1 Ml Dropper Bottle Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for 1 ml dropper bottle

In an increasingly interconnected global market, sourcing the right 1 ml dropper bottle can be a daunting task for B2B buyers, especially when navigating diverse regulations and material preferences across continents. Whether you are in the pharmaceutical, cosmetic, or essential oil industries, the need for precise, reliable dispensing solutions is paramount. This guide is designed to demystify the complexities of selecting the perfect 1 ml dropper bottle for your business needs.

We delve into the various types of dropper bottles available, from glass to plastic, and explore their specific applications across different sectors. The guide also covers critical aspects such as supplier vetting processes, pricing strategies, and compliance with international standards, ensuring you have the tools to make informed purchasing decisions.

Our focus on international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe—including markets like Vietnam and Saudi Arabia—positions this guide as a vital resource. By understanding regional preferences and requirements, you can streamline your sourcing process and enhance your supply chain efficiency. With this comprehensive overview, you will be empowered to navigate the global market confidently, ensuring that you select the best dropper bottles that meet your operational and regulatory demands.

Understanding 1 ml dropper bottle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Graduated Glass Dropper | Made of borosilicate glass; features graduated markings for precise measurements. | Laboratories, pharmaceuticals, essential oils | Pros: Accurate dosing, chemical inertness. Cons: Fragile, higher cost than plastic. |

| Amber Glass Dropper | UV-protective amber glass; ideal for light-sensitive solutions. | Cosmetic formulations, pharmaceutical products | Pros: Protects contents from UV degradation. Cons: Heavier and more expensive than clear glass. |

| LDPE Plastic Dropper | Made from low-density polyethylene; flexible and lightweight. | Chemical dispensing, food and beverage industries | Pros: Durable, chemical resistance, lower cost. Cons: Less precise than glass, potential leaching. |

| Plastic Pipette | Simple design, often disposable; typically made from LDPE or HDPE. | Home use, educational purposes, small-scale dispensing | Pros: Cost-effective, easy to use. Cons: Not suitable for high-precision tasks, limited reusability. |

| Specialty Dropper Bottles | Various materials and designs tailored for specific applications (e.g., with control tips). | Laboratory research, specific chemical applications | Pros: Customizable for specific needs, precise dispensing. Cons: May require higher investment, specific sourcing. |

What are the Characteristics of Graduated Glass Droppers?

Graduated glass droppers are crafted from borosilicate glass, providing excellent chemical resistance and durability. The graduated markings allow for precise measurement, making them ideal for laboratory and pharmaceutical applications where accuracy is paramount. B2B buyers should consider their fragility and higher price point compared to plastic alternatives, but their reliability in delivering consistent dosages makes them a preferred choice for many professionals.

How Do Amber Glass Droppers Benefit B2B Buyers?

Amber glass droppers are specifically designed to protect light-sensitive substances from UV radiation. This makes them particularly useful in the cosmetic and pharmaceutical sectors, where product integrity is essential. While they offer superior protection, buyers should be aware of their heavier weight and higher cost. However, the investment can be justified by the enhanced shelf life and effectiveness of the products contained within.

What Advantages Do LDPE Plastic Droppers Offer?

LDPE plastic droppers are lightweight, flexible, and highly resistant to a wide range of chemicals, making them suitable for various industries, including food and beverage. Their lower cost and durability are significant advantages for bulk purchasing. However, they may lack the precision of glass droppers, which is a critical consideration for applications requiring exact measurements. Buyers should assess their specific needs when choosing between plastic and glass options.

Why Choose Plastic Pipettes for Basic Dispensing Needs?

Plastic pipettes are simple, often disposable tools that offer a cost-effective solution for low-precision dispensing tasks. Ideal for educational settings and home use, they are made from materials like LDPE or HDPE. While they are easy to use and affordable, they are not designed for high-precision applications. B2B buyers should consider their intended use and the importance of accuracy in their operations before opting for plastic pipettes.

What Makes Specialty Dropper Bottles a Smart Investment?

Specialty dropper bottles come in various materials and designs tailored to specific applications, featuring control tips for precise dispensing. These are particularly beneficial in laboratory research and specialized chemical applications where accuracy and customization are crucial. While they may require a higher investment and careful sourcing, the ability to meet specific operational needs can lead to enhanced efficiency and effectiveness in dispensing tasks.

Key Industrial Applications of 1 ml dropper bottle

| Industry/Sector | Specific Application of 1 ml dropper bottle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceutical | Dispensing liquid medications in precise doses | Ensures accurate dosing, enhancing patient safety and compliance | Regulatory compliance, material safety, and sterility requirements |

| Cosmetics and Personal Care | Sample distribution of serums and essential oils | Facilitates easy testing and customer trials, boosting product sales | Packaging aesthetics, UV protection for sensitive ingredients |

| Food and Beverage | Adding flavor extracts or food coloring | Allows for precise flavoring, enhancing product consistency | Food-grade materials, regulatory approvals, and traceability |

| Chemical Laboratories | Delivering reagents and chemicals for experiments | Promotes accuracy and reduces waste in laboratory settings | Chemical compatibility, durability, and volume consistency |

| Agriculture | Application of fertilizers or pesticides in small quantities | Enhances targeted application, reducing environmental impact | Sourcing for chemical resistance and compliance with agricultural regulations |

How is the 1 ml dropper bottle used in the pharmaceutical sector, and what problems does it solve?

In the pharmaceutical industry, 1 ml dropper bottles are critical for dispensing liquid medications. These bottles allow healthcare professionals and patients to measure precise doses, which is essential for patient safety and adherence to treatment regimens. They help mitigate the risk of overdosing or underdosing, a common problem with liquid medications. For international buyers, sourcing dropper bottles that meet stringent regulatory standards for safety and sterility is vital, especially in regions with diverse regulatory landscapes.

What applications exist for 1 ml dropper bottles in the cosmetics and personal care industry?

Within the cosmetics sector, 1 ml dropper bottles are ideal for distributing samples of serums, oils, and other liquid products. This application allows consumers to test products before committing to a full purchase, enhancing customer engagement and satisfaction. The ability to protect sensitive ingredients from UV light is particularly beneficial, as many active components in cosmetics are light-sensitive. Buyers must consider the aesthetic appeal and functionality of the packaging, ensuring it aligns with brand identity and consumer expectations.

How do 1 ml dropper bottles benefit the food and beverage industry?

In the food and beverage sector, 1 ml dropper bottles are utilized for adding flavor extracts, colorings, or other liquid ingredients in precise amounts. This capability ensures consistency across batches, which is crucial for maintaining product quality and customer satisfaction. Additionally, these bottles can enhance portion control, minimizing waste. When sourcing for this application, businesses should prioritize food-grade materials and compliance with local food safety regulations to ensure consumer safety.

What role do 1 ml dropper bottles play in chemical laboratories?

In chemical laboratories, 1 ml dropper bottles serve as essential tools for dispensing reagents and conducting experiments. They promote accuracy in measurement, which is vital for reproducibility in scientific research. Furthermore, these bottles help minimize waste by allowing precise delivery of chemicals. Buyers in this sector should focus on the chemical compatibility of the materials used in the bottles, ensuring they can safely contain various reagents without degradation.

How are 1 ml dropper bottles used in agriculture, and what advantages do they provide?

In agriculture, 1 ml dropper bottles are employed for the targeted application of fertilizers, pesticides, or other treatments in small quantities. This precision reduces the environmental impact and conserves resources, aligning with sustainable practices in modern agriculture. For international buyers, it is essential to source dropper bottles that are chemically resistant and compliant with local agricultural regulations, ensuring effective and safe application of agricultural products.

3 Common User Pain Points for ‘1 ml dropper bottle’ & Their Solutions

Scenario 1: Inconsistent Dispensing Leads to Product Variability

The Problem: B2B buyers often face the challenge of inconsistent dispensing when using 1 ml dropper bottles, particularly in industries like pharmaceuticals and cosmetics. This inconsistency can lead to variability in product formulations, affecting quality control and potentially resulting in customer complaints. For instance, if a manufacturer is using dropper bottles for essential oils or active ingredients, the amount dispensed can vary significantly from one bottle to another, leading to ineffective products or even safety issues.

The Solution: To address this problem, buyers should prioritize sourcing high-quality 1 ml dropper bottles equipped with precise dispensing mechanisms. Look for bottles with calibrated markings that ensure accurate measurements, and consider those with a controlled dispensing tip that provides a consistent drop size. Additionally, conducting thorough supplier evaluations can help identify manufacturers that adhere to strict quality control processes. Implementing regular training for staff on the correct usage and handling of dropper bottles can further mitigate inconsistencies, ensuring that every drop counts towards maintaining product integrity.

Scenario 2: Chemical Compatibility Issues

The Problem: Many buyers encounter compatibility issues when selecting 1 ml dropper bottles for specific chemicals, particularly in laboratory or industrial settings. For example, using a plastic dropper bottle for aggressive solvents can lead to chemical leaching or degradation of the bottle material, which compromises the product and poses safety risks. This can be particularly problematic in regions with limited access to quality labware, where buyers may not have adequate information on material compatibility.

The Solution: To overcome this challenge, buyers should conduct thorough research on the materials used in 1 ml dropper bottles, focusing on chemical resistance ratings. Bottles made from borosilicate glass or high-density polyethylene (HDPE) are often more suitable for a wider range of chemicals. It’s advisable to consult technical data sheets and speak directly with manufacturers about the specific chemicals to be used. Establishing a relationship with suppliers who provide comprehensive material safety data sheets (MSDS) can also ensure that buyers make informed decisions that prioritize safety and product efficacy.

Scenario 3: Supply Chain Disruptions Affecting Availability

The Problem: International B2B buyers frequently experience supply chain disruptions that affect the availability of 1 ml dropper bottles. Factors such as geopolitical issues, shipping delays, and fluctuating demand can lead to stockouts, impacting production schedules and customer satisfaction. For companies in regions like Africa and South America, these disruptions can be particularly challenging due to limited local suppliers and reliance on imports.

The Solution: To mitigate supply chain risks, buyers should diversify their supplier base by sourcing from multiple manufacturers across different regions. Establishing relationships with local suppliers can provide a buffer against international shipping delays. Implementing a just-in-time inventory system can also help manage stock levels more effectively, ensuring that there are always sufficient supplies on hand. Furthermore, investing in demand forecasting tools can assist in predicting needs more accurately, allowing companies to place orders well in advance of expected demand spikes. Engaging with suppliers to develop contingency plans for unforeseen disruptions can further enhance resilience in the supply chain.

Strategic Material Selection Guide for 1 ml dropper bottle

When selecting materials for 1 ml dropper bottles, it is essential to consider the properties, advantages, disadvantages, and application impacts of each material. This decision is particularly critical for international B2B buyers, who must also navigate compliance and market preferences specific to their regions. Below is an analysis of four common materials used in 1 ml dropper bottles: glass, polyethylene (PE), low-density polyethylene (LDPE), and borosilicate glass.

What are the Key Properties of Glass for 1 ml Dropper Bottles?

Glass is a traditional material for dropper bottles, known for its chemical inertness and durability. It can withstand a wide range of temperatures and pressures, making it suitable for various applications. Notably, glass dropper bottles are resistant to corrosion, ensuring that they maintain their integrity when storing reactive substances.

Pros: Glass offers excellent protection against UV light, especially in amber variants, making it ideal for light-sensitive products. It is also non-reactive, ensuring that the contents remain pure without contamination.

Cons: The primary disadvantage of glass is its fragility; it can break easily if dropped, which may lead to increased costs due to product loss. Additionally, glass manufacturing can be more complex and costly compared to plastic alternatives.

Impact on Application: Glass is suitable for high-value applications, such as pharmaceuticals and essential oils, where purity and stability are paramount.

Considerations for International Buyers: Buyers must ensure compliance with local regulations regarding glass packaging and may need to consider the environmental impact of glass disposal in their regions.

How Does Polyethylene (PE) Perform in 1 ml Dropper Bottles?

Polyethylene is a widely used plastic for dropper bottles, particularly in applications requiring flexibility and resilience. It is lightweight and can withstand a range of temperatures, although it may not be suitable for high-heat applications.

Pros: PE is cost-effective and offers good chemical resistance, making it suitable for dispensing a variety of liquids, including acids and bases.

Cons: While PE is durable, it may not provide the same level of protection against UV light as glass, potentially leading to degradation of sensitive contents over time.

Impact on Application: PE is well-suited for applications where cost is a significant factor, such as in consumer products or less sensitive chemicals.

Considerations for International Buyers: Compliance with food safety standards and recycling regulations is crucial, especially in regions like Europe where sustainability is a priority.

What Advantages Does Low-Density Polyethylene (LDPE) Offer?

Low-density polyethylene (LDPE) is another plastic option that is often used for dropper bottles. It is known for its flexibility and ease of use, which can enhance the dispensing process.

Pros: LDPE is highly resistant to impact and is less likely to break compared to glass. It also offers good chemical resistance, making it suitable for various applications.

Cons: LDPE may not be as chemically inert as glass, which could lead to leaching of chemicals into the contents over time. Additionally, it has a lower temperature tolerance compared to glass.

Impact on Application: LDPE is ideal for applications requiring frequent handling, such as in laboratories or for personal care products.

Considerations for International Buyers: Buyers should verify that LDPE products meet local compliance standards, particularly in the pharmaceutical and food industries.

Why Choose Borosilicate Glass for 1 ml Dropper Bottles?

Borosilicate glass is a specialized type of glass known for its thermal resistance and durability. It is often used in laboratory settings due to its ability to withstand sudden temperature changes without breaking.

Pros: Borosilicate glass is highly resistant to thermal shock and chemical corrosion, making it suitable for a wide range of applications, including those involving strong acids and bases.

Cons: The cost of borosilicate glass is generally higher than standard glass or plastic options, which may be a consideration for budget-conscious buyers.

Impact on Application: This material is ideal for high-performance applications, such as in laboratories or for high-value chemical storage.

Considerations for International Buyers: Compliance with specific laboratory standards and certifications is essential, especially in regions with strict regulatory environments.

Summary Table of Material Selection

| Material | Typical Use Case for 1 ml dropper bottle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Pharmaceuticals, essential oils | Excellent chemical inertness and UV protection | Fragile, higher manufacturing complexity | High |

| Polyethylene (PE) | Consumer products, less sensitive liquids | Cost-effective, good chemical resistance | Less UV protection, potential leaching | Low |

| Low-Density Polyethylene (LDPE) | Personal care products, laboratories | Impact-resistant, flexible | Lower chemical inertness, lower temperature tolerance | Low |

| Borosilicate Glass | Laboratory use, high-value chemicals | Thermal shock resistance, highly durable | Higher cost compared to other materials | High |

This guide provides a comprehensive overview of the strategic material selection process for 1 ml dropper bottles, facilitating informed decisions for international B2B buyers across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for 1 ml dropper bottle

What Are the Main Stages in the Manufacturing Process of 1 ml Dropper Bottles?

The manufacturing of 1 ml dropper bottles involves several critical stages, each designed to ensure the final product meets stringent quality standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality materials. Commonly, borosilicate or soda-lime glass is chosen for its durability and chemical resistance, while certain applications may require food-grade plastics like LDPE or HDPE. These materials are sourced from reputable suppliers to ensure compliance with international standards.

-

Forming: In this stage, raw materials are shaped into the desired bottle form. Glass dropper bottles are typically produced using blow molding or press-and-blow techniques, where molten glass is formed into pre-designed molds. For plastic bottles, injection molding is the preferred method, ensuring precise dimensions and uniformity.

-

Assembly: After forming, the dropper components are assembled. This includes the dropper tip, which may feature a control mechanism for accurate dispensing, and the closure, which is often made from polypropylene or silicone. The assembly process is crucial for ensuring that each component fits seamlessly to prevent leaks.

-

Finishing: The final stage involves surface treatment and inspection. Bottles may undergo polishing, labeling, or coating processes to enhance their functionality and aesthetics. This stage also includes rigorous cleaning to eliminate any contaminants that may affect product integrity.

What Quality Assurance Measures Are Critical for 1 ml Dropper Bottles?

Quality assurance is vital to ensure that 1 ml dropper bottles meet industry standards and customer expectations. This includes compliance with international standards such as ISO 9001, as well as industry-specific certifications like CE for European markets and API for pharmaceutical applications.

-

International Standards: Compliance with ISO 9001 ensures that manufacturers have established quality management systems. This standard emphasizes continuous improvement, customer satisfaction, and process efficiency, which are essential for maintaining product quality.

-

Industry-Specific Certifications: Depending on the intended use of the dropper bottles, additional certifications may be required. For instance, bottles used in pharmaceutical applications must comply with the API standards, which govern the manufacturing of active pharmaceutical ingredients.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor the quality of the products being produced.

– Final Quality Control (FQC): Once the bottles are assembled, they undergo a final inspection to verify their integrity, functionality, and compliance with specifications.

Which Testing Methods Are Commonly Used for 1 ml Dropper Bottles?

Several testing methods are employed to validate the quality and safety of 1 ml dropper bottles. These include:

-

Leak Testing: Essential for ensuring that the dropper mechanism is airtight. This is often performed using pressure testing or water immersion tests to detect any leaks.

-

Chemical Resistance Testing: For bottles intended to hold sensitive chemicals, tests are conducted to ensure they can withstand exposure to various substances without degradation.

-

Dropper Functionality Tests: This involves evaluating the dropper’s dispensing accuracy and consistency to ensure it meets user requirements.

-

Visual Inspection: Manual or automated visual checks are conducted to identify any defects in the bottles, such as cracks or inconsistencies in shape.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and adherence to industry standards. This firsthand observation can provide invaluable insights into a supplier’s operational integrity.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the types of tests performed, the frequency of inspections, and the results of these evaluations. This documentation is critical for maintaining transparency.

-

Third-Party Inspections: Engaging third-party organizations to conduct independent inspections can provide an unbiased assessment of a supplier’s quality control practices. This is particularly important for buyers in regions where local regulations may vary.

-

Certifications and Compliance Documentation: Buyers should verify that suppliers possess relevant certifications and compliance documents. This includes ISO certifications, CE markings, and any other pertinent quality assurance credentials that demonstrate adherence to international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances when it comes to quality control in the manufacturing of 1 ml dropper bottles. Key considerations include:

-

Regulatory Variations: Different regions have varying regulatory requirements that affect product quality. Buyers should familiarize themselves with local regulations in their target markets to ensure compliance.

-

Cultural and Language Barriers: Effective communication with suppliers is crucial for quality assurance. Buyers may need to engage translators or local representatives to facilitate clear communication regarding quality expectations and standards.

-

Supply Chain Management: Buyers should consider the entire supply chain when evaluating quality control. This includes assessing the reliability of raw material suppliers and the logistics involved in transporting products, as these factors can impact the overall quality of the dropper bottles.

-

Market-Specific Preferences: Understanding the specific needs and preferences of markets in Africa, South America, the Middle East, and Europe can guide buyers in selecting suppliers that align with local consumer expectations.

In conclusion, the manufacturing processes and quality assurance measures for 1 ml dropper bottles are intricate and require careful consideration by B2B buyers. By understanding these processes and implementing effective verification strategies, buyers can ensure they source high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1 ml dropper bottle’

This guide serves as a practical checklist for B2B buyers looking to procure 1 ml dropper bottles. Sourcing the right dropper bottle can significantly impact product quality, usability, and compliance with industry standards. Follow these steps to ensure a smooth and effective procurement process.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clarify the technical requirements for the 1 ml dropper bottles you need. Consider factors such as material (glass vs. plastic), color (clear, amber), and type (graduated vs. non-graduated). Clearly defined specifications will streamline the selection process and ensure that the bottles meet your product needs.

- Material Considerations: Glass dropper bottles are ideal for chemical resistance and UV protection, while plastic options may be lighter and more durable.

- Usage Requirements: Determine if you need bottles for sensitive materials, which would necessitate amber glass for UV protection.

Step 2: Research Potential Suppliers

Take the time to identify and research potential suppliers that specialize in 1 ml dropper bottles. Look for companies with a proven track record in your industry and those that comply with international quality standards.

- Supplier Reputation: Check for reviews, testimonials, and case studies from previous clients to gauge reliability.

- Industry Experience: Suppliers with experience in your specific sector are more likely to understand your unique needs.

Step 3: Evaluate Supplier Certifications

Certifications can provide assurance that suppliers adhere to quality and safety standards. Verify that potential suppliers have relevant certifications such as ISO, FDA, or CE, which are crucial for products used in pharmaceuticals or food packaging.

- Quality Management Systems: Look for suppliers with ISO 9001 certification to ensure consistent quality management practices.

- Regulatory Compliance: Confirm that the materials used in the bottles meet local and international regulatory requirements.

Step 4: Request Samples

Before making a bulk order, request samples from shortlisted suppliers. Testing samples allows you to evaluate the quality, usability, and compatibility of the dropper bottles with your products.

- Quality Assurance: Examine the samples for any defects, such as leaks or poor sealing mechanisms.

- Functionality Testing: Ensure that the dropper tip dispenses accurately and consistently, meeting your operational needs.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers and compare them not only based on price but also on terms of service, payment options, and delivery timelines. A lower price might not always equate to better value.

- Total Cost of Ownership: Consider factors such as shipping costs, minimum order quantities, and potential import duties.

- Payment Flexibility: Evaluate the payment terms offered by suppliers, as favorable terms can improve cash flow.

Step 6: Negotiate Contract Terms

Once you’ve selected a supplier, negotiate the terms of the contract carefully. Ensure all agreements regarding pricing, delivery schedules, and quality expectations are clearly defined.

- Delivery Expectations: Specify lead times and penalties for delays to mitigate risks associated with supply chain disruptions.

- Quality Control Provisions: Include clauses that allow for quality checks and returns if the products do not meet the specified standards.

Step 7: Plan for Ongoing Communication

Establish a clear line of communication with your chosen supplier to address any concerns that may arise post-purchase. Regular check-ins can help maintain a positive relationship and ensure ongoing product quality.

- Feedback Mechanism: Implement a system for providing feedback on product performance and service quality.

- Problem Resolution: Have a strategy in place for quickly resolving any issues related to product defects or delivery delays.

By following this checklist, B2B buyers can effectively navigate the procurement process for 1 ml dropper bottles, ensuring they select the best products for their needs while minimizing risks and costs.

Comprehensive Cost and Pricing Analysis for 1 ml dropper bottle Sourcing

What Are the Key Cost Components for 1 ml Dropper Bottles?

When sourcing 1 ml dropper bottles, understanding the cost structure is crucial for effective budgeting and pricing negotiations. The primary cost components include:

-

Materials: The material chosen significantly impacts the overall cost. Common options include borosilicate glass, which offers high chemical resistance, and low-density polyethylene (LDPE), which is more economical but less durable. High-quality materials often lead to a higher price but provide better longevity and safety for sensitive liquids.

-

Labor: Manufacturing labor costs can vary by region. For instance, labor costs in Southeast Asia, such as Vietnam, may be lower than those in Europe or the Middle East. This difference can affect the total production cost, especially for larger orders.

-

Manufacturing Overhead: This includes expenses related to the factory, utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can reduce overhead, impacting the final price.

-

Tooling: Custom tooling for specific designs or features, such as specialized dropper tips, can add to initial costs. However, this investment may be justified by the potential for higher margins on custom products.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the dropper bottles meet safety and quality standards. While this adds to costs, it helps avoid costly returns and enhances brand reputation.

-

Logistics: Shipping costs can vary widely based on the supplier’s location and the destination. Factors such as distance, shipping method, and Incoterms (e.g., FOB, CIF) play a significant role in determining logistics costs.

-

Margin: Suppliers typically add a markup to cover their operational costs and profit margins. This margin can vary based on market competition and demand.

How Do Price Influencers Affect 1 ml Dropper Bottle Sourcing?

Several factors can influence the pricing of 1 ml dropper bottles:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating for higher quantities can yield significant savings.

-

Specifications and Customization: Custom features, such as different colors or specialized dispensing tips, can increase costs. Buyers should assess whether these features are necessary for their application.

-

Materials and Quality Certifications: Bottles made from premium materials or those that have undergone rigorous testing for safety and compliance with international standards (ISO, FDA) typically command higher prices. Understanding the importance of these certifications for your specific market can help justify the costs.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality may charge more, but the assurance of product reliability can be worth the extra cost.

-

Incoterms: The choice of Incoterms affects shipping responsibilities and costs. Buyers should select terms that minimize risk and control expenses, especially when sourcing internationally.

What Tips Can Help Buyers Optimize Costs When Sourcing 1 ml Dropper Bottles?

-

Negotiation: Engage suppliers in discussions about pricing, especially if you anticipate placing large orders or developing a long-term partnership. Don’t hesitate to ask for discounts based on volume or prompt payment.

-

Cost-Efficiency: Consider the total cost of ownership (TCO) rather than just the purchase price. This includes potential shipping costs, customs duties, and the cost of returns or replacements if quality issues arise.

-

Pricing Nuances for International Buyers: Understand regional pricing dynamics. For buyers in Africa, South America, and the Middle East, fluctuating exchange rates and import tariffs can significantly affect costs. Research local regulations and potential subsidies that might impact pricing.

-

Supplier Diversification: Avoid relying on a single supplier. Having multiple sources can foster competitive pricing and ensure you are not overly dependent on one manufacturer, which can be risky.

-

Market Research: Stay informed about market trends and competitor pricing. This knowledge can empower you during negotiations and help you identify the best sourcing options.

By carefully considering these cost components and influencers, B2B buyers can make informed decisions that optimize their sourcing strategies for 1 ml dropper bottles.

Alternatives Analysis: Comparing 1 ml dropper bottle With Other Solutions

Exploring Alternatives to the 1 ml Dropper Bottle

When it comes to dispensing small volumes of liquids, the 1 ml dropper bottle is a popular choice in various industries, from pharmaceuticals to cosmetics. However, there are several alternative solutions that serve similar purposes. Understanding the differences among these options can help B2B buyers make informed decisions based on their specific operational needs.

| Comparison Aspect | 1 ml Dropper Bottle | Alternative 1: Pipette | Alternative 2: Syringe |

|---|---|---|---|

| Performance | Accurate drop dispensing | Highly precise volume control | Versatile for various volumes |

| Cost | Moderate cost per unit | Generally low cost | Moderate cost per unit |

| Ease of Implementation | Simple to use | Requires practice for accuracy | Easy to use, but may require training |

| Maintenance | Minimal cleaning required | Requires thorough cleaning | Requires regular maintenance and cleaning |

| Best Use Case | Essential oils, serums | Laboratory settings, precise measurements | Medical applications, dosing |

What Are the Advantages and Disadvantages of Using a Pipette?

Pipettes are favored in laboratory environments for their precision. They allow for the measurement of specific volumes with high accuracy, making them ideal for scientific applications where exact dosing is crucial. However, using a pipette requires a degree of training and practice to ensure accuracy. While they are generally low-cost, their dependency on user skill can introduce variability in performance, which may not be ideal for all applications.

How Does a Syringe Compare to a 1 ml Dropper Bottle?

Syringes offer versatility in liquid dispensing, allowing for a wide range of volumes to be administered, from very small amounts to larger doses. This makes them suitable for medical applications, such as vaccinations or precise medication dosing. However, they can require more maintenance than dropper bottles, as they must be cleaned and sterilized between uses. Additionally, syringes may not provide the same level of ease in dispensing small volumes as a dropper bottle, particularly for non-viscous liquids.

Conclusion: Which Solution Should B2B Buyers Choose?

Selecting the right dispensing solution hinges on the specific needs of your operation. For applications requiring precise dosing in a lab setting, pipettes might be the best option, while syringes are ideal for medical contexts. Conversely, for straightforward liquid dispensing in cosmetics or essential oil applications, the 1 ml dropper bottle remains a reliable choice. B2B buyers should consider factors such as cost, ease of use, and the required precision of their applications when making a decision. Tailoring the choice to the specific context will enhance operational efficiency and product quality.

Essential Technical Properties and Trade Terminology for 1 ml dropper bottle

What Are the Key Technical Properties of a 1 ml Dropper Bottle?

When sourcing 1 ml dropper bottles for your business needs, understanding the essential technical properties is crucial for ensuring product quality and compatibility with your applications. Here are some of the critical specifications to consider:

-

Material Grade

The material from which a dropper bottle is made significantly affects its usability. Common materials include borosilicate glass, which is chemically inert and ideal for sensitive substances, and LDPE (Low-Density Polyethylene), known for its flexibility and chemical resistance. For B2B buyers, selecting the appropriate material can prevent chemical reactions that may compromise the integrity of the product being stored or dispensed. -

Volume Tolerance

Tolerance specifications indicate the acceptable range of volume a dropper bottle can hold. For instance, a 1 ml dropper bottle may have a tolerance of ±0.1 ml. This precision is essential in fields like pharmaceuticals or laboratories where accurate dosing is critical. Understanding tolerance helps buyers ensure that their dispensing needs are met without excess waste or misdosing. -

Drop Size Control

The ability to control drop size is vital for applications requiring precise measurements, such as in essential oils or laboratory reagents. Dropper bottles typically specify drop size in microliters (e.g., 20 µL per drop). This feature aids in achieving consistent results, making it a key consideration for B2B clients focused on quality assurance in their products. -

Closure Type

The type of closure, whether screw cap or dropper control tip, impacts the bottle’s usability and security. A secure closure prevents leakage and contamination, which is particularly important when dealing with sensitive materials. B2B buyers should evaluate closure options to ensure they align with their operational standards and product requirements. -

Sterility

For applications in healthcare or research, sterility is often non-negotiable. Some dropper bottles come pre-sterilized, making them suitable for use with biological samples or pharmaceuticals. Understanding the sterility requirements is essential for B2B buyers who operate in regulated environments. -

Color and UV Protection

Amber or colored glass provides protection against UV rays, making it suitable for light-sensitive materials. This property is particularly relevant for businesses in cosmetics or pharmaceuticals where product degradation due to light exposure can lead to significant losses. Selecting the right color can extend product shelf life and maintain efficacy.

What Are Common Trade Terms in the 1 ml Dropper Bottle Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms you may encounter:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces components or products that may be marketed by another company under its brand. Understanding OEM relationships is vital for businesses looking to source high-quality dropper bottles that meet their specifications. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest order size that a supplier is willing to accept. For B2B buyers, knowing the MOQ helps in budgeting and inventory planning. It can also indicate the supplier’s production capabilities and commitment to quality. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to obtain price quotes for specific products. This process is crucial for B2B buyers seeking competitive pricing and evaluating multiple suppliers for their dropper bottle needs. -

Incoterms (International Commercial Terms)

These are international rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is essential for B2B transactions, particularly when importing dropper bottles from international suppliers. -

Lead Time

This refers to the amount of time it takes from placing an order to receiving the product. Understanding lead time helps businesses plan their inventory and production schedules effectively, ensuring that they meet market demands without delays. -

Certification Compliance

This term indicates that a product meets specific industry standards or regulations, such as ISO certifications. For buyers in regulated industries, confirming certification compliance is essential to ensure product safety and quality.

By familiarizing yourself with these technical properties and trade terms, you can make informed decisions when sourcing 1 ml dropper bottles that align with your business needs and regulatory requirements.

Navigating Market Dynamics and Sourcing Trends in the 1 ml dropper bottle Sector

What Are the Current Market Dynamics and Key Trends in the 1 ml Dropper Bottle Sector?

The global market for 1 ml dropper bottles is experiencing notable growth driven by increasing demand across various sectors, including pharmaceuticals, cosmetics, and essential oils. The rise in the health and wellness trend, particularly in regions like Africa, South America, and the Middle East, has led to heightened interest in precision dispensing solutions. Furthermore, the ongoing digital transformation in supply chain management is facilitating smoother transactions and enhancing buyer-supplier relationships. Technologies such as AI and machine learning are improving inventory management and forecasting, which are crucial for international buyers looking to optimize their sourcing processes.

In terms of product innovation, there is a growing trend towards multifunctional dropper bottles, which not only serve as dispensing tools but also as storage solutions. Moreover, the shift towards e-commerce is reshaping the distribution landscape, making it essential for B2B buyers to seek suppliers who can meet the demands of online retail. As a result, suppliers that offer customizable options and rapid delivery services are gaining a competitive edge.

Additionally, emerging markets like Vietnam and Saudi Arabia are seeing increased investments in manufacturing capabilities, further diversifying sourcing options for international buyers. This is particularly significant as businesses seek to mitigate risks associated with supply chain disruptions and geopolitical uncertainties.

How Is Sustainability and Ethical Sourcing Influencing the 1 ml Dropper Bottle Market?

Sustainability is becoming a central theme in the sourcing of 1 ml dropper bottles. International B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing environmental impact. The use of eco-friendly materials, such as recycled plastics and biodegradable alternatives, is gaining traction. Furthermore, certifications like ISO 14001, which focus on effective environmental management systems, are becoming key differentiators in supplier selection.

Ethical sourcing practices are equally vital, particularly for companies looking to enhance their corporate social responsibility (CSR) profiles. Buyers are urged to conduct thorough due diligence on suppliers to ensure compliance with ethical labor practices and environmental regulations. This not only safeguards brand reputation but also aligns with the growing consumer preference for ethically produced goods.

As the market evolves, businesses are exploring partnerships with manufacturers who can provide transparency in their supply chains, ensuring that every component of the dropper bottle—from materials to production processes—adheres to sustainability standards. This trend is not only beneficial for the environment but also enhances marketability in increasingly eco-conscious consumer bases.

What Has Been the Evolution of the 1 ml Dropper Bottle?

The evolution of the 1 ml dropper bottle can be traced back to its origins in the pharmaceutical industry, where precise dosing was essential. Initially made from glass, these bottles have transformed significantly over the years. The introduction of plastic materials offered a lightweight, shatter-resistant alternative, making them more accessible for various applications.

Over time, design innovations, such as the incorporation of control dispensing tips and various closure types, have improved functionality and user experience. The contemporary market now features an array of options tailored to specific needs—ranging from amber glass bottles that protect light-sensitive substances to eco-friendly plastic variants designed for sustainability. This evolution reflects broader trends in consumer preferences and regulatory requirements, shaping the future landscape of the 1 ml dropper bottle sector.

By understanding these dynamics, international B2B buyers can better navigate their sourcing strategies to align with market trends, sustainability goals, and evolving consumer demands.

Frequently Asked Questions (FAQs) for B2B Buyers of 1 ml dropper bottle

-

How can I ensure the quality of 1 ml dropper bottles when sourcing internationally?

To ensure the quality of 1 ml dropper bottles, conduct thorough supplier vetting. Request samples to assess material quality, manufacturing processes, and compliance with international standards such as ISO. Utilize third-party quality assurance services to inspect the products before shipment. Establish clear quality criteria and specifications in your purchase agreements to minimize discrepancies. -

What are the most important features to look for in 1 ml dropper bottles?

Key features to consider include material (glass or plastic), chemical resistance, UV protection (especially for amber bottles), and ease of dispensing. The dropper tip should provide consistent drop sizes for accuracy. Additionally, consider whether the bottles are sterile if they will be used for pharmaceuticals or sensitive formulations. -

What is the typical minimum order quantity (MOQ) for 1 ml dropper bottles?

MOQs for 1 ml dropper bottles can vary widely based on the supplier and the customization options you choose. Typically, standard products may have an MOQ ranging from 500 to 1,000 units, while customized bottles could require a higher MOQ. It’s advisable to discuss your specific needs with suppliers to negotiate favorable terms. -

How can I customize my 1 ml dropper bottles for branding purposes?

Customization options for 1 ml dropper bottles may include printing your brand logo, choosing specific colors, and altering the bottle shape or size. Many suppliers offer customization services; however, be prepared for potential increases in lead time and MOQ. Provide clear design files and specifications to ensure the final product aligns with your brand identity. -

What payment terms should I expect when sourcing 1 ml dropper bottles internationally?

Payment terms can vary by supplier but commonly include options like 30% upfront and 70% before shipment, or full payment in advance. It’s essential to clarify payment methods accepted (e.g., wire transfer, PayPal, letters of credit) and any associated fees. Consider negotiating terms that align with your cash flow needs while ensuring the supplier’s confidence in fulfilling the order. -

What logistics considerations should I keep in mind when importing 1 ml dropper bottles?

Logistics considerations include shipping methods (air vs. sea), customs regulations, and potential duties or tariffs. Ensure your supplier provides necessary documentation for customs clearance, such as invoices and packing lists. Engage with a reliable freight forwarder to navigate the complexities of international shipping and ensure timely delivery. -

How do I handle potential disputes with suppliers of 1 ml dropper bottles?

To minimize disputes, establish clear terms and conditions in your purchase agreements, including quality standards, delivery timelines, and payment schedules. Maintain open communication with suppliers throughout the process. If a dispute arises, attempt to resolve it amicably through discussion. If necessary, refer to third-party mediation or arbitration services for resolution. -

What are the best practices for storing 1 ml dropper bottles after purchase?

Store 1 ml dropper bottles in a cool, dry place to prevent degradation of materials. Keep them away from direct sunlight, especially if they are made of plastic or contain light-sensitive liquids. Ensure they are stored upright to prevent leaks and contamination. Regularly inspect stored bottles for any signs of damage or wear that could affect their usability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 1 Ml Dropper Bottle Manufacturers & Suppliers List

1. Your Oil Tools – Dropper Bottles

Domain: youroiltools.com

Registered: 2014 (11 years)

Introduction: Shop our collection of dropper bottles at Your Oil Tools. Perfect for precise dispensing of essential oils, tinctures, and DIY creations, these high-quality bottles come in a variety of sizes and styles. Explore durable, reliable options for all your liquid storage and application needs. Available products include: 1 ml Amber Glass Vials w/ Black Dropper (Pack of 5) – $4.99, 1 ml Clear Glass Vials…

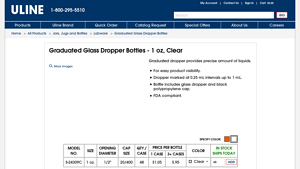

2. Uline – Graduated Glass Dropper Bottles

Domain: uline.com

Registered: 1995 (30 years)

Introduction: {‘product_name’: ‘Graduated Glass Dropper Bottles’, ‘size’: ‘1 oz’, ‘color’: ‘Clear’, ‘model_number’: ‘S-24309C’, ‘price_per_case’: {’48_units’: ‘$1.05’, ‘144_units’: ‘$0.95’}, ‘features’: [‘Graduated dropper for precise liquid measurement’, ‘Marked at 0.25 mL intervals up to 1 mL’, ‘Includes glass dropper and black polypropylene cap’, ‘FDA compliant’], ‘dimensions’: {‘height_with_dropper’: ‘4 inc…

3. Home Science Tools – 1 mL Glass Pipet

Domain: homesciencetools.com

Registered: 2005 (20 years)

Introduction: Pipet (medicine dropper) | 1 mL capacity | Basic glass pipet also known as an eye dropper or pipette | Holds about 1ml or 20 drops | Ages 8+ | In Stock & Ready to Ship | Price: $0.95 | SKU: CE-DROPPER | Free Shipping on Most Orders $100+ | Return unused products within 60 days.

4. Specialty Bottle – 1 oz Clear Boston Round Glass Bottle with Dropper

Domain: specialtybottle.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “1 oz Clear Boston Round Glass Bottle with Dropper”, “Capacity”: “1 oz”, “Closure”: “20/400 black rubber dropper with glass pipette”, “Case Quantity”: “360”, “Width”: “1.25 inches”, “Height”: “4 inches”, “Type”: “bottle”, “Description”: “Modest 1-ounce capacity and a black dropper top make this Boston round bottle a good home for eye-dropper medicine, tinctures, essential oils and…

5. Premium Vials – Clear Glass Dropper Bottles

Domain: premiumvials.com

Registered: 2013 (12 years)

Introduction: 100, 1ml (1/4 dram) Clear Glass Dropper Bottle, Empty Essential Oil Dropper Bottle, Mini Glass Eye Dropper Vials with Pipette, Includes 1 Funnel & 3 Droppers, Suitable for Travel, Sample Testing, and Perfume Liquid Container.

6. Virospack – Customizable Droppers

Domain: virospack.com

Registered: 1997 (28 years)

Introduction: Virospack produces high-quality, customizable droppers designed for precision in cosmetics, essential oils, and medications. A standard dropper typically holds about 1 mL of liquid, which is equivalent to one full squeeze of the bulb. Factors such as design variations, liquid viscosity, and user technique can influence the dropper’s capacity. Droppers are essential in cosmetics for precise applica…

Strategic Sourcing Conclusion and Outlook for 1 ml dropper bottle

As the demand for 1 ml dropper bottles continues to rise across diverse industries, strategic sourcing becomes essential for international B2B buyers. Key takeaways from this guide emphasize the importance of selecting high-quality materials, such as borosilicate glass or LDPE, which offer durability and chemical resistance. Understanding the specific needs of your market—whether it’s for pharmaceuticals, essential oils, or laboratory use—will enhance your procurement strategy and ensure that you select the right product for your applications.

Furthermore, leveraging reliable suppliers with a proven track record can significantly reduce risks associated with sourcing. When engaging with manufacturers, consider not only the cost but also their ability to meet regulatory standards and offer timely delivery. This approach will enhance your supply chain efficiency and foster long-term partnerships.

Looking ahead, the global market for 1 ml dropper bottles is poised for growth, driven by increased consumer awareness and demand for precision in dispensing. Now is the time for buyers from Africa, South America, the Middle East, and Europe to align their sourcing strategies with market trends. Embrace this opportunity to secure competitive advantages and elevate your business in the evolving landscape of dropper bottle supply.