthetic of their spaces.

Strategic Material Selection Guide for ollies wood flooring

What Are the Common Materials Used in Ollies Wood Flooring?

When selecting materials for Ollies wood flooring, it is essential to understand the properties, advantages, and limitations of each option. Below, we analyze four common materials used in Ollies wood flooring, focusing on their performance, suitability for various applications, and considerations for international buyers.

1. Laminate Flooring

Key Properties: Laminate flooring typically consists of a high-density fiberboard (HDF) core topped with a printed layer that mimics wood. It is known for its durability and resistance to scratches, moisture, and fading.

Pros & Cons: The primary advantage of laminate flooring is its cost-effectiveness, making it an attractive option for budget-conscious buyers. It is relatively easy to install due to its click-lock design. However, laminate flooring can be less durable than solid wood and may not be suitable for high-moisture environments, which can lead to warping over time.

Impact on Application: Laminate flooring is compatible with various underlayments, enhancing sound absorption and comfort. However, it may not perform well in extremely humid climates typical in some regions of Africa and South America.

Considerations for International Buyers: Compliance with international standards such as ASTM and EN is crucial. Buyers should also consider local climate conditions, as laminate may not be ideal in areas with high humidity, necessitating alternative flooring solutions.

2. Engineered Wood Flooring

Key Properties: Engineered wood flooring consists of a top layer of real wood veneer over layers of plywood or HDF. This construction provides stability and resistance to temperature fluctuations.

Pros & Cons: Engineered wood offers the aesthetic appeal of solid wood while being more stable and resistant to moisture. It can be sanded and refinished, although not as many times as solid wood. The downside is that it can be more expensive than laminate and may not have the same lifespan as solid wood.

Impact on Application: Engineered wood is suitable for various applications, including residential and light commercial settings. Its stability makes it a good choice for areas with fluctuating temperatures, such as regions in the Middle East and Europe.

Considerations for International Buyers: Buyers should ensure that the engineered wood meets local regulations and standards, such as the EU Timber Regulation. Additionally, understanding the sourcing of the wood veneer is essential for sustainability compliance.

3. Vinyl Plank Flooring

Key Properties: Vinyl plank flooring is made from polyvinyl chloride (PVC) and is designed to mimic the appearance of wood. It is waterproof and highly durable, making it suitable for high-traffic areas.

Pros & Cons: The primary advantage of vinyl plank flooring is its water resistance, making it ideal for bathrooms and kitchens. It is also easy to maintain and install. However, it may not provide the same warmth and aesthetic appeal as natural wood, which can be a drawback for some buyers.

Impact on Application: Vinyl is compatible with various subfloor types and can be installed over existing floors, which is advantageous for renovations. Its waterproof nature makes it an excellent choice for humid climates, particularly in tropical regions of Africa and South America.

Considerations for International Buyers: Compliance with standards like ASTM F1700 for resilient flooring is important. Buyers should also consider the environmental impact of PVC products and seek certifications like FloorScore for indoor air quality.

4. Solid Hardwood Flooring

Key Properties: Solid hardwood flooring is made from a single piece of wood, providing unmatched durability and aesthetic appeal. It can be sanded and refinished multiple times, extending its lifespan.

Pros & Cons: The key advantage of solid hardwood is its longevity and the ability to enhance property value. However, it is more expensive and can be susceptible to moisture damage, making it less suitable for humid environments.

Impact on Application: Solid hardwood is best suited for residential applications and areas with controlled climate conditions. It performs well in dry climates but may warp in high humidity, limiting its use in certain regions.

Considerations for International Buyers: Buyers should verify that the wood is sourced sustainably and complies with regulations such as the Lacey Act in the U.S. and the EU Timber Regulation. Understanding local preferences for wood species can also influence purchasing decisions.

Summary Table of Material Selection for Ollies Wood Flooring

| Material | Typical Use Case for ollies wood flooring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Laminate Flooring | Budget residential spaces | Cost-effective and easy to install | Less durable in high moisture environments | Low |

| Engineered Wood Flooring | Residential and light commercial settings | Aesthetic appeal with better stability | More expensive than laminate | Medium |

| Vinyl Plank Flooring | High-traffic and moisture-prone areas | Waterproof and durable | Less warmth and aesthetic compared to wood | Low |

| Solid Hardwood Flooring | Premium residential applications | Longevity and property value enhancement | Susceptible to moisture and high cost | High |

This comprehensive analysis provides B2B buyers with essential insights into material selection for Ollies wood flooring, enabling informed purchasing decisions that align with regional preferences and standards.

In-depth Look: Manufacturing Processes and Quality Assurance for ollies wood flooring

What Are the Key Stages in the Manufacturing Process of Ollies Wood Flooring?

The manufacturing process for Ollies wood flooring involves several critical stages, each designed to ensure high-quality products that meet the diverse needs of international buyers. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first stage involves sourcing high-quality raw materials, primarily wood, which is often sourced from sustainable forests. The wood undergoes drying processes to reduce moisture content, which is essential for preventing warping and ensuring stability. This step may also include the selection of wood species based on durability and aesthetic appeal.

-

Forming: In the forming stage, the dried wood is cut into specific sizes and shapes. Advanced machinery is used for precision cutting, ensuring uniformity across the production batch. Techniques such as lamination may be employed, where multiple layers of wood are bonded together to enhance strength and reduce the risk of expansion or contraction due to humidity changes.

-

Assembly: This stage focuses on the assembly of the flooring planks. Depending on the product line, various methods are employed, including tongue-and-groove systems or click-lock mechanisms, which facilitate easy installation. The assembly process also ensures that the flooring panels fit seamlessly, providing a polished finish that is appealing to consumers.

-

Finishing: The final stage is the finishing process, where the wood flooring is treated with protective coatings to enhance durability and resistance to wear. This may involve staining, sealing, and applying varnishes or finishes that are eco-friendly and compliant with international safety standards. The finishing process not only improves the aesthetic quality but also provides resistance against moisture and scratches, making the flooring suitable for different environments.

What Quality Control Measures Are Implemented in Ollies Wood Flooring Production?

Quality control (QC) is a crucial component in the production of Ollies wood flooring, ensuring that products meet both international standards and customer expectations. Key quality assurance measures include adherence to recognized international standards, systematic QC checkpoints, and rigorous testing methods.

-

International Standards Compliance: Ollies wood flooring manufacturing aligns with various international standards, such as ISO 9001, which focuses on quality management systems. Additionally, compliance with CE marking indicates that the products meet EU safety, health, and environmental protection standards. For markets in regions such as Africa and the Middle East, certifications may also adhere to specific local regulations.

-

Quality Control Checkpoints: The QC process includes several critical checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards before being used in production.

– In-Process Quality Control (IPQC): During manufacturing, random samples are taken at various stages to monitor quality and compliance with specifications.

– Final Quality Control (FQC): Once the flooring is finished, a thorough inspection is conducted to verify that the products meet quality and aesthetic standards before packaging and shipment. -

Common Testing Methods: Various testing methods are employed to ensure the flooring’s durability and functionality. These may include:

– Moisture Content Testing: To ensure wood stability.

– Surface Scratch Resistance Tests: To evaluate durability against wear.

– Dimensional Stability Tests: To assess how well the flooring maintains its shape under varying environmental conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those in international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability and compliance with local regulations. Here are several strategies for effective verification:

-

Supplier Audits: Conducting regular audits of suppliers allows buyers to assess their manufacturing processes, quality control measures, and adherence to international standards. This may include on-site visits where buyers can observe production methods and QC practices firsthand.

-

Requesting Quality Control Reports: Buyers should request detailed QC reports from suppliers, which should outline the testing methods used, results obtained, and any corrective actions taken in response to quality issues. These reports provide valuable insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality control processes. These agencies can conduct random inspections and testing to validate the quality of the flooring products before shipment.

-

Understanding QC and Certification Nuances: B2B buyers should familiarize themselves with the specific quality certifications relevant to their markets. For example, in the EU, CE certification is crucial, while buyers in the Middle East may need to consider Gulf Cooperation Council (GCC) compliance. Understanding these nuances helps buyers ensure that the products they import meet necessary safety and quality standards.

What Challenges Do International Buyers Face Regarding Quality Assurance?

International buyers, particularly from regions like Africa, South America, and the Middle East, face unique challenges in ensuring quality assurance when sourcing wood flooring. These challenges can include varying regulatory standards, communication barriers, and logistical issues related to product quality during transportation.

-

Varying Regulatory Standards: Different countries have distinct regulations regarding product safety and quality. Buyers must navigate these complexities to ensure that the flooring they import complies with local laws, which can vary significantly across regions.

-

Communication Barriers: Language differences and cultural nuances can complicate negotiations and quality assurance discussions. Establishing clear communication channels and working with suppliers who understand international business practices can mitigate these challenges.

-

Logistical Issues: Transportation can pose risks to product quality. Ensuring that flooring materials are adequately protected during transit to prevent damage or degradation is critical. Buyers should work closely with suppliers to understand how products are packaged and handled during shipping.

By understanding the manufacturing processes and quality assurance measures in place for Ollies wood flooring, B2B buyers can make informed decisions, ensuring that they source high-quality products that meet their needs and compliance standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ollies wood flooring’

This guide serves as a practical checklist for B2B buyers interested in sourcing Ollie’s wood flooring products. Whether you’re in Africa, South America, the Middle East, or Europe, following these steps will help you make informed decisions and secure quality flooring at competitive prices.

Step 1: Define Your Technical Specifications

Clearly outline the specific requirements for the flooring you need. This includes dimensions, thickness, and material type. For instance, if you are considering waterproof options, ensure the specifications reflect this feature. Documenting these details will streamline your communication with suppliers and help you avoid misaligned expectations.

Step 2: Research Market Trends and Pricing

Investigate current market trends to understand pricing and demand. Look for reports or articles that detail flooring trends in your target regions. Knowing the average market price for various wood flooring types will empower you to negotiate effectively and recognize a good deal when you see one.

Step 3: Identify and Evaluate Potential Suppliers

Conduct thorough research to identify reliable suppliers. Look for companies with a proven track record in flooring distribution, especially those that cater to your region. Request company profiles, product catalogs, and references from other businesses in your sector to assess their credibility and service quality.

- Check for Local Presence: Suppliers with local warehouses may offer faster delivery times and reduced shipping costs.

- Review Certifications: Ensure they comply with international quality and safety standards.

Step 4: Verify Product Quality

Request samples to evaluate the quality of the flooring. Examine the finish, durability, and ease of installation. It’s vital to assess if the flooring meets your technical specifications and quality expectations.

- Check for Warranties: Review warranty terms to understand the manufacturer’s commitment to product quality.

- Inspect for Certifications: Look for certifications that indicate eco-friendliness or adherence to industry standards.

Step 5: Assess Logistics and Shipping Options

Understand the logistics involved in sourcing the flooring. Confirm shipping methods, lead times, and costs associated with delivery. A reliable supplier should provide clear information on how they handle international shipments, especially if you are sourcing from a different continent.

- Evaluate Shipping Costs: Factor in these costs when calculating the overall price of the flooring.

- Discuss Return Policies: Clarify the procedures for returns or exchanges in case the product does not meet expectations.

Step 6: Negotiate Terms and Place Your Order

Engage in negotiations to secure the best possible terms. Discuss pricing, payment methods, and delivery schedules. Be prepared to walk away if the terms do not meet your budget or requirements, as there are often multiple suppliers available.

- Consider Bulk Discounts: If ordering large quantities, inquire about discounts that may apply.

- Finalize Payment Terms: Ensure that the payment terms are clear and manageable for your business.

Step 7: Establish a Relationship for Future Orders

Aim to build a long-term relationship with your supplier. After the initial order, maintain communication to foster a partnership that can lead to better pricing, priority service, and exclusive offers in the future.

- Provide Feedback: Share your experience with the supplier to help them improve their service.

- Stay Updated on New Products: Regularly check in for new product offerings or promotions that may benefit your business.

By following this checklist, you will position your business to source Ollie’s wood flooring effectively and confidently, ensuring a successful procurement process tailored to your specific needs.

Comprehensive Cost and Pricing Analysis for ollies wood flooring Sourcing

What Are the Key Cost Components for Sourcing Ollies Wood Flooring?

When analyzing the cost structure for sourcing Ollies wood flooring, several cost components must be considered. Materials represent a significant portion of the cost, influenced by the type of wood or laminate used. For instance, high-quality wood species or specialized finishes can increase material costs. Labor costs also play a crucial role, encompassing the workforce required for manufacturing, installation, and quality control processes.

Manufacturing overhead includes expenses related to factory operations, such as utilities and maintenance. Tooling costs are associated with the equipment needed for production; this is particularly relevant for custom or specialized flooring products. Quality control (QC) measures ensure that products meet specified standards, which can add additional costs but ultimately enhance product reliability and customer satisfaction.

Logistics costs, including shipping and handling, are critical, especially for international buyers. These costs can fluctuate based on distance, shipping method, and any tariffs or duties imposed. Lastly, the desired margin for profit must be factored in, influencing the final pricing strategy.

How Do Price Influencers Affect the Cost of Ollies Wood Flooring?

Several factors can influence the pricing of Ollies wood flooring. Volume and minimum order quantity (MOQ) are essential considerations; larger orders typically lead to lower per-unit costs due to economies of scale. Customization requests, such as specific dimensions or finishes, can also impact the price. The quality of materials used, coupled with certifications (like FSC certification for sustainable sourcing), may elevate costs but can be attractive selling points for eco-conscious buyers.

Supplier factors, including their reputation and reliability, can also affect pricing. Established suppliers may command higher prices but offer greater assurance of quality and service. Understanding the Incoterms related to shipping agreements is vital for international transactions, as they define responsibilities and costs between buyers and sellers.

What Negotiation Strategies Can International B2B Buyers Use?

International buyers from regions such as Africa, South America, the Middle East, and Europe should employ effective negotiation strategies to secure the best pricing for Ollies wood flooring. Building a relationship with suppliers can foster trust and lead to better deals. It’s beneficial to present data on competitor pricing to leverage negotiations effectively.

Buyers should also consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also long-term costs associated with maintenance, durability, and potential rework. Discussing payment terms can also provide flexibility; for instance, negotiating for extended payment periods may ease cash flow issues.

Understanding local market conditions and aligning purchasing strategies with seasonal trends can enhance negotiation outcomes. Buyers should remain aware of pricing nuances, such as currency fluctuations and regional tariffs, which can impact overall costs.

What Are the Pricing Nuances for International B2B Buyers?

International B2B buyers should be mindful of the unique pricing nuances when sourcing Ollies wood flooring. Currency fluctuations can significantly affect pricing, making it essential to lock in rates when possible. Additionally, varying import duties and tariffs based on country-specific regulations can alter the final cost structure.

Buyers should also assess the local demand for wood flooring products to gauge appropriate pricing strategies. Engaging in market research can provide insights into consumer preferences and competitive pricing, enabling buyers to make informed decisions.

Lastly, it’s crucial to maintain a disclaimer regarding indicative prices, as they can fluctuate based on market conditions, availability, and other external factors. Staying informed and adaptable will empower buyers to navigate the complexities of sourcing Ollies wood flooring effectively.

Alternatives Analysis: Comparing ollies wood flooring With Other Solutions

Exploring Alternatives to Ollies Wood Flooring

In the competitive flooring market, businesses often seek alternatives that offer similar benefits to Ollies wood flooring, which is known for its affordability and aesthetic appeal. This analysis will compare Ollies wood flooring with two viable alternatives: laminate flooring and waterproof vinyl plank flooring. Each option has unique advantages and challenges that can influence a buyer’s decision.

| Comparison Aspect | Ollies Wood Flooring | Laminate Flooring | Waterproof Vinyl Plank Flooring |

|---|---|---|---|

| Performance | Good durability and aesthetic quality | Durable, but can scratch easily | Highly durable and water-resistant |

| Cost | Competitive pricing | Generally lower cost | Mid-range pricing |

| Ease of Implementation | Requires professional installation | Easy DIY installation | Easy DIY installation |

| Maintenance | Moderate upkeep | Easy to clean, but can stain | Very low maintenance |

| Best Use Case | Residential and light commercial | Residential spaces | High-moisture areas like bathrooms and kitchens |

What Are the Pros and Cons of Laminate Flooring?

Laminate flooring presents a cost-effective alternative to Ollies wood flooring. It is typically less expensive and offers a variety of styles and finishes. The installation process is user-friendly, making it a suitable choice for DIY projects. However, laminate flooring can be prone to scratching and may not perform well in high-moisture environments. Its lifespan, while decent, is generally shorter compared to Ollies wood flooring, making it less suitable for heavy commercial use.

How Does Waterproof Vinyl Plank Flooring Compare?

Waterproof vinyl plank flooring stands out for its resilience, particularly in moisture-rich environments. This makes it ideal for areas such as bathrooms and kitchens, where traditional wood flooring might warp. Its ease of installation and maintenance are significant advantages, as it can be cleaned effortlessly and doesn’t require extensive care. However, the cost is typically higher than that of laminate flooring, and while it mimics wood aesthetics, it may not provide the same authentic look and feel as Ollies wood flooring.

How to Choose the Right Flooring Solution for Your Needs

When selecting the right flooring solution, B2B buyers should consider several factors, including the specific application, budget constraints, and maintenance capabilities. Ollies wood flooring is an excellent choice for those seeking a balance of aesthetics and performance in residential and light commercial settings. Laminate flooring is ideal for budget-conscious projects, while waterproof vinyl plank flooring excels in high-moisture areas. By evaluating these aspects, buyers can make informed decisions that align with their unique requirements and operational goals.

Essential Technical Properties and Trade Terminology for ollies wood flooring

What Are the Key Technical Properties of Ollies Wood Flooring?

When considering Ollies wood flooring, understanding its technical properties is crucial for B2B buyers. Here are several essential specifications to keep in mind:

-

Material Grade

Material grade refers to the quality classification of the wood used in flooring. Higher grades indicate fewer imperfections and better durability, which can significantly influence the lifespan and aesthetics of the flooring. For businesses, choosing the right material grade can affect not only the product’s performance but also customer satisfaction and brand reputation. -

Thickness

The thickness of wood flooring impacts its durability and stability. Typical thicknesses range from 8mm to 12mm for engineered wood products. Thicker boards generally provide better resistance to wear and can handle foot traffic more effectively. For B2B buyers, selecting the appropriate thickness is essential for meeting the specific needs of various projects, from residential to commercial applications. -

Wear Layer

The wear layer is the topmost layer of a wood floor that protects against scratches, dents, and stains. Measured in mils, a thicker wear layer usually translates to better durability. For businesses, understanding the wear layer’s thickness can inform decisions on which products are suitable for high-traffic areas or environments prone to wear and tear. -

Moisture Resistance

This property is crucial for wood flooring, especially in humid climates. Moisture resistance can be enhanced through treatments or the use of specific materials. For B2B buyers, evaluating moisture resistance is vital when selecting flooring for areas like kitchens and bathrooms or in regions with high humidity, ensuring longevity and minimizing maintenance costs. -

Installation Method

Different installation methods, such as glue-down, nail-down, or floating, can affect the ease of installation and long-term performance of the flooring. Understanding these methods allows B2B buyers to plan installation processes efficiently and select products that align with their operational capabilities.

Which Trade Terms Should B2B Buyers Know When Purchasing Ollies Wood Flooring?

Familiarity with industry jargon can streamline communications and negotiations in the purchasing process. Here are some common trade terms relevant to Ollies wood flooring:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of flooring, knowing the OEM can help buyers assess quality and warranty options, as well as ensure compatibility with other products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to avoid overstocking or underordering, ensuring that they meet project demands without incurring unnecessary costs. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests pricing and other details from suppliers. For buyers of Ollies wood flooring, using an RFQ can facilitate competitive pricing and terms, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping agreements. Understanding Incoterms is critical for B2B buyers involved in international transactions, as they clarify costs, risks, and logistics involved in transporting flooring products. -

Lead Time

Lead time is the amount of time it takes from placing an order until the product is delivered. For B2B buyers, knowing the lead time can help in project planning and inventory management, ensuring that flooring is available when needed. -

Warranty Period

This term refers to the time frame during which the manufacturer guarantees the product against defects. A clear understanding of the warranty period helps buyers assess the risk associated with their investment and ensures they can provide adequate support to their customers.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing Ollies wood flooring, ultimately enhancing their competitive edge in the market.

Navigating Market Dynamics and Sourcing Trends in the ollies wood flooring Sector

What Are the Current Market Dynamics and Key Trends in the Ollies Wood Flooring Sector?

The ollies wood flooring sector is experiencing significant growth driven by various global factors, including increasing urbanization, a rise in disposable incomes, and growing consumer preferences for aesthetically pleasing and durable flooring options. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for cost-effective solutions that do not compromise on quality. The competitive pricing strategies employed by retailers such as Ollie’s Bargain Outlet, which offers substantial discounts compared to traditional retailers, appeal to these buyers.

Emerging technologies are reshaping sourcing trends in the flooring industry. For instance, the adoption of advanced manufacturing processes and digital supply chain management tools is enhancing efficiency and transparency. Buyers can leverage these technologies to streamline procurement processes, optimize inventory management, and improve decision-making. Additionally, the growing trend of e-commerce in the flooring sector is making it easier for international buyers to source products from various markets, enabling them to compare prices and specifications seamlessly.

Sourcing strategies are also evolving, with a marked emphasis on local suppliers in emerging markets. This shift is largely motivated by the desire to reduce lead times and logistics costs. Furthermore, the demand for customized flooring solutions is on the rise, encouraging suppliers to offer a wider variety of styles and finishes to meet diverse consumer preferences.

How Does Sustainability and Ethical Sourcing Impact the Ollies Wood Flooring Sector?

Sustainability and ethical sourcing are becoming increasingly pivotal in the ollies wood flooring sector. As environmental awareness grows, buyers are more inclined to choose products that align with sustainable practices. The flooring industry faces scrutiny regarding deforestation and its ecological impact, making it essential for companies to adopt responsible sourcing methods.

B2B buyers should prioritize suppliers that adhere to environmental standards and possess certifications like FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification). These certifications ensure that the wood used in flooring products is sourced from sustainably managed forests. Additionally, many manufacturers are now exploring alternative materials, such as reclaimed wood or sustainably harvested bamboo, which offer environmentally friendly options without sacrificing quality.

Investing in ‘green’ materials not only enhances a company’s reputation but also meets the growing consumer demand for sustainable products. By choosing ethically sourced ollies wood flooring, international buyers can contribute to a more sustainable future while also tapping into a market that increasingly values corporate responsibility.

What Is the Brief Evolution and History of the Ollies Wood Flooring Sector?

The ollies wood flooring sector has evolved significantly over the past few decades. Initially dominated by traditional hardwood options, the market has expanded to include various alternatives, including laminate and vinyl flooring, which offer the aesthetic appeal of wood at a lower cost. This diversification has allowed suppliers to cater to a broader range of consumer needs and budgets.

The rise of discount retailers like Ollie’s Bargain Outlet has further transformed the sector, providing consumers access to high-quality flooring at competitive prices. This shift has been particularly beneficial for international B2B buyers, who can now source diverse flooring options without incurring exorbitant costs. As the market continues to grow, innovation in design and manufacturing processes will likely play a crucial role in shaping the future of ollies wood flooring.

Frequently Asked Questions (FAQs) for B2B Buyers of ollies wood flooring

-

How do I ensure the quality of Ollie’s wood flooring products?

To ensure the quality of Ollie’s wood flooring, start by requesting samples of the materials you are interested in. Evaluate the samples for durability, finish, and overall appearance. Additionally, inquire about the manufacturer’s quality assurance processes and any certifications that validate product quality. Establishing a relationship with the supplier can also provide insights into their production practices and any available warranties, which are crucial for long-term investments. -

What is the best type of wood flooring for high-traffic areas?

For high-traffic areas, consider engineered wood flooring, as it offers enhanced durability compared to traditional solid wood. Engineered wood typically features a thicker veneer layer that withstands wear and tear better, making it suitable for commercial spaces. Look for options with a high Janka hardness rating and a protective finish that can resist scratches and stains. Ollie’s selection may include various styles and finishes, so be sure to evaluate each option based on your specific requirements. -

What are the minimum order quantities (MOQs) for Ollie’s wood flooring?

Minimum order quantities for Ollie’s wood flooring can vary based on the specific product line and regional availability. Generally, larger orders may be required for wholesale pricing, while smaller quantities might be available for retail purchases. It’s advisable to contact Ollie’s directly or check their website for detailed information regarding MOQs on the products you’re interested in, particularly if you’re sourcing for international projects. -

What payment terms are typically offered for international orders?

Payment terms for international orders can vary widely. Most suppliers, including Ollie’s, may offer options such as advance payment, letter of credit, or partial payment upon order confirmation. It is essential to discuss and negotiate terms that suit both parties, considering factors like order size, delivery timelines, and your business’s creditworthiness. Ensure all terms are documented clearly to avoid misunderstandings during the transaction process. -

How can I customize Ollie’s wood flooring products for my project?

Customization options for Ollie’s wood flooring may include choices in color, finish, and size. To explore these possibilities, it’s best to reach out directly to Ollie’s representatives, as they can provide guidance on available customization options based on your project’s specifications. Additionally, discussing your needs early in the sourcing process allows for better alignment with production capabilities and timelines. -

What are the logistics considerations when importing Ollie’s wood flooring?

When importing Ollie’s wood flooring, consider factors such as shipping methods, customs regulations, and delivery timelines. Work with a reliable freight forwarder familiar with international shipping to ensure compliance with import regulations in your country. Also, factor in potential duties, taxes, and insurance costs to your overall budget. Planning ahead for these logistics will help streamline the import process and prevent delays. -

How do I vet a supplier of Ollie’s wood flooring for reliability?

To vet a supplier of Ollie’s wood flooring, conduct thorough research that includes checking reviews, ratings, and references from other businesses that have worked with them. Verify their business credentials, such as registration and compliance with industry standards. Additionally, consider visiting their facilities if possible or requesting a virtual tour to assess their operations and quality control measures. Establishing communication can also help gauge their responsiveness and customer service quality. -

What should I know about warranty and return policies for Ollie’s wood flooring?

Understanding warranty and return policies is crucial when sourcing Ollie’s wood flooring. Review the specific terms associated with the products you intend to purchase, as warranties can vary in duration and coverage. Most warranties cover defects in materials and workmanship but may not include damage from improper installation or maintenance. Clarify return policies to ensure you can return or exchange any unsatisfactory products, especially for bulk orders that may require flexibility.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Ollies Wood Flooring Manufacturers & Suppliers List

1. Ollies – Vinyl Planks

2. Instagram Scraping Services – Monthly Page Plans

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact for scraping Instagram services, specify number of pages to scrape per month.

3. Yelp – Flooring Services

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: The Best 10 Flooring near Ollie’s Bargain Outlet in Greensboro, NC includes various services and products such as: Hardwood Floor Installation, Carpet Installation, Tile Flooring, Vinyl Flooring, Laminate Floor Installation, Epoxy Flooring, Concrete Staining, and more. Notable businesses include Premier Hardwood Flooring, specializing in real hardwood floors with 30 years of experience; Flooring T…

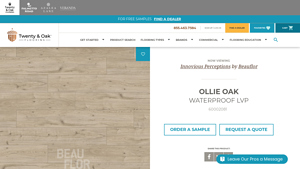

4. Beauflor – Ollie Oak

Domain: twentyandoak.com

Registered: 2018 (7 years)

Introduction: {‘brand’: ‘Beauflor’, ‘collection’: ‘Innovious Perceptions’, ‘product_name’: ‘Ollie Oak’, ‘SKU’: ‘60002081’, ‘size’: ‘8.78″ x 58.74″‘, ‘width’: ‘8.78″‘, ‘length’: ‘58.74″‘, ‘thickness’: ‘6 mm’, ‘structure’: ‘Rigid Core’, ‘install_type’: ‘Float’, ‘profile’: ‘Painted Bevel’, ‘gloss_level’: ‘Matte’, ‘wear_layer’: ’22 mil’, ‘type’: ‘Waterproof’, ‘sq_ft_per_box’: ‘21.48’, ‘suitable_rooms’: [‘Living Roo…

5. Mohawk – Laminate Flooring

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Mohawk Laminate Flooring for Family Room at Ollies Outlet in Lavale.

Strategic Sourcing Conclusion and Outlook for ollies wood flooring

In summary, strategic sourcing of Ollie’s wood flooring offers significant advantages for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By leveraging Ollie’s extensive range of quality flooring products at competitive prices, businesses can maximize their cost-efficiency while still delivering exceptional value to their customers. The unique selling proposition of Ollie’s, including the emphasis on first-quality merchandise at bargain prices, positions it as a compelling choice for buyers looking to enhance their inventory without compromising on quality.

Furthermore, the strategic partnerships that Ollie’s maintains with reputable brands ensure a consistent supply of diverse flooring options, catering to varied market demands. As the flooring industry continues to evolve, embracing innovation and sustainability will be key. International buyers are encouraged to explore Ollie’s offerings and consider how these products can meet their specific regional needs.

Looking ahead, the potential for growth in the wood flooring market remains strong. We invite you to connect with Ollie’s to discover how their strategic sourcing solutions can empower your business to thrive in an increasingly competitive landscape. Together, we can lay the foundation for a successful partnership that enhances your product offerings and drives profitability.