Is Your R20 Battery Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for r20 battery

In the ever-evolving landscape of global commerce, sourcing reliable power solutions such as the R20 battery can pose significant challenges for B2B buyers. As businesses across Africa, South America, the Middle East, and Europe increasingly rely on portable electronic devices, understanding the intricacies of R20 battery procurement is essential. This guide serves as a comprehensive resource that addresses various aspects of R20 batteries, including types, applications, supplier vetting processes, and cost considerations, enabling international buyers to make informed purchasing decisions.

The R20 battery, also known as the D battery, is widely used in everyday devices such as flashlights, alarms, and toys, making it a critical component for many businesses. Given the diverse regulatory landscapes and market dynamics in regions like Germany and Vietnam, navigating the supply chain effectively is paramount. This guide empowers B2B buyers by offering actionable insights into selecting the right battery type, understanding performance specifications, and identifying reputable suppliers, ensuring that you can meet your operational needs without compromising on quality or sustainability.

By leveraging this resource, businesses can enhance their procurement strategies, reduce costs, and ensure the reliability of their electronic devices. Whether you are a distributor, retailer, or manufacturer, this guide is designed to equip you with the knowledge necessary to thrive in the competitive global market for R20 batteries.

Understanding r20 battery Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Zinc Chloride (R20) | 1.5V, mercury-free, good performance in low-drain devices | Alarms, flashlights, toys | Pros: Cost-effective, environmentally friendly. Cons: Limited shelf life, not ideal for high-drain devices. |

| Alkaline (LR20) | Higher capacity than zinc chloride, 1.5V, longer shelf life | Consumer electronics, remote controls | Pros: Better performance in high-drain applications. Cons: More expensive than zinc chloride. |

| Lithium (R20) | 1.5V, lightweight, excellent energy density | Professional equipment, cameras | Pros: Long shelf life, stable performance in extreme temperatures. Cons: Higher cost, not rechargeable. |

| Rechargeable NiMH (D size) | 1.2V, rechargeable, lower self-discharge rate | Electric toys, portable devices | Pros: Cost-effective over time, eco-friendly. Cons: Lower voltage than non-rechargeable options. |

| Carbon Zinc (R20) | Basic battery type, 1.5V, lower capacity | Low-drain devices, flashlights | Pros: Very affordable, widely available. Cons: Shorter lifespan, not suitable for high-drain applications. |

What Are the Key Characteristics of Zinc Chloride R20 Batteries?

Zinc chloride R20 batteries are a popular choice for many standard electronic devices, providing a stable 1.5V output. They are mercury-free, making them environmentally friendly, which is increasingly important for businesses focused on sustainability. These batteries are particularly suitable for low-drain applications such as alarms, flashlights, and toys. Buyers should consider their limited shelf life, which may necessitate more frequent purchases.

How Do Alkaline R20 Batteries Compare to Other Types?

Alkaline R20 batteries offer a higher capacity and longer shelf life compared to zinc chloride batteries, making them ideal for consumer electronics and remote controls. Their performance shines in high-drain applications, where they can provide more consistent energy output. However, they come at a higher price point, which could impact budget-sensitive B2B buyers. Businesses should assess their specific power needs against the cost when choosing alkaline batteries.

What Advantages Do Lithium R20 Batteries Offer for Professional Use?

Lithium R20 batteries are recognized for their lightweight design and superior energy density. They maintain a stable voltage output of 1.5V and have an extended shelf life, making them suitable for professional equipment like cameras and high-performance devices. While their cost is higher, the benefits of reliability and performance in extreme temperatures make them a worthwhile investment for businesses that require dependable power solutions.

Why Consider Rechargeable NiMH R20 Batteries for Long-Term Use?

Rechargeable NiMH (Nickel-Metal Hydride) R20 batteries present a sustainable option for businesses looking to reduce waste and long-term costs. With a nominal voltage of 1.2V, they are ideal for electric toys and portable devices that require frequent battery changes. Although they offer a lower voltage than traditional alkaline batteries, their rechargeability and lower self-discharge rate make them a practical choice for environmentally conscious buyers.

What Are the Limitations of Carbon Zinc R20 Batteries?

Carbon zinc R20 batteries are the most basic type available, providing a nominal voltage of 1.5V at a very low cost. They are best suited for low-drain devices, such as flashlights and remote controls. However, their shorter lifespan and performance limitations in high-drain applications make them less suitable for businesses requiring reliable power for demanding electronics. Buyers should weigh the low initial cost against the potential need for more frequent replacements.

Key Industrial Applications of r20 battery

| Industry/Sector | Specific Application of r20 battery | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Portable audio devices (e.g., radios, speakers) | Reliable power source for extended use, enhancing customer satisfaction and product performance. | Ensure compatibility with device specifications and consider bulk purchasing for cost efficiency. |

| Security Systems | Alarm systems and emergency lighting | Ensures operational readiness during power outages, enhancing safety and reliability. | Focus on battery longevity and environmental compliance to meet safety standards. |

| Automotive Accessories | Flashlights and portable jump starters | Provides dependable power for emergency situations, improving customer trust and product usability. | Consider sourcing from reputable manufacturers to guarantee quality and performance. |

| Toys and Recreational Products | Battery-operated toys and gadgets | Enhances user experience by ensuring toys operate consistently, leading to higher customer retention. | Assess battery life and safety certifications, especially for products targeting children. |

| Industrial Equipment | Remote controls and portable tools | Increases operational efficiency by ensuring devices are always powered when needed. | Evaluate sourcing options that offer competitive pricing and reliable delivery schedules. |

How Are r20 Batteries Used in Consumer Electronics?

In the consumer electronics sector, r20 batteries are commonly utilized in portable audio devices such as radios and Bluetooth speakers. These batteries provide a reliable power source, ensuring that devices operate effectively during outdoor events or travel. Businesses benefit from enhanced customer satisfaction due to the consistent performance of their products. Buyers should ensure that the batteries are compatible with their devices and consider bulk purchasing options to reduce costs, especially in regions like Africa and South America where logistical challenges may arise.

What Role Do r20 Batteries Play in Security Systems?

In security systems, r20 batteries are essential for powering alarm systems and emergency lighting. They ensure that these critical devices remain operational during power outages, thereby enhancing safety and reliability. Businesses benefit from the peace of mind that comes with knowing their security measures are always functional. When sourcing r20 batteries for security applications, buyers should prioritize longevity and environmental compliance to meet safety standards, particularly in regions with strict regulations.

How Are r20 Batteries Used in Automotive Accessories?

Automotive accessories, such as flashlights and portable jump starters, frequently employ r20 batteries. These batteries offer dependable power for emergency situations, thereby improving customer trust in the product’s reliability. Businesses that incorporate r20 batteries into their automotive accessories can enhance the usability of their products. Buyers should consider sourcing batteries from reputable manufacturers to ensure quality and performance, especially in competitive markets in Europe and the Middle East.

What Are the Applications of r20 Batteries in Toys and Recreational Products?

In the toy industry, r20 batteries are widely used in battery-operated toys and gadgets. These batteries enhance the user experience by ensuring toys operate consistently, which leads to higher customer retention rates. Businesses benefit from the reliability that these batteries provide, allowing for extended playtime. When sourcing r20 batteries for toys, it is crucial to assess battery life and safety certifications, particularly for products targeting children, to meet regulatory standards across various markets.

How Do r20 Batteries Support Industrial Equipment?

In the industrial sector, r20 batteries are often used in remote controls and portable tools, increasing operational efficiency by ensuring devices are powered when needed. Businesses that depend on these tools benefit from minimized downtime and improved productivity. Buyers should evaluate sourcing options that offer competitive pricing and reliable delivery schedules to maintain a steady supply chain, particularly in regions where access to quality batteries may be limited.

3 Common User Pain Points for ‘r20 battery’ & Their Solutions

Scenario 1: Inconsistent Battery Performance in Critical Applications

The Problem: B2B buyers often encounter issues with the R20 battery’s performance in critical applications, such as emergency lighting, medical devices, or safety alarms. These batteries may not provide consistent power output, leading to device failure when reliability is paramount. This inconsistency can result in significant operational disruptions and can compromise safety, particularly in industries where battery-powered devices are essential for maintaining safety protocols. The stakes are high, and unreliable batteries can erode trust in suppliers and negatively impact business operations.

The Solution: To mitigate performance issues, it is crucial for buyers to source R20 batteries from reputable manufacturers who adhere to strict quality control measures. Look for batteries that are certified and tested for performance under varying load conditions. Additionally, conducting regular performance assessments on battery-operated devices can help identify any discrepancies early. Implementing a proactive inventory management system that tracks battery usage and expiration dates can also ensure that only fresh batteries are utilized in critical applications. Consider establishing a partnership with suppliers who offer performance guarantees or warranties, as this can further protect against unexpected failures.

Scenario 2: Environmental Compliance and Disposal Challenges

The Problem: With increasing regulatory scrutiny on environmental impacts, B2B buyers face challenges related to the disposal and environmental compliance of R20 batteries. Many batteries contain hazardous materials, and improper disposal can lead to legal ramifications and damage a company’s reputation. Buyers in sectors such as manufacturing, healthcare, and retail must ensure that their battery procurement and disposal processes align with local regulations, which can be particularly complex in regions with stringent environmental laws.

The Solution: To address these compliance issues, it is essential for businesses to partner with suppliers who provide clear information regarding the environmental impact of their R20 batteries. Opt for batteries that are mercury-free and comply with international environmental standards. Establish a comprehensive waste management strategy that includes recycling programs for used batteries. Collaborate with certified e-waste recycling companies that can handle the disposal in accordance with local regulations. Additionally, providing training to employees on proper disposal methods can further enhance compliance and demonstrate corporate responsibility.

Scenario 3: Cost Management and Bulk Purchasing Decisions

The Problem: Cost management is a common concern for B2B buyers, especially when purchasing R20 batteries in bulk. Fluctuations in battery prices can affect budgeting and financial forecasting. Additionally, buyers may struggle to find a balance between cost and quality, leading to decisions that could impact product performance and overall operational efficiency. This scenario is particularly relevant for businesses that rely heavily on battery-operated devices, where the total cost of ownership must be carefully calculated.

The Solution: To optimize purchasing decisions, buyers should conduct a thorough market analysis to compare prices and quality across different suppliers. Establishing long-term relationships with battery manufacturers can lead to favorable pricing agreements and discounts for bulk purchases. Consider leveraging group purchasing organizations (GPOs) that allow businesses to pool their purchasing power for better rates. Additionally, investing in energy-efficient devices that require fewer battery replacements can reduce overall costs in the long run. Implementing a centralized procurement strategy can also streamline purchasing processes and lead to better cost management and inventory control.

Strategic Material Selection Guide for r20 battery

What Are the Key Materials Used in r20 Batteries?

The r20 battery, commonly known as the D battery, is a critical component in various electronic devices, including flashlights, alarms, and toys. The materials used in its construction significantly influence its performance, durability, and suitability for different applications. Here, we analyze four common materials used in r20 batteries: zinc chloride, zinc-carbon, alkaline, and lithium.

How Does Zinc Chloride Enhance r20 Battery Performance?

Zinc chloride is a prevalent material in the production of r20 batteries. It provides a stable voltage output of 1.5V, making it ideal for low-drain devices.

Key Properties: Zinc chloride batteries are characterized by their good performance at moderate temperatures and relatively low self-discharge rates. They are also mercury-free, aligning with environmental regulations.

Pros & Cons: The advantages of zinc chloride include its cost-effectiveness and safety profile. However, they have a shorter shelf life compared to alkaline batteries and are less efficient in high-drain applications.

Impact on Application: Zinc chloride batteries are suitable for devices that require steady, low power over extended periods. They are not recommended for high-drain devices, as they may deplete quickly.

Considerations for International Buyers: Compliance with international standards such as ASTM and JIS is crucial. Buyers in regions like Europe and the Middle East often prefer environmentally friendly products, making zinc chloride a favorable option.

What Benefits Do Zinc-Carbon Batteries Offer?

Zinc-carbon batteries are another common choice for r20 batteries, known for their affordability and availability.

Key Properties: These batteries typically exhibit a voltage of 1.5V and are made from a combination of zinc and manganese dioxide.

Pros & Cons: While zinc-carbon batteries are low-cost and widely available, they have a limited lifespan and are less efficient than alkaline batteries. Their performance can degrade significantly in high-drain applications.

Impact on Application: These batteries are best suited for low-drain devices such as remote controls and clocks. Their limited capacity makes them unsuitable for devices requiring high energy output.

Considerations for International Buyers: Buyers should be aware of the varying quality standards across regions. In Europe, for instance, preference is often given to batteries that meet specific environmental and safety regulations.

How Do Alkaline Batteries Compare in the r20 Category?

Alkaline batteries are widely recognized for their superior performance and longer shelf life compared to zinc-carbon and zinc chloride options.

Key Properties: Alkaline batteries provide a stable voltage of 1.5V and perform well across a wide temperature range. They also have lower self-discharge rates, making them suitable for long-term storage.

Pros & Cons: The primary advantage of alkaline batteries is their durability and efficiency in high-drain applications. However, they are more expensive than zinc-carbon and zinc chloride batteries.

Impact on Application: Alkaline batteries are ideal for devices that require consistent power over time, such as digital cameras and portable audio devices.

Considerations for International Buyers: Alkaline batteries often meet stringent international standards, making them a preferred choice for buyers in Europe and North America. However, their higher cost may be a consideration for buyers in emerging markets.

What Role Do Lithium Batteries Play in r20 Applications?

Lithium batteries are becoming increasingly popular in the r20 category due to their high energy density and long shelf life.

Key Properties: Lithium batteries offer a voltage of 1.5V and are known for their lightweight design and excellent performance in extreme temperatures.

Pros & Cons: The main advantage of lithium batteries is their longevity and ability to perform well in high-drain devices. However, they are significantly more expensive than other battery types.

Impact on Application: Lithium batteries are suitable for high-performance devices that require reliable power, such as high-end flashlights and medical devices.

Considerations for International Buyers: Buyers should consider the regulatory landscape, as lithium batteries are subject to strict shipping and safety regulations. Compliance with international standards is essential for market acceptance.

Summary Table of Material Selection for r20 Batteries

| Material | Typical Use Case for r20 battery | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Zinc Chloride | Low-drain devices (e.g., toys, alarms) | Cost-effective and safe | Shorter shelf life | Low |

| Zinc-Carbon | Low-drain devices (e.g., remote controls) | Widely available and affordable | Limited lifespan and efficiency | Low |

| Alkaline | High-drain devices (e.g., cameras) | Superior performance and durability | Higher cost than other types | Med |

| Lithium | High-performance devices (e.g., flashlights) | Long shelf life and lightweight | High cost | High |

This strategic material selection guide provides international B2B buyers with essential insights into the various materials used in r20 batteries, helping them make informed purchasing decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for r20 battery

What Are the Main Stages of R20 Battery Manufacturing?

The manufacturing process of R20 batteries, commonly known as D batteries, involves several critical stages, each requiring precision and adherence to quality standards. Understanding these stages can help B2B buyers assess potential suppliers more effectively.

Material Preparation: What Raw Materials Are Used in R20 Battery Production?

The first step in the manufacturing of R20 batteries is the preparation of raw materials. Key components include zinc, manganese dioxide, and an electrolyte solution, typically a zinc chloride mixture. These materials are sourced from reputable suppliers who meet environmental regulations and quality standards. For international B2B buyers, verifying the sustainability and ethical sourcing of these materials can be essential, especially when considering suppliers from diverse regions such as Africa and South America.

How Are R20 Batteries Formed?

Once the materials are prepared, they undergo the forming process, where the active materials are mixed and shaped into electrodes. The zinc and manganese compounds are combined and pressed into cylindrical shapes that will later serve as the positive and negative terminals of the battery. This process often involves techniques such as die-casting and extrusion, which ensure uniformity and adherence to dimensional specifications.

What Assembly Techniques Are Employed in R20 Battery Production?

The assembly stage follows the forming process, where the individual components are brought together. The cylindrical electrodes are placed within a battery casing, and the electrolyte is added. This assembly is performed in a controlled environment to prevent contamination. Automated machinery is frequently used to enhance precision and efficiency, which is crucial for maintaining competitive production costs.

What Finishing Processes Are Involved in R20 Battery Manufacturing?

After assembly, the batteries undergo finishing processes, including sealing and labeling. Sealing is vital to prevent leakage and ensure the longevity of the battery. The labeling process often includes important regulatory information, such as compliance with international standards like CE or RoHS. For B2B buyers, understanding these finishing processes can provide insight into the supplier’s commitment to quality and safety.

How Is Quality Assurance Implemented in R20 Battery Manufacturing?

Quality assurance is paramount in the production of R20 batteries, ensuring that each unit meets stringent performance and safety standards. Manufacturers typically adhere to international standards such as ISO 9001, which outlines the criteria for a quality management system. Compliance with such standards is crucial for establishing credibility in international markets.

What Are the Key Quality Control Checkpoints in R20 Battery Production?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This stage assesses the quality of raw materials before they are used in production. Suppliers should provide certificates of compliance to ensure materials meet specifications.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are tested to identify any deviations from quality standards. This might include measuring voltage, capacity, and physical dimensions.

-

Final Quality Control (FQC): Before packaging, finished batteries are subjected to rigorous testing, including performance tests under various conditions to ensure reliability and safety.

What Testing Methods Are Commonly Used for R20 Batteries?

Various testing methods are employed to evaluate the performance and safety of R20 batteries. These include:

- Electrical Testing: Assessing voltage, current capacity, and discharge rates.

- Environmental Testing: Evaluating performance under extreme temperatures and humidity.

- Leakage Testing: Ensuring that batteries are sealed properly to prevent leakage of electrolytes.

These tests are crucial for B2B buyers looking to ensure that their suppliers produce reliable and safe products.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential. Here are some actionable steps:

-

Request Documentation: Ask suppliers for quality assurance documentation, including their ISO certifications and internal QC reports.

-

Conduct Audits: Periodic audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can help verify that the manufacturing processes and final products meet specified quality benchmarks.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing R20 batteries from international suppliers, B2B buyers must consider specific nuances:

-

Regulatory Compliance: Different regions may have varying regulations concerning battery production. Buyers should be aware of local compliance requirements, such as CE for Europe or other regional certifications.

-

Cultural Differences in Quality Standards: Understanding the local manufacturing culture can provide insights into a supplier’s approach to quality assurance. This is particularly relevant in regions like Africa and the Middle East, where traditional practices may influence modern manufacturing.

-

Supply Chain Transparency: Buyers should prioritize suppliers who maintain transparency in their supply chains, ensuring ethical sourcing and production practices.

Conclusion: Why Is Understanding Manufacturing and QC Processes Essential for B2B Buyers?

In summary, a comprehensive understanding of the manufacturing processes and quality assurance practices for R20 batteries is vital for B2B buyers. By scrutinizing each stage of production—from material preparation to final testing—buyers can make informed decisions, mitigate risks, and ensure that they are sourcing high-quality, reliable products that meet their specific needs. This diligence is particularly crucial in international markets where standards and regulations may vary significantly.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘r20 battery’

In the competitive landscape of battery procurement, especially for international B2B buyers, the R20 battery presents unique considerations. This practical sourcing guide aims to equip you with a comprehensive checklist to ensure you make informed purchasing decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for the R20 battery is critical. Identify the voltage (1.5V), chemistry (zinc chloride), and dimensions (34.2 x 61.5 mm) that your applications require. This will help you avoid compatibility issues with devices such as flashlights, alarms, and toys.

Step 2: Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers of R20 batteries. Utilize online directories, trade shows, and industry recommendations to compile a list of potential vendors. Focus on suppliers with experience in your target markets, particularly in regions like Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Supplier Certifications

Before proceeding with a purchase, verify the certifications and compliance of your potential suppliers. Look for ISO certifications, environmental compliance (like RoHS), and safety certifications. These credentials ensure that the batteries meet international quality standards and are safe for use.

Step 4: Request Samples for Testing

Always request samples before placing a bulk order. Testing the batteries in your specific applications will help you assess their performance and reliability. Look for factors such as longevity, discharge rates, and compatibility with your devices, ensuring they meet your operational needs.

Step 5: Negotiate Terms and Pricing

Engage in negotiations with suppliers to secure favorable terms and pricing. Consider factors such as minimum order quantities, bulk discounts, and payment terms. Ensure that the pricing structure aligns with your budget while allowing for flexibility in your purchasing strategy.

Step 6: Review Shipping and Logistics Options

Evaluate the shipping and logistics options provided by your suppliers. Consider delivery times, shipping costs, and the reliability of the logistics partners. Efficient shipping is crucial for maintaining your supply chain, especially if you operate in regions with logistical challenges.

Step 7: Establish a Quality Assurance Process

Once you have procured the batteries, implement a quality assurance process to monitor their performance. Regularly assess the batteries in use to ensure they meet your specifications and performance expectations. Establish feedback mechanisms with your suppliers to address any issues promptly.

By following this checklist, B2B buyers can make informed decisions when sourcing R20 batteries, ensuring quality, reliability, and compatibility with their applications. This strategic approach will not only enhance operational efficiency but also foster long-term supplier relationships.

Comprehensive Cost and Pricing Analysis for r20 battery Sourcing

What Are the Key Cost Components in R20 Battery Sourcing?

When sourcing R20 batteries, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: R20 batteries typically consist of zinc chloride and other non-toxic components, which can influence the overall material cost. The prices of raw materials fluctuate based on global demand, availability, and supplier contracts.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as some parts of Africa and South America, manufacturing can be more cost-effective. However, in regions like Europe, labor costs can be higher, which may be reflected in the pricing.

-

Manufacturing Overhead: This includes costs associated with factory operation, equipment maintenance, and energy consumption. Efficient manufacturing processes can help reduce overhead costs, making it essential to evaluate suppliers based on their production efficiency.

-

Tooling: If customization is required, tooling costs can add up. This is particularly relevant for buyers who need batteries that meet specific specifications or certifications.

-

Quality Control (QC): Ensuring the batteries meet safety and performance standards requires investment in quality assurance processes. Buyers should look for suppliers that prioritize QC to avoid potential issues later.

-

Logistics: The cost of transporting batteries can vary greatly depending on the distance from the supplier and the chosen shipping method. This includes freight costs, insurance, and handling fees.

-

Margin: Suppliers will typically include a profit margin in their pricing, which can vary based on market conditions and competition.

How Do Price Influencers Affect R20 Battery Costs?

Several factors can influence the pricing of R20 batteries, including volume, specifications, materials, quality certifications, supplier characteristics, and Incoterms.

-

Volume/MOQ: Ordering in bulk can lead to significant cost savings. Many suppliers offer tiered pricing, where the per-unit cost decreases with larger orders.

-

Specifications/Customization: Custom specifications can increase costs due to additional tooling and QC requirements. Buyers should clearly define their needs to avoid unnecessary expenses.

-

Materials: The choice of materials can greatly influence price. Premium materials may enhance performance but will also increase costs.

-

Quality/Certifications: Batteries that meet international safety and environmental standards often command higher prices. However, investing in certified products can reduce liability and enhance brand reputation.

-

Supplier Factors: The reliability, reputation, and location of suppliers can also affect pricing. Established suppliers with strong track records may charge more, but they often provide better quality assurance and customer support.

-

Incoterms: Understanding the terms of shipping and delivery is vital. Different Incoterms can impact the total cost, including who bears responsibility for transportation, insurance, and tariffs.

What Are the Best Buyer Tips for Cost Efficiency in R20 Battery Sourcing?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, several strategies can optimize sourcing costs:

-

Negotiation: Don’t hesitate to negotiate prices and terms with suppliers. Building a relationship can lead to better deals and more favorable terms over time.

-

Total Cost of Ownership (TCO): Consider not only the purchase price but also the long-term costs associated with the batteries, including disposal, recycling, and replacement.

-

Pricing Nuances: Be aware of currency fluctuations and international trade regulations that may impact pricing. Understanding these factors can help in making informed purchasing decisions.

-

Supplier Evaluation: Conduct thorough due diligence on potential suppliers. Look for reviews, certifications, and their ability to meet delivery schedules and quality standards.

-

Market Research: Stay informed about market trends and pricing fluctuations in the battery industry. This knowledge can empower buyers to make strategic decisions and capitalize on favorable market conditions.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable for buyers to obtain current quotes and conduct comprehensive evaluations to ensure the best sourcing decisions.

Alternatives Analysis: Comparing r20 battery With Other Solutions

Understanding Alternatives to the R20 Battery

In the realm of power solutions for various electronic devices, the R20 battery, also known as the D battery, is a prevalent option. However, as the market evolves, buyers must consider alternatives that might offer better performance, cost-effectiveness, or environmental benefits. Below, we explore two viable alternatives to the R20 battery: rechargeable lithium-ion batteries and alkaline batteries.

Comparison Table

| Comparison Aspect | R20 Battery | Rechargeable Lithium-Ion Battery | Alkaline Battery |

|---|---|---|---|

| Performance | Good for standard devices; 1.5V output | Higher energy density; longer lifespan | Reliable for short-term use; 1.5V output |

| Cost | Moderate initial cost; multiple uses may add up | Higher upfront cost; cost-effective over time | Low initial cost; requires frequent replacements |

| Ease of Implementation | Simple to use; no special handling needed | Requires a charger; slightly more complex | Easy to use; no special equipment needed |

| Maintenance | Single-use; no maintenance needed | Requires periodic charging; battery management system recommended | Single-use; no maintenance needed |

| Best Use Case | Toys, flashlights, alarms | High-drain devices like power tools and laptops | Remote controls, clocks, low-drain devices |

Detailed Breakdown of Alternatives

Rechargeable Lithium-Ion Battery

Rechargeable lithium-ion batteries have gained immense popularity due to their high energy density and long lifespan. They are ideal for high-drain devices, such as power tools and laptops, where consistent power is essential. However, they come with a higher upfront cost compared to R20 batteries. The need for a compatible charger and battery management system can complicate implementation, making them less appealing for simple applications. Nevertheless, for businesses that prioritize sustainability and long-term cost savings, lithium-ion batteries are a superior choice.

Alkaline Battery

Alkaline batteries are another alternative that many businesses consider. They provide reliable power for low-drain devices such as remote controls and clocks. Alkaline batteries share the same voltage as R20 batteries (1.5V) and are easy to use without requiring any special equipment. However, their performance may diminish faster in high-drain applications, leading to more frequent replacements, which can increase overall costs. For applications with lower power demands, alkaline batteries offer a low-cost, convenient option.

Conclusion: How to Choose the Right Battery Solution

When selecting the appropriate power solution, B2B buyers should consider several factors, including the specific energy demands of their devices, budget constraints, and long-term sustainability goals. The R20 battery remains a viable choice for everyday devices, while alternatives like rechargeable lithium-ion and alkaline batteries may better suit specific applications. Evaluating the unique requirements of each use case will enable businesses to make informed decisions that align with their operational needs and financial considerations.

Essential Technical Properties and Trade Terminology for r20 battery

What Are the Key Technical Properties of R20 Batteries?

When evaluating R20 batteries for procurement, several critical specifications are essential for B2B buyers to consider:

-

Voltage: R20 batteries typically operate at a nominal voltage of 1.5V. This specification is crucial as it determines the battery’s compatibility with devices designed to operate within specific voltage ranges. For businesses, ensuring that the voltage aligns with the operational requirements of equipment prevents device malfunction and potential damage.

-

Chemical Composition: Most R20 batteries are made with zinc chloride technology, which is mercury-free. Understanding the chemical makeup is vital for compliance with environmental regulations and safety standards, particularly in regions with strict waste management laws. Buyers should prioritize suppliers who offer eco-friendly options to enhance corporate responsibility and sustainability efforts.

-

Dimensions: R20 batteries have standardized dimensions of approximately 34.2 mm in diameter and 61.5 mm in height. This uniformity is critical for compatibility with various devices, from flashlights to toys. For manufacturers or retailers, ensuring that battery dimensions meet industry standards can streamline inventory management and reduce compatibility issues.

-

Capacity: The capacity of R20 batteries, typically measured in milliamp-hours (mAh), indicates how long a battery can power a device before depletion. Higher capacity batteries can reduce the frequency of replacements, which is particularly important for businesses that rely on battery-operated devices. Evaluating capacity helps in optimizing supply chain management and cost efficiency.

-

Shelf Life: The shelf life of R20 batteries can vary based on their chemical composition and storage conditions. Typically, a shelf life of 3 to 5 years is common. Businesses should consider shelf life when planning inventory, as longer shelf life can reduce the risk of stock obsolescence and waste.

-

Disposal and Recycling: As the global market increasingly shifts towards sustainability, understanding the disposal requirements for R20 batteries is crucial. Buyers should inquire about recycling programs offered by suppliers, which can enhance corporate sustainability initiatives and comply with local regulations on battery disposal.

What Common Trade Terms Should B2B Buyers of R20 Batteries Know?

Familiarity with industry jargon can significantly streamline negotiations and procurement processes. Here are some essential terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers looking to source R20 batteries that meet specific quality and performance standards, ensuring product reliability.

-

MOQ (Minimum Order Quantity): MOQ refers to the smallest amount of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budgeting and inventory management, as it can affect cash flow and storage capabilities.

-

RFQ (Request for Quotation): An RFQ is a document that solicits price quotes from suppliers for specific quantities and specifications of products. B2B buyers should utilize RFQs to obtain competitive pricing and ensure they are making informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps B2B buyers navigate shipping logistics and cost responsibilities effectively.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the goods. For businesses that rely on timely delivery, understanding lead times can help in planning and ensuring that operations run smoothly without interruptions.

-

Certification Standards: These are industry-specific benchmarks that products must meet to ensure quality and safety. Familiarity with certification standards relevant to R20 batteries can aid buyers in selecting products that comply with regulatory requirements, thus minimizing legal risks.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing R20 batteries, ensuring compatibility, compliance, and efficiency in their operations.

Navigating Market Dynamics and Sourcing Trends in the r20 battery Sector

What Are the Key Market Dynamics and Sourcing Trends in the R20 Battery Sector?

The R20 battery sector is witnessing significant transformations driven by technological advancements and changing consumer preferences. Globally, the demand for R20 batteries, particularly zinc chloride variants, is on the rise due to their applications in essential devices like flashlights, alarms, and toys. Emerging markets in Africa and South America are fueling this demand, as urbanization and increased consumer electronics penetration create new opportunities for battery suppliers. Additionally, the Middle East and Europe are experiencing a shift towards more reliable and eco-friendly battery solutions, prompting buyers to seek out suppliers who prioritize quality and sustainability.

The integration of smart technology within the battery sector is also noteworthy. Companies are increasingly adopting smart inventory management systems and data analytics tools to enhance sourcing efficiency. This trend is particularly relevant for international B2B buyers, who can leverage these technologies to optimize their supply chains and reduce costs. Moreover, the rise of e-commerce platforms is transforming how buyers procure R20 batteries, enabling easier access to suppliers and competitive pricing.

How Is Sustainability and Ethical Sourcing Addressed in the R20 Battery Sector?

Sustainability is becoming a core focus within the R20 battery sector, as buyers prioritize environmental impact in their sourcing decisions. The use of mercury-free materials, such as zinc chloride, is gaining traction, aligning with global regulations aimed at reducing hazardous substances in consumer products. Suppliers who can demonstrate adherence to environmental standards and certifications will likely have a competitive advantage.

Ethical sourcing practices are equally critical. B2B buyers are increasingly scrutinizing their supply chains to ensure that materials are sourced responsibly, minimizing harm to ecosystems and local communities. The adoption of ‘green’ certifications can enhance a supplier’s reputation and appeal, particularly in Europe, where regulatory compliance is stringent. Companies that transparently communicate their sustainability initiatives and ethical sourcing commitments are positioned to meet the evolving demands of conscious consumers and business partners alike.

What Is the Historical Context of R20 Batteries and Their Relevance Today?

The R20 battery, also known as the D battery, has a storied history dating back to the early 20th century. Initially designed for high-drain devices, these batteries have evolved to meet modern energy needs while adhering to stricter environmental regulations. The transition from traditional zinc-carbon batteries to more efficient and eco-friendly zinc chloride formulations marks a significant advancement in the industry.

Today, R20 batteries continue to play a crucial role in powering everyday devices, making them indispensable in both consumer and industrial applications. As the market evolves, understanding the historical context of these batteries helps B2B buyers appreciate the advancements in technology and sustainability that define the sector today. This knowledge equips them to make informed purchasing decisions that align with both operational needs and corporate social responsibility goals.

Frequently Asked Questions (FAQs) for B2B Buyers of r20 battery

-

How do I ensure the quality of R20 batteries from suppliers?

To ensure quality, request certifications such as ISO 9001 or relevant safety certifications for the R20 batteries. Conduct a factory audit if possible, or utilize third-party inspection services to verify product quality before shipment. Additionally, consider ordering samples for testing in your applications. Establish clear quality assurance protocols in your purchase agreements to hold suppliers accountable for any defects. -

What is the best type of R20 battery for high-drain devices?

For high-drain devices, consider using alkaline R20 batteries instead of zinc chloride types, as they typically provide higher energy density and longer run times. Ensure that the supplier can provide performance data, such as discharge curves, to help you choose the best option for your specific applications. Always discuss your application needs with the supplier to find the most suitable battery type. -

What are the typical minimum order quantities (MOQ) for R20 batteries?

MOQs for R20 batteries can vary widely depending on the supplier and your location. Generally, manufacturers may set MOQs between 500 to 5,000 units for bulk orders. It’s advisable to negotiate MOQs with suppliers, especially if you are testing the market or have limited storage capacity. Some suppliers may offer flexible terms for first-time buyers or larger contracts. -

What payment terms should I expect when sourcing R20 batteries internationally?

Payment terms can vary, but common practices include advance payment, letters of credit, or net 30 to 90 days after delivery. Be sure to clarify these terms upfront to avoid any misunderstandings. Using secure payment methods and escrow services can also protect your investment. Always assess the financial stability of your supplier to minimize risks associated with payment. -

How can I verify the reliability of an R20 battery supplier?

To verify a supplier’s reliability, research their business history, customer reviews, and any certifications they hold. Request references from previous clients and follow up to gauge their satisfaction. Additionally, consider using platforms that facilitate supplier vetting, such as Alibaba or Global Sources, which provide ratings and reviews. Engaging in small trial orders can also help assess reliability before committing to larger purchases. -

What logistics considerations should I keep in mind when importing R20 batteries?

When importing R20 batteries, consider shipping regulations related to hazardous materials, as batteries can fall under specific transport guidelines. Choose a logistics partner experienced in handling battery shipments to ensure compliance with international shipping laws. Factor in lead times for customs clearance and delivery, and consider insurance options for added protection against potential losses during transit. -

Can R20 batteries be customized for branding or packaging?

Yes, many suppliers offer customization options for branding, including packaging design and labeling. Discuss your branding needs during the sourcing process to determine the feasibility and associated costs. Custom packaging can enhance your product’s visibility and appeal in the market, but be mindful of potential MOQ requirements for custom orders. -

What are the environmental considerations when sourcing R20 batteries?

When sourcing R20 batteries, prioritize suppliers who adhere to environmental regulations and offer eco-friendly products. Look for batteries that are mercury-free and comply with regulations such as RoHS (Restriction of Hazardous Substances). Inquire about the supplier’s recycling programs or end-of-life management options for batteries to ensure sustainable practices align with your corporate social responsibility goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 R20 Battery Manufacturers & Suppliers List

1. Panasonic – D R20 Heavy Duty Batteries

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”: “10 X Panasonic D R20 Battery Heavy Duty Universal Cell Batteries 1.5 Bulk E:2027”, “brand”: “Panasonic”, “model”: “D R20”, “type”: “Heavy Duty Universal Cell Batteries”, “voltage”: “1.5V”, “condition”: “New”, “quantity_available”: “More than 10 available”, “price”: “Approx. $16.24 GBP 11.99”, “seller_feedback”: “99.7% positive feedback”, “returns”: “Accepted”}

2. Teimo – R20 Battery

Domain: my-summer-car.fandom.com

Registered: 1996 (29 years)

Introduction: {‘name’: ‘R20 battery’, ‘release_date’: ’22 October 2021′, ‘usable’: ‘Yes’, ‘equipable’: ‘No’, ‘purchasable’: ‘Yes’, ‘price’: ‘34.5 Mk (Box contains four R20 batteries)’, ‘source’: “Teimo’s shop”, ‘usage’: ‘Powering the portable radio and flashlight’, ‘battery_type’: ‘1.5V D dry cells’, ‘manufacturer’: ‘LEAD ER’, ‘radio_battery_requirement’: ’10 batteries’, ‘flashlight_battery_requirement’: ‘4 bat…

3. Botland – D R20 Batteries

Domain: botland.store

Registered: 2020 (5 years)

Introduction: This company, Botland – D R20 Batteries, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. WinPow – Dry Battery R20 Size D 1.5 V

Domain: winpowhub.com

Registered: 2018 (7 years)

Introduction: {“Product Name”: “Dry Battery R20 Size D 1.5 V”, “Type”: “Zinc Carbon Battery”, “Nominal Voltage”: “1.5 V”, “Capacity”: “10.8 mAH”, “Dimensions”: {“Length”: “1.42 inches”, “Diameter”: “0.57 inches”}, “Weight”: “0.45 ounces”, “Chemical Composition”: “Zinc/Manganese Dioxide”, “Applications”: [“Toys”, “Watches”, “Hearing Aids”, “Cameras”, “Calculators”, “Parking Lock”, “MP3”, “Radio Recorder”, “Flash…

5. Velamp – R20 D 1.5V Zinc Carbon Battery

Domain: velamp.com

Registered: 2005 (20 years)

Introduction: {“name”: “R20 D 1.5V Zinc Carbon Battery”, “packaging”: “Blister of 2 pieces”, “price”: “€3.90”, “tax_included”: true, “reference”: “R20/2BP”, “ean13”: “8003910900547”, “description”: “Blister Pack of 2 batteries. Long autonomy. Quality comparable to the big brands. Excellent for watches, remote controls.”, “technology”: “Stack technology ZINC CARBON”, “warranty”: “2 YEARS”}

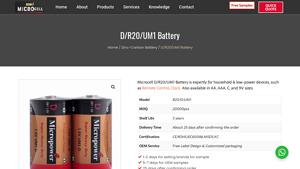

6. Micropower – Zinc-Carbon Battery R20/D/UM1

Domain: micropower-battery.com

Registered: 2020 (5 years)

Introduction: Model: R20/D/UM1

Type: Zinc-Carbon Battery

Voltage: 1.5V

Dimensions: Height 59.5-61.5mm, Diameter 32.5-34.5mm

Shelf Life: 3 years

Minimum Order Quantity (MOQ): 20,000 pcs

Delivery Time: About 25 days after confirming the order

Certifications: CE, RoHS, IEC60086, MSDS, KC

Applications: Household and low-power devices such as remote controls, clocks, gas stoves, torches, water heaters, electronic or…

Strategic Sourcing Conclusion and Outlook for r20 battery

What Are the Key Insights for B2B Buyers in the R20 Battery Market?

In conclusion, the R20 battery presents a robust opportunity for B2B buyers seeking reliable energy solutions. The increasing demand for environmentally friendly options, such as mercury-free zinc chloride batteries, highlights the importance of aligning sourcing strategies with sustainability goals. Buyers should consider the specifications and performance metrics that directly impact device functionality, such as voltage stability and longevity.

Strategic sourcing is essential in optimizing costs while ensuring quality and availability, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Establishing strong relationships with suppliers can lead to better pricing and access to innovations in battery technology.

How Can International Buyers Prepare for Future Trends in the R20 Battery Market?

Looking ahead, the R20 battery market is poised for growth driven by technological advancements and an expanding range of applications, from consumer electronics to industrial uses. International buyers are encouraged to stay informed about market trends and leverage strategic partnerships to enhance their supply chains.

Engaging with suppliers who prioritize sustainability and innovation will be critical in navigating this evolving landscape. Now is the time to assess your sourcing strategies and explore opportunities that align with your business goals. Embrace the future of energy solutions with confidence and agility.