3-Wheel Personal Transporter 35V Battery Box: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for 3-wheel personal transporter 35v battery box

In an increasingly competitive landscape, sourcing a reliable 3-wheel personal transporter 35v battery box poses significant challenges for international B2B buyers. With the rapid expansion of urban mobility solutions across regions like Africa, South America, the Middle East, and Europe, the demand for high-quality battery boxes that support efficient transportation solutions has never been greater. This comprehensive guide aims to address these challenges by providing insights into various types of battery boxes, their applications, and how they can enhance the performance of 3-wheel personal transporters.

As buyers navigate the complexities of the global market, understanding the nuances of battery specifications, compatibility, and supplier reliability is crucial. This guide delves into essential topics such as key features to consider, the importance of supplier vetting, and cost analysis to help you make informed purchasing decisions. Additionally, we will explore the evolving market trends, ensuring that you remain ahead of the curve in your sourcing strategies.

By empowering B2B buyers with actionable insights, this guide serves as a vital resource for those looking to optimize their procurement processes and enhance their product offerings. Whether you are based in bustling cities like Ho Chi Minh or emerging markets like Lagos, our expertise will equip you with the knowledge needed to secure the best battery solutions for your business.

Understanding 3-wheel personal transporter 35v battery box Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Lead-Acid Battery Box | Cost-effective, widely available, heavy, requires regular maintenance | Rental services, budget-conscious buyers | Pros: Low initial cost, easy to source. Cons: Heavier, shorter lifespan, requires maintenance. |

| Lithium-Ion Battery Box | Lightweight, longer lifespan, faster charging | High-end personal transporters, export to developed markets | Pros: Longer range, less weight, minimal maintenance. Cons: Higher upfront cost, requires specialized charging. |

| Sealed Gel Battery Box | Maintenance-free, resistant to vibrations and extreme temperatures | Outdoor and rugged terrain applications | Pros: Safe, versatile, can handle varying conditions. Cons: Heavier than lithium-ion, slightly lower energy density. |

| Modular Battery Box | Customizable capacity and configuration options | Manufacturers, fleet operators | Pros: Flexible power solutions, tailored to specific needs. Cons: Potentially complex installation, higher costs. |

| Quick-Charge Battery Box | Specialized for fast charging, compatible with various transporters | High-usage environments, logistics companies | Pros: Reduces downtime, increases operational efficiency. Cons: Higher cost, may require specific infrastructure for charging. |

What Are the Characteristics of Standard Lead-Acid Battery Boxes?

Standard lead-acid battery boxes are the most common type used in 3-wheel personal transporters. They are cost-effective and easily sourced, making them a popular choice for budget-conscious buyers or rental services. However, they are heavier and require regular maintenance, which can be a drawback for businesses looking for low-maintenance solutions. B2B buyers should consider the total cost of ownership, including potential maintenance and replacement costs over time.

How Do Lithium-Ion Battery Boxes Stand Out?

Lithium-ion battery boxes are known for their lightweight design and longer lifespan compared to lead-acid options. This type is ideal for high-end personal transporters and markets where performance and efficiency are prioritized. Although they have a higher upfront cost, their minimal maintenance needs and faster charging capabilities can lead to lower operational costs in the long run. B2B buyers should assess the specific energy needs of their transporters to determine if this option aligns with their operational goals.

What Are the Advantages of Sealed Gel Battery Boxes?

Sealed gel battery boxes offer a maintenance-free solution that is resistant to vibrations and extreme temperatures. They are particularly suitable for outdoor applications and rugged terrains, making them an excellent choice for businesses operating in challenging environments. While they are heavier than lithium-ion batteries and have slightly lower energy density, their safety and versatility make them a reliable option. Buyers should consider the environmental conditions their transporters will face when selecting this type.

Why Choose Modular Battery Boxes?

Modular battery boxes provide customizable capacity and configuration options, making them ideal for manufacturers and fleet operators. This flexibility allows businesses to tailor their power solutions according to specific needs, which can be a significant advantage in diverse operational settings. However, the complexity of installation and potentially higher costs may deter some buyers. It’s crucial for B2B purchasers to evaluate their scalability requirements and installation capabilities before opting for this solution.

What Benefits Do Quick-Charge Battery Boxes Offer?

Quick-charge battery boxes are designed for rapid charging, significantly reducing downtime for transporters. This feature is particularly beneficial for high-usage environments and logistics companies that require their vehicles to be operational at all times. While the higher cost and specific infrastructure requirements may present challenges, the efficiency gains can justify the investment for many businesses. Buyers should analyze their charging infrastructure and usage patterns to determine if this type is the right fit for their operations.

Key Industrial Applications of 3-wheel personal transporter 35v battery box

| Industry/Sector | Specific Application of 3-wheel personal transporter 35v battery box | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Mobility solutions for patients in hospitals and care facilities | Enhances patient mobility and independence, reducing staff workload | Reliability and durability of battery, ease of charging, and maintenance support |

| Tourism and Hospitality | Personal transport for tourists in resorts and theme parks | Improves guest experience and accessibility, leading to higher satisfaction ratings | Battery life, charging infrastructure, and compatibility with various terrains |

| Logistics and Warehousing | Internal transport for moving goods and personnel | Streamlines operations and reduces time spent on manual transport | Load capacity, battery efficiency, and ease of maintenance |

| Urban Mobility | Eco-friendly transport options for city dwellers | Promotes sustainable transport solutions and reduces congestion | Battery range, charging options, and compliance with local regulations |

| Retail | Customer transport in large retail spaces or malls | Enhances customer experience and increases foot traffic | Battery reliability, ease of use, and support for varied customer demographics |

How is the 3-wheel personal transporter 35v battery box utilized in the healthcare sector?

In healthcare settings, the 3-wheel personal transporter with a 35v battery box is increasingly used to facilitate patient mobility within hospitals and care facilities. This application addresses the challenge of moving patients efficiently, allowing them to navigate the premises independently or with minimal assistance. For international buyers, especially in regions like Africa and the Middle East, the focus should be on sourcing reliable battery solutions that require minimal maintenance and can withstand frequent use in demanding environments.

What role does the 3-wheel personal transporter play in tourism and hospitality?

In the tourism sector, 3-wheel personal transporters equipped with robust 35v battery boxes are essential for enhancing guest experiences at resorts, theme parks, and tourist attractions. They provide an efficient means for tourists to explore large areas without fatigue. B2B buyers in South America and Europe should prioritize battery longevity and quick charging capabilities to ensure seamless operations during peak tourist seasons.

How does the 3-wheel personal transporter benefit logistics and warehousing?

For logistics and warehousing, the 3-wheel personal transporter is an effective solution for internal transportation, allowing staff to move goods and themselves efficiently across expansive facilities. This application can significantly reduce the time and labor costs associated with manual transport methods. Buyers in regions like Nigeria and Vietnam should consider the load capacity and battery efficiency to ensure the transporters meet the demands of their specific operations.

Why is urban mobility important for the 3-wheel personal transporter?

As cities seek eco-friendly transport solutions, the 3-wheel personal transporter with a 35v battery box offers a sustainable alternative for urban dwellers. These vehicles help reduce traffic congestion and promote greener transportation methods. International buyers must assess the battery range and local compliance to ensure their transporters can operate effectively within urban environments.

How can retail spaces leverage the 3-wheel personal transporter?

In retail environments, 3-wheel personal transporters can enhance customer experience by providing mobility solutions in large stores or shopping malls. This application not only improves accessibility for shoppers but also increases foot traffic by making it easier for customers to navigate the space. Buyers should focus on battery reliability and user-friendliness to cater to diverse customer needs.

3 Common User Pain Points for ‘3-wheel personal transporter 35v battery box’ & Their Solutions

Scenario 1: Navigating Battery Longevity and Replacement Costs

The Problem: Many B2B buyers, especially those in emerging markets such as Africa and South America, often face the challenge of battery longevity and the associated costs of replacement for 3-wheel personal transporters. These buyers may be purchasing these vehicles for delivery services or mobility solutions in regions where reliable transportation is crucial. When the battery life diminishes prematurely, it can lead to unexpected downtime, increased operational costs, and disruptions in service delivery. Additionally, sourcing replacement batteries can be difficult due to shipping logistics and potential import taxes.

The Solution: To mitigate these issues, B2B buyers should prioritize investing in high-quality battery boxes that offer longer life cycles and warranties. When sourcing, look for suppliers that provide detailed specifications about battery life expectancy under various operating conditions. Consider purchasing from manufacturers who offer battery management systems to monitor health and performance, which can help extend battery life. Establishing relationships with local distributors can also facilitate quicker access to replacements, minimizing downtime. Furthermore, buyers should engage in regular maintenance checks to ensure optimal performance and identify potential issues before they escalate.

Scenario 2: Compatibility Issues with Existing Transporters

The Problem: B2B buyers frequently encounter compatibility issues when integrating new 35v battery boxes with existing 3-wheel personal transporters. This is particularly common in regions where various models and brands are in circulation, leading to confusion over specifications and compatibility. Such misalignments can result in costly modifications or the inability to utilize the purchased battery boxes, causing frustration and inefficiencies in operations.

The Solution: To address compatibility concerns, buyers should conduct thorough research on the specifications of their existing fleet before making purchases. Engage with manufacturers to obtain detailed compatibility charts and ensure that the battery box aligns with the specific model of the transporter. Additionally, consider opting for modular battery systems that can be easily adapted to different models. Creating a standardized fleet can also alleviate these issues, as it simplifies the procurement process and ensures that all components are compatible. Establish a direct communication line with manufacturers for technical support during installation to resolve any unforeseen issues promptly.

Scenario 3: Understanding Regulatory Compliance and Safety Standards

The Problem: International B2B buyers, particularly in regions with stringent import regulations, may struggle with ensuring that their 3-wheel personal transporter battery boxes comply with local safety and environmental standards. Non-compliance can lead to significant legal ramifications, including fines or the inability to sell or operate the transporters within the region, jeopardizing investments and operational capabilities.

The Solution: To navigate regulatory compliance, buyers should stay informed about the specific safety standards and regulations applicable to battery-powered vehicles in their target markets. Collaborating with local regulatory bodies or industry associations can provide insights into current requirements. When sourcing battery boxes, choose suppliers who demonstrate compliance with international safety standards, such as ISO certifications. Request documentation and certifications during the procurement process to ensure transparency. Additionally, consider attending industry workshops or webinars that focus on compliance issues to remain current with evolving regulations, thereby positioning your business as a responsible and informed player in the market.

Strategic Material Selection Guide for 3-wheel personal transporter 35v battery box

What Materials Are Commonly Used for 3-Wheel Personal Transporter 35V Battery Boxes?

When selecting materials for a 3-wheel personal transporter 35V battery box, several factors must be considered, including durability, cost, manufacturing complexity, and compliance with international standards. Below are analyses of four common materials used in the construction of battery boxes for electric scooters.

How Does Polypropylene Perform in Battery Box Applications?

Polypropylene (PP) is a thermoplastic polymer known for its excellent chemical resistance and lightweight properties. It can withstand temperatures ranging from -20°C to 100°C, making it suitable for various environmental conditions.

Pros: Polypropylene is relatively inexpensive and easy to mold, which simplifies manufacturing. Its resistance to corrosion and impact makes it ideal for outdoor applications.

Cons: While it is durable, it may not provide the same structural strength as metals. Additionally, it has a lower temperature resistance compared to other materials, which could be a concern in high-heat environments.

Impact on Application: Polypropylene is compatible with various battery chemistries and is often used in environments where moisture and chemicals are present.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding plastic materials, as some regions may have restrictions on certain types of plastics.

What Are the Benefits of Using Aluminum for Battery Boxes?

Aluminum is a lightweight metal known for its strength-to-weight ratio and excellent corrosion resistance. It can withstand temperatures from -50°C to 150°C, making it suitable for diverse climates.

Pros: Aluminum offers high durability and is resistant to rust, which is crucial for outdoor use. Its lightweight nature contributes to the overall efficiency of the transporter.

Cons: The cost of aluminum is higher than that of plastics, and its manufacturing process can be more complex, requiring specialized equipment.

Impact on Application: Aluminum’s thermal conductivity helps dissipate heat generated by batteries, enhancing performance and longevity.

Considerations for International Buyers: Compliance with standards like ASTM and DIN is essential. Buyers should also consider the sourcing of aluminum to ensure it meets quality standards.

Why Is Steel a Common Choice for Battery Box Construction?

Steel, particularly stainless steel, is known for its exceptional strength and durability. It can handle high-pressure environments and extreme temperatures, making it a versatile choice.

Pros: Steel provides excellent structural integrity and is highly resistant to wear and tear. It can also be treated for corrosion resistance, extending its lifespan.

Cons: The weight of steel can be a disadvantage in terms of overall vehicle efficiency. Additionally, the cost of stainless steel can be significantly higher than other materials.

Impact on Application: Steel is suitable for heavy-duty applications where robustness is essential, but it may require additional insulation to protect batteries from temperature fluctuations.

Considerations for International Buyers: Steel products must comply with various international standards, and buyers should be aware of potential tariffs or import duties.

How Does ABS Plastic Compare in Battery Box Applications?

Acrylonitrile Butadiene Styrene (ABS) is a common thermoplastic known for its impact resistance and toughness. It operates effectively within a temperature range of -20°C to 80°C.

Pros: ABS is relatively inexpensive and easy to process, making it a popular choice for manufacturers. Its impact resistance is beneficial for protecting batteries during transportation.

Cons: ABS has lower chemical resistance compared to polypropylene and may degrade when exposed to certain solvents.

Impact on Application: ABS is suitable for indoor applications or environments with limited exposure to harsh chemicals.

Considerations for International Buyers: Buyers should verify that ABS complies with local environmental regulations, especially regarding its disposal and recycling.

Summary Table of Material Selection for Battery Boxes

| Material | Typical Use Case for 3-wheel personal transporter 35v battery box | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Lightweight battery boxes for moderate climates | Chemical resistance | Limited structural strength | Low |

| Aluminum | Battery boxes in diverse climates with heat dissipation needs | High strength-to-weight ratio | Higher cost and manufacturing complexity | Med |

| Steel | Heavy-duty applications requiring robust protection | Exceptional durability | Heavier and more expensive | High |

| ABS | Indoor battery boxes with impact protection | Cost-effective and tough | Lower chemical resistance | Low |

This detailed analysis provides B2B buyers with essential insights into material selection for 3-wheel personal transporter battery boxes, enabling informed decision-making that aligns with operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 3-wheel personal transporter 35v battery box

What Are the Main Stages in the Manufacturing Process of a 3-Wheel Personal Transporter 35V Battery Box?

The manufacturing of a 3-wheel personal transporter 35V battery box involves several critical stages, each essential to ensuring the final product meets quality and safety standards.

Material Preparation

The first step involves selecting high-quality materials that can withstand various environmental conditions. Typically, manufacturers use durable plastic or aluminum for the casing, along with copper or aluminum for the internal wiring. Each material must undergo rigorous testing for electrical conductivity, corrosion resistance, and thermal stability. Suppliers should provide material certifications that confirm compliance with international standards.

Forming

The forming stage includes processes like injection molding or extrusion, depending on the chosen materials. For plastics, injection molding is often preferred as it allows for precise shaping and can produce complex geometries efficiently. For metal components, processes such as stamping or CNC machining may be employed to achieve the necessary specifications. During this phase, manufacturers must ensure that tolerances are strictly adhered to, as even minor deviations can affect the battery box’s performance.

Assembly

Once individual components are formed, the assembly process begins. This stage typically involves the integration of the battery cells, wiring harnesses, and protective casing. Automation plays a significant role here, as robotic systems can enhance consistency and reduce assembly time. Manual assembly may still be used for quality-sensitive components, ensuring skilled workers handle delicate or critical elements. Each assembly line should be equipped with jigs and fixtures to facilitate accurate placement and alignment of components.

Finishing

The final manufacturing stage is finishing, which includes surface treatments, painting, or coating to enhance aesthetics and durability. For instance, applying a weather-resistant coating can protect against moisture and UV degradation. Additionally, labeling and branding are completed during this phase. Final products are often subjected to visual inspections to ensure they meet quality standards before packaging.

How Is Quality Assurance Implemented in the Production of Battery Boxes?

Quality assurance (QA) is a cornerstone of the manufacturing process, ensuring that each battery box meets both regulatory standards and customer expectations.

What International Standards Are Relevant for Battery Box Manufacturing?

In the context of battery box manufacturing, international standards like ISO 9001 are pivotal. This standard outlines requirements for a quality management system, ensuring consistent product quality and continuous improvement. Other relevant certifications include CE marking for safety compliance in Europe and UL certification for electrical safety. These certifications not only enhance product credibility but also facilitate market access in various regions.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early. The following are common checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival at the facility. Suppliers must provide certificates of conformity, and materials should be tested for compliance with specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to ensure that processes are followed correctly. This includes monitoring machine calibration, environmental conditions, and operator adherence to protocols.

-

Final Quality Control (FQC): After assembly, the final products undergo extensive testing, including electrical performance tests, thermal cycling, and safety tests. This step is crucial to verify that the battery box functions as intended and meets all safety standards.

What Testing Methods Are Commonly Used in Battery Box Quality Control?

Testing methods can vary widely depending on the specific requirements of the battery box. Common methods include:

-

Electrical Testing: This verifies that the battery box can handle the specified voltage and current loads without overheating or failing.

-

Environmental Testing: Battery boxes may be subjected to humidity, temperature extremes, and vibration tests to ensure they can withstand various operational conditions.

-

Safety Testing: This includes short-circuit tests, overcharge tests, and drop tests to ensure the battery box is safe for users.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must conduct due diligence when selecting suppliers to ensure they adhere to quality control standards. Here are some actionable strategies:

-

Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes, quality control measures, and adherence to international standards. This can reveal insights into their operational capabilities and commitment to quality.

-

Quality Reports: Request detailed quality assurance reports that outline testing methodologies, results, and compliance with relevant standards. This documentation should be regularly updated and readily available.

-

Third-Party Inspections: Engage third-party inspection services to verify quality control practices. These independent inspections can provide an unbiased assessment of the supplier’s compliance with industry standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers face unique challenges when sourcing battery boxes, particularly concerning compliance with local regulations and standards. For instance, buyers from Africa, South America, and the Middle East should be aware of regional certifications that may differ from those in Europe or North America. Understanding these nuances is crucial for avoiding legal and logistical issues.

Additionally, the language barrier can pose challenges in understanding quality documentation. Therefore, it is advisable to work with suppliers who can provide materials in the buyer’s preferred language and format.

In conclusion, the manufacturing processes and quality assurance protocols for a 3-wheel personal transporter 35V battery box are multifaceted and essential for ensuring product reliability and safety. By understanding these processes, B2B buyers can make informed decisions when sourcing these critical components.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3-wheel personal transporter 35v battery box’

The following practical sourcing guide provides a step-by-step checklist designed for international B2B buyers looking to procure a 3-wheel personal transporter 35v battery box. This guide will help ensure that your purchasing process is efficient, cost-effective, and aligned with your specific operational needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications required for the 35v battery box. This includes dimensions, weight capacity, voltage requirements, and compatibility with existing equipment. Precise specifications will help streamline your search for suppliers and ensure that the product meets your operational standards.

- Consider battery type: Determine if you need lithium-ion, lead-acid, or another battery type based on performance and cost.

- Evaluate power requirements: Ensure the battery box can support the power needs of the 3-wheel personal transporter, including peak load and runtime.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in 35v battery boxes. Look for companies with a proven track record in manufacturing and distributing electric vehicle components.

- Check online directories: Utilize platforms like Alibaba, ThomasNet, or industry-specific directories to find suppliers.

- Seek recommendations: Reach out to industry contacts or associations for referrals to reputable suppliers.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify that potential suppliers hold relevant certifications. Certifications such as ISO 9001 for quality management or CE marking for compliance with European standards are crucial indicators of a supplier’s reliability.

- Request documentation: Ask suppliers for copies of their certifications and quality assurance processes.

- Understand compliance: Ensure the battery box complies with local regulations in your target markets (e.g., RoHS, UL certification).

Step 4: Request Samples and Prototypes

Before finalizing your order, request samples or prototypes of the battery box. Testing samples will allow you to assess the quality, fit, and functionality of the product.

- Conduct performance tests: Evaluate the battery box under real-world conditions to verify its performance and durability.

- Assess compatibility: Ensure the battery box integrates seamlessly with your existing 3-wheel personal transporters.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, begin negotiations on pricing and terms. This step is critical in ensuring that you receive the best possible deal while maintaining quality.

- Discuss bulk pricing: Inquire about discounts for larger orders or long-term contracts.

- Clarify payment terms: Ensure that payment terms are clear, including deposits, delivery schedules, and penalties for late delivery.

Step 6: Establish Logistics and Shipping Arrangements

Plan the logistics of shipping the battery boxes to your location. This includes determining shipping methods, lead times, and customs clearance procedures.

- Choose reliable shipping partners: Collaborate with logistics companies that have experience in international shipping of electronic components.

- Understand import regulations: Familiarize yourself with import duties and taxes in your country to avoid unexpected costs.

Step 7: Implement Quality Control Measures

After procurement, establish quality control measures to monitor the performance of the battery boxes. Regular inspections and maintenance will ensure that your investment remains functional and reliable.

- Create a maintenance schedule: Develop a routine maintenance plan to check battery health and performance.

- Monitor supplier performance: Keep records of supplier reliability and product performance for future procurement decisions.

By following these steps, B2B buyers can effectively source a reliable 3-wheel personal transporter 35v battery box that meets their specific needs and enhances operational efficiency.

Comprehensive Cost and Pricing Analysis for 3-wheel personal transporter 35v battery box Sourcing

What are the Key Cost Components in Sourcing a 3-Wheel Personal Transporter 35V Battery Box?

When considering the procurement of a 35V battery box for a 3-wheel personal transporter, it is essential to analyze the cost structure carefully. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality lithium-ion batteries, for instance, can be more expensive than lead-acid alternatives but offer better performance and longevity.

-

Labor: Labor costs vary by region and can be influenced by local wage standards. Skilled labor may be required for assembly, which can increase costs, particularly in regions with higher labor rates.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Initial tooling costs for producing battery boxes can be substantial, especially if custom designs are required. These costs are often amortized over the production run.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability, which can incur additional costs but is vital for maintaining safety and performance standards.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, can significantly impact the total cost. The distance from the manufacturing site to the buyer’s location plays a crucial role.

-

Margin: Suppliers typically apply a profit margin to cover their expenses and generate profit. Understanding this margin can provide insight into pricing flexibility during negotiations.

How Do Price Influencers Affect the Cost of a 3-Wheel Personal Transporter Battery Box?

Several factors can influence the pricing of a 35V battery box:

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk can lead to significant discounts. Suppliers often have tiered pricing structures that reward larger orders.

-

Specifications and Customization: Custom features or specifications, such as enhanced battery capacity or unique dimensions, can raise costs. Standardized products generally come at lower prices.

-

Materials and Quality Certifications: The use of high-grade materials and certifications (e.g., ISO, CE) can enhance the product’s value but will also increase costs. Buyers should evaluate the importance of certifications based on their target market.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more but offer better quality assurance and after-sales support.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) agreed upon can influence total costs. Terms like CIF (Cost, Insurance, Freight) may shift the burden of logistics costs to the seller, impacting the overall price.

What Negotiation Tips Can Help International B2B Buyers Secure Better Pricing?

For international buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, effective negotiation can yield favorable pricing:

-

Research and Prepare: Understand the market rates and have comparable quotes ready. This information can provide leverage during negotiations.

-

Focus on Total Cost of Ownership (TCO): Emphasizing TCO rather than just upfront costs can lead to discussions about quality and long-term savings, which might justify higher initial prices.

-

Be Clear About Needs: Clearly communicate specifications and expectations to avoid misunderstandings that could lead to unexpected costs.

-

Build Relationships: Establishing a rapport with suppliers can lead to more flexible pricing and favorable terms. Long-term partnerships often yield better deals.

-

Explore Payment Terms: Negotiating favorable payment terms can improve cash flow and reduce upfront financial burdens.

What Should International Buyers Consider Regarding Pricing Nuances?

International buyers must be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rates can significantly impact costs. Locking in prices at favorable rates can protect against currency volatility.

-

Import Tariffs and Duties: Understanding local regulations and potential tariffs on imported goods is crucial. These can add to the overall cost unexpectedly.

-

Cultural Differences: Negotiation styles and business practices vary globally. Awareness of cultural nuances can facilitate smoother discussions and agreements.

In conclusion, sourcing a 35V battery box for a 3-wheel personal transporter involves a complex interplay of cost components, pricing influencers, and negotiation strategies. By understanding these elements, B2B buyers can make informed decisions that lead to successful procurement. Please note that the prices mentioned are indicative and may vary based on market conditions and supplier negotiations.

Alternatives Analysis: Comparing 3-wheel personal transporter 35v battery box With Other Solutions

Understanding Alternative Solutions for Personal Transport Battery Systems

In the growing market for personal transport solutions, particularly in regions like Africa, South America, the Middle East, and Europe, various battery systems are available to power 3-wheel personal transporters. Understanding the alternatives to the 3-wheel personal transporter 35V battery box is crucial for international B2B buyers looking to optimize their investment. This analysis will compare the 35V battery box against two viable alternatives: a 36V lithium-ion battery pack and a solar-powered battery system.

| Comparison Aspect | 3-Wheel Personal Transporter 35V Battery Box | 36V Lithium-Ion Battery Pack | Solar-Powered Battery System |

|---|---|---|---|

| Performance | Reliable for urban mobility; good range | Higher energy density; longer lifespan | Varies based on sunlight; eco-friendly |

| Cost | Moderate upfront cost; affordable replacements | Higher initial investment; lower long-term cost | Variable; installation can be expensive |

| Ease of Implementation | Simple plug-and-play installation | Requires proper fitting; professional help may be needed | Needs installation of solar panels; complex setup |

| Maintenance | Low maintenance; straightforward to replace | Moderate; requires monitoring and occasional replacements | Low maintenance, but panels need cleaning |

| Best Use Case | Urban commuting; short to medium distances | Long-distance travel; frequent use | Remote areas with ample sunlight; eco-conscious users |

What are the Advantages and Disadvantages of a 36V Lithium-Ion Battery Pack?

The 36V lithium-ion battery pack is a popular alternative due to its higher energy density compared to traditional battery systems. This results in a longer lifespan and improved performance for personal transporters. Although the initial investment is higher, the long-term cost benefits are appealing, particularly for businesses that require frequent use. However, installation can be complex, necessitating professional assistance, which may deter some buyers.

How Does a Solar-Powered Battery System Compare?

The solar-powered battery system offers an innovative and eco-friendly solution for powering personal transporters. This alternative harnesses renewable energy, making it particularly appealing for businesses focused on sustainability. While operational costs can be low once installed, the initial setup can be expensive, and efficiency varies significantly based on geographical location and sunlight availability. Additionally, the complexity of installation may require specialized technicians, adding to the overall cost.

Conclusion: How to Choose the Right Battery Solution for Your Needs?

Selecting the right battery solution depends on specific business needs, budget constraints, and operational environments. The 3-wheel personal transporter 35V battery box is suitable for urban commuting with moderate costs and ease of maintenance. In contrast, the 36V lithium-ion battery pack is ideal for businesses requiring longer operational ranges and who are prepared for a higher initial investment. On the other hand, the solar-powered system is best for eco-conscious organizations operating in sunny regions, despite its higher setup costs and complexity. By carefully assessing these aspects, B2B buyers can make informed decisions that align with their operational requirements and financial strategies.

Essential Technical Properties and Trade Terminology for 3-wheel personal transporter 35v battery box

What Are the Key Technical Properties of a 3-Wheel Personal Transporter 35V Battery Box?

Understanding the critical specifications of a 35V battery box for a 3-wheel personal transporter is essential for B2B buyers to ensure product compatibility and performance. Here are several key properties to consider:

-

Voltage Rating (35V)

The voltage rating indicates the electrical potential of the battery box. A 35V rating is tailored for efficient energy delivery to the motor and other electronic components of the transporter. It’s crucial for buyers to match this rating with the specifications of the electric scooter to prevent performance issues or electrical failures. -

Battery Capacity (Ah)

Measured in amp-hours (Ah), this specification indicates the total charge the battery can hold. For personal transporters, a higher capacity allows for extended usage between charges, which is essential for end-users in regions with limited access to charging stations. Buyers should look for capacity ratings that meet their operational demands. -

Material Composition

The casing material of the battery box affects durability and weight. Common materials include high-density polyethylene (HDPE) or aluminum, which offer resistance to environmental conditions and impacts. Buyers should prioritize materials that align with their operational environments, especially in regions with extreme weather. -

Temperature Tolerance

Battery performance can significantly fluctuate with temperature. A battery box designed to operate effectively within a range of temperatures (e.g., -20°C to +60°C) ensures reliability in diverse climates. This is particularly relevant for buyers in Africa or South America, where temperature variations can be significant. -

Connector Types and Compatibility

The type of connectors used in the battery box must be compatible with the personal transporter’s wiring harness. Various connector types (such as XT60 or Anderson Powerpole) can affect ease of installation and replacement. Buyers should confirm compatibility to avoid installation delays and additional costs. -

Weight and Dimensions

The overall weight and dimensions of the battery box play a critical role in the transporter’s design and usability. An excessively heavy battery can affect the maneuverability of the scooter, particularly in markets with varied terrain. Buyers should ensure that the specifications align with the intended use cases of their clientele.

What Are Common Trade Terms Related to 3-Wheel Personal Transporter Battery Boxes?

Familiarity with industry jargon can enhance communication and negotiation between buyers and suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding whether a battery box is OEM can provide insight into its quality and compatibility with existing models. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity a supplier is willing to sell. This is critical for B2B buyers to determine if they can meet the supplier’s requirements without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a standard business process to invite suppliers to bid on the supply of specific goods or services. Buyers should prepare detailed RFQs to receive accurate pricing and terms from suppliers for battery boxes. -

Incoterms (International Commercial Terms)

These are international rules that define the responsibilities of buyers and sellers in the delivery of goods. Familiarity with Incoterms helps buyers understand shipping costs, insurance, and risk management. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is essential for inventory planning and ensuring that supply aligns with market demand. -

Warranty Period

This term indicates the duration for which the manufacturer guarantees the performance of the battery box. A longer warranty can be a sign of confidence in the product’s durability, which is particularly appealing to B2B buyers concerned about reliability.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing 35V battery boxes for 3-wheel personal transporters, ensuring better alignment with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the 3-wheel personal transporter 35v battery box Sector

What Are the Current Market Dynamics for the 3-Wheel Personal Transporter 35V Battery Box?

The global market for 3-wheel personal transporters, particularly those utilizing a 35V battery box, is witnessing significant growth driven by urbanization, aging populations, and a shift towards eco-friendly transportation solutions. This surge is especially evident in regions like Africa, South America, the Middle East, and Europe, where consumers increasingly favor personal mobility options over traditional vehicles. The demand for these transporters is being fueled by advancements in battery technology, leading to longer-lasting and more efficient battery packs, which are critical for ensuring reliability and user satisfaction.

Emerging B2B tech trends include the adoption of smart technologies in personal transporters, such as IoT-enabled systems for monitoring battery health and performance. This is complemented by a rise in e-commerce platforms that streamline sourcing processes for international buyers. Companies are increasingly focusing on optimizing their supply chains to respond to market fluctuations and consumer needs, which is vital for maintaining competitiveness. Buyers from regions like Vietnam and Nigeria are particularly interested in establishing direct relationships with manufacturers to ensure quality and reduce lead times.

How Are Sustainability and Ethical Sourcing Impacting the 3-Wheel Personal Transporter Battery Box Sector?

Sustainability is becoming a critical consideration for businesses sourcing 3-wheel personal transporter battery boxes. The environmental impact of battery production and disposal is under scrutiny, prompting manufacturers to adopt more sustainable practices. Ethical sourcing is essential, as companies increasingly seek suppliers who prioritize environmental stewardship and social responsibility in their operations.

The importance of green certifications and materials cannot be overstated. B2B buyers are encouraged to look for suppliers who utilize recycled materials or sustainable manufacturing processes, as these factors can enhance brand reputation and appeal to eco-conscious consumers. Additionally, establishing supply chains that emphasize transparency and ethical labor practices is becoming a requirement rather than a choice. This not only mitigates risks associated with supply chain disruptions but also aligns with the growing global emphasis on corporate social responsibility.

What Is the Evolution of the 3-Wheel Personal Transporter Market?

The 3-wheel personal transporter market has evolved significantly over the past few decades. Initially dominated by simple, manual designs, the introduction of electric models has transformed the landscape. With advancements in battery technology and electric propulsion systems, manufacturers are now able to produce more efficient and user-friendly transporters.

This evolution has been accompanied by a greater focus on safety features, such as improved braking systems and stability control, making these vehicles more appealing to a broader demographic. As urban mobility needs continue to change, the sector is likely to see further innovations aimed at enhancing user experience, sustainability, and integration with smart city infrastructures.

In summary, international B2B buyers must navigate a rapidly changing market characterized by technological advancements, a growing emphasis on sustainability, and evolving consumer preferences. Embracing these trends is crucial for securing a competitive edge in the dynamic landscape of 3-wheel personal transporters.

Frequently Asked Questions (FAQs) for B2B Buyers of 3-wheel personal transporter 35v battery box

-

How do I choose the right battery box for a 3-wheel personal transporter?

Selecting the appropriate battery box for your 3-wheel personal transporter involves several factors. Firstly, ensure the battery box is compatible with your transporter’s specifications, including voltage and amperage. Look for quality construction materials that offer durability in various environments, especially in regions with extreme weather conditions. Additionally, consider the manufacturer’s reputation and warranty offerings, as these can indicate reliability and support in case of defects. -

What is the best battery type for a 3-wheel personal transporter?

The best battery type for a 3-wheel personal transporter typically includes lithium-ion or sealed lead-acid batteries. Lithium-ion batteries are lighter, have a longer lifespan, and offer faster charging times, making them ideal for frequent use. On the other hand, sealed lead-acid batteries are more cost-effective and suitable for less demanding applications. Assess your usage patterns and budget to determine which battery type aligns best with your operational needs. -

What are the minimum order quantities (MOQ) for battery boxes?

Minimum order quantities (MOQ) for battery boxes can vary widely depending on the manufacturer and the specific model. Typically, MOQs range from 50 to 500 units for B2B purchases. It’s advisable to directly contact suppliers to negotiate terms, especially if you require lower quantities for testing or initial market entry. Some manufacturers may offer flexibility for established relationships or larger future orders. -

What payment terms should I expect when sourcing battery boxes internationally?

When sourcing battery boxes internationally, common payment terms include a 30% deposit upon order confirmation, with the remaining 70% due before shipment. Some suppliers may offer letters of credit or payment through platforms like PayPal for added security. Always clarify payment terms upfront and consider negotiating better terms based on order size and relationship with the supplier. -

How do I vet suppliers for battery boxes?

Vetting suppliers for battery boxes involves assessing their business credentials, quality certifications, and production capabilities. Look for suppliers with ISO certifications, as this indicates adherence to quality management standards. Request references from other B2B clients and check online reviews. Additionally, consider visiting the supplier’s facility if feasible, or conducting a virtual audit to ensure their manufacturing practices meet your expectations. -

What logistics considerations should I keep in mind when importing battery boxes?

Logistics considerations for importing battery boxes include understanding shipping methods, customs regulations, and lead times. Determine whether air freight or sea freight is more suitable based on your urgency and budget. Familiarize yourself with import duties and taxes in your destination country to avoid unexpected costs. Partnering with a reliable logistics provider can streamline the process and ensure timely delivery. -

What quality assurance measures should be in place for battery boxes?

Quality assurance measures for battery boxes should include rigorous testing protocols for performance and safety. Ensure that the supplier conducts regular inspections and provides certification for compliance with international standards such as CE or UL. Request samples for evaluation before placing a large order, and consider including clauses in your contract that stipulate penalties for non-compliance or defective products. -

Can I customize battery boxes for specific applications?

Yes, many manufacturers offer customization options for battery boxes to meet specific application requirements. Customizations can include size adjustments, battery capacity modifications, and unique connector types. When discussing customization, provide detailed specifications and any relevant operational conditions. Be prepared for possible additional costs and longer lead times associated with custom orders, and ensure that the supplier has the capability to meet your specific needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 3-Wheel Personal Transporter 35V Battery Box Manufacturers & Suppliers List

1. Reddit – Best 3-Wheel Personal Transporter 36v Battery Box

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Best 3-Wheel Personal Transporter 36v Battery Box [2025]:

– Popularity: Gaining traction as a convenient and eco-friendly mode of transportation.

– Critical Component: 36v battery box houses and protects the battery pack powering the motor.

– Importance: Selecting the right battery box is essential for longevity, performance, and safety.

– Key Features:

– Housing Material: High-density polyethyl…

2. TRX® – Electric Scooter Parts

Domain: electricscooterparts.com

Registered: 2002 (23 years)

Introduction: TRX® Personal Transporter Electric Scooter Parts include: 1. Belt – High quality replacement drive belt, Item # BLT-425-5M-15, Price: $14.95 2. Battery Set – Set of three batteries with 12 month warranty, Item # BAT-12V8AHX3, Price: $74.85 3. Battery Wiring Harness – Item # TRX-BATTERYHARNESS, Price: $14.95 4. Battery Charger – Item # CHR-36V1.6A3P, Price: $29.95 5. Quick-Charge Battery Charger – …

3. Zip’r – Mobility Scooter Battery Box

Domain: zipr.com

Registered: 2003 (22 years)

Introduction: Zip’r Mobility Scooter Battery Box with (2) Batteries for Zipr Traveler & Xtra Mobility Scooters. Price: $300.00. Features: Replacement for damaged or missing battery box, compatible with Zip’r Traveler and Xtra 3-wheel & 4-wheel mobility scooters. Includes a 12V 14Ah deep cycle gel battery set with non-spillable construction, maintenance-free, classified as non-hazardous for transport on boats, t…

4. EV Rider – Transport Battery Box

Domain: mobilityscootersdirect.com

Registered: 2013 (12 years)

Introduction: Battery Box For Mobility Scooters & Wheelchairs – Tax-Free & Free Shipping – Ships Within 3 to 5 Days – Wide variety of replacement battery boxes, cases, and bags for mobility scooters and power chairs. OEM Replacement options available. Competitively priced.

1. EV Rider Transport (S19/S19+ & S34FD) SLA or Lithium Battery Case – Price: $250.00 (MSRP: $280.00, You Save: $30.00)

2. Pride Revo 2.0…

5. MotoTec – Electric Trike 48V 500W Personal Transporter

Domain: bikehighway.com

Registered: 1999 (26 years)

Introduction: {‘name’: ‘MotoTec Electric Trike 48V 500W Personal Transporter’, ‘sku’: ‘BigToys-MT-TRK-500’, ‘price’: ‘$899.99’, ‘motor_power’: ‘500 Watt Brushless Hub Motor’, ‘battery’: ‘Four 12v 12ah Batteries (48v total)’, ‘maximum_weight_capacity’: ‘240 lbs’, ‘recommended_age’: ’13 and up’, ‘charger_included’: ‘Yes’, ‘battery_life’: ‘Over 300 charges’, ‘recharge_time’: ‘4 – 8 hrs’, ‘climbing_ability’: ’10 de…

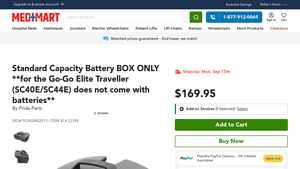

6. Go-Go – Standard Capacity Battery Box Assembly

Domain: medmartonline.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “Standard Capacity Battery Box Assembly for the Go-Go Elite Traveller (SC40E/SC44E)”, “sku”: “PLSASMB2013”, “item_id”: “22394”, “price”: “$169.95”, “old_price”: “$234.53”, “savings”: “$64.58”, “features”: [“12 Ah”, “Installs & removes easily”, “Removable battery box”], “compatibility”: [“Go-Go Elite Traveller (SC40E/SC44E)”, “Go-Go Ultra X (SC40X/SC44X)”], “warranty”: “1-year warr…

Strategic Sourcing Conclusion and Outlook for 3-wheel personal transporter 35v battery box

In the rapidly evolving market for 3-wheel personal transporters, the strategic sourcing of 35v battery boxes is pivotal for enhancing operational efficiency and product reliability. By prioritizing high-quality components, such as durable battery systems and compatible charging solutions, businesses can significantly improve the performance and longevity of their transporters. Establishing partnerships with reputable suppliers not only ensures access to superior products but also fosters a collaborative approach to innovation and sustainability.

As international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, it is crucial to leverage strategic sourcing to navigate market challenges effectively. This involves evaluating suppliers based on their product offerings, warranty services, and technological advancements. By adopting a proactive sourcing strategy, companies can mitigate risks associated with supply chain disruptions and capitalize on emerging market opportunities.

Looking ahead, the demand for efficient and reliable 3-wheel personal transporters will continue to rise. Embrace this opportunity to enhance your procurement strategies and position your business at the forefront of the industry. Engage with suppliers who share your vision for quality and innovation, and together, drive the future of personal transportation.