20 Inch Spinner Rims For Sale: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for 20 inch spinner rims for sale

In the competitive landscape of automotive accessories, sourcing high-quality 20 inch spinner rims for sale poses significant challenges for international B2B buyers. With a plethora of suppliers and varying quality standards, making an informed decision is crucial. This guide aims to streamline your purchasing process by providing a comprehensive overview of the types of spinner rims available, their applications, and critical factors for supplier vetting.

We will explore essential considerations such as material quality, design trends, and pricing strategies, empowering you to identify the best options for your market. Additionally, we will delve into the logistics of importing these products, focusing on regulatory requirements and shipping considerations relevant to regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and Nigeria.

By leveraging the insights offered in this guide, you will be equipped to navigate the complexities of the global market for 20 inch spinner rims. Our expert analysis will help you mitigate risks, enhance your supply chain efficiency, and ultimately secure high-value products that meet your customers’ expectations. Embrace the opportunity to elevate your automotive offerings and drive your business forward with the right spinner rims.

Understanding 20 inch spinner rims for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Chrome Spinner Rims | Polished chrome finish, high shine, aesthetic appeal | Luxury vehicles, custom car markets | Pros: Eye-catching design; Cons: Prone to scratches and corrosion. |

| Brushed Aluminum Spinners | Matte finish, less reflective, modern look | Performance cars, off-road vehicles | Pros: Durable; Cons: Less flashy than chrome. |

| Custom Color Spinner Rims | Variety of colors and finishes available | Specialty automotive shops | Pros: Unique customization options; Cons: Potentially longer lead times. |

| Forged Spinner Rims | Lightweight, high strength, superior performance | Racing applications, high-performance vehicles | Pros: Enhanced performance; Cons: Higher price point. |

| Multi-Bolt Pattern Rims | Versatile bolt patterns for various vehicle types | General automotive market | Pros: Compatibility with multiple vehicles; Cons: May require adapters for specific fits. |

What Are Chrome Spinner Rims and Their Suitability for B2B Buyers?

Chrome spinner rims are characterized by their polished chrome finish, offering a high-gloss aesthetic that enhances the visual appeal of luxury vehicles. These rims are particularly popular in the custom car market, where aesthetics play a crucial role in purchasing decisions. B2B buyers should consider the potential for scratches and corrosion, which can be a concern in harsher environments. When sourcing chrome spinner rims, it’s essential to assess the supplier’s quality assurance processes to ensure durability.

How Do Brushed Aluminum Spinners Differ from Other Types?

Brushed aluminum spinners feature a matte finish that provides a modern, understated look compared to their chrome counterparts. These rims are favored in performance and off-road vehicles due to their lightweight properties and durability. B2B buyers should evaluate the specific applications for which these rims are intended, as their less reflective surface may appeal more to customers seeking functionality over flashiness. Ensuring the availability of various sizes and offsets can enhance marketability.

Why Choose Custom Color Spinner Rims for Your Inventory?

Custom color spinner rims offer an extensive range of color and finish options, allowing businesses to cater to niche markets and specific customer preferences. Specialty automotive shops often seek these rims for unique builds or personalized vehicles. B2B buyers should be aware of potential lead times associated with custom orders and should establish clear communication with suppliers regarding color availability and production timelines to meet customer demands effectively.

What Advantages Do Forged Spinner Rims Provide?

Forged spinner rims are designed for high performance and strength, making them ideal for racing applications and high-performance vehicles. These rims are generally lighter than cast alternatives, enhancing vehicle handling and speed. However, they come at a higher price point, which may affect purchasing decisions. B2B buyers should assess their target market’s willingness to invest in premium products and consider stocking a range of forged options to cater to performance-focused customers.

How Do Multi-Bolt Pattern Rims Enhance Versatility?

Multi-bolt pattern rims offer compatibility with various vehicle types, making them a practical choice for the general automotive market. This versatility can be attractive to B2B buyers who want to minimize inventory complexity while maximizing sales opportunities. However, buyers should be cautious about potential fitment issues and ensure that they have the necessary adapters for specific vehicle models. Clear communication with suppliers about compatibility and fitment specifications is vital for successful transactions.

Key Industrial Applications of 20 inch spinner rims for sale

| Industry/Sector | Specific Application of 20 inch spinner rims for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Customization | High-end vehicle modifications | Enhances vehicle aesthetics and brand image | Quality assurance, fitment compatibility, and design options |

| Luxury Car Rentals | Fleet enhancement for luxury rentals | Attracts clientele looking for unique experiences | Durability, maintenance support, and visual appeal |

| Event and Show Car Industry | Showcasing vehicles at exhibitions and car shows | Increases visibility and marketability of vehicles | Customization options, shipping logistics, and lead times |

| Automotive Retail | Sale of aftermarket accessories | Expands product offerings and increases sales potential | Supplier reliability, pricing, and inventory management |

| Transportation Services | Upgrading company vehicle fleets | Improves image and customer satisfaction | Bulk purchasing discounts, warranty terms, and fitment verification |

How Are 20 Inch Spinner Rims Used in Automotive Customization?

In the automotive customization sector, 20 inch spinner rims are often used to enhance the aesthetics of high-end vehicles. Customization shops utilize these rims to create a unique look that appeals to discerning customers. The key requirements for buyers in this sector include ensuring compatibility with various vehicle models and maintaining high standards of quality. International buyers, particularly in regions like Europe and Africa, may prioritize suppliers who can provide detailed specifications and customization options that align with local trends and preferences.

What Benefits Do Luxury Car Rentals Gain from 20 Inch Spinner Rims?

Luxury car rental companies apply 20 inch spinner rims to enhance their fleet’s appeal. These rims not only improve the visual allure of vehicles but also attract clients seeking exclusive experiences. For these businesses, sourcing durable and stylish rims is crucial, as they must withstand varied driving conditions while maintaining their aesthetic appeal. In regions such as the Middle East, where luxury rentals are in high demand, suppliers must ensure timely delivery and robust customer support to facilitate smooth operations.

Why Are 20 Inch Spinner Rims Essential in the Event and Show Car Industry?

In the event and show car industry, 20 inch spinner rims are essential for showcasing vehicles at exhibitions and car shows. These rims help vehicles stand out, enhancing their marketability and appeal to potential buyers. Companies in this sector require customization options to align with branding and thematic presentations. Additionally, sourcing logistics are critical, as timely delivery and quality assurance can significantly impact exhibition success, especially for international participants from diverse markets.

How Do Automotive Retailers Benefit from Offering 20 Inch Spinner Rims?

Automotive retailers leverage 20 inch spinner rims as a part of their aftermarket accessories to enhance their product offerings. By providing these stylish rims, retailers can attract customers looking to personalize their vehicles, thus increasing sales potential. Key considerations for these businesses include supplier reliability and pricing strategies to ensure competitiveness in the market. Retailers in regions like South America may also focus on local preferences for rim designs and finishes to cater to their customer base effectively.

What Impact Do 20 Inch Spinner Rims Have on Transportation Services?

Transportation services that upgrade their vehicle fleets with 20 inch spinner rims can significantly improve their brand image and customer satisfaction. Enhanced aesthetics can lead to a more favorable perception of the service, attracting more clients. These businesses often seek bulk purchasing discounts and favorable warranty terms to optimize costs. For international buyers, particularly in Africa and Europe, verifying fitment and ensuring compliance with local regulations are paramount to successful sourcing.

3 Common User Pain Points for ’20 inch spinner rims for sale’ & Their Solutions

Scenario 1: Sourcing Quality Spinner Rims for Diverse Markets

The Problem: B2B buyers often face challenges in sourcing high-quality 20-inch spinner rims that meet the specific needs of their regional markets. In regions like Africa or South America, buyers may encounter issues such as limited supplier options, varying quality standards, and difficulty in obtaining certifications for compliance with local regulations. This can lead to frustration and potential financial losses if the products do not meet customer expectations or local laws.

The Solution: To effectively source quality spinner rims, buyers should prioritize establishing relationships with reputable suppliers who have a proven track record in their specific markets. Conduct thorough research on potential suppliers, checking for reviews, certifications, and product samples. Additionally, consider attending trade shows and industry exhibitions where suppliers showcase their products. This not only allows for direct interaction with manufacturers but also provides opportunities to negotiate bulk purchase deals. Leveraging platforms that specialize in B2B transactions can also help identify suppliers who offer competitive pricing and quality assurance. Lastly, implementing a quality control process that includes pre-shipment inspections can further mitigate risks associated with product quality.

Scenario 2: Understanding Compatibility and Fitment Requirements

The Problem: A common pain point for B2B buyers is the confusion surrounding the compatibility of 20-inch spinner rims with different vehicle makes and models. Mismatched bolt patterns, offsets, and sizes can lead to costly returns and dissatisfied customers. Buyers from regions with a diverse vehicle population, such as the Middle East and Europe, may find it particularly challenging to ensure that their inventory meets the varying specifications of different vehicles.

The Solution: To navigate compatibility issues, buyers should invest time in understanding the specific fitment requirements for the vehicles they intend to serve. This involves compiling a comprehensive database of vehicle specifications, including bolt patterns, offsets, and diameter requirements. Collaborating with manufacturers who provide detailed fitment guides or using digital tools that allow for fitment checks can streamline this process. Additionally, offering a consultation service to customers can enhance the buying experience and help identify the correct rims for their vehicles. Implementing a return policy that allows for exchanges based on fitment issues can also help maintain customer satisfaction while establishing a reputation for reliability.

Scenario 3: Navigating Import Regulations and Shipping Challenges

The Problem: For international B2B buyers, navigating the complex landscape of import regulations and shipping logistics for 20-inch spinner rims can pose significant challenges. Import duties, taxes, and compliance with local automotive standards can complicate the purchasing process and add unexpected costs. This is especially true for buyers in regions like Nigeria or Germany, where regulations can vary significantly.

The Solution: To effectively manage import challenges, buyers should familiarize themselves with the import regulations specific to their region. Consulting with a customs broker or logistics expert can provide insights into the necessary documentation, duties, and compliance standards required for importing automotive parts. Additionally, working with suppliers who offer international shipping solutions can simplify logistics and ensure timely delivery. Establishing a clear understanding of potential costs involved in importing can help buyers budget effectively, reducing the risk of unforeseen expenses. Furthermore, maintaining open communication with suppliers regarding shipping timelines and potential delays can foster a smoother purchasing experience. By prioritizing compliance and logistics, buyers can mitigate risks and streamline the import process, enhancing their overall business efficiency.

Strategic Material Selection Guide for 20 inch spinner rims for sale

When selecting materials for 20-inch spinner rims, various factors must be considered, including performance, durability, cost, and compliance with international standards. Below is an analysis of four common materials used in the manufacturing of spinner rims, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Aluminum in Spinner Rims?

Aluminum is a widely used material for spinner rims due to its favorable properties. It is lightweight, which enhances vehicle performance and fuel efficiency. Aluminum also exhibits good corrosion resistance, making it suitable for various environments, including humid and coastal regions. The material can withstand moderate temperature variations but may not perform well under extreme heat.

Pros & Cons:

Aluminum rims are generally more affordable than other materials like forged alloys. However, they can be less durable than heavier alternatives, making them susceptible to bending or cracking under high-stress conditions. Manufacturing complexity is moderate, as aluminum can be easily cast or forged into intricate designs.

Impact on Application:

Aluminum rims are compatible with most vehicles and are often preferred for their aesthetic appeal. However, international buyers should ensure that the aluminum used meets local quality standards, such as ASTM or DIN specifications.

How Does Steel Compare as a Material for Spinner Rims?

Steel is another common material for spinner rims, known for its exceptional strength and durability. It can handle higher loads and is less prone to damage from impacts compared to aluminum. Steel rims typically have a higher temperature and pressure rating, making them suitable for rugged applications.

Pros & Cons:

The primary advantage of steel rims is their durability and lower cost compared to aluminum. However, they are heavier, which can negatively impact fuel efficiency and vehicle performance. The manufacturing process is relatively straightforward, but the aesthetic options are limited compared to aluminum or forged materials.

Impact on Application:

Steel rims are often used in off-road and heavy-duty applications. International buyers should be aware of the potential for rust and corrosion, especially in regions with high humidity or salt exposure. Compliance with local standards is essential to ensure quality and safety.

What Advantages Do Forged Alloys Offer for Spinner Rims?

Forged alloys, typically made from a combination of aluminum and other metals, provide excellent strength-to-weight ratios. These rims are engineered to withstand extreme conditions, making them ideal for high-performance vehicles. They also offer superior corrosion resistance and can be customized for various finishes.

Pros & Cons:

The key advantage of forged alloy rims is their durability and lightweight nature, which enhances vehicle performance. However, they come at a higher cost due to the complex manufacturing process. The production of forged rims requires advanced technology, making them less accessible for budget-conscious buyers.

Impact on Application:

Forged alloy rims are suitable for luxury and performance vehicles, appealing to buyers looking for high-quality aesthetics and performance. International buyers should verify compliance with specific standards, as the manufacturing process can vary significantly across regions.

Why Are Composite Materials Emerging in Spinner Rim Production?

Composite materials, often a blend of plastics and fibers, are gaining traction in the spinner rim market. They offer unique properties such as lightweight, flexibility, and resistance to corrosion. Composites can also be molded into intricate designs, providing aesthetic advantages.

Pros & Cons:

The primary advantage of composite materials is their lightweight nature, which improves fuel efficiency. However, they may not offer the same level of strength as metals, leading to potential concerns in high-stress applications. Manufacturing complexity is high, requiring specialized techniques.

Impact on Application:

Composites are suitable for niche markets, particularly in electric and hybrid vehicles where weight savings are crucial. International buyers should ensure that composite materials meet local safety and performance standards, as regulations can vary widely.

Summary Table of Material Selection for 20-Inch Spinner Rims

| Material | Typical Use Case for 20 inch spinner rims for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General passenger vehicles, aesthetic applications | Lightweight, good corrosion resistance | Less durable under stress | Medium |

| Steel | Off-road, heavy-duty applications | High strength and durability | Heavier, less aesthetic options | Low |

| Forged Alloys | Luxury and high-performance vehicles | Excellent strength-to-weight ratio | High cost, complex manufacturing | High |

| Composite | Niche markets, electric/hybrid vehicles | Lightweight, design flexibility | May lack strength in high-stress applications | Medium |

This analysis provides a comprehensive overview of the materials commonly used in the production of 20-inch spinner rims. By understanding the properties, advantages, and limitations of each material, international B2B buyers can make informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 20 inch spinner rims for sale

What Are the Main Stages in the Manufacturing Process of 20 Inch Spinner Rims?

The manufacturing of 20-inch spinner rims is a complex process that involves several key stages. Understanding these stages can help B2B buyers assess potential suppliers and the quality of the products they offer.

1. Material Preparation

The process begins with the selection of high-quality raw materials. Aluminum and alloy metals are commonly used due to their lightweight and durable properties. The material is sourced from reputable suppliers, ensuring compliance with international standards. In many cases, the aluminum undergoes a series of quality checks to verify its composition and strength.

2. Forming Techniques

Once the materials are prepared, they undergo forming processes, which can include casting, forging, or machining.

- Casting involves pouring molten metal into a mold to create the rim shape. This method allows for intricate designs but requires careful control of the cooling process to avoid defects.

- Forging utilizes high pressure to shape the metal, resulting in a denser and stronger rim. This method is particularly favored for performance applications where durability is critical.

- Machining is often employed to achieve precise dimensions and finishes, enhancing the aesthetic appeal of the rims.

3. Assembly Process

After forming, the rims are assembled. This stage can involve several components, including the spinner mechanism, which allows the rim to rotate independently of the wheel. Precision is key, as any misalignment can lead to performance issues.

- Welding or bolting are common techniques used to secure parts together.

- Quality control checkpoints are instituted to ensure that every component fits correctly before moving to the next stage.

4. Finishing Techniques

Finishing is crucial for both aesthetic and functional purposes. Rims typically undergo several processes, including polishing, painting, or chrome plating.

- Polishing enhances shine and removes surface imperfections.

- Powder coating or painting provides an additional layer of protection against environmental damage.

- Chrome plating gives a distinctive look and adds durability but requires strict adherence to environmental regulations to avoid harmful waste.

How Is Quality Assurance Managed in the Production of Spinner Rims?

Quality assurance (QA) is integral to the manufacturing process of spinner rims. Implementing rigorous QA protocols ensures that products meet international standards and customer expectations.

What International Standards Are Relevant for Spinner Rim Quality?

Many manufacturers adhere to international standards such as ISO 9001, which outlines the criteria for a quality management system. Compliance with ISO standards ensures that products are consistently produced to meet customer and regulatory requirements.

- CE marking is another standard that indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API certification may be relevant for manufacturers producing specialized automotive components, ensuring they meet the required industry specifications.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are critical at various stages of production:

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials and components for compliance with specifications before they enter production.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing stages, IPQC ensures that processes are being followed correctly and that any deviations are addressed immediately.

-

Final Quality Control (FQC): This final checkpoint involves a comprehensive inspection of the finished product, checking for defects and ensuring that the rim meets the specifications laid out by the design and engineering teams.

What Common Testing Methods Are Used to Ensure Quality?

Manufacturers employ a variety of testing methods to verify the quality of spinner rims:

- Visual Inspection: This involves checking for surface defects, alignment, and overall finish.

- Dimensional Testing: Using calipers and gauges, manufacturers verify that the rims meet the specified measurements.

- Stress Testing: This method assesses the strength and durability of the rims under load conditions, simulating real-world usage.

- Corrosion Resistance Testing: Rims undergo tests to evaluate their resistance to rust and other environmental factors, particularly important for buyers in coastal regions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality assurance processes of potential suppliers.

What Should Buyers Look for in Supplier Audits and Reports?

Requesting detailed audit reports can provide insights into a supplier’s quality management system. Key aspects to evaluate include:

- Audit Frequency: Regular audits indicate a commitment to quality.

- Non-Conformance Reports: These documents reveal any issues encountered during production and how they were resolved.

- Corrective Actions: Understanding how suppliers address quality issues can offer reassurance about their commitment to improvement.

Are Third-Party Inspections Necessary?

Engaging third-party inspection agencies can add an extra layer of assurance. These agencies can conduct independent assessments of the manufacturing process, ensuring that the products meet all specifications and standards. This is particularly valuable for international buyers who may not have the resources to conduct onsite inspections.

What Are the Quality Control Nuances for International Buyers?

International buyers must be aware of specific nuances related to quality control:

- Certification Recognition: Not all certifications are recognized globally. Buyers should ensure that the certifications held by suppliers are valid in their respective markets.

- Language Barriers: Documentation may be in a different language, making it essential to have access to translations or bilingual staff for accurate interpretation.

- Cultural Differences in Business Practices: Understanding cultural approaches to quality and production can enhance communication and negotiation with suppliers.

By grasping these manufacturing and quality assurance processes, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ’20 inch spinner rims for sale’

Introduction

Navigating the procurement of 20-inch spinner rims requires a systematic approach to ensure quality, compatibility, and cost-effectiveness. This guide provides a practical checklist for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, to make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s crucial to determine the exact specifications you need for the spinner rims. Consider factors such as:

– Diameter and Width: Ensure the rims fit the vehicles in question.

– Bolt Pattern: Check compatibility with the target vehicle’s hub.

– Offset and Load Rating: Confirm that the rims can support the intended load and performance requirements.

Step 2: Research Potential Suppliers

A thorough research phase will help you identify reputable suppliers. Look for:

– Industry Experience: Suppliers with a proven track record in the wheel industry are more likely to provide reliable products.

– Online Reviews and Testimonials: Evaluate feedback from previous customers to gauge satisfaction levels and product quality.

Step 3: Evaluate Supplier Certifications

Ensure that potential suppliers meet industry standards and certifications. This step is critical for:

– Quality Assurance: Certifications indicate compliance with safety and manufacturing standards.

– International Trade Compliance: Verify that suppliers can meet any specific import/export regulations relevant to your region.

Step 4: Request Samples and Product Specifications

Before making a bulk purchase, request samples of the spinner rims to assess quality. Pay attention to:

– Material Quality: Examine the finish and durability of the rims.

– Technical Documentation: Ensure that you receive detailed specifications and installation guidelines.

Step 5: Negotiate Pricing and Terms

Engage in discussions with suppliers regarding pricing and payment terms. Key points to cover include:

– Volume Discounts: Inquire about pricing breaks for larger orders.

– Payment Terms: Establish clear payment schedules, including options for financing if available.

Step 6: Confirm Shipping and Delivery Logistics

Understanding shipping logistics is vital for timely procurement. Consider:

– Shipping Costs and Times: Factor these into your overall budget and timeline.

– Customs and Duties: Be aware of any additional fees that may apply when importing goods.

Step 7: Establish a Clear Return Policy

Finally, ensure that there is a clear return policy in place. This protects your business from:

– Defective Products: Know how to handle returns for faulty rims.

– Compatibility Issues: Confirm that you can return items that do not fit your requirements.

By following this checklist, B2B buyers can streamline their sourcing process for 20-inch spinner rims, ensuring they make informed decisions that align with their business needs.

Comprehensive Cost and Pricing Analysis for 20 inch spinner rims for sale Sourcing

What Are the Key Cost Components for 20 Inch Spinner Rims?

When sourcing 20 inch spinner rims, understanding the cost structure is essential for effective budgeting and pricing strategies. The primary components include:

-

Materials: The choice of materials significantly affects costs. High-quality alloys or chrome finishes typically incur higher expenses compared to standard steel. Customization options, such as unique finishes or designs, can further increase material costs.

-

Labor: Labor costs involve both manufacturing and assembly processes. Skilled labor is often required for intricate designs, which can elevate the overall labor expenses.

-

Manufacturing Overhead: This encompasses utilities, rent, and administrative expenses related to the production facility. Efficient production methods can help minimize these costs, ultimately benefiting the pricing structure.

-

Tooling: Initial investments in molds and tools are necessary for producing spinner rims. These costs can be amortized over larger production runs, making it crucial to consider the volume of the order when negotiating prices.

-

Quality Control (QC): Ensuring the rims meet safety and quality standards is vital. Implementing rigorous QC processes may lead to higher upfront costs but can prevent costly returns or recalls in the future.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors such as distance, shipping mode, and customs duties can significantly impact the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the average margins in the industry can help buyers gauge whether a price is reasonable.

How Do Price Influencers Impact the Sourcing of Spinner Rims?

Several factors can influence the pricing of 20 inch spinner rims, particularly in international markets:

-

Volume/MOQ: Manufacturers often offer lower prices for larger orders. Understanding the minimum order quantities (MOQ) can help buyers negotiate better terms.

-

Specifications and Customization: Rims with unique specifications or custom designs may attract premium prices. Buyers should assess their needs carefully to avoid unnecessary expenses.

-

Materials and Quality Certifications: Rims made from certified materials or those that meet specific safety standards may come at a higher cost. Buyers should weigh the benefits of quality against budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more for their expertise and customer service, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding International Commercial Terms (Incoterms) is crucial for cost management. Different terms can affect who bears the risk and costs during shipping, influencing the total price.

What Tips Can Buyers Use to Negotiate Pricing Effectively?

B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, can adopt several strategies to enhance their purchasing experience:

-

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. Suppliers may have flexibility in their pricing structures, particularly for larger orders.

-

Focus on Cost-Efficiency: Assess the total cost of ownership (TCO) rather than just the upfront price. Consider factors like durability, maintenance, and potential resale value.

-

Understand Pricing Nuances: Be aware of regional market dynamics and how they may affect pricing. For instance, tariffs and import duties can significantly increase costs for buyers in Africa or South America.

-

Establish Long-Term Relationships: Building a strong relationship with suppliers can lead to better pricing and service. Regular communication and trust can facilitate more favorable terms over time.

Conclusion

Sourcing 20 inch spinner rims involves a comprehensive understanding of the cost structure and pricing influencers. By leveraging negotiation strategies and focusing on total cost efficiency, international buyers can navigate the complexities of the market effectively. It is important to note that prices may vary based on numerous factors, and buyers should conduct thorough research before making commitments.

Alternatives Analysis: Comparing 20 inch spinner rims for sale With Other Solutions

Exploring Alternatives to 20 Inch Spinner Rims for Sale

In the realm of automotive customization, 20 inch spinner rims are a popular choice due to their unique aesthetic and performance capabilities. However, businesses looking to enhance their vehicle offerings may consider alternative solutions that meet similar needs. This analysis will compare 20 inch spinner rims with two viable alternatives: custom alloy wheels and traditional static rims.

Comparison Table

| Comparison Aspect | 20 Inch Spinner Rims For Sale | Custom Alloy Wheels | Traditional Static Rims |

|---|---|---|---|

| Performance | Enhanced visual appeal, spinning feature for style | Lightweight, improved handling and performance | Reliable performance, good for various terrains |

| Cost | Generally higher, $450-$1,800 | Moderate, $300-$1,500 | Lower, $100-$800 |

| Ease of Implementation | Requires specialized installation | Standard installation, can be customized | Simple installation process |

| Maintenance | More complex due to moving parts | Moderate, depends on finish | Low maintenance required |

| Best Use Case | Luxury vehicles, show cars | Performance vehicles, daily drivers | Utility vehicles, budget-conscious consumers |

Detailed Breakdown of Alternatives

Custom Alloy Wheels

Custom alloy wheels are a popular alternative to spinner rims, offering a blend of style and performance. These wheels are designed to be lightweight, which can enhance vehicle handling and fuel efficiency. They come in various designs and finishes, allowing for personalization. However, the cost can vary significantly based on the customization level and brand, often ranging from $300 to $1,500. Maintenance is moderate; while they may require periodic cleaning to maintain their appearance, they do not have the mechanical complexity of spinner rims.

Traditional Static Rims

Traditional static rims are the most straightforward option. These wheels are known for their reliability and durability, making them suitable for a wide range of vehicles, including utility and budget-conscious models. They are typically less expensive than both spinner rims and custom alloys, with prices ranging from $100 to $800. The installation process is simple, making them accessible for many users. However, they lack the aesthetic appeal and unique design features of spinner rims and custom alloys, making them less desirable for luxury or performance-focused vehicles.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate wheel solution, B2B buyers should consider their specific market needs and customer preferences. For businesses targeting luxury or performance-focused clients, 20 inch spinner rims may provide the aesthetic appeal and unique features desired. Conversely, if the goal is to offer reliable and cost-effective solutions, traditional static rims or custom alloy wheels may better serve the target market. Ultimately, understanding the performance requirements, cost implications, and maintenance needs will guide businesses in making informed decisions that align with their brand and customer expectations.

Essential Technical Properties and Trade Terminology for 20 inch spinner rims for sale

What Are the Key Technical Properties of 20 Inch Spinner Rims?

When sourcing 20 inch spinner rims, understanding the essential technical specifications is crucial for ensuring product quality, compatibility, and performance. Here are some critical specifications to consider:

-

Material Grade

Spinner rims are typically made from aluminum or alloy materials, which offer a balance of strength and weight. The material grade affects the rim’s durability, performance, and aesthetic appeal. High-grade materials can withstand stress and impact better, making them essential for vehicles that encounter rough terrains. -

Bolt Pattern

The bolt pattern refers to the arrangement of the holes used to attach the rim to the vehicle. Common bolt patterns for 20 inch rims include 5×108, 5×110, and 5×114. Ensuring the correct bolt pattern is vital for proper fitment, as mismatched patterns can lead to installation issues and compromise safety. -

Offset

Offset indicates the distance between the wheel’s mounting surface and its centerline. A correct offset is critical for maintaining proper alignment and handling characteristics of the vehicle. It impacts the wheel’s positioning relative to the fender and suspension components, affecting both aesthetics and performance. -

Width

The width of the rim, often measured in inches, influences the type of tires that can be mounted and the overall stability of the vehicle. Wider rims can enhance grip and handling but may require specific tire sizes to maintain performance standards. -

Finish

The finish of the spinner rim, whether chrome, brushed, or custom colors, not only affects aesthetic appeal but also provides protective qualities against corrosion and wear. Different finishes may require varying levels of maintenance and can influence resale value. -

Weight Rating

Each rim has a specified weight rating, which denotes the maximum load it can safely carry. This is particularly important for commercial applications where the vehicle may be loaded with heavy cargo. Exceeding this rating can lead to rim failure and safety hazards.

What Are Common Trade Terms Related to 20 Inch Spinner Rims?

Familiarity with industry jargon can streamline communication and negotiation processes between buyers and suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. In the context of spinner rims, OEM parts are often preferred for their guaranteed compatibility and quality assurance, making them a popular choice among B2B buyers. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ is essential for managing inventory and cost efficiency, especially for businesses looking to stock up on spinner rims for resale. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing information on specific products. For B2B buyers, issuing an RFQ for 20 inch spinner rims can help in comparing costs and identifying the best suppliers. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is crucial for understanding shipping costs and responsibilities when purchasing spinner rims from international suppliers. -

Fitment Guarantee

This term refers to a commitment from the supplier that the rims will fit the specified vehicle models. A fitment guarantee is particularly important for buyers who want assurance that the products will meet their application needs without requiring modifications. -

Aftermarket

The aftermarket encompasses all parts and accessories sold after the original sale of the vehicle. For B2B buyers, understanding the aftermarket landscape for spinner rims can lead to opportunities in customization and enhancements for vehicles, appealing to a broader customer base.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing 20 inch spinner rims, ensuring compatibility, quality, and cost-effectiveness for their business needs.

Navigating Market Dynamics and Sourcing Trends in the 20 inch spinner rims for sale Sector

What Are the Key Trends Influencing the 20 Inch Spinner Rims Market?

The global market for 20 inch spinner rims is witnessing dynamic growth driven by several factors. Increasing consumer demand for vehicle customization, particularly in regions like Africa, South America, the Middle East, and Europe, has propelled the spinner rim segment. A noticeable trend is the rising popularity of luxury and performance vehicles, which often feature larger rims as a standard. This shift is particularly evident in markets like Germany and Nigeria, where automotive culture is rapidly evolving, and customization is becoming a statement of identity.

Emerging B2B technology trends are also reshaping sourcing practices in this sector. E-commerce platforms are facilitating direct trade between manufacturers and international buyers, reducing intermediary costs. Advanced analytics and AI-driven insights are helping businesses understand market demand and optimize inventory management. Furthermore, the integration of augmented reality (AR) tools allows buyers to visualize products on their vehicles before purchasing, enhancing the customer experience.

Market dynamics are heavily influenced by the competitive landscape, with numerous manufacturers offering a wide range of designs and finishes. Additionally, the need for compliance with international quality standards is crucial for suppliers aiming to penetrate global markets. As buyers prioritize quality and unique designs, suppliers must remain agile and responsive to changing market conditions.

How Important Is Sustainability and Ethical Sourcing in the Spinner Rim Industry?

Sustainability and ethical sourcing have become paramount in the B2B landscape, particularly for industries such as automotive accessories, including 20 inch spinner rims. The environmental impact of manufacturing processes is under scrutiny, compelling suppliers to adopt more sustainable practices. This includes the use of recycled materials in rim production and energy-efficient manufacturing techniques that reduce carbon footprints.

Moreover, buyers are increasingly seeking suppliers who adhere to ethical sourcing practices. This involves ensuring fair labor practices throughout the supply chain and obtaining materials from suppliers who provide transparent sourcing information. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can significantly enhance a supplier’s reputation and appeal to conscientious buyers.

The emphasis on ‘green’ materials is also gaining traction. Many manufacturers are exploring the use of alternative materials that minimize environmental impact without compromising quality. This shift not only meets regulatory requirements but also aligns with the values of an eco-conscious consumer base, making it a vital consideration for international buyers.

What Is the Evolution of the Spinner Rim Market?

The spinner rim market has evolved significantly since its inception in the late 1990s. Initially popularized by hip-hop culture and urban style, spinner rims quickly became a symbol of luxury and status. Over the years, technological advancements have allowed for more intricate designs and finishes, catering to a diverse range of consumer preferences.

In the early 2000s, the market saw a surge in demand as customization became a mainstream trend among vehicle owners. This led to an influx of manufacturers and suppliers entering the market, increasing competition and variety. Today, the spinner rim industry not only caters to individual consumers but also to B2B buyers looking for unique products that can enhance their brand offerings. As the market continues to grow, the focus on innovation, sustainability, and ethical practices will likely shape its future trajectory.

Frequently Asked Questions (FAQs) for B2B Buyers of 20 inch spinner rims for sale

-

1. How do I choose the right supplier for 20 inch spinner rims?

Selecting the right supplier for 20 inch spinner rims involves assessing their reputation, product quality, and customer service. Begin by researching potential suppliers through online reviews and industry forums. Request samples of their products to evaluate quality firsthand. Ensure they have a robust supply chain that can meet your demands, and inquire about their experience in international shipping and customs regulations. It’s also beneficial to check their certifications and compliance with industry standards to ensure reliability. -

2. What customization options are available for 20 inch spinner rims?

Many suppliers offer various customization options for 20 inch spinner rims, including finishes (chrome, matte, brushed), colors, and designs. You can also request specific bolt patterns and offsets tailored to your vehicle’s specifications. When discussing customization, be clear about your requirements and ask for visual samples or prototypes. This can help you ensure that the final product meets your branding and aesthetic needs. -

3. What are the typical minimum order quantities (MOQs) for spinner rims?

Minimum order quantities (MOQs) for 20 inch spinner rims can vary significantly based on the supplier and the complexity of the order. Generally, MOQs range from 10 to 50 sets, depending on the customization and materials used. It’s advisable to discuss MOQs with potential suppliers to understand their flexibility. Some suppliers may offer lower MOQs for standard products, while customized orders might require a higher minimum. -

4. What payment terms should I expect when ordering spinner rims internationally?

Payment terms for international orders of spinner rims can vary widely. Common options include upfront payment, partial payment (deposit) with the balance due upon shipment, or net payment terms (e.g., 30 days post-delivery). Always clarify payment methods accepted, such as bank transfers, letters of credit, or online payment platforms. Negotiating favorable terms can improve cash flow, especially if you are ordering large quantities. -

5. How can I ensure quality assurance for my spinner rim orders?

To ensure quality assurance for your orders of 20 inch spinner rims, request detailed product specifications and certifications from suppliers. You may also consider third-party inspection services to conduct quality checks before shipment. It’s beneficial to establish clear acceptance criteria and a return policy in case the products do not meet your standards. Regular communication with your supplier throughout the manufacturing process can help prevent issues. -

6. What logistics considerations should I keep in mind when importing spinner rims?

When importing spinner rims, consider logistics factors such as shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling automotive parts to streamline the process. Ensure you understand customs duties, taxes, and regulations specific to your country to avoid unexpected costs. It’s also wise to track your shipment to manage any potential delays proactively. -

7. What are the common challenges when sourcing spinner rims internationally?

Common challenges in sourcing spinner rims internationally include language barriers, cultural differences, and varying quality standards. Additionally, navigating customs regulations and shipping logistics can be complex. To mitigate these challenges, work with suppliers who have experience in international trade and can provide clear communication. Establishing a good relationship with your supplier can also help overcome these hurdles effectively. -

8. How can I effectively communicate my needs to suppliers of spinner rims?

Effective communication with suppliers involves being clear and concise about your requirements. Prepare a detailed request for quotation (RFQ) that outlines specifications, quantities, delivery timelines, and any customization needs. Use visual aids, such as sketches or photos, to illustrate your expectations. Regular follow-ups and open dialogues can help ensure that both parties are aligned, reducing the risk of misunderstandings and ensuring a smoother transaction process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 20 Inch Spinner Rims For Sale Manufacturers & Suppliers List

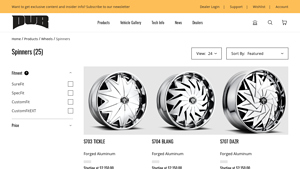

1. DUB Wheels – Forged Aluminum Spinners

Domain: dubwheels.com

Registered: 2009 (16 years)

Introduction: Spinners | DUB Wheels

– Product Types: Forged Aluminum Spinners

– Starting Price: $2,150.00

– Models Available:

– S703 TICKLE

– S704 BLANG

– S707 DAZR

– S710 LIXX

– S712 CUTTA

– S713 DIRAGIO

– S723 BOOGEE

– S727 CHILL

– S733 HURRICAYNE

– S750 BANDITO

– S757 DRAMA

– S768 SWYRL

– S777 BELLAGIO

– S787 JOKER

– S788 GANGA

– S810 TURBO

– S811 CHINCHILLA

– S816 CHOPPA

…

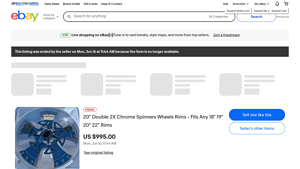

2. m midnightdeals4u – 20 Double 2X Chrome Spinners Wheels Rims

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”:”20″ Double 2X Chrome Spinners Wheels Rims – Fits Any 18″ 19″ 20″ 22″ Rims”,”price”:”$995.00″,”condition”:”New”,”rim_material”:”aluminum alloy”,”wheel_style”:”5 Spoke”,”quantity_available”:7,”shipping_estimate”:”Mon, Sep 8 – Thu, Sep 11″,”seller_name”:”m midnightdeals4u”,”seller_feedback”:”100% positive feedback”,”item_number”:”255752954439″}

3. DUB Spinners – Chrome & Brushed Wheels

Domain: caliwheels.com

Registered: 2000 (25 years)

Introduction: DUB Spinners Wheels include various models such as: Bandito – S750 Chrome, Bellagio – S777 Chrome, Blang – S704 Chrome, Boogee – S723 Chrome, Chill – S727 Chrome, Chinchilla – S811 Brushed, Choppa – S816 Brushed, Cojones – S817 Brushed, Cutta – S712 Chrome, Dazr – S707 Chrome, Diragio – S713 Chrome, Drama – S757 Chrome, Hurricayne – S733 Chrome, Joker – S787 Chrome, Lixx – S710 Chrome, Mandate – S…

4. JK Motorsports – Custom Wheels & Rims

Domain: wheelsandspinners.com

Registered: 2003 (22 years)

Introduction: Spinners from JK Motorsports include a variety of rims and wheels such as custom wheels, chrome rims, and big rims. The site features a wide selection of products with various specifications including diameter, finish, brand, bolt pattern, and offset range. Notable brands include DUB, American Racing, Asanti, and more. Prices for spinners range from $85.00 to $1,840.00. Specific products include t…

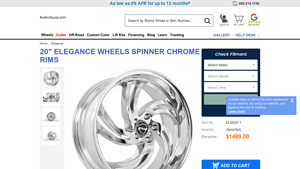

5. Elegance – Spinner Wheels 20×8.5 Chrome

Domain: audiocityusa.com

Registered: 2008 (17 years)

Introduction: {“item_number”:”ELG025-1″,”brand”:”Elegance”,”model”:”Spinner”,”size”:”20×8.5″,”finish”:”Chrome”,”quantity”:”4 pcs (1 set)”,”price”:”$1489.00″,”bolt_pattern”:”5×108 / 5×110 / 5×112 / 5×114 / 5×115 / 5×120 (According to Vehicle)”,”offset”:”Low to High (According to Vehicle)”,”condition”:”Brand New”,”lugs_and_locks”:”Not Included”,”custom_color_options”:”Available custom color combinations (optional…

6. Elegance – 20×8.5 Chrome Spinner Wheels

Domain: bbwheelsonline.com

Registered: 2012 (13 years)

Introduction: {“name”: “Elegance Spinner Wheels Rims”, “size”: “20×8.5”, “bolt_pattern”: “5×114.3”, “finish”: “Chrome”, “offset”: “32mm”, “model”: “ESPINNER -051432CH”, “shipping”: “Free Shipping To Lower 48 States”, “financing”: “Financing all Credit Types”}

7. Reddit – Spinner Rims

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Spinner rims, also known as spinning hubcaps, are still available for purchase. They were popular in the past and can add a unique aesthetic to vehicles, especially those with 17 or 18-inch stock wheels. Users are encouraged to search for them under the term “spinning hubcaps”.

8. Movement Products – Spinwheel Spinner Wheel Adapters

Domain: movementproducts.com

Registered: 2015 (10 years)

Introduction: Spinwheel Spinner Wheel Adapters are designed to enhance the functionality of your vehicle’s wheels. These adapters allow for easy installation of spinner wheels, providing a stylish and unique look. They are compatible with various wheel types and are made from durable materials to ensure longevity and performance. Ideal for automotive enthusiasts looking to customize their vehicles.

9. Wayne’s Wheels – Custom Spinning Wheels

Domain: wayneswheels.net

Introduction: Custom Spinning Wheels and Spinners available at Wayne’s Wheels. Key products include DUB Flash Spinners in sizes 22, 24, 26, 28, 30, 32 inches. Various spinner styles from brands such as Chopper Spinners, Creative Design, Davin Spinning Wheels, DUB LEDS, and more. Specific DUB spinner models include: DUB Blang, DUB Chinchilla, DUB Choppa, DUB Cojones, DUB Cutta, DUB Cyclone, DUB DAZR, DUB FLO, DU…

Strategic Sourcing Conclusion and Outlook for 20 inch spinner rims for sale

In the dynamic market for 20-inch spinner rims, strategic sourcing emerges as a crucial factor for international B2B buyers. By leveraging a diverse range of suppliers and understanding regional preferences, buyers can not only secure competitive pricing but also enhance their product offerings. The demand for customization and high-quality materials underscores the importance of establishing robust relationships with reliable manufacturers and distributors, particularly in regions like Africa, South America, the Middle East, and Europe.

Furthermore, aligning sourcing strategies with market trends—such as the growing popularity of chrome finishes and unique designs—will empower businesses to meet consumer expectations more effectively. As the industry continues to evolve, staying ahead of technological advancements and sustainability practices will also be vital.

Looking forward, international buyers should prioritize building strategic partnerships and exploring innovative sourcing avenues to remain competitive. Embrace the opportunity to enhance your inventory and cater to diverse markets by actively engaging with suppliers who share your vision for quality and excellence. Start your sourcing journey today to capitalize on the potential of the spinner rim market.