A Deep Dive into Ex Works Vs Fob Solution

Introduction: Navigating the Global Market for ex works vs fob

Navigating the complexities of international shipping can be daunting, especially when determining the most cost-effective and reliable method for transporting goods. For B2B buyers sourcing products from global suppliers, understanding the differences between Ex Works (EXW) and Free on Board (FOB) is crucial. This guide delves into the intricacies of these Incoterms, providing insights on their applications, advantages, and potential pitfalls, tailored specifically for international buyers from regions such as Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia.

In this comprehensive resource, you will discover the fundamental differences between EXW and FOB, how to evaluate the suitability of each term based on your business needs, and the implications for cost management and risk allocation. We will also cover key considerations for supplier vetting, ensuring that you choose partners who can meet your logistical requirements effectively. By equipping yourself with this knowledge, you can make informed purchasing decisions that align with your business objectives and risk tolerance.

With the right understanding of these shipping terms, B2B buyers can streamline their supply chain processes, optimize costs, and foster successful international trade relationships. This guide serves as your essential roadmap in navigating the global market, empowering you to confidently engage in international transactions.

Understanding ex works vs fob Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

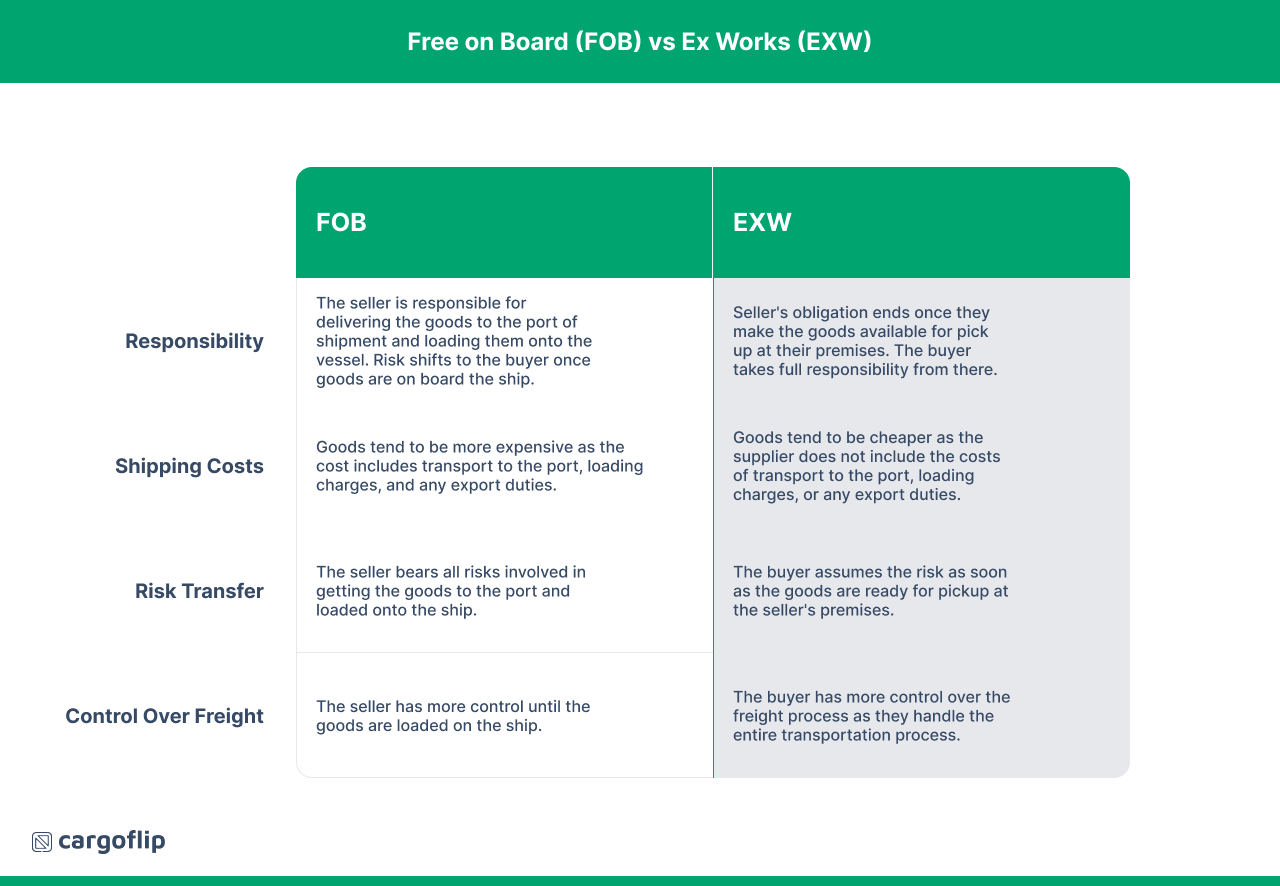

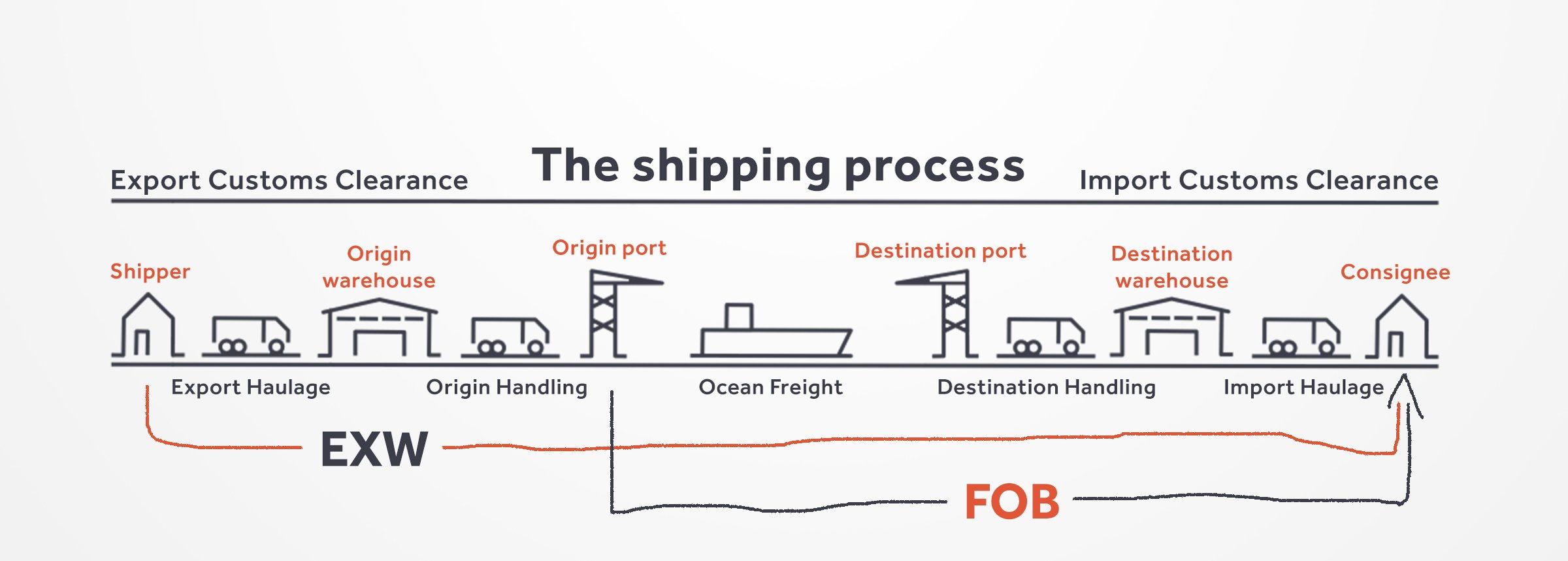

| EXW (Ex Works) | Seller makes goods available at their location; buyer assumes all transport costs and risks. | Importing from manufacturers, especially in developing markets. | Pros: Lower initial cost; full control over shipping. Cons: High responsibility for logistics; potential for unexpected costs. |

| FOB (Free On Board) | Seller is responsible for goods until loaded onto the ship; risk transfers to buyer once on board. | Bulk shipments, especially in maritime trade. | Pros: Reduced risk during transport; seller manages logistics until loading. Cons: Potentially higher costs due to seller’s logistics management. |

| FOB Origin | Similar to FOB, but risk and ownership transfer at the seller’s location, not the port. | Domestic and international shipping. | Pros: Buyer can negotiate shipping options; lower risk during transit. Cons: Buyer must manage logistics from seller’s location. |

| FOB Destination | Ownership transfers when goods arrive at the buyer’s location; seller bears risk until delivery. | High-value goods requiring secure transport. | Pros: Lower risk for buyer during transit; seller ensures delivery. Cons: Higher costs due to seller’s responsibility for transport. |

| EXW with Freight Forwarder | Buyer engages a freight forwarder to manage logistics from seller’s location. | Complex shipments needing expert handling. | Pros: Professional management of logistics; tailored shipping solutions. Cons: Additional costs for freight forwarding services. |

What Are the Key Characteristics of EXW (Ex Works) for B2B Buyers?

EXW, or Ex Works, places minimal responsibility on the seller, who only needs to make the goods available at their premises. This term is particularly suitable for buyers familiar with local logistics in the seller’s country, as they assume all transport costs and risks from the point of pickup. B2B buyers should consider their logistical capabilities and potential hidden costs when opting for EXW, as they bear the burden of managing transportation and customs clearance.

How Does FOB (Free On Board) Benefit B2B Transactions?

FOB (Free On Board) requires the seller to load the goods onto the buyer’s chosen vessel, transferring risk and ownership at that point. This term is ideal for bulk shipments, especially in maritime trade, where buyers may prefer to minimize risk during transport. Buyers should evaluate their risk tolerance and the seller’s reliability when using FOB, as it allows for more control over shipping arrangements while providing a layer of security until the goods are loaded.

What Are the Implications of FOB Origin for Buyers?

FOB Origin is a variation where ownership and risk transfer at the seller’s location rather than at the port. This term is useful for domestic and international shipping, allowing buyers to negotiate their shipping options. However, buyers must be prepared to manage logistics from the seller’s site, which can be challenging without established local contacts. Understanding the implications of this arrangement is crucial for effective cost management and risk mitigation.

Why Choose FOB Destination for High-Value Goods?

FOB Destination ensures that ownership transfers only when the goods arrive at the buyer’s location, with the seller bearing the risk during transit. This arrangement is beneficial for high-value or fragile goods, as it reduces buyer risk significantly. However, it typically incurs higher costs since the seller is responsible for transport. Buyers should weigh the benefits of reduced risk against the potential for increased expenses when considering this option.

How Does EXW with a Freight Forwarder Enhance B2B Shipping?

Choosing EXW with a freight forwarder allows buyers to leverage the expertise of logistics professionals to manage transportation from the seller’s location. This combination is particularly advantageous for complex shipments requiring specialized handling. While this option can add costs due to freight forwarding services, it provides buyers with tailored shipping solutions and reduces the burden of logistics management. Understanding the trade-offs between cost and convenience is essential for buyers seeking efficient shipping solutions.

Key Industrial Applications of ex works vs fob

| Industry/Sector | Specific Application of ex works vs fob | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Sourcing raw materials for production | EXW reduces upfront costs; FOB offers risk mitigation | Supplier reliability, transportation logistics, and customs compliance |

| Electronics | Importing components for assembly | FOB ensures safer transport; EXW allows cost control | Understanding local regulations and shipping practices |

| Agriculture | Exporting agricultural products | FOB simplifies logistics; EXW reduces seller’s liability | Quality assurance, seasonal demand, and shipping timelines |

| Construction | Procurement of construction materials | FOB minimizes risk during transit; EXW offers flexibility | Supplier relationship, transportation infrastructure, and tariffs |

| Textiles | Importing fabrics and garments | FOB provides better risk management; EXW can lower costs | Customs regulations, sourcing quality, and lead times |

How is ‘Ex Works vs FOB’ Applied in the Manufacturing Sector?

In the manufacturing sector, companies often engage in sourcing raw materials from international suppliers. When using the EXW Incoterm, the seller is responsible only for making the goods available at their location, which can lead to reduced upfront costs for the buyer. However, this places the onus of transportation and risk on the buyer, which can be challenging if they lack local logistical knowledge. Conversely, the FOB term allows the seller to manage transportation until the goods are loaded onto the vessel, providing a safety net for buyers who may be less experienced in international shipping.

What are the Benefits of ‘Ex Works vs FOB’ in the Electronics Industry?

In the electronics industry, the choice between EXW and FOB is critical when importing components for assembly. The FOB term is preferred as it ensures that the seller is responsible for the goods until they are safely loaded on the shipping vessel, thus minimizing risk during transport. This is particularly important for high-value items. On the other hand, EXW may appeal to buyers looking to control costs, as they can negotiate their own shipping arrangements. However, buyers must be well-versed in local regulations and shipping practices to mitigate risks effectively.

How Do ‘Ex Works vs FOB’ Impact Agricultural Exports?

For agricultural exports, the choice between EXW and FOB can significantly affect logistical efficiency. FOB is often favored as it simplifies the logistics chain, transferring risk from the seller to the buyer only once the goods are on board the vessel. This is crucial for perishable goods that require timely shipping. In contrast, EXW can reduce the seller’s liability, making it a viable option for buyers who have established logistics networks. However, buyers must ensure quality assurance and be mindful of seasonal demand fluctuations when making this choice.

Why is ‘Ex Works vs FOB’ Important in the Construction Industry?

In the construction industry, procurement of materials often involves complex logistics, making the choice between EXW and FOB critical. FOB minimizes the risk during transit, as the seller is responsible for the goods until they reach the designated shipping point. This can be particularly beneficial for large, heavy materials that require careful handling. On the other hand, EXW provides flexibility, allowing buyers to manage transportation according to their specific needs. Buyers must consider their relationships with suppliers, as well as the transportation infrastructure available in the seller’s location.

How Does ‘Ex Works vs FOB’ Affect the Textile Industry?

In the textile industry, the import of fabrics and garments can be influenced by the choice of Incoterms. FOB is advantageous as it provides better risk management, ensuring that the seller handles the goods until they are loaded for shipment. This is essential for maintaining quality during transport. Conversely, EXW can lower costs for buyers, but they must navigate customs regulations and ensure sourcing quality. Timely delivery is also a critical factor, making the understanding of lead times essential for successful international transactions.

3 Common User Pain Points for ‘ex works vs fob’ & Their Solutions

Scenario 1: Navigating Unexpected Costs with EXW

The Problem: Many B2B buyers, particularly those unfamiliar with the intricacies of international shipping, face unexpected costs when opting for the EXW (Ex Works) shipping term. Buyers may assume that purchasing goods at a lower price point means reduced overall expenses. However, once they realize they must handle all logistics—from transportation to insurance—they often encounter unanticipated fees. This can lead to budget overruns and operational delays, frustrating buyers who were counting on a smooth procurement process.

The Solution: To mitigate unexpected costs with EXW, buyers should conduct thorough pre-shipment planning and cost analysis. Start by requesting detailed quotes from logistics providers for all aspects of the shipping process, including transportation, insurance, and customs clearance. Understanding the total landed cost is crucial. Additionally, build a strong relationship with a reliable freight forwarder who can offer guidance on potential pitfalls and provide competitive rates. Clearly communicate with the supplier about the packaging and readiness of goods to avoid delays in pickup. By understanding the logistics landscape and engaging with experienced partners, buyers can transform their approach to EXW shipping, ensuring they remain within budget.

Scenario 2: Managing Risk and Liability with FOB

The Problem: Buyers often grapple with the complexities of risk management when choosing the FOB (Free On Board) term. While FOB can provide a sense of security—since the seller is responsible for the goods until they are loaded onto the vessel—buyers can still face significant risks if there are issues during the loading process or if the seller fails to meet their obligations. This can lead to disputes, delays, and, ultimately, financial losses.

The Solution: To effectively manage risks associated with FOB, buyers should ensure that all terms are explicitly outlined in the contract. This includes specifying the loading procedures, timelines, and responsibilities. Conduct due diligence on suppliers to evaluate their reliability and history in fulfilling FOB terms. Additionally, consider negotiating insurance coverage that protects the goods during the loading phase. By actively engaging with suppliers and establishing clear expectations, buyers can safeguard their interests and minimize the risk of disputes or losses.

Scenario 3: The Challenge of Supplier Reliability in International Shipping

The Problem: Buyers from different regions often encounter issues with supplier reliability, especially when using EXW. If a supplier does not adhere to the agreed-upon terms for making goods available, buyers may experience delays that can disrupt their operations and supply chains. This is particularly critical for businesses that rely on just-in-time inventory systems or have tight project timelines.

The Solution: To combat supplier reliability challenges, buyers should implement a rigorous vetting process before finalizing contracts. This involves checking references, reviewing previous shipping performance, and assessing the supplier’s logistics capabilities. Establishing clear communication channels and setting milestones for production and readiness can also help ensure accountability. Additionally, consider including performance-based clauses in contracts that incentivize timely delivery and adherence to agreed-upon terms. By fostering transparency and setting expectations, buyers can significantly reduce the likelihood of disruptions and enhance their overall supply chain resilience.

Strategic Material Selection Guide for ex works vs fob

What Are the Key Materials to Consider for Ex Works vs. FOB?

When navigating the complexities of international shipping terms like Ex Works (EXW) and Free on Board (FOB), understanding the materials involved in your products is crucial. Different materials have unique properties, advantages, and limitations that can significantly impact the choice between EXW and FOB. Below, we analyze four common materials—steel, aluminum, plastics, and ceramics—highlighting their characteristics and implications for international B2B buyers.

How Does Steel Perform in Ex Works vs. FOB Shipping?

Key Properties: Steel is known for its high strength and durability, making it suitable for various applications. It typically has a high-temperature rating and excellent corrosion resistance when treated properly.

Pros & Cons: The durability of steel makes it a preferred choice for heavy-duty applications. However, it can be expensive to manufacture, especially when considering the costs of corrosion-resistant coatings. In terms of shipping, steel’s weight may lead to higher freight costs, particularly under EXW terms where the buyer is responsible for transportation.

Impact on Application: Steel is compatible with a wide range of media, including water and various chemicals, but it may corrode if exposed to harsh environments without proper treatment.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with local standards such as DIN or ASTM. Additionally, understanding the logistics of transporting heavy materials is vital for cost management.

What Advantages Does Aluminum Offer in Shipping Terms?

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance. It can withstand moderate temperatures and is often used in applications requiring weight savings.

Pros & Cons: Its lightweight nature reduces shipping costs, making it advantageous for EXW terms where buyers manage logistics. However, aluminum can be more expensive than steel, and its manufacturing process can be complex, impacting overall costs.

Impact on Application: Aluminum is suitable for various media, including food and beverages, due to its non-reactive properties. This makes it ideal for industries like packaging and automotive.

Considerations for International Buyers: Compliance with standards such as JIS for aluminum products is essential, particularly in Asia. Buyers should also consider the availability of local suppliers to reduce logistics complexities.

How Do Plastics Compare in International Shipping?

Key Properties: Plastics are versatile materials with varying temperature and pressure ratings, depending on the type. They often exhibit good chemical resistance but can be less durable than metals.

Pros & Cons: The low weight of plastics can lead to significant savings in shipping costs, particularly under EXW terms. However, their susceptibility to environmental factors can limit their application in certain industries.

Impact on Application: Plastics are compatible with many media, but their performance can vary widely. For example, some plastics may degrade when exposed to UV light, affecting their suitability for outdoor applications.

Considerations for International Buyers: Buyers should be aware of compliance with regional standards for plastics, such as REACH in Europe. Understanding the environmental impact and recycling options is also becoming increasingly important.

What Role Do Ceramics Play in Shipping Decisions?

Key Properties: Ceramics are known for their high-temperature resistance and hardness but can be brittle. They are often used in applications requiring wear resistance.

Pros & Cons: While ceramics can be cost-effective in terms of performance, their fragility can lead to increased shipping risks, particularly under EXW terms where the buyer assumes all responsibility for transport.

Impact on Application: Ceramics are suitable for high-temperature applications and can withstand harsh chemicals, making them ideal for industries like aerospace and electronics.

Considerations for International Buyers: Buyers should ensure compliance with international standards for ceramics, such as ISO certifications. Understanding the handling and shipping requirements for fragile materials is crucial to prevent damage during transport.

Summary Table of Material Considerations for Ex Works vs. FOB

| Material | Typical Use Case for ex works vs fob | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, construction materials | High durability and strength | High shipping costs due to weight | High |

| Aluminum | Automotive parts, packaging | Lightweight, reducing shipping costs | Higher material costs and complex manufacturing | Medium |

| Plastics | Consumer goods, electronics | Low weight, cost-effective shipping | Environmental sensitivity and durability issues | Low |

| Ceramics | Aerospace components, electronics | High-temperature resistance | Fragility increases shipping risks | Medium |

This analysis underscores the importance of material selection in the context of EXW and FOB shipping terms. B2B buyers must carefully consider these factors to optimize their logistics and ensure compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for ex works vs fob

What Are the Main Stages of Manufacturing Processes in Ex Works and FOB Transactions?

In the context of international shipping, understanding the manufacturing processes is vital for B2B buyers, especially when choosing between Ex Works (EXW) and Free On Board (FOB) terms. The manufacturing process typically involves several key stages:

-

Material Preparation: This initial stage includes sourcing raw materials and components necessary for production. Suppliers must ensure that materials meet quality standards, which can vary by region. For instance, buyers from Europe may expect stringent compliance with CE marking requirements, while those from the Middle East might prioritize certifications specific to local regulations.

-

Forming: In this stage, raw materials are transformed into usable products through various techniques, such as machining, molding, or welding. The choice of forming technique often depends on the product type and desired specifications. Buyers should inquire about the technologies used and ensure they align with industry standards.

-

Assembly: After forming, components are assembled into final products. This stage often requires skilled labor and precise handling to maintain quality. It’s crucial for buyers to understand the assembly process as it directly impacts the final product’s integrity and functionality.

-

Finishing: The final stage includes processes such as painting, coating, or polishing to enhance product appearance and protect against environmental factors. Quality control during this stage is essential, as it can significantly affect customer satisfaction.

How Do Quality Control Practices Differ for EXW and FOB?

Quality assurance is critical in both EXW and FOB agreements, but the responsibilities differ significantly between the two. Here’s a breakdown of quality control (QC) practices relevant to international B2B buyers:

-

Relevant International Standards: Many manufacturers aim to achieve ISO 9001 certification, which indicates a commitment to quality management systems. In addition, industry-specific standards like CE (for European markets) or API (for petroleum and natural gas industries) can further assure product quality. Buyers should verify that their suppliers adhere to these standards.

-

QC Checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt. Buyers should ensure that suppliers have robust IQC processes to prevent defects from the start.

– In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC checks are essential for identifying issues before they escalate. Buyers can request reports or samples to verify that these checks are being performed.

– Final Quality Control (FQC): This final checkpoint occurs after production but before shipment. Buyers should inquire about the procedures for FQC, as this is the last opportunity to catch any defects. -

Common Testing Methods: Testing methods may include visual inspections, functional tests, and material analysis. B2B buyers should ask about the testing procedures to ensure they meet their quality expectations.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

B2B buyers can take several proactive steps to verify the quality control measures of their suppliers, particularly when dealing with EXW and FOB terms:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes and quality management systems firsthand. This is particularly important for buyers from regions like Africa or South America, where local compliance may vary.

-

Quality Assurance Reports: Requesting documentation such as quality assurance reports can provide insight into the supplier’s QC processes. These reports should detail the results of IQC, IPQC, and FQC checks.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can perform inspections at various stages of production, ensuring that products meet the required specifications before shipment.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international B2B buyers, especially those from diverse regions like Europe, the Middle East, and Africa, understanding the nuances of quality control and certification is essential:

-

Regional Compliance: Different regions have varying regulatory requirements. For example, European buyers may need suppliers to comply with EU regulations, while Middle Eastern buyers may have different standards. It’s crucial to discuss these requirements upfront to avoid complications.

-

Cultural Considerations: Cultural differences can affect communication and expectations regarding quality. Buyers should be aware of these differences and establish clear, written agreements that outline quality expectations and responsibilities.

-

Traceability and Documentation: Maintaining traceability of materials and components is vital for quality assurance. Buyers should ensure that suppliers provide proper documentation to trace the origin of materials and the history of quality checks performed throughout the manufacturing process.

-

Product Liability and Risk Management: Understanding the risk transfer associated with EXW and FOB terms is crucial. Under FOB, the seller bears responsibility for the goods until they are loaded onto the ship, while under EXW, the buyer assumes responsibility at the seller’s location. Buyers must consider these factors in their risk management strategies.

Conclusion: Making Informed Decisions in Manufacturing and Quality Control

Choosing between EXW and FOB terms involves understanding not only the manufacturing processes but also the quality assurance practices that accompany them. B2B buyers must engage with suppliers to clarify their manufacturing techniques, QC checkpoints, and compliance with international standards. By taking proactive measures to verify supplier quality control and understanding regional nuances, buyers can make informed decisions that align with their business goals. This diligence ultimately leads to better product quality, enhanced supplier relationships, and successful international trade engagements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ex works vs fob’

Introduction

Navigating the complexities of international shipping can be challenging, especially when deciding between Ex Works (EXW) and Free on Board (FOB) Incoterms. This guide is designed to assist B2B buyers in making informed decisions by providing a clear, actionable checklist to evaluate which shipping method best aligns with their business objectives, capabilities, and risk tolerance.

Step 1: Assess Your Shipping Experience

Understanding your familiarity with international shipping logistics is crucial. If you have extensive experience and knowledge of the shipping landscape in the supplier’s country, EXW may be suitable. Conversely, if you’re less experienced, FOB can offer more security as the seller manages the shipping process until the goods are loaded.

- Considerations:

- Evaluate previous shipping experiences.

- Reflect on any challenges faced with past suppliers.

Step 2: Determine Your Risk Tolerance

Each Incoterm places different levels of risk on the buyer and seller. With FOB, the seller bears responsibility until the goods are loaded onto the vessel, while EXW shifts most risk to the buyer immediately upon availability. Assessing your organization’s risk appetite will guide you in selecting the appropriate Incoterm.

- Considerations:

- Analyze potential risks associated with shipping logistics.

- Identify your comfort level with taking on risks.

Step 3: Clarify Your Cost Management Strategy

Understanding how shipping costs are managed under each Incoterm is essential. FOB typically involves the seller covering costs up to the loading point, which may simplify budgeting. However, EXW allows for direct negotiation of transportation costs, giving you control over your expenditures.

- Considerations:

- Estimate total shipping costs under both terms.

- Explore potential cost-saving opportunities with EXW.

Step 4: Evaluate Supplier Capabilities

Before finalizing your decision, it’s important to evaluate your supplier’s logistics capabilities. A reliable supplier who understands the shipping process can provide more assurance if you choose EXW. On the other hand, if there are doubts about their logistics proficiency, opting for FOB may mitigate risks.

- Considerations:

- Request details about the supplier’s logistics processes.

- Look for reviews or testimonials from other buyers regarding their shipping reliability.

Step 5: Review Documentation Requirements

Proper documentation is vital in international trade. Ensure that you understand the paperwork involved with both EXW and FOB. FOB typically requires the seller to provide a bill of lading and export documentation, while EXW requires you to manage your own documents, which can lead to complications if not handled correctly.

- Considerations:

- Familiarize yourself with necessary shipping documents.

- Verify who is responsible for customs clearance and related documentation.

Step 6: Communicate Clearly with Suppliers

Clear communication with your suppliers regarding your preferred Incoterm is essential. Make sure both parties understand their responsibilities and expectations to avoid disputes later on. This step can save you time and reduce misunderstandings throughout the shipping process.

- Considerations:

- Discuss your chosen Incoterm and confirm supplier agreement.

- Establish a point of contact for any shipping-related inquiries.

Step 7: Monitor and Review Your Shipping Strategy

Once your shipping process is underway, regularly review its effectiveness. Monitor the performance of your chosen Incoterm and adjust as necessary for future shipments. This ongoing assessment will help you refine your strategy and optimize costs and risks.

- Considerations:

- Gather feedback from stakeholders involved in the shipping process.

- Analyze shipping outcomes to inform future decisions.

By following this checklist, you can make a well-informed decision between EXW and FOB, aligning your shipping strategy with your business objectives and operational capabilities.

Comprehensive Cost and Pricing Analysis for ex works vs fob Sourcing

What Are the Key Cost Components in EXW and FOB Sourcing?

When comparing EXW (Ex Works) and FOB (Free on Board) sourcing, it’s essential to dissect the cost structure involved. Each Incoterm delineates distinct responsibilities that can significantly impact the overall cost of sourcing goods internationally.

-

Materials: The base cost of raw materials remains constant regardless of the Incoterm chosen. However, fluctuations in material prices can affect the overall cost structure, especially if the supplier offers discounts based on volume or long-term contracts.

-

Labor: Labor costs can vary widely depending on the region of the supplier. For instance, sourcing from countries with lower labor costs can provide significant savings. However, the complexity of labor regulations and potential labor strikes must be factored in, particularly for buyers in Africa or South America.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses tied to production. Depending on the chosen Incoterm, these costs may be absorbed differently. For EXW, the buyer may need to account for additional overhead in logistics and transport planning.

-

Tooling and Quality Control (QC): Investing in tooling can be significant for customized products. Quality control measures may also differ; FOB contracts often imply that sellers will maintain higher quality standards during shipping, as they are responsible until goods are loaded.

-

Logistics: This is perhaps the most variable cost component. Under EXW, buyers bear the full cost of logistics from the seller’s location to their destination, which can include local transport, international freight, and customs clearance. Conversely, FOB allows for some logistics costs to be covered by the seller, simplifying budgeting for the buyer.

-

Margin: Suppliers typically build their profit margins into the pricing structure. Understanding how each Incoterm affects supplier margins can help buyers negotiate better terms.

What Influences Pricing Beyond Basic Costs?

The choice between EXW and FOB also involves several price influencers that can sway the final cost:

-

Volume and Minimum Order Quantity (MOQ): Larger orders can lead to discounted pricing. Suppliers may offer better rates for FOB arrangements, as they bear initial shipping costs.

-

Specifications and Customization: Customized products often come with higher costs due to tooling and longer production times. Buyers should clarify these aspects early in negotiations to avoid unexpected expenses.

-

Quality and Certifications: The need for specific certifications can impact pricing. Buyers in Europe, for example, may require CE marking, which can lead to increased costs if not factored in from the outset.

-

Supplier Factors: The reliability and reputation of the supplier can influence price negotiations. Established suppliers may offer more favorable terms under FOB, knowing they can manage logistics efficiently.

-

Incoterms Understanding: A comprehensive understanding of the chosen Incoterm is crucial. Misinterpretations can lead to hidden costs, particularly in international trade.

What Are the Best Buyer Tips for Cost-Efficiency?

B2B buyers should adopt strategic approaches to maximize cost efficiency when dealing with EXW and FOB:

-

Negotiation Strategies: Leverage volume to negotiate better terms, especially for FOB contracts where the seller incurs more upfront costs. Highlighting long-term relationships can also lead to more favorable pricing.

-

Total Cost of Ownership (TCO): Evaluate the complete cost associated with sourcing, including logistics, duties, and potential risks. This perspective helps in making informed decisions that go beyond initial price tags.

-

Consider Pricing Nuances for International Trade: Buyers from regions like Africa and the Middle East should be aware of local tariffs and customs processes. Understanding these nuances can prevent costly delays and additional expenses.

-

Disclaimer for Indicative Prices: Given the dynamic nature of international trade, prices can fluctuate based on geopolitical conditions, market demand, and currency exchange rates. Always request updated quotes and factor in potential price changes before finalizing contracts.

By understanding these cost components, pricing influencers, and strategic negotiation tips, B2B buyers can navigate the complexities of EXW and FOB sourcing more effectively.

Alternatives Analysis: Comparing ex works vs fob With Other Solutions

Introduction: Exploring Alternatives to Ex Works and FOB

In the realm of international trade, the choice of shipping terms significantly impacts the efficiency and cost-effectiveness of transactions. While Ex Works (EXW) and Free on Board (FOB) are popular Incoterms, alternative solutions also exist that can better cater to specific business needs. This analysis aims to compare EXW and FOB against two viable alternatives: Delivered Duty Paid (DDP) and Cost and Freight (CFR). By understanding the strengths and weaknesses of each option, B2B buyers can make informed decisions tailored to their operational requirements.

Comparison Table

| Comparison Aspect | Ex Works Vs FOB | Delivered Duty Paid (DDP) | Cost and Freight (CFR) |

|---|---|---|---|

| Performance | Moderate control; risk on buyer after pickup (EXW) or after loading (FOB) | High control; seller manages all costs until delivery | Moderate control; seller handles transport to port, buyer takes over from there |

| Cost | Lower initial cost (EXW); higher potential shipping costs (FOB) | Higher due to seller’s responsibility for duties and taxes | Moderate; includes freight but not insurance or duties |

| Ease of Implementation | Requires buyer’s logistics knowledge (EXW) or shipping coordination (FOB) | Simplified for buyer; seller handles logistics | Requires buyer to arrange insurance and unloading |

| Maintenance | Low ongoing costs; buyer manages logistics | Higher ongoing costs; potential for disputes over duties | Moderate; requires ongoing insurance management |

| Best Use Case | Buyers with strong local logistics; low-value items (EXW) | Buyers desiring convenience and assurance of delivery | Buyers who want cost control but with some seller involvement |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Delivered Duty Paid (DDP)?

Delivered Duty Paid (DDP) is an Incoterm that places maximum responsibility on the seller. They handle all costs associated with shipping, including duties and taxes, until the goods reach the buyer’s location.

Pros: DDP offers a seamless experience for buyers, who don’t have to worry about customs clearance or additional charges upon arrival. This can be particularly advantageous for businesses that lack experience in navigating international trade complexities.

Cons: However, DDP can be costlier, as sellers often include these expenses in the product price. Additionally, it may lead to disputes if there are discrepancies in the duties assessed by customs authorities.

How Does Cost and Freight (CFR) Compare?

Cost and Freight (CFR) is another popular alternative where the seller pays for transportation to the port of destination, but the buyer assumes responsibility once the goods are loaded onto the vessel.

Pros: CFR strikes a balance between seller and buyer responsibilities, allowing for some cost management while still providing a level of control to the buyer. It can be a suitable option for larger shipments where buyers want to negotiate freight costs directly.

Cons: The downside is that buyers need to arrange for insurance and unloading at the destination port, which can complicate logistics. Additionally, the risk transfers to the buyer once the goods are on board, which may not be ideal for all businesses.

Conclusion: How Should B2B Buyers Choose the Right Shipping Solution?

Selecting the right shipping solution involves evaluating several factors, including the buyer’s logistical capabilities, the value of the goods, and the overall trade relationship with the seller. For businesses with strong local logistics expertise, EXW may be advantageous due to its lower initial costs. Conversely, DDP can simplify the shipping process for those seeking convenience. CFR offers a middle ground, providing some seller support while allowing buyers to control freight costs. Ultimately, understanding the nuances of each option will empower B2B buyers to choose the most suitable Incoterm for their specific needs, enhancing their international trade efficiency.

Essential Technical Properties and Trade Terminology for ex works vs fob

What Are the Key Technical Properties Related to Ex Works and FOB?

Understanding the technical specifications associated with Ex Works (EXW) and Free on Board (FOB) is essential for international B2B transactions. Here are critical properties that buyers should consider:

-

Risk Allocation

– Definition: Risk allocation refers to the assignment of responsibility for loss or damage of goods during transit.

– Importance: Under EXW, the buyer assumes all risks once the goods are made available, while FOB transfers risk to the buyer only after the goods are loaded onto the vessel. Understanding this allocation helps in assessing potential liabilities and insurance needs. -

Cost Responsibility

– Definition: This specification outlines who bears the costs associated with shipping, including freight, insurance, and customs duties.

– Importance: In EXW, the buyer covers all transport costs from the seller’s location, whereas, in FOB, the seller is responsible for costs until the goods are loaded. Knowing these cost implications aids in budget planning and financial forecasting. -

Loading and Unloading Responsibilities

– Definition: This aspect delineates who is responsible for loading the goods onto the transport vehicle and unloading them at the destination.

– Importance: FOB requires the seller to handle loading, while EXW places this responsibility on the buyer. Clarity on these roles can prevent logistical misunderstandings and ensure smoother operations. -

Shipping Point

– Definition: The shipping point is the exact location where the transfer of responsibility occurs.

– Importance: For FOB, this is typically the port of loading, while for EXW, it can be the seller’s facility. Identifying the shipping point helps buyers plan their logistics and comply with local regulations. -

Documentation Requirements

– Definition: This involves the necessary paperwork for customs clearance and shipping, including bills of lading and invoices.

– Importance: Accurate documentation is crucial for smooth international transactions, and the requirements may differ between EXW and FOB. Understanding these needs helps avoid customs delays and penalties.

What Are Common Trade Terms in Ex Works and FOB Transactions?

Familiarity with industry jargon can significantly enhance communication and negotiation processes in international trade. Here are some essential terms to know:

-

Incoterms

– Definition: International Commercial Terms (Incoterms) are standardized trade terms that define the responsibilities of buyers and sellers in international contracts.

– Importance: Knowing Incoterms like EXW and FOB helps businesses understand their obligations and rights, thereby reducing disputes and enhancing contract clarity. -

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: In the context of FOB and EXW, knowing whether you’re dealing with an OEM can inform your negotiation strategy and expectations regarding product quality and delivery timelines. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest amount of a product that a supplier is willing to sell.

– Importance: Understanding MOQ is crucial when using EXW or FOB, as it can impact inventory management and overall shipping costs. It helps buyers gauge their purchasing power and cost-effectiveness. -

RFQ (Request for Quotation)

– Definition: An RFQ is a business document issued by a buyer to request pricing and terms from suppliers for specific goods or services.

– Importance: Utilizing RFQs effectively can lead to better pricing and terms, particularly when negotiating FOB agreements where shipping costs are a significant factor. -

Freight Forwarder

– Definition: A freight forwarder is an intermediary that arranges the transportation of goods on behalf of the buyer or seller.

– Importance: In both EXW and FOB scenarios, engaging a reliable freight forwarder can simplify logistics, ensuring that goods are shipped efficiently and comply with international regulations.

By understanding these critical technical properties and trade terms, B2B buyers can navigate the complexities of international trade more effectively, making informed decisions that align with their operational goals.

Navigating Market Dynamics and Sourcing Trends in the ex works vs fob Sector

What Are the Current Market Dynamics Influencing EXW and FOB Options for International Buyers?

The global marketplace is experiencing rapid transformations driven by technological advancements and changing trade regulations. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of Ex Works (EXW) and Free on Board (FOB) is crucial. One significant trend is the increasing reliance on digital platforms for sourcing and logistics management. Technologies like blockchain and IoT are streamlining supply chain operations, enhancing transparency, and reducing costs. This trend is especially vital for buyers in emerging markets, where access to real-time data can facilitate better decision-making.

Moreover, geopolitical shifts and trade agreements are influencing shipping practices. Buyers need to stay informed about regional trade dynamics, tariffs, and regulations that could affect their choice between EXW and FOB. For instance, while FOB may offer greater security by shifting liability to the seller at the point of loading, EXW can provide cost advantages in markets with competitive logistics services. Understanding these dynamics enables buyers to optimize their sourcing strategies, ensuring they select the most beneficial Incoterms for their needs.

How Are Sustainability and Ethical Sourcing Impacting EXW and FOB Decisions?

Sustainability is becoming a non-negotiable aspect of B2B sourcing, influencing decisions around EXW and FOB. Buyers are increasingly aware of the environmental impacts of their supply chains and are seeking suppliers that prioritize ethical practices. This shift is prompting a demand for ‘green’ certifications and materials, which can affect pricing and logistics.

When considering EXW, buyers may face challenges in ensuring that their suppliers adhere to sustainable practices since the responsibility for transport and logistics falls entirely on them. Conversely, FOB arrangements may provide more leverage for buyers to negotiate eco-friendly practices with sellers, as the seller is responsible for the goods until they are loaded onto the ship. Therefore, buyers should assess suppliers not only based on cost but also on their commitment to sustainability and ethical sourcing. This approach not only aligns with corporate social responsibility goals but can also enhance brand reputation in increasingly eco-conscious markets.

What Is the Historical Context of EXW and FOB in International Trade?

The use of EXW and FOB as Incoterms has evolved significantly since their introduction. Established by the International Chamber of Commerce (ICC) in the early 20th century, these terms were designed to standardize shipping practices and clarify the responsibilities of buyers and sellers. Over the decades, as global trade expanded and logistics became more complex, these terms adapted to reflect new realities in shipping practices and international regulations.

Initially, FOB was favored for its clear delineation of responsibility, particularly in maritime shipping. However, with the rise of global supply chains and diverse modes of transport, EXW gained traction for its flexibility and cost-effectiveness. Today, both terms are critical in shaping the strategies of international B2B buyers, particularly as they navigate an increasingly interconnected and dynamic market landscape. Understanding their historical context allows buyers to make informed decisions that align with current trends and future market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of ex works vs fob

-

How do I choose between EXW and FOB for my international shipments?

Choosing between EXW and FOB depends on your operational capabilities and risk tolerance. If you have experience in handling logistics and customs in the seller’s country, EXW may be more cost-effective as it provides you with greater control over transportation and associated costs. Conversely, if you prefer a more hands-off approach and want to minimize risk, FOB is advisable as the seller manages the shipment until it’s loaded onto the vessel, ensuring a smoother transition and fewer responsibilities on your end. -

What are the key responsibilities of buyers under EXW and FOB?

Under EXW, the buyer is responsible for all logistics, including loading, transportation, insurance, and customs clearance once the goods are made available at the seller’s premises. In contrast, under FOB, the seller handles the loading and export clearance, transferring responsibility to the buyer only once the goods are on board the ship. Understanding these responsibilities is crucial for managing costs and risks effectively. -

What are the implications of EXW on shipping costs?

EXW can often lead to lower initial costs since the seller only needs to prepare the goods for collection. However, the buyer must manage all subsequent logistics, which can lead to higher overall expenses if not planned carefully. It’s essential to obtain quotes from freight forwarders and calculate total shipping costs, including potential customs duties, to make an informed decision. -

How can I ensure quality when sourcing goods under EXW terms?

To ensure quality when sourcing under EXW terms, conduct thorough supplier vetting before placing an order. Request samples, visit the supplier’s facilities if possible, and establish clear quality assurance protocols in your purchase agreement. Additionally, consider hiring a third-party inspection service to evaluate the goods before you arrange transport, ensuring they meet your specifications. -

What are the payment terms typically associated with EXW and FOB?

Payment terms can vary widely but typically align with the level of risk and responsibility assumed by each party. Under EXW, sellers may require payment in full before the goods are made available, as they bear minimal risk. For FOB, payment may be structured to occur after the seller has fulfilled their shipping obligations, providing buyers with added security. Always clarify payment terms in advance to prevent misunderstandings. -

Can I customize my order under EXW and FOB terms?

Yes, customization options are generally available under both EXW and FOB terms, but the process may differ. For EXW, you will need to coordinate with the supplier to ensure the customization aligns with your logistical plans. With FOB, you can discuss customization during the order process, as the seller may handle specific requirements before shipping. Always confirm customization capabilities and costs upfront. -

What logistics considerations should I keep in mind when using FOB?

When using FOB, consider the logistics of the shipping process, including selecting a reliable freight forwarder and understanding the port procedures at both the origin and destination. Ensure that all necessary documentation, such as the bill of lading and customs forms, is prepared in advance. Additionally, be aware of potential delays or issues at the port that could affect delivery timelines and plan accordingly. -

How does international trade legislation affect EXW and FOB agreements?

International trade legislation, including Incoterms set by the International Chamber of Commerce, governs the responsibilities and liabilities of both parties in EXW and FOB agreements. It’s crucial to familiarize yourself with these regulations, as they dictate cost responsibilities, risk transfer points, and customs obligations. Additionally, consider any local laws or regulations in the seller’s country that could impact your shipping and logistics processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Ex Works Vs Fob Manufacturers & Suppliers List

1. Unicargo – Incoterms Explained: FOB & EXW

Domain: unicargo.com

Registered: 1997 (28 years)

Introduction: FOB (Free On Board) and EXW (Ex Works) are two Incoterms used in international shipping. FOB requires the seller to load goods onto the buyer’s chosen ship, covering costs and risks until that point. The buyer then assumes responsibility for transportation and associated costs. EXW places minimal responsibility on the seller, who only needs to make goods available at a specified location, while th…

2. Investopedia – International Shipping Terms

Domain: investopedia.com

Registered: 1999 (26 years)

Introduction: Ex Works (EXW) and Free on Board (FOB) are international shipping terms (Incoterms) that define the responsibilities of buyers and sellers in shipping goods. EXW requires the seller to make the product available at a designated location, with the buyer incurring all transportation costs and risks. FOB obligates the seller to load goods onto the buyer’s transport at the shipping point, retaining re…

3. CargoFlip – Key Incoterms Explained

Domain: cargoflip.com

Registered: 2019 (6 years)

Introduction: Ex Works (EXW) and Free on Board (FOB) are two key Incoterms in international trade. EXW signifies the seller’s minimum obligation, where the buyer assumes all responsibilities once the goods are made available at the seller’s premises. FOB indicates the point at which the buyer takes responsibility for the goods, with two arrangements: FOB origin (seller responsible until goods reach shipping poi…

4. China Division – International Shipping Terms Explained

Domain: chinadivision.com

Registered: 2015 (10 years)

Introduction: The text explains the differences between three international shipping terms: FCA (Free Carrier), FOB (Free On Board), and EXW (Ex Works).

1. **FCA (Free Carrier)**:

– Seller delivers goods to a carrier designated by the buyer at a specified location.

– Applicable to all transport modes (land, sea, air, rail).

– Seller is responsible for export customs clearance; buyer assumes respon…

5. Eurosender – EXW vs FOB: Key Differences

Domain: eurosender.com

Registered: 2014 (11 years)

Introduction: EXW (Ex Works) and FOB (Free On Board) are Incoterms used in international freight transport. Key differences include: 1. Responsibility Shift: Under FOB, the seller is responsible for loading goods onto the vessel; under EXW, the seller only makes goods available at a designated location. 2. Transport Costs: FOB sellers pay for transport to the vessel; EXW buyers bear all further transport costs….

6. Supplyia – Incoterms Explained: EXW & FOB

Domain: supplyia.com

Registered: 2020 (5 years)

Introduction: EXW (Ex Works) and FOB (Free on Board) are Incoterms related to international shipments. EXW means the seller makes a product available at a specific location, and the buyer is responsible for all costs and risks from that point onward. FOB means the seller loads the goods onto the vessel, after which the buyer assumes responsibility. Pros of EXW include lower costs and more control for the buyer,…

7. WorldCraft Logistics – EXW and FOB Shipping Solutions

Domain: worldcraftlogistics.com

Registered: 2013 (12 years)

Introduction: EXW (Ex Works) and FOB (Free on Board) are international trade terms that define responsibilities of buyers and sellers in transportation of goods. EXW means the seller makes goods available at their location, with the buyer responsible for all transportation costs and risks. FOB requires the seller to deliver goods to a specified destination for transfer to a carrier chosen by the buyer, with cos…

Strategic Sourcing Conclusion and Outlook for ex works vs fob

In the realm of international trade, understanding the distinctions between Ex Works (EXW) and Free on Board (FOB) is crucial for effective strategic sourcing. EXW places the onus of logistics and risk on the buyer from the seller’s premises, offering potential cost savings but demanding greater shipping expertise. Conversely, FOB provides a more structured approach where the seller manages risks and costs until the goods are loaded onto the vessel, offering buyers a layer of security in their transactions.

For B2B buyers from Africa, South America, the Middle East, and Europe, the choice between these Incoterms should align with your operational capabilities, risk tolerance, and the reliability of your suppliers. Assessing your logistics knowledge and supplier relationship can lead to more informed decisions, ultimately enhancing your supply chain efficiency.

Looking ahead, as global trade continues to evolve, leveraging strategic sourcing practices will be vital for optimizing costs and mitigating risks. Engage with your suppliers, understand your logistical landscape, and make choices that align with your business objectives. The right Incoterm can not only streamline your operations but also position your business for sustainable growth in an increasingly competitive marketplace.