Choosing Your Fob Or Exw: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for fob or exw

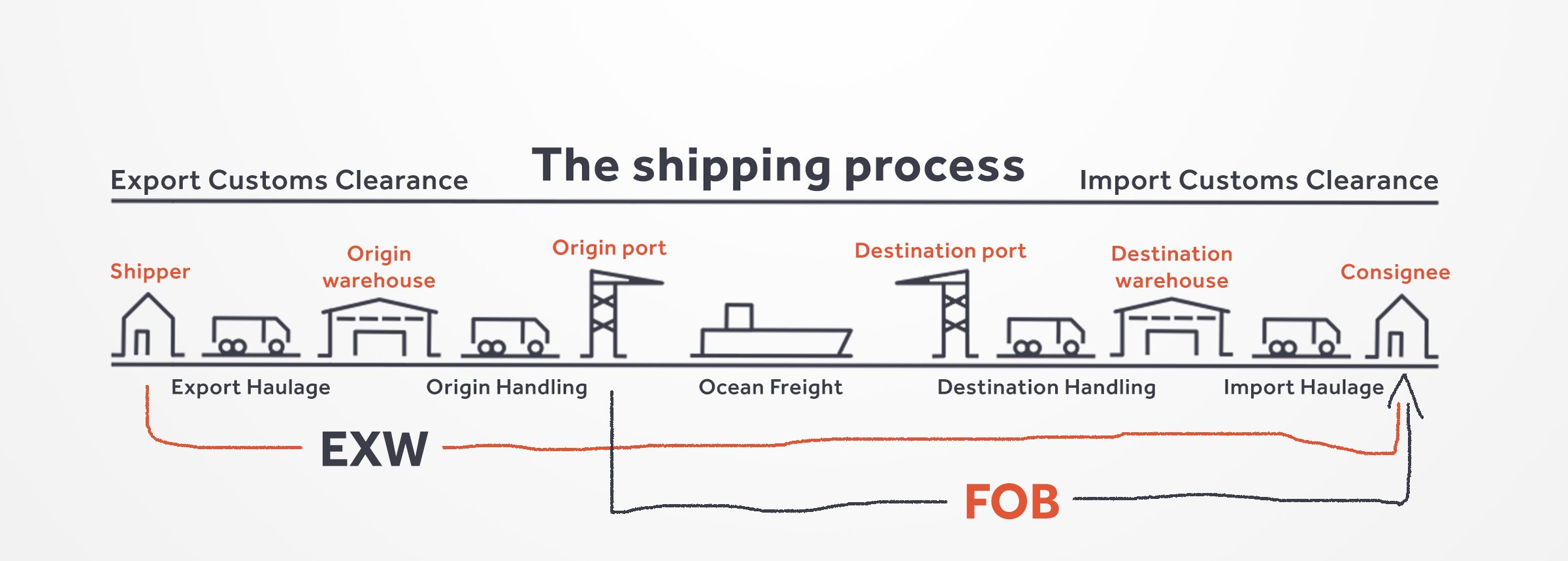

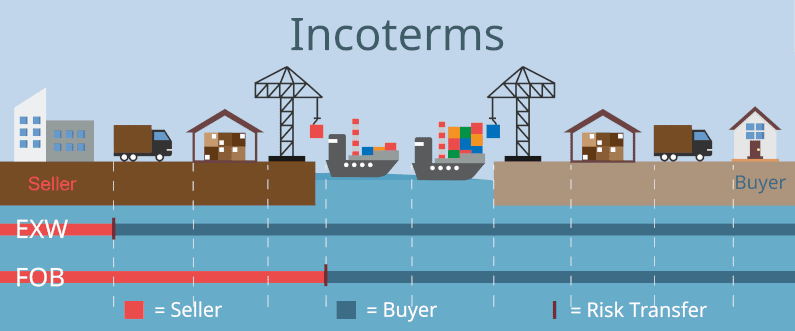

In the intricate landscape of international trade, navigating the complexities of shipping terms like FOB (Free On Board) and EXW (Ex Works) can be a significant challenge for B2B buyers. Understanding these Incoterms is crucial, especially when sourcing products from suppliers in diverse regions such as Africa, South America, the Middle East, and Europe. This guide is designed to demystify FOB and EXW, providing a comprehensive overview of their definitions, applications, and implications for cost management and risk allocation.

By exploring the key differences between these terms, buyers will gain insights into how to effectively vet suppliers, negotiate shipping arrangements, and ultimately make informed purchasing decisions. The guide will cover critical aspects such as the responsibilities of sellers and buyers, the financial implications of each term, and best practices for minimizing risks during the shipping process.

Arming yourself with this knowledge will empower you to optimize your supply chain and ensure smoother transactions with international partners, whether you are in Nigeria, Saudi Arabia, or elsewhere. Understanding FOB and EXW is not just about compliance; it’s about leveraging these terms to enhance your operational efficiency and drive your business forward in the global marketplace.

Understanding fob or exw Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| FOB (Free on Board) | Seller covers costs until goods are loaded onto the vessel. | Bulk shipments, high-value goods | Pros: Lower risk until loading; Cons: Higher shipping costs. |

| EXW (Ex Works) | Seller only needs to make goods available at their location. | Small shipments, low-value goods | Pros: Lower initial price; Cons: Higher responsibility and risk. |

| CIF (Cost, Insurance, and Freight) | Seller covers costs, insurance, and freight to the destination port. | International shipping with insurance needs | Pros: Comprehensive coverage; Cons: Potentially higher costs. |

| DAP (Delivered at Place) | Seller delivers goods ready for unloading at the buyer’s location. | Final delivery logistics | Pros: Minimal buyer effort; Cons: Less control over shipping costs. |

| FCA (Free Carrier) | Seller delivers goods to a carrier at a specified location. | Multi-modal transport | Pros: Flexible transport options; Cons: Responsibility shifts early. |

What Are the Key Characteristics of FOB (Free on Board)?

FOB (Free on Board) is a widely used Incoterm that designates the seller’s responsibility for all costs and risks associated with the shipment until the goods are loaded onto the shipping vessel. This term is particularly beneficial for businesses that require assurance that their goods will be handled properly until they are on board. FOB is suitable for bulk shipments or high-value goods, making it a preferred choice for companies that prioritize risk management in international transactions. Buyers should consider their experience with logistics and the reliability of their suppliers when opting for FOB.

How Does EXW (Ex Works) Work in International Trade?

EXW (Ex Works) places the minimum responsibility on the seller, who merely needs to make the goods available for pickup at their premises. The buyer assumes all costs and risks associated with transporting the goods from the seller’s location to their final destination. This Incoterm is ideal for small shipments or low-value goods, as it often results in lower initial pricing. However, buyers must be well-versed in logistics and customs regulations in the seller’s country to mitigate risks effectively. Companies with strong logistics networks may find EXW advantageous for controlling shipping costs.

What Are the Benefits of CIF (Cost, Insurance, and Freight)?

CIF (Cost, Insurance, and Freight) mandates that the seller covers the costs, insurance, and freight charges to transport goods to the destination port. This term is particularly useful for international shipping where buyers want comprehensive coverage against potential risks during transit. CIF is favored by businesses that prioritize insurance and risk mitigation in their shipping processes. However, buyers should be aware that the total cost may be higher due to the seller’s insurance and freight charges, making it essential to evaluate the overall value proposition.

Why Choose DAP (Delivered at Place) for Your Shipping Needs?

DAP (Delivered at Place) means that the seller is responsible for delivering goods to a specified destination, ready for unloading. This term simplifies the logistics for buyers, as they do not need to manage the complexities of transportation until the goods arrive. DAP is particularly useful for businesses that want to minimize their logistical involvement and ensure a seamless delivery process. However, buyers may face higher costs associated with this convenience, and they should assess whether the added expense aligns with their operational budgets.

What Are the Advantages of FCA (Free Carrier)?

FCA (Free Carrier) allows the seller to deliver goods to a carrier at a specified location, which can be advantageous for companies that utilize multiple modes of transport. This Incoterm offers flexibility in logistics, making it suitable for businesses that engage in complex supply chains. The responsibility for costs and risks shifts early in the process, which can be beneficial for buyers with established logistics capabilities. However, buyers should be prepared to manage more responsibility from the outset, ensuring they have the necessary resources to handle the logistics efficiently.

Key Industrial Applications of fob or exw

| Industry/Sector | Specific Application of fob or exw | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Importing machinery and raw materials | Reduces shipping costs and risks for buyers | Assess supplier reliability and local logistics capabilities |

| Agriculture | Exporting agricultural products | Ensures timely delivery and cost control | Understand export regulations and seasonal availability |

| Electronics | Sourcing electronic components from overseas | Greater control over shipping and logistics costs | Evaluate the supplier’s export compliance and shipping options |

| Textiles | Importing fabrics and finished garments | Streamlines supply chain management | Consider local customs duties and tariffs |

| Construction | Procurement of construction materials | Minimizes delays in project timelines | Verify supplier’s ability to meet delivery schedules and standards |

How is FOB or EXW Used in Manufacturing for International Buyers?

In the manufacturing sector, FOB and EXW are critical for importing machinery and raw materials. Buyers often prefer FOB to mitigate risks, as the seller manages logistics until loading. This arrangement is beneficial for companies in regions like Nigeria, where local shipping knowledge may be limited. Buyers must assess supplier reliability and their ability to handle export documentation to avoid delays in production.

What Are the Benefits of FOB or EXW in Agriculture?

For agricultural exports, using FOB can help ensure that products reach their destination promptly, maintaining freshness and quality. This is particularly important for buyers in South America who deal with perishable goods. FOB allows sellers to manage logistics up to the shipping point, which can be crucial for compliance with international food safety standards. Buyers should be aware of export regulations and seasonal availability to optimize their sourcing strategies.

How Do Electronics Companies Leverage FOB or EXW?

Electronics companies frequently utilize FOB to source components from overseas suppliers. This method allows buyers to have more control over shipping logistics and costs, which is essential for managing tight production schedules. For buyers in the Middle East, understanding the supplier’s export compliance is vital to avoid potential legal issues. Additionally, evaluating shipping options and timelines can enhance supply chain efficiency.

What is the Role of FOB or EXW in the Textile Industry?

In the textile industry, FOB is often chosen for importing fabrics and finished garments, allowing sellers to handle logistics until the goods are loaded. This is especially beneficial for European buyers looking to streamline their supply chains. Buyers must consider local customs duties and tariffs that may impact overall costs. Ensuring that suppliers are capable of meeting quality standards and delivery timelines is crucial for maintaining competitive advantage.

How Do Construction Firms Benefit from FOB or EXW?

Construction firms utilize FOB and EXW when procuring construction materials. FOB is advantageous as it minimizes delays, ensuring that materials arrive on schedule for project timelines. Buyers in Africa should verify suppliers’ ability to meet delivery standards and timelines, as delays can lead to significant project cost overruns. Understanding the logistics involved and potential risks associated with international shipping is essential for effective project management.

3 Common User Pain Points for ‘fob or exw’ & Their Solutions

Scenario 1: Navigating Hidden Costs in FOB Transactions

The Problem: As an international B2B buyer, you might find that while Free on Board (FOB) seems advantageous because the seller handles costs until the goods are loaded onto the vessel, hidden costs can quickly add up. Issues such as unexpected freight charges, insurance fees, and customs duties may not be clearly communicated upfront. This lack of transparency can lead to budget overruns and strain your financial planning, especially for buyers in regions like Africa or South America, where logistics can be more complex.

The Solution: To mitigate hidden costs in FOB transactions, establish clear communication with your supplier before finalizing the deal. Request a detailed breakdown of all anticipated costs associated with the shipment, including freight, insurance, and any potential customs fees. Consider using a freight forwarder who specializes in your supplier’s region, as they can provide insights into local practices and help negotiate better terms. Additionally, utilize Incoterms 2020 guidelines in your contracts, ensuring that all parties understand their responsibilities. This proactive approach will enhance transparency and help you avoid unpleasant surprises in your shipping budget.

Scenario 2: Managing Risk with EXW Shipping

The Problem: When opting for Ex Works (EXW), many buyers underestimate the risks involved, as the seller’s responsibility ends when the goods are made available at their location. This can lead to difficulties in logistics management, especially for buyers unfamiliar with local regulations or transport networks. For example, a buyer in Nigeria purchasing machinery from Europe may struggle with local transport arrangements, customs clearance, and potential delays, which could jeopardize project timelines.

The Solution: To effectively manage risks associated with EXW shipping, invest time in understanding the logistics landscape of the seller’s country. Engage a reputable freight forwarder who can assist with local transport, customs clearance, and ensure compliance with regulations. Additionally, build a checklist that outlines each step of the process from pickup to delivery, including timelines and responsibilities. By taking these proactive measures, you can reduce uncertainty and ensure a smoother logistics process, ultimately safeguarding your project timelines.

Scenario 3: Miscommunication Over Shipping Terms

The Problem: Misunderstandings regarding the terms of shipping can lead to significant issues for B2B buyers dealing with FOB or EXW. A common scenario occurs when buyers assume that the seller will handle all logistics after the goods are loaded (in the case of FOB) or that the seller will assist with loading (in the case of EXW). This miscommunication can result in delays, additional costs, and frustration, particularly for buyers operating in regions with complex supply chains, such as the Middle East.

The Solution: To avoid miscommunication, it is crucial to clarify expectations in the contract before signing. Create a comprehensive shipping agreement that specifies who is responsible for each aspect of the shipping process. Use clear language to define responsibilities related to loading, transportation, insurance, and customs. Furthermore, consider regular check-ins with your supplier and logistics partners to ensure everyone is on the same page. This collaborative approach will foster better relationships and minimize the risk of misunderstandings, leading to a more efficient shipping experience.

Strategic Material Selection Guide for fob or exw

What Are the Key Properties of Common Materials Used in FOB or EXW Shipping?

When selecting materials for international shipping under FOB (Free On Board) or EXW (Ex Works) terms, it’s essential to consider their properties, advantages, and limitations. The choice of material can significantly impact the durability, cost, and suitability of the end product, especially for international B2B buyers from regions like Africa, South America, the Middle East, and Europe.

How Do Metals Perform in FOB or EXW Shipping?

Key Properties: Metals, such as steel and aluminum, are known for their high strength-to-weight ratios and excellent durability. They can withstand high temperatures and pressures, making them suitable for various applications, including machinery and structural components.

Pros & Cons: The primary advantage of metals is their durability and resistance to wear and tear, which makes them ideal for heavy-duty applications. However, they can be prone to corrosion if not treated properly, which can be a significant drawback in humid or coastal environments. Additionally, the manufacturing complexity and costs can vary widely based on the type of metal and required finishes.

Impact on Application: Metals are often used in environments where mechanical strength and structural integrity are critical. For instance, steel is commonly used in construction, while aluminum is favored for lightweight applications.

Considerations for International Buyers: Buyers should be aware of compliance with international standards such as ASTM or DIN, particularly in regions like Saudi Arabia and Nigeria, where local regulations may dictate specific material grades or treatments.

What Role Do Plastics Play in FOB or EXW Shipping?

Key Properties: Plastics, including polyethylene and polypropylene, offer excellent chemical resistance and are lightweight, making them suitable for a wide range of applications, from packaging to automotive components.

Pros & Cons: The key advantage of plastics is their versatility and lower cost compared to metals. They are also resistant to corrosion, which is beneficial in chemical handling. However, they may not withstand high temperatures as effectively as metals and can be less durable in harsh environments.

Impact on Application: Plastics are often used in applications requiring corrosion resistance and lightweight properties, such as in the packaging industry or for components in consumer electronics.

Considerations for International Buyers: Buyers should consider the specific grades of plastics that meet local regulations, such as those in Europe, where compliance with REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is mandatory.

How Do Composites Enhance FOB or EXW Shipping?

Key Properties: Composite materials, such as fiberglass and carbon fiber, combine the strengths of different materials to provide high strength, low weight, and excellent fatigue resistance.

Pros & Cons: Composites offer significant advantages in terms of weight savings and strength, making them ideal for aerospace and automotive applications. However, they can be more expensive to manufacture and may require specialized handling during shipping.

Impact on Application: Composites are particularly useful in applications where weight is a critical factor, such as in aircraft or high-performance vehicles.

Considerations for International Buyers: Buyers should ensure that composite materials meet international standards and certifications, particularly in the aerospace sector, where compliance with stringent regulations is crucial.

What Are the Benefits of Wood in FOB or EXW Shipping?

Key Properties: Wood is a natural material known for its strength and aesthetic appeal. It is relatively lightweight and can be treated for various environmental conditions.

Pros & Cons: The primary advantage of wood is its renewability and ease of processing, making it suitable for a variety of applications, from furniture to construction. However, wood can be susceptible to moisture and pests, which may limit its use in certain environments.

Impact on Application: Wood is often used in applications where aesthetic qualities are important, such as in furniture or decorative elements.

Considerations for International Buyers: Buyers should be aware of the phytosanitary regulations that may apply to wood products, especially when importing into regions with strict pest control measures.

Summary Table of Material Selection for FOB or EXW Shipping

| Material | Typical Use Case for FOB or EXW | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Metals | Machinery, structural components | High durability and strength | Prone to corrosion without treatment | Medium |

| Plastics | Packaging, automotive components | Lightweight and cost-effective | Limited high-temperature performance | Low |

| Composites | Aerospace, high-performance vehicles | High strength-to-weight ratio | Higher manufacturing costs | High |

| Wood | Furniture, decorative elements | Aesthetic appeal and renewability | Susceptible to moisture and pests | Medium |

This detailed analysis provides international B2B buyers with insights into material selection for FOB and EXW shipping, ensuring informed decision-making tailored to their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for fob or exw

What Are the Key Stages in the Manufacturing Process for FOB and EXW?

Understanding the manufacturing processes involved in FOB (Free On Board) and EXW (Ex Works) agreements is essential for B2B buyers. These processes typically encompass several stages, including material preparation, forming, assembly, and finishing. Each stage is critical in ensuring that the final product meets the buyer’s specifications and quality standards.

How Does Material Preparation Impact Quality in FOB and EXW?

Material preparation is the first step in the manufacturing process. It involves selecting raw materials and components that meet the required specifications. For FOB agreements, the seller is responsible for ensuring that materials are ready for loading onto the transport vessel. In contrast, under EXW terms, the buyer must verify the quality of materials since they will take responsibility for transporting them.

In both scenarios, material quality is paramount. Buyers should ensure that suppliers use high-grade materials that comply with international standards, such as ASTM or ISO standards. It is advisable for buyers to request material certifications and conduct initial quality checks to mitigate risks associated with poor-quality inputs.

What Forming Techniques Are Commonly Used in Manufacturing?

The forming stage is where raw materials are shaped into the desired form. This can involve processes such as casting, forging, machining, or molding, depending on the product being manufactured. For instance, metal components might undergo machining processes, while plastic parts may be molded.

In FOB scenarios, the seller is responsible for the forming process, including ensuring that the techniques used are appropriate for the materials and product specifications. Buyers can request process documentation and reports to verify that the forming techniques align with industry standards.

How Important Is Assembly in the Manufacturing Process?

Assembly is a critical stage where various components are put together to create the final product. This stage can involve manual labor, automated assembly lines, or a combination of both. For FOB agreements, the seller must ensure that assembly is completed before the goods are loaded onto the shipping vessel.

Buyers should inquire about the assembly techniques used, particularly if the final product involves multiple components. Quality assurance during assembly can be enhanced through the implementation of standardized assembly procedures and training for assembly personnel. Buyers can request assembly line audits or reviews of assembly process documentation to ensure compliance with quality standards.

What Finishing Techniques Should B2B Buyers Be Aware Of?

Finishing processes enhance the aesthetic and functional qualities of the product, such as painting, coating, or polishing. This stage is crucial for ensuring that the product meets the buyer’s specifications regarding appearance and durability.

For FOB agreements, the seller is responsible for completing finishing processes before the goods are loaded. Buyers should specify their finishing requirements clearly in the purchase agreement and request samples or prototypes before final production. This helps ensure that the final product meets expectations in terms of quality and appearance.

What Quality Assurance Standards Are Relevant for FOB and EXW?

Quality assurance (QA) is vital in ensuring that products meet both buyer expectations and regulatory requirements. International standards such as ISO 9001 set the framework for quality management systems, helping organizations ensure consistent quality in their products and services.

Which International Standards Should B2B Buyers Consider?

When engaging with suppliers under FOB or EXW terms, B2B buyers should be aware of relevant international standards that apply to their industry. For example:

- ISO 9001: Focuses on quality management systems and continuous improvement.

- CE Marking: Required for products sold within the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Standards: Applicable in the oil and gas industry, ensuring product quality and reliability.

Buyers should verify that suppliers hold the necessary certifications and comply with these standards. Requesting copies of certification and audit reports can provide reassurance regarding the supplier’s commitment to quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is a systematic process that helps identify defects and ensure that products meet specified requirements. Common QC checkpoints include:

- Incoming Quality Control (IQC): Inspection of materials and components upon arrival at the manufacturing facility.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to identify and rectify issues early.

- Final Quality Control (FQC): Comprehensive inspection of finished products before shipment.

Implementing these checkpoints can significantly reduce the risk of defects and ensure that products are manufactured to the highest standards. Buyers should inquire about the QC processes and ask for reports from each checkpoint.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should adopt a proactive approach to supplier verification. This can include:

- Conducting Audits: Regular audits of the supplier’s facilities can provide insight into their manufacturing processes and quality control measures. Buyers should consider both announced and unannounced audits to get a comprehensive view.

- Requesting Reports: Buyers can request detailed QC reports that outline inspection results, defect rates, and corrective actions taken. These reports can help buyers assess the supplier’s commitment to quality.

- Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These inspectors can conduct pre-shipment inspections to verify that products meet specified standards before they are loaded for shipment.

What Nuances Should International B2B Buyers Be Aware Of?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances when dealing with FOB and EXW agreements. These include:

- Understanding Local Regulations: Different countries have varying regulations regarding product quality, safety standards, and import/export procedures. Buyers should familiarize themselves with the regulations in both the supplier’s and their own countries to avoid compliance issues.

- Cultural Differences: Communication styles and business practices can vary significantly across regions. Building strong relationships with suppliers and understanding cultural nuances can facilitate smoother transactions and quality assurance processes.

- Logistics Challenges: International shipping can introduce additional complexities, such as customs clearance and transportation delays. Buyers should work closely with logistics partners to ensure timely delivery and compliance with shipping regulations.

In conclusion, understanding the manufacturing processes and quality assurance measures associated with FOB and EXW agreements is crucial for B2B buyers. By being proactive in verifying supplier quality, requesting relevant certifications, and conducting thorough inspections, buyers can mitigate risks and ensure that they receive high-quality products that meet their specifications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fob or exw’

When engaging in international procurement, understanding the nuances of shipping terms like FOB (Free On Board) and EXW (Ex Works) is essential. This guide provides a step-by-step checklist to help B2B buyers navigate the complexities of these Incoterms, ensuring a smooth sourcing process.

Step 1: Assess Your Shipping Needs

Before deciding between FOB and EXW, evaluate your shipping requirements. Consider factors such as the type of goods, destination, and delivery timelines. Understanding your specific needs will help you choose the most suitable Incoterm that aligns with your logistics capabilities and risk tolerance.

Step 2: Understand the Responsibilities of Each Incoterm

Familiarize yourself with the obligations each party holds under FOB and EXW. For FOB, the seller is responsible for costs and risks until the goods are loaded onto the vessel, while with EXW, the buyer takes on all responsibility as soon as the goods are made available for pickup. Knowing these distinctions is crucial for managing expectations and ensuring compliance with your contract.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they can meet your shipping requirements. Request company profiles, references, and previous case studies to gauge their reliability. Look for suppliers with a proven track record in handling the specific Incoterms you are considering, as their experience can significantly impact the efficiency of your procurement process.

Step 4: Negotiate Terms Clearly

When entering negotiations, be clear about the Incoterms you wish to use and ensure both parties understand their responsibilities. Outline specific terms related to costs, insurance, and risk transfer in your agreement. A well-defined contract minimizes disputes and clarifies obligations for both the buyer and seller.

Step 5: Determine Insurance Needs

Evaluate the insurance coverage required under each Incoterm. With FOB, the seller typically covers insurance until the goods are loaded, while with EXW, the buyer must arrange their own insurance from the seller’s location. Assessing your insurance needs protects your investment and mitigates potential losses during transit.

Step 6: Plan for Logistics and Customs Clearance

Consider logistics and customs clearance requirements early in the process. For FOB shipments, ensure that the seller can handle export clearance efficiently, while for EXW, you must be prepared to manage all logistics and customs processes. Efficient planning here can prevent delays and additional costs.

Step 7: Monitor Shipment Progress

After placing an order, closely monitor the shipment’s progress. Use tracking systems to stay informed about transit times and any potential issues. Regular communication with your supplier can help address concerns quickly and ensure that your goods arrive on time and in good condition.

By following this checklist, international B2B buyers can effectively navigate the complexities of sourcing with FOB and EXW terms, leading to more successful procurement processes.

Comprehensive Cost and Pricing Analysis for fob or exw Sourcing

What Are the Key Cost Components in FOB and EXW Sourcing?

When sourcing goods internationally, understanding the cost structure associated with FOB (Free On Board) and EXW (Ex Works) is crucial for effective budgeting and financial planning. Both Incoterms define different responsibilities and liabilities that can significantly influence the overall costs incurred by a buyer.

Materials and Labor

The primary costs in any sourcing strategy stem from materials and labor. For both FOB and EXW, the quality and type of materials directly impact the cost. Suppliers may offer different grades of materials, which can lead to variations in pricing. Labor costs will also vary depending on the supplier’s location and the complexity of the manufacturing process.

Manufacturing Overhead and Tooling Costs

Manufacturing overhead includes expenses such as utilities, rent, and equipment depreciation. Tooling costs may arise from the need for specialized molds or machinery to produce specific items. Understanding these components helps in negotiating better pricing, especially when dealing with suppliers in regions with lower overhead costs.

Quality Control (QC) Expenses

Quality assurance processes are vital in maintaining product standards. The costs associated with QC can vary depending on the supplier’s quality management systems and certifications. Buyers should inquire about these processes to ensure they align with their quality expectations and are reflected in the final price.

Logistics and Freight Costs

Logistics is a critical element in the cost structure for both FOB and EXW. For FOB, the seller handles logistics up to the shipping point, which may provide a more predictable cost structure. Conversely, with EXW, the buyer assumes full responsibility for logistics, potentially increasing the total cost, especially if they lack familiarity with local transportation networks.

Margin Considerations

Both FOB and EXW arrangements will include a profit margin for the supplier. This margin can vary based on several factors, including order volume, the complexity of the product, and the competitive landscape. Buyers should assess whether the margin justifies the value provided, particularly when sourcing from different regions.

How Do Volume and Customization Influence Pricing?

Volume and Minimum Order Quantities (MOQ)

Purchasing in larger volumes typically leads to lower per-unit costs due to economies of scale. Suppliers are often more willing to negotiate favorable terms when buyers meet or exceed MOQs. This is particularly relevant in regions like Africa and South America, where local suppliers may offer discounts for bulk purchases.

Specifications and Customization

Customization can significantly impact pricing. More complex specifications often require additional resources or modifications to production processes, which can inflate costs. Buyers should weigh the benefits of customization against its cost implications to ensure it aligns with their overall budget.

What Pricing Nuances Should International B2B Buyers Consider?

Understanding Total Cost of Ownership (TCO)

Buyers must consider not just the upfront costs but the Total Cost of Ownership, which includes logistics, duties, taxes, and potential risks associated with shipping delays or damages. This holistic view of costs can inform better sourcing decisions and ensure that the chosen Incoterm aligns with financial goals.

Negotiation Strategies for Cost Efficiency

Effective negotiation is vital for achieving cost efficiency. Buyers should prepare by researching market prices, understanding supplier capabilities, and leveraging competitive quotes. Establishing long-term relationships with suppliers can also yield better pricing and terms over time.

How Do Supplier Factors and Incoterms Affect Pricing?

Supplier Reputation and Capability

The supplier’s reputation and capability can affect pricing. Reliable suppliers with established quality standards may charge a premium, while less reputable suppliers might offer lower prices at the risk of compromised quality. Evaluating suppliers based on their performance history and customer feedback can mitigate risks.

Impact of Incoterms on Pricing

The choice between FOB and EXW can significantly influence overall costs. FOB may provide more predictable costs as the seller assumes responsibility until loading, while EXW may expose buyers to unforeseen logistics costs. Understanding these implications is essential for making informed sourcing decisions.

Conclusion

While FOB and EXW offer different advantages and challenges, the key to successful sourcing lies in understanding the cost components, pricing influencers, and strategic negotiation. Buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should approach sourcing with a comprehensive understanding of the financial landscape to ensure optimal purchasing decisions. As always, indicative prices should be approached with caution, as fluctuations in currency, market demand, and supplier capabilities can influence the final costs.

Alternatives Analysis: Comparing fob or exw With Other Solutions

Exploring Alternative Shipping Solutions to FOB and EXW

In the realm of international trade, selecting the right shipping method is crucial for B2B buyers. While FOB (Free On Board) and EXW (Ex Works) are popular Incoterms, there are alternative solutions that may better suit specific business needs. This section will compare FOB and EXW against other viable shipping methods: DDP (Delivered Duty Paid) and CIF (Cost, Insurance, and Freight). Each method offers unique advantages and considerations, enabling buyers to make informed decisions.

| Comparison Aspect | FOB or EXW | DDP (Delivered Duty Paid) | CIF (Cost, Insurance, and Freight) |

|---|---|---|---|

| Performance | Moderate risk management; buyer assumes significant responsibilities (EXW) or seller until loading (FOB) | High; seller manages all logistics, including customs and duties | Good; seller covers transport and insurance to the destination port |

| Cost | Variable; depends on buyer’s logistics management (EXW) or seller’s shipping costs (FOB) | Higher due to seller’s comprehensive service | Moderate; costs include freight and insurance, but buyer manages destination charges |

| Ease of Implementation | Requires understanding of logistics; can be complex for inexperienced buyers | Simple for buyers; minimal logistics involvement required | Moderate; buyer must understand insurance and freight arrangements |

| Maintenance | Low; once goods are shipped, little ongoing responsibility | Low; seller handles all logistics until delivery | Moderate; buyer needs to manage any post-arrival logistics |

| Best Use Case | Suitable for experienced buyers with established logistics | Ideal for buyers wanting a hassle-free experience with full delivery | Best for buyers wanting insurance and freight managed but maintaining some control over logistics |

What Are the Advantages and Disadvantages of DDP?

DDP (Delivered Duty Paid) offers a comprehensive solution for international shipping, where the seller assumes all responsibilities until the goods are delivered to the buyer’s specified location. This method simplifies the process for buyers, as they do not need to deal with customs, duties, or logistics management. However, DDP can be more expensive due to the extensive services provided by the seller, which may include hidden costs. Buyers may also find themselves reliant on the seller’s logistics capabilities, which can be a concern if the seller is not experienced in international shipping.

How Does CIF Compare in Shipping Solutions?

CIF (Cost, Insurance, and Freight) is another popular alternative that offers a middle ground between FOB and DDP. Under CIF, the seller covers the costs of shipping and insurance to the destination port, making it a safer option for buyers who want to mitigate risks associated with loss or damage during transit. However, once the goods reach the port, the buyer takes on responsibility for further transportation and customs clearance. This can be a disadvantage for buyers unfamiliar with the logistics of importing goods, as they need to handle the complexities post-arrival.

Conclusion: How to Choose the Right Shipping Method for Your Business

Selecting the right shipping method depends on various factors, including your experience with logistics, budget constraints, and the level of control you desire over the shipping process. If you prefer a hands-off approach with minimal hassle, DDP might be the best choice. Alternatively, if you are comfortable managing logistics and want to save costs, CIF could be advantageous. Meanwhile, FOB and EXW are suitable for businesses with established logistics networks or those looking for cost-effective solutions. Ultimately, evaluating the specific needs of your business will guide you to the most appropriate shipping method for your international transactions.

Essential Technical Properties and Trade Terminology for fob or exw

What Are the Key Technical Properties of FOB and EXW Shipping Terms?

When engaging in international trade, understanding the technical specifications of shipping terms like FOB (Free On Board) and EXW (Ex Works) is vital. Here are some critical properties to consider:

1. Risk and Responsibility Transfer Point

In FOB transactions, the seller retains responsibility for the goods until they are loaded onto the vessel at the designated port. In contrast, under EXW, the seller’s responsibility ends once the goods are made available for pickup. Understanding where the risk shifts is crucial for buyers to manage potential liabilities effectively.

2. Cost Allocation

FOB includes costs related to loading the goods onto the vessel, export duties, and transportation to the port. EXW minimizes the seller’s costs, making the buyer responsible for all transportation costs from the seller’s location onward. This distinction helps buyers assess total landed costs and negotiate better terms.

3. Customs Clearance

With FOB, the seller often handles the customs clearance and export documentation until the goods are loaded. Conversely, under EXW, the buyer must manage all customs procedures. This understanding is essential for ensuring compliance and avoiding delays in delivery.

4. Freight Arrangements

In FOB agreements, the buyer typically engages a freight forwarder to arrange transport after the goods are loaded. With EXW, the buyer bears the full responsibility for logistics, necessitating a deeper understanding of shipping routes and costs. Familiarity with these arrangements can lead to more efficient and cost-effective shipping solutions.

5. Shipping Mode Flexibility

FOB is generally used for sea freight, while EXW can be applied to any mode of transport, including road and air. This flexibility allows buyers to choose the most suitable transport method based on their specific needs and market conditions.

6. Delivery Location Specifications

Both terms require clear communication regarding the delivery location. In FOB, the location is the loading port, while EXW specifies a location for pickup, typically at the seller’s premises. Precise definitions prevent misunderstandings and ensure smooth transactions.

What Are the Common Trade Terms Related to FOB and EXW?

To navigate international trade effectively, familiarity with industry terminology is essential. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking to source components or finished goods.

2. MOQ (Minimum Order Quantity)

MOQ defines the smallest number of units a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchasing strategies and avoid excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific goods or services. It is an essential tool for buyers to compare offers and select suppliers based on their needs.

4. Incoterms (International Commercial Terms)

Incoterms are a set of globally recognized rules that define the responsibilities of buyers and sellers in international trade. Familiarity with these terms, including FOB and EXW, is critical for ensuring clarity in contracts.

5. Bill of Lading

This legal document serves as a receipt for goods and outlines the terms of the transportation agreement. Understanding the bill of lading is vital for buyers to track shipments and manage claims if issues arise.

6. Freight Forwarder

A freight forwarder is an intermediary that arranges the transportation of goods on behalf of shippers. Engaging a reliable freight forwarder can help buyers navigate complex logistics and ensure timely delivery.

Understanding these technical properties and industry terminology will empower B2B buyers to make informed decisions, optimize their supply chain, and mitigate risks associated with international shipping.

Navigating Market Dynamics and Sourcing Trends in the fob or exw Sector

What Are the Current Market Dynamics and Key Trends in FOB or EXW Sourcing?

The global landscape for international B2B sourcing using FOB (Free On Board) and EXW (Ex Works) Incoterms is shaped by several driving factors. One significant trend is the increasing reliance on digital platforms for logistics and supply chain management, which enhances transparency and efficiency. Technologies such as blockchain and AI are being adopted to streamline operations, reduce costs, and mitigate risks associated with international trade, making it easier for buyers in regions like Africa, South America, the Middle East, and Europe to manage their shipments effectively.

Moreover, geopolitical tensions and trade regulations continue to influence sourcing strategies. For instance, buyers from Nigeria or Saudi Arabia must navigate tariffs and trade agreements that can impact FOB and EXW arrangements. The rise of regional trade agreements is also noteworthy; such agreements often simplify logistics and reduce costs, allowing B2B buyers to leverage FOB terms more effectively by minimizing risks associated with shipping.

Sustainability is another emerging trend. Buyers are increasingly looking for suppliers who can demonstrate environmentally responsible practices, which can influence their choice between FOB and EXW. Understanding the implications of these terms in the context of sustainability can lead to more informed decision-making, enabling companies to align their sourcing strategies with corporate social responsibility goals.

How Does Sustainability and Ethical Sourcing Impact FOB or EXW Decisions?

Sustainability and ethical sourcing are now pivotal considerations for B2B buyers, especially in the context of FOB and EXW agreements. The environmental impact of shipping practices can no longer be overlooked, as companies face growing pressure from consumers and regulators to adopt greener practices. Buyers are increasingly assessing the carbon footprint of their logistics choices, including transportation modes and routes, which can affect the total cost of ownership for goods.

Incorporating sustainable materials and seeking suppliers with green certifications can enhance a company’s reputation and marketability. For instance, choosing suppliers that prioritize eco-friendly packaging or use renewable energy in their operations can significantly influence sourcing decisions. Buyers utilizing FOB terms may find it easier to negotiate sustainable shipping options since the seller retains responsibility until goods are loaded, allowing for collaboration on eco-friendly logistics.

Furthermore, ethical supply chains are vital in fostering trust and transparency. Buyers from regions like South America and Africa are becoming more vigilant about ensuring that their suppliers adhere to fair labor practices and environmental standards. This focus on ethical sourcing not only aligns with global sustainability trends but can also open doors to new markets and consumer segments that prioritize these values.

What Is the Historical Context of FOB and EXW in B2B Trade?

The concepts of FOB and EXW have evolved significantly since the introduction of Incoterms by the International Chamber of Commerce (ICC) in 1936. Initially developed to standardize shipping terms, these Incoterms have become essential tools for facilitating international trade. Over the decades, as global commerce expanded, the need for clear definitions of responsibilities and risks associated with shipping became paramount.

FOB emerged as a favored option for many traders because it offered a balanced approach to risk and cost management. It allows sellers to take on responsibility until goods are loaded, which can foster trust in new buyer-supplier relationships. Conversely, EXW has gained traction among companies that prefer to control their logistics processes, particularly with advancements in technology that enable easier management of shipping and customs.

As international trade continues to adapt to new challenges—ranging from environmental concerns to technological advancements—FOB and EXW remain relevant, allowing businesses to tailor their sourcing strategies to meet evolving market demands. Understanding the historical context of these terms provides valuable insights into their application in today’s dynamic B2B landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of fob or exw

-

How do I choose between FOB and EXW for my international shipments?

Choosing between FOB and EXW largely depends on your experience with international shipping and your specific needs. If you are less experienced or prefer a structured approach, FOB can be advantageous as it shifts more risk to the seller until the goods are loaded onto the vessel. Conversely, if you are familiar with the logistics in the seller’s country and want to control transportation costs, EXW might be the better choice. Always assess your risk tolerance, supplier reliability, and the nature of the goods to make an informed decision. -

What are the key responsibilities of buyers and sellers under FOB and EXW?

Under FOB (Free on Board), the seller is responsible for all costs and risks associated with the goods until they are loaded onto the shipping vessel. After loading, the buyer assumes responsibility. In contrast, EXW (Ex Works) places minimal responsibility on the seller, who only needs to make the goods available for pickup. The buyer bears all transportation costs and risks from the seller’s location onward. Understanding these responsibilities helps in contract negotiations and logistics planning. -

How can I vet suppliers when considering FOB or EXW terms?

Vetting suppliers is crucial, especially when using FOB or EXW terms. Start by checking their business credentials, customer reviews, and financial stability. Conduct site visits if possible, and inquire about their logistics capabilities and experience with international shipping. Establish clear communication channels and request references from other buyers. A reliable supplier will provide transparency about their processes and demonstrate a commitment to quality assurance. -

What payment terms should I consider when sourcing with FOB or EXW?

When negotiating payment terms for FOB or EXW agreements, consider options such as letters of credit, advance payments, or payment upon delivery. FOB arrangements may allow for more flexibility since the seller handles initial logistics, while EXW might require upfront payments to cover transportation costs. Ensure that the payment terms are clearly defined in your contract to avoid misunderstandings and protect your investment. -

How do I handle customs clearance for FOB and EXW shipments?

For FOB shipments, the seller is generally responsible for export clearance, while the buyer must manage import clearance. With EXW, the buyer is responsible for both export and import clearance, which may require a thorough understanding of customs regulations in both countries. Engage a customs broker to facilitate the process, ensuring all necessary documentation is complete and compliant with local laws to avoid delays. -

What are the implications of Minimum Order Quantities (MOQ) when using FOB or EXW?

Minimum Order Quantities (MOQ) can significantly impact your sourcing strategy. Suppliers may set higher MOQs for FOB terms to cover their logistics costs, while EXW may offer more flexibility as the buyer manages transportation. Always clarify MOQs upfront and assess whether they align with your business needs. If MOQs are prohibitive, consider negotiating lower quantities or seeking alternative suppliers who can accommodate your order size. -

How can I ensure quality assurance (QA) when sourcing internationally under FOB or EXW?

Implementing a robust quality assurance process is essential when sourcing internationally. For FOB, the seller should conduct quality checks before loading the goods. In the case of EXW, the buyer assumes more responsibility, so consider arranging third-party inspections at the seller’s location. Establish clear quality specifications in your contract and consider including penalties for non-compliance to incentivize adherence to your quality standards. -

What logistical challenges should I anticipate when using FOB or EXW?

Logistical challenges can vary significantly between FOB and EXW arrangements. With FOB, you may face delays if the seller encounters issues loading goods onto the vessel. For EXW, the buyer must coordinate all logistics, which can be complex if unfamiliar with local transport systems. Plan for potential disruptions by researching local logistics providers, understanding customs processes, and building contingency plans to mitigate risks in your supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Fob Or Exw Manufacturers & Suppliers List

1. Shipping Terms – EXW, FOB, DDP Explained

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: EXW (Ex Works): Equal to unit price. The buyer is responsible for all transportation costs and risks.

FOB (Free On Board): Roughly equals EXW + China delivery fee + surcharge fees at loading port. The supplier prepares declaration documents.

DDP (Delivered Duty Paid): Roughly equals FOB + customs clearance + import duties. The supplier handles all processes of the shipment.

Additional Tip: Clar…

2. EW Medico – PROSENSO™ Nitrile & Latex Gloves

Domain: ewmedico.com

Registered: 2020 (5 years)

Introduction: PROSENSO™ BLUE NITRILE GLOVES, PROSENSO™ BLUE FEATHER NITRILE GLOVES, PROSENSO™ BLACK NITRILE GLOVES, PROSENSO™ WHITE NITRILE GLOVES, PROSENSO™ PEARL LATEX GLOVES, PROSENSO™ BIODEGRADABLE GLOVES, PROSENSO™ SURGICAL PPE

3. Eurosender – Understanding EXW and FOB Incoterms

Domain: eurosender.com

Registered: 2014 (11 years)

Introduction: EXW (Ex Works) and FOB (Free On Board) are Incoterms used in international freight transport to define seller and buyer responsibilities. Key differences include:

1. Responsibility Shift: Under FOB, the seller is responsible for loading goods onto the vessel; under EXW, the seller only makes goods available at a designated location.

2. Transport Costs: FOB sellers pay for transport to the vessel…

Strategic Sourcing Conclusion and Outlook for fob or exw

In navigating the complexities of international trade, understanding the distinctions between FOB (Free on Board) and EXW (Ex Works) is vital for B2B buyers. Each Incoterm offers unique advantages and challenges. FOB is often preferred for those seeking a more structured approach, as it minimizes risk until goods are loaded onto the vessel, providing an added layer of security for less experienced buyers. Conversely, EXW can be more cost-effective for seasoned buyers who have established logistics capabilities, allowing them to negotiate shipping costs directly.

Strategic sourcing is essential in optimizing these Incoterms to align with your business objectives. By carefully assessing your risk tolerance, supplier relationships, and logistical expertise, you can make informed decisions that enhance your supply chain efficiency.

As international trade continues to evolve, staying informed about these Incoterms will empower you to seize new opportunities. Engage with your suppliers to explore the best shipping options that suit your needs, whether you are sourcing from Africa, South America, the Middle East, or Europe. The right choice between FOB and EXW could not only streamline your operations but also foster stronger partnerships across borders. Embrace these insights to drive your business forward in the global marketplace.