91 Modal 9 Elastane: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for 91 modal 9 elastane

In today’s competitive textile market, sourcing high-quality fabrics like 91 modal 9 elastane can be a daunting challenge for B2B buyers, particularly those catering to the evolving demands of consumers across Africa, South America, the Middle East, and Europe. This innovative blend offers exceptional softness, breathability, and stretch, making it a preferred choice for a variety of applications, from stylish apparel to comfortable loungewear. However, navigating the complexities of global supply chains, varying quality standards, and fluctuating prices can overwhelm even the most seasoned procurement specialists.

This comprehensive guide delves into the multifaceted world of 91 modal 9 elastane, providing essential insights that empower international buyers to make informed purchasing decisions. We will explore the different types of modal elastane fabrics available, their diverse applications in the fashion industry, and key considerations for supplier vetting. Additionally, we will analyze cost structures and market trends, helping buyers to optimize their sourcing strategies while ensuring they receive the best value for their investments.

By equipping B2B buyers with actionable knowledge and practical tips, this guide aims to streamline the sourcing process, enhance product quality, and ultimately drive business growth. Whether you are based in the bustling markets of Germany or the emerging economies of Saudi Arabia, understanding the nuances of 91 modal 9 elastane will position your business for success in a dynamic global landscape.

Understanding 91 modal 9 elastane Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Modal Elastane | Soft, breathable fabric with moderate stretch | Apparel (t-shirts, dresses, activewear) | Pros: Excellent comfort and drape. Cons: May require special care for longevity. |

| Ribbed Modal Elastane | Textured surface with enhanced elasticity | Underwear, loungewear | Pros: Good fit and support. Cons: Texture may not appeal to all consumers. |

| Micro Modal Elastane | Ultra-soft with a luxurious feel, lightweight | Sleepwear, intimate apparel | Pros: Superior softness and breathability. Cons: Higher cost compared to standard modal. |

| Printed Modal Elastane | Available in various prints and colors | Fashion garments, children’s wear | Pros: Versatile design options. Cons: Print durability may vary. |

| Eco-Friendly Modal Elastane | Made from sustainably sourced materials | Sustainable fashion lines | Pros: Appeals to eco-conscious consumers. Cons: May have limited availability. |

What Are the Characteristics of Standard Modal Elastane?

Standard Modal Elastane blends 91% modal with 9% elastane, resulting in a fabric that is soft to the touch and highly breathable. This type is often used in casual apparel such as t-shirts and dresses, making it suitable for year-round wear. When purchasing, B2B buyers should consider the fabric’s care requirements, as modal often demands gentle washing to maintain its quality. This fabric’s excellent drape enhances the overall aesthetic of garments, appealing to brands focused on comfort and style.

How Does Ribbed Modal Elastane Differ?

Ribbed Modal Elastane features a textured surface that provides additional elasticity and a snug fit. It is primarily used in underwear and loungewear due to its ability to conform to the body’s shape while offering comfort. B2B buyers should evaluate the target market’s preferences, as the ribbed texture may not resonate with every consumer. This variation is advantageous for brands seeking to offer supportive and stylish undergarments, balancing comfort with functionality.

What Makes Micro Modal Elastane a Premium Choice?

Micro Modal Elastane is a finer version of modal, offering an exceptionally soft and luxurious feel. It is lightweight and breathable, making it ideal for sleepwear and intimate apparel. B2B buyers should note that while it provides unparalleled comfort, its higher cost may be a consideration for budget-conscious brands. This fabric is particularly appealing to luxury markets, where the softness and quality can justify the price point.

What Are the Benefits of Printed Modal Elastane?

Printed Modal Elastane comes in a variety of colors and patterns, catering to fashion-forward applications, including children’s wear and trendy garments. The versatility of printed modal allows brands to differentiate their offerings in a competitive market. However, buyers should consider the durability of prints, as some may fade over time or require specific care to maintain vibrancy. This type is excellent for businesses looking to attract consumers seeking unique and stylish clothing options.

How Does Eco-Friendly Modal Elastane Align with Market Trends?

Eco-Friendly Modal Elastane is produced from sustainably sourced materials, aligning with the growing trend towards sustainability in fashion. This type appeals to eco-conscious consumers and brands committed to reducing their environmental footprint. B2B buyers should assess the availability of these fabrics, as they may be limited compared to conventional options. Investing in eco-friendly modal elastane can enhance a brand’s image and attract a dedicated customer base focused on sustainability.

Key Industrial Applications of 91 modal 9 elastane

| Industry/Sector | Specific Application of 91 modal 9 elastane | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Activewear and Athleisure Clothing | Offers superior comfort and flexibility, enhancing customer satisfaction and repeat purchases. | Focus on fabric durability, stretchability, and sustainable sourcing practices. |

| Underwear and Loungewear | High-End Underwear and Sleepwear | Provides a luxurious feel and breathability, appealing to high-end markets. | Ensure compliance with international quality standards and certifications. |

| Home Textiles | Luxury Bedding and Sleep Products | Enhances product appeal through softness and moisture-wicking properties, leading to higher sales. | Source from suppliers that prioritize eco-friendly production methods. |

| Medical Textiles | Compression Garments and Post-Surgical Wear | Facilitates recovery with breathable, flexible fabrics that adapt to body movements. | Verify the fabric’s hypoallergenic properties and certifications for medical use. |

| Sports Equipment | Performance Gear and Accessories | Improves athlete performance through moisture management and comfort during physical activity. | Consider the fabric’s performance in various environmental conditions and its durability over time. |

How is 91 Modal 9 Elastane Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, 91 modal 9 elastane is predominantly utilized for activewear and athleisure clothing. This blend offers exceptional comfort and flexibility, making it ideal for garments that require a high degree of stretch. For international buyers, particularly from regions like Africa and Europe, sourcing this fabric can enhance product offerings by meeting the growing consumer demand for stylish yet functional clothing. Buyers should prioritize suppliers that provide consistent quality and durability to ensure customer satisfaction.

What Role Does 91 Modal 9 Elastane Play in Underwear and Loungewear?

This fabric is a popular choice in the production of high-end underwear and loungewear due to its silk-like softness and superior breathability. The blend ensures a snug yet comfortable fit, which is crucial for products in this category. For B2B buyers from South America and the Middle East, establishing relationships with manufacturers who emphasize quality and comfort can lead to increased brand loyalty and market share. Compliance with international quality standards is essential to maintain product integrity.

How Does 91 Modal 9 Elastane Enhance Home Textiles?

In home textiles, 91 modal 9 elastane is increasingly being used in luxury bedding and sleep products. The fabric’s softness and moisture-wicking properties significantly enhance the sleeping experience, making it a sought-after choice among consumers. For businesses sourcing this material, focusing on suppliers that engage in sustainable practices can improve brand image and attract environmentally conscious consumers, particularly in European markets.

What are the Benefits of Using 91 Modal 9 Elastane in Medical Textiles?

The medical textiles sector benefits from 91 modal 9 elastane in the production of compression garments and post-surgical wear. The fabric’s breathability and flexibility support patient comfort during recovery. For international buyers, it is crucial to ensure that the sourced materials meet hypoallergenic standards and relevant medical certifications, particularly in regions with stringent healthcare regulations.

How is 91 Modal 9 Elastane Utilized in Sports Equipment?

In sports equipment, 91 modal 9 elastane is employed in performance gear and accessories to enhance athletic performance. Its moisture management capabilities keep athletes comfortable during intense activities. B2B buyers should consider the fabric’s durability and performance under various environmental conditions, ensuring that their products can withstand rigorous use while maintaining comfort, particularly for markets in hotter climates like those in the Middle East.

3 Common User Pain Points for ’91 modal 9 elastane’ & Their Solutions

Scenario 1: Challenges in Sourcing Quality ’91 Modal 9 Elastane’ Fabric

The Problem: B2B buyers often struggle to find reliable suppliers who can consistently deliver high-quality ’91 modal 9 elastane’ fabric. Many suppliers may promise premium materials but fail to meet the required standards, leading to issues with fabric performance, such as pilling, fading, and inadequate stretch. This inconsistency can disrupt production schedules and damage the buyer’s reputation in the market, especially in regions like Europe and the Middle East where quality expectations are particularly high.

The Solution: To mitigate sourcing challenges, B2B buyers should conduct thorough supplier evaluations. This includes requesting samples and third-party testing reports to verify fabric quality. Establishing long-term partnerships with suppliers who have a proven track record can also provide assurance of consistent quality. Additionally, buyers should specify their requirements clearly in purchase orders, including details about weight, stretch percentages, and colorfastness. Engaging in direct communication with suppliers can help clarify expectations and build a relationship based on trust and transparency.

Scenario 2: Concerns About Fabric Performance in Diverse Climates

The Problem: Buyers from regions with varying climates, such as Africa and South America, often face the challenge of ensuring that ’91 modal 9 elastane’ fabrics perform well under different environmental conditions. In hot, humid climates, for instance, breathability and moisture-wicking properties are crucial, while cooler regions may require fabrics that retain heat. If the fabric does not perform as expected, it can lead to customer dissatisfaction and increased returns.

The Solution: To address performance concerns, buyers should collaborate closely with manufacturers to understand the fabric’s properties. They should inquire about the specific characteristics of ’91 modal 9 elastane’, such as its moisture management capabilities and thermal insulation. Testing the fabric under local conditions can also provide valuable insights. Additionally, buyers can look for blends that incorporate other fibers known for their performance in specific climates, ensuring that the final product meets the needs of the target market. Providing detailed care instructions and product descriptions can also help end-users understand how to maintain the fabric’s performance over time.

Scenario 3: Navigating Compliance and Sustainability Regulations

The Problem: B2B buyers increasingly face scrutiny regarding compliance with sustainability standards and regulations, especially in Europe and parts of the Middle East. The production of ’91 modal 9 elastane’ fabric can involve environmental concerns, such as water usage and chemical treatments. Buyers may find it challenging to ensure that their fabric sourcing aligns with both legal requirements and consumer expectations for sustainability, which can impact brand image and marketability.

The Solution: To navigate compliance challenges, buyers should prioritize sourcing from suppliers who demonstrate commitment to sustainable practices. This includes requesting certifications such as OEKO-TEX® or Global Organic Textile Standard (GOTS) that validate environmental responsibility. Buyers should engage in conversations about the manufacturing processes used for ’91 modal 9 elastane’, ensuring that they align with their own sustainability goals. Implementing a supply chain audit process can help in assessing compliance and identifying any potential risks. Furthermore, communicating these sustainable practices to consumers can enhance brand loyalty and create a competitive advantage in the marketplace.

Strategic Material Selection Guide for 91 modal 9 elastane

What Are the Key Properties of 91 Modal 9 Elastane?

91 modal 9 elastane is a blend that combines the luxurious feel of modal with the stretch and recovery properties of elastane. Modal, derived from beech tree pulp, is known for its softness, breathability, and moisture-wicking capabilities, making it an ideal choice for clothing that requires comfort and performance. The addition of 9% elastane enhances the fabric’s elasticity, allowing for better fit and movement, which is particularly beneficial for activewear and fitted garments.

What Are the Advantages and Disadvantages of Using 91 Modal 9 Elastane?

Pros:

– Comfort: The fabric’s softness and breathability make it ideal for summer garments and year-round wear.

– Durability: Modal is less prone to fading and retains its shape well, while elastane provides excellent stretch and recovery.

– Versatility: This blend is suitable for a wide range of applications, including t-shirts, dresses, and activewear.

Cons:

– Cost: Modal can be more expensive than cotton or polyester blends, which may affect pricing strategies for B2B buyers.

– Care Requirements: Modal fabrics typically require gentle washing and drying to maintain their quality, which could complicate manufacturing processes in regions with different care standards.

How Does 91 Modal 9 Elastane Impact Application in Different Industries?

91 modal 9 elastane is particularly well-suited for the fashion and apparel industry, where comfort and fit are paramount. Its moisture-wicking properties make it favorable for activewear, while the luxurious feel appeals to high-end fashion brands. However, its care requirements may limit its use in certain markets where consumers prioritize low-maintenance fabrics.

What Should International B2B Buyers Consider When Sourcing 91 Modal 9 Elastane?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, it is crucial to consider compliance with local textile standards. Buyers should ensure that the materials meet relevant regulations such as ASTM in the U.S. or DIN in Germany. Additionally, understanding the local market’s preferences for fabric care and sustainability can influence sourcing decisions. For example, in regions with high humidity, the breathability of modal is a significant selling point, while in colder climates, the fabric’s warmth and layering potential may be more relevant.

Summary Table of Material Analysis

| Material | Typical Use Case for 91 modal 9 elastane | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 91 Modal 9 Elastane | Activewear, fitted garments, casual wear | Exceptional comfort and breathability | Higher cost compared to cotton blends | Medium |

| Cotton Blend | Everyday clothing, casual wear | Cost-effective and widely available | Less stretch and recovery than elastane | Low |

| Polyester Blend | Sportswear, outdoor apparel | High durability and moisture resistance | Can feel less breathable compared to modal | Low |

| Wool Blend | Cold-weather garments, luxury apparel | Excellent insulation and moisture-wicking | Higher care requirements and cost | High |

This analysis provides a comprehensive overview of the strategic material selection for 91 modal 9 elastane, equipping B2B buyers with the necessary insights to make informed sourcing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for 91 modal 9 elastane

What are the Key Stages in the Manufacturing Process of 91 Modal 9 Elastane?

The manufacturing process of 91 modal 9 elastane encompasses several critical stages, ensuring that the final product meets the high standards expected in the textile industry. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality modal fibers and elastane. Modal is derived from beech trees, known for its softness and breathability, while elastane provides the necessary stretch and recovery. Suppliers should ensure that the raw materials are certified and sourced sustainably to meet international environmental standards.

-

Forming: In this stage, the modal fibers are blended with elastane in precise proportions (91% modal to 9% elastane). This blend is then spun into yarns using advanced spinning techniques. The yarns undergo various treatments to enhance their properties, such as softness and moisture-wicking capabilities, which are crucial for garments intended for both comfort and performance.

-

Assembly: The yarns are knitted into fabric using high-speed knitting machines. The choice of knit structure affects the fabric’s stretch, drape, and overall feel. Manufacturers often utilize circular knitting techniques to achieve a uniform fabric that provides excellent four-way stretch, making it suitable for various applications, from apparel to activewear.

-

Finishing: After knitting, the fabric undergoes several finishing processes, including dyeing, printing, and softening treatments. These processes not only enhance the aesthetic appeal but also improve the fabric’s performance characteristics. Quality assurance teams monitor these processes closely to ensure color fastness, shrinkage control, and overall fabric durability.

How is Quality Assurance Implemented in the Production of 91 Modal 9 Elastane?

Quality assurance (QA) is integral to the manufacturing of 91 modal 9 elastane, ensuring that the final products meet both international standards and specific customer requirements. The QA process typically involves compliance with ISO 9001 and other industry-specific certifications.

-

International Standards Compliance: ISO 9001 is a globally recognized standard for quality management systems. Manufacturers must establish a documented quality management framework that emphasizes continuous improvement and customer satisfaction. Compliance with this standard can reassure B2B buyers of the supplier’s commitment to quality.

-

Quality Control Checkpoints: Effective quality control involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Regular inspections during the manufacturing stages help identify and rectify any deviations from quality standards before they escalate.

– Final Quality Control (FQC): The finished products undergo comprehensive testing for defects, ensuring they meet both functional and aesthetic criteria. -

Common Testing Methods: Various testing methods are employed to assess the quality of 91 modal 9 elastane fabrics. These include:

– Physical Testing: Assessing fabric strength, elasticity, and durability through tensile tests and abrasion resistance tests.

– Chemical Testing: Ensuring that the fabric is free from harmful substances by conducting tests that adhere to OEKO-TEX® standards.

– Performance Testing: Evaluating moisture management and breathability through standardized tests like the AATCC test method.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive measures to verify the quality control processes of their suppliers. This is particularly important for international transactions, where standards may vary.

-

Conducting Audits: Buyers should request audits of the supplier’s manufacturing facilities. These audits can help identify any gaps in compliance with international standards and provide insights into the supplier’s operational efficiency.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports that outline their testing methods, results, and any corrective actions taken in response to quality issues. These reports should be comprehensive and transparent.

-

Utilizing Third-Party Inspection Services: Engaging third-party inspection services can add an extra layer of assurance. These services can conduct independent assessments of the manufacturing process, ensuring that the supplier adheres to the agreed-upon standards.

What are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control and certification nuances when sourcing 91 modal 9 elastane. Different regions may have specific requirements or certifications that must be met.

-

Regional Standards: In Europe, for example, compliance with the CE marking may be necessary for certain textile products, indicating conformity with health, safety, and environmental protection standards. In the Middle East, buyers may need to be aware of local regulations that could affect the importation of textile goods.

-

Sustainability Certifications: As sustainability becomes a significant focus, certifications such as GOTS (Global Organic Textile Standard) and OEKO-TEX® are increasingly important. These certifications verify that the products are produced in an environmentally friendly manner and are safe for human use.

-

Cultural Considerations: Understanding cultural preferences and expectations in different regions can also influence quality standards. For example, fabric softness and breathability may be more critical in hotter climates, while durability might be prioritized in colder regions.

Conclusion

The manufacturing processes and quality assurance protocols for 91 modal 9 elastane are crucial for ensuring that the final products meet the high expectations of international B2B buyers. By understanding these processes and implementing rigorous quality control measures, manufacturers can produce superior fabrics that satisfy diverse market demands. B2B buyers can enhance their procurement strategies by actively verifying supplier quality control processes and ensuring compliance with relevant international standards and certifications.

Practical Sourcing Guide: A Step-by-Step Checklist for ’91 modal 9 elastane’

To assist B2B buyers in procuring high-quality ’91 modal 9 elastane’, this practical sourcing guide provides a structured checklist. This guide outlines essential steps to ensure you find a reliable supplier and secure the best product for your business needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications for the ’91 modal 9 elastane’ fabric you require. This includes defining the desired weight, stretch percentage, color options, and intended end-use applications. Precise specifications help suppliers understand your needs and ensure that the fabric will meet your quality standards.

Step 2: Conduct Market Research

Engage in thorough market research to identify potential suppliers who specialize in modal-elastane blends. Look for suppliers with a proven track record in your target markets, such as Africa, South America, the Middle East, and Europe. Researching market trends and competitor offerings can also provide insights into pricing and quality standards.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their production capabilities, quality control measures, and delivery timelines to ensure they align with your operational needs.

- Look for certifications: Check for industry certifications (e.g., OEKO-TEX, GOTS) that validate the quality and sustainability of the fabric.

- Review customer feedback: Analyze reviews and testimonials to gauge the reliability and service quality of potential suppliers.

Step 4: Request Samples

Always request fabric samples before making a bulk order. This allows you to assess the quality, feel, and performance of the ’91 modal 9 elastane’ fabric in real-world conditions. Pay attention to attributes like softness, breathability, stretch, and drape.

- Test durability: Conduct tests for colorfastness, shrinkage, and stretch recovery to ensure the fabric meets your expectations.

- Evaluate suitability: Consider how well the fabric meets the specific needs of your end products, whether it’s for apparel, activewear, or other applications.

Step 5: Negotiate Terms and Pricing

Engage in negotiations with your selected suppliers to finalize pricing, payment terms, and delivery schedules. Ensure that the terms are favorable and align with your budget constraints while maintaining quality standards.

- Consider bulk discounts: Inquire about pricing breaks for larger orders, which can significantly reduce costs.

- Clarify shipping and handling: Understand the shipping options and costs involved, especially for international deliveries.

Step 6: Verify Compliance with Regulations

Ensure that the supplier adheres to international regulations and standards relevant to your market. This includes checking for compliance with safety, environmental, and labor regulations.

- Document verification: Request documentation proving compliance, such as safety data sheets and labor practice policies.

- Understand import/export requirements: Familiarize yourself with any tariffs, taxes, or legal requirements for importing the fabric into your region.

Step 7: Establish a Quality Control Process

Once you’ve selected a supplier and placed your order, establish a quality control process for incoming materials. This should include regular inspections and testing to ensure the fabric meets your specifications consistently.

- Define quality benchmarks: Set clear benchmarks for quality assessment, including acceptable tolerance levels for defects.

- Maintain open communication: Keep a line of communication open with your supplier for feedback and issue resolution.

Following this checklist will help you navigate the complexities of sourcing ’91 modal 9 elastane’ effectively, ensuring you secure a high-quality product that meets your business needs.

Comprehensive Cost and Pricing Analysis for 91 modal 9 elastane Sourcing

What Are the Key Cost Components in Sourcing 91 Modal 9 Elastane?

When sourcing 91 modal 9 elastane, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The price of modal and elastane fibers significantly impacts the overall fabric cost. Modal, derived from beech tree pulp, is often more expensive than conventional fabrics due to its production process. Elastane, known for its stretchability, also adds to the cost. Currently, prices for modal typically hover around $10.99 per yard, while elastane contributes an additional margin.

-

Labor: Labor costs vary widely based on geographic location and manufacturing practices. Regions with lower labor costs, such as parts of Asia, may offer competitive pricing, but buyers should consider quality and ethical labor practices.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can reduce these overheads, impacting the final price.

-

Tooling: Custom tooling or machinery required for specific fabric treatments or product designs can incur significant upfront costs. This is particularly relevant if buyers require unique specifications or finishes.

-

Quality Control (QC): Investing in robust QC processes ensures that the final product meets the desired standards. This may involve additional costs but is essential for maintaining quality, especially for high-end markets.

-

Logistics: Shipping costs can vary dramatically based on origin, destination, and shipping method. Additionally, international buyers must navigate customs duties and tariffs, which can further affect pricing.

-

Margin: Suppliers typically add a margin to cover their risks and profit. Understanding the typical margins in the industry can help buyers negotiate better prices.

How Do Price Influencers Affect the Cost of 91 Modal 9 Elastane?

Several factors influence the pricing of 91 modal 9 elastane, including:

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs. Suppliers are more willing to negotiate prices for larger orders, making it essential for buyers to assess their needs carefully.

-

Specifications/Customization: Custom specifications, such as unique colors or finishes, may increase costs. Buyers should balance the need for customization with budget constraints.

-

Material Quality/Certifications: Fabrics that meet specific quality standards or certifications (e.g., eco-friendly certifications) may come at a premium. Buyers should evaluate whether these certifications align with their market demands.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may command higher prices due to their track record, while newer suppliers might offer lower rates to gain market share.

-

Incoterms: The terms of shipping and delivery can greatly influence total costs. Understanding Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital for assessing responsibility for shipping costs and risks.

What Are Effective Buyer Tips for Sourcing 91 Modal 9 Elastane?

International B2B buyers should consider several strategies when sourcing 91 modal 9 elastane:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Establishing a good rapport can lead to better terms and discounts.

-

Cost-Efficiency: Analyze the total cost of ownership rather than just the upfront price. Consider factors such as durability, maintenance, and lifecycle costs to determine the best value.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local market conditions, which can affect pricing.

-

Disclaimer for Indicative Prices: It’s essential to recognize that prices can fluctuate based on market conditions, supplier negotiations, and order specifics. Always request updated quotes and be prepared for price changes.

By understanding the comprehensive cost structure and pricing dynamics associated with 91 modal 9 elastane, B2B buyers can make informed sourcing decisions that align with their business objectives.

Alternatives Analysis: Comparing 91 modal 9 elastane With Other Solutions

Understanding Alternatives to 91 Modal 9 Elastane

In the textile industry, selecting the right fabric is crucial for meeting the demands of various markets. While 91 modal 9 elastane offers a unique blend of softness, breathability, and stretch, it is essential for B2B buyers to consider alternative fabrics that may better suit specific applications or budget constraints. This analysis compares 91 modal 9 elastane with two viable alternatives: cotton-spandex blends and bamboo viscose.

Comparison Table

| Comparison Aspect | 91 Modal 9 Elastane | Cotton-Spandex Blend | Bamboo Viscose |

|---|---|---|---|

| Performance | Soft, breathable, excellent drape | Moderate softness, good stretch | Extremely soft, moisture-wicking |

| Cost | Moderate to high | Generally lower | Moderate to high |

| Ease of Implementation | Easy to sew and manipulate | Easy to sew, but may require more care | Requires careful handling to avoid damage |

| Maintenance | Machine washable, gentle cycle | Machine washable, durable | Machine washable, prone to shrinkage |

| Best Use Case | Activewear, casual wear, intimates | Everyday wear, casual clothing | Eco-friendly fashion, loungewear |

Pros and Cons of Each Alternative

Cotton-Spandex Blend

Cotton-spandex blends are widely used in the textile industry due to their affordability and versatility. The cotton provides breathability and comfort, while the spandex adds stretch, making it suitable for everyday garments. However, while the fabric is durable, it may not match the luxurious feel and drape of 91 modal 9 elastane. Additionally, cotton can sometimes retain moisture, which may not be ideal for activewear.

Bamboo Viscose

Bamboo viscose is gaining popularity for its eco-friendly properties and exceptional softness. It is highly breathable and has moisture-wicking capabilities, making it an excellent choice for warmer climates. However, it can be more expensive than traditional cotton blends and may require careful maintenance to prevent shrinkage and damage. While bamboo is sustainable, the production process can vary significantly, impacting its overall environmental footprint.

Choosing the Right Solution for Your Needs

When selecting between 91 modal 9 elastane and its alternatives, B2B buyers should consider their specific use cases, budget constraints, and sustainability goals. If a luxurious feel and excellent drape are priorities, 91 modal 9 elastane stands out. Conversely, if cost and everyday wear are more critical, cotton-spandex blends may offer a more economical solution. For companies focused on sustainability, bamboo viscose is an attractive option, provided they account for its maintenance requirements. Ultimately, the right choice depends on aligning the fabric’s properties with the intended application and market expectations.

Essential Technical Properties and Trade Terminology for 91 modal 9 elastane

What Are the Key Technical Properties of 91 Modal 9 Elastane?

1. Material Composition

The blend of 91% modal and 9% elastane creates a fabric that combines the softness and breathability of modal with the stretch and recovery properties of elastane. This makes it ideal for garments that require flexibility and comfort, such as activewear and fitted clothing. For B2B buyers, understanding material composition is crucial for sourcing fabrics that meet specific performance criteria for their products.

2. Stretch Percentage

The 9% elastane content provides excellent four-way stretch, allowing the fabric to move in all directions while retaining its shape. This characteristic is essential for manufacturers of fitted clothing, such as activewear and lingerie, where comfort and fit are paramount. Buyers should consider stretch specifications to ensure that the final products will meet consumer expectations regarding fit and wearability.

3. Weight and Drape

Typically weighing around 250 grams per square meter (gsm), 91 modal 9 elastane offers a medium-weight fabric that drapes beautifully. This fluid drape is suitable for a variety of applications, from casual wear to more sophisticated styles. Buyers need to evaluate weight and drape when selecting fabrics, as these factors affect not only the aesthetic but also the garment’s performance and comfort.

4. Breathability and Moisture Management

Modal is known for its breathability and moisture-wicking properties, making it a popular choice for summer garments and activewear. The fabric allows air circulation and keeps the wearer cool and dry. For B2B buyers, especially in regions with warm climates, the breathability of fabrics is a key consideration for ensuring customer satisfaction.

5. Care Instructions

Understanding the care requirements of 91 modal 9 elastane is vital for manufacturers and retailers. Typically, the fabric can be machine washed on a gentle cycle and tumble dried on low. However, avoiding high heat and bleach is crucial to maintain the fabric’s quality. Buyers should be aware of these care instructions to effectively communicate them to end consumers and ensure the longevity of the garments.

Which Trade Terms Are Commonly Used in the 91 Modal 9 Elastane Industry?

1. OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of 91 modal 9 elastane, an OEM may produce garments or fabric blends that are then branded and sold by a different company. Understanding OEM relationships can help buyers identify reliable suppliers and manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ specifies the smallest amount of a product that a supplier is willing to sell. For 91 modal 9 elastane, MOQs can vary significantly between manufacturers. Buyers must consider MOQ when planning their inventory and production schedules to avoid excess costs or stock shortages.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and other terms from potential suppliers. In the context of sourcing 91 modal 9 elastane, an RFQ would typically outline the desired specifications, quantities, and delivery timelines. This process is essential for ensuring competitive pricing and securing favorable contract terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international trade. For B2B transactions involving 91 modal 9 elastane, understanding Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for clarifying shipping responsibilities and costs, which can significantly impact overall pricing and logistics.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For fabrics like 91 modal 9 elastane, lead times can vary based on factors such as production schedules and shipping methods. Buyers should account for lead times in their planning to ensure that they meet market demands and production timelines.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing 91 modal 9 elastane, ensuring they select the right materials and terms to meet their business needs.

Navigating Market Dynamics and Sourcing Trends in the 91 modal 9 elastane Sector

What Are the Key Market Dynamics and Trends Influencing the 91 Modal 9 Elastane Sector?

The global market for 91 modal 9 elastane is driven by an increasing demand for high-performance fabrics that offer both comfort and durability. This blend of modal and elastane is particularly favored for its soft texture, breathability, and four-way stretch, making it ideal for a variety of applications including activewear, loungewear, and undergarments. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly looking for versatile materials that can cater to diverse consumer preferences and climatic conditions.

Emerging technologies in fabric production, such as digital textile printing and automated cutting, are transforming sourcing strategies. These advancements allow for quicker turnaround times and greater customization, enabling businesses to respond rapidly to changing market demands. Additionally, the rise of e-commerce platforms is facilitating direct sourcing from manufacturers, offering buyers increased access to a wider range of suppliers and products, particularly in regions like Germany and Saudi Arabia where demand is escalating.

Sustainability is another significant trend influencing the modal elastane market. As consumers become more environmentally conscious, B2B buyers are prioritizing suppliers who emphasize sustainable practices and materials. This trend is evident across various sectors, from fashion to activewear, where brands are committed to reducing their carbon footprint and enhancing product lifecycle management.

How Is Sustainability Shaping the Sourcing Strategies for 91 Modal 9 Elastane?

Sustainability and ethical sourcing are paramount in the modal elastane sector. The environmental impact of textile production has prompted B2B buyers to seek out suppliers who adopt eco-friendly practices. Modal fibers are derived from beech trees, which require less water and energy compared to conventional cotton, making them a more sustainable option. Furthermore, the addition of elastane enhances the fabric’s lifespan, reducing waste in the long run.

Buyers should also look for ‘green’ certifications such as OEKO-TEX® and Global Organic Textile Standard (GOTS) when sourcing 91 modal 9 elastane. These certifications ensure that the materials used meet strict environmental and social criteria, promoting ethical supply chains. By partnering with certified suppliers, businesses can enhance their brand reputation, attract environmentally conscious consumers, and comply with increasing regulatory demands for sustainability in textiles.

Moreover, the trend towards circular fashion is gaining momentum, encouraging brands to consider the entire lifecycle of their products. B2B buyers can explore options for recycling and upcycling modal elastane fabrics, contributing to a circular economy and reducing the overall environmental footprint of their product offerings.

What Is the Historical Context of 91 Modal 9 Elastane Development?

The evolution of modal elastane fabrics can be traced back to the late 20th century when modal was introduced as a more sustainable alternative to cotton. The integration of elastane into modal fibers emerged in response to the demand for stretchable materials that offer both comfort and fit. This combination gained traction in the early 2000s, particularly in the activewear and lingerie markets, where performance and aesthetics are crucial.

As consumer preferences evolved, the modal elastane blend became synonymous with luxury and functionality, appealing to a diverse demographic. Today, it is widely used in a variety of applications, from everyday clothing to high-end fashion, reflecting its versatility and the growing trend towards sustainable textile innovations. For B2B buyers, understanding this historical context is essential for making informed sourcing decisions that align with current market demands and consumer values.

Frequently Asked Questions (FAQs) for B2B Buyers of 91 modal 9 elastane

-

How do I ensure the quality of 91 modal 9 elastane fabric before purchasing?

To ensure quality, request samples from potential suppliers. Look for certifications that indicate adherence to industry standards, such as OEKO-TEX or ISO certifications. Conduct a thorough supplier audit, if possible, to assess their manufacturing processes and quality control measures. Additionally, inquire about their testing methods for durability, breathability, and stretch to confirm that the fabric meets your specifications. -

What are the key benefits of using 91 modal 9 elastane in apparel manufacturing?

The blend of 91% modal and 9% elastane offers exceptional softness, breathability, and a luxurious drape, making it ideal for various garments, including activewear and casual clothing. This fabric provides excellent stretch and recovery, ensuring comfort and a flattering fit. Furthermore, modal is environmentally friendly, as it is derived from beech tree pulp, which may appeal to sustainability-conscious consumers. -

What is the minimum order quantity (MOQ) for 91 modal 9 elastane?

MOQs can vary significantly among suppliers. Typically, you can expect MOQs to range from 100 to 1,000 meters, depending on the supplier’s capabilities and your specific requirements. It’s essential to discuss your needs directly with potential suppliers, as some may offer flexibility in MOQs for new clients or larger orders. -

What customization options are available for 91 modal 9 elastane fabrics?

Customization options often include color matching, fabric weight adjustments, and pattern printing. Many suppliers also offer bespoke blends or finishes to cater to specific market demands. When sourcing, discuss your customization needs early in the process to ensure the supplier can accommodate your requests and provide samples for approval. -

What payment terms should I expect when sourcing 91 modal 9 elastane?

Payment terms can vary widely, but common practices include a deposit (often 30-50%) upfront with the balance due upon delivery or after inspection. Some suppliers may offer credit terms for established relationships. Always clarify payment options, including currency and method, to avoid misunderstandings and ensure smooth transactions. -

How can I effectively vet suppliers of 91 modal 9 elastane?

Begin by researching potential suppliers through industry platforms and trade shows. Request references from previous clients and review their production capabilities and certifications. Conduct a site visit if feasible, or utilize third-party inspection services. Additionally, assess their communication responsiveness and willingness to accommodate your specific needs, which can indicate their reliability. -

What are the best shipping options for importing 91 modal 9 elastane?

Choosing the right shipping method depends on your timeline and budget. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but slower. Ensure your supplier is familiar with international shipping regulations and can provide necessary documentation, such as bills of lading and customs declarations, to facilitate a smooth import process. -

What should I know about the logistics of sourcing 91 modal 9 elastane from different regions?

Logistics can be complex when sourcing internationally, as it involves understanding trade regulations, tariffs, and shipping costs. Familiarize yourself with the specific import/export laws of your country and the supplier’s country. Collaborating with a freight forwarder can help navigate these complexities, ensuring compliance and timely delivery. Always factor in lead times for production and shipping when planning your inventory.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 91 Modal 9 Elastane Manufacturers & Suppliers List

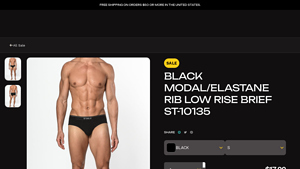

1. St33le – Black Modal/Elastane Rib Low Rise Brief

Domain: st33lebrand.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “Black Modal/Elastane Rib Low Rise Brief”, “style_number”: “ST-10135”, “color”: “Black”, “sizes_available”: [“S”, “M”, “L”, “XL”], “price”: “$17.00”, “fabric”: “91% Modal, 9% Elastane”, “features”: [“Front pouch lining”, “Seamless sides and back”, “No-roll signature logo elastic waistband”, “Relaxed leg binding with flatlock stitching”, “Two way stretch rib fabric”], “care_instruc…

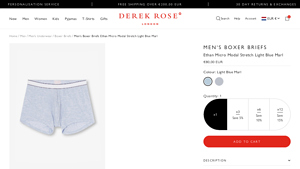

2. Derek Rose – Ethan Micro Modal Boxer Briefs

Domain: derek-rose.com

Registered: 2001 (24 years)

Introduction: Men’s Boxer Briefs Ethan Micro Modal Stretch Light Blue Marl

3. Reddit – Fabric Composition Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 95% modal, 5% spandex and 95% viscose, 5% elastane are similar fabrics. Modal and viscose are both types of rayon, with modal specifically derived from beech fiber. Spandex and elastane are the same material. While both fabric blends behave similarly, differences in manufacturing can affect texture and quality. Modal is generally considered to feel nicer and hold up better than viscose.

4. Runtang Textile – 190gsm Modal Spandex Jersey Fabric

Domain: runtangtextile.com

Registered: 2020 (5 years)

Introduction: 190gsm 91% Modal 9% Spandex Elastane Single Jersey Knit Fabric 175cm DS42038; Weight: 190gsm; Composition: 91% Modal, 9% Spandex Elastane; Width: 175cm; MOQ: 300 kg; Lead Time: 15-25 days; Sample Availability: A4 Sample; Features: Soft, Comfortable, Durable, Suitable for Apparel, Home Decor; Color: Luxurious Lilac.

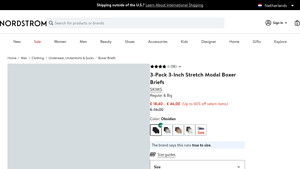

5. SKIMS – 3-Pack 3-Inch Stretch Modal Boxer Briefs

Domain: nordstrom.com

Registered: 1994 (31 years)

Introduction: {“brand”:”SKIMS”,”product_name”:”3-Pack 3-Inch Stretch Modal Boxer Briefs”,”sizes_available”:”Regular, Big”,”material”:”Modal blend”,”features”:”Soft stretch fabric, breathable, comfortable fit, tagless design”,”pack_size”:”3-pack”,”care_instructions”:”Machine wash, tumble dry”}

6. Ultratextile – 91% Modal 9% Elastane Rib Fabric

Domain: ultratextile.cn

Registered: 2022 (3 years)

Introduction: {“Article Ref.”: “XT-NZ2376”, “Fabric Name”: “91%Modal 9%Elastane 1*1Rib Fabric”, “Weight/Width”: “190gsm/175cm-cuttable”, “Features”: [“Soft Skin Touch”, “Cooling Hand”], “Application”: [“Tops”, “T-shirts”], “Finishes/Properties”: [“Wicking”], “Colors”: “Custom-Dye”, “Sample Availabilities”: “Available / FOC”, “Dyeing Method”: “Piece Dye”, “L/D & S/O Time”: “5 Days / 10 Days”, “Development Time”:…

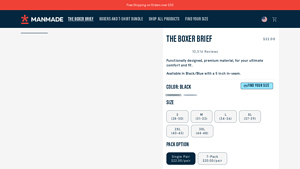

7. Manmade – Boxer Brief

Domain: us.manmadebrand.com

Registered: 2020 (5 years)

Introduction: The Boxer Brief is designed for comfort and support, featuring a soft, breathable fabric that moves with you. It includes a no-roll waistband and a contoured pouch for added support. Available in various sizes and colors, it is ideal for everyday wear.

Strategic Sourcing Conclusion and Outlook for 91 modal 9 elastane

In today’s competitive textile market, the strategic sourcing of 91 modal 9 elastane stands out as a pivotal decision for B2B buyers looking to enhance their product offerings. This fabric’s unique blend of luxury, breathability, and stretchability makes it ideal for a variety of garments, from activewear to casual fashion. By prioritizing high-quality materials like modal elastane, businesses can not only meet consumer demand for comfort and style but also strengthen their brand reputation in international markets.

Buyers from regions such as Africa, South America, the Middle East, and Europe should consider leveraging strategic sourcing to establish reliable supplier relationships. This approach can lead to cost savings, improved supply chain efficiency, and access to innovative fabric technologies. Furthermore, as sustainability becomes a focal point in the industry, sourcing modal elastane—which is often produced from sustainably harvested beech trees—can align with eco-friendly initiatives and consumer preferences.

Looking ahead, the demand for high-quality, versatile textiles will only increase. Now is the time to act. By investing in strategic sourcing of 91 modal 9 elastane, businesses can position themselves at the forefront of the fashion industry, ensuring they meet the evolving needs of global consumers.